fuel NISSAN ALMERA 2001 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 725 of 2898

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG

TROUBLE DIAGNOSIS - INDEX..................................10

Alphabetical & P No. Index for DTC .........................10

PRECAUTIONS.............................................................16

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER².............16

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T.........................................16

Engine Fuel & Emission Control System ..................17

Wiring Diagrams and Trouble Diagnosis ...................19

PREPARATION.............................................................20

Special Service Tools ................................................20

Commercial Service Tools .........................................20

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................21

Engine Control Component Parts Location ...............21

Circuit Diagram ..........................................................25

System Diagram ........................................................29

Vacuum Hose Drawing ..............................................30

System Chart .............................................................31

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................32

Multiport Fuel Injection (MFI) System .......................32

Electronic Ignition (EI) System ..................................34

Air Conditioning Cut Control ......................................35

Fuel Cut Control (at no load & high engine

speed) ........................................................................36

Evaporative Emission System ...................................36

Positive Crankcase Ventilation ..................................39

BASIC SERVICE PROCEDURE...................................40

Fuel Pressure Release ..............................................40

Fuel Pressure Check .................................................40

Fuel Pressure Regulator Check ................................41

Injector .......................................................................41

How to Check Idle Speed and Ignition Timing ..........43

Preparation ................................................................44

Inspection Procedure .................................................47

Idle Air Volume Learning ...........................................57ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................59

Introduction ................................................................59

Two Trip Detection Logic ...........................................59

Emission-related Diagnostic Information ...................60

NATS (Nissan Anti-theft System) ..............................74

Malfunction Indicator (MI) ..........................................74

OBD System Operation Chart (With Euro-OBD

Models Only)..............................................................78

CONSULT-II ...............................................................83

Generic Scan Tool (GST) ..........................................94

TROUBLE DIAGNOSIS - INTRODUCTION..................96

Introduction ................................................................96

Work Flow ..................................................................98

TROUBLE DIAGNOSIS - BASIC INSPECTION.........100

Basic Inspection/Sedan ...........................................100

Basic Inspection/Hatchback.....................................128

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................153

DTC Inspection Priority Chart..................................153

Fail-safe Chart .........................................................154

Symptom Matrix Chart .............................................155

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................159

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................161

ECM Terminals and Reference Value .....................164

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..173

Description ...............................................................173

Testing Condition .....................................................173

Inspection Procedure ...............................................173

Diagnostic Procedure ..............................................174

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................177

Description ...............................................................177

Diagnostic Procedure ..............................................177

TROUBLE DIAGNOSIS FOR POWER SUPPLY........178

Main Power Supply and Ground Circuit ..................178

Page 727 of 2898

On Board Diagnosis Logic.......................................252

DTC Confirmation Procedure ..................................253

Wiring Diagram ........................................................254

Diagnostic Procedure ..............................................256

Component Inspection .............................................257

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)...................258

Component Description ...........................................258

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................258

ECM Terminals and Reference Value .....................258

On Board Diagnosis Logic.......................................258

DTC Confirmation Procedure ..................................259

Overall Function Check ...........................................260

Wiring Diagram ........................................................261

Diagnostic Procedure ..............................................263

Component Inspection .............................................265

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING).................267

Component Description ...........................................267

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................267

ECM Terminals and Reference Value .....................267

On Board Diagnosis Logic.......................................267

DTC Confirmation Procedure ..................................268

Overall Function Check ...........................................269

Wiring Diagram ........................................................270

Diagnostic Procedure ..............................................272

Component Inspection .............................................273

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR).........................................................................275

Component Description ...........................................275

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................275

ECM Terminals and Reference Value .....................275

On Board Diagnosis Logic.......................................275

DTC Confirmation Procedure ..................................276

Overall Function Check ...........................................277

Wiring Diagram ........................................................278

Diagnostic Procedure ..............................................280

Component Inspection .............................................282

DTC P0140 HEATED OXYGEN SENSOR 2

(REAR) (HIGH VOLTAGE)..........................................284

Component Description ...........................................284

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................284

ECM Terminals and Reference Value .....................284

On Board Diagnosis Logic.......................................284

DTC Confirmation Procedure ..................................285

Overall Function Check ...........................................285

Wiring Diagram ........................................................286

Diagnostic Procedure ..............................................288Component Inspection .............................................289

DTC P0141 HEATED OXYGEN SENSOR 2

HEATER (REAR).........................................................291

Description ...............................................................291

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................291

ECM Terminals and Reference Value .....................291

On Board Diagnosis Logic.......................................292

DTC Confirmation Procedure ..................................292

Wiring Diagram ........................................................293

Diagnostic Procedure ..............................................295

Component Inspection .............................................296

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION (LEAN SIDE)............................................297

On Board Diagnosis Logic.......................................297

DTC Confirmation Procedure ..................................297

Wiring Diagram ........................................................299

Diagnostic Procedure ..............................................301

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION (RICH SIDE).............................................305

On Board Diagnosis Logic.......................................305

DTC Confirmation Procedure ..................................305

Wiring Diagram ........................................................307

Diagnostic Procedure ..............................................309

DTC P0180 FUEL TANK TEMPERATURE

SENSOR (WHERE FITTED)........................................313

Component Description ...........................................313

On Board Diagnosis Logic.......................................313

DTC Confirmation Procedure ..................................313

Wiring Diagram ........................................................315

Diagnostic Procedure ..............................................316

Component Inspection .............................................317

DTC P0300 - P0304 NO.4-1CYLINDER

MISFIRE, MULTIPLE CYLINDER MISFIRE...............318

On Board Diagnosis Logic.......................................318

DTC Confirmation Procedure ..................................318

Diagnostic Procedure ..............................................319

DTC P0325 KNOCK SENSOR (KS)...........................324

Component Description ...........................................324

ECM Terminals and Reference Value .....................324

On Board Diagnosis Logic.......................................324

DTC Confirmation Procedure ..................................324

Wiring Diagram ........................................................325

Diagnostic Procedure ..............................................326

Component Inspection .............................................327

DTC P0335 CRANKSHAFT POSITION SENSOR

(POS)............................................................................328

Component Description ...........................................328

ECM Terminals and Reference Value .....................328

On Board Diagnosis Logic.......................................329

DTC Confirmation Procedure ..................................329

Wiring Diagram ........................................................330

CONTENTS(Cont'd)

