check engine NISSAN ALMERA N15 1995 Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 785 of 1701

![NISSAN ALMERA N15 1995 Manual PDF @

(Go tonext page)

(;]

1

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

~

RPM.

turning

idleadjusting

Base idlespeed: RefertoEC-36.

screw.

II

t

K

CHECK THROTTLE POSITIONSENSOR

NG

NISSAN ALMERA N15 1995 Manual PDF @

(Go tonext page)

(;]

1

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

~

RPM.

turning

idleadjusting

Base idlespeed: RefertoEC-36.

screw.

II

t

K

CHECK THROTTLE POSITIONSENSOR

NG](/img/5/57349/w960_57349-784.png)

@

(Go tonext page)

(;]

1

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

~

RPM.

turning

idleadjusting

Base idlespeed: RefertoEC-36.

screw.

II

t

K

CHECK THROTTLE POSITIONSENSOR

NG

Adjust output

voltage

to

~

IDLE POSITION.

0.50

:l:

0.1V byrotating

00

1.

Perform ''THRTlPOSSEN throttle

position sensor

ADJ" in"WORK SUPPORT" body.

mode.

2. Check thatoutput

voltage

of

throttle position sensoris

approx. 0.35to0.65V (Throttle

valve

fullycloses.) and"ClSD

THlIP SW"stays "ON".

OR

00

Measure

output

voltage

ofthrot-

tle position sensorusing

voltmeter,

andcheck thatitis

approx. 0.35to0.65V. (Throttle

valve

fullyclosed.)

OK

RESETIDLEPOSITION

MEMORY.

1. Warm upengine suffi-

ciently.

2. Turn ignition switch

"OFF" andwait at

least 5seconds.

3. Disconnect

throttle

position sensorhar-

ness connector.

4.

Start

engine andwait

at least 5seconds in

"N" position .

5. Reconnect throttle

position sensorhar-

ness connector while

running engine.

TROUBLE

DIAGNOSIS -General Description

Basic Inspection (Coni'd)

@

• THRTl POSSEN ADJ.

0

* **

ADJ MONITOR

***

THRTL POSSEN 0.52V

==========

MONITOR

==========

CMPS.RPM (REF)Orpm

CLSD THLIPOSI ON

SEF516Q

SEF12BR EC-66

Page 787 of 1701

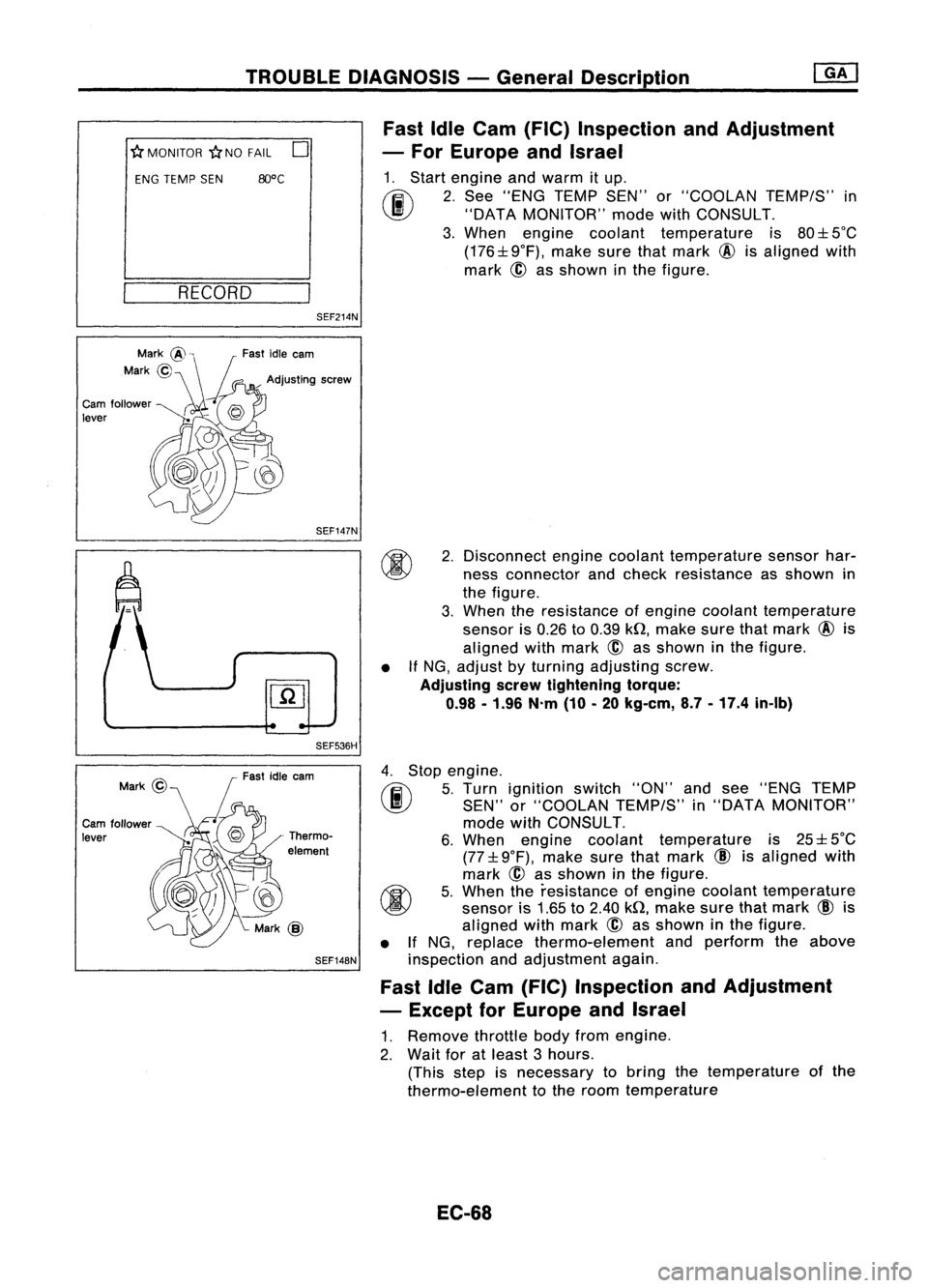

TROUBLEDIAGNOSIS -General Description

*

MONITOR

*

NO FAIL

ENG TEMP SEN 80°C

RECORD

Cam follower

lever

o

SEF214N

SEF147N Fast

IdleCam (FIC) Inspection andAdjustment

- For Europe andIsrael

1. Start engine andwarm itup.

(ij\

2.See "ENG TEMP SEN"or"COOLAN TEMP/S"in

~ "DATAMONITOR" modewithCONSULT.

3. When engine coolant temperature is80:l: 5°C

(176:l:9°F), makesurethatmark @isaligned with

mark ~asshown inthe figure.

SEF536H •

2.

Disconnect enginecoolant temperature sensorhar-

ness connector andcheck resistance asshown in

the figure.

3. When theresistance ofengine coolant temperature

sensor is0.26 to0.39 kQ,make surethatmark @is

aligned withmark

@

asshown inthe figure.

If NG, adjust byturning adjusting screw.

Adjusting serewtightening torque:

0.98 -1.96 N.m(10-20 kg-em, 8.7-17.4 in-Ib)

Cam follower

lever Fast

idleearn

Thermo-

element

SEF148N

4.

Stop engine.

rF.i\

5.Turn ignition switch"ON"andsee "ENG TEMP

~ SEN"or"COOLAN TEMP/S"in"DATA MONITOR"

mode withCONSULT.

6. When engine coolant temperature is25:l: 5°C

(77:l: 9°F), make surethatmark

CID

isaligned with

mark @asshown inthe figure.

~ 5.When theresistance ofengine coolant temperature

~ sensoris1.65 to2.40 kQ,make surethatmark

CID

is

aligned withmark

@

asshown inthe figure.

• IfNG, replace thermo-element andperform theabove

inspection andadjustment again.

Fast IdleCam (FIC) Inspection andAdjustment

- Except forEurope andIsrael

1. Remove throttlebodyfromengine.

2. Wait foratleast 3hours.

(This stepisnecessary tobring thetemperature ofthe

thermo-element tothe room temperature

EC-68

Page 788 of 1701

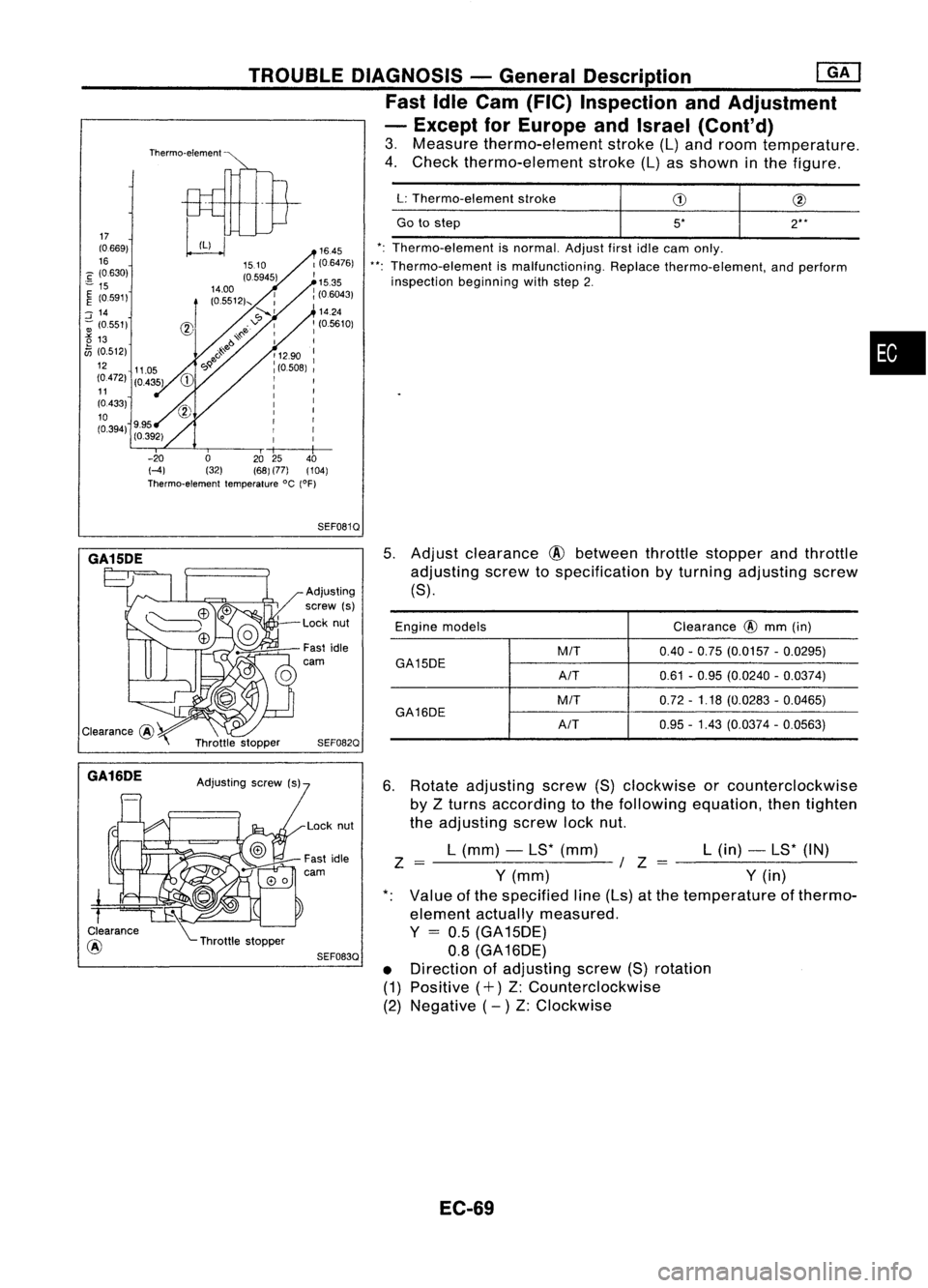

•

2**

5*

Go

tostep

L:

Thermo-element stroke

*: Thermo-element isnormal. Adjustfirstidlecam only.

**: Thermo-element ismalfunctioning. Replacethermo-element, andperform

inspection beginningwithstep 2.

TROUBLE

DIAGNOSIS -General Description ~

Fast IdleCam (FIC) Inspection andAdjustment

- Except forEurope andIsrael (Cont'd)

3. Measure thermo-element stroke(L)and room temperature.

4. Check thermo-element stroke(L)asshown inthe figure.

Thermo-element

1645

1(0.6476)

I

15.35

: (06043)

'14.24

: (05610)

I

: 1290 :

I

(0.508)

I

I I

I I

I I

: I

I

r

I

r

r

I

I

I

-20 02025 40

HI (32)(68)(77) (104)

Thermo-element temperature°C(OF)

17

(0.669)

16

C (0630)

"" 15

~ (0591)

::J

14

-; (0.551)

t5

13

fJi

(0.512)

12 11.05

(0472) (0435)

11

(0433)

10

(0.394) 9.95

(0.392)

SEF0810

GA15DE

*.

GA16DE

Clearance

@ Adjusting

screw (s)

Lock nut

Fast idle

carn

SEF0820

SEF0830

5.

Adjust clearance

@

between throttlestopper andthrottle

adjusting screwtospecification byturning adjusting screw

(8).

Engine models Clearance

@

mm (in)

M/T 0.40-0.75 (0.0157 -0.0295)

GA15DE A/T0.61

-0.95 (0.0240 -0.0374)

M/T 0.72

-1.18 (0.0283 -0.0465)

GA16DE

A/T0.95

-1.43 (0.0374 -0.0563)

6. Rotate adjusting screw(8)clockwise orcounterclockwise

by Zturns according tothe following equation, thentighten

the adjusting screwlocknut.

L (mm) -L8* (mm) L(in) -L8* (IN)

Z =-------~ /Z =--------

Y

(mm)

Y

(in)

Value ofthe specified line(Ls) atthe temperature ofthermo-

element actuallymeasured.

Y

=

0.5 (GA 15DE)

0.8 (GA 16DE)

• Direction ofadjusting screw(8)rotation

(1) Positive (+)Z:Counterclockwise

(2) Negative (- )Z: Clockwise

EC-69

Page 793 of 1701

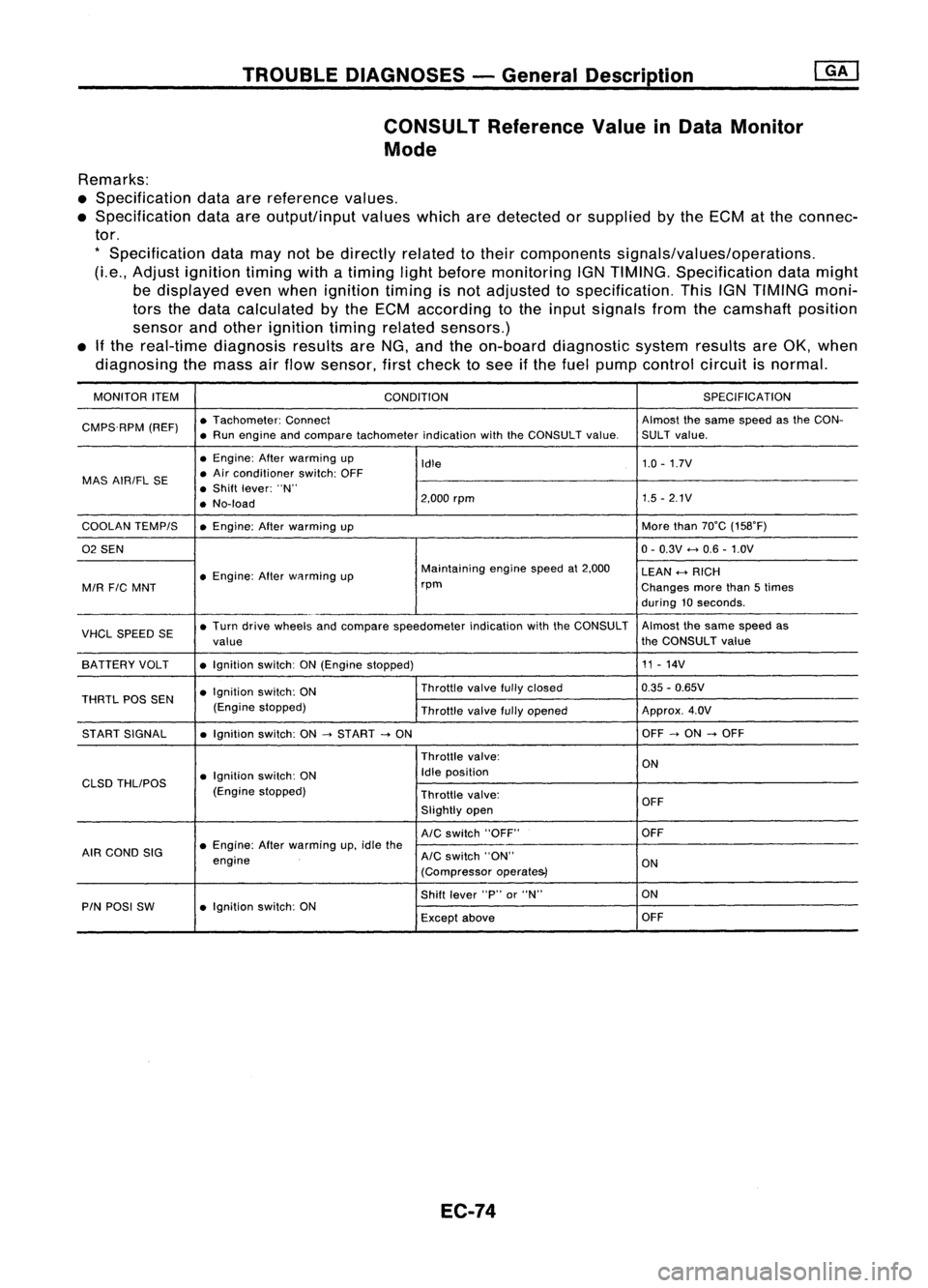

TROUBLEDIAGNOSES -General Description

CONSULT ReferenceValueinData Monitor

Mode

Remarks:

• Specification dataarereference values.

• Specification dataareoutput/input valueswhicharedetected orsupplied bythe ECM atthe connec-

tor.

*

Specification datamaynotbedirectly relatedtotheir components signals/values/operations.

(Le., Adjust ignition timingwithatiming lightbefore monitoring IGNTIMING. Specification datamight

be displayed evenwhen ignition timingisnot adjusted tospecification. ThisIGNTIMING moni-

tors thedata calculated bythe ECM according tothe input signals fromthecamshaft position

sensor andother ignition timingrelated sensors.)

• Ifthe real-time diagnosis resultsareNG, and theon-board diagnostic systemresultsareOK, when

diagnosing themass airflow sensor, firstcheck tosee ifthe fuel pump control circuitisnormal.

MONITOR ITEM

CONDITION SPEC

IFICA TION

CMPS.RPM (REF)•

Tachometer: Connect Almostthesame speed asthe CON-

• Run engine andcompare tachometer indicationwiththeCONSULT value.SULT value.

• Engine: Afterwarming up

Idle 1.0

-1.7V

MAS AIRIFL SE •

Air conditioner switch:OFF

• Shift lever: "N"

• No-load 2,000

rpm 1.5

-2.1V

COOLAN TEMPIS •Engine: Afterwarming up More

than70°C (158°F)

02 SEN 0-

0.3V

<-+

0.6 -1.0V

• Engine: Afterwflrming up Maintaining

enginespeedat2,000

LEAN

<-+

RICH

MIR

FIC

MNT rpm

Changesmorethan5times

during 10seconds .

VHCL SPEED SE•

Turn drive wheels andcompare speedometer indicationwiththeCONSULT Almost

thesame speed as

value the

CONSULT value

SA TTERY VOLT •Ignition switch:ON(Engine stopped) 11

-14V

• Ignition switch:ON Throttle

valvefullyclosed 0.35

-0.65V

THRTL POSSEN

(Enginestopped)

Throttlevalvefullyopened Approx.

4.0V

ST ART SIGNAL •Ignition switch:ON

-->

START

-->

ON OFF

-->

ON

-->

OFF

Throttle valve:

ON

• Ignition switch:ON Idle

position

CLSD THLIPOS

(Enginestopped)

Throttlevalve:

OFF

Slightly open

AIC

switch "OFF" OFF

AIR COND SIG •

Engine: Afterwarming up,idle the

engine

AIC

switch "ON"

ON

(Compressor operate&)

Shift lever "P"or"N" ON

PIN POSI SW •Ignition switch:ON

Exceptabove OFF

EC-74

Page 798 of 1701

![NISSAN ALMERA N15 1995 Manual PDF TROUBLEDIAGNOSES -General Description @K]

ECM Terminals andReference Value(Conl'd)

ECM INSPECTION TABLE-GA16DE forAustralia

Specification dataarereference valuesandaremeasured betweeneachterminal NISSAN ALMERA N15 1995 Manual PDF TROUBLEDIAGNOSES -General Description @K]

ECM Terminals andReference Value(Conl'd)

ECM INSPECTION TABLE-GA16DE forAustralia

Specification dataarereference valuesandaremeasured betweeneachterminal](/img/5/57349/w960_57349-797.png)

TROUBLEDIAGNOSES -General Description @K]

ECM Terminals andReference Value(Conl'd)

ECM INSPECTION TABLE-GA16DE forAustralia

Specification dataarereference valuesandaremeasured betweeneachterminal and

@

(ECCS ground).

TER- WIRE

MINAL ITEM

CONDITION DATA

NO. COLOR

[Efl9ineisrunning.

I

0.3-0.6V

L Idle speed

1

WIB

Ignitionsignal

I

Engine isrunning.

I

L Engine speedis2,000 rpm. Approximately

0.9V

2

GYIR

Ignition

check IEngine

isrunning.

I

Approximately12V

L Idle speed

3 LIB Tachometer [Engine

isrunning.

I

Approximately0.9V

L Idle speed

IEngine isrunning.

I

Ilgnition switch"OFF'.'

0-1V

4

WIG

ECCS

relay(Self-shut- L

For afew seconds afterturning ignition

off) switch

"OFF"

Ilgnition switch"OFF"

I

BATTERYVOLTAGE

L Afew seconds passedafterturning ignition

(11-14V)

switch "OFF"

Ilgnition switch"ON"

I

L For 5seconds afterturning ignition switch

0.07-0.20V

"ON"

8

BIP Fuel

pump relay I

Engine isrunning.

I

Ilgnition switch"ON"

I

BATTERYVOLTAGE

L More than5seconds afterturning ignition

(11-14V)

switch "ON"

10

BIW

ECCSground IEngine

isrunning.

I

Engineground

L Idle speed

IEngine isrunning.

I

BATTERYVOLTAGE

Cooling fanrelay ~Cooling fanisnot operating.

(11-14V).

13 LG

(Highspeed: For

AIT

Cooling

fanisoperating atlow speed.

models)

I

Engine isrunning.

I

L Cooling fanisoperating athigh speed. Approximately

OV

IEngine isrunning.

I

BATTERYVOLTAGE

Cooling fanrelay L

Cooling fanisnot operating. (11-14V)

14 LGIR

(Lowspeed)

I

Engine isrunning.

I

L_

Cooling fanisoperating. 0.07

-0.30V

I

Engine isrunning.

I

L Both

AIC

switch andblower switchare 0.08

-0.2V

15

Y

Air

conditioner relay "ON".

IEngine isrunning.

I

BATTERYVOLTAGE

LAIC switchis"OFF". (11

-14V)

EC-79

•

Page 802 of 1701

![NISSAN ALMERA N15 1995 Manual PDF TROUBLEDIAGNOSES -General Description @K]

ECM Terminals andReference Value(Conl'd)

ECM INSPECTION TABLE-Except GA16DE forAustralia

Specification dataarereference valuesandaremeasured betweeneacht NISSAN ALMERA N15 1995 Manual PDF TROUBLEDIAGNOSES -General Description @K]

ECM Terminals andReference Value(Conl'd)

ECM INSPECTION TABLE-Except GA16DE forAustralia

Specification dataarereference valuesandaremeasured betweeneacht](/img/5/57349/w960_57349-801.png)

TROUBLEDIAGNOSES -General Description @K]

ECM Terminals andReference Value(Conl'd)

ECM INSPECTION TABLE-Except GA16DE forAustralia

Specification dataarereference valuesandaremeasured betweeneachterminal and

@

(ECCS ground).

TERMINAL WIRE

NO. COLOR ITEM

CONDITION DATA

IEngine isrunning.1

0.2-0.3V

L

Idle speed

1

WIB

Ignitionsignal

IEngineisru~

L

Engine speedis2,000 rpm. Approximately

0.7V

Tachometer IEngineisrunning.1

2 LIB

(Modelswithtachome-

L

Idle speed 0.7

-0.9V

ter)

3 GYIR

Ignitioncheck jEngine

isrunning.1

Approximately13V

L

Idle speed

Engine isrunning.'

I

Ignition switch"OFF"I

0-1V

ECCS relay(Self-shut-

L

For afew seconds afterturning ignition

4

WIG

off) switch

"OFF"

llgnition switch"OFF"I

BATTERYVOLTAGE

L

Afew seconds afterturning ignition

(11-14V)

switch "OFF"andthereafter

IEngine isrunning.1

BATTERYVOLTAGE

Cooling fanrelay (Low

L

Cooling fanisnot operating. (11-14V)

9 LGIR

speed) IEngineisrunning.1

L

Cooling fanisoperating. Approximately

OV

IEngine isrunning.1

BATTERYVOLTAGE

Cooling fanrelay (High

t

Cooling fanisnot operating.

(11-14V)

10 LG Cooling

fanisoperating atlow speed.

speed) IEngineisrunning.1

L

Cooling fanisoperating athigh speed. Approximately

OV

IEngine isrunning.1

L

Both

AIC

switch andblower fanswitch Approximately

OV

11 Yor

GAir

conditioner relay are

"ON".

IEngine isrunning.1

BATTERYVOLTAGE

LAIC

switchis"OFF". (11

-14V)

IEngine isrunning.1

BATTERYVOLTAGE

VTC solenoid valve

L

Idle speed (11

-14V)

12 YIR (GA

16DE engine mod-

IEngineisrunning.1

els except forEurope

and Israel)

L

Engine isracing quickly fromidleto4,000 Approximately

OV

rpm at1st position.

EC-83

•

Page 810 of 1701

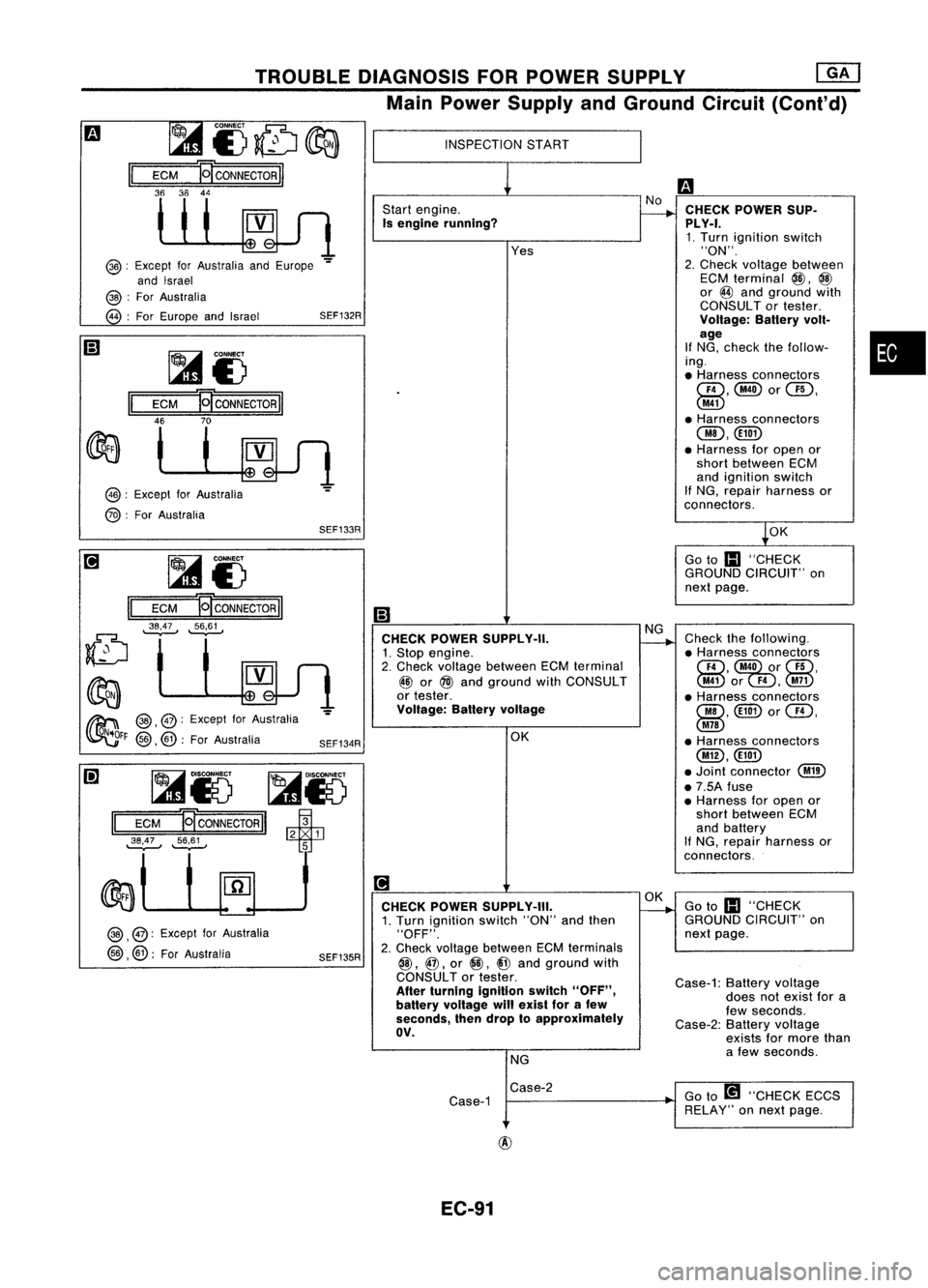

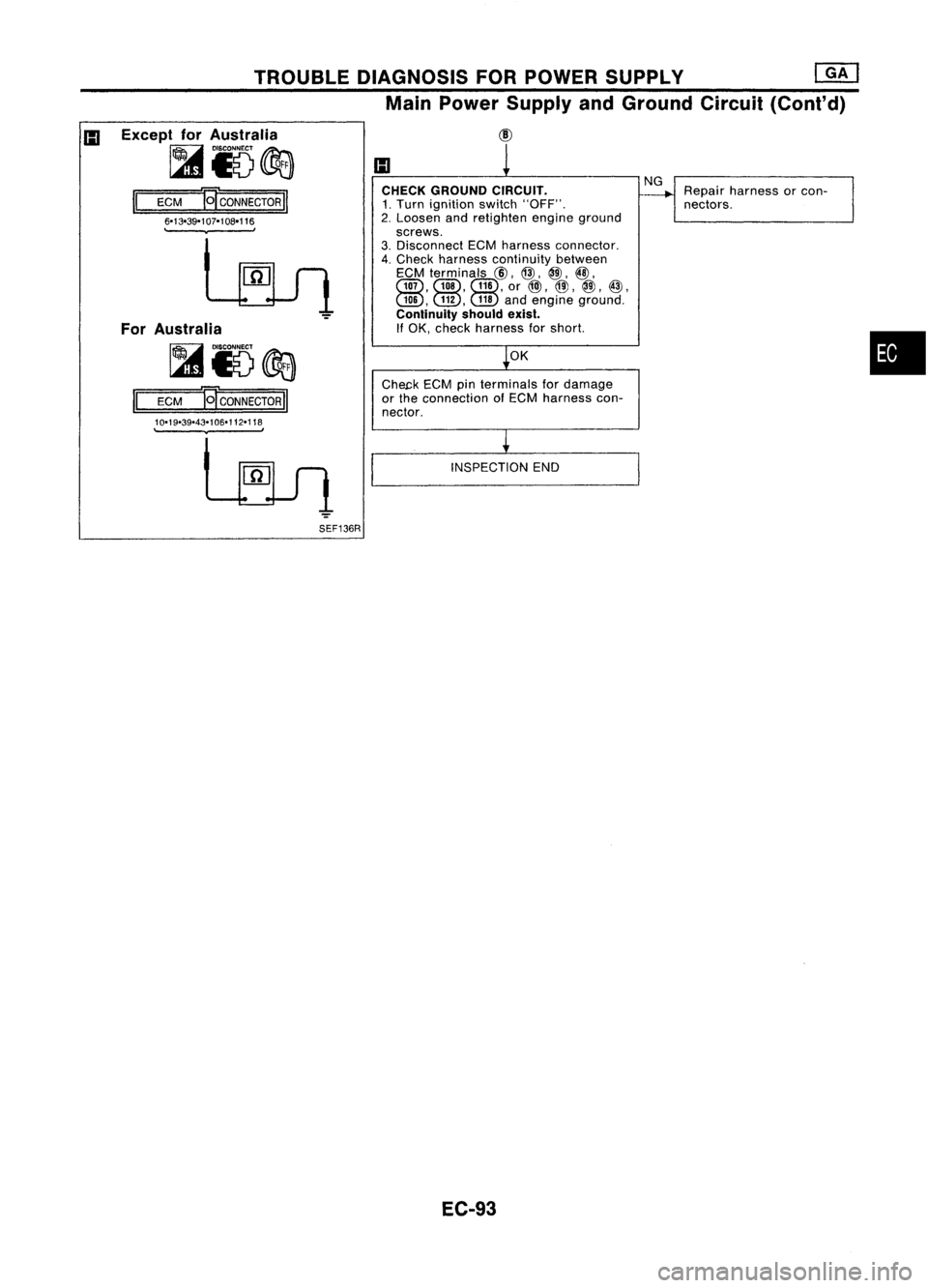

TROUBLEDIAGNOSIS FORPOWER SUPPLY ~

Main Power Supply andGround Circuit(Cont'd)

•

-!.OK

Go to

III

"CHECK

GROUND CIRCUIT" on

next page.

CHECK

POWER SUP-

PLY-I. 1. Turn ignition switch

"ON".

2. Check Yoltage between

ECM terminal

@,

@

or

@

and ground with

CONSULT ortester.

Voltage: Batteryvolt-

age

If NG, check thefollow-

ing .

• Harness connectors

GD,@orUD,

@

• Harness connectors

OO,@))

• Harness foropen or

short between ECM

and ignition switch

If NG, repair harness or

connectors.

Check thefollowing.

• Harness connectors

CID,

@O)ui)r

UD,

@or

F4,@

• Harness connectors

00, @))

or

Cill,

@

• Harness connectors

@,@))

• Joint connector

@

• 7.5A fuse

• Harness foropen or

short between ECM

and battery

If NG, repair harness or

connectors.

INSPECTION

START

Start engine.

Is engine running?

CHECK POWER SUPPLY-II.

1. Stop engine.

2. Check voltage between ECMterminal

~ or

@)

and ground withCONSULT

or tester.

Voltage: Batteryvoltage

OKYes

SEF134R

~i)

ECM

E[coNNECTORII

~;~~ ~i)

II

ECM

P!CONNECTORII

46 70

SEF133R

II

ECM

36 36

~85 ~r5

II

ECM

EJ

CONNECTOR

II

~53 1

~'.S~ ~

@:

Except forAustralia andEurope

-=

and Israel

@ :

For Australia

@ :

For Europe andIsrael SEF132R

@:

Except forAustralia

@ :

For Australia

~ @,@:

Except forAustralia

~FF

@,

@:

ForAustralia

@ ,

@: Except forAustralia

@ ,@:

ForAustralia

SEF135R

[!]

CHECK POWER SUPPLY-III.

1. Turn ignition switch"ON"andthen

"OFF".

2. Check Yoltage between ECMterminals

@,

@,

or

@,

i@

and ground with

CONSULT ortester.

After turning ignition switch"OFF",

battery voltage willexist forafew

seconds, thendrop toapproximately

av.

NG ~

Goto

III

"CHECK

GROUND CIRCUIT" on

next page.

Case-1: Batteryvoltage

does notexist fora

few seconds.

Case-2: Batteryvoltage

exists formore than

a few seconds.

Case-2

Case-1 Go

to[!1 "CHECK ECCS

RELAY" onnext page.

EC-91

Page 812 of 1701

TROUBLEDIAGNOSIS FORPOWER SUPPLY

em

Main Power Supply andGround Circuit(Cont'd)

Except forAustralia

~i5~

II

ECM

B'

CONNECTOR

II

6-13-39-107-108-116

.

,

For Australia

~i5@a

II

ECM

B'

CONNECTOR

II

10-19-39-43-106-112-118

.

,

SEF136R CHECK

GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Loosen andretighten engineground

screws.

3. Disconnect ECMharness connector.

4. Check harness continuity between

ECM terminals

@,

@,

@,@,

Gill, Gill,Gill,

or

@),

@,

@,

@,

GID, GID,

@

andengine ground.

Continuity shouldexist.

If OK, check harness forshort.

OK

Che~k ECMpinterminals fordamage

or the connection ofECM harness con-

nector.

INSPECTION END

EC-93

NG

Repair harness orcon-

nectors.

•

Page 813 of 1701

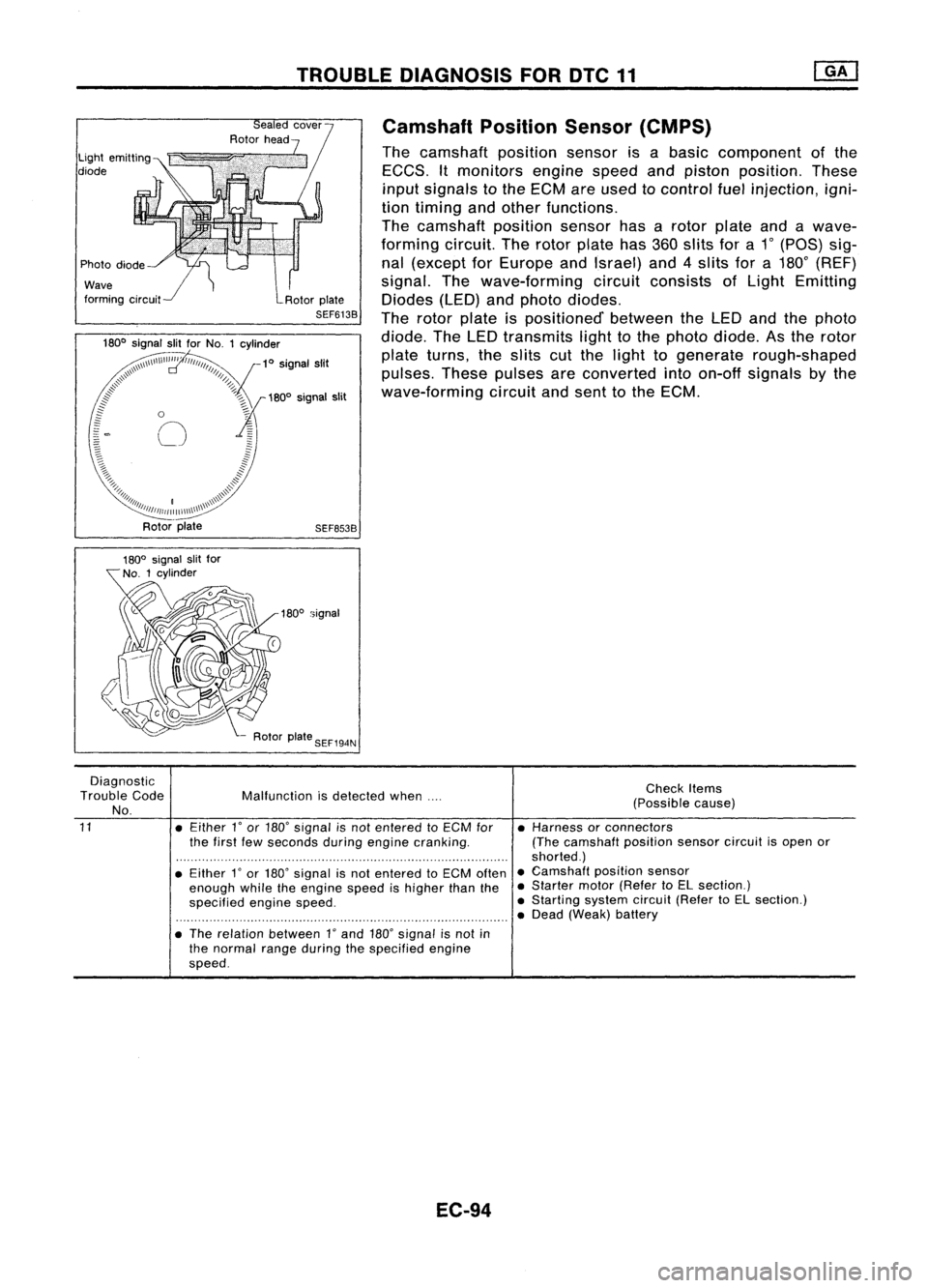

TROUBLEDIAGNOSIS FORDTC11

Light emitting

diode

Wave

forming circuit

Camshaft

PositionSensor(CMPS)

The camshaft positionsensorisabasic component ofthe

EGGS. Itmonitors enginespeedandpiston position. These

input signals tothe EGM areused tocontrol fuelinjection, igni-

tion timing andother functions.

The camshaft positionsensorhasarotor plate andawave-

forming circuit.Therotor plate has360slits fora1

0

(paS) sig-

nal (except forEurope andIsrael) and4slits fora180

0

(REF)

signal. Thewave-forming circuitconsists ofLight Emitting

Diodes