NISSAN ALMERA 2001 Service Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA, Model: NISSAN ALMERA 2001Pages: 2898, PDF Size: 60.76 MB

Page 821 of 2898

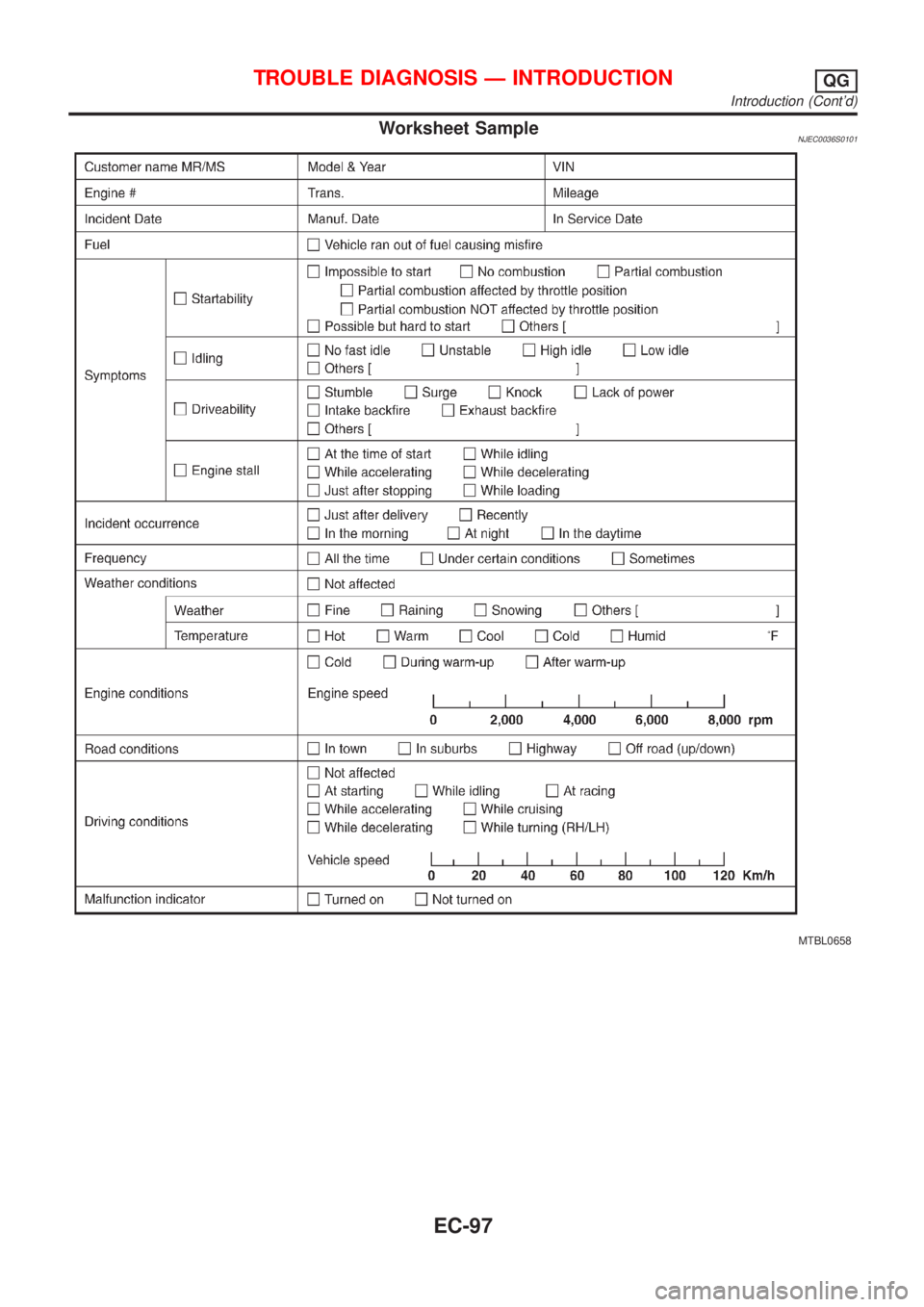

Worksheet SampleNJEC0036S0101

MTBL0658

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG

Introduction (Cont'd)

EC-97

Page 822 of 2898

![NISSAN ALMERA 2001 Service Manual Work FlowNJEC0563

SEF510ZD

*1 EC-154

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º or

ª[1t]º, perform ªTROUBLE DIAG-

NOSIS FOR INTERMITTENT

INCIDENTº, EC-177.

*3 If the incident can NISSAN ALMERA 2001 Service Manual Work FlowNJEC0563

SEF510ZD

*1 EC-154

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º or

ª[1t]º, perform ªTROUBLE DIAG-

NOSIS FOR INTERMITTENT

INCIDENTº, EC-177.

