NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2341 of 2898

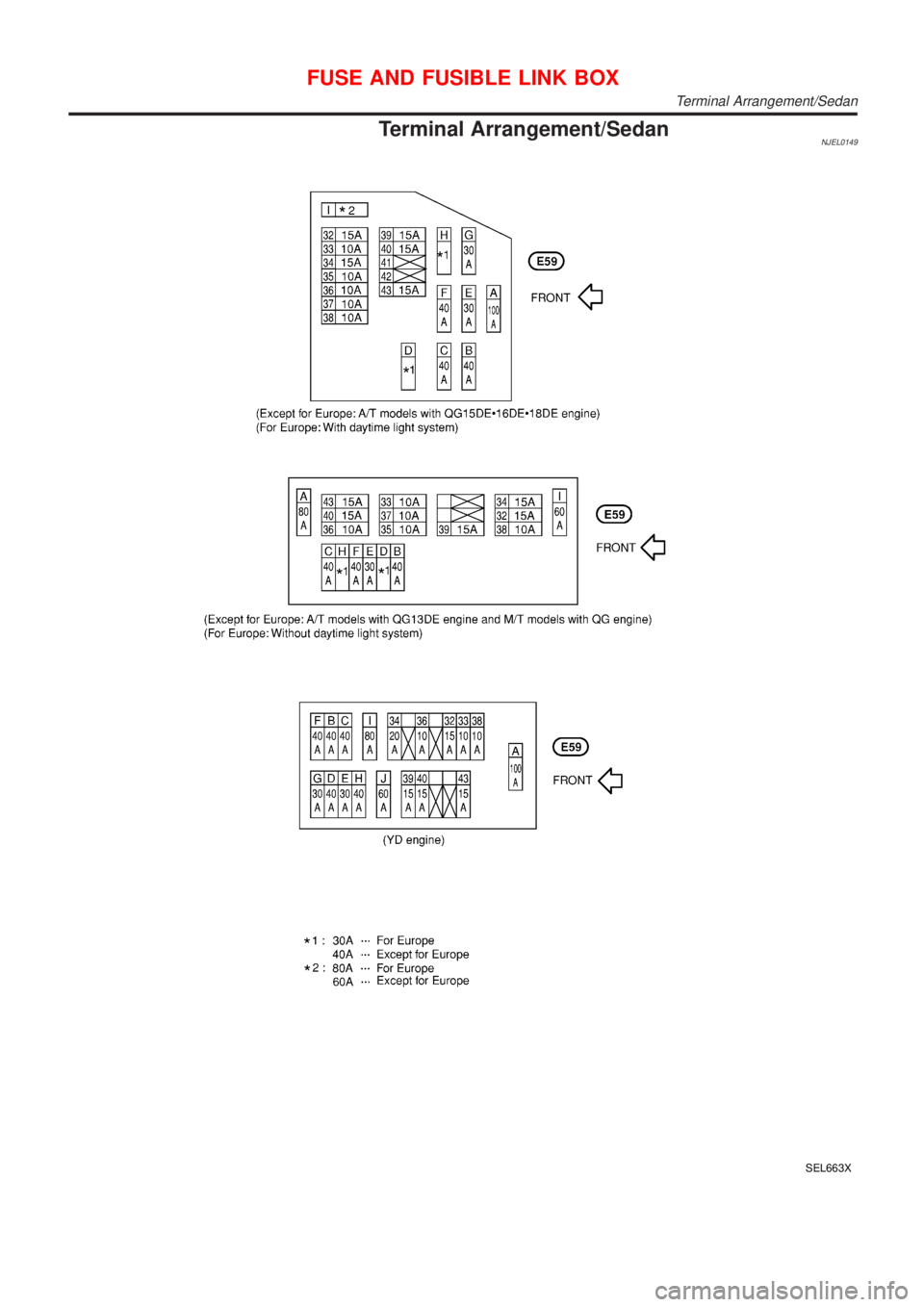

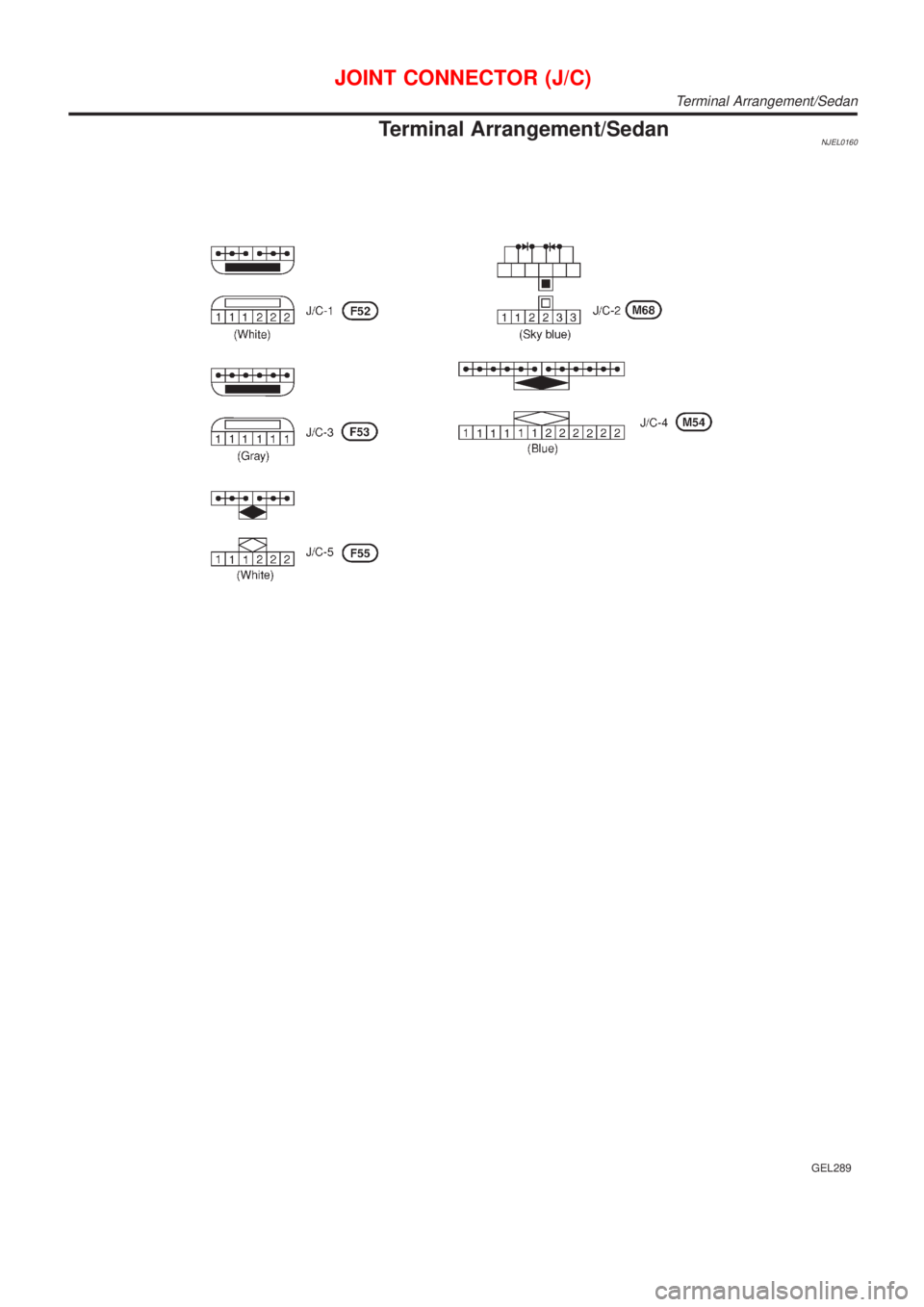

Termina lArrangement/Sedan

SEL663X

Terminal Arrangement/Sedan

