check engine NISSAN ALMERA N15 1995 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 838 of 1701

TROUBLEDIAGNOSIS FOROTC34

PIEZO-ELEMENT Malfunction isdetected when....

Diagnostic

Trouble Code

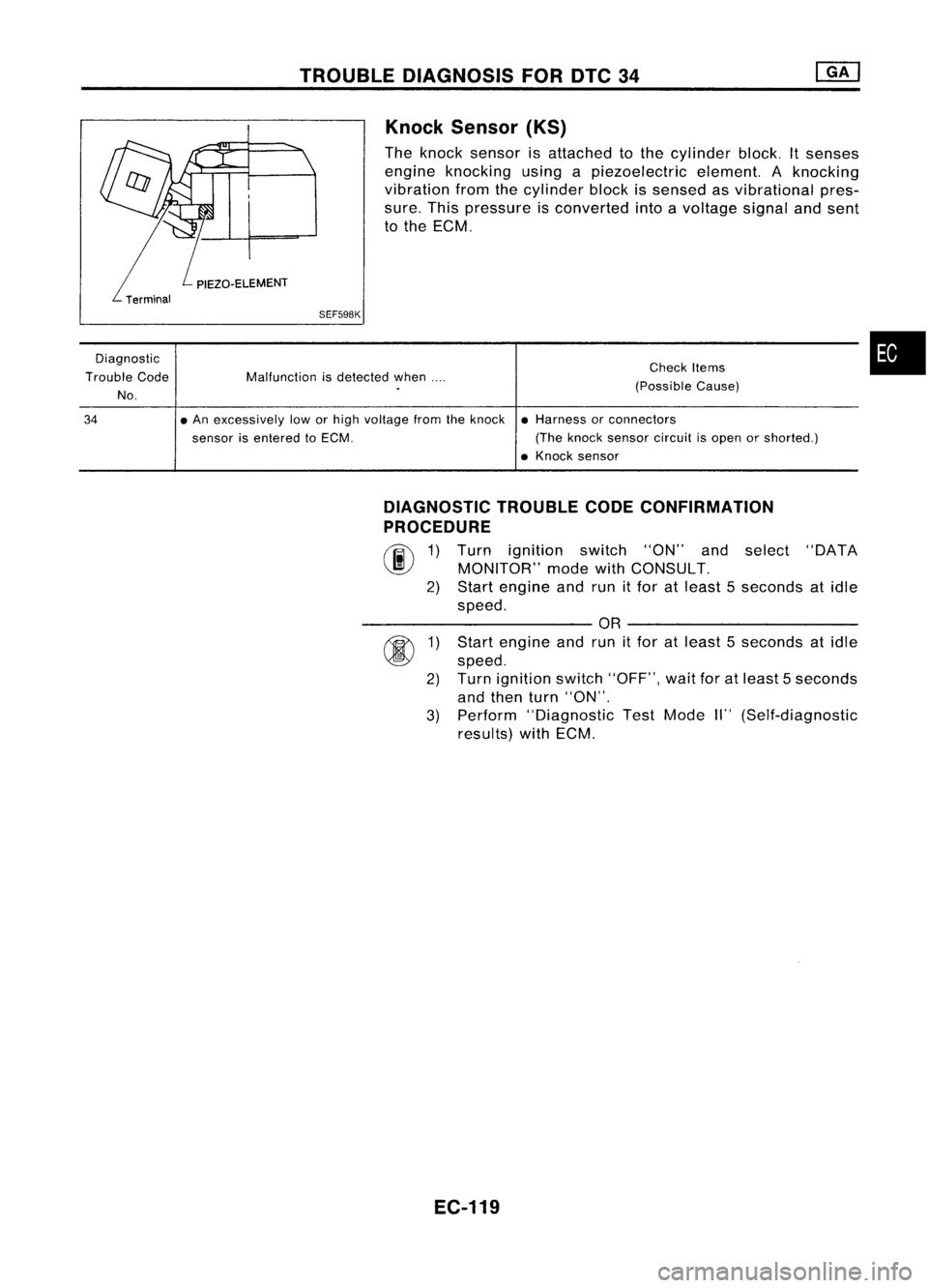

No. SEF598KKnock

Sensor (KS)

The knock sensor isattached tothe cylinder block.Itsenses

engine knocking usingapiezoelectric element.Aknocking

vibration fromthecylinder blockissensed asvibrational pres-

sure. Thispressure isconverted intoavoltage signalandsent

to the ECM.

CheckItems

(Possible Cause)

•

00

1)

2)

3)

34

•An excessively loworhigh voltage fromtheknock •Harness orconnectors

sensor isentered toECM. (Theknock sensor circuitisopen orshorted.)

• Knock sensor

DIAGNOSTIC TROUBLECODECONFIRMATION

PROCEDURE

rif\

1)Turn ignition switch"ON"andselect "DATA

\J!I)

MONITOR" modewithCONSULT.

2) Start engine andrunitfor atleast 5seconds atidle

speed.

---------- OR----------

Start engine andrunitfor atleast 5seconds atidle

speed.

Turn ignition switch"OFF", waitforatleast 5seconds

and then turn"ON".

Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-119

Page 841 of 1701

Replaceknocksensor.

NG

NG

Check thefollowing.

• Harness connectors

@,@

If NG, repair harness or

connectors.