*3 If the incident can](/img/5/57348/w960_57348-821.png)

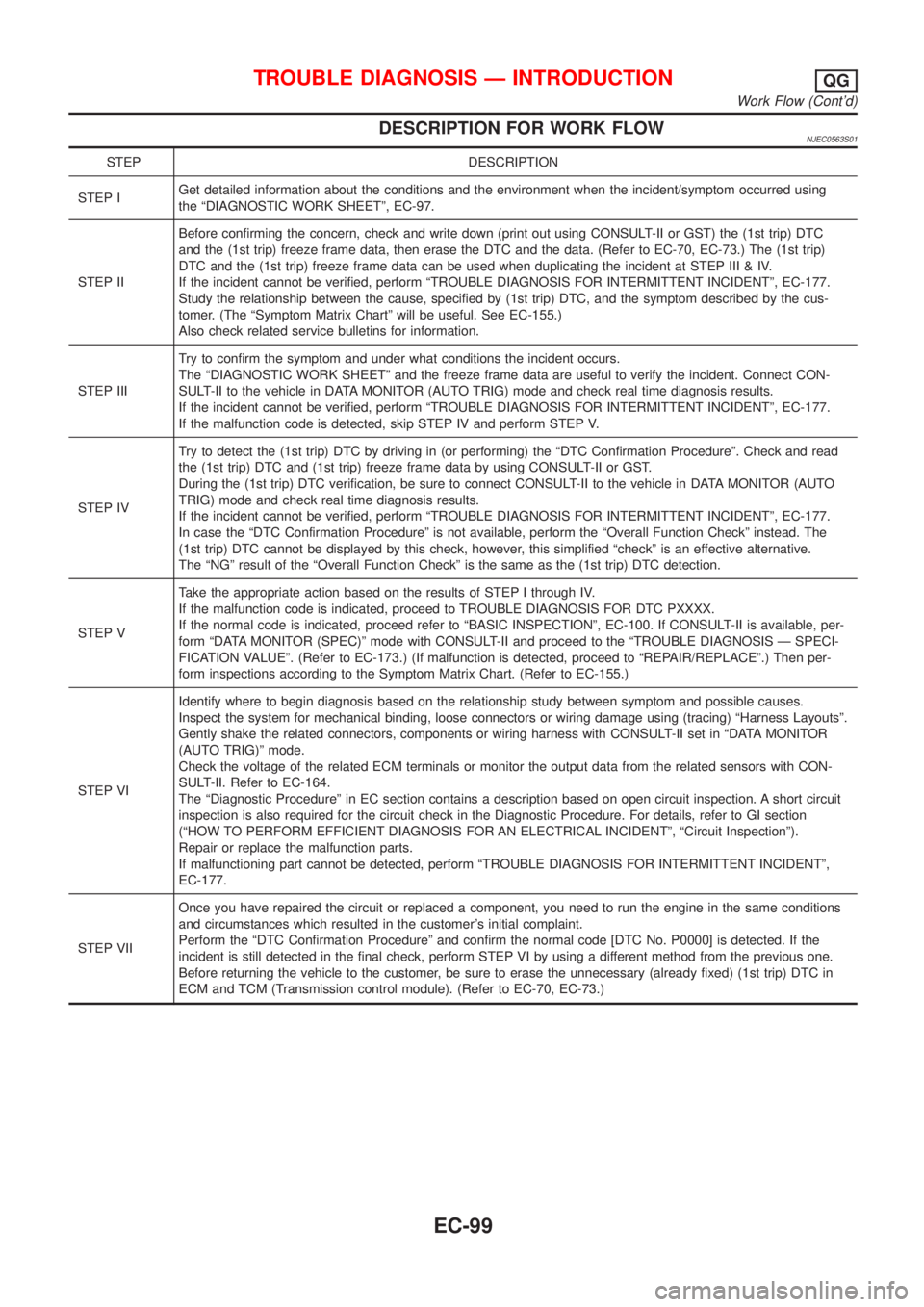

Work FlowNJEC0563

SEF510ZD

*1 EC-154

*2 If time data of ªSELF-DIAG

RESULTSº is other than ª0º or

ª[1t]º, perform ªTROUBLE DIAG-

NOSIS FOR INTERMITTENT

INCIDENTº, EC-177.

*3 If the incident cannot be verified,

perform ªTROUBLE DIAGNOSIS

FOR INTERMITTENT INCIDENTº,

EC-177.*4 If the on board diagnostic system

cannot be performed, check main

power supply and ground circuit.

Refer to ªTROUBLE DIAGNOSIS

FOR POWER SUPPLYº, EC-178.

*5 If malfunctioning part cannot bedetected, perform ªTROUBLE

DIAGNOSIS FOR INTERMIT-

TENT INCIDENTº, EC-177.

*6 EC-66

*7 EC-173

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG

Work Flow

EC-98

Page 823 of 2898

DESCRIPTION FOR WORK FLOWNJEC0563S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using

the ªDIAGNOSTIC WORK SHEETº, EC-97.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or GST) the (1st trip) DTC

and the (1st trip) freeze frame data, then erase the DTC and the data. (Refer to EC-70, EC-73.) The (1st trip)

DTC and the (1st trip) freeze frame data can be used when duplicating the incident at STEP III & IV.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The ªSymptom Matrix Chartº will be useful. See EC-155.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) DTC by driving in (or performing) the ªDTC Confirmation Procedureº. Check and read

the (1st trip) DTC and (1st trip) freeze frame data by using CONSULT-II or GST.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-177.

In case the ªDTC Confirmation Procedureº is not available, perform the ªOverall Function Checkº instead. The

(1st trip) DTC cannot be displayed by this check, however, this simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOverall Function Checkº is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed refer to ªBASIC INSPECTIONº, EC-100. If CONSULT-II is available, per-

form ªDATA MONITOR (SPEC)º mode with CONSULT-II and proceed to the ªTROUBLE DIAGNOSIS Ð SPECI-

FICATION VALUEº. (Refer to EC-173.) (If malfunction is detected, proceed to ªREPAIR/REPLACEº.) Then per-

form inspections according to the Symptom Matrix Chart. (Refer to EC-155.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-164.

The ªDiagnostic Procedureº in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI section

(ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº, ªCircuit Inspectionº).

