check engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 972 of 1701

![NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-HEATED OXYGENSENSORMONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays theconditi NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-HEATED OXYGENSENSORMONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays theconditi](/img/5/57349/w960_57349-971.png)

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-HEATED OXYGENSENSORMONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays thecondition ofthe fuel mixture (leanor

rich) which ismonitored bythe heated oxygen sensor.

MALFUNCTION INDICATORLAMPFuelmixture condition inthe exhaust gasAirfuel ratio feedback controlcondition

ON Lean

Closedloopsystem

OFF Rich

Remains ONorOFF Anycondition

Openloopsystem

To check theheated oxygen sensorfunction, startengine inDiagnostic TestMode II.Then warm itup

until engine coolant temperature indicatorpointstomiddle ofgauge.

Next runengine atabout 2,000rpmforabout 2minutes underno-load conditions. Makesurethatthe•

MALFUNCTION INDICATORLAMPcomes ONmore than5times within 10seconds withengine running

at 2,000 rpmunder no-load.

EC-253

Page 975 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

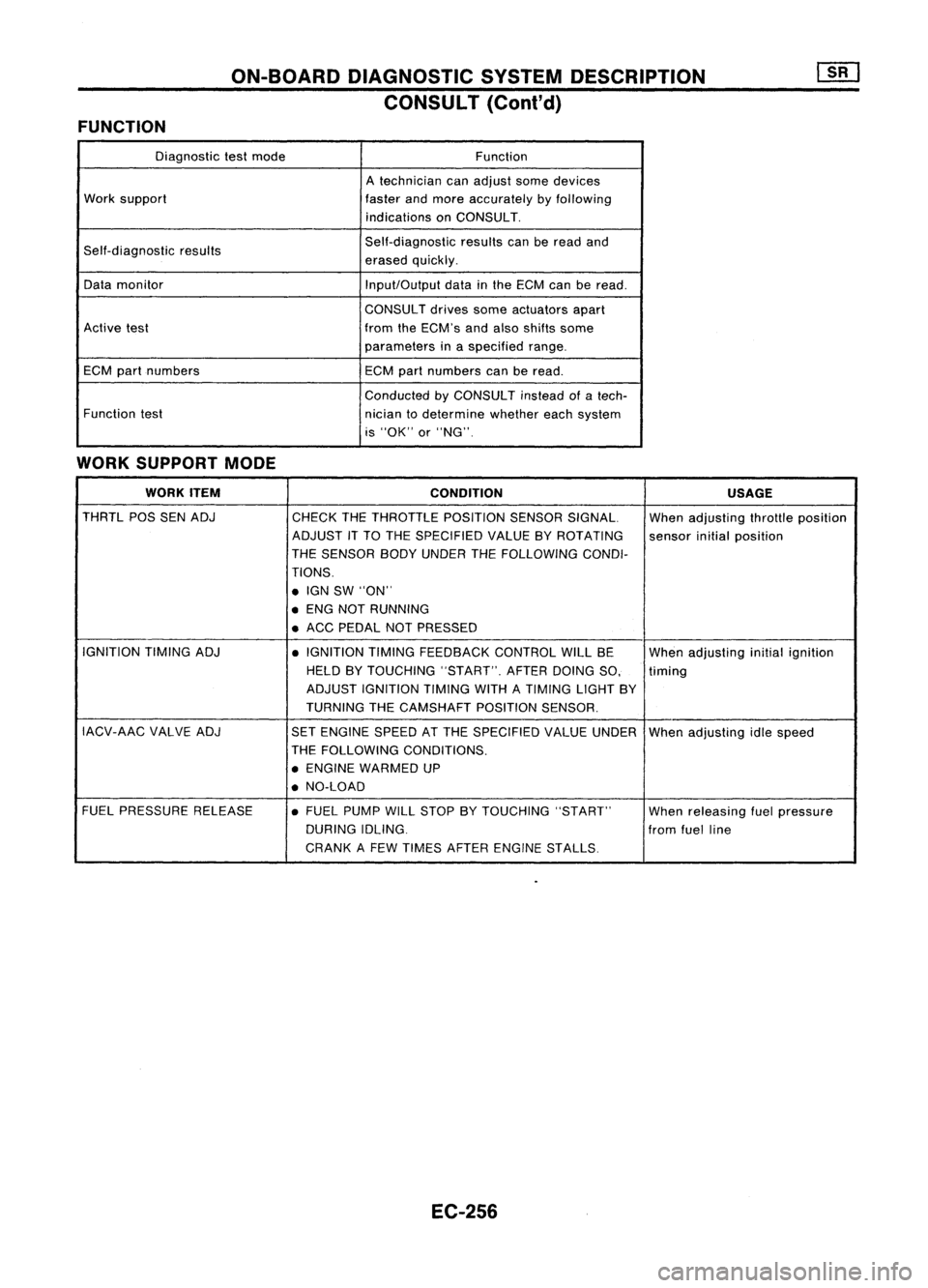

FUNCTION

Diagnostictestmode Function

A technician canadjust somedevices

Work support

fasterandmore accurately byfollowing

indications onCONSULT.

Self-diagnostic results Self-diagnostic

resultscanberead and

erased quickly.

Data monitor

Input/Outputdatainthe ECM canberead.

CONSULT drivessomeactuators apart

Active test fromtheECM's andalso shifts some

parameters inaspecified range.

ECM partnumbers

ECMpartnumbers canberead.

Conducted byCONSULT insteadofatech-

Function test

niciantodetermine whethereachsystem

is "OK" or"NG".