r

OK

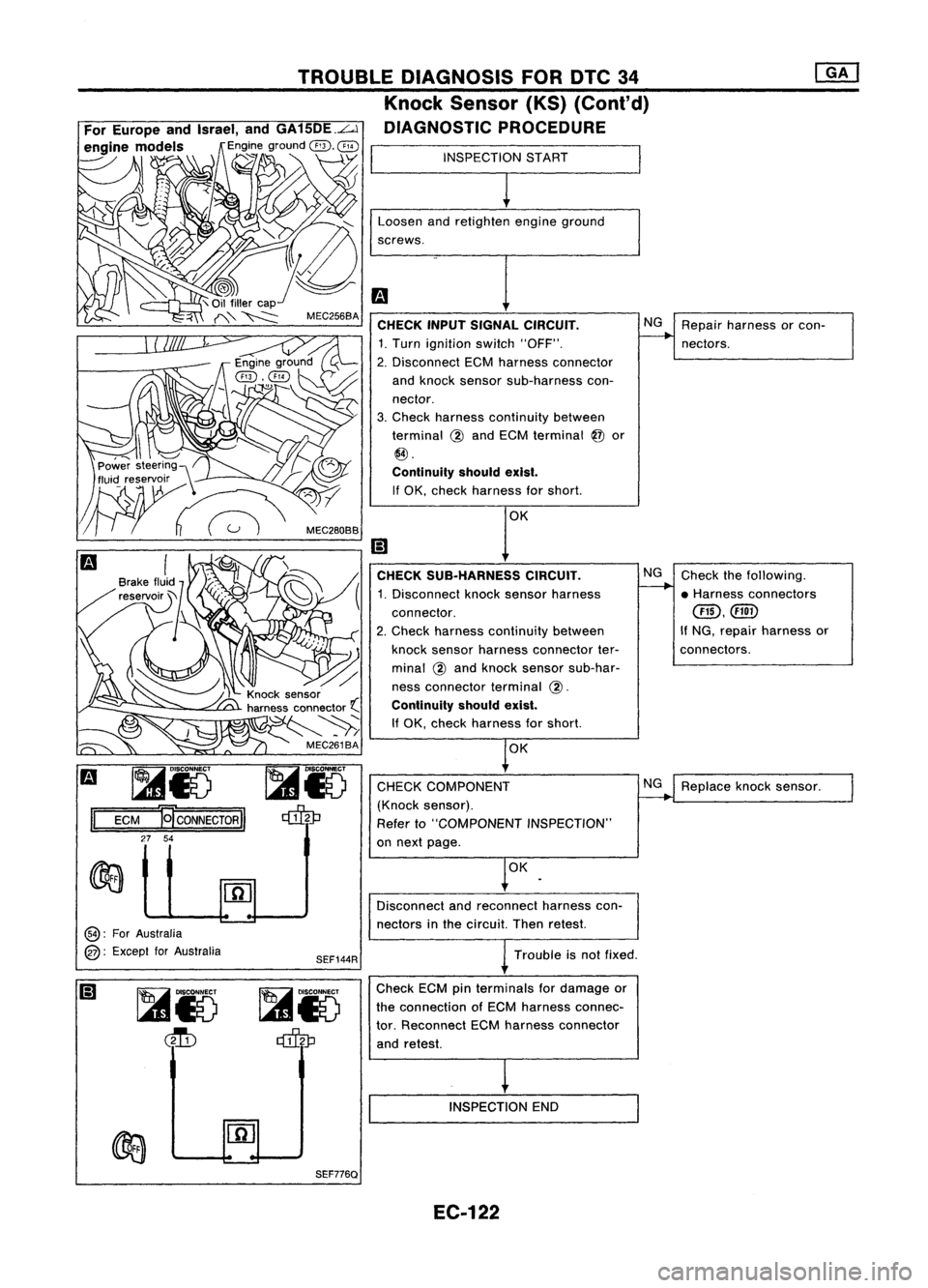

CHECK

SUB.HARNESS CIRCUIT.

1. Disconnect knocksensor harness

connector.

2. Check harness continuity between

knock sensor harness connector ter-

minal @and knock sensor sub-har-

ness connector terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

CHECK COMPONENT

(Knock sensor).

Refer to"COMPONENT INSPECTION"

on next page.

Loosen

andretighten engineground

screws.

Fa

CHECK INPUTSIGNAL CIRCUIT. NG

Repair harness orcon-

1. Turn ignition switch"OFF".

--.

nectors.

2. Disconnect ECMharness connector

and knock sensor sub-harness con-

nector.

3. Check harness continuity between

terminal @and ECM terminal

@

or

@.

Continuity shouldexist.

If OK, check harness forshort.

TROUBLE

DIAGNOSIS FORDTC34

Knock Sensor (KS)(Conl'd)

DIAGNOSTIC PROCEDURE

For Europe andIsrael, andGA15DE.L..l

en~ine m\~~:e?, Is

Eng~eground

@'~@)

1 _

- \.Y

INSPECTIONSTART

J--

Fa

~i5

II

ECM

]9'CONNECTORII

27 54

,~\

C-/

Power steerin9\'

fluid reservoir /'\ /-:

.~~ :,c"",

OK

@:

ForAustralia

@:

Except forAustralia

SEF144RDisconnect

andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage or

the connection ofECM harness connec-

tor. Reconnect ECMharness connector

and retest.

INSPECTION END

SEF776Q EC.122

Page 843 of 1701

TROUBLEDIAGNOSIS FOROTC41

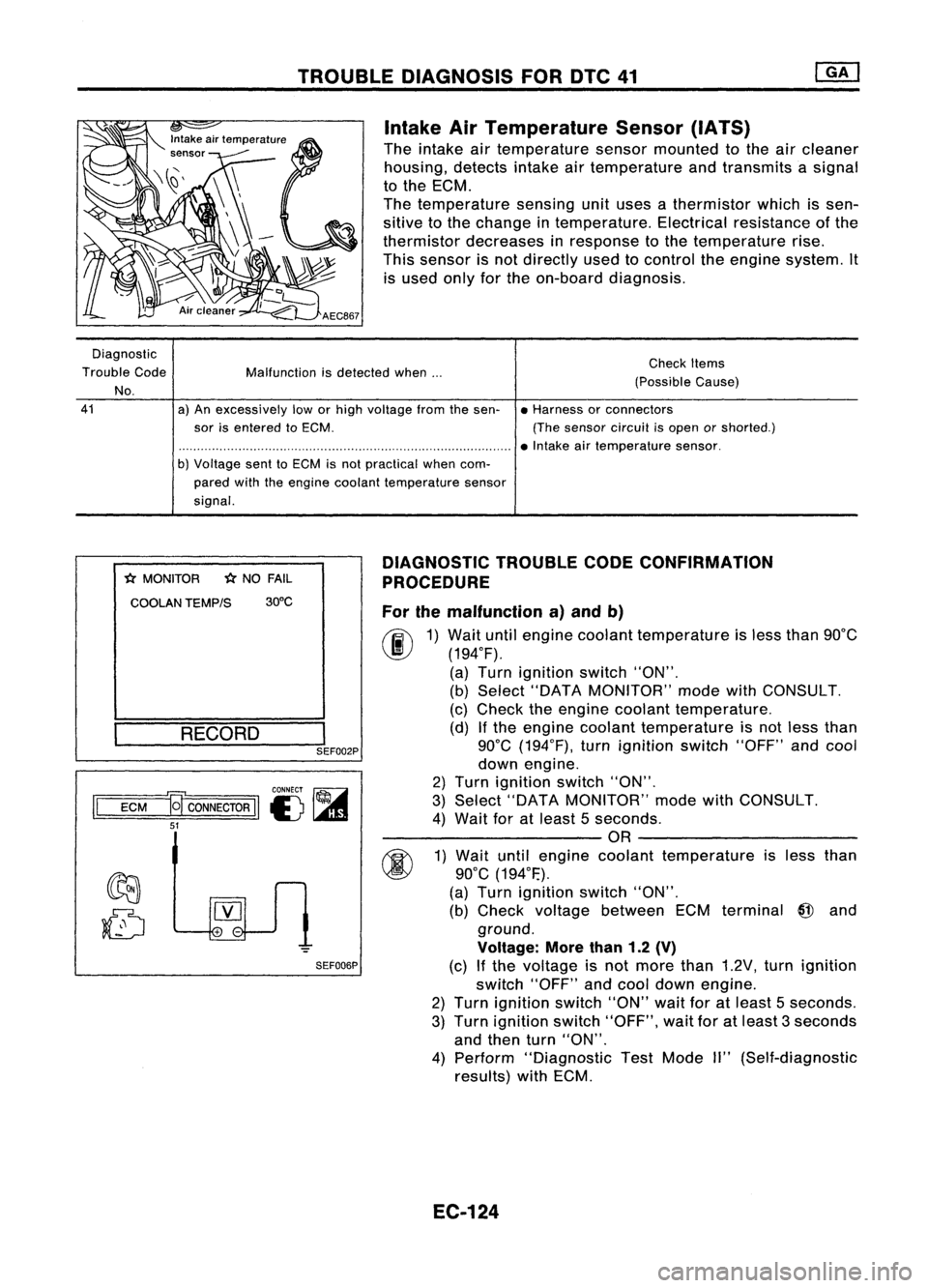

Intake AirTemperature Sensor(IATS)

The intake airtemperature sensormounted tothe aircleaner

housing, detectsintakeairtemperature andtransmits asignal

to the ECM.