EC-3

Page 730 of 2898

Diagnostic Procedure ..............................................487

Component Inspection .............................................490

EGR VOLUME CONTROL SYSTEM (WHERE

FITTED)........................................................................491

Description ...............................................................491

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................492

ECM Terminals and Reference Value .....................493

Wiring Diagram ........................................................494

Diagnostic Procedure ..............................................496

Component Inspection .............................................501

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE......................................................503

Description ...............................................................503

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................503

ECM Terminals and Reference Value .....................504

Wiring Diagram ........................................................505

Diagnostic Procedure ..............................................507

Component Inspection .............................................510

IDLE AIR CONTROL VALVE (IACV) - AUXILIARY

AIR CONTROL............................................................ 511

Description ............................................................... 511

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................512

ECM Terminals and Reference Value .....................512

Wiring Diagram ........................................................513

Diagnostic Procedure ..............................................515

Component Inspection .............................................519

CLOSED THROTTLE POSITION SWITCH

(WHERE FITTED)........................................................520

Component Description ...........................................520

ECM Terminals and Reference Value .....................520

Wiring Diagram ........................................................521

Diagnostic Procedure ..............................................522

Component Inspection .............................................525

INTAKE VALVE TIMING CONTROL SOLENOID

VALVE..........................................................................526

Component Description ...........................................526

Operation .................................................................526

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................526

ECM Terminals and Reference Value .....................526

Wiring Diagram ........................................................527

Diagnostic Procedure ..............................................529

Component Inspection .............................................531

A/T COMMUNICATION LINE......................................532

System Description ..................................................532

Wiring Diagram ........................................................533

Diagnostic Procedure ..............................................534

PARK/NEUTRAL POSITION (PNP) SWITCH............536

Component Description ...........................................536CONSULT-II Reference Value in Data Monitor

Mode ........................................................................536

ECM Terminals and Reference Value .....................536

Wiring Diagram ........................................................537

Diagnostic Procedure ..............................................538

INJECTOR...................................................................541

Component Description ...........................................541

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................541

ECM Terminals and Reference Value .....................541

Wiring Diagram ........................................................542

Diagnostic Procedure ..............................................544

Component Inspection .............................................546

IGNITION SIGNAL.......................................................547

Component Description ...........................................547

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................547

ECM Terminals and Reference Value .....................547

Wiring Diagram ........................................................548

Diagnostic Procedure ..............................................551

Component Inspection .............................................555

START SIGNAL...........................................................557

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................557

ECM Terminals and Reference Value .....................557

Wiring Diagram ........................................................558

Diagnostic Procedure ..............................................559

FUEL PUMP.................................................................561

System Description ..................................................561

Component Description ...........................................561

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................561

ECM Terminals and Reference Value .....................562

Wiring Diagram ........................................................563

Diagnostic Procedure ..............................................564

Component Inspection .............................................566

POWER STEERING OIL PRESSURE SWITCH.........567

Component Description ...........................................567

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................567

ECM Terminals and Reference Value .....................567

Wiring Diagram ........................................................568

Diagnostic Procedure ..............................................569

Component Inspection .............................................570

REFRIGERANT PRESSURE SENSOR......................572

Description ...............................................................572

ECM Terminals and Reference Value .....................572

Wiring Diagram ........................................................573

Diagnostic Procedure ..............................................575

ELECTRICAL LOAD SIGNAL.....................................578

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................578

CONTENTS(Cont'd)

EC-6

Page 731 of 2898

ECM Terminals and Reference Value .....................578

Wiring Diagram ........................................................579

Diagnostic Procedure - Load Signal - .....................583

Diagnostic Procedure - Heater Control Panel

(Fan Switch) - ..........................................................589

Component Inspection .............................................590

MI & DATA LINK CONNECTORS..............................591

Wiring Diagram ........................................................591

SERVICE DATA AND SPECIFICATIONS (SDS).......593

Fuel Pressure Regulator..........................................593

Idle Speed and Ignition Timing ................................593

Mass Air Flow Sensor..............................................593

Intake Air Temperature Sensor ................................593

Engine Coolant Temperature Sensor ......................593

Throttle Position Sensor ..........................................593

Heated Oxygen Sensor 1 Heater (Front) ................593

Heated Oxygen Sensor 2 Heater (Rear).................593

Fuel Tank Temperature Sensor (Where Fitted) .......594

EGR Volume Control Valve (Where Fitted) .............594

EGR Temperature Sensor (Where Fitted) ...............594

EVAP Canister Purge Volume Control Valve ..........594

IACV-AAC Valve ......................................................594

Injector .....................................................................594

Ignition Coil with Power Transistor ..........................594

Condenser ...............................................................594

Fuel Pump ...............................................................594

Crankshaft Position Sensor (POS) ..........................595

Camshaft Position Sensor (PHASE) .......................595

YD

TROUBLE DIAGNOSIS - INDEX................................596

Alphabetical & P No. Index for DTC .......................596

PRECAUTIONS...........................................................598

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...........598

Engine Fuel & Emission Control System ................599

Precautions ..............................................................600

Wiring Diagrams and Trouble Diagnosis .................601

PREPARATION...........................................................602

Special Service Tools ..............................................602

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.......................................................................603

Engine Control Component Parts Location .............603

Circuit Diagram ........................................................606

System Diagram ......................................................608

System Chart ...........................................................609

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION.............................................610

Fuel Injection Control System .................................610

Fuel Injection Timing Control System...................... 611

Air Conditioning Cut Control ....................................612Fuel Cut Control (at no load & high engine

speed) ......................................................................612

Crankcase Ventilation System .................................613

BASIC SERVICE PROCEDURE.................................614

Injection Tube and Injection Nozzle ........................614

Electronic Control Fuel Injection Pump ...................618

Fuel Filter .................................................................625

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION.............................................................627