WORK SUPPORT MODE

WORK ITEM

CONDITION USAGE

THRTL POSSENADJ

CHECKTHETHROTTLE POSITIONSENSORSIGNAL. Whenadjusting throttleposition

ADJUST ITTO THE SPECIFIED VALUEBYROTATING

sensorinitialposition

THE SENSOR BODYUNDER THEFOLLOWING CONDI-

TIONS .

• IGN SW"ON"

• ENG NOTRUNNING

• ACC PEDAL NOTPRESSED

IGNITION TIMINGADJ

•IGNITION TIMINGFEEDBACK CONTROLWILLBE

Whenadjusting initialignition

HELD BYTOUCHING "START".AFTERDOINGSO, timing

ADJUST IGNITION TIMINGWITHATIMING LIGHTBY

TURNING THECAMSHAFT POSITIONSENSOR.

IACV-AAC VALVEADJ

SETENGINE SPEEDATTHE SPECIFIED VALUEUNDER

Whenadjusting idlespeed

THE FOLLOWING CONDITIONS.

• ENGINE WARMED UP

• NO-LOAD

FUEL PRESSURE RELEASE •FUEL PUMP WILLSTOP BYTOUCHING "START"

Whenreleasing fuelpressure

DURING IDLING.

fromfuelline

CRANK AFEW TIMES AFTER ENGINE STALLS

EC-256

Page 978 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Conl'd)

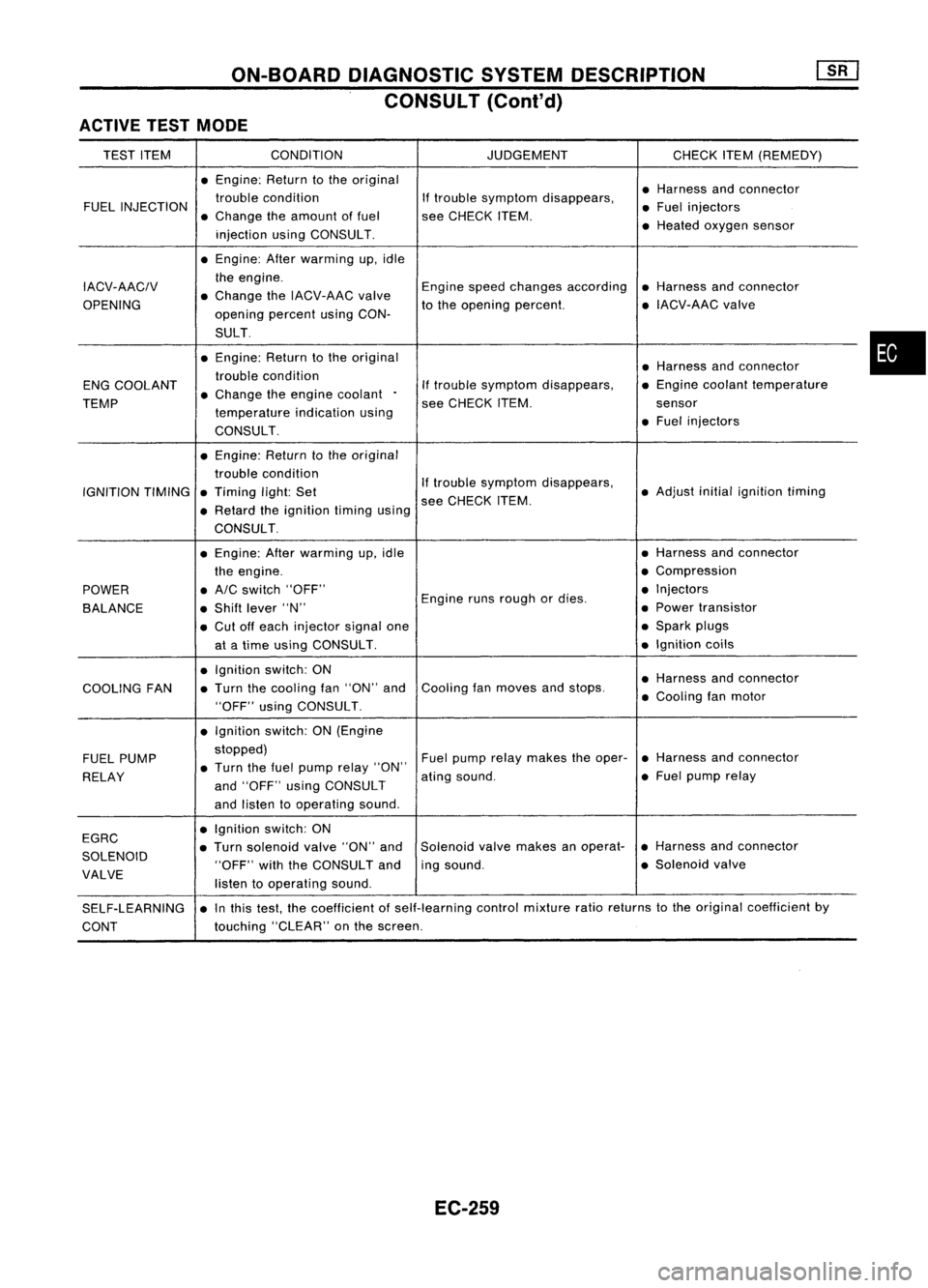

ACTIVE TESTMODE

TEST ITEM CONDITION JUDGEMENTCHECKITEM(REMEDY)

• Engine: Returntothe original

•Harness andconnector

FUEL INJECTION trouble

condition

Iftrouble symptom disappears,

•Fuel injectors

• Change theamount offuel

seeCHECK ITEM.