The temperature sensingunituses athermistor whichissen-

sitive tothe change intemperature. Electricalresistance ofthe

thermistor decreases inresponse tothe temperature rise.

This sensor isnot directly usedtocontrol theengine system. It

is used onlyforthe on-board diagnosis.

Diagnostic

Trouble Code

No.

41

Malfunction

isdetected when...

a) An excessively loworhigh voltage fromthesen-

sor isentered toECM.

b) Voltage senttoECM isnot practical whencom-

pared withtheengine coolant temperature sensor

signal. Check

Items

(Possible Cause)

• Harness orconnectors

(The sensor circuitisopen orshorted.)

• Intake airtemperature sensor.

*

MONITOR

*

NO FAIL

COOLAN TEMP/S 30°C

RECORD

I

SEF002P

CONNECT ~

II

ECM

a

CONNECTOR

II

I) ~

51

SEF006PDIAGNOSTIC

TROUBLECODECONFIRMATION

PROCEDURE

For themalfunction a)and b)

fF.I\

1)Wait untilengine coolant temperature isless than 90°C

~ (194°F).

(a) Turn ignition switch"ON".

(b) Select "DATA MONITOR" modewithCONSULT.

(c) Check theengine coolant temperature.

(d) Ifthe engine coolant temperature isnot less than

90°C (194°F), turnignition switch"OFF"andcool

down engine.

2) Turn ignition switch"ON".

3) Select "DATA MONITOR" modewithCONSULT.

4) Wait foratleast 5seconds.

---------OR ---------

~ 1)Wait untilengine coolant temperature isless than

~ 90°C(194°F.).

(a) Turn ignition switch"ON".

(b) Check voltage between ECMterminal

@

and

ground.

Voltage: Morethan1.2(V)

(c) Ifthe voltage isnot more than1.2V, turnignition

switch "OFF"andcool down engine.

2) Turn ignition switch"ON"waitforatleast 5seconds.

3) Turn ignition switch"OFF", waitforatleast 3seconds

and then turn"ON".

4) Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-124

Page 845 of 1701

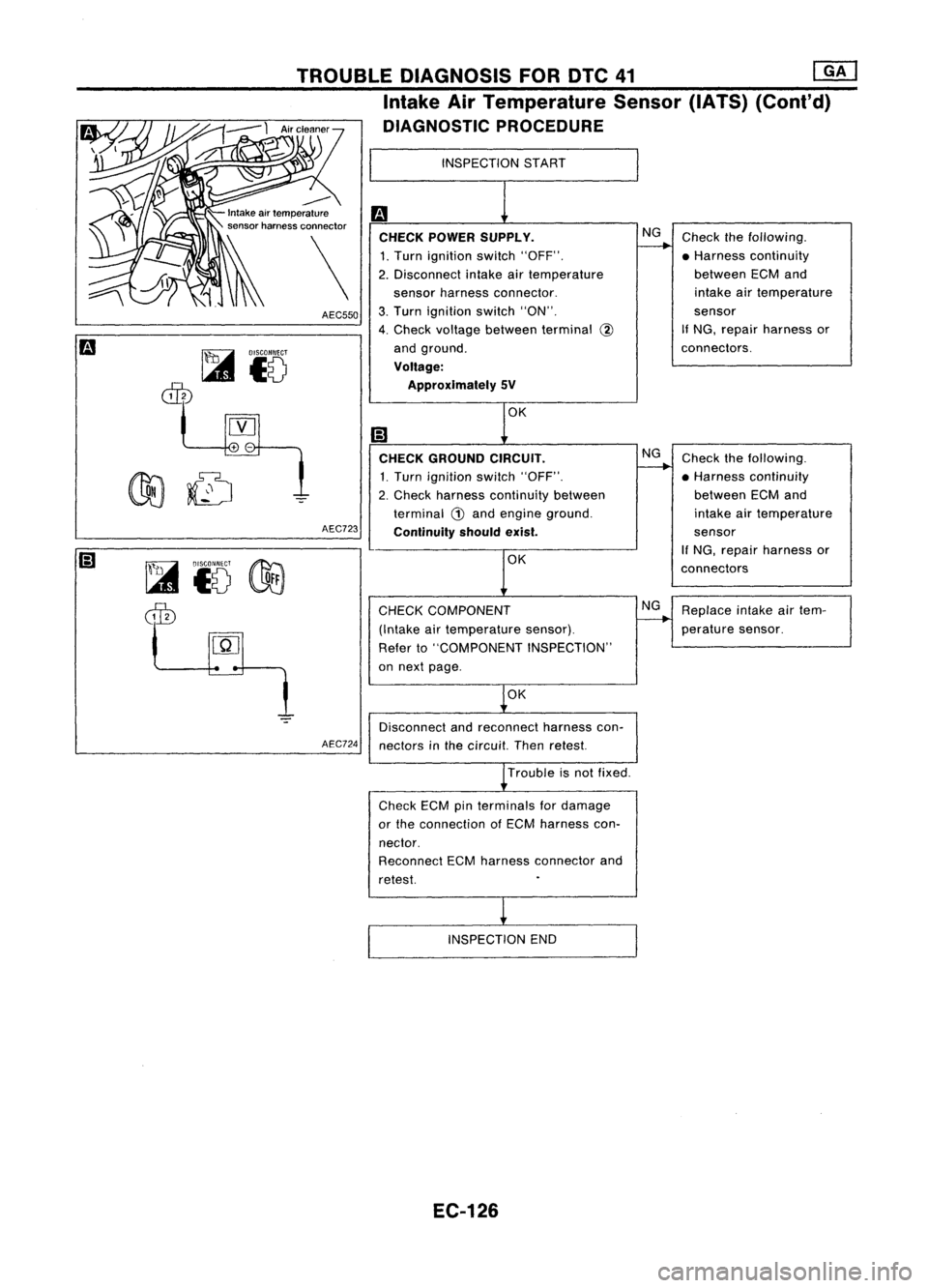

Checkthefollowing.

• Harness continuity

between ECMand

intake airtemperature

sensor

If NG, repair harness or

connectors.

NG

INSPECTION

START

CHECK POWER SUPPLY.

1. Turn ignition switch"OFF".

2. Disconnect intakeairtemperature

sensor harness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal @

and ground.