Page 2342 of 2898

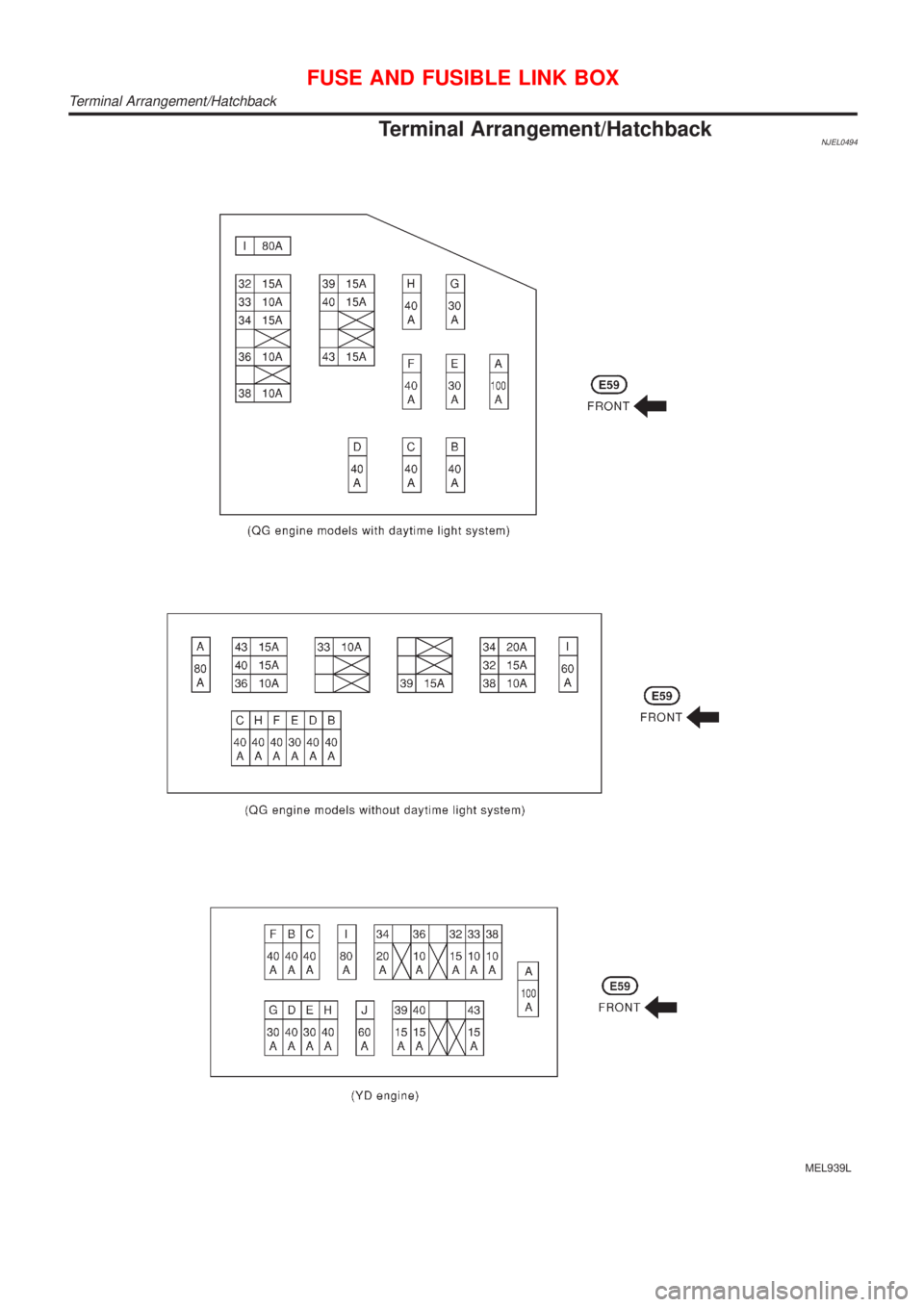

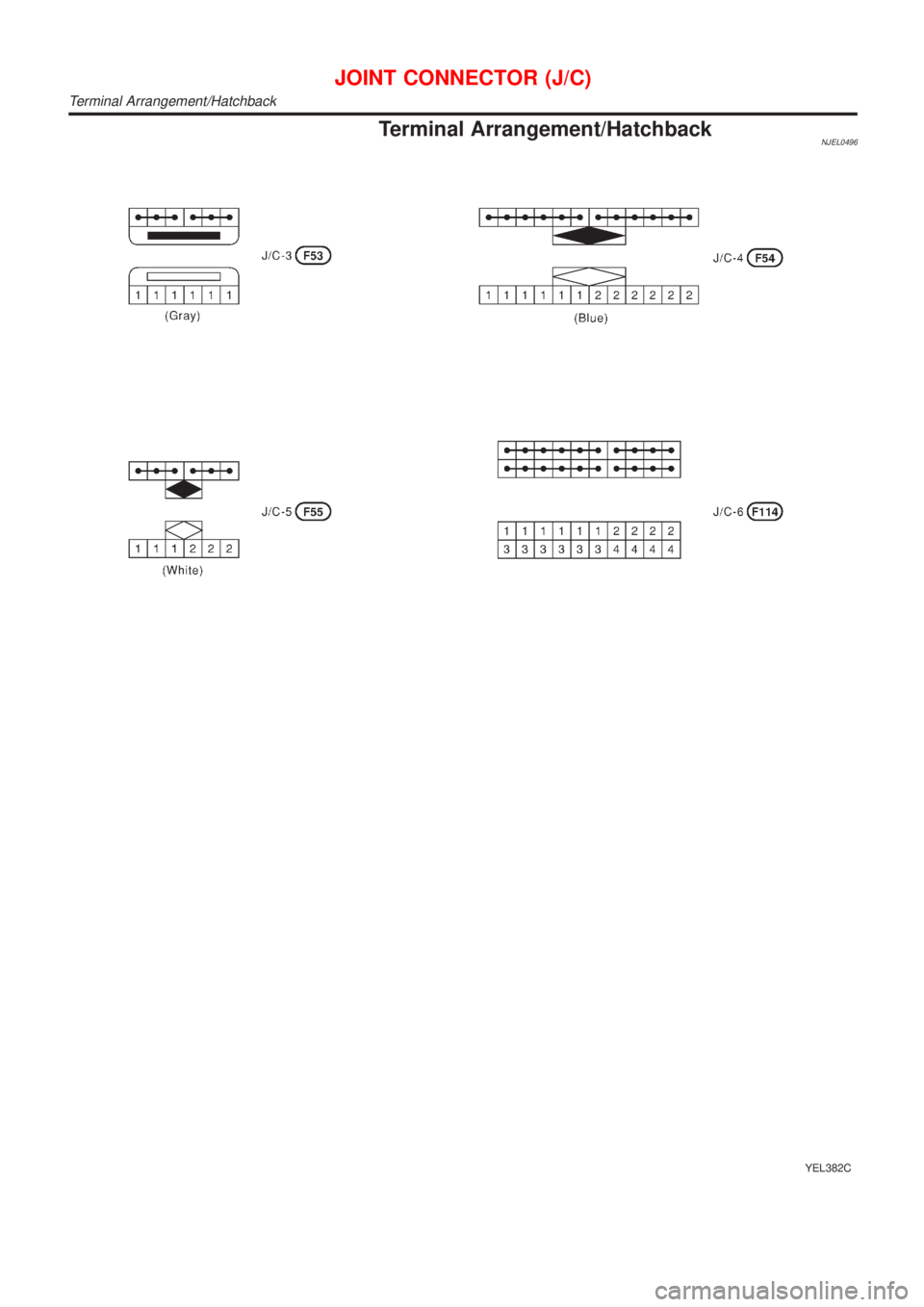

Termina lArrangement/Hatchback

MEL939L

Terminal Arrangement/Hatchback

Page 2343 of 2898