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº,

EC-177.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDTC Confirmation Procedureº and confirm the normal code [DTC No. P0000] is detected. If the

incident is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM and TCM (Transmission control module). (Refer to EC-70, EC-73.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG

Work Flow (Cont'd)

EC-99

Page 824 of 2898

Basic Inspection/SedanNJEC1736Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

On vehicle equipped with daytime light systems, set lighting

switch to the 1st position to light only small lamps.

+Air conditioner switch is OFF,

+Rear window defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

MODELS WITH THROTTLE POSITION SWITCHNJEC1736S01

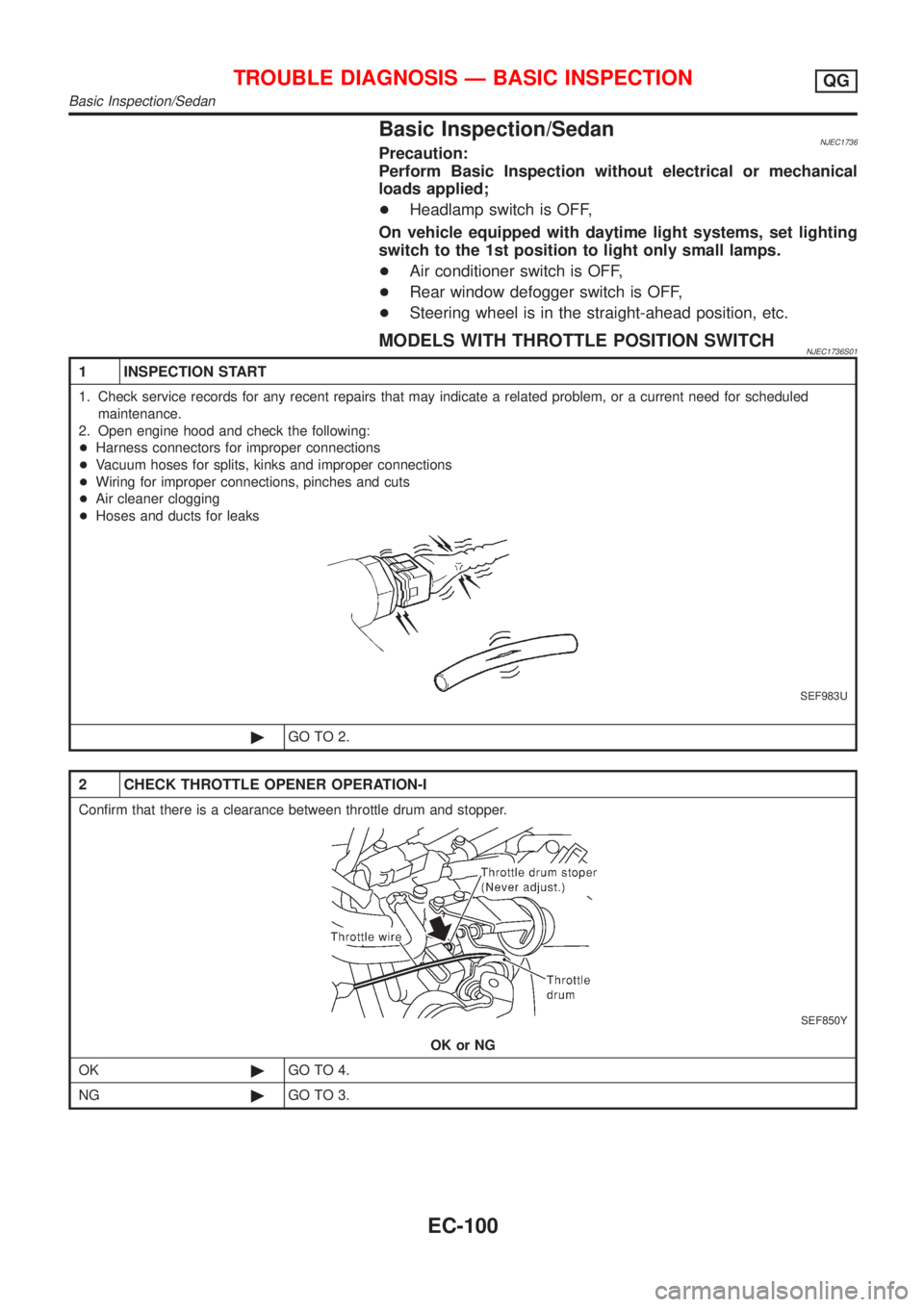

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

+Harness connectors for improper connections

+Vacuum hoses for splits, kinks and improper connections

+Wiring for improper connections, pinches and cuts

+Air cleaner clogging

+Hoses and ducts for leaks

SEF983U

©GO TO 2.

2 CHECK THROTTLE OPENER OPERATION-I

Confirm that there is a clearance between throttle drum and stopper.

