check engine NISSAN ALMERA 2001 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 131 of 2898

Diagnostic ProcedureNJAT0039

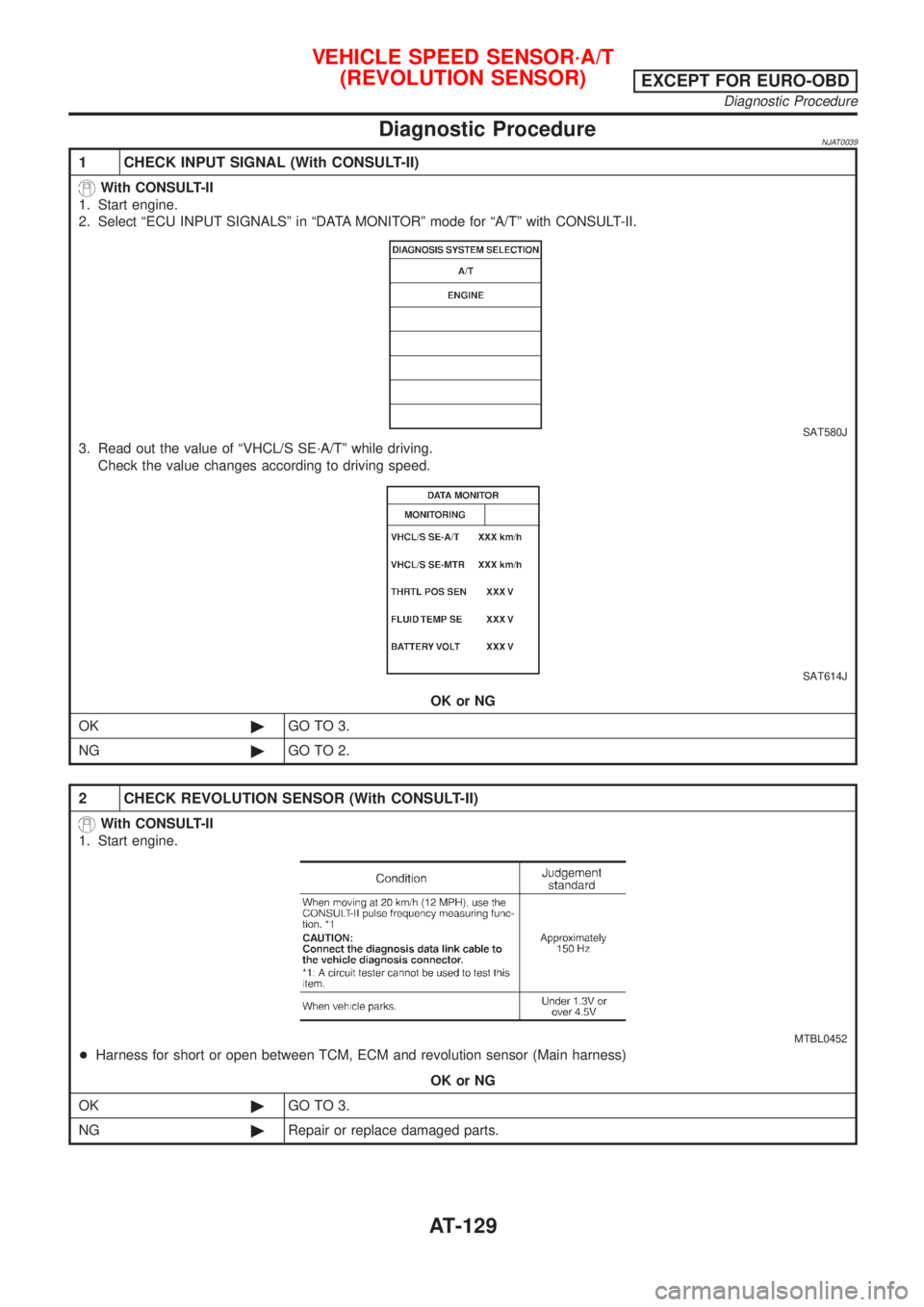

1 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

SAT580J

3. Read out the value of ªVHCL/S SE´A/Tº while driving.

Check the value changes according to driving speed.

SAT614J

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 CHECK REVOLUTION SENSOR (With CONSULT-II)

With CONSULT-II

1. Start engine.

MTBL0452

+Harness for short or open between TCM, ECM and revolution sensor (Main harness)

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

VEHICLE SPEED SENSOR´A/T

(REVOLUTION SENSOR)

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-129

Page 133 of 2898

SAT059K

DescriptionNJAT0079The vehicle speed sensor´MTR is built into the speedometer

assembly. The sensor functions as an auxiliary device to the revo-

lution sensor when it is malfunctioning. The TCM will then use a

signal sent from the vehicle speed sensor´MTR.

TCM TERMINALS AND REFERENCE VALUENJAT0079S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

40 PU/RVehicle speed sen-

sor

When moving vehicle at 2 to 3

km/h (1 to 2 MPH) for1m(3ft)or

more.Voltage varies

between less

than 1V and

more than 4.5V

ON BOARD DIAGNOSIS LOGICNJAT0079S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: VHCL SPEED SEN´MTR

TCM does not receive the proper voltage

signal from the sensor.+Harness or connectors

(The sensor circuit is open or shorted.)

