instrument panel NISSAN ALMERA 2001 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 2503 of 2898

Headlining - See Roof trim ........................ BT-43

Heated oxygen sensor (HO2S)

(front) .......... EC-216, 224, 230, 236, 245, 450

Heated oxygen sensor (HO2S) heater

(front) ........................................... EC-252, 457

Heated oxygen sensor (HO2S) heater

(rear) ............................................ EC-291, 469

Heated oxygen sensor (rear) ......... EC-258, 267,

275, 284, 462

Heated seat ............................................. EL-288

Height (Dimensions) ................................... GI-43

High clutch ............................................... AT-407

Hood ............................................................ BT-7

Horn ......................................................... EL-234

How to erase DTC for OBD system .. EC-70, 73,

627

I

IACV-AAC valve .............................. EC-376, 511

IATS - Wiring diagram .................... EC-196, 444

IGN/SG - Wiring diagram ........................ EC-548

ILL - Wiring diagram ................................ EL-112

INJECT - Wiring diagram ........................ EC-542

INT/L - Wiring diagram .................... EL-141, 143

IVC - Wiring diagram ...................... EC-395, 527

Identification plate ...................................... GI-40

Idle air control (IAC) system ........... EC-376, 511

Idle air control valve (IACV) ............ EC-376, 511

Idle speed ......................................... EC-43, 641

Ignition timing ............................................ EC-43

Illumination ............................................... EL-108

Injection nozzle ....................................... EC-614

Injector removal and installation ............... EC-41

Input shaft (FF M/T) ............... MT-36, 64, 93, 98

Instrument panel ........................................ BT-25

Intake air temperature sensor ......... EC-194, 442

Intake valve timing control solenoid

valve ............................................ EC-393, 526

Interior lamp on-off control .............. EL-116, 128

Interior lamp ............................................. EL-115

Interior ........................................................ BT-31

J

Jacking points ............................................ GI-45

Joint connector (J/C) ............................... EL-583

Junction box (J/B) .................................... EL-577

K

Keyless entry system - See Multi-remote control

system ..................................................... EL-392

Knock sensor (KS) .......................... EC-324, 325

Knuckle spindle ........................................... AX-5

L

LOAD - Wiring diagram .......................... EC-579

Length (Dimensions) .................................. GI-43

License lamp ............................................. EL-81

Lifting points ............................................... GI-46

Line pressure solenoid valve ................... AT-232

Line pressure test (A/T) ............................. AT-84

Liquid gasket application ...................... EM-4, 77

Location of electrical units ....................... EL-517

Lock, door .................................................. BT-21

Low and reverse brake ............................ AT-419

Lubricant (R134a) A/C .............................. HA-80

Lubricants ................................................. MA-16

Lubrication circuit (engine) .................... LC-4, 27

M

M/T major overhaul ....................... MT-30, 54, 92

M/T removal and installation ..................... MT-23

MAFS - Wiring diagram .................. EC-189, 673

MAIN - Wiring diagram ................... EC-178, 666

MAJOR OVERHALL ................................ AT-357

METER - Wiring diagram ........................ EL-151

MIL & Data link connectors circuit .......... EC-591

MIL/DL - Wiring diagram ................. EC-591, 831

MIRROR - Wiring diagram .............. EL-294, 295

Magnet clutch ............................................ HA-83

Mainshaft (M/T) .................... MT-39, 69, 93, 103

Malfunction indicator lamp (MIL) ...... EC-74, 628

Manual air conditioner - Wiring

diagram .................................................. HA-27

Manual transaxle number .......................... GI-42

Mass air flow sensor (MAFS) ......... EC-187, 673

Master cylinder (brake) ............................. BR-14

Master cylinder (clutch) ............................. CL-11

Meter ........................................................ EL-144

Mirror defogger ........................................ EL-240

Mirror, door ................................................ BT-75

Misfire ...................................................... EC-318

Mode door control linkage

adjustment ............................................. HA-41

Model variation ........................................... GI-38

Molding - See Exterior ............................... BT-47

Multi-remote control system .................... EL-392

Multiport fuel injection (MFI) system ......... EC-32

Multiport fuel injection precautions ............... GI-6

N

NATS (Nissan Anti-theft System)

