NISSAN ALMERA 2001 Service Manual

ALMERA 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57348/w960_57348-0.png

NISSAN ALMERA 2001 Service Manual

Trending: headlamp, service interval, maintenance, roof rack, fog light bulb, warning, engine overheat

Page 2331 of 2898

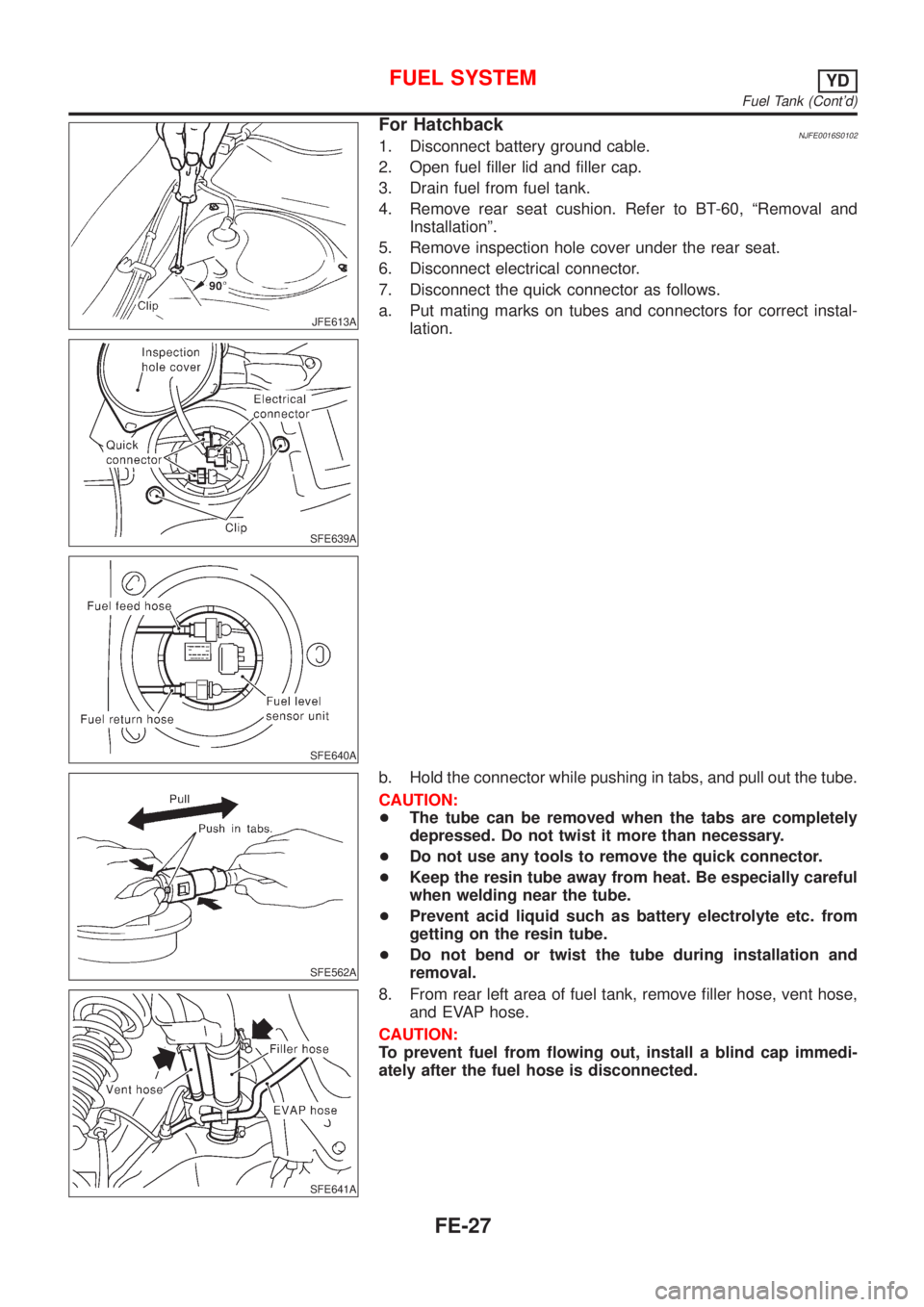

JFE613A

SFE639A

SFE640A

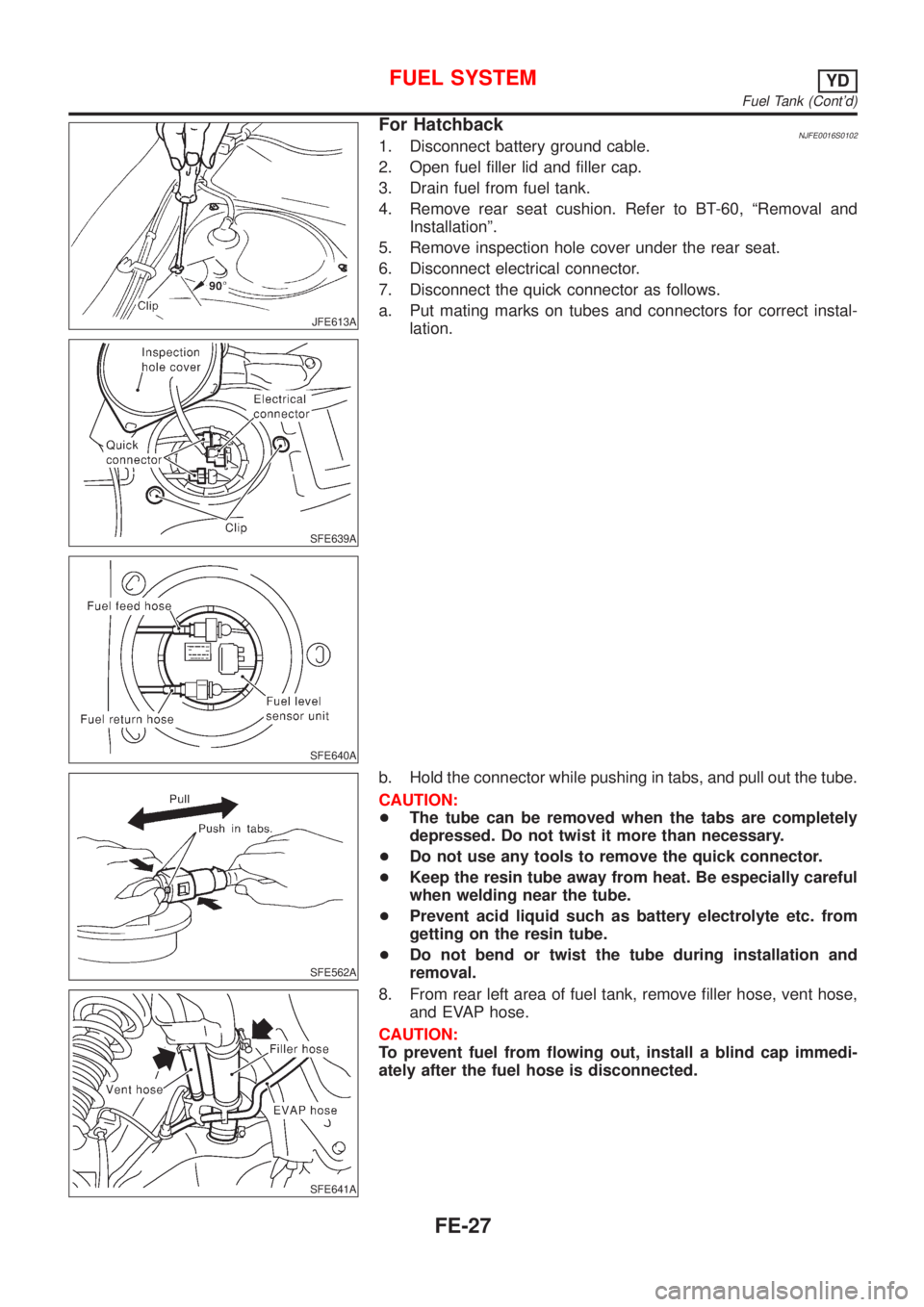

For HatchbackNJFE0016S01021. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-60, ªRemoval and

Installationº.

5. Remove inspection hole cover under the rear seat.

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct instal-

lation.

SFE562A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

+The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

+Do not use any tools to remove the quick connector.