SEF850Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan

EC-100

Page 825 of 2898

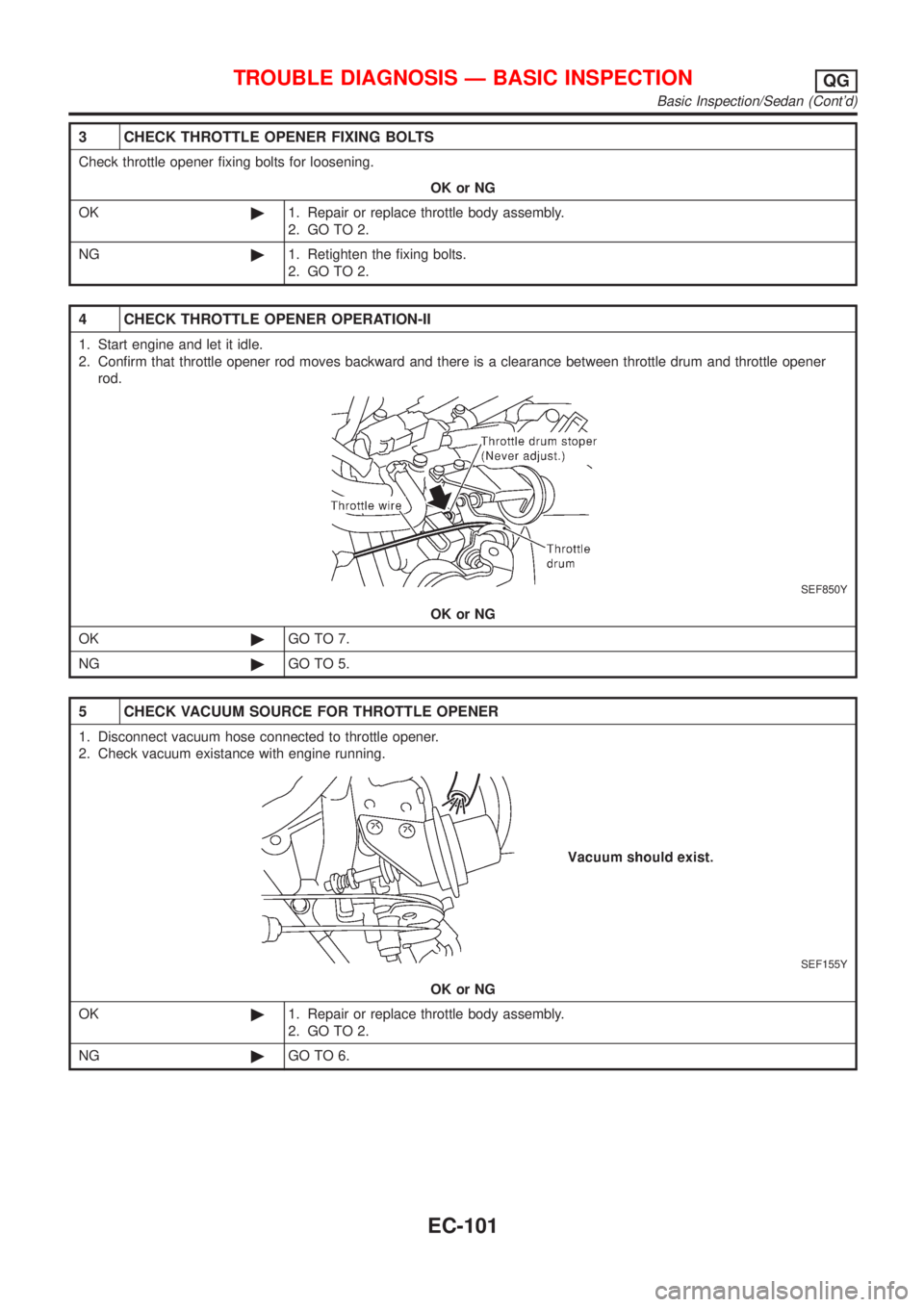

3 CHECK THROTTLE OPENER FIXING BOLTS

Check throttle opener fixing bolts for loosening.

OK or NG

OK©1. Repair or replace throttle body assembly.

2. GO TO 2.

NG©1. Retighten the fixing bolts.

2. GO TO 2.

4 CHECK THROTTLE OPENER OPERATION-II

1. Start engine and let it idle.

2. Confirm that throttle opener rod moves backward and there is a clearance between throttle drum and throttle opener

rod.

SEF850Y

OK or NG

OK©GO TO 7.

NG©GO TO 5.

5 CHECK VACUUM SOURCE FOR THROTTLE OPENER

1. Disconnect vacuum hose connected to throttle opener.

2. Check vacuum existance with engine running.

SEF155Y

OK or NG

OK©1. Repair or replace throttle body assembly.