precautions ................................................... GI-3

NATS (Nissan Anti-theft System) ............ EL-422

NATS - Wiring diagram ................... EL-425, 427

NVH troubleshooting (AX) ........................... AX-3

NVH troubleshooting (BR) .......................... BR-7

NVH troubleshooting (MT) ........................ MT-13

NVH troubleshooting (ST) ........................... ST-5

ALPHABETICAL INDEX

IDX-5

Page 2556 of 2898

NJMA0036

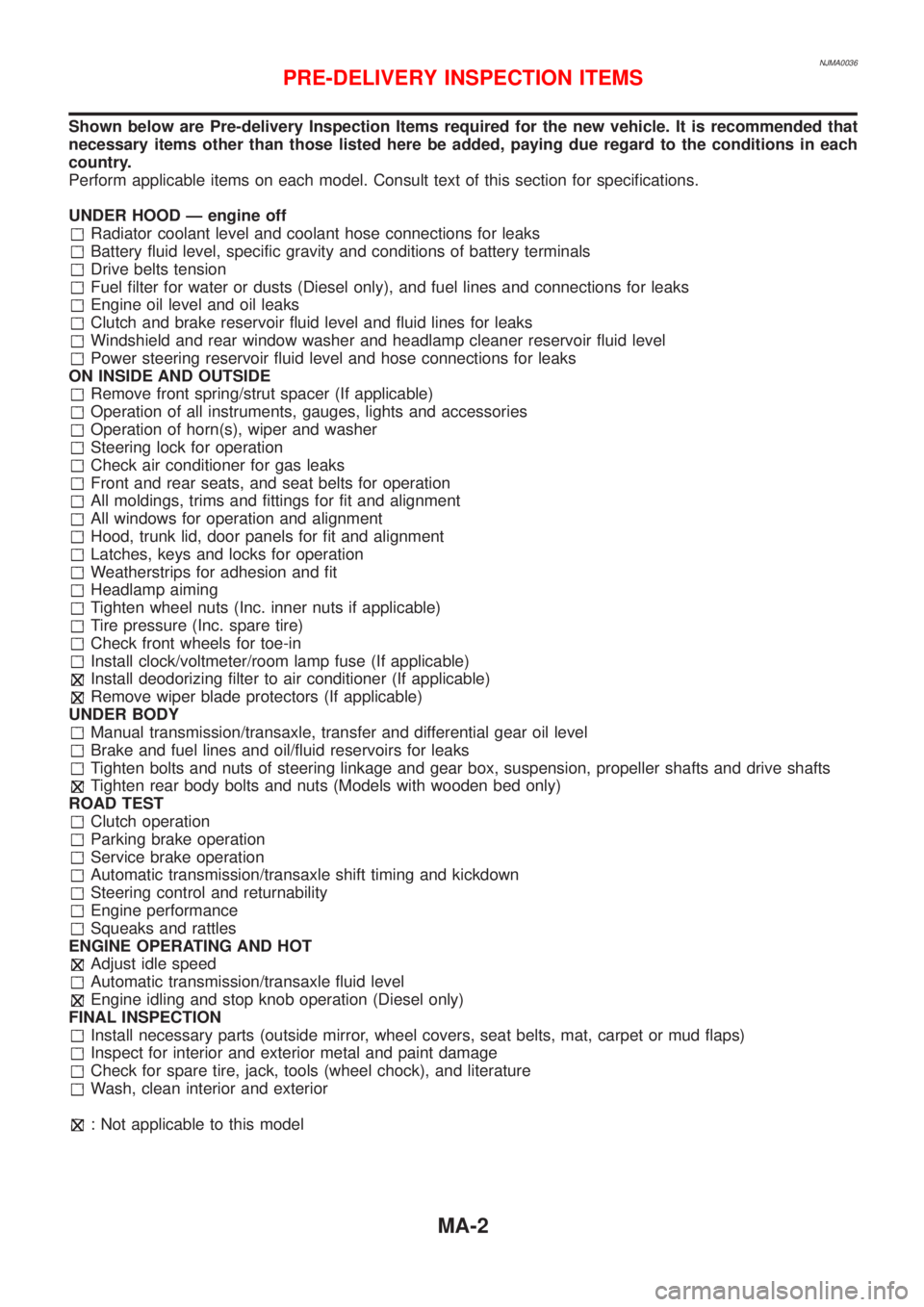

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 2711 of 2898

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NJRS0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL N16 is as follows (The composition

varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTION FOR SEAT BELT SERVICENJRS0002CAUTION:

+Before removing the seat belt pre-tensioner assembly, turn the ignition switch off, disconnect both

battery cables and wait at least 3 minutes.

+Do not use electrical test equipment for seat belt pre-tensioner connector.

+After replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner connector, check the system function. Refer to ªSRS Operation Checkº for details. (RS-59)

+Do not use disassemble buckle or seat belt assembly.

+Replace anchor bolts if they are deformed or worn out.

+Never oil tongue and buckle.

+If any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

+If webbing is cut, frayed, or damaged, replace seat belt assembly.

+When replacing seat belt assembly, use a genuine seat belt assembly.

After A CollisionNJRS0002S01WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly (including anchor bolts) if:

+The seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

+The seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

+The seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for dam-

age or distortion and repair as necessary before installing a new seat belt assembly.

+Anchor bolts are deformed or worn out.

+The seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

SEAT BELTS

Precautions

RS-3

Page 2728 of 2898

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NJRS0006The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to NISSAN MODEL N16 is as follows (The composition

varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICENJRS0007+Do not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

+Before servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

+Diagnosis sensor unit must always be installed with their arrow marks ªÜº pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

+The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

+Handle air bag module carefully. Always place driver and front passenger air bag modules with the pad

side facing upward and place front side air bag module standing with stud bolt side setting bottom.

+Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

+After air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSISNJRS0008When you read wiring diagrams, refer to the following:

+GI-11, ªHOW TO READ WIRING DIAGRAMSº

+EL-10, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

+GI-32, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

+GI-21, ªHOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Precautions

RS-20

Page 2733 of 2898

SRS797-A

Maintenance ItemsNJRS0012CAUTION:

Do not use electrical test equipment to check SRS circuit.

1. Check operation of ªAIR BAGº warning lamp.

After turning ignition key to ªONº position, ªAIR BAGº warning

lamp illuminates. The ªAIR BAGº warning lamp will go off after

about 7 seconds if no malfunction is detected. If any of the fol-

lowing ªAIR BAGº warning lamp conditions occur, immediately

check the air bag system. Refer to RS-59 for details.

+The ªAIR BAGº warning lamp does not illuminate when the

ignition switch is turned ªONº.

+The ªAIR BAGº warning lamp does not go off about 7 seconds

after the ignition switch is turned ªONº.

+The ªAIR BAGº warning lamp blinks after about 7 seconds after

the ignition switch is turned ªONº.

2. Visually check SRS components.

1) Diagnosis sensor unit

+Check diagnosis sensor unit and bracket for dents, cracks and

deformities.

+Check connectors for damage, and terminals for deformities.

2) Air bag module and steering wheel

+Remove air bag module from steering wheel, instrument panel

or seatback. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

+Install driver air bag module to steering wheel to check fit or

alignment with the wheel.

+Check steering wheel for excessive free play.

+Install front passenger air bag module to instrument panel to

check fit or alignment with the instrument panel.

+Install front side air bag module to seatback to check fit and

alignment with the seat.

3) Spiral cable

+Check spiral cable for dents, cracks, or deformities.

+Check connectors and protective tape for damage.

+Check steering wheel for noise, binding or heavy operation.

4) Main harness, body harness, side air bag module sub-harness

+Check connectors for poor connections, damage, and termi-

nals for deformities.

+Check harnesses for binding, chafing or cut.

5) Front seat belt pre-tensioner

+Check harness cover and connectors for damage, terminals

for deformities, and harness for binding.

+Check belts for damage and anchors for loose mounting.

+Check retractor for smooth operation.

+Perform self-diagnosis for seat belt pre-tensioner using ªAIR

BAGº warning lamp or CONSULT-II.

Refer to ªSRS Operation Checkº for details. (RS-59)

6) Side air bag (satellite) sensor

+Check side air bag (satellite) sensor (including bracket portion)

for dents, cracks or deformities.

+Check connectors for damage, and terminals for deformities.

CAUTION:

Replace previously used special bolts, hex bolts and ground

bolt with new ones.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Maintenance Items