DTC and MI Detection Logic ...................................627

Diagnostic Trouble Code (DTC) ..............................627

Malfunction Indicator (MI) ........................................628

CONSULT-II .............................................................632

TROUBLE DIAGNOSIS - INTRODUCTION................637

Introduction ..............................................................637

Work Flow ................................................................639

TROUBLE DIAGNOSIS - BASIC INSPECTION.........641

Basic Inspection.......................................................641

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................646

Symptom Matrix Chart .............................................646

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................656

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................658

ECM Terminals and Reference Value .....................659

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................665

Description ...............................................................665

Diagnostic Procedure ..............................................665

TROUBLE DIAGNOSIS FOR POWER SUPPLY........666

Main Power Supply and Ground Circuit ..................666

DTC P0100 MASS AIR FLOW SEN...........................673

Component Description ...........................................673

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................673

ECM Terminals and Reference Value .....................673

On Board Diagnosis Logic.......................................673

DTC Confirmation Procedure ..................................673

Wiring Diagram ........................................................675

Diagnostic Procedure ..............................................677

DTC P0115 COOLANT TEMP SEN............................680

Description ...............................................................680

On Board Diagnosis Logic.......................................680

DTC Confirmation Procedure ..................................680

Wiring Diagram ........................................................682

Diagnostic Procedure ..............................................683

DTC P0120 ACCEL POS SENSOR............................685

Description ...............................................................685

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................685

ECM Terminals and Reference Value .....................685

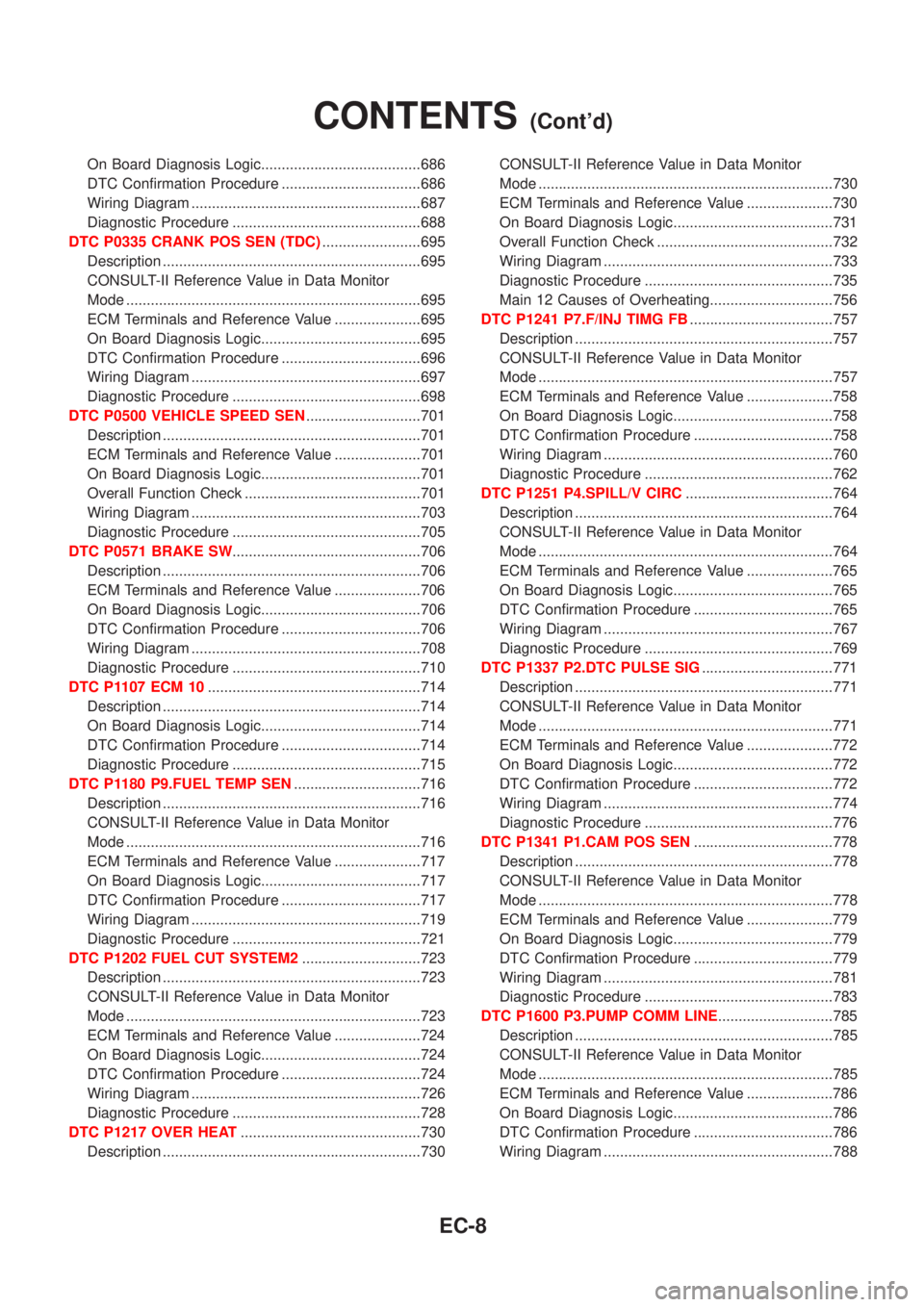

CONTENTS(Cont'd)