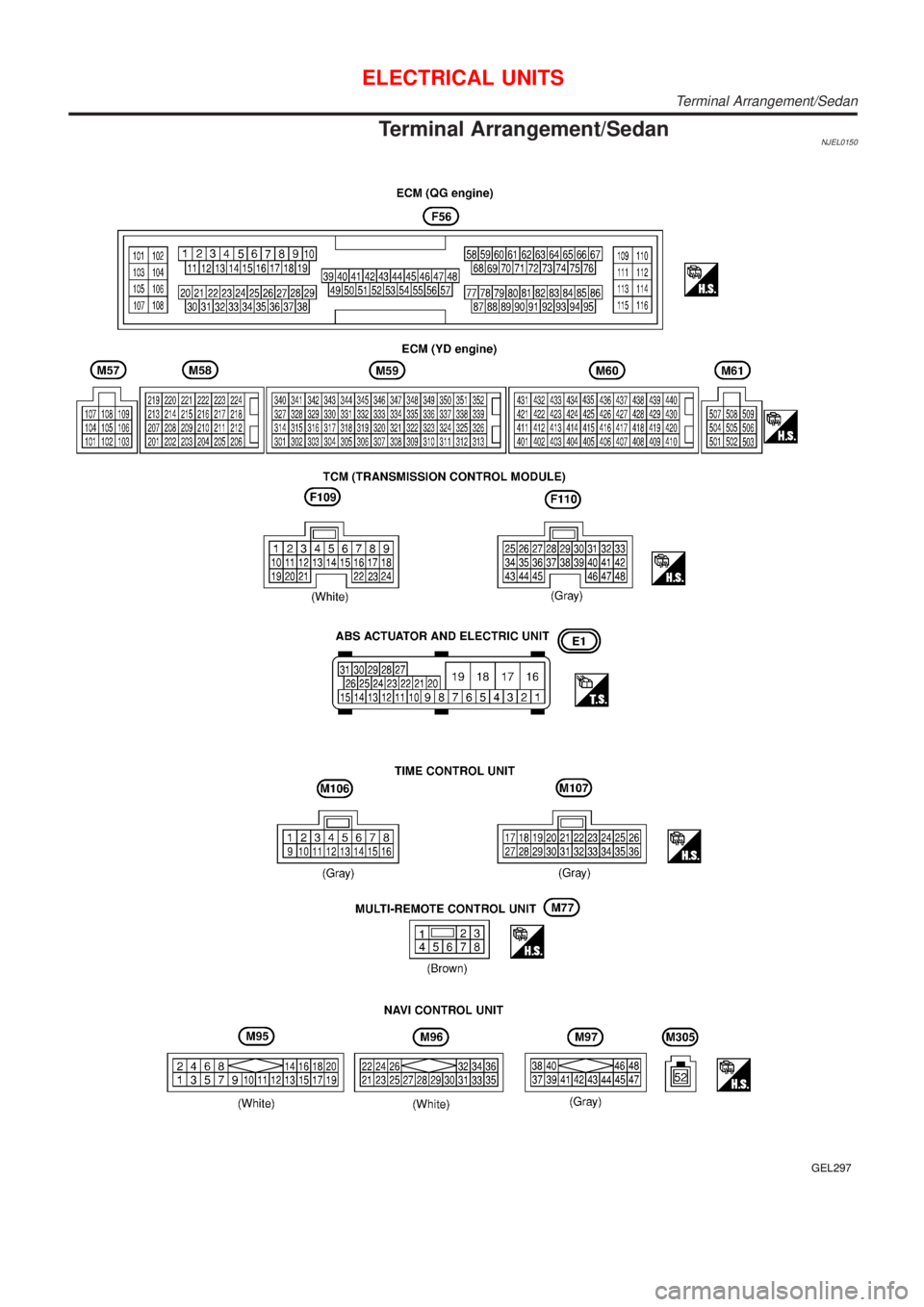

Termina lArrangement/Sedan

GEL297

Terminal Arrangement/Sedan

Page 2344 of 2898

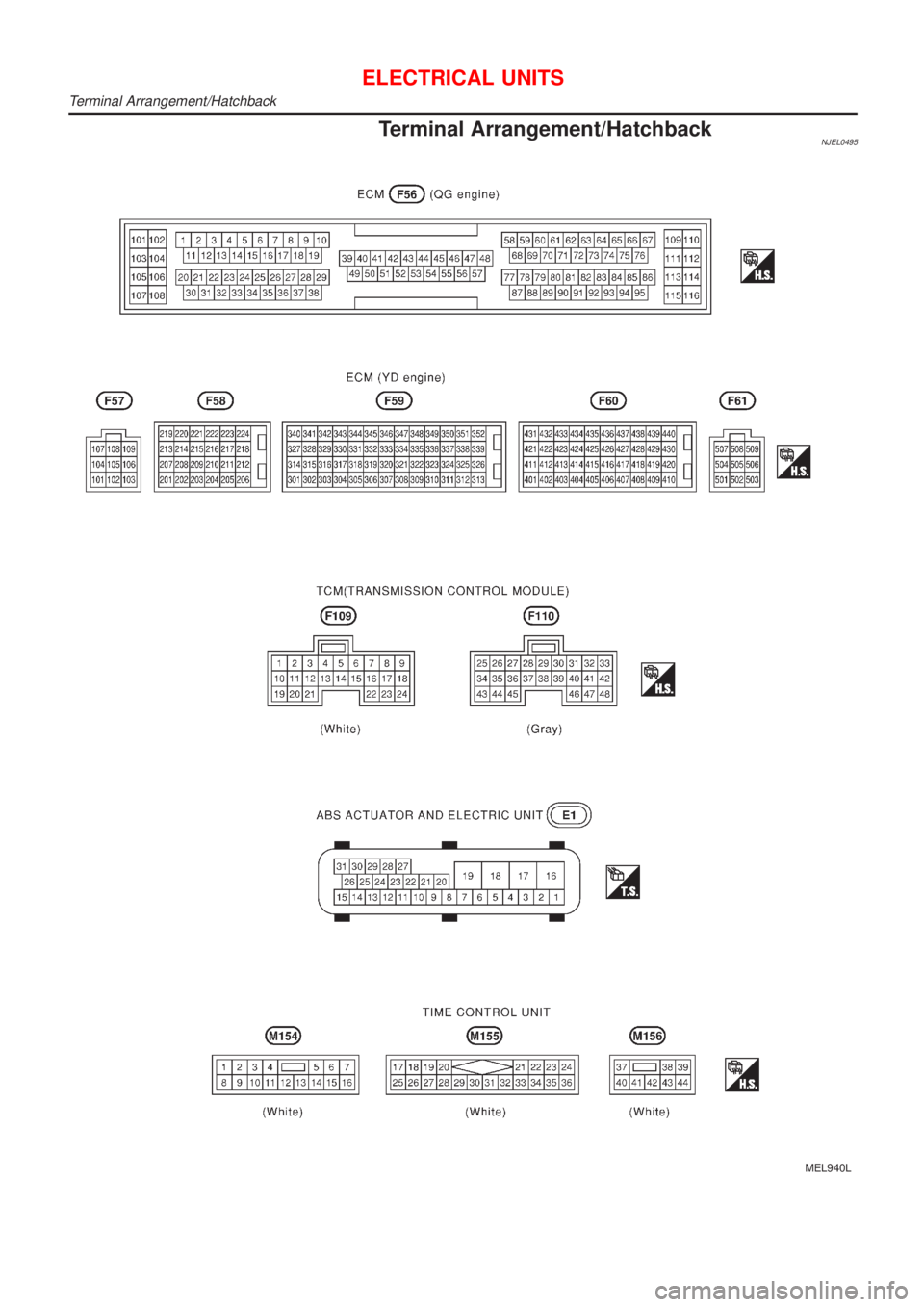

Termina lArrangement/Hatchback

MEL940L