+Keep the resin tube away from heat. Be especially careful

when welding near the tube.

+Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

+Do not bend or twist the tube during installation and

removal.

SFE641A

8. From rear left area of fuel tank, remove filler hose, vent hose,

and EVAP hose.

CAUTION:

To prevent fuel from flowing out, install a blind cap immedi-

ately after the fuel hose is disconnected.

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-27

Page 2332 of 2898

SFE642A

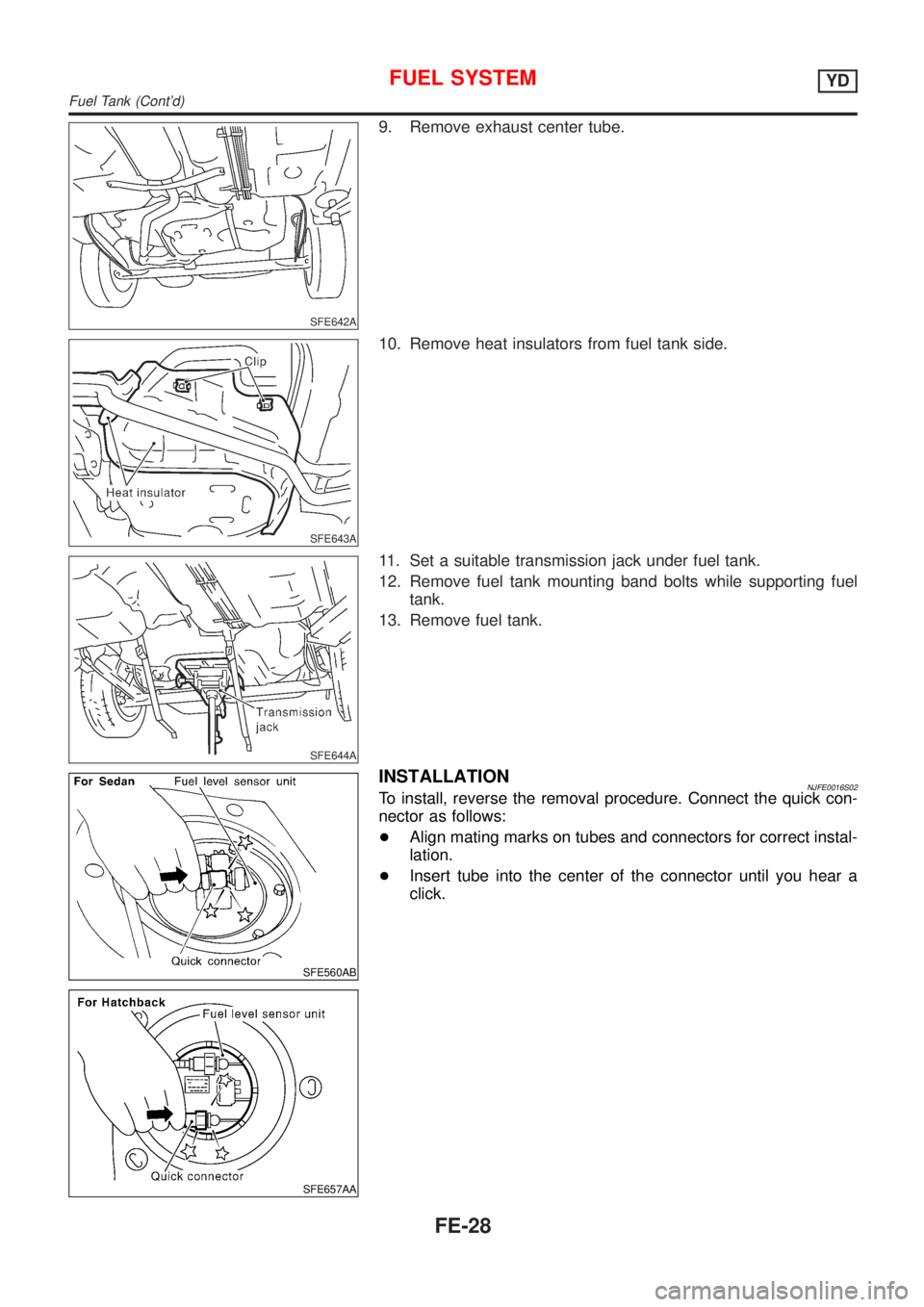

9. Remove exhaust center tube.

SFE643A

10. Remove heat insulators from fuel tank side.

SFE644A

11. Set a suitable transmission jack under fuel tank.

12. Remove fuel tank mounting band bolts while supporting fuel

tank.