+Vehicle speed sensor

: 2nd judgement flicker

SAT580J

SAT807H

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENJAT0079S04After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINJAT0079S04011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with CONSULT-

II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position and vehicle speed higher than 20

km/h (12 MPH).

Without CONSULT-IINJAT0079S04021) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position and vehicle speed higher than 20

km/h (12 MPH).

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-44.

VHCL SPEED SEN´MTR VEHICLE

SPEED SENSOR´MTR

EXCEPT FOR EURO-OBD

Description

AT-131

Page 135 of 2898

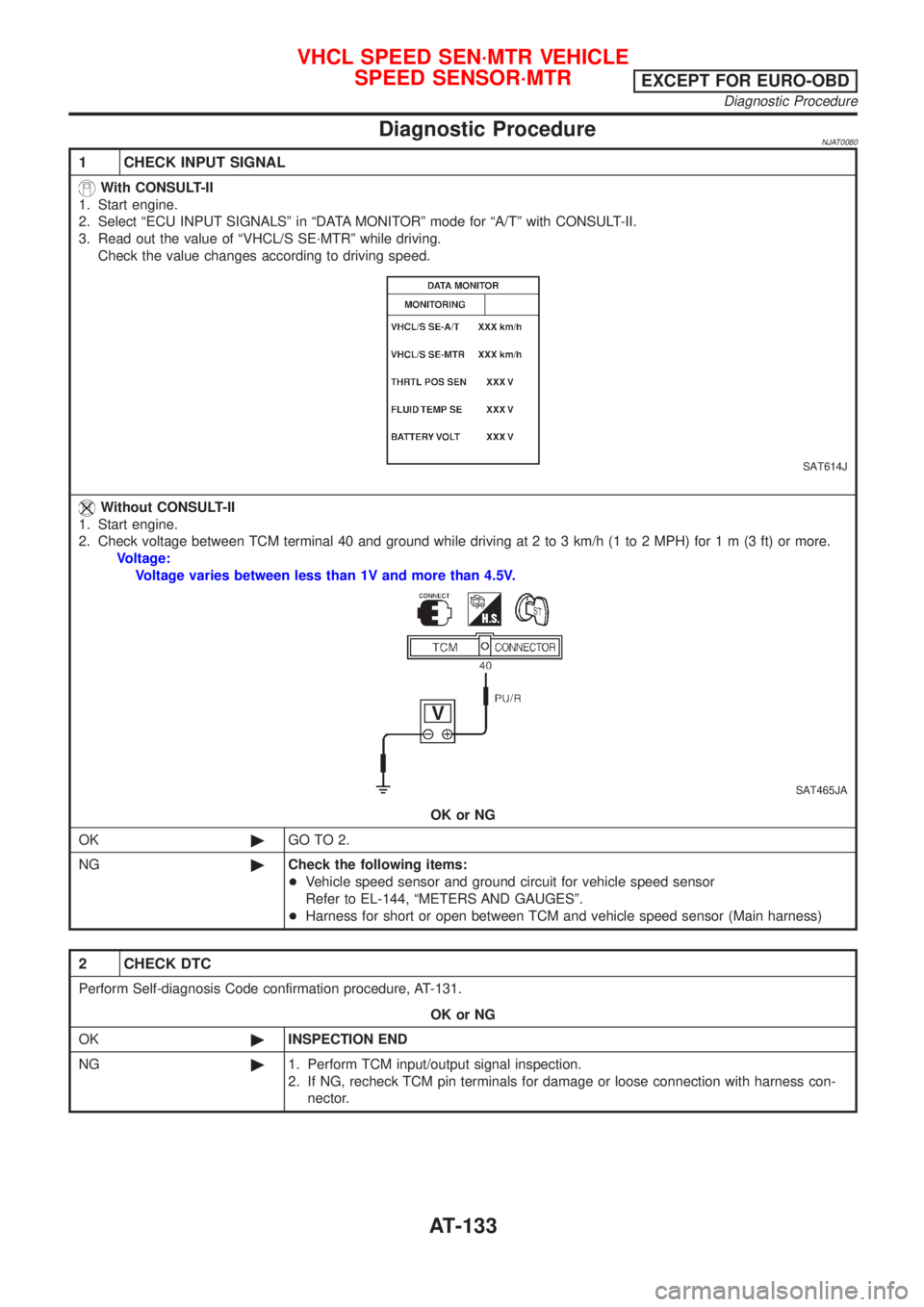

Diagnostic ProcedureNJAT0080

1 CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªVHCL/S SE´MTRº while driving.

Check the value changes according to driving speed.

SAT614J

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 40 and ground while driving at 2 to 3 km/h (1 to 2 MPH) for1m(3ft)ormore.

Voltage:

Voltage varies between less than 1V and more than 4.5V.

SAT465JA

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Vehicle speed sensor and ground circuit for vehicle speed sensor

Refer to EL-144, ªMETERS AND GAUGESº.