EC-7

Page 732 of 2898

On Board Diagnosis Logic.......................................686

DTC Confirmation Procedure ..................................686

Wiring Diagram ........................................................687

Diagnostic Procedure ..............................................688

DTC P0335 CRANK POS SEN (TDC)........................695

Description ...............................................................695

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................695

ECM Terminals and Reference Value .....................695

On Board Diagnosis Logic.......................................695

DTC Confirmation Procedure ..................................696

Wiring Diagram ........................................................697

Diagnostic Procedure ..............................................698

DTC P0500 VEHICLE SPEED SEN............................701

Description ...............................................................701

ECM Terminals and Reference Value .....................701

On Board Diagnosis Logic.......................................701

Overall Function Check ...........................................701

Wiring Diagram ........................................................703

Diagnostic Procedure ..............................................705

DTC P0571 BRAKE SW..............................................706

Description ...............................................................706

ECM Terminals and Reference Value .....................706

On Board Diagnosis Logic.......................................706

DTC Confirmation Procedure ..................................706

Wiring Diagram ........................................................708

Diagnostic Procedure ..............................................710

DTC P1107 ECM 10....................................................714

Description ...............................................................714

On Board Diagnosis Logic.......................................714

DTC Confirmation Procedure ..................................714

Diagnostic Procedure ..............................................715

DTC P1180 P9.FUEL TEMP SEN...............................716

Description ...............................................................716

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................716

ECM Terminals and Reference Value .....................717

On Board Diagnosis Logic.......................................717

DTC Confirmation Procedure ..................................717

Wiring Diagram ........................................................719

Diagnostic Procedure ..............................................721

DTC P1202 FUEL CUT SYSTEM2.............................723

Description ...............................................................723

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................723

ECM Terminals and Reference Value .....................724

On Board Diagnosis Logic.......................................724

DTC Confirmation Procedure ..................................724

Wiring Diagram ........................................................726

Diagnostic Procedure ..............................................728

DTC P1217 OVER HEAT............................................730

Description ...............................................................730CONSULT-II Reference Value in Data Monitor

Mode ........................................................................730

ECM Terminals and Reference Value .....................730

On Board Diagnosis Logic.......................................731

Overall Function Check ...........................................732

Wiring Diagram ........................................................733

Diagnostic Procedure ..............................................735

Main 12 Causes of Overheating..............................756

DTC P1241 P7.F/INJ TIMG FB...................................757

Description ...............................................................757

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................757

ECM Terminals and Reference Value .....................758

On Board Diagnosis Logic.......................................758

DTC Confirmation Procedure ..................................758

Wiring Diagram ........................................................760

Diagnostic Procedure ..............................................762

DTC P1251 P4.SPILL/V CIRC....................................764

Description ...............................................................764

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................764

ECM Terminals and Reference Value .....................765

On Board Diagnosis Logic.......................................765

DTC Confirmation Procedure ..................................765

Wiring Diagram ........................................................767

Diagnostic Procedure ..............................................769

DTC P1337 P2.DTC PULSE SIG................................771

Description ...............................................................771

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................771

ECM Terminals and Reference Value .....................772

On Board Diagnosis Logic.......................................772

DTC Confirmation Procedure ..................................772

Wiring Diagram ........................................................774

Diagnostic Procedure ..............................................776

DTC P1341 P1.CAM POS SEN..................................778

Description ...............................................................778

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................778

ECM Terminals and Reference Value .....................779

On Board Diagnosis Logic.......................................779

DTC Confirmation Procedure ..................................779

Wiring Diagram ........................................................781

Diagnostic Procedure ..............................................783

DTC P1600 P3.PUMP COMM LINE............................785

Description ...............................................................785

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................785

ECM Terminals and Reference Value .....................786

On Board Diagnosis Logic.......................................786

DTC Confirmation Procedure ..................................786

Wiring Diagram ........................................................788

CONTENTS(Cont'd)