13. Remove fuel tank.

SFE560AB

SFE657AA

INSTALLATIONNJFE0016S02To install, reverse the removal procedure. Connect the quick con-

nector as follows:

+Align mating marks on tubes and connectors for correct instal-

lation.

+Insert tube into the center of the connector until you hear a

click.

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-28

Page 2333 of 2898

SFE561AB

SFE658AA

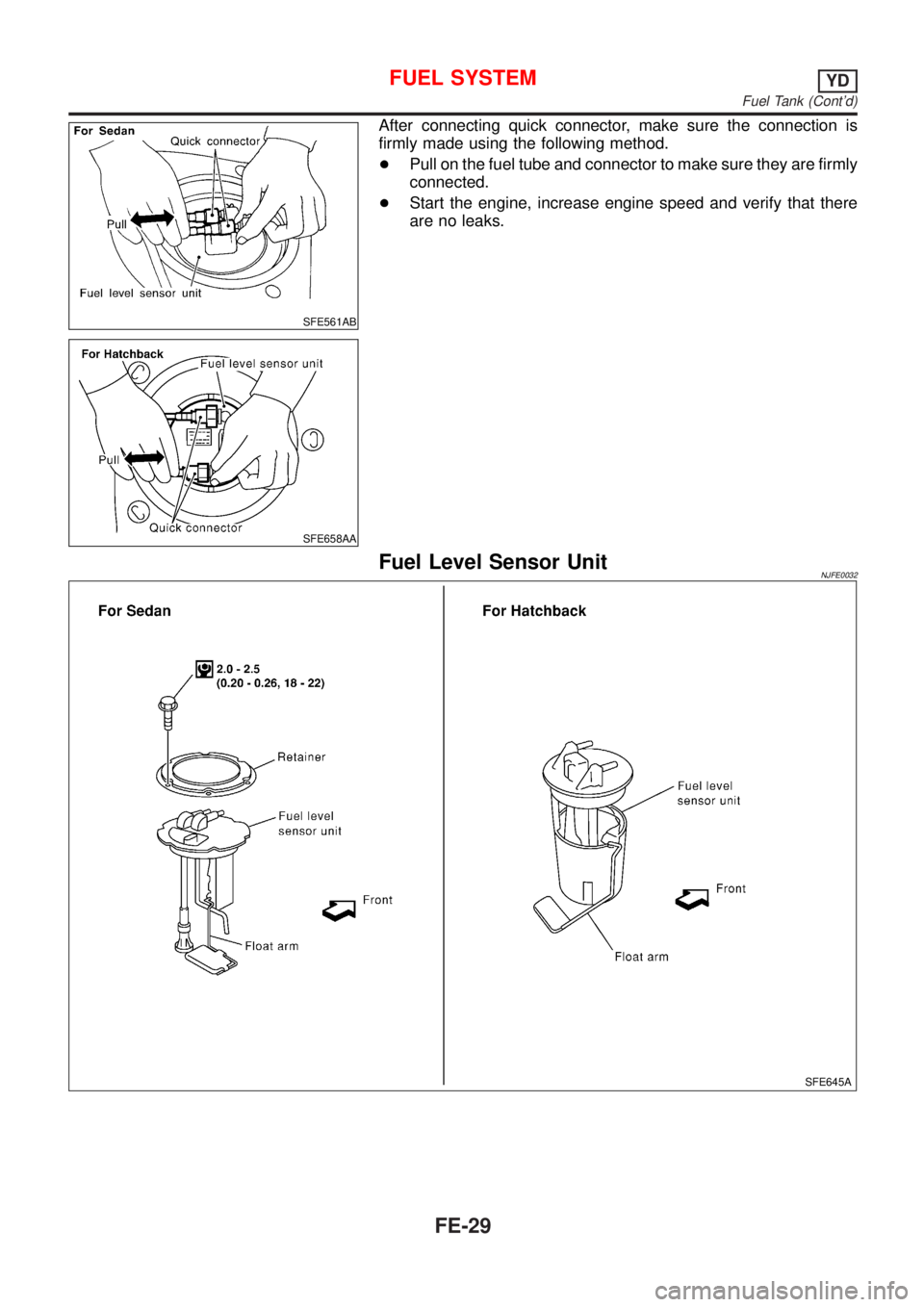

After connecting quick connector, make sure the connection is

firmly made using the following method.

+Pull on the fuel tube and connector to make sure they are firmly

connected.

+Start the engine, increase engine speed and verify that there

are no leaks.