+Harness for short or open between TCM and vehicle speed sensor (Main harness)

2 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-131.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

VHCL SPEED SEN´MTR VEHICLE

SPEED SENSOR´MTR

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-133

Page 137 of 2898

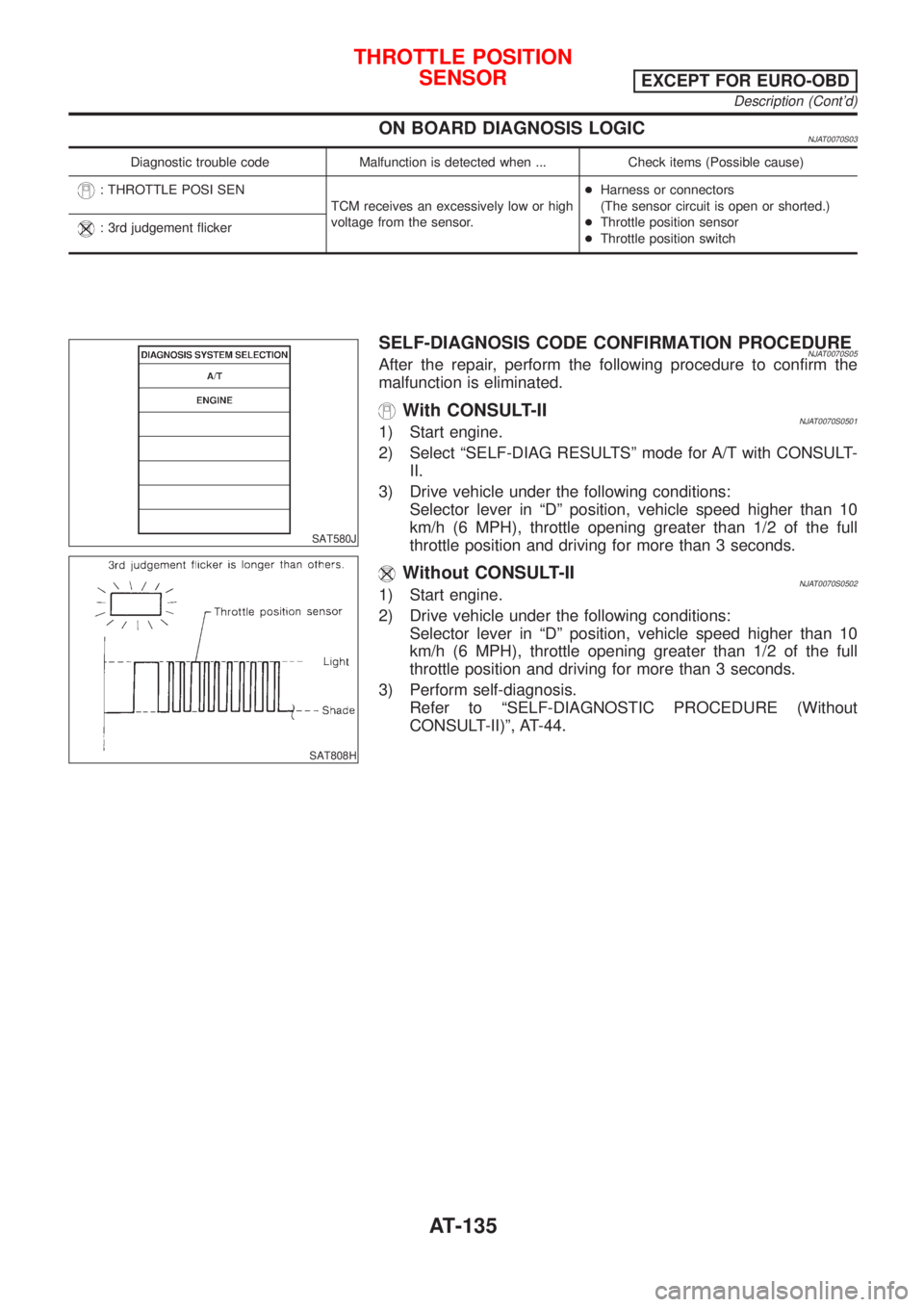

ON BOARD DIAGNOSIS LOGICNJAT0070S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: THROTTLE POSI SEN

TCM receives an excessively low or high

voltage from the sensor.+Harness or connectors

(The sensor circuit is open or shorted.)

+Throttle position sensor

+Throttle position switch

: 3rd judgement flicker

SAT580J

SAT808H

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENJAT0070S05After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINJAT0070S05011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with CONSULT-

II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher than 10

km/h (6 MPH), throttle opening greater than 1/2 of the full

throttle position and driving for more than 3 seconds.

Without CONSULT-IINJAT0070S05021) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher than 10

km/h (6 MPH), throttle opening greater than 1/2 of the full

throttle position and driving for more than 3 seconds.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-44.