EC-8

Page 734 of 2898

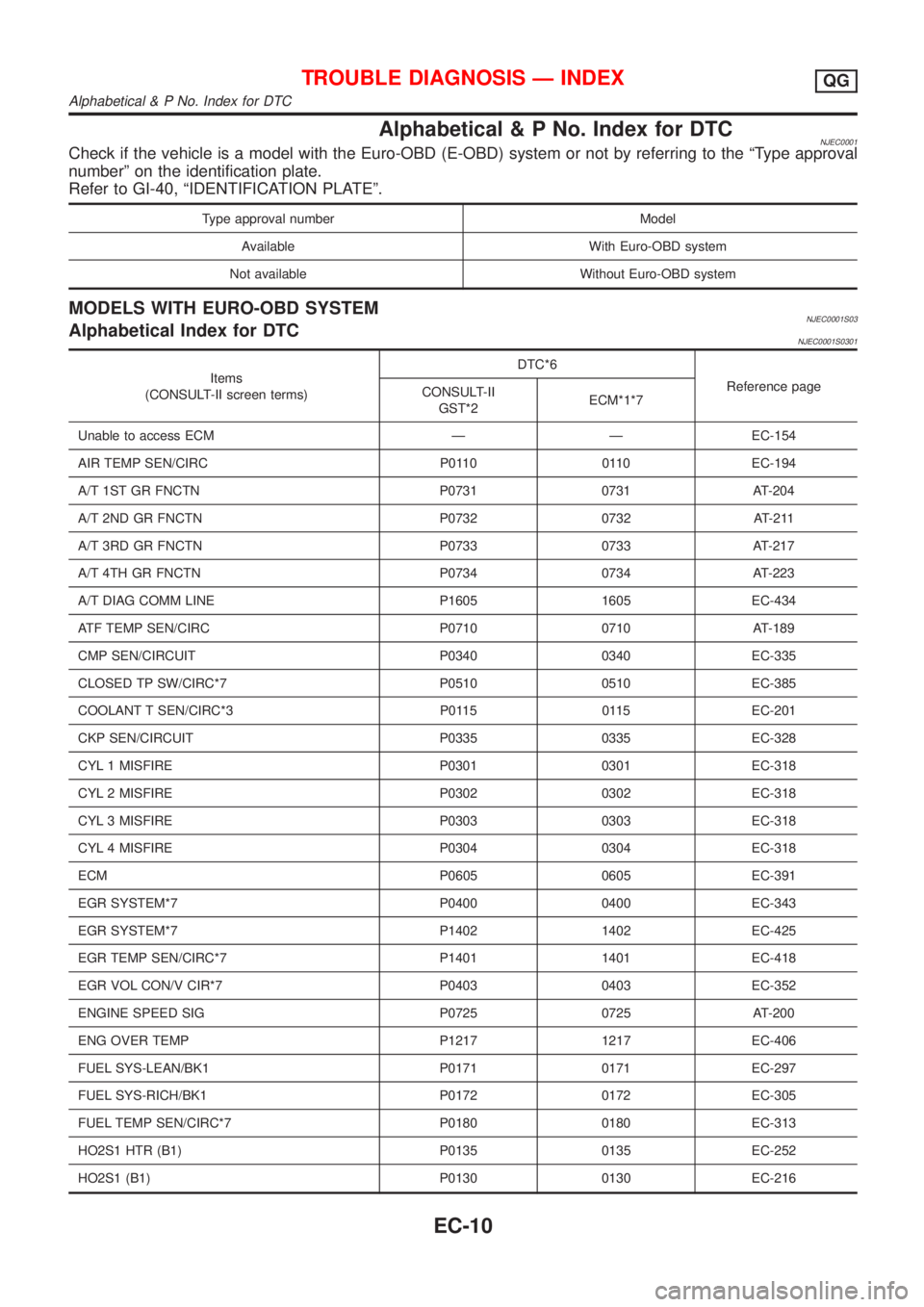

Alphabetical & P No. Index for DTCNJEC0001Check if the vehicle is a model with the Euro-OBD (E-OBD) system or not by referring to the ªType approval

numberº on the identification plate.

Refer to GI-40, ªIDENTIFICATION PLATEº.