Voltage: Approximately SV

TROUBLE

DIAGNOSIS FORDTC41

rnJ

Intake AirTemperature Sensor(IATS)(Cont'd)

DIAGNOSTIC PROCEDURE

--

~

Intake airtemperature

'" '\ sensor harness connector

AEC550

~ DISCONNECT

ciili

10

AEC723

~i5 ~

dID

CHECK

GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Check harness continuity between

terminal

G)

and engine ground.

Continuity shouldexist.

OK

CHECK COMPONENT

(Intake airtemperature sensor).

Refer to"COMPONENT INSPECTION"

on next page.

NG

NG

Check

thefollowing.

• Harness continuity

between ECMand

intake airtemperature

sensor

If NG, repair harness or

connectors

Replace intakeairtem-

perature sensor.

OK

Disconnect andreconnect harnesscon-

AEC724

nectorsinthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector.

Reconnect ECMharness connector and

retest.

INSPECTION END

EC-126

Page 850 of 1701

•

INSPECTION

START

m

1

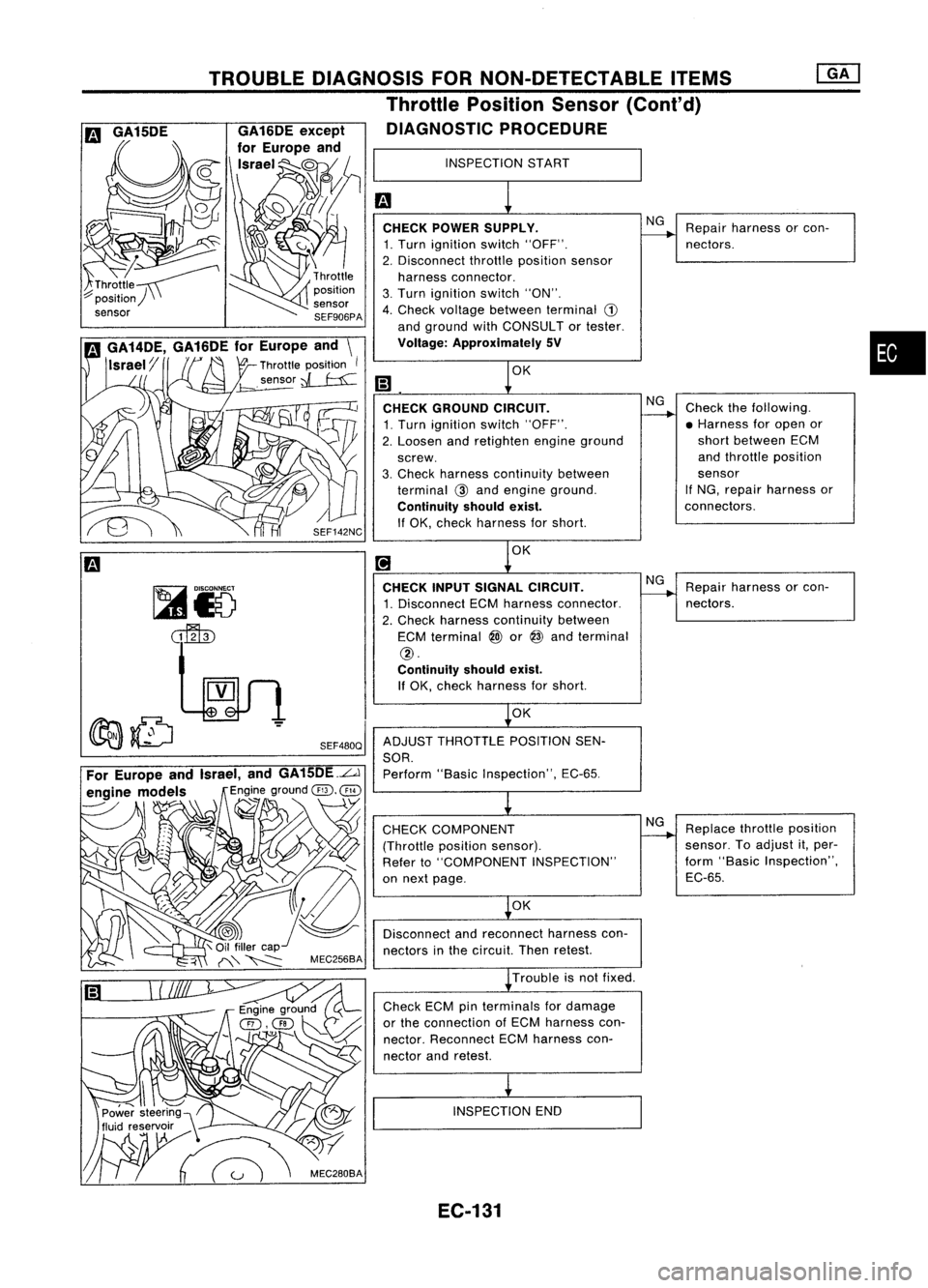

CHECK POWER SUPPLY.

NG

Repair harness orcon-

------.

1. Turn ignition switch"OFF". nectors.

2. Disconnect throttleposition sensor

harness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

CD

and ground withCONSULTor tester.

Voltage: Approximately SV

m

1

0K

CHECK GROUND CIRCUIT.

NG

Check thefollowing.

1. Turn ignition switch"OFF".

------.

•Harness foropen or

2. Loosen andretighten engineground short

between ECM

screw. and

throttle position

3. Check harness continuity between sensor

terminal

@

and engine ground. If

NG, repair harness or

Continuity shouldexist.

connectors.

If OK, check harness forshort.

[!J

1

0K

CHECK INPUTSIGNAL CIRCUIT.

NG

Repair harness orcon-

1. Disconnect ECMharness connector.

------.

nectors.

2. Check harness continuity between

ECM terminal

@)

or

@

and terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

~OK

ADJUST THROTTLE POSITIONSEN-

SOR. Perform "BasicInspection", EC-65.

~

CHECK COMPONENT NG

Replace throttleposition

(Throttle positionsensor).

------.

sensor. Toadjust it,per-

Refer to"COMPONENT INSPECTION" form

"Basic Inspection",

on next page. EC-65.

~OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

~ Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

i

INSPECTION END

SEF480Q

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Throttle Position Sensor(Cont'd)

DIAGNOSTIC PROCEDURE

,~\ C/

Power steering)\

~

m

GA15DE

EC-131

Page 859 of 1701

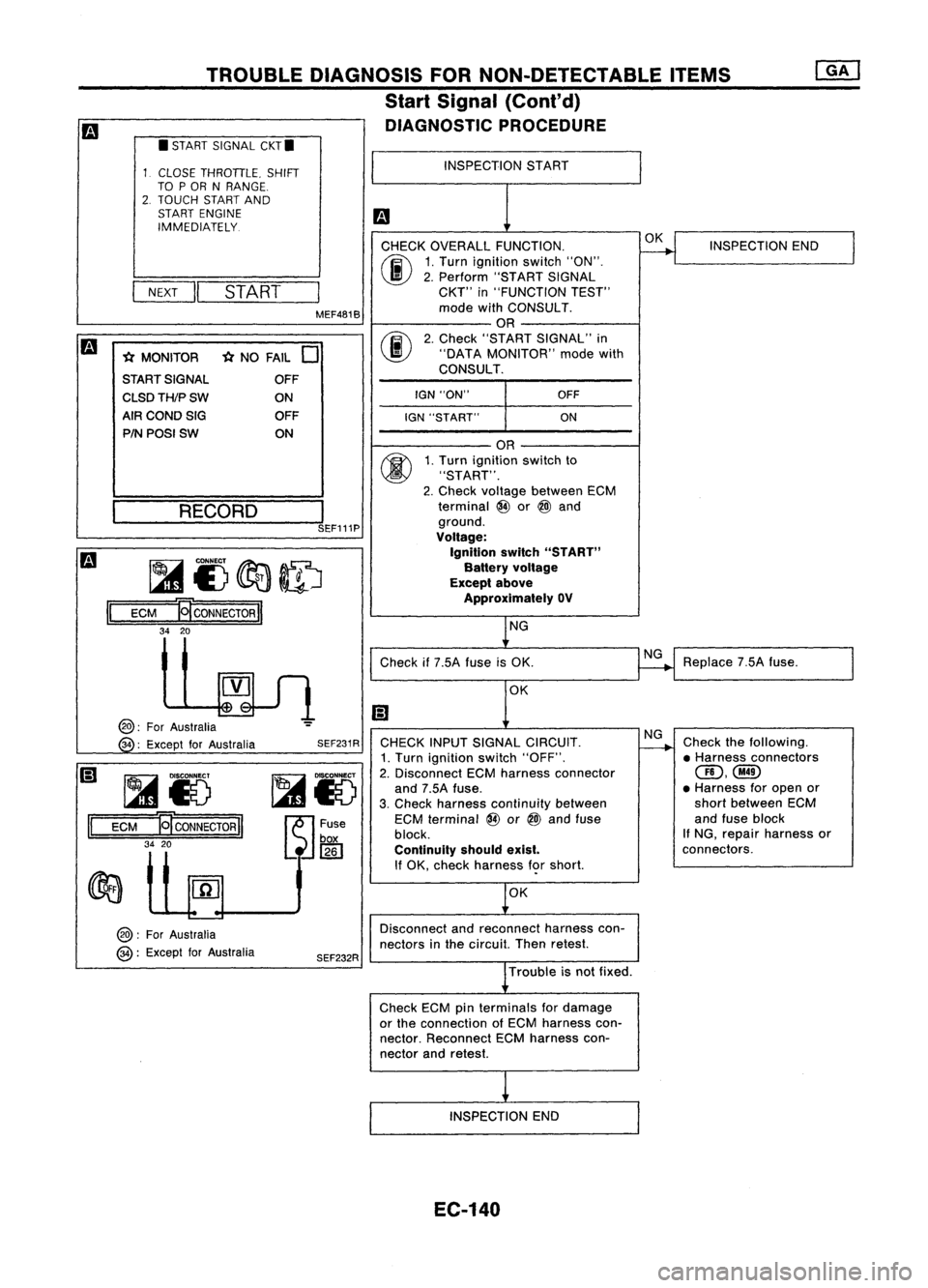

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Start Signal (Cont'd)

DIAGNOSTIC PROCEDURE

CHECK OVERALL FUNCTION.

00

1.

Turn ignition switch"ON".

I

II

2.

Perform "STARTSIGNAL

NEXT

START

CKT"

in"FUNCTION TEST"

MEF481B mode

withCONSULT.

OR

m

00

2.

Check "START SIGNAL" in

* MONITOR *

NO FAIL

0

"DATA

MONITOR" modewith

START SIGNAL CONSULT.

OFF

I

CLSDTH/PSW

ONIGN

"ON" OFF

AIR COND SIG OFF

IGN"START" ON

PIN POSI SW ON

II

•

START SIGNAL CKT.

CLOSE THROTTLE. SHIFT

TO POR NRANGE.

2. TOUCH STARTAND

START ENGINE

IMMEDIATELY.

~ __ RE_C_O_R_D_---,l

SEF111P

~I)~ID

ECM

B

CONNECTOR

II

34 20

INSPECTION

START

OR

1. Turn ignition switchto

"START".

2. Check voltage between ECM

terminal @or

@l

and

ground.

Voltage:

Ignition switch"START"

Battery voltage

Except above

Approximately OV

NG OK

INSPECTION END

II

@:

ForAustralia

34 :Except forAustralia

~Io

ECM

ET

CONNECTOR

II

34 20

@:

ForAustralia

@:

Except forAustralia SEF231R

SEF232R Check

if7.5A fuseisOK.

OK

CHECK INPUTSIGNAL CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect ECMharness connector

and 7.5A fuse.

3. Check harness continuity between

ECM terminal @or

@l

and fuse

block.

Continuity shouldexist.

If OK, check harness f<;>rshort.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

EC-140

NG

NG

Replace

7.5Afuse.

Check thefollowing.

• Harness connectors

(ID,@

• Harness foropen or

short between ECM

and fuse block

If NG, repair harness or

connectors.