THROTTLE POSITION

SENSOR

EXCEPT FOR EURO-OBD

Description (Cont'd)

AT-135

Page 139 of 2898

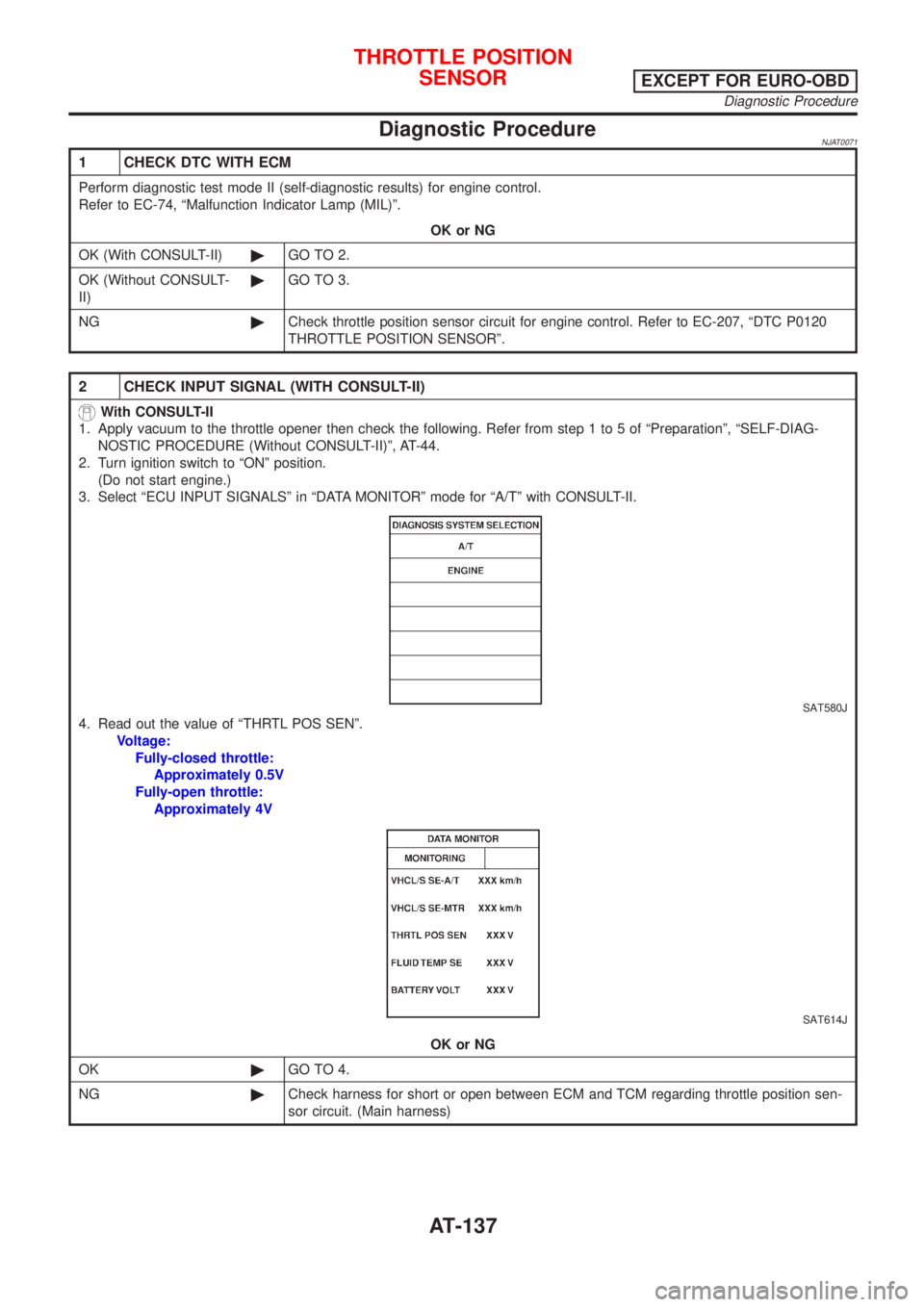

Diagnostic ProcedureNJAT0071

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control.

Refer to EC-74, ªMalfunction Indicator Lamp (MIL)º.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Check throttle position sensor circuit for engine control. Refer to EC-207, ªDTC P0120

THROTTLE POSITION SENSORº.

2 CHECK INPUT SIGNAL (WITH CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener then check the following. Refer from step 1 to 5 of ªPreparationº, ªSELF-DIAG-

NOSTIC PROCEDURE (Without CONSULT-II)º, AT-44.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