•Heated oxygen sensor

injection usingCONSULT .

• Engine: Afterwarming up,idle

IACV-AACIV the

engine.

Enginespeedchanges according •Harness andconnector

OPENING •

Change theIACV-AAC valve

tothe opening percent. •

IACV-AAC valve

opening percentusingCON-

SULT.

• Engine: Returntothe original

•Harness andconnector

ENG COOLANT trouble

condition

Iftrouble symptom disappears, •

Engine coolant temperature

• Change theengine coolant

.

TEMP see

CHECK ITEM. sensor

temperature indicationusing

•Fuel injectors

CONSULT .

• Engine: Returntothe original

trouble condition

Iftrouble symptom disappears,

IGNITION TIMING•Timing light:Set •

Adjust initialignition timing

• Retard theignition timingusingsee

CHECK ITEM.

CONSULT.

• Engine: Afterwarming up,idle •

Harness andconnector

the engine. •

Compression

POWER

•

AIC

switch "OFF"

Enginerunsrough ordies. •

Injectors

BALANCE •

Shift lever "N" •

Power transistor

• Cut offeach injector signalone •

Spark plugs

at atime using CONSULT . •

Ignition coils

• Ignition switch:ON

•Harness andconnector

COOLING FAN•

Turn thecooling fan"ON" andCooling

fanmoves andstops.

•Cooling fanmotor

"OFF" usingCONSULT .

• Ignition switch:ON(Engine

FUEL PUMP stopped)

Fuelpump relaymakes theoper- •

Harness andconnector

RELAY •

Turn thefuel pump relay"ON"

atingsound. •

Fuel pump relay

and "OFF" usingCONSULT

and listen tooperating sound.

EGRC •

Ignition switch:ON

• Turn solenoid valve"ON"and Solenoid

valvemakes anoperat- •

Harness andconnector

SOLENOID "OFF"withtheCONSULT andingsound. •

Solenoid valve

VALVE listentooperating sound.

SELF-LEARNING •

In this test, thecoefficient ofself-learning controlmixture ratioreturns tothe original coefficient by

CONT touching

"CLEAR" onthe screen.

EC-259

•

Page 979 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Conl'd)

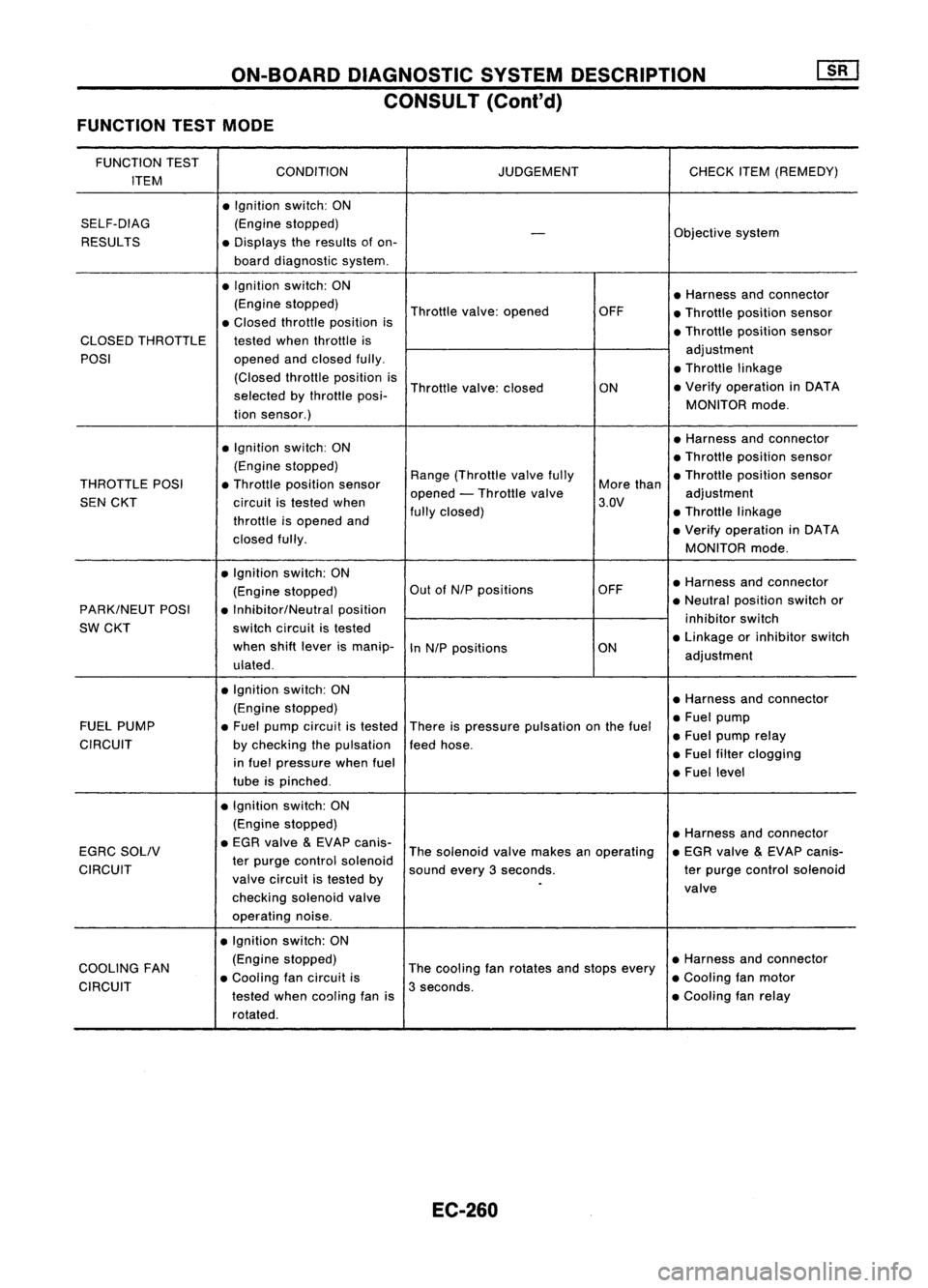

FUNCTION TESTMODE

FUNCTION TEST

CONDITION JUDGEMENTCHECKITEM(REMEDY)

ITEM

•Ignition switch:ON

SELF-DIAG (Enginestopped)

Objectivesystem

-

RESULTS •Displays theresults ofon-

board diagnostic system.