RS-25

Page 2734 of 2898

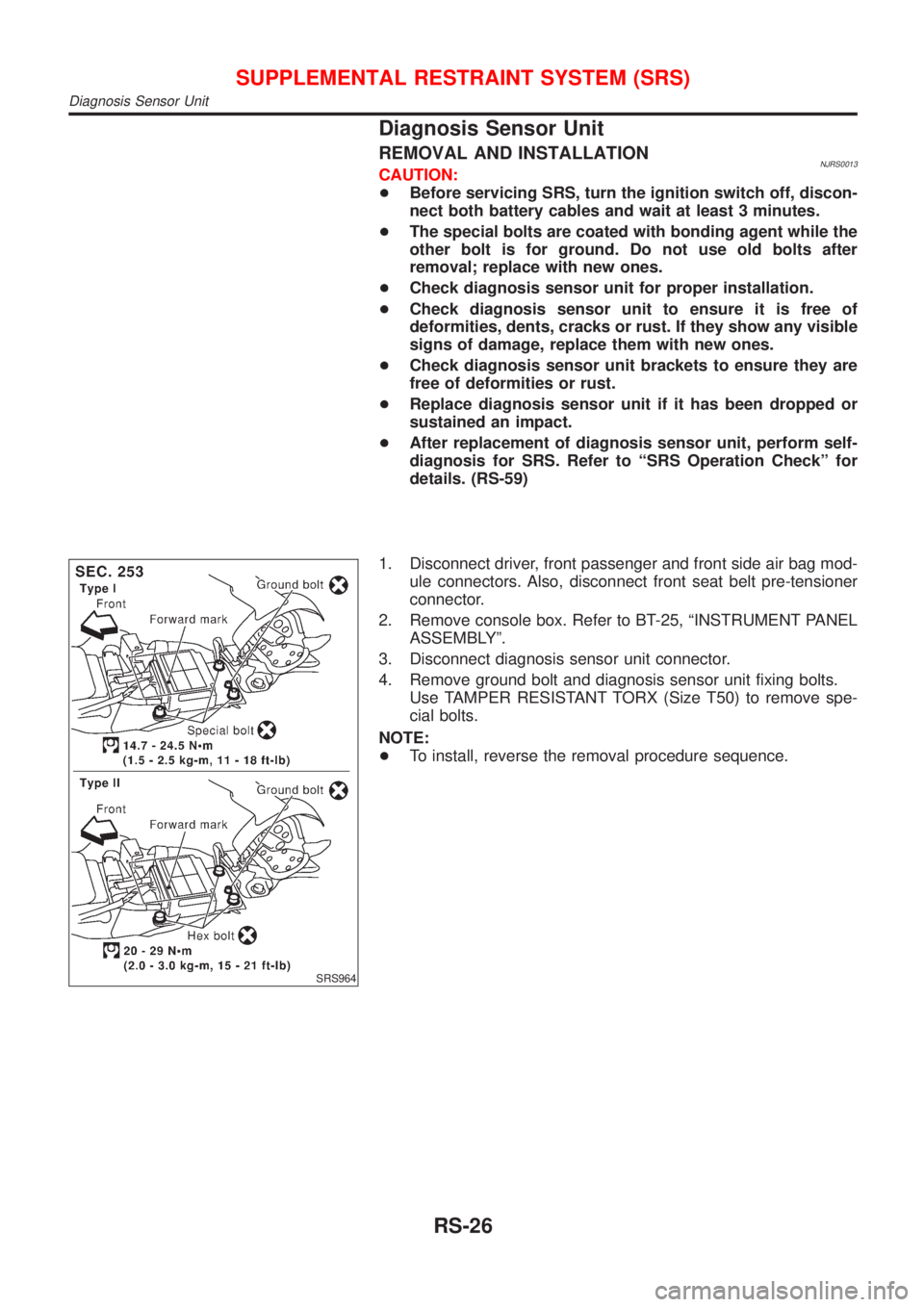

Diagnosis Sensor Unit

REMOVAL AND INSTALLATIONNJRS0013CAUTION:

+Before servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait at least 3 minutes.

+The special bolts are coated with bonding agent while the

other bolt is for ground. Do not use old bolts after

removal; replace with new ones.

+Check diagnosis sensor unit for proper installation.

+Check diagnosis sensor unit to ensure it is free of

deformities, dents, cracks or rust. If they show any visible

signs of damage, replace them with new ones.

+Check diagnosis sensor unit brackets to ensure they are

free of deformities or rust.

+Replace diagnosis sensor unit if it has been dropped or

sustained an impact.

+After replacement of diagnosis sensor unit, perform self-

diagnosis for SRS. Refer to ªSRS Operation Checkº for

details. (RS-59)

SRS964

1. Disconnect driver, front passenger and front side air bag mod-

ule connectors. Also, disconnect front seat belt pre-tensioner

connector.

2. Remove console box. Refer to BT-25, ªINSTRUMENT PANEL

ASSEMBLYº.

3. Disconnect diagnosis sensor unit connector.

4. Remove ground bolt and diagnosis sensor unit fixing bolts.

Use TAMPER RESISTANT TORX (Size T50) to remove spe-

cial bolts.

NOTE:

+To install, reverse the removal procedure sequence.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Diagnosis Sensor Unit