2. GO TO 2.

NG©GO TO 6.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-101

Page 826 of 2898

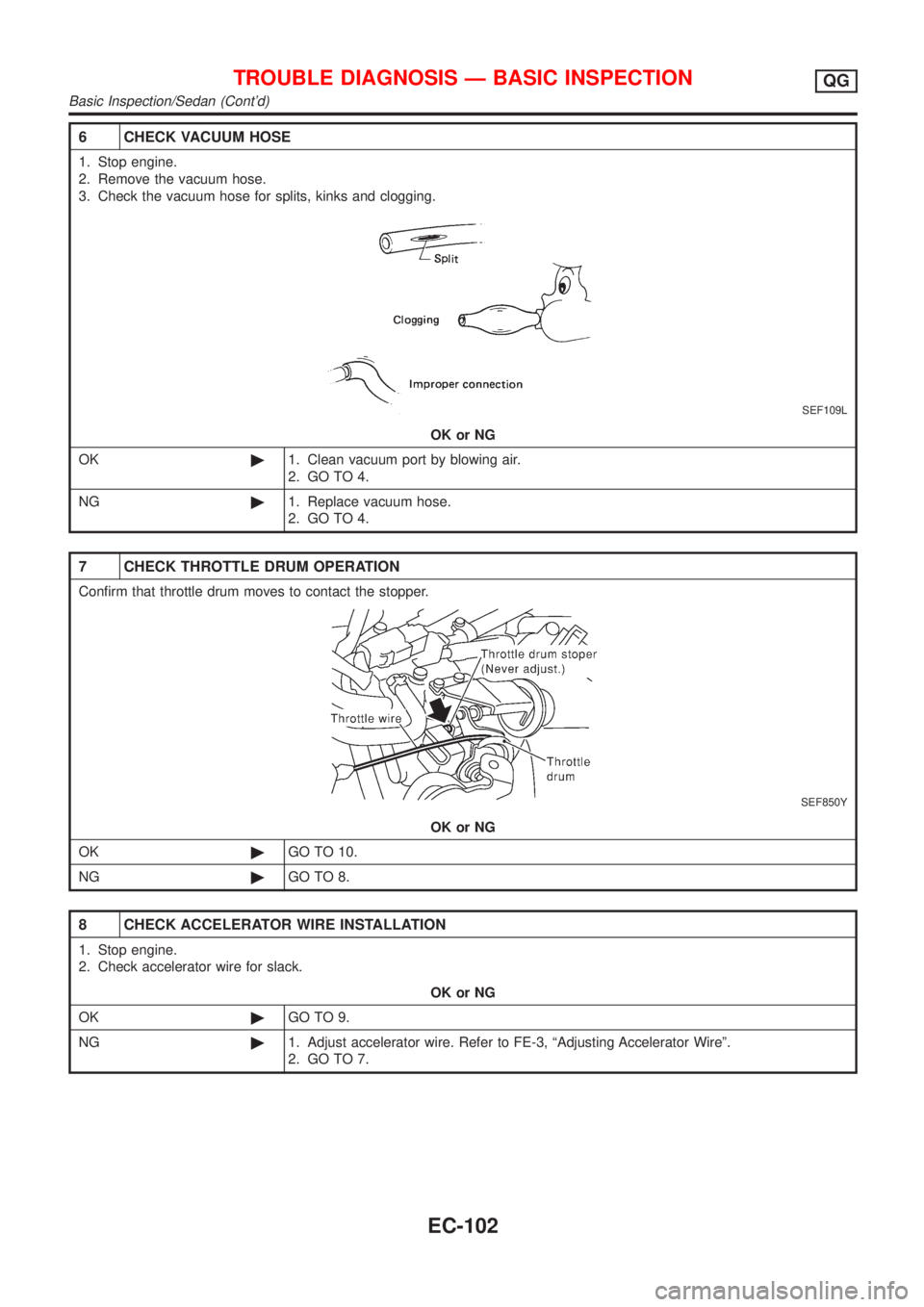

6 CHECK VACUUM HOSE

1. Stop engine.

2. Remove the vacuum hose.

3. Check the vacuum hose for splits, kinks and clogging.

SEF109L

OK or NG

OK©1. Clean vacuum port by blowing air.

2. GO TO 4.

NG©1. Replace vacuum hose.

2. GO TO 4.

7 CHECK THROTTLE DRUM OPERATION

Confirm that throttle drum moves to contact the stopper.

SEF850Y

OK or NG

OK©GO TO 10.

NG©GO TO 8.

8 CHECK ACCELERATOR WIRE INSTALLATION

1. Stop engine.

2. Check accelerator wire for slack.

OK or NG

OK©GO TO 9.

NG©1. Adjust accelerator wire. Refer to FE-3, ªAdjusting Accelerator Wireº.

2. GO TO 7.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-102

Page 827 of 2898

9 CHECK THROTTLE VALVE OPERATION

1. Remove intake air ducts.

2. Check throttle valve operation when moving throttle drum by hand.

OK or NG

OK©1. Retighten the throttle drum fixing nuts.

2. GO TO 7.

NG©1. Clean the throttle body and throttle valve.