SAT580J

4. Read out the value of ªTHRTL POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

SAT614J

OK or NG

OK©GO TO 4.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

THROTTLE POSITION

SENSOR

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-137

Page 140 of 2898

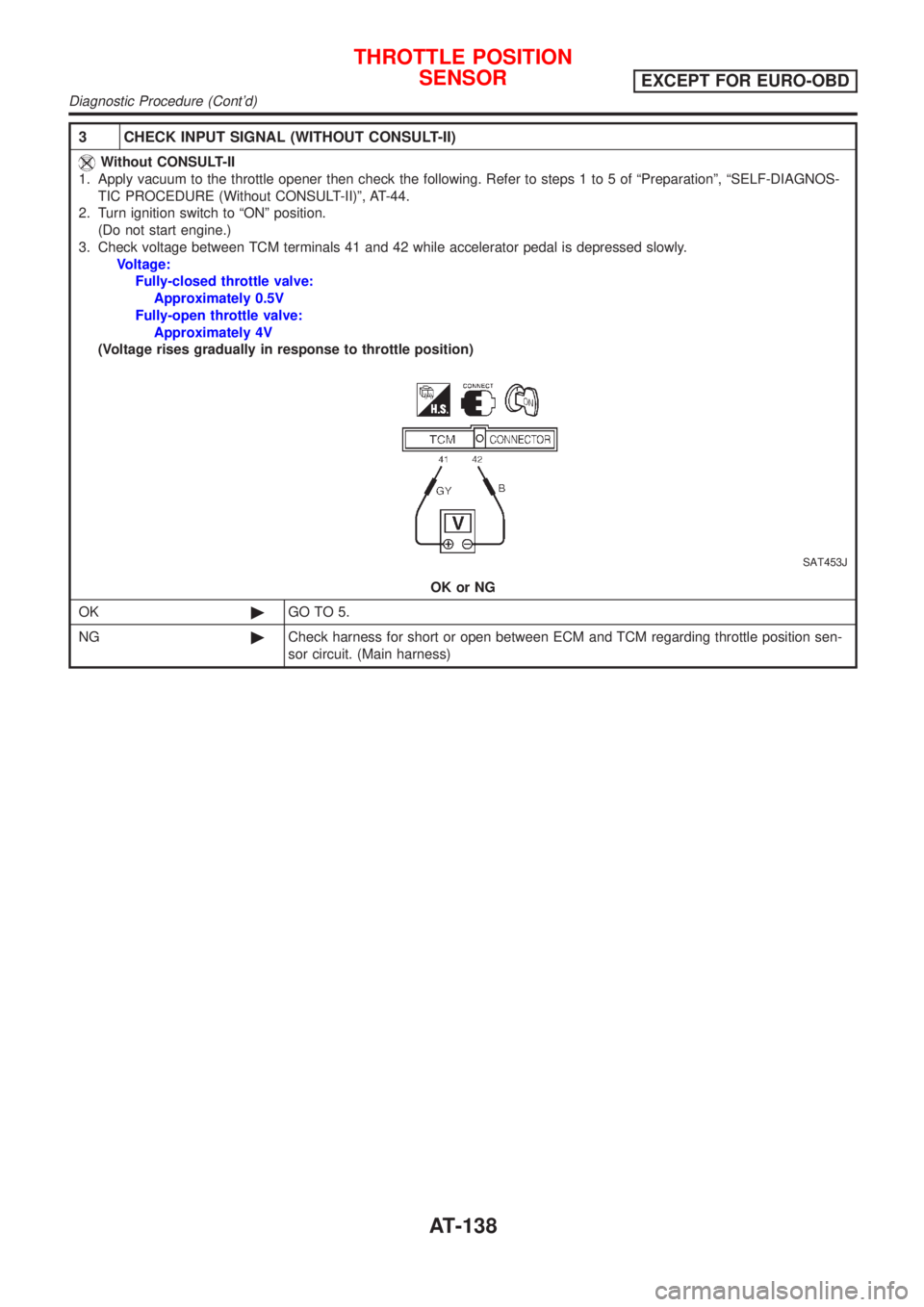

3 CHECK INPUT SIGNAL (WITHOUT CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener then check the following. Refer to steps 1 to 5 of ªPreparationº, ªSELF-DIAGNOS-

TIC PROCEDURE (Without CONSULT-II)º, AT-44.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 41 and 42 while accelerator pedal is depressed slowly.

Voltage:

Fully-closed throttle valve:

Approximately 0.5V

Fully-open throttle valve:

Approximately 4V

(Voltage rises gradually in response to throttle position)