Terminal Arrangement/Hatchback

Page 2345 of 2898

Termina lArrangement/Sedan

GEL289

Terminal Arrangement/Sedan

Page 2346 of 2898

Termina lArrangement/Hatchback

YEL382C

Terminal Arrangement/Hatchback

Page 2347 of 2898

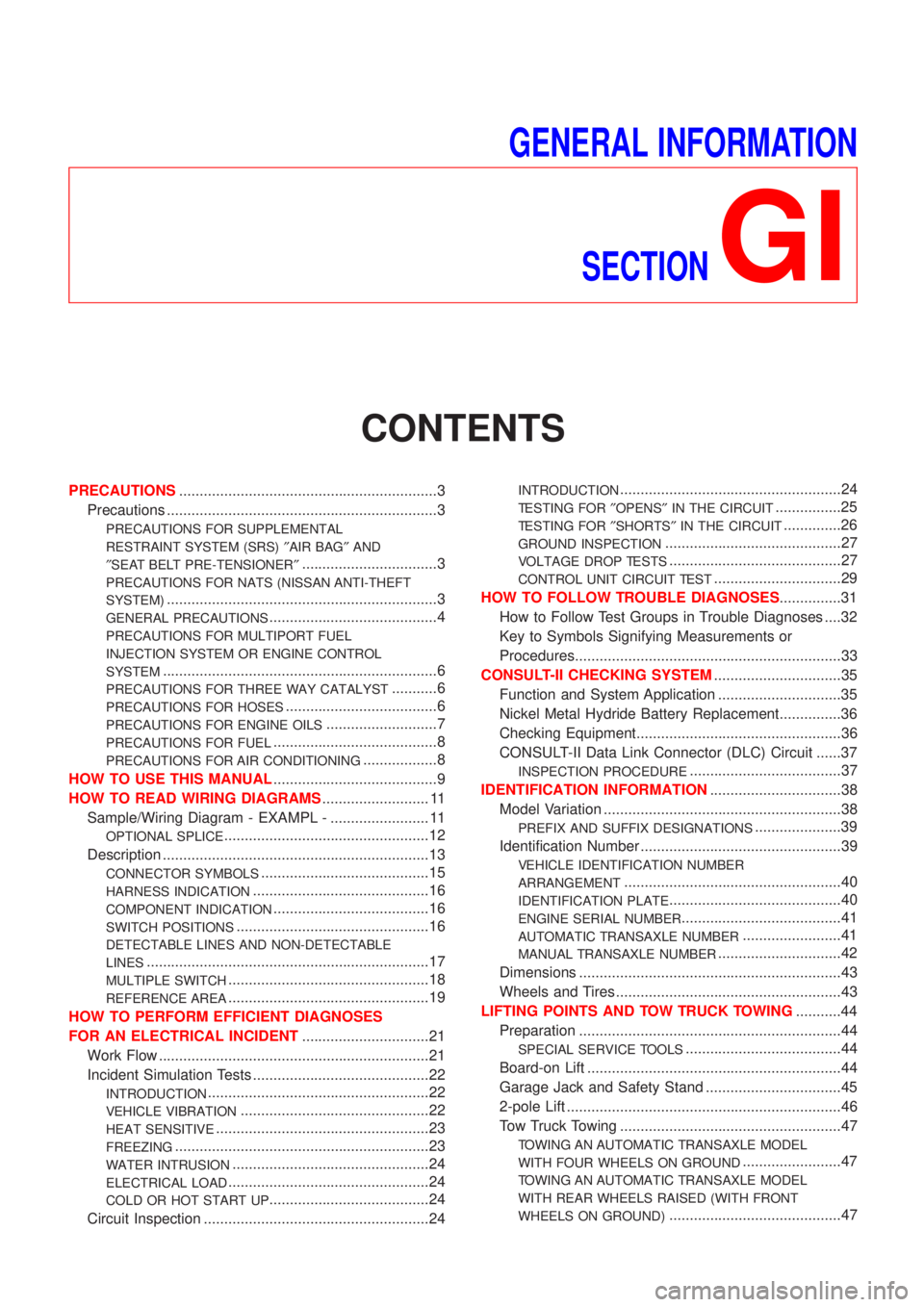

GENERAL INFORMATION

SECTION

GI

CONTENTS

PRECAUTIONS...............................................................3

Precautions ..................................................................3

PRECAUTIONS FOR SUPPLEMENTAL

RESTRAINT SYSTEM (SRS)²AIR BAG²AND

²SEAT BELT PRE-TENSIONER²

.................................3

PRECAUTIONS FOR NATS (NISSAN ANTI-THEFT

SYSTEM)