2. GO TO 7.

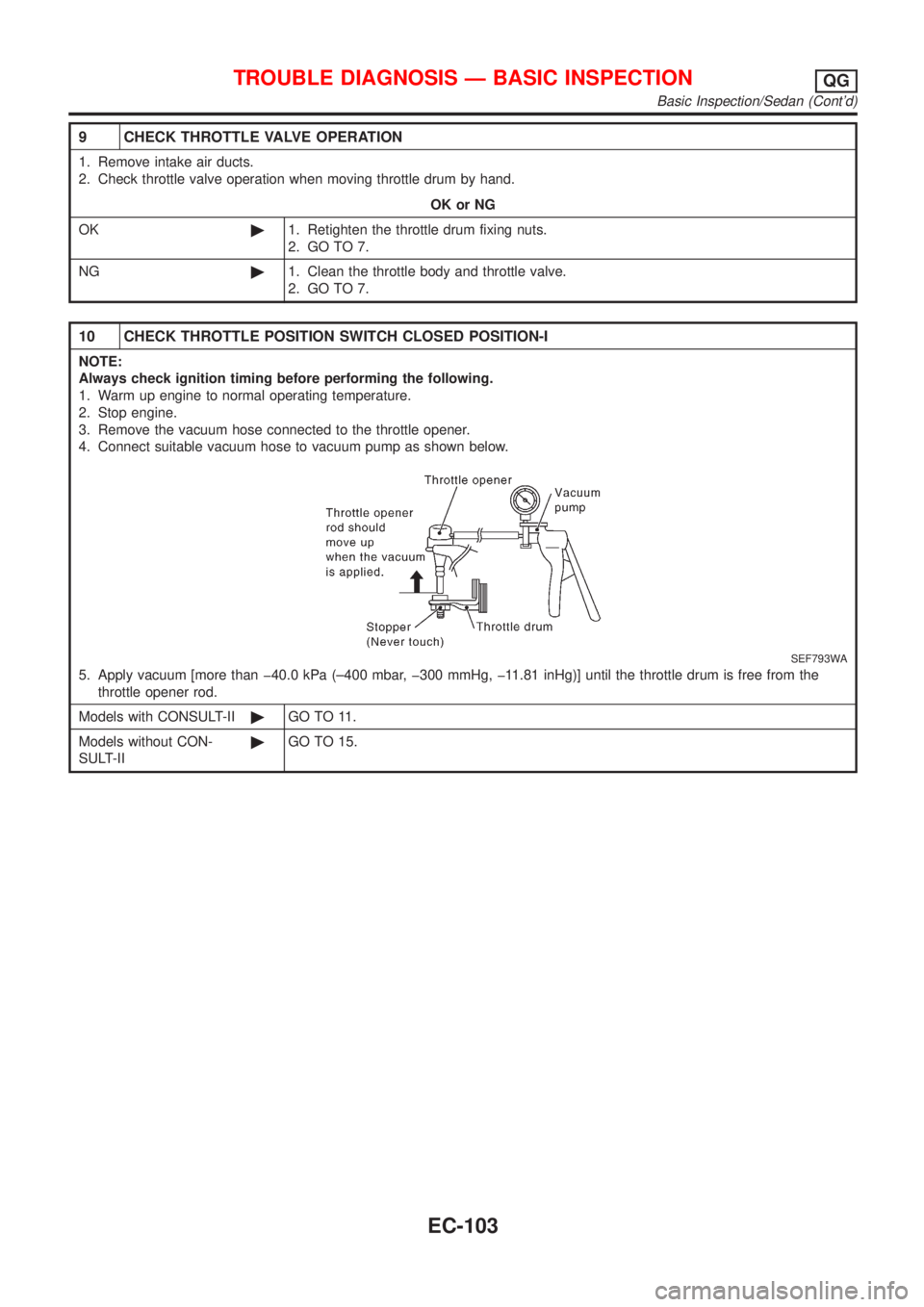

10 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-I

NOTE:

Always check ignition timing before performing the following.

1. Warm up engine to normal operating temperature.

2. Stop engine.

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to vacuum pump as shown below.

SEF793WA

5. Apply vacuum [more than þ40.0 kPa (±400 mbar, þ300 mmHg, þ11.81 inHg)] until the throttle drum is free from the

throttle opener rod.

Models with CONSULT-II©GO TO 11.