SAT453J

OK or NG

OK©GO TO 5.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

THROTTLE POSITION

SENSOR

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-138

Page 141 of 2898

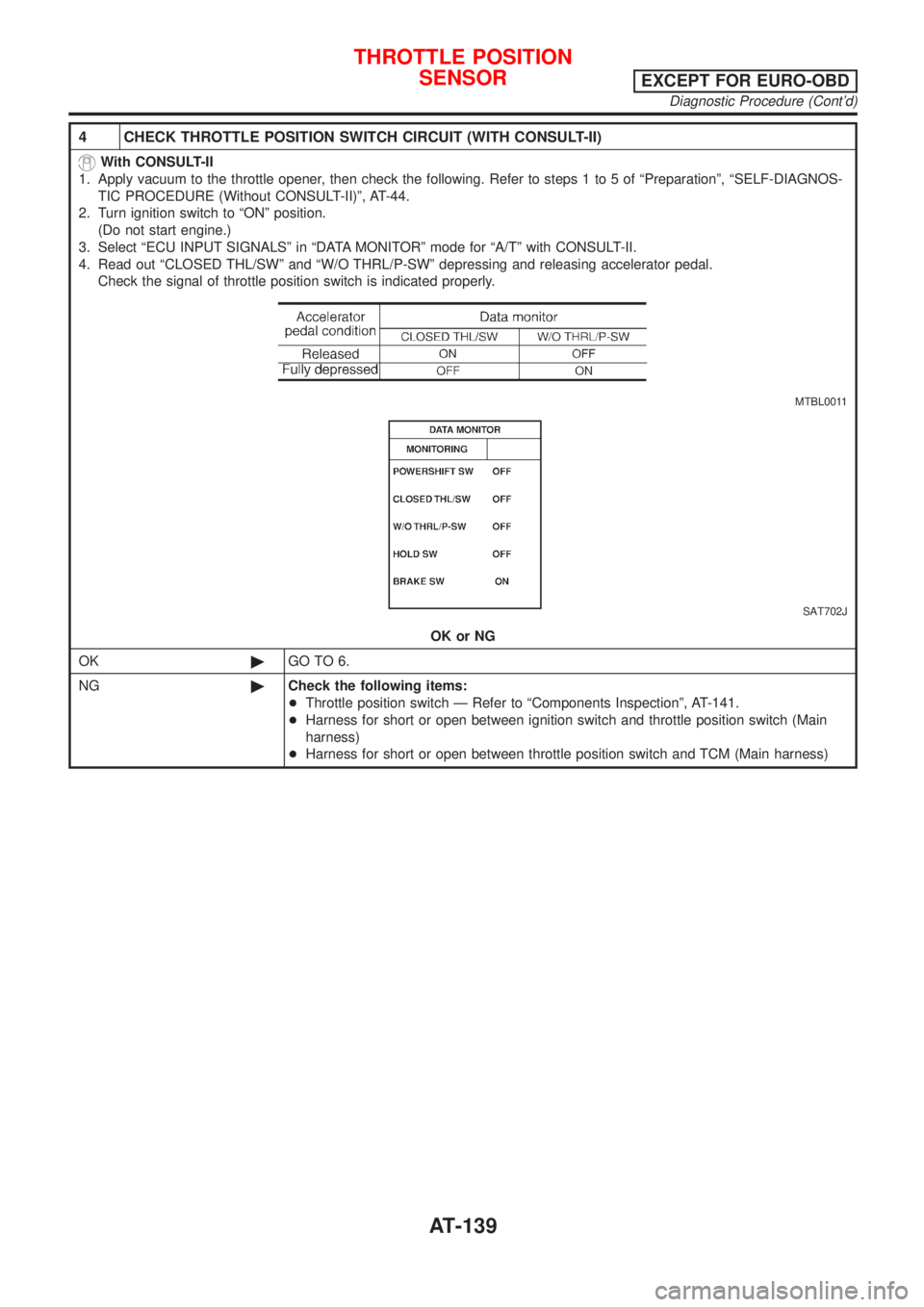

4 CHECK THROTTLE POSITION SWITCH CIRCUIT (WITH CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 to 5 of ªPreparationº, ªSELF-DIAGNOS-

TIC PROCEDURE (Without CONSULT-II)º, AT-44.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT702J

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-141.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