..................................................................3

GENERAL PRECAUTIONS.........................................4

PRECAUTIONS FOR MULTIPORT FUEL

INJECTION SYSTEM OR ENGINE CONTROL

SYSTEM

...................................................................6

PRECAUTIONS FOR THREE WAY CATALYST...........6

PRECAUTIONS FOR HOSES.....................................6

PRECAUTIONS FOR ENGINE OILS...........................7

PRECAUTIONS FOR FUEL........................................8

PRECAUTIONS FOR AIR CONDITIONING..................8

HOW TO USE THIS MANUAL........................................9

HOW TO READ WIRING DIAGRAMS.......................... 11

Sample/Wiring Diagram - EXAMPL - ........................ 11

OPTIONAL SPLICE..................................................12

Description .................................................................13

CONNECTOR SYMBOLS.........................................15

HARNESS INDICATION...........................................16

COMPONENT INDICATION......................................16

SWITCH POSITIONS...............................................16

DETECTABLE LINES AND NON-DETECTABLE

LINES

.....................................................................17

MULTIPLE SWITCH.................................................18

REFERENCE AREA.................................................19

HOW TO PERFORM EFFICIENT DIAGNOSES

FOR AN ELECTRICAL INCIDENT...............................21

Work Flow ..................................................................21

Incident Simulation Tests ...........................................22

INTRODUCTION......................................................22

VEHICLE VIBRATION..............................................22

HEAT SENSITIVE....................................................23

FREEZING..............................................................23

WATER INTRUSION................................................24

ELECTRICAL LOAD.................................................24

COLD OR HOT START UP.......................................24

Circuit Inspection .......................................................24

INTRODUCTION......................................................24

TESTING FOR²OPENS²IN THE CIRCUIT................25

TESTING FOR²SHORTS²IN THE CIRCUIT..............26

GROUND INSPECTION...........................................27

VOLTAGE DROP TESTS..........................................27

CONTROL UNIT CIRCUIT TEST...............................29

HOW TO FOLLOW TROUBLE DIAGNOSES...............31

How to Follow Test Groups in Trouble Diagnoses ....32

Key to Symbols Signifying Measurements or

Procedures.................................................................33

CONSULT-II CHECKING SYSTEM...............................35

Function and System Application ..............................35

Nickel Metal Hydride Battery Replacement...............36

Checking Equipment..................................................36

CONSULT-II Data Link Connector (DLC) Circuit ......37

INSPECTION PROCEDURE.....................................37

IDENTIFICATION INFORMATION................................38

Model Variation ..........................................................38

PREFIX AND SUFFIX DESIGNATIONS.....................39

Identification Number .................................................39

VEHICLE IDENTIFICATION NUMBER

ARRANGEMENT

.....................................................40

IDENTIFICATION PLATE..........................................40

ENGINE SERIAL NUMBER.......................................41

AUTOMATIC TRANSAXLE NUMBER........................41

MANUAL TRANSAXLE NUMBER..............................42

Dimensions ................................................................43

Wheels and Tires .......................................................43

LIFTING POINTS AND TOW TRUCK TOWING...........44

Preparation ................................................................44

SPECIAL SERVICE TOOLS......................................44

Board-on Lift ..............................................................44

Garage Jack and Safety Stand .................................45

2-pole Lift ...................................................................46

Tow Truck Towing ......................................................47

TOWING AN AUTOMATIC TRANSAXLE MODEL

WITH FOUR WHEELS ON GROUND

........................47

TOWING AN AUTOMATIC TRANSAXLE MODEL

WITH REAR WHEELS RAISED (WITH FRONT

WHEELS ON GROUND)

..........................................47

Page 2348 of 2898

TOWING POINT.......................................................48

TIGHTENING TORQUE OF STANDARD BOLTS........49

ISO 15031-2 TERMINOLOGY LIST..............................50ISO 15031-2 Terminology List ...................................50

CONTENTS(Cont'd)

GI-2

Page 2349 of 2898

PrecautionsNJGI0001Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

SGI646

PRECAUTIONS FOR SUPPLEMENTAL RESTRAINT

SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NJGI0001S01The Supplemental Restraint System such as ªAIR BAGº and ªSEAT

BELT PRE-TENSIONERº used along with a seat belt, helps to

reduce the risk or severity of injury to the driver and front passen-

ger for certain types of collision. The SRS system composition

which is available to NISSAN MODEL N16 is as follows (The com-

position varies according to the destination and optional equip-

ment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag

module (located in the center of the steering wheel), front pas-

senger air bag module (located on the instrument panel on

passenger side), front seat belt pre-tensioners, a diagnoses

sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air

bag module (located in the outer side of front seat), side air bag

(satellite) sensor, diagnoses sensor unit (one of components of

air bags for a frontal collision), wiring harness, warning lamp

(one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance should be performed by an authorized

NISSAN dealer.

+Improper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

SRS wiring harnesses can be identified by yellow harness

connector.

PRECAUTIONS FOR NATS (NISSAN ANTI-THEFT

SYSTEM)

NJGI0001S02NATS will immobilize the engine if someone tries to start it without

the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

The security indicator is located on the instrument panel or in the

PRECAUTIONS

Precautions

GI-3

Page 2350 of 2898

combination meter. The indicator blinks when the ignition switch is

in ªOFFº or ªACCº position. Therefore, NATS warns outsiders that

the vehicle is equipped with the anti-theft system.

+When NATS detects trouble, the security indicator lamp lights

up while ignition switch is in ªONº position.