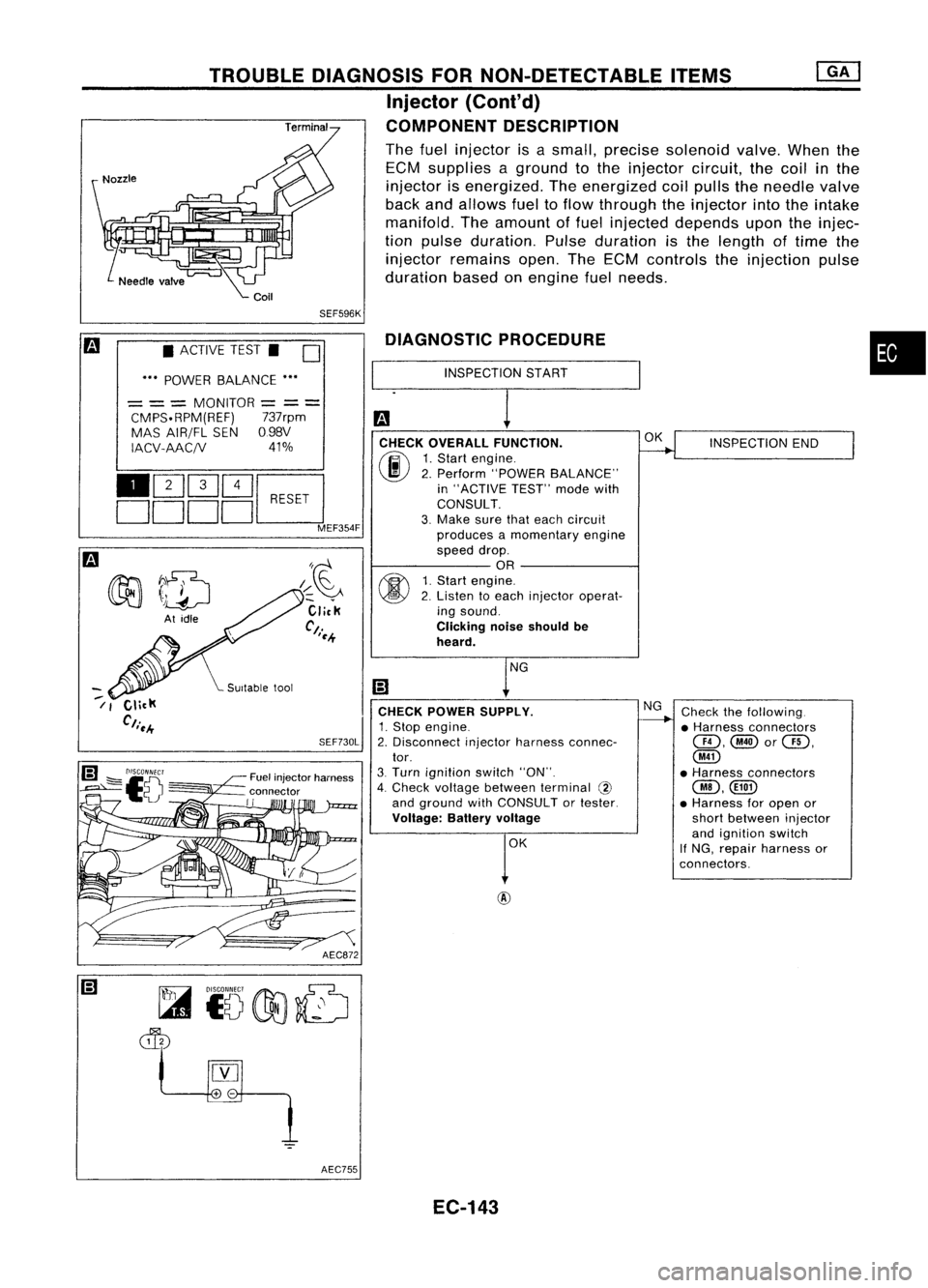

Page 862 of 1701

•

INSPECTION END

Check thefollowing.

• Harness connectors

@,@or@,

@

• Harness connectors

@,CillD

• Harness foropen or

short between injector

and ignition switch

If NG, repair harness or

connectors.

OK

NG

DIAGNOSTIC

PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

(F.I\

1.Start engine.

~ 2.Perform "POWER BALANCE"

in "ACTIVE TEST"modewith

CONSULT.

3. Make surethateach circuit

produces amomentary engine

speed drop.

OR

fff\

1.Start engine.

~ 2.Listen toeach injector operat-

ing sound.

Clicking noiseshould be

heard.

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect injectorharness connec-

tor.

3. Turn ignition switch"ON".

4. Check voltage between terminal @

and ground withCONSULT ortester.

Voltage: Batteryvoltage

AEC872

SEF730L

/~~

Click

Ct.

'~.+

Fuel injector harness

connector

II

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Injector (Cont'd)

COMPONENT DESCRIPTION

The fuel injector isasmall, precise solenoid valve.Whenthe

ECM supplies aground tothe injector circuit,thecoil

in

the

injector isenergized. Theenergized coilpulls theneedle valve

back andallows fueltoflow through theinjector intotheintake

manifold. Theamount offuel injected depends upontheinjec-

tion pulse duration. Pulseduration isthe length oftime the

injector remains open.TheECM controls theinjection pulse

duration basedonengine fuelneeds.

SEF596K

• ACTIVE TEST.

D

••• POWER BALANCE •••

= ==

MONITOR

=

==

CMPS.RPM(REF) 737rpm

MAS AIR/FL SEN098V

IACV-AAC/V 41%

110Q]Q]~

DDDDc:J

MEF354F

~7~

~ \)drJ

At idle

--

/ I

AEC755EC-143

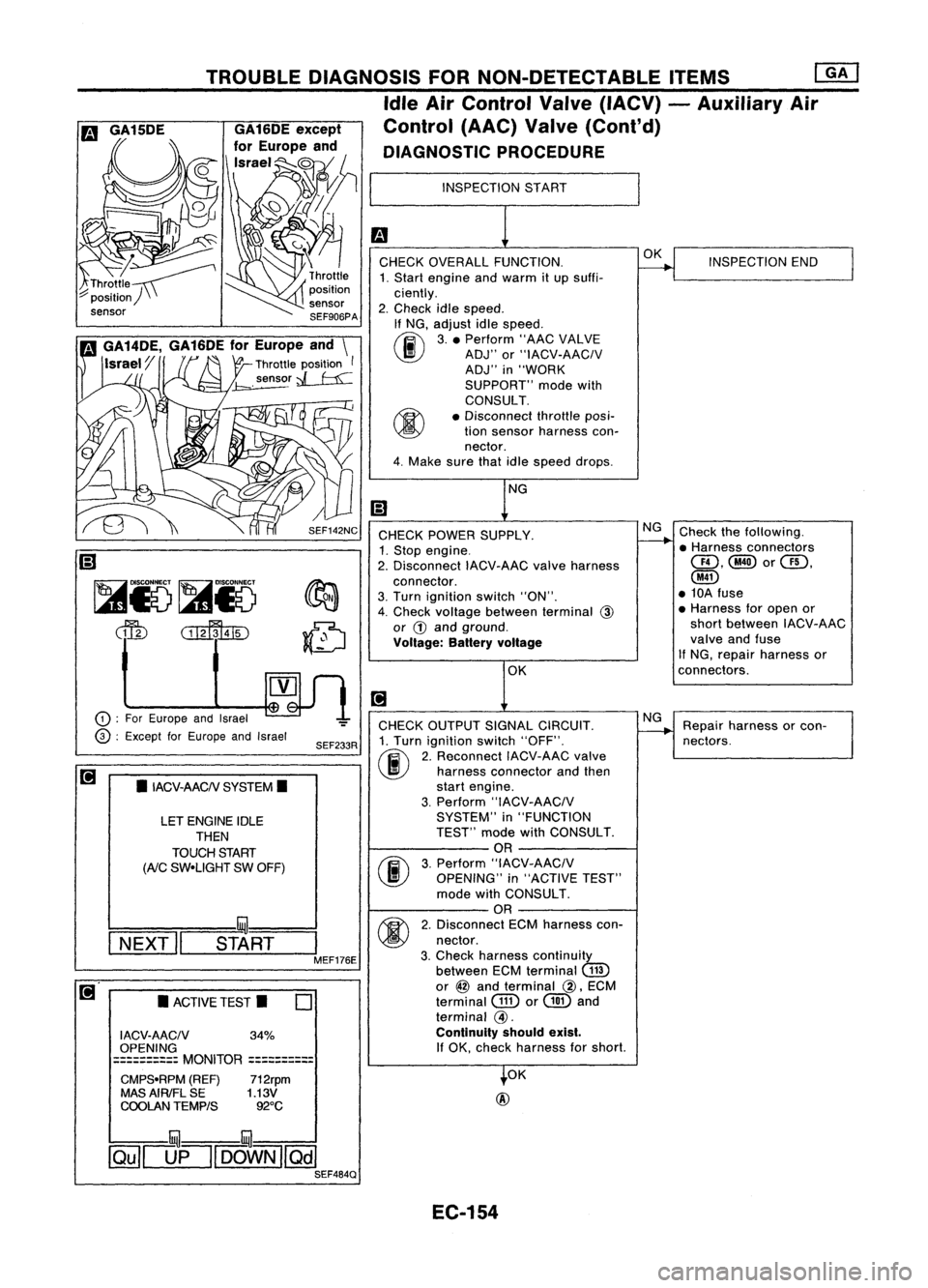

Page 873 of 1701

Repairharness orcon-

nectors. INSPECTION

END

Check thefollowing.