THROTTLE POSITION

SENSOR

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-139

Page 142 of 2898

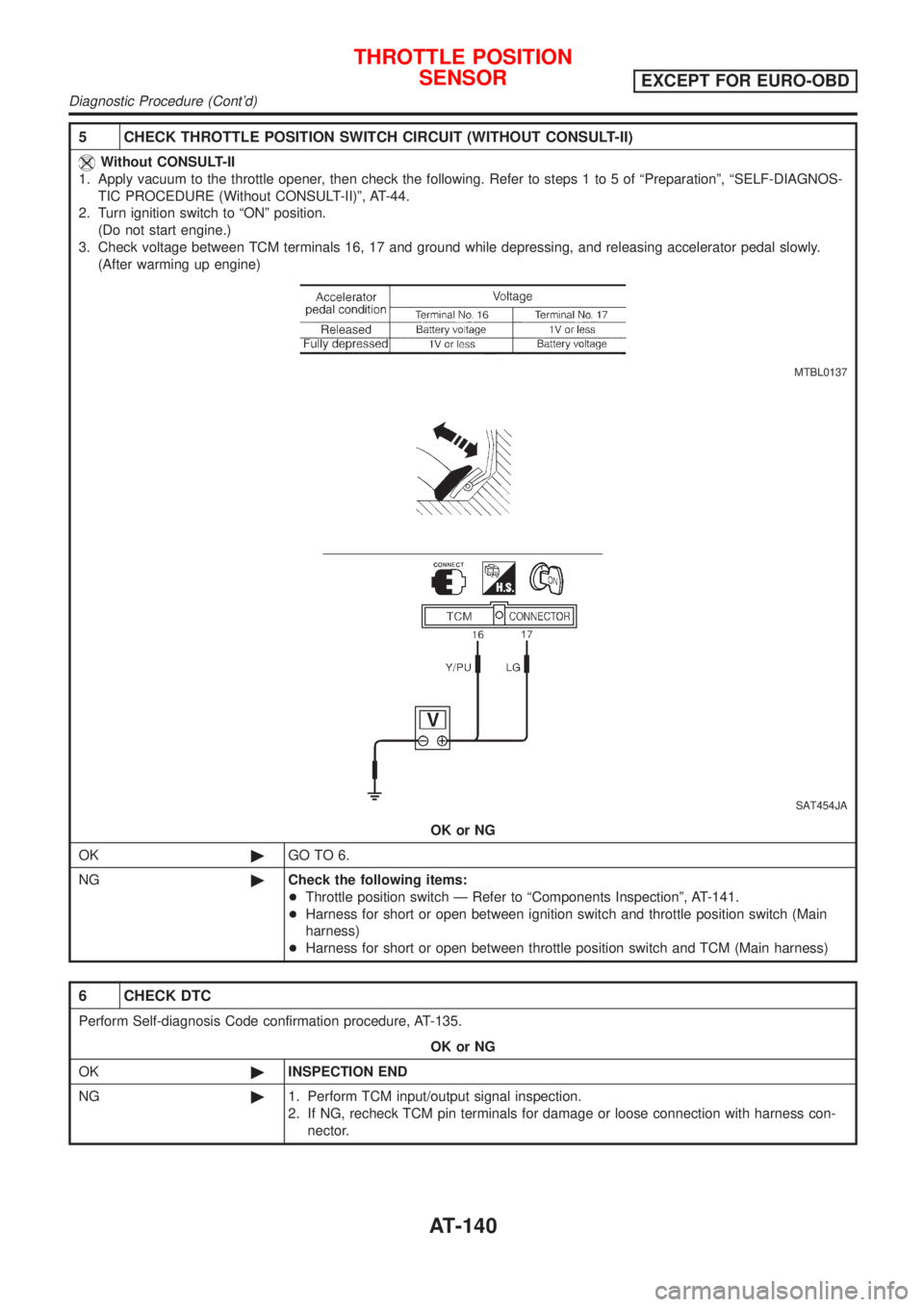

5 CHECK THROTTLE POSITION SWITCH CIRCUIT (WITHOUT CONSULT-II)

Without CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 to 5 of ªPreparationº, ªSELF-DIAGNOS-

TIC PROCEDURE (Without CONSULT-II)º, AT-44.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Check voltage between TCM terminals 16, 17 and ground while depressing, and releasing accelerator pedal slowly.

(After warming up engine)

MTBL0137

SAT454JA

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-141.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

6 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-135.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

THROTTLE POSITION

SENSOR

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-140

Page 147 of 2898

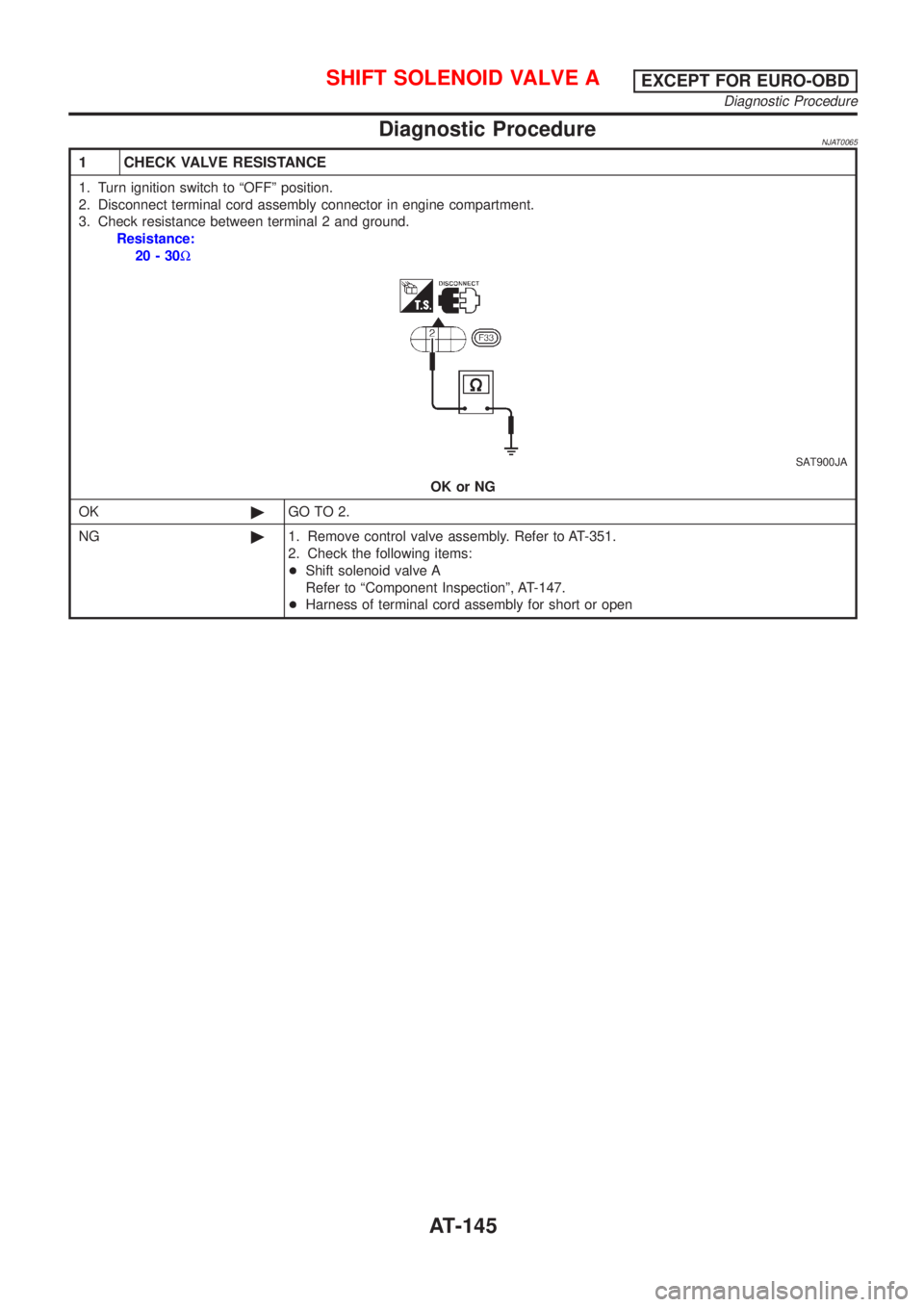

Diagnostic ProcedureNJAT0065

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 2 and ground.

Resistance:

20-30W

SAT900JA

OK or NG

OK©GO TO 2.

NG©1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Shift solenoid valve A

Refer to ªComponent Inspectionº, AT-147.

+Harness of terminal cord assembly for short or open

SHIFT SOLENOID VALVE AEXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-145

Page 153 of 2898

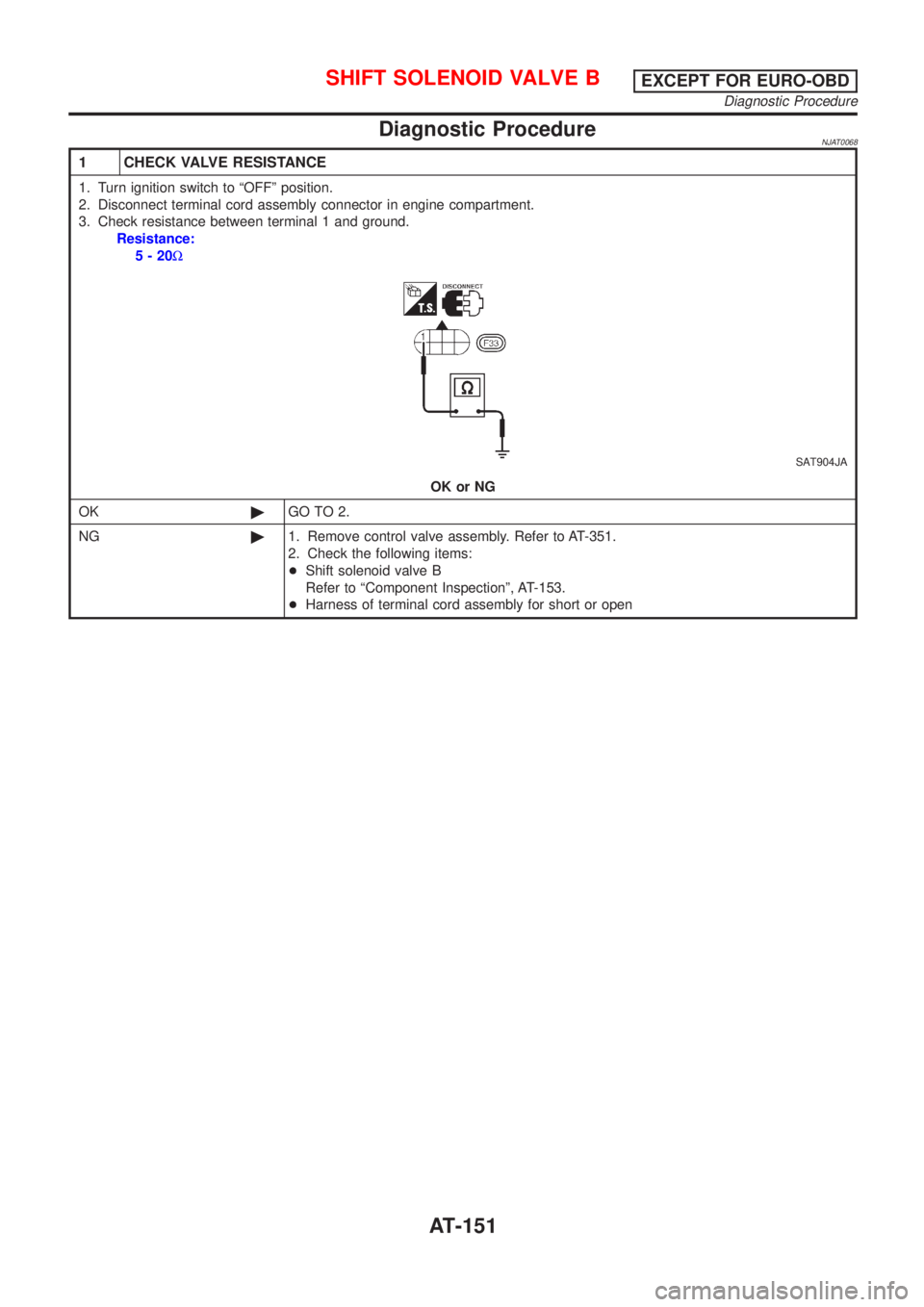

Diagnostic ProcedureNJAT0068

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 1 and ground.

Resistance:

5-20W

SAT904JA

OK or NG

OK©GO TO 2.

NG©1. Remove control valve assembly. Refer to AT-351.

2. Check the following items:

+Shift solenoid valve B

Refer to ªComponent Inspectionº, AT-153.

+Harness of terminal cord assembly for short or open

SHIFT SOLENOID VALVE BEXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-151