RS-26

Page 2743 of 2898

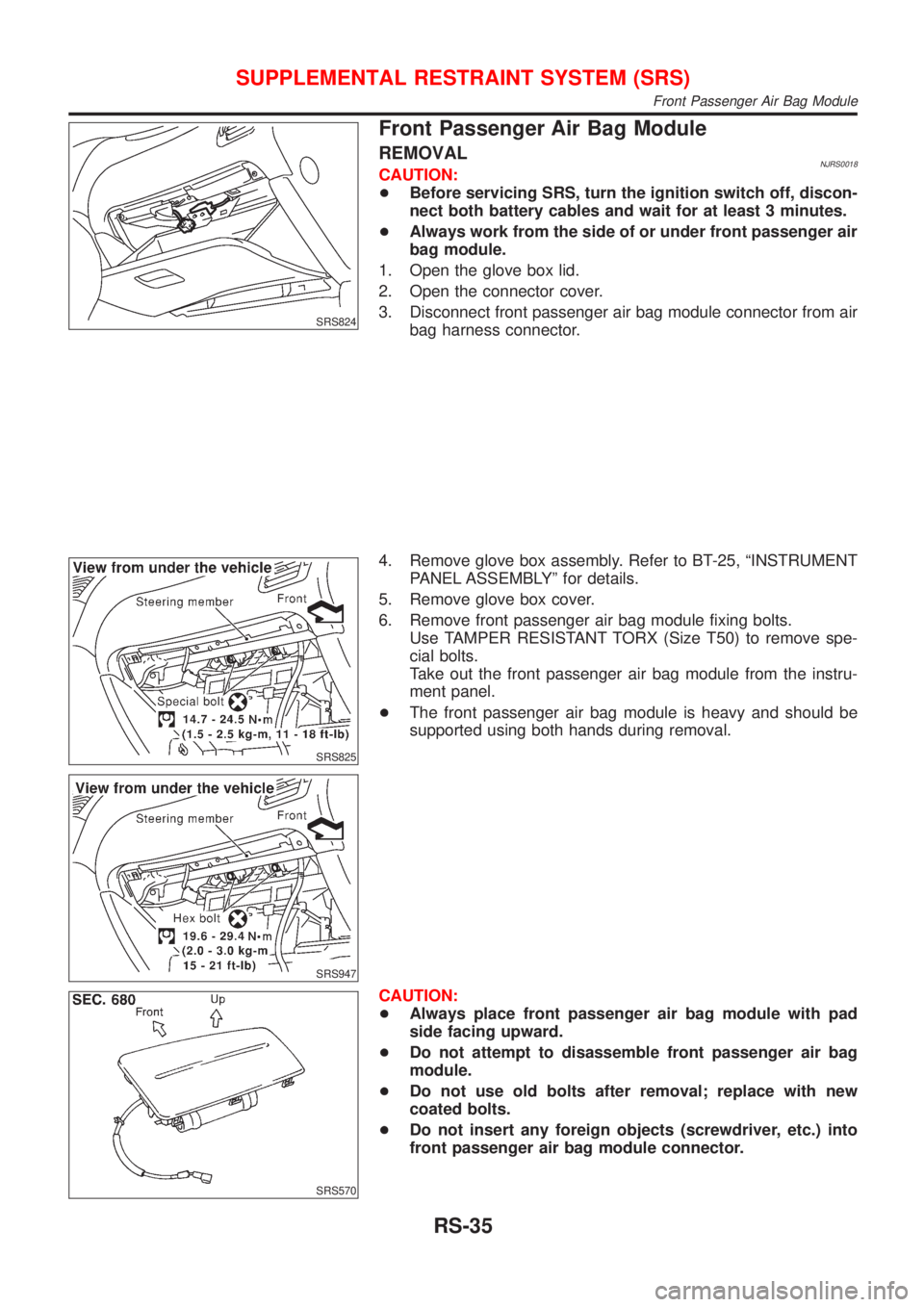

SRS824

Front Passenger Air Bag Module

REMOVALNJRS0018CAUTION:

+Before servicing SRS, turn the ignition switch off, discon-

nect both battery cables and wait for at least 3 minutes.

+Always work from the side of or under front passenger air

bag module.

1. Open the glove box lid.

2. Open the connector cover.

3. Disconnect front passenger air bag module connector from air

bag harness connector.

SRS825

SRS947

4. Remove glove box assembly. Refer to BT-25, ªINSTRUMENT

PANEL ASSEMBLYº for details.

5. Remove glove box cover.

6. Remove front passenger air bag module fixing bolts.

Use TAMPER RESISTANT TORX (Size T50) to remove spe-

cial bolts.

Take out the front passenger air bag module from the instru-

ment panel.

+The front passenger air bag module is heavy and should be

supported using both hands during removal.

SRS570

CAUTION:

+Always place front passenger air bag module with pad

side facing upward.

+Do not attempt to disassemble front passenger air bag

module.

+Do not use old bolts after removal; replace with new

coated bolts.

+Do not insert any foreign objects (screwdriver, etc.) into

front passenger air bag module connector.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Passenger Air Bag Module