Fuel Level Sensor UnitNJFE0032

SFE645A

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-29

Page 2334 of 2898

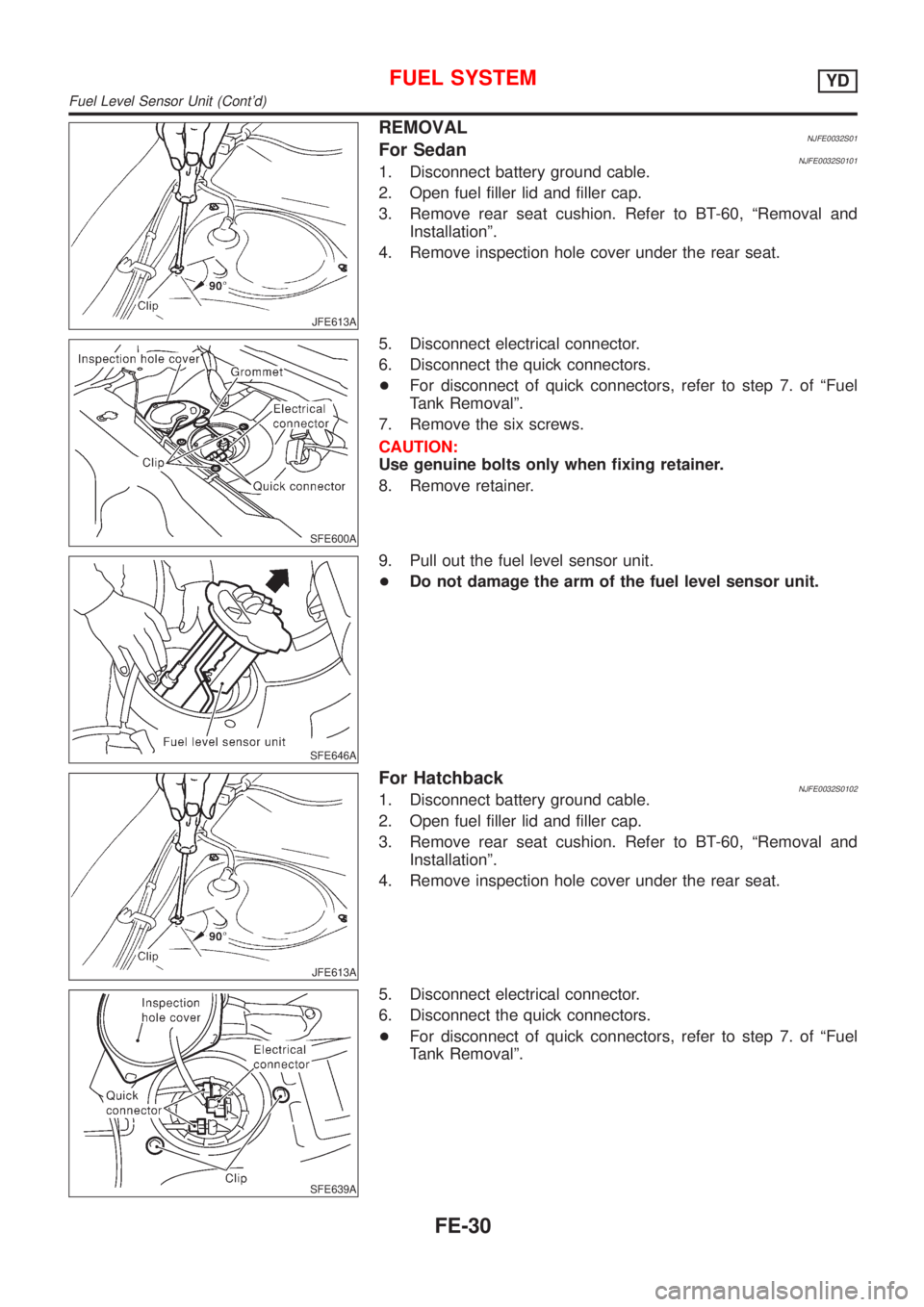

JFE613A

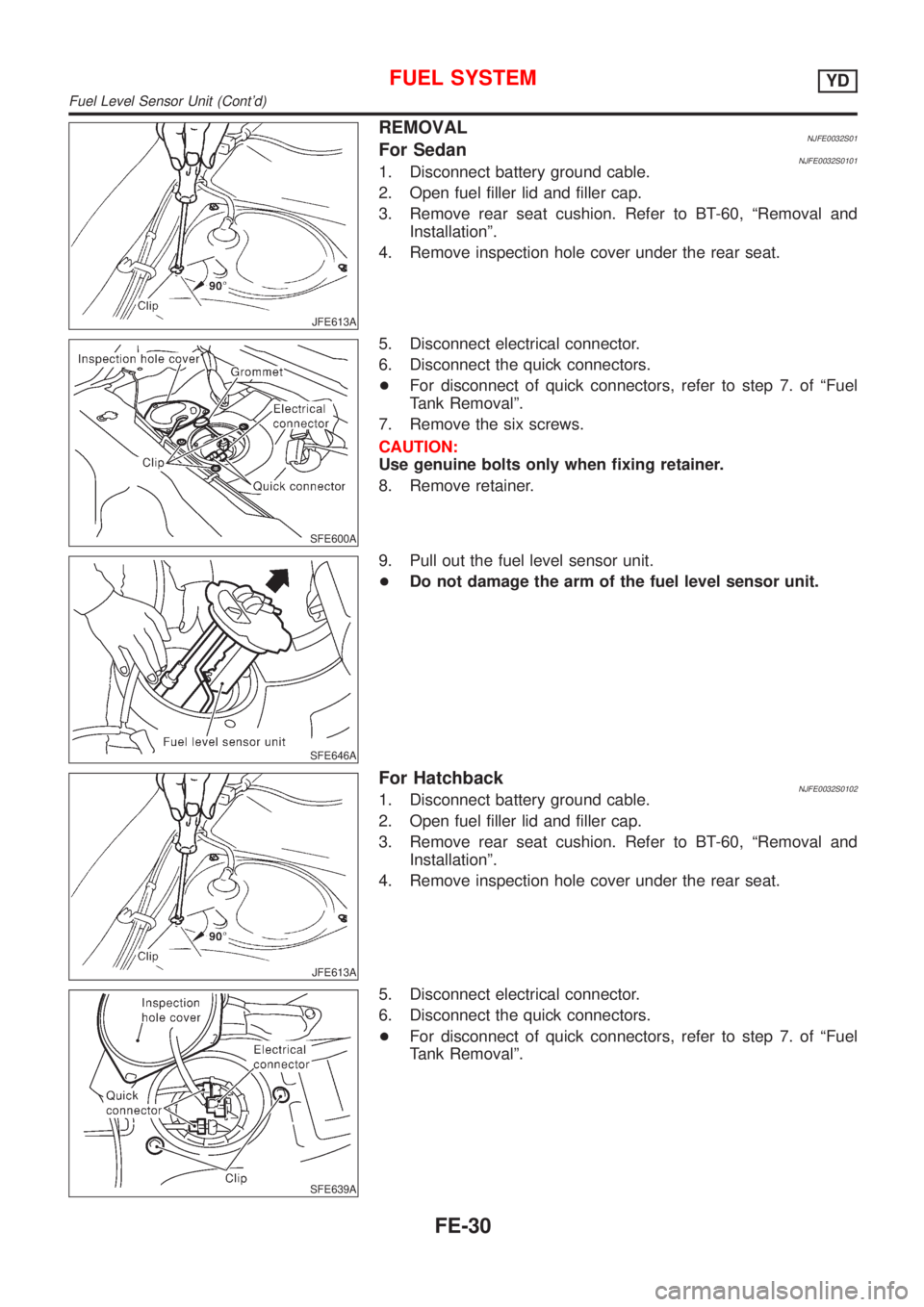

REMOVALNJFE0032S01For SedanNJFE0032S01011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Remove rear seat cushion. Refer to BT-60, ªRemoval and

Installationº.

4. Remove inspection hole cover under the rear seat.

SFE600A

5. Disconnect electrical connector.

6. Disconnect the quick connectors.

+For disconnect of quick connectors, refer to step 7. of ªFuel

Tank Removalº.

7. Remove the six screws.

CAUTION:

Use genuine bolts only when fixing retainer.