• Harness connectors

QD,@orQD,

@

• 10A fuse

• Harness foropen or

short between IACV-AAC

valve andfuse

If NG, repair harness or

connectors.

NG OK

NG

OK

INSPECTION

START

CHECK OVERALL FUNCTION.

1. Start engine andwarm itup suffi-

ciently.

2. Check idlespeed.

If NG, adjust idlespeed.

~ 3.• Perform "AACVALVE

~ ADJ"or"IACV-AACIV

ADJ" in"WORK

SUPPORT" modewith

CONSULT.

• Disconnect throttleposi-

tion sensor harness con-

nector.

4. Make surethatidlespeed drops.

OK

@

CHECK

POWER SUPPLY.

1. Stop engine.

2. Disconnect IACV-AACvalveharness

connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

@

or

G)

and ground.

Voltage: Batteryvoltage

CHECK OUTPUT SIGNALCIRCUIT.

1. Turn ignition switch"OFF".

(ij\

2.Reconnect IACV-AACvalve

~ harnessconnector andthen

start engine.

3. Perform "IACV-AACIV

SYSTEM" in"FUNCTION

TEST" modewithCONSULT.

OR

(F.I\

3.Perform "IACV-AACIV

~ OPENING" in"ACTIVE TEST"

mode withCONSULT.

OR

M

2.Disconnect ECMharness con-

~ nectar.

3. Check harness continuity

between ECMterminal

(ill)

or

@

and terminal

@,

ECM

terminal

GID

or

@

and

terminal

@.

Continuity shouldexist.

If

OK, check harness forshort.

SEF233R

SEF142NC

o

•

ACTIVE TEST.

LET

ENGINE IDLE

THEN

TOUCH START

(AiC

SW-UGHT SWOFF)

•

IACV-AACN SYSTEM.

I ACV-AACN 34%

OPENING

==========

MONITOR

==========

CMPS-RPM (REF)712rpm

MAS AIRIFL SE 1.13V

COOLAN TEMPtS 92°C

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

ffiJ

Idle AirControl Valve(IACV) -Auxiliary Air

Control (AAC)Valve(Cont'd)

DIAGNOSTIC PROCEDURE

!:::=====mul===

I

NEXT" START

I

MEF176E

CD

:

For Europe andIsrael

@ :

Except forEurope andIsrael

~

Ii)

~i5~i5

dfu

CillffuID

illU--illU

~[]fl[OOWN][Qill SEF484Q

EC-154

Page 881 of 1701

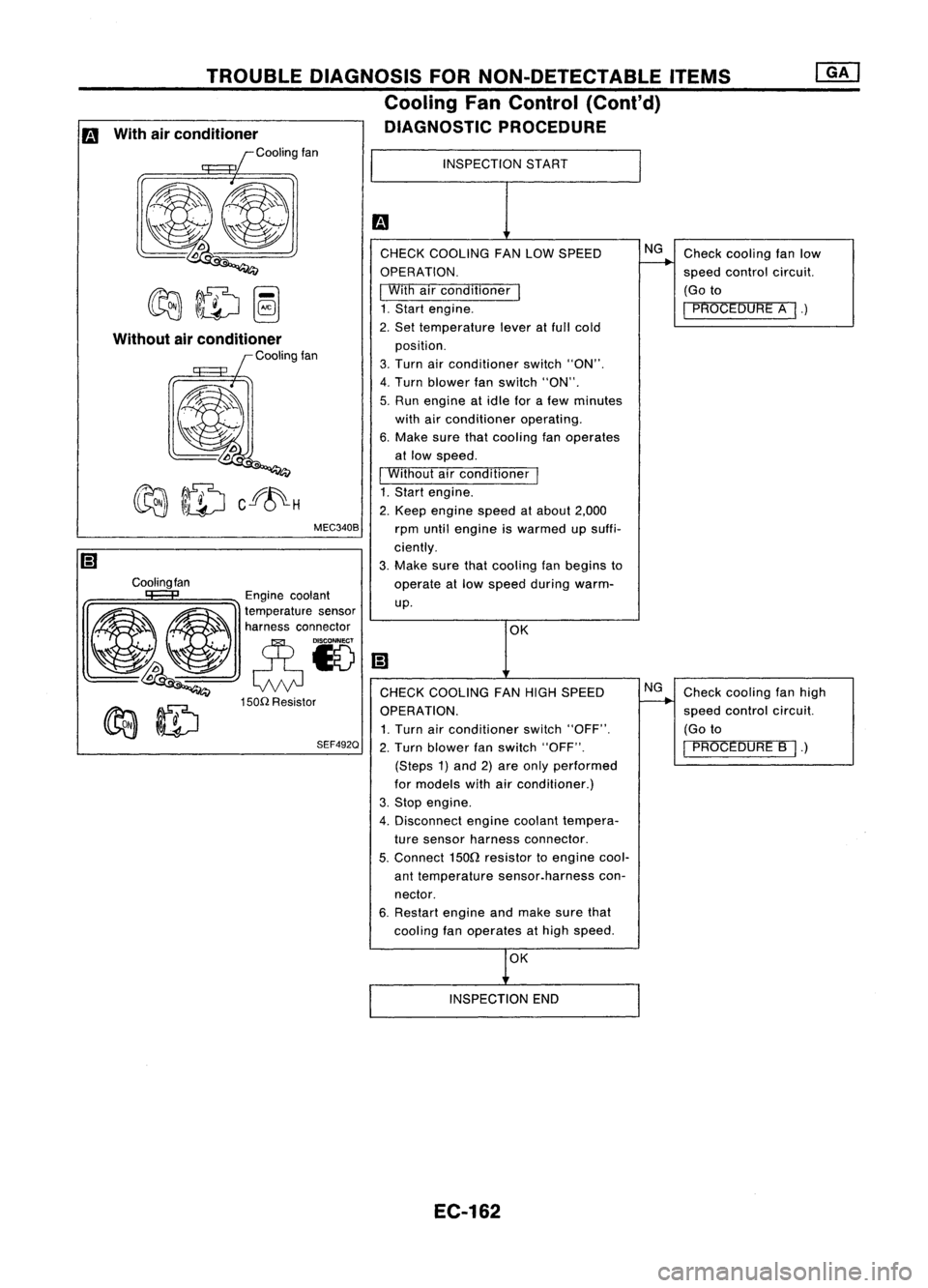

Checkcooling fanlow

speed control circuit.