Models without CON-

SULT-II©GO TO 15.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-103

Page 828 of 2898

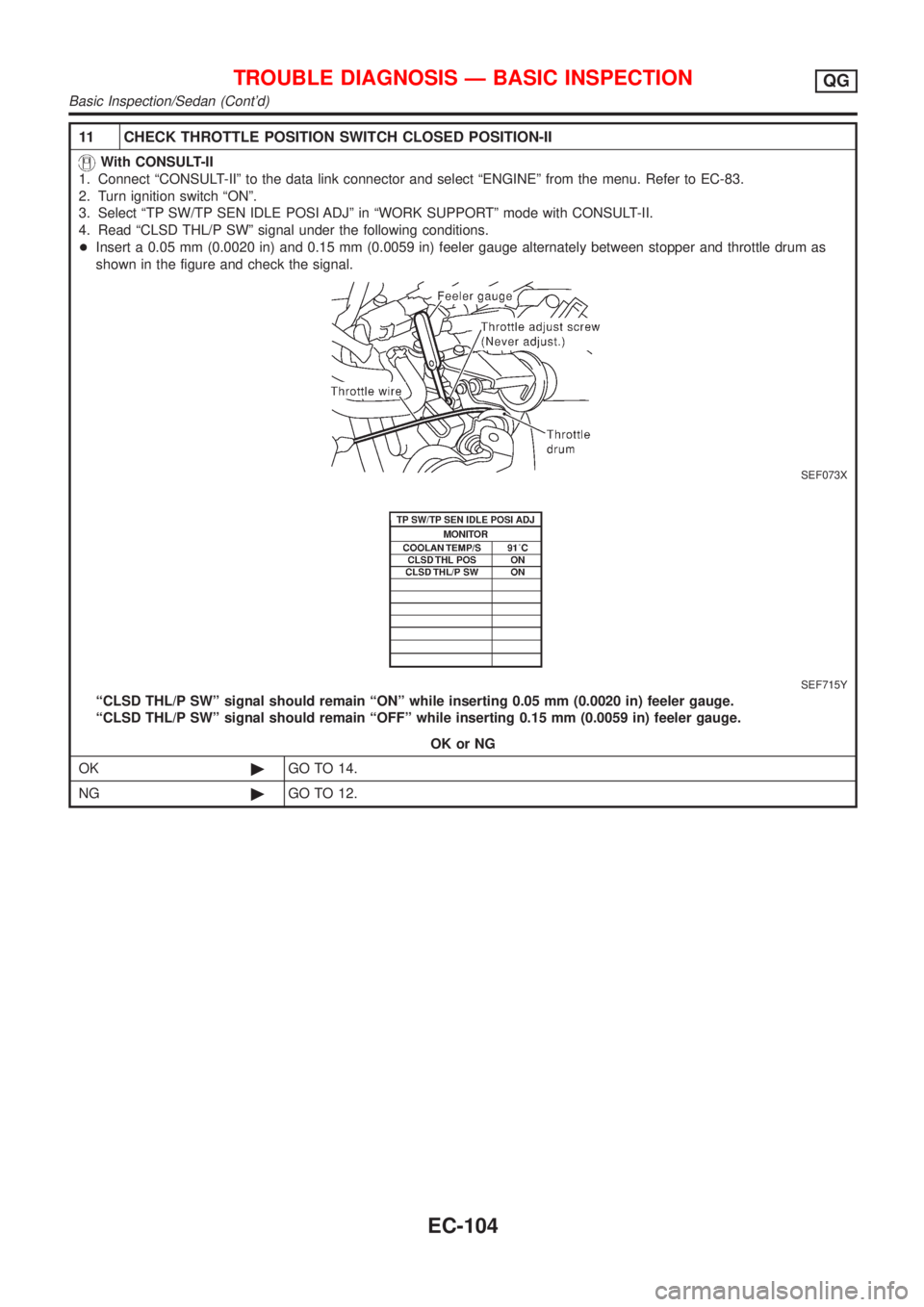

11 CHECK THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Connect ªCONSULT-IIº to the data link connector and select ªENGINEº from the menu. Refer to EC-83.

2. Turn ignition switch ªONº.

3. Select ªTP SW/TP SEN IDLE POSI ADJº in ªWORK SUPPORTº mode with CONSULT-II.

4. Read ªCLSD THL/P SWº signal under the following conditions.

+Insert a 0.05 mm (0.0020 in) and 0.15 mm (0.0059 in) feeler gauge alternately between stopper and throttle drum as

shown in the figure and check the signal.

SEF073X

SEF715Y

ªCLSD THL/P SWº signal should remain ªONº while inserting 0.05 mm (0.0020 in) feeler gauge.

ªCLSD THL/P SWº signal should remain ªOFFº while inserting 0.15 mm (0.0059 in) feeler gauge.

OK or NG

OK©GO TO 14.