RS-35

Page 2744 of 2898

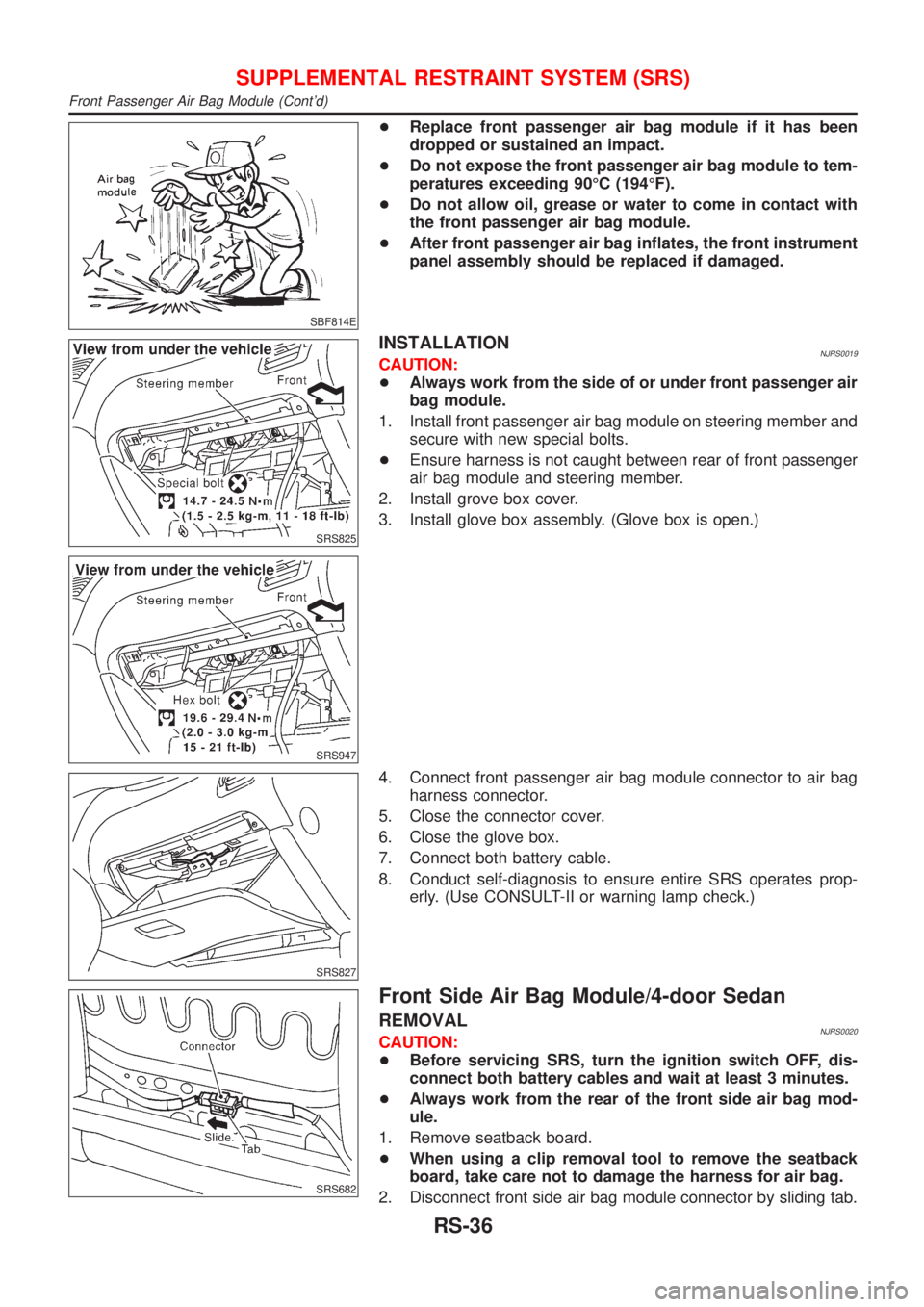

SBF814E

+Replace front passenger air bag module if it has been

dropped or sustained an impact.

+Do not expose the front passenger air bag module to tem-

peratures exceeding 90ÉC (194ÉF).

+Do not allow oil, grease or water to come in contact with

the front passenger air bag module.

+After front passenger air bag inflates, the front instrument

panel assembly should be replaced if damaged.

SRS825

SRS947

INSTALLATIONNJRS0019CAUTION:

+Always work from the side of or under front passenger air

bag module.

1. Install front passenger air bag module on steering member and

secure with new special bolts.

+Ensure harness is not caught between rear of front passenger

air bag module and steering member.

2. Install grove box cover.

3. Install glove box assembly. (Glove box is open.)

SRS827

4. Connect front passenger air bag module connector to air bag

harness connector.

5. Close the connector cover.

6. Close the glove box.

7. Connect both battery cable.

8. Conduct self-diagnosis to ensure entire SRS operates prop-

erly. (Use CONSULT-II or warning lamp check.)

SRS682

Front Side Air Bag Module/4-door Sedan

REMOVALNJRS0020CAUTION:

+Before servicing SRS, turn the ignition switch OFF, dis-

connect both battery cables and wait at least 3 minutes.

+Always work from the rear of the front side air bag mod-

ule.

1. Remove seatback board.

+When using a clip removal tool to remove the seatback

board, take care not to damage the harness for air bag.

2. Disconnect front side air bag module connector by sliding tab.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Front Passenger Air Bag Module (Cont'd)

RS-36

Page 2793 of 2898

Collision Diagnosis=NJRS0033FOR FRONTAL COLLISIONNJRS0033S07To repair the SRS, perform the following steps.

When SRS (except the side air bag) is activated in a collision:

1) Replace the diagnosis sensor unit.

2) Remove the air bag modules (except the side air bag module) and front seat belt pre-tensioner assem-

blies.

3) Check the SRS components using the table shown below:

+Replace any SRS components showing visible signs of damage (dents, cracks and deformation).

4) Install new air bag modules (except the side air bag module) and front seat belt pre-tensioner assemblies.

5) Conduct self-diagnosis using CONSULT-II or ªAIR BAGº warning lamp. Refer to ªSRS Operation Checkº

for details (RS-59). Ensure entire SRS operation properly.

When SRS is not activated in a collision:

1) Check the SRS components using the table shown below:

+Replace any SRS components showing visible signs of damage (dents, cracks and deformation).

2) Conduct self-diagnosis using CONSULT-II or ªAIR BAGº warning lamp. Refer to ªSRS Operation Checkº

for details (RS-59). Ensure entire SRS operation properly.