8. Remove retainer.

SFE646A

9. Pull out the fuel level sensor unit.

+Do not damage the arm of the fuel level sensor unit.

JFE613A

For HatchbackNJFE0032S01021. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Remove rear seat cushion. Refer to BT-60, ªRemoval and

Installationº.

4. Remove inspection hole cover under the rear seat.

SFE639A

5. Disconnect electrical connector.

6. Disconnect the quick connectors.

+For disconnect of quick connectors, refer to step 7. of ªFuel

Tank Removalº.

FUEL SYSTEMYD

Fuel Level Sensor Unit (Cont'd)

FE-30

Page 2335 of 2898

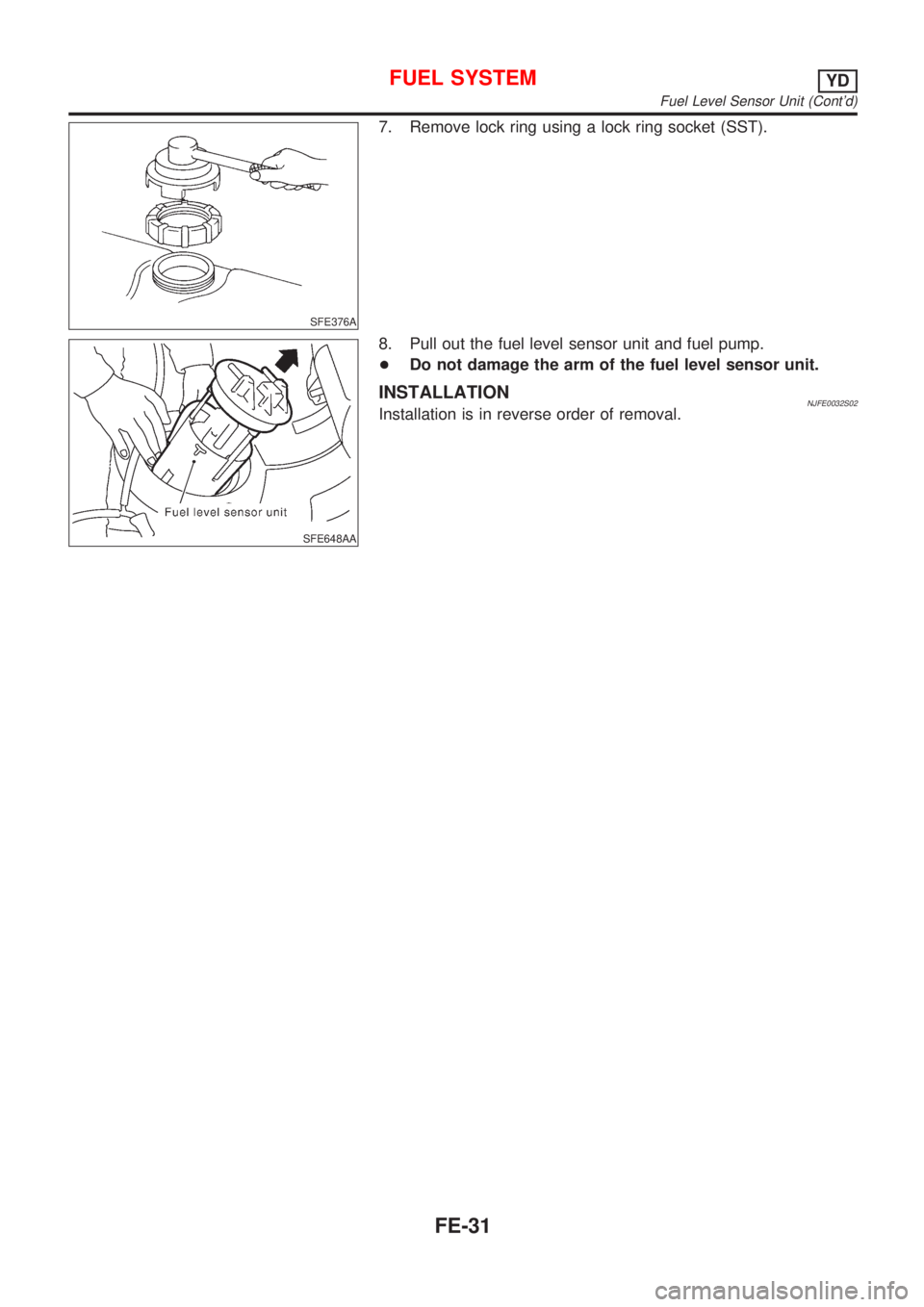

SFE376A

7. Remove lock ring using a lock ring socket (SST).

SFE648AA

8. Pull out the fuel level sensor unit and fuel pump.

+Do not damage the arm of the fuel level sensor unit.

INSTALLATIONNJFE0032S02Installation is in reverse order of removal.

FUEL SYSTEMYD

Fuel Level Sensor Unit (Cont'd)