(Go to

I

PROCEDURE A

I.)

Check cooling fanhigh

speed control circuit.

(Go to

I

PROCEDURE B

I.)

NG

NG

OK

INSPECTION

START

CHECK COOLING FANLOW SPEED

OPERATION.

I

With airconditioner

I

1. Start engine.

2. Set temperature leveratfull cold

position.

3. Turn airconditioner switch"ON".

4. Turn blower fanswitch "ON".

5. Run engine atidle forafew minutes

with airconditioner operating.

6. Make surethatcooling fanoperates

at low speed.

I

Without airconditioner

I

1. Start engine.

2. Keep engine speedatabout 2,000

rpm until engine iswarmed upsuffi-

ciently.

3. Make surethatcooling fanbegins to

operate atlow speed during warm-

up.

MEC340B

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cant'd)

DIAGNOSTIC PROCEDURE

Cooling fan

Without

airconditioner

Coolingfan

Engine coolant

~ ~ ~a~~:;:t:a::;'~~'

~~ eN

lDoo

Q

CHECKCOOLING FANHIGH SPEED

150n

Resistor

~ ~ OPERATION.

~ ~ 1.Turn airconditioner switch"OFF".

SEF492Q

2.Turn blower fanswitch "OFF".

(Steps 1)and 2)are only performed

for models withairconditioner.)

3. Stop engine.

4. Disconnect enginecoolant tempera-

ture sensor harness connector.

5.

Connect

1500

resistor toengine cool-

ant temperature sensor.harness con-

nector.

6. Restart engineandmake surethat

cooling fanoperates athigh speed.

m

With airconditioner

Coolingfan

OK

INSPECTION END

EC-162

Page 882 of 1701

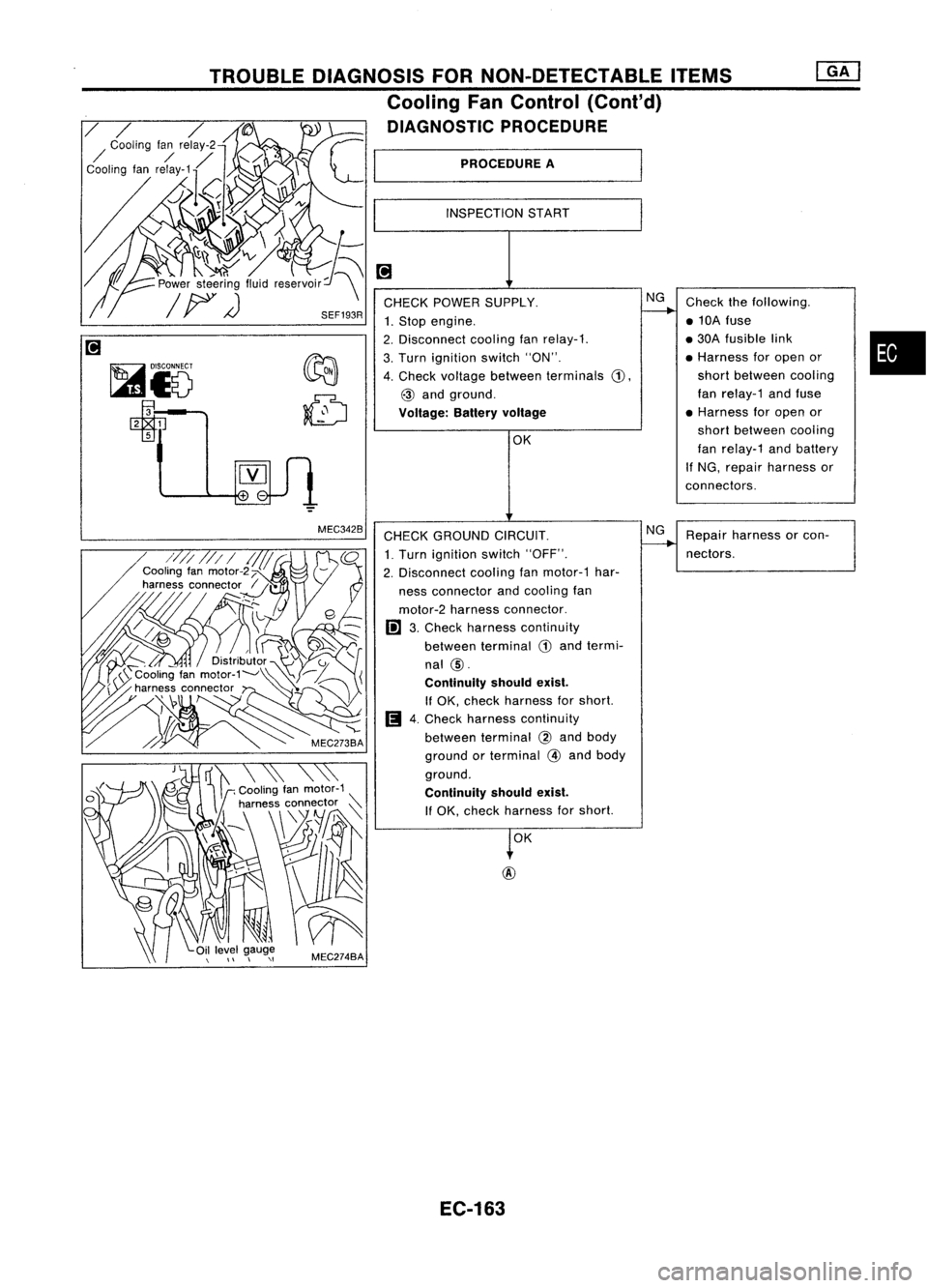

•

Check

thefollowing.

• 10A fuse

• 30A fusible link

• Harness foropen or

short between cooling

fan relay-1 andfuse

• Harness foropen or

short between cooling

fan relay-1 andbattery

If NG, repair harness or

connectors.

OK

PROCEDURE

A

INSPECTION START

CHECK POWER SUPPLY. NG

1. Stop engine.

2. Disconnect coolingfanrelay-1.

3. Turn ignition switch"ON".

4. Check voltage between terminals

G),

@

and ground.

Voltage: Batteryvoltage

SEF193R

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cont'd)

DIAGNOSTIC PROCEDURE

MEC342B

CHECKGROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect coolingfanmotor-1 har-

ness connector andcooling fan

motor-2 harness connector.

I!l

3.Check harness continuity

between terminal

CD

and termi-

nal

@.

Continuity shouldexist.

If OK, check harness forshort.

Ii

4.Check harness continuity

between terminal

@

and body

ground orterminal

@

and body

ground.

Continuity shouldexist.

If OK, check harness forshort.

OK

@

NG

Repair harness orcon-

nectors.

EC-163