This lighting up indicates that the anti-theft is not functioning,

so prompt service is required.

+When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs),

CONSULT-II hardware and CONSULT-II NATS software is

necessary.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

+When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner. A

maximum of five key IDs can be registered into NATS.

+When failing to start the engine first time using the key of

NATS, start as follows.

a) Leave the ignition key in ªONº position for approximately 5

seconds.

b) Turn ignition key to ªOFFº or ªLOCKº position and wait approxi-

mately 5 seconds.

c) Repeat step 1 and 2 again.

d) Restart the engine while keeping the key separate from any

others on key-chain.

SGI285

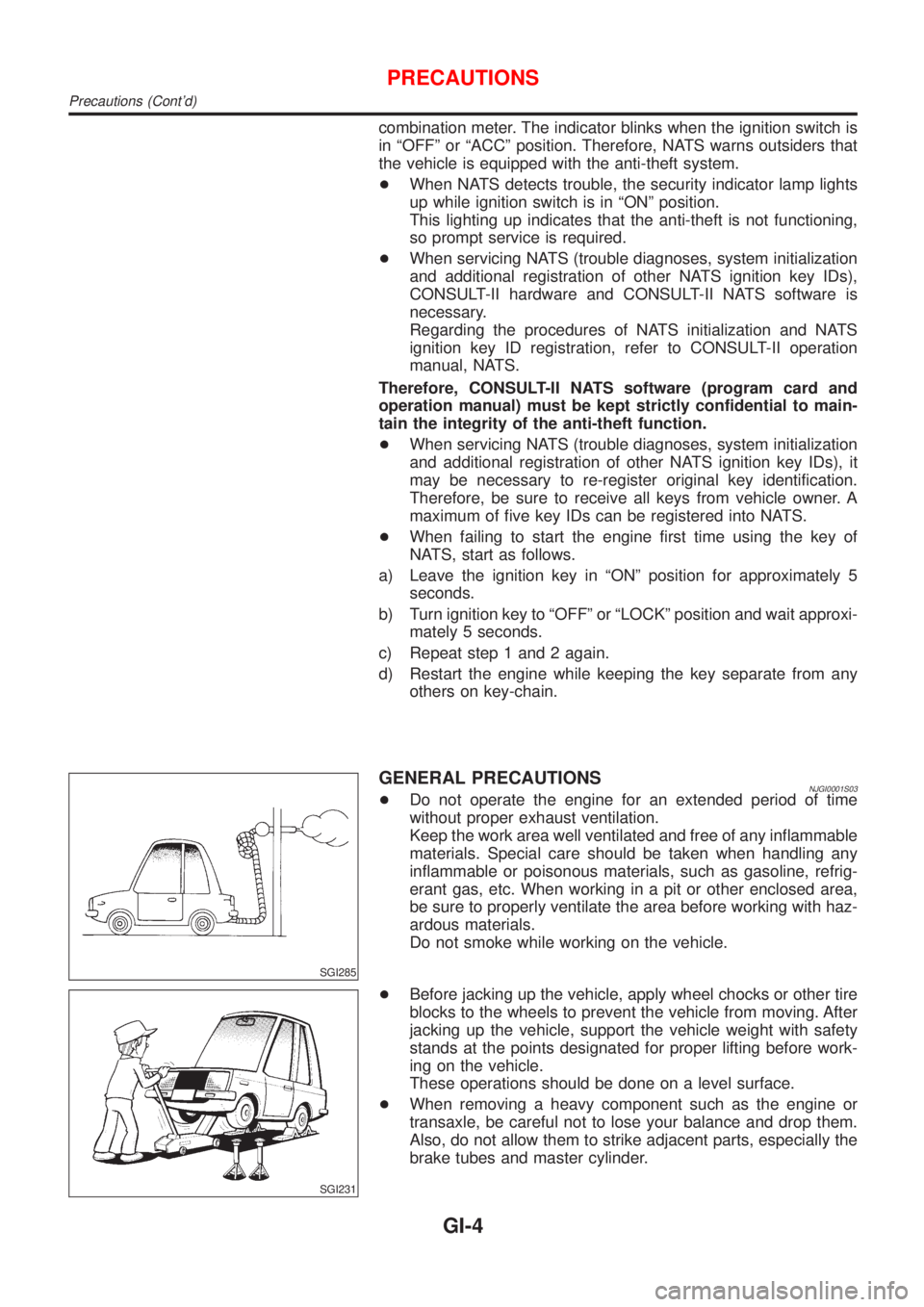

GENERAL PRECAUTIONSNJGI0001S03+Do not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

+Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

+When removing a heavy component such as the engine or

transaxle, be careful not to lose your balance and drop them.

Also, do not allow them to strike adjacent parts, especially the

brake tubes and master cylinder.

PRECAUTIONS

Precautions (Cont'd)

GI-4