FE-31

Page 2336 of 2898

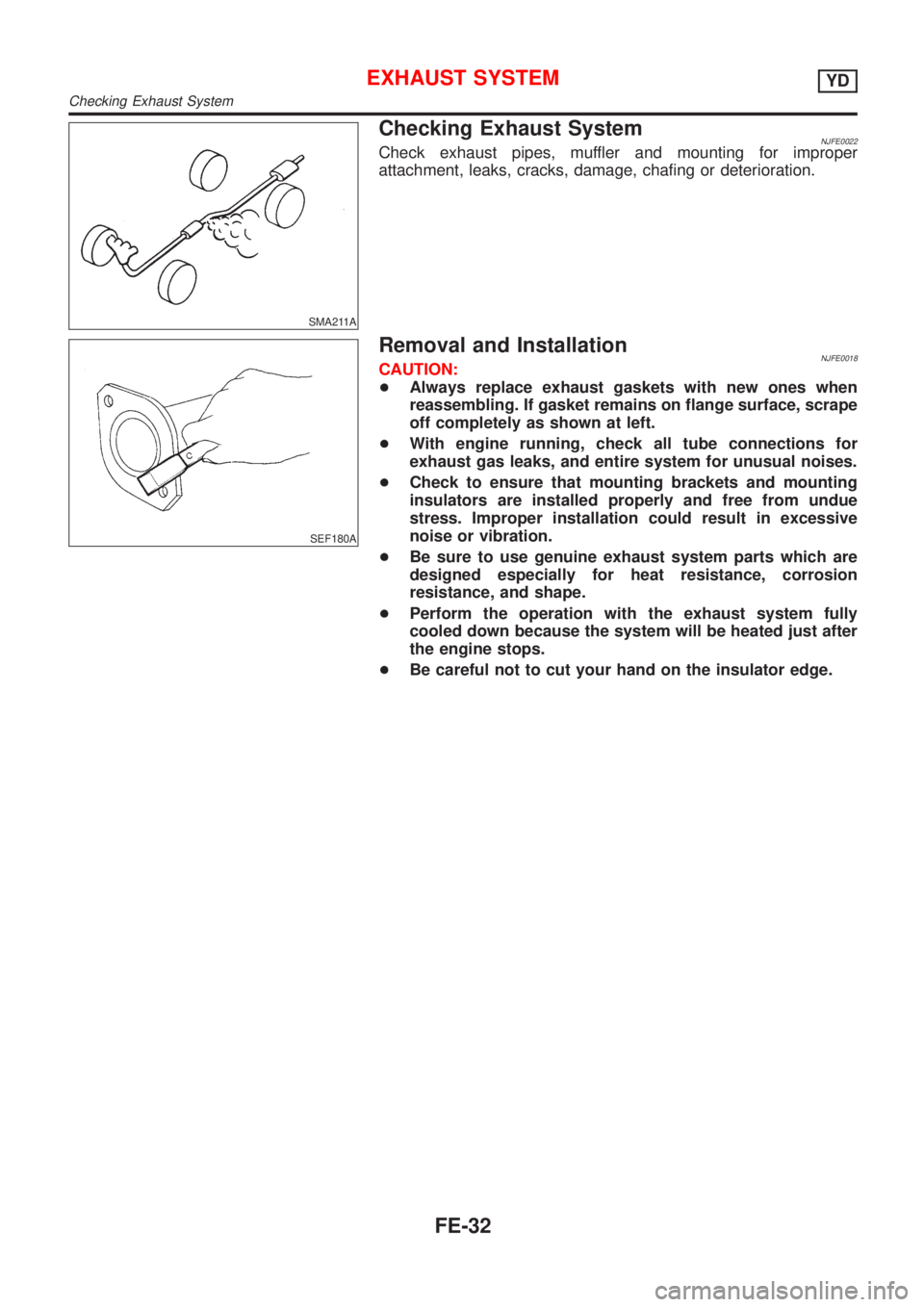

SMA211A

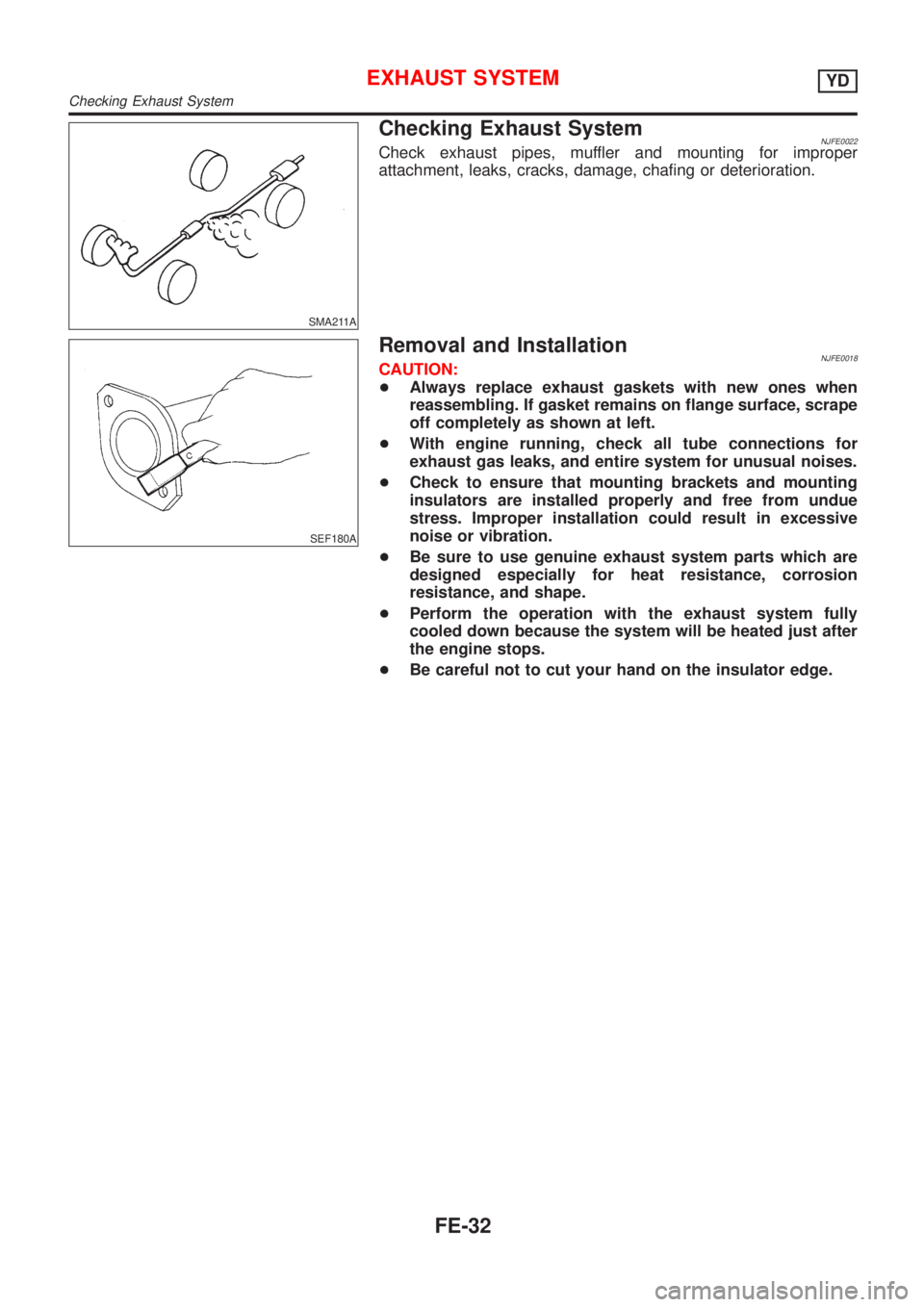

Checking Exhaust SystemNJFE0022Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

SEF180A

Removal and InstallationNJFE0018CAUTION:

+Always replace exhaust gaskets with new ones when

reassembling. If gasket remains on flange surface, scrape

off completely as shown at left.