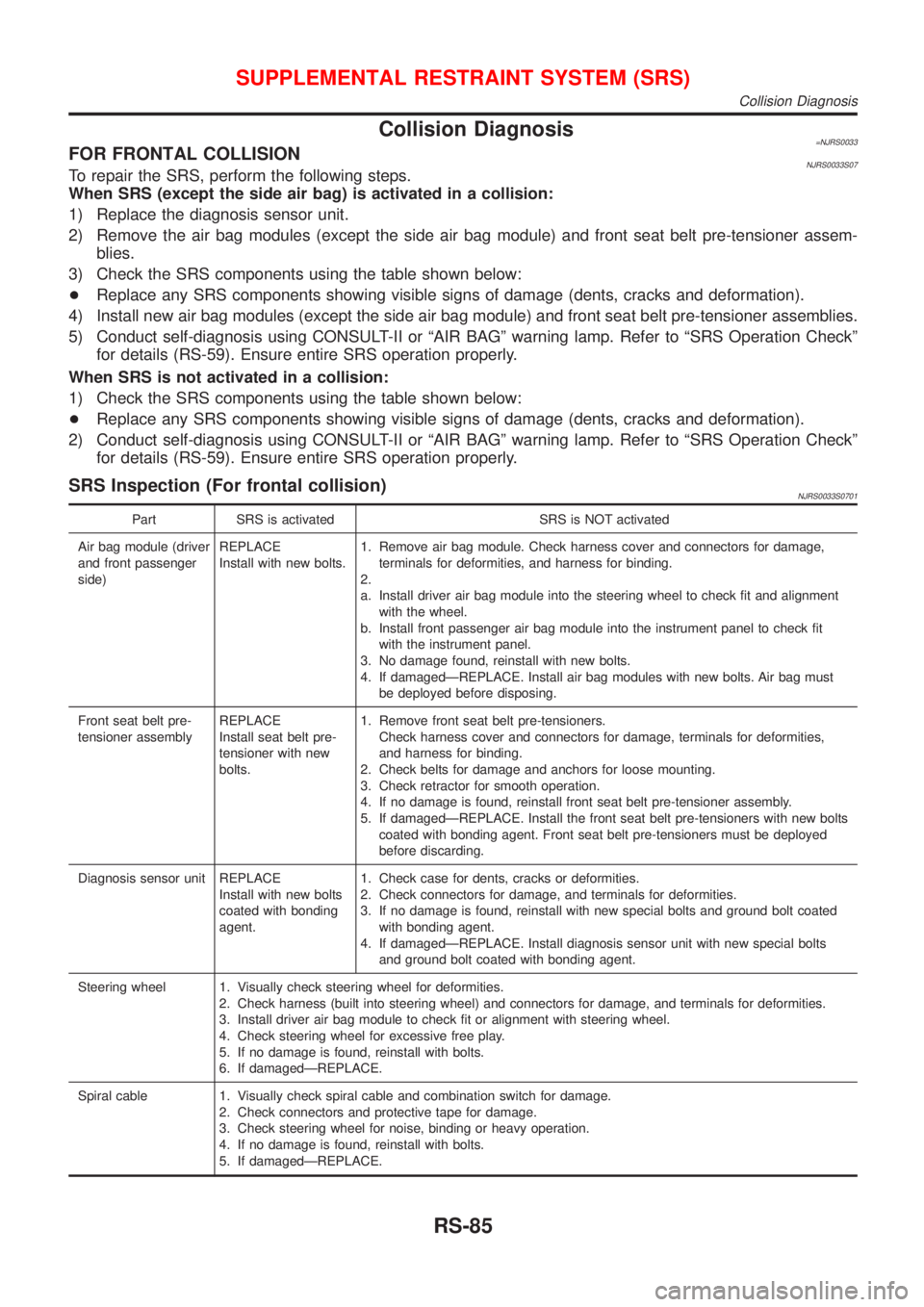

SRS Inspection (For frontal collision)NJRS0033S0701

Part SRS is activated SRS is NOT activated

Air bag module (driver

and front passenger

side)REPLACE

Install with new bolts.1. Remove air bag module. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

2.

a. Install driver air bag module into the steering wheel to check fit and alignment

with the wheel.

b. Install front passenger air bag module into the instrument panel to check fit

with the instrument panel.

3. No damage found, reinstall with new bolts.

4. If damagedÐREPLACE. Install air bag modules with new bolts. Air bag must

be deployed before disposing.

Front seat belt pre-

tensioner assemblyREPLACE

Install seat belt pre-

tensioner with new

bolts.1. Remove front seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities,

and harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. If no damage is found, reinstall front seat belt pre-tensioner assembly.

5. If damagedÐREPLACE. Install the front seat belt pre-tensioners with new bolts

coated with bonding agent. Front seat belt pre-tensioners must be deployed

before discarding.

Diagnosis sensor unit REPLACE

Install with new bolts

coated with bonding

agent.1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new special bolts and ground bolt coated

with bonding agent.