Type approval number Model

Available With Euro-OBD system

Not available Without Euro-OBD system

MODELS WITH EURO-OBD SYSTEMNJEC0001S03Alphabetical Index for DTCNJEC0001S0301

Items

(CONSULT-II screen terms)DTC*6

Reference page

CONSULT-II

GST*2ECM*1*7

Unable to access ECM Ð Ð EC-154

AIR TEMP SEN/CIRC P0110 0110 EC-194

A/T 1ST GR FNCTN P0731 0731 AT-204

A/T 2ND GR FNCTN P0732 0732 AT-211

A/T 3RD GR FNCTN P0733 0733 AT-217

A/T 4TH GR FNCTN P0734 0734 AT-223

A/T DIAG COMM LINE P1605 1605 EC-434

ATF TEMP SEN/CIRC P0710 0710 AT-189

CMP SEN/CIRCUIT P0340 0340 EC-335

CLOSED TP SW/CIRC*7 P0510 0510 EC-385

COOLANT T SEN/CIRC*3 P0115 0115 EC-201

CKP SEN/CIRCUIT P0335 0335 EC-328

CYL 1 MISFIRE P0301 0301 EC-318

CYL 2 MISFIRE P0302 0302 EC-318

CYL 3 MISFIRE P0303 0303 EC-318

CYL 4 MISFIRE P0304 0304 EC-318

ECM P0605 0605 EC-391

EGR SYSTEM*7 P0400 0400 EC-343

EGR SYSTEM*7 P1402 1402 EC-425

EGR TEMP SEN/CIRC*7 P1401 1401 EC-418

EGR VOL CON/V CIR*7 P0403 0403 EC-352

ENGINE SPEED SIG P0725 0725 AT-200

ENG OVER TEMP P1217 1217 EC-406

FUEL SYS-LEAN/BK1 P0171 0171 EC-297

FUEL SYS-RICH/BK1 P0172 0172 EC-305

FUEL TEMP SEN/CIRC*7 P0180 0180 EC-313

HO2S1 HTR (B1) P0135 0135 EC-252

HO2S1 (B1) P0130 0130 EC-216

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC

EC-10

Page 736 of 2898

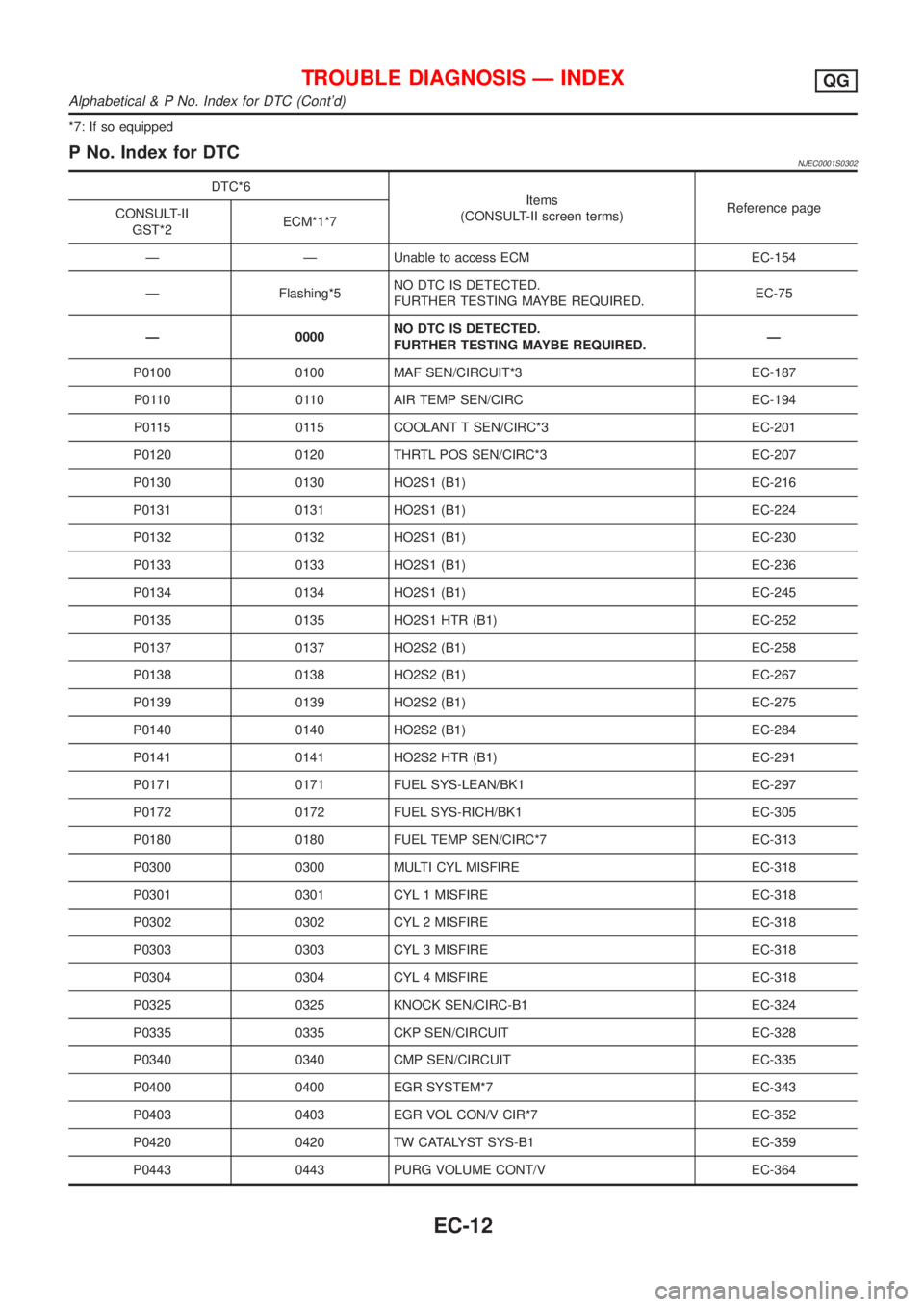

*7: If so equipped

P No. Index for DTCNJEC0001S0302

DTC*6

Items

(CONSULT-II screen terms)Reference page

CONSULT-II

GST*2ECM*1*7

Ð Ð Unable to access ECM EC-154

Ð Flashing*5NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.EC-75

Ð 0000NO DTC IS DETECTED.

FURTHER TESTING MAYBE REQUIRED.Ð

P0100 0100 MAF SEN/CIRCUIT*3 EC-187

P0110 0110 AIR TEMP SEN/CIRC EC-194

P0115 0115 COOLANT T SEN/CIRC*3 EC-201

P0120 0120 THRTL POS SEN/CIRC*3 EC-207

P0130 0130 HO2S1 (B1) EC-216

P0131 0131 HO2S1 (B1) EC-224

P0132 0132 HO2S1 (B1) EC-230

P0133 0133 HO2S1 (B1) EC-236

P0134 0134 HO2S1 (B1) EC-245

P0135 0135 HO2S1 HTR (B1) EC-252

P0137 0137 HO2S2 (B1) EC-258

P0138 0138 HO2S2 (B1) EC-267

P0139 0139 HO2S2 (B1) EC-275

P0140 0140 HO2S2 (B1) EC-284

P0141 0141 HO2S2 HTR (B1) EC-291

P0171 0171 FUEL SYS-LEAN/BK1 EC-297

P0172 0172 FUEL SYS-RICH/BK1 EC-305

P0180 0180 FUEL TEMP SEN/CIRC*7 EC-313

P0300 0300 MULTI CYL MISFIRE EC-318

P0301 0301 CYL 1 MISFIRE EC-318

P0302 0302 CYL 2 MISFIRE EC-318

P0303 0303 CYL 3 MISFIRE EC-318

P0304 0304 CYL 4 MISFIRE EC-318

P0325 0325 KNOCK SEN/CIRC-B1 EC-324

P0335 0335 CKP SEN/CIRCUIT EC-328

P0340 0340 CMP SEN/CIRCUIT EC-335

P0400 0400 EGR SYSTEM*7 EC-343

P0403 0403 EGR VOL CON/V CIR*7 EC-352

P0420 0420 TW CATALYST SYS-B1 EC-359

P0443 0443 PURG VOLUME CONT/V EC-364

TROUBLE DIAGNOSIS Ð INDEXQG

Alphabetical & P No. Index for DTC (Cont'd)