NG©GO TO 12.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-104

Page 829 of 2898

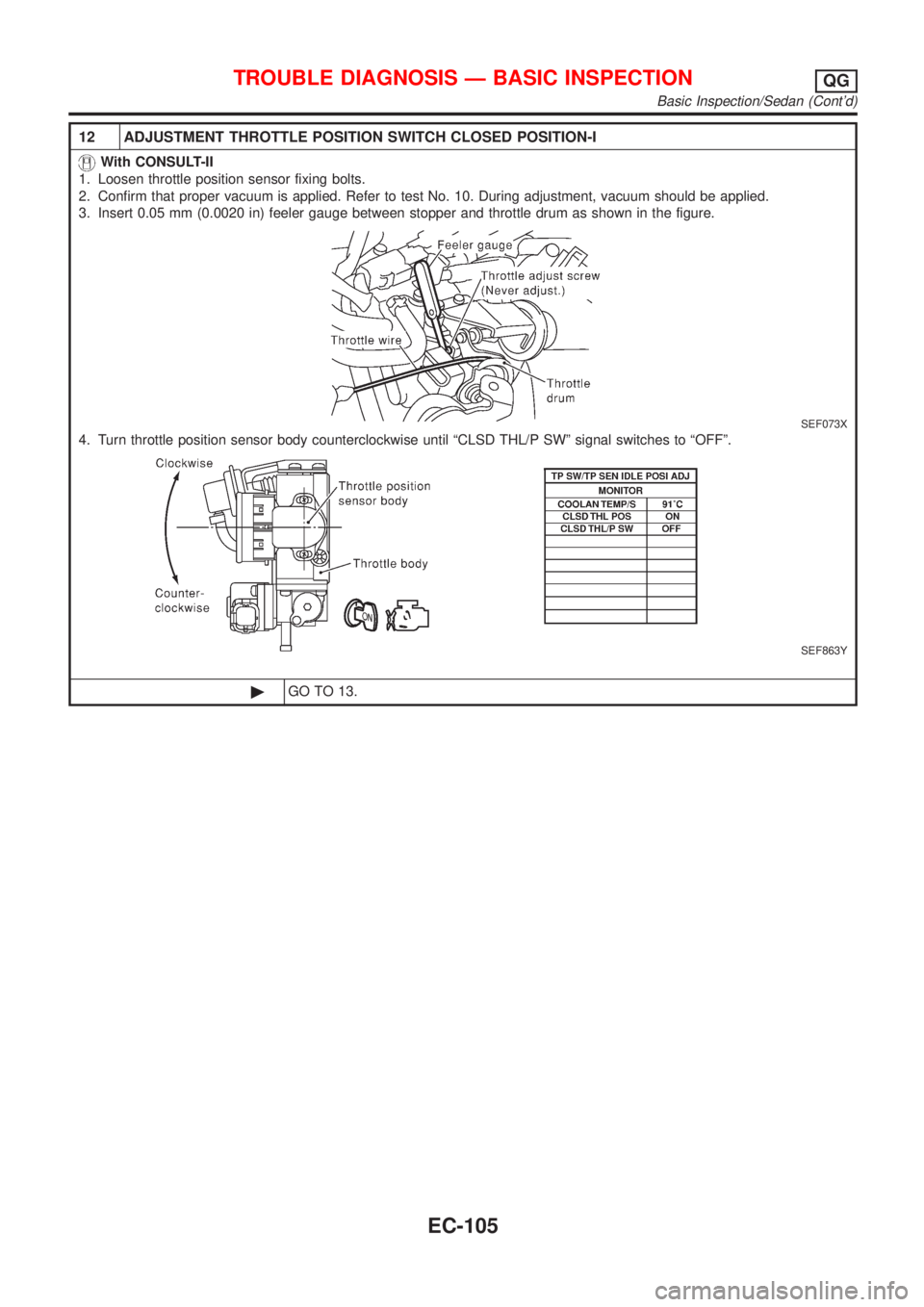

12 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-I

With CONSULT-II

1. Loosen throttle position sensor fixing bolts.

2. Confirm that proper vacuum is applied. Refer to test No. 10. During adjustment, vacuum should be applied.

3. Insert 0.05 mm (0.0020 in) feeler gauge between stopper and throttle drum as shown in the figure.

SEF073X

4. Turn throttle position sensor body counterclockwise until ªCLSD THL/P SWº signal switches to ªOFFº.

SEF863Y

©GO TO 13.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-105

Page 830 of 2898

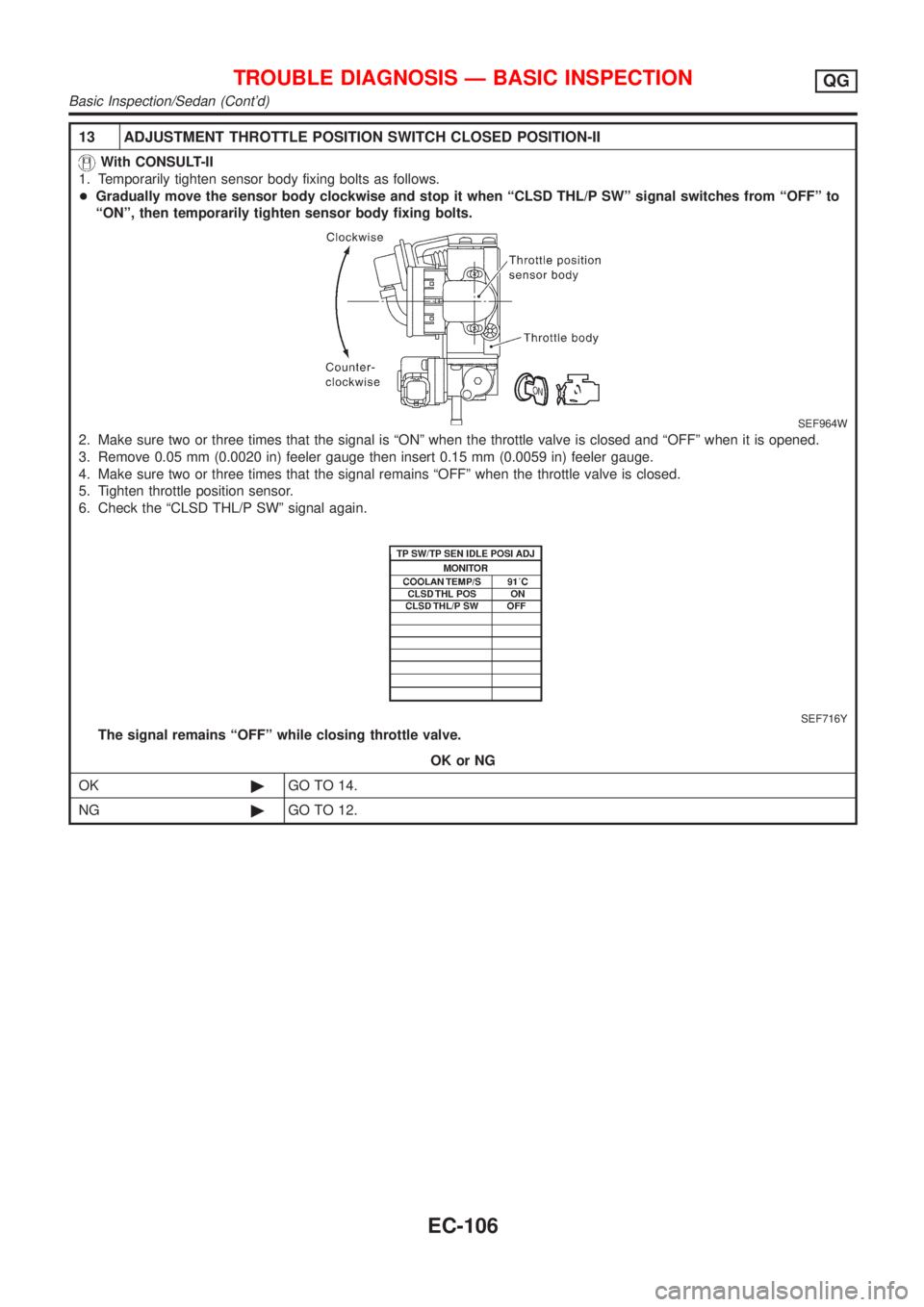

13 ADJUSTMENT THROTTLE POSITION SWITCH CLOSED POSITION-II

With CONSULT-II

1. Temporarily tighten sensor body fixing bolts as follows.

+Gradually move the sensor body clockwise and stop it when ªCLSD THL/P SWº signal switches from ªOFFº to

ªONº, then temporarily tighten sensor body fixing bolts.

SEF964W

2. Make sure two or three times that the signal is ªONº when the throttle valve is closed and ªOFFº when it is opened.

3. Remove 0.05 mm (0.0020 in) feeler gauge then insert 0.15 mm (0.0059 in) feeler gauge.

4. Make sure two or three times that the signal remains ªOFFº when the throttle valve is closed.

5. Tighten throttle position sensor.

6. Check the ªCLSD THL/P SWº signal again.

SEF716Y

The signal remains ªOFFº while closing throttle valve.

OK or NG

OK©GO TO 14.

NG©GO TO 12.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection/Sedan (Cont'd)

EC-106