+With engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

+Check to ensure that mounting brackets and mounting

insulators are installed properly and free from undue

stress. Improper installation could result in excessive

noise or vibration.

+Be sure to use genuine exhaust system parts which are

designed especially for heat resistance, corrosion

resistance, and shape.

+Perform the operation with the exhaust system fully

cooled down because the system will be heated just after

the engine stops.

+Be careful not to cut your hand on the insulator edge.

EXHAUST SYSTEMYD

Checking Exhaust System

FE-32

Page 2337 of 2898

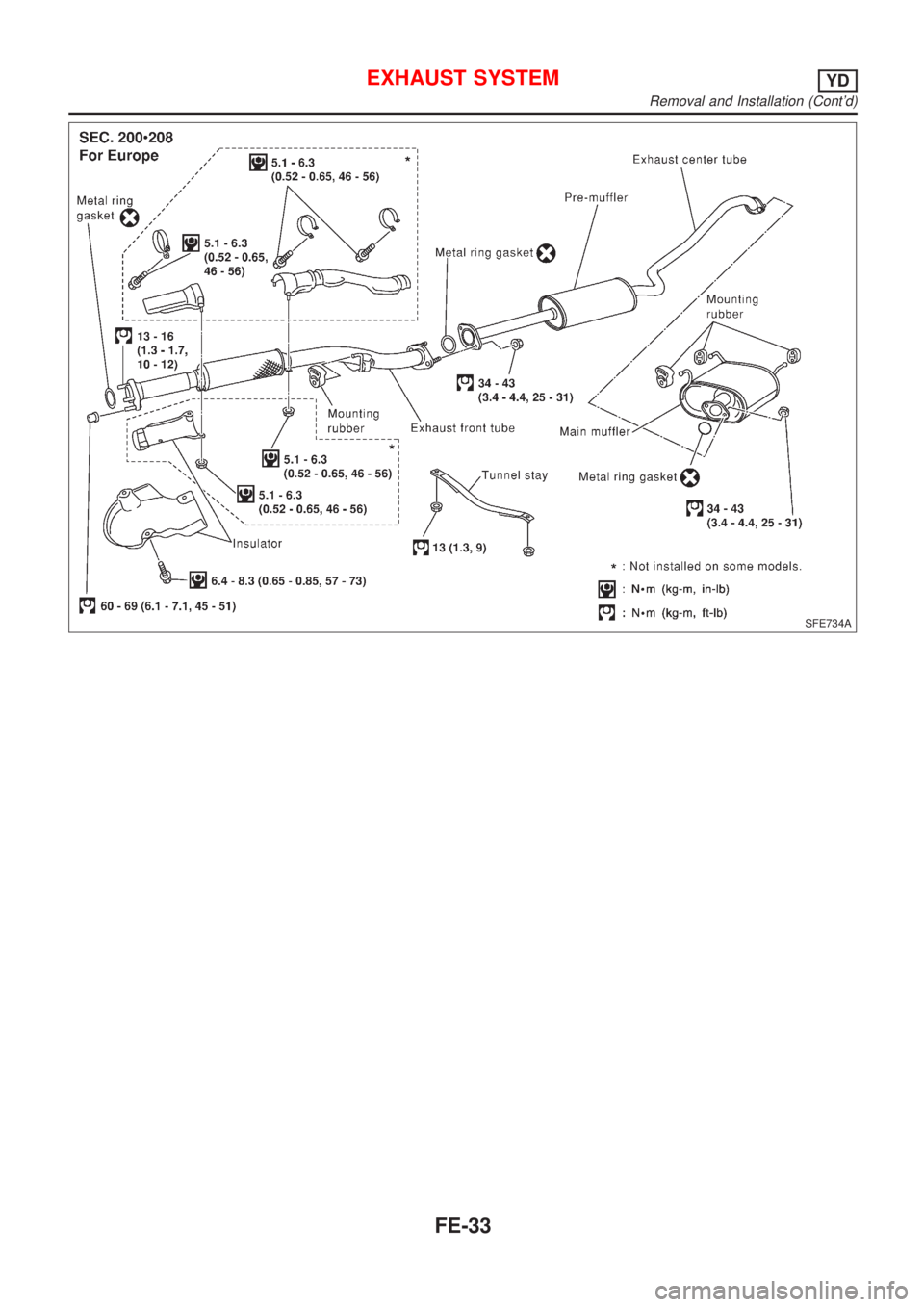

SFE734A

EXHAUST SYSTEMYD

Removal and Installation (Cont'd)

FE-33

Page 2338 of 2898

EXHAUST SYSTEM

Removal and Installation (Cont'd)