EC-12

Page 740 of 2898

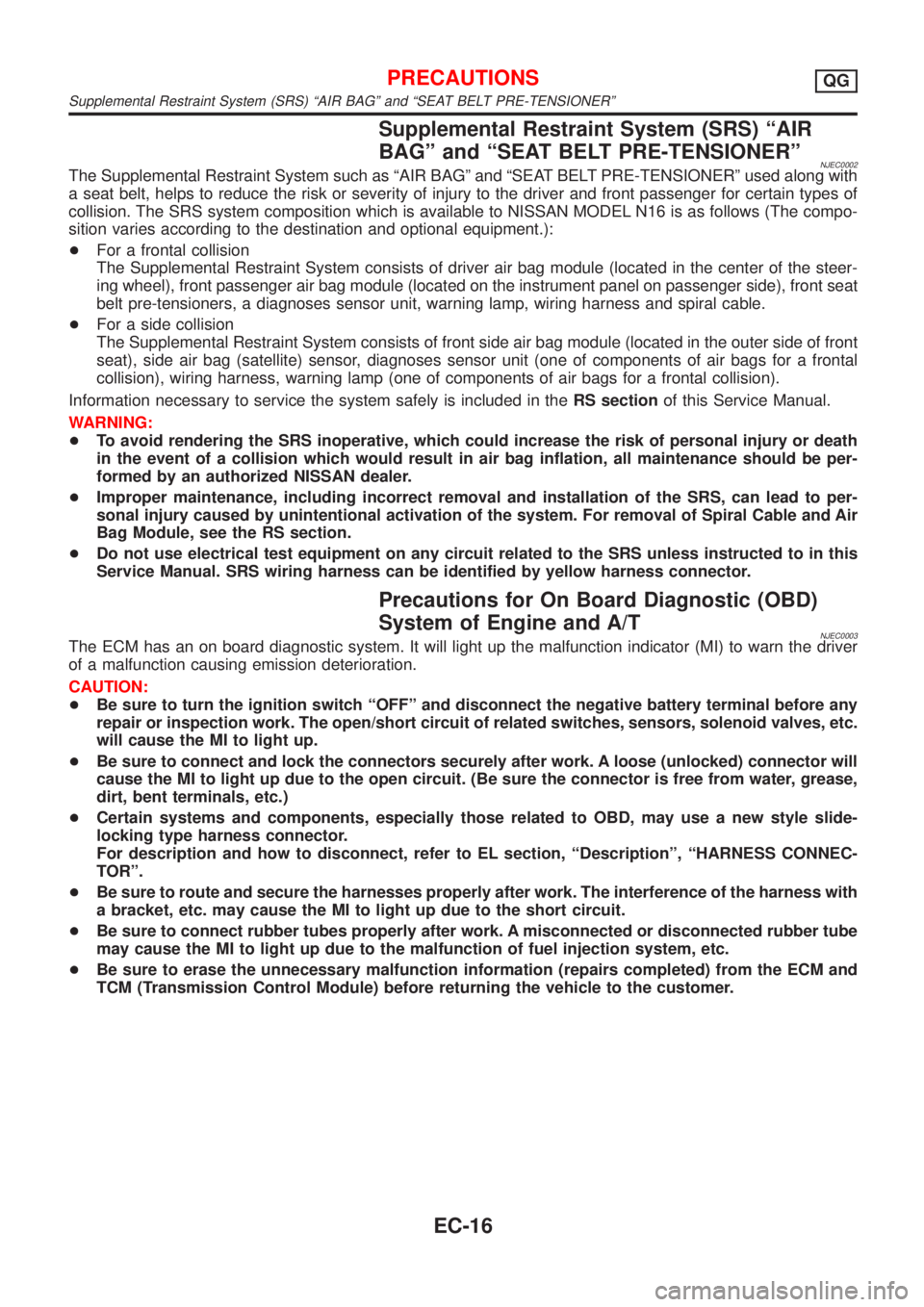

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJEC0002The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnoses sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnoses sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harness can be identified by yellow harness connector.

Precautions for On Board Diagnostic (OBD)

System of Engine and A/T

NJEC0003The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver

of a malfunction causing emission deterioration.

CAUTION:

+Be sure to turn the ignition switch ªOFFº and disconnect the negative battery terminal before any

repair or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc.

will cause the MI to light up.

+Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

+Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector.

For description and how to disconnect, refer to EL section, ªDescriptionº, ªHARNESS CONNEC-

TORº.

+Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MI to light up due to the short circuit.

+Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of fuel injection system, etc.

+Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission Control Module) before returning the vehicle to the customer.

PRECAUTIONSQG

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EC-16

Page 741 of 2898

SEF706Y

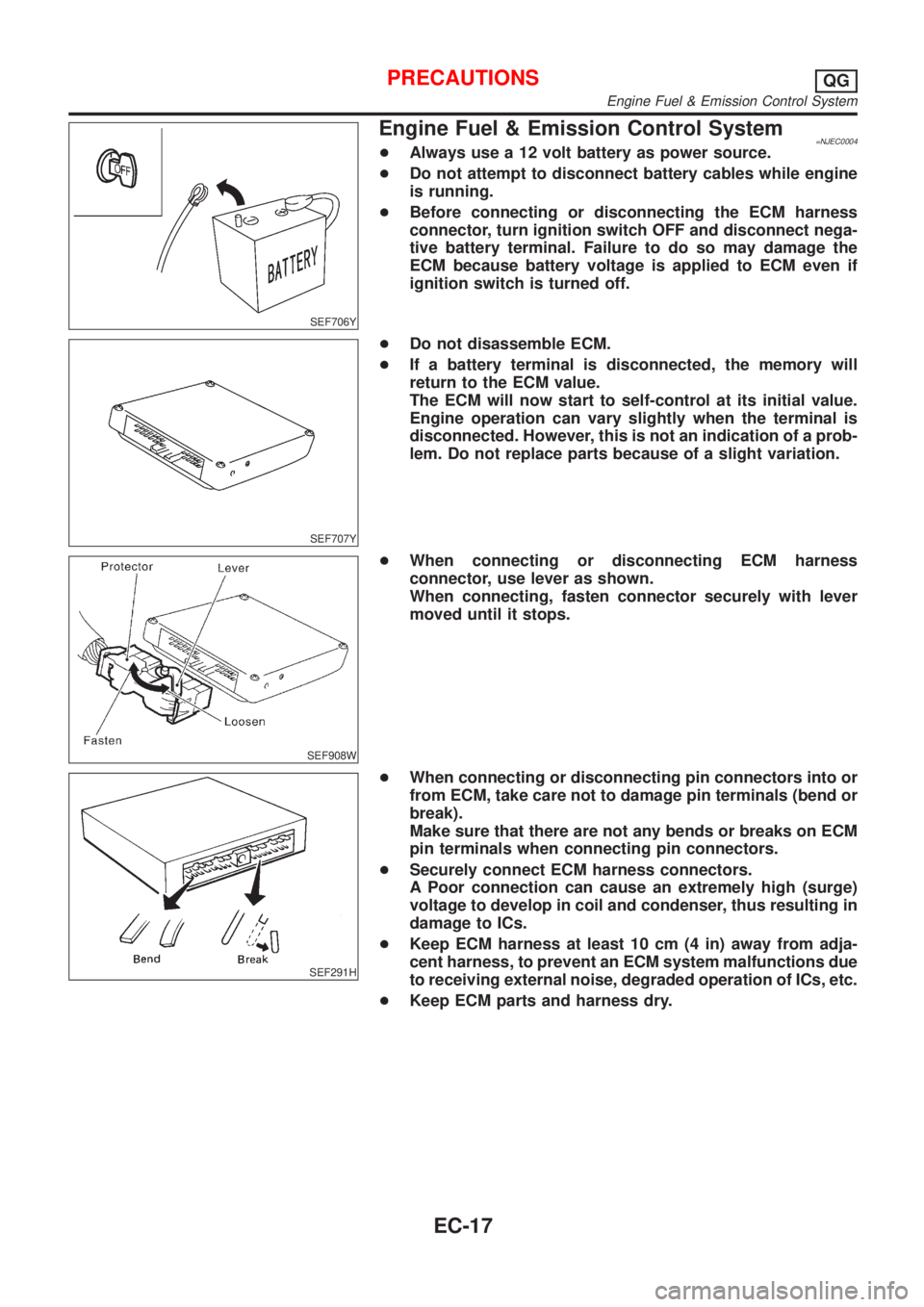

Engine Fuel & Emission Control System=NJEC0004+Always use a 12 volt battery as power source.

+Do not attempt to disconnect battery cables while engine

is running.

+Before connecting or disconnecting the ECM harness

connector, turn ignition switch OFF and disconnect nega-

tive battery terminal. Failure to do so may damage the

ECM because battery voltage is applied to ECM even if

ignition switch is turned off.