• Ignition switch:ON

•Harness andconnector

(Engine stopped)

Throttlevalve:opened OFF

•Throttle position sensor

• Closed throttle position is

•Throttle position sensor

CLOSED THROTTLE testedwhenthrottle is

POSI opened

andclosed fully. adjustment

• Throttle linkage

(Closed throttleposition is

Throttle valve:closed

ON•

Verify operation inDATA

selected bythrottle posi-

MONITORmode.

tion sensor.)

• Ignition switch:ON •

Harness andconnector

• Throttle position sensor

(Engine stopped)

Range(Throttle valvefully •Throttle position sensor

THROTTLE POSI•Throttle position sensor

opened-Throttle valve More

than

adjustment

SEN CKT circuitistested when 3.QV

throttle isopened and fully

closed) •Throttle linkage

• Verify operation inDATA

closed fully.

MONITORmode.

• Ignition switch:ON

•Harness andconnector

(Engine stopped) Out

ofN/P positions OFF

PARK/NEUT POSI•Inhibitor/Neutral position •

Neutral position switchor

SW CKT switch

circuit istested inhibitor

switch

when shiftlever ismanip-

InN/P positions ON•

Linkage orinhibitor switch

ulated . adjustment

• Ignition. switch:ON

•Harness andconnector

(Engine stopped)

•Fuel pump

FUEL PUMP •Fuel pump circuit istested

Thereispressure pulsation onthe fuel

•Fuel pump relay

CIRCUIT bychecking thepulsation feedhose.

in fuel pressure whenfuel •

Fuel filter clogging

tube ispinched . •

Fuel level

• Ignition switch:ON

(Engine stopped)

•Harness andconnector

EGRC SOLIV •

EGR valve

&

EVAP canis-

Thesolenoid valvemakes anoperating •

EGR valve

&

EVAP canis-

CIRCUIT ter

purge control solenoid

soundevery3seconds. terpurge control solenoid

valve circuit istested by

.

valve

checking solenoidvalve

operating noise.

• Ignition switch:ON

COOLING FAN (Engine

stopped)

Thecooling fanrotates andstops every •

Harness andconnector

• Cooling fancircuit is •Cooling fanmotor

CIRCUIT testedwhencoaling fanis3

seconds.

•Cooling fanrelay

rotated.

EC-260

Page 980 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

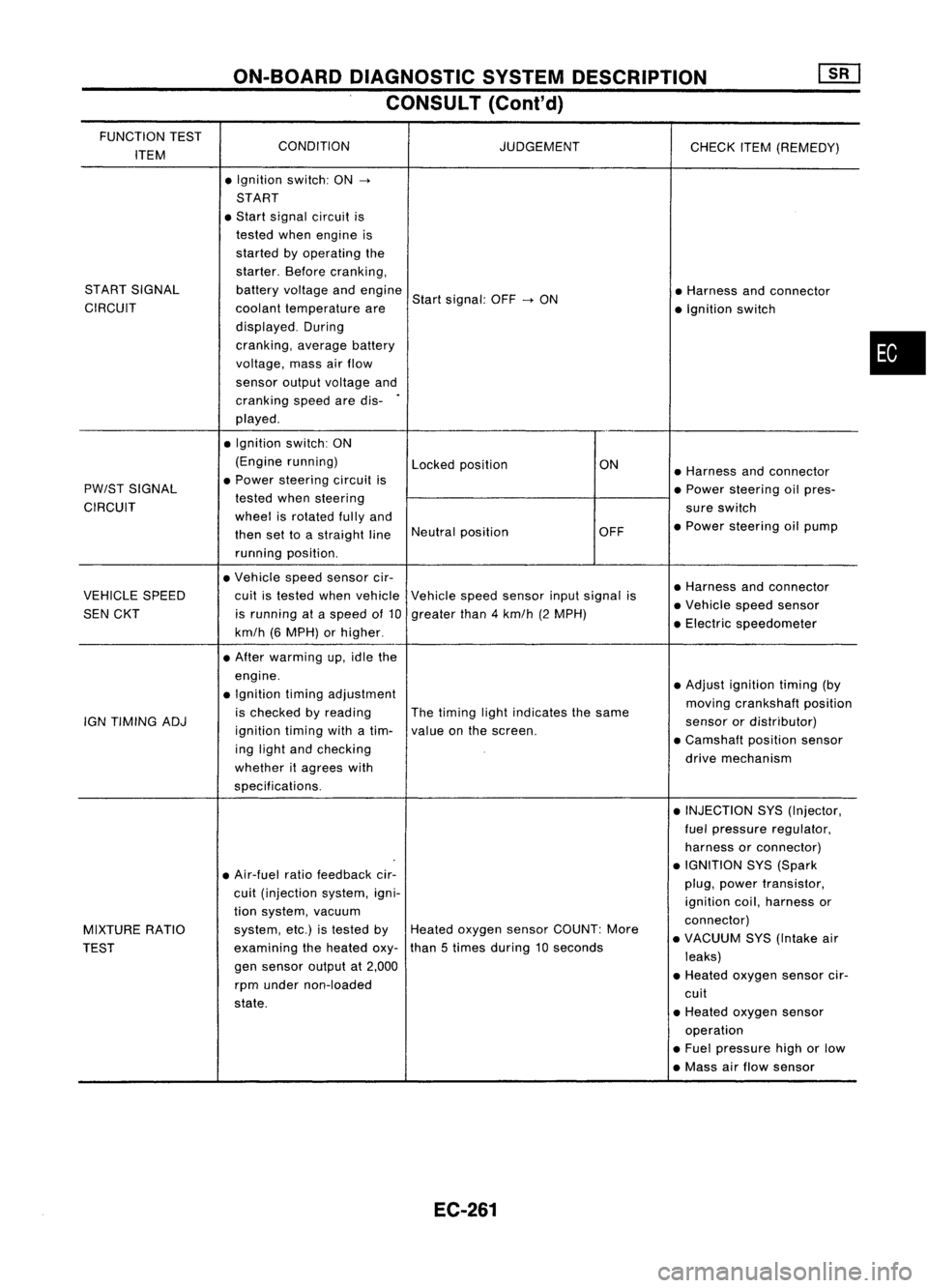

CONSULT (Cont'd)

FUNCTION TEST

CONDITION

ITEM JUDGEMENT

CHECKITEM(REMEDY)

• Ignition switch:ON

->

START

• Start signal circuit is

tested whenengine is

started byoperating the

starter. Beforecranking,

START SIGNAL batteryvoltage andengine

Startsignal: OFF

->

ON •

Harness andconnector

CIRCUIT coolanttemperature are

•Ignition switch

displayed. During

cranking, averagebattery

voltage, massairflow

sensor outputvoltage and

cranking speedaredis-

.

played .

• Ignition switch:ON

(Engine running)

Lockedposition ON

•Harness andconnector

PW/ST SIGNAL •

Power steering circuitis

•Power steering oilpres-

CIRCUIT tested

whensteering

sureswitch

wheel isrotated fullyand

•Power steering oilpump

then settoastraight lineNeutral

position OFF

running position.

• Vehicle speedsensor cir-

•Harness andconnector

VEHICLE SPEED cuitistested whenvehicle Vehiclespeedsensor inputsignal is

•Vehicle speedsensor

SEN CKT isrunning ataspeed of10 greater than4km/h (2MPH)

•Electric speedometer

km/h (6MPH) orhigher .

• After warming up,idle the

engine. •Adjust ignition timing(by

• Ignition timingadjustment

movingcrankshaft position

is checked byreading Thetiming lightindicates thesame

IGN TIMING ADJ

ignitiontimingwithatim- valueonthe screen. sensor

ordistributor)

ing light andchecking •

Camshaft positionsensor

whether itagrees with drive

mechanism

specifications. •INJECTION SYS(Injector,

fuel pressure regulator,

harness orconnector)

• Air-fuel ratiofeedback cir- •

IGNITION SYS(Spark

cuit (injection system,igni- plug,

power transistor,

ignition coil,harness or

tion system, vacuum

connector)

MIXTURE RATIO system,

etc.)istested byHeated oxygen sensorCOUNT: More

•VACUUM SYS(Intake air

TEST examining

theheated oxy-than

5times during 10seconds

leaks)

gen sensor outputat2,000

•Heated oxygen sensorcir-

rpm under non-loaded

cuit

state. •Heated oxygen sensor

operation

• Fuel pressure highorlow

• Mass airflow sensor

EC-261

•

Page 981 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

FUNCTION TEST

CONDITION JUDGEMENTCHECKITEM(REMEDY)

ITEM

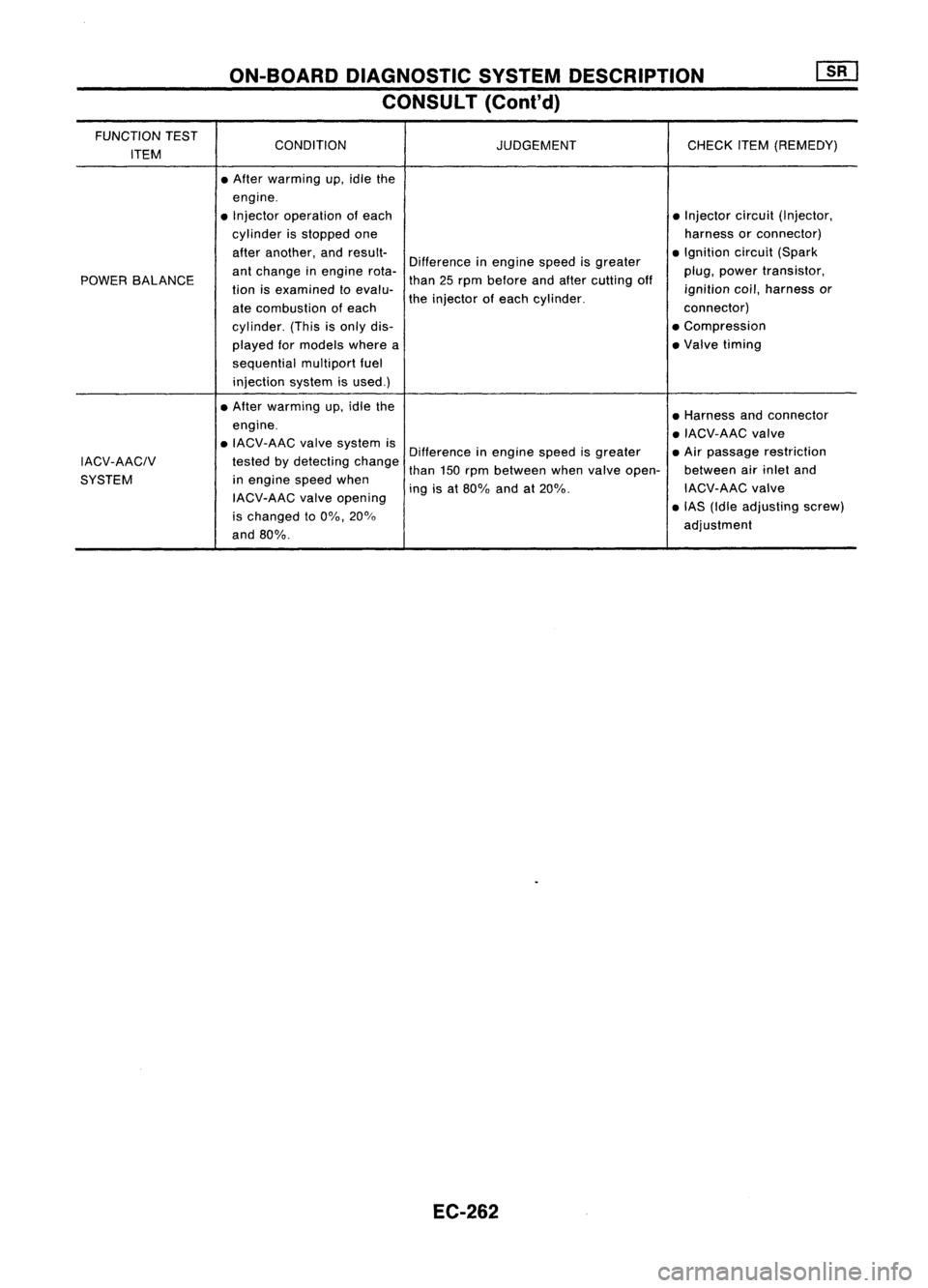

•After warming up,idle the

engine.

• Injector operation ofeach •Injector circuit(Injector,

cylinder isstopped one harness

orconnector)

after another, andresult-

Difference inengine speedisgreater •

Ignition circuit(Spark

ant change inengine rota- plug,

power transistor,

POWER BALANCE

tionisexamined toevalu- than

25rpm before andafter cutting off

ignition coil,harness or

ate combustion ofeach the

injector ofeach cylinder.

connector)

cylinder. (Thisisonly dis- •

Compression

played formodels wherea •

Valve timing

sequential multiportfuel

injection systemisused.)

• After warming up,idle the

•Harness andconnector

engine. •IACV-AAC

valve

• IACV-AAC valvesystem is

Difference inengine speedisgreater •

Air passage restriction

IACV-AACIV testedbydetecting change

than150rpm between whenvalve open- between

airinlet and

SYSTEM inengine speedwhen

ingisat 80% andat20%. IACV-AAC

valve

IACV-AAC valveopening

•IAS (Idle adjusting screw)

is changed to0%,20%

adjustment

and 80%.

EC-262

Page 983 of 1701

TROUBLEDIAGNOSIS -General Description

Sensors

~ ECMActuators

~~.~ MEF036D

SEF234G Introduction

The engine hasanECM tocontrol majorsystems suchasfuel

control, ignitioncontrol, idleaircontrol system, etc.The ECM

accepts inputsignals fromsensors andinstantly drivesactua-

tors. Itis essential thatboth input andoutput signals areproper

and stable. Atthe same time,itis important thatthere areno

problems suchasvacuum leaks,fouled sparkplugs, orother

problems withtheengine.

It is much moredifficult todiagnose aproblem thatoccurs

intermittently ratherthancontinuously. Mostintermittent prob-

lems arecaused bypoor electric connections orimproper wir-

ing. Inthis case, careful checking ofsuspected circuitsmay

help prevent thereplacement ofgood parts.

A visual checkonlymaynotfind thecause ofthe problems. A

road testwith CONSULT oracircuit testerconnected shouldbe

performed. Followthe"Work Flow"onthe next page.

Before undertaking actualchecks, takejustafew minutes to

talk with acustomer whoapproaches withadriveability com-

plaint. Thecustomer cansupply goodinformation aboutsuch

problems, especially intermittent ones.Findoutwhat symptoms

are present andunder whatconditions theyoccur. A"Diagnos-

tic Worksheet" liketheexample onEC-267 shouldbeused.

Start yourdiagnosis bylooking for"conventional" problems

first. Thiswillhelp troubleshoot driveabilityproblemsonan

electronically controlledenginevehicle.

EC-264

Page 985 of 1701

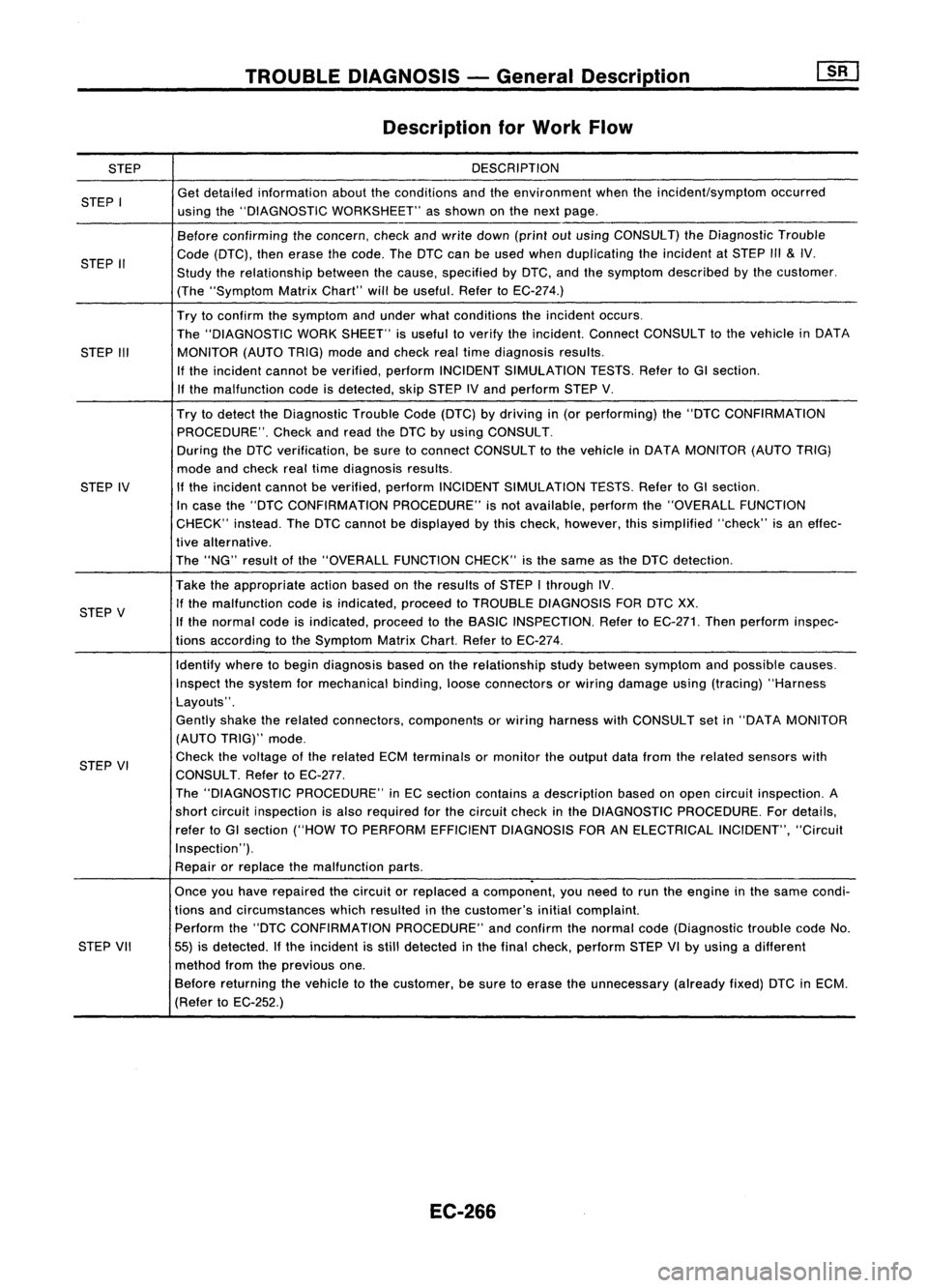

STEP

STEP I

STEP II

STEP III

STEP IV

STEP V

STEP VI

STEP VII

TROUBLE

DIAGNOSIS -General Description

Description forWork Flow

DESCRIPTION

Get detailed information abouttheconditions andtheenvironment whentheincident/symptom occurred

using the"DIAGNOSTIC WORKSHEET" asshown onthe next page.

Before confirming theconcern, checkandwrite down (printoutusing CONSULT) theDiagnostic Trouble

Code (DTC), thenerase thecode. TheDTC canbeused when duplicating theincident atSTEP

1/1

&

IV.

Study therelationship betweenthecause, specified byDTC, andthesymptom described bythe customer.

(The "Symptom MatrixChart" willbeuseful. RefertoEC-274.)

Try toconfirm thesymptom andunder whatconditions theincident occurs.

The "DIAGNOSTIC WORKSHEET" isuseful toverify theincident. ConnectCONSULT tothe vehicle inDATA

MONITOR (AUTOTRIG)modeandcheck realtime diagnosis results.

If the incident cannotbeverified, performINCIDENT SIMULATION TESTS.RefertoGI section.

If the malfunction codeisdetected, skipSTEP IVand perform STEPV.

Try todetect theDiagnostic TroubleCode(DTC) bydriving in(or performing) the"DTC CONFIRMATION

PROCEDURE". Checkandread theDTC byusing CONSULT.

During theDTC verification, besure toconnect CONSULT tothe vehicle inDATA MONITOR (AUTOTRIG)

mode andcheck realtime diagnosis results.

If the incident cannotbeverified, performINCIDENT SIMULATION TESTS.RefertoGI section.

In case the"DTC CONFIRMATION PROCEDURE"isnot available, performthe"OVERALL FUNCTION

CHECK" instead.TheDTC cannot bedisplayed bythis check, however, thissimplified "check"isan effec-

tive alternative.

The "NG" result ofthe "OVERALL FUNCTIONCHECK"isthe same asthe DTC detection.

Take theappropriate actionbasedonthe results ofSTEP Ithrough IV.

If the malfunction codeisindicated, proceedtoTROUBLE DIAGNOSIS FORDTCXX.

If the normal codeisindicated, proceedtothe BASIC INSPECTION. RefertoEC-271. Thenperform inspec-

tions according tothe Symptom MatrixChart.RefertoEC-274.

Identify wheretobegin diagnosis basedonthe relationship studybetween symptom andpossible causes.

Inspect thesystem formechanical binding,looseconnectors orwiring damage using(tracing) "Harness

Layouts".

Gently shaketherelated connectors, components orwiring harness withCONSULT setin"DATA MONITOR

(AUTO TRIG)" mode.

Check thevoltage ofthe related ECMterminals ormonitor theoutput datafrom therelated sensors with

CONSULT. RefertoEC-277.

The "DIAGNOSTIC PROCEDURE" inEC section contains adescription basedonopen circuit inspection. A

short circuit inspection isalso required forthe circuit checkinthe DIAGNOSTIC PROCEDURE. Fordetails,

refer toGI section ("HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT","Circuit

Inspection").

Repair orreplace themalfunction parts.

.

Once youhave repaired thecircuit orreplaced acomponent, youneed torun theengine inthe same condi-

tions andcircumstances whichresulted inthe customer's initialcomplaint.

Perform the"DTC CONFIRMATION PROCEDURE"andconfirm thenormal code(Diagnostic troublecodeNo.

55) isdetected. Ifthe incident isstill detected inthe final check, perform STEPVIby using adifferent

method fromtheprevious one.

Before returning thevehicle tothe customer, besure toerase theunnecessary (alreadyfixed)DTCinECM.

(Refer toEC-252.)

EC-266

Page 988 of 1701

![NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS -General Description

ill]

Diagnostic TroubleCode(DTC) Chart(Cont'd)

x:

Applicable

-: Not applicable

"DTC *1

*2

Check Items CONFIRMATION

"OVERALLFUNC-

Fail ReferencePag NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS -General Description

ill]

Diagnostic TroubleCode(DTC) Chart(Cont'd)

x:

Applicable

-: Not applicable

"DTC *1

*2

Check Items CONFIRMATION

"OVERALLFUNC-

Fail ReferencePag](/img/5/57349/w960_57349-987.png)

TROUBLEDIAGNOSIS -General Description

ill]

Diagnostic TroubleCode(DTC) Chart(Cont'd)

x:

Applicable

-: Not applicable

"DTC *1

*2

Check Items CONFIRMATION

"OVERALLFUNC-

Fail ReferencePage

(Possible Cause) PROCEDURE"

TIONCHECK"

Safe

Quick Ref. QuickRef. System

• Harness orconnectors

(The sensor circuitisopen orshorted.)

• Camshaft positionsensor

RUNNING

--

EC-289

• Starter motor

• Starting systemcircuit(ELsection)

• Dead (Weak) battery

• Harness orconnectors

-

(The sensor circuitisopen orshorted.) RUNNING

RUNNING

X

EC-293

• Mass airflow sensor

• Harness orconnectors

(The sensor circuitisopen orshorted.) IGN:

ON

-

X

EC-297

• Engine coolant temperature sensor

• Harness orconnectors

(The ignition primary circuitisopen orshorted.)

• Power transistor unit RUNNING

--

EC-301

• Camshaft positionsensor

• Camshaft positionsensorcircuit

• Harness orconnectors

(The sensor circuitisopen orshorted.) RUNNING

--

EC-306

• Knock sensor

• Harness orconnectors

(The sensor circuitisopen orshorted.)

-

IGN:

ON

X

EC-309

• Throttle position sensor

• No failure

--

-

-

*2: •The "OVERALL FUNCTIONCHECK"isasimplified andeffective waytoinspect acomponent orcircuit.

In some cases, the"OVERALL FUNCTIONCHECK"isused rather thana"DIAGNOSTIC TROUBLECODECONFIRMA-

TION PROCEDURE".

When noDTC CONFIRMATION PROCEDUREisavailable, the"NG" result ofthe OVERALL FUNCTION CHECKcanbe

considered tomean thesame asaDTC detection .

• During an"NG" OVERALL FUNCTION CHECK,theDTC might notbeconfirmed.

EC-269

•

Page 990 of 1701

TROUBLEDIAGNOSIS -General Descrip_ti_on

1S_R_'

Basic Inspection

Precaution:

Perform BasicInspection withoutelectrical ormechanical loads

applied;

• Headlamp switchisOFF,

• Air conditioner switchisOFF,

• Rear defogger switchisOFF,

• Steering wheelisinthe straight-ahead position,etc.

m

BEFORE STARTING

1. Check service records forany recent •

repairs thatmay indicate arelated

problem, orthe current needfor

scheduled maintenance.

2. Open engine hoodandcheck thefol-

lowing:

• Harness connectors forimproper con-

nections

• Vacuum hosesforsplits, kinks,or

improper connections

• Wiring forimproper connections,

pinches, orcuts

Goto

(I.

No

CONNECT

CONSULTTOTHE VEHICLE.

Connect "CONSULT" tothe data link

connector forCONSULT andselect

"ENGINE" fromthemenu. Referto

EC-254.

DOES ENGINE START?

\\

~

~ SEF1421

START

•

IGN TIMING ADJ.

0

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR.

SEF555N

Yes

CHECK IGNITION TIMING.

(ij\

1.Warm upengine sufficiently.

~ 2.Select "IGNTIMING ADJ"in

"WORK SUPPORT" mode.

3. Touch "START".

4. Check ignition timingatidle

using timing light.

Ignition timing:

15°::f:2° BTDC

~ 1Warm upengine sufficiently.

~ 2:

Stop engine anddisconnect

throttle position sensorhar-

ness connector.

3. Start engine.

4. Check ignition timingatidle

using timing light.

Ignition timing:

15°::f:2° BTDC

OK

(Go to

@

onnext page.) Adjust

ignition timingby

turning distributor.

EC-271