FE-34

Page 2339 of 2898

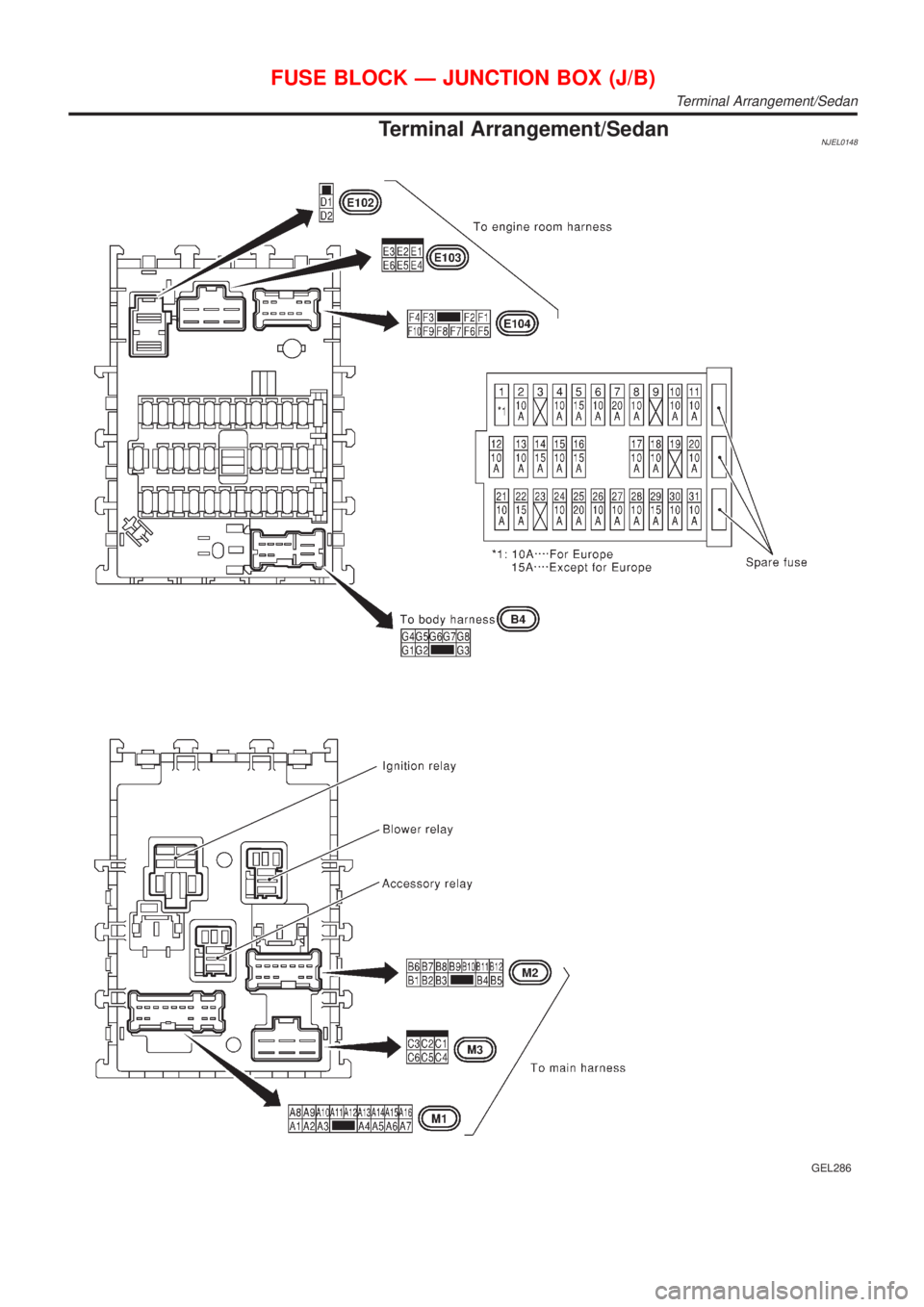

Termina lArrangement/Sedan

GEL286

Terminal Arrangement/Sedan

Page 2340 of 2898

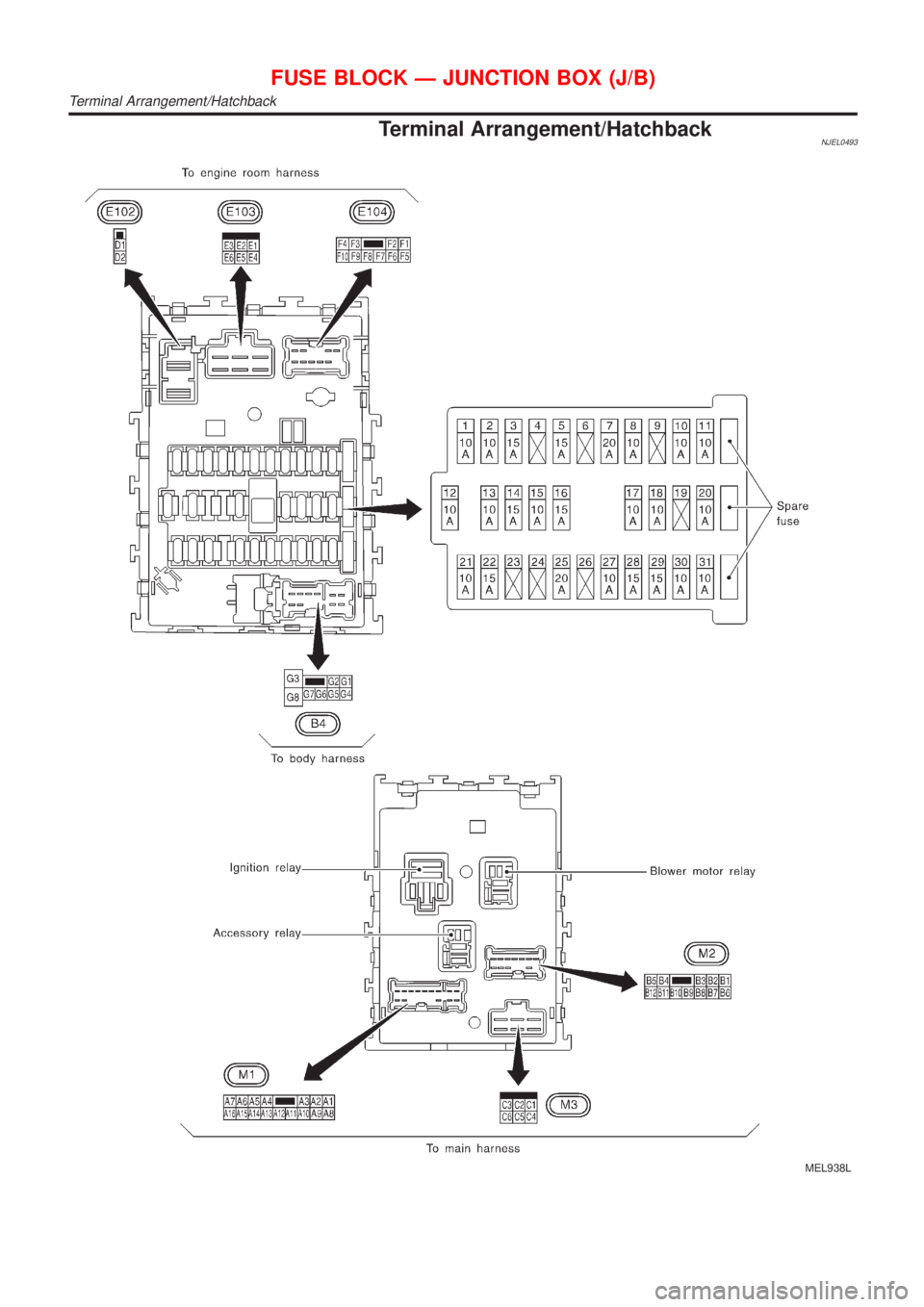

Termina lArrangement/Hatchback

MEL938L

Terminal Arrangement/Hatchback

Trending: cooling, warning lights, open gas tank, cruise control, maintenance schedule, headrest, steering wheel adjustment