SEF707Y

+Do not disassemble ECM.

+If a battery terminal is disconnected, the memory will

return to the ECM value.

The ECM will now start to self-control at its initial value.

Engine operation can vary slightly when the terminal is

disconnected. However, this is not an indication of a prob-

lem. Do not replace parts because of a slight variation.

SEF908W

+When connecting or disconnecting ECM harness

connector, use lever as shown.

When connecting, fasten connector securely with lever

moved until it stops.

SEF291H

+When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminals when connecting pin connectors.

+Securely connect ECM harness connectors.

A Poor connection can cause an extremely high (surge)

voltage to develop in coil and condenser, thus resulting in

damage to ICs.

+Keep ECM harness at least 10 cm (4 in) away from adja-

cent harness, to prevent an ECM system malfunctions due

to receiving external noise, degraded operation of ICs, etc.

+Keep ECM parts and harness dry.

PRECAUTIONSQG

Engine Fuel & Emission Control System

EC-17

Page 742 of 2898

MEF040D

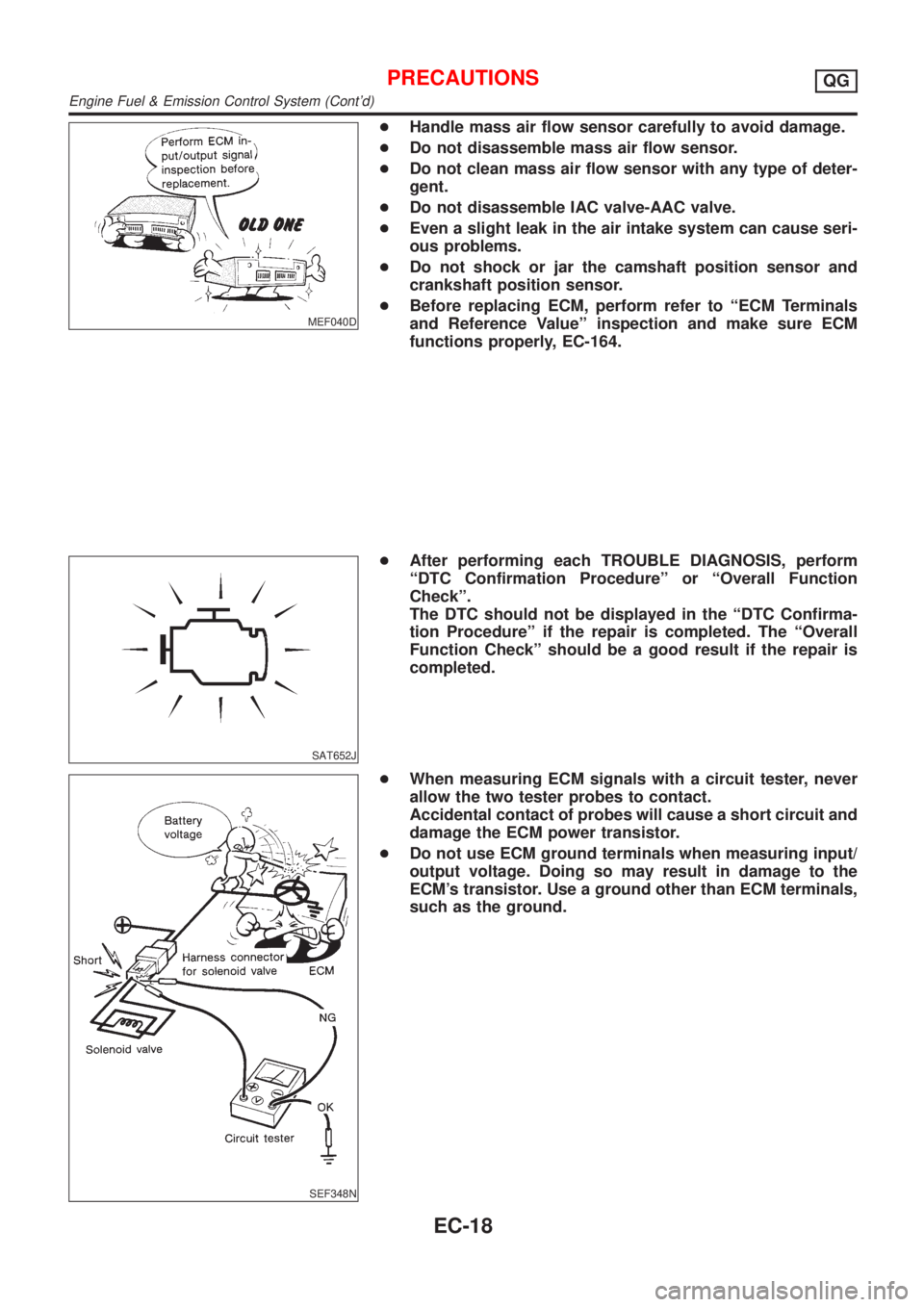

+Handle mass air flow sensor carefully to avoid damage.

+Do not disassemble mass air flow sensor.

+Do not clean mass air flow sensor with any type of deter-

gent.

+Do not disassemble IAC valve-AAC valve.

+Even a slight leak in the air intake system can cause seri-

ous problems.

+Do not shock or jar the camshaft position sensor and

crankshaft position sensor.

+Before replacing ECM, perform refer to ªECM Terminals

and Reference Valueº inspection and make sure ECM

functions properly, EC-164.

SAT652J

+After performing each TROUBLE DIAGNOSIS, perform

ªDTC Confirmation Procedureº or ªOverall Function

Checkº.

The DTC should not be displayed in the ªDTC Confirma-

tion Procedureº if the repair is completed. The ªOverall

Function Checkº should be a good result if the repair is

completed.

SEF348N

+When measuring ECM signals with a circuit tester, never

allow the two tester probes to contact.

Accidental contact of probes will cause a short circuit and

damage the ECM power transistor.

+Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the

ECM's transistor. Use a ground other than ECM terminals,

such as the ground.

PRECAUTIONSQG

Engine Fuel & Emission Control System (Cont'd)

EC-18