4. If damagedÐREPLACE. Install diagnosis sensor unit with new special bolts

and ground bolt coated with bonding agent.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install driver air bag module to check fit or alignment with steering wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall with bolts.

6. If damagedÐREPLACE.

Spiral cable 1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall with bolts.

5. If damagedÐREPLACE.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Collision Diagnosis

RS-85

Page 2794 of 2898

Part SRS is activated SRS is NOT activated

Harness and Connec-

tors1. Check connectors for poor connection, damage, and terminals for deformities.

2. Check harness for binding, chafing, cuts, or deformities.

3. If no damage is found, reinstall the harness and connectors.

4. DamagedÐREPLACE damaged section of harness. Do not attempt to repair, splice or modify any SRS

harness.

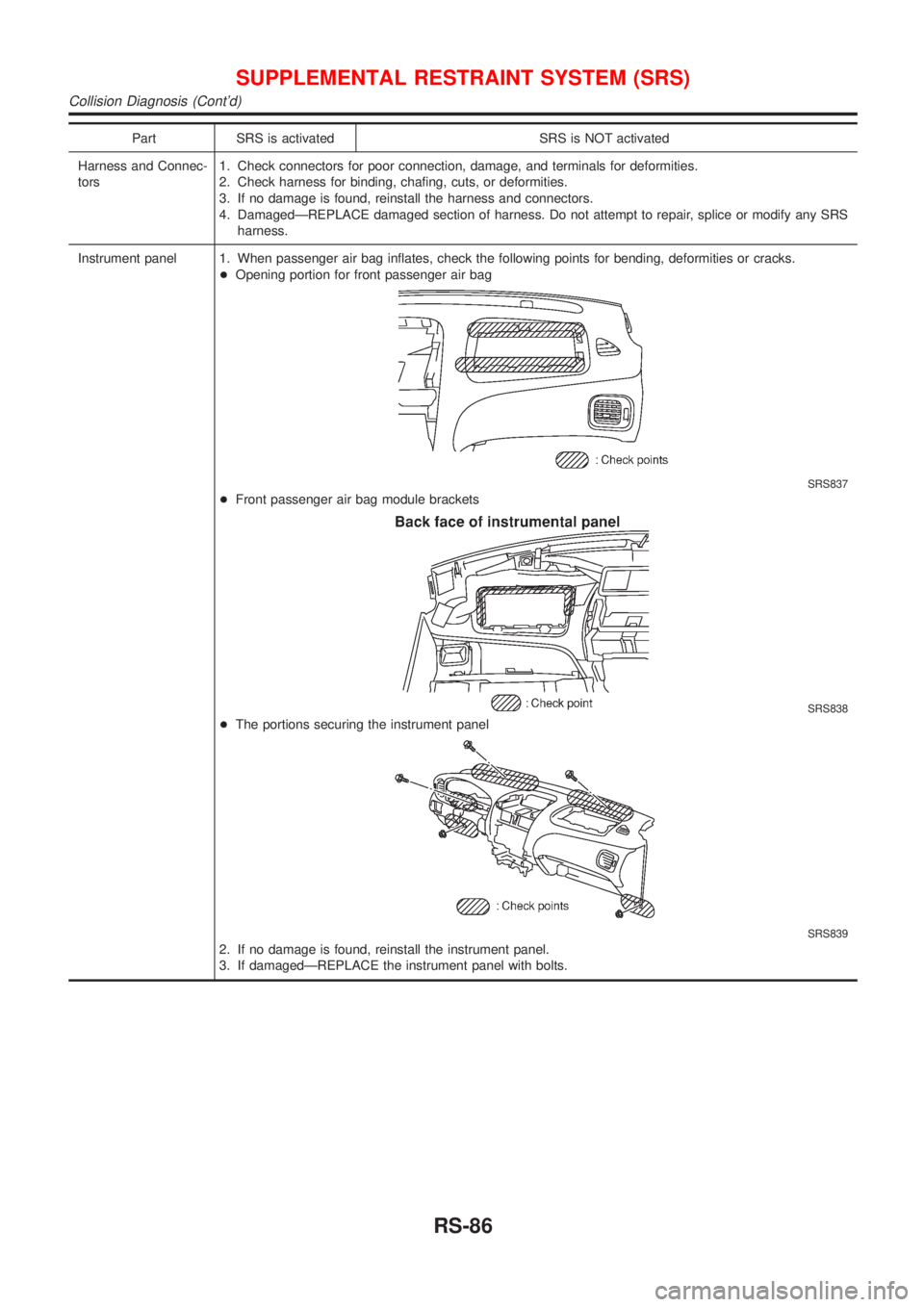

Instrument panel 1. When passenger air bag inflates, check the following points for bending, deformities or cracks.

+Opening portion for front passenger air bag

SRS837

+Front passenger air bag module brackets

SRS838

+The portions securing the instrument panel

SRS839

2. If no damage is found, reinstall the instrument panel.

3. If damagedÐREPLACE the instrument panel with bolts.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Collision Diagnosis (Cont'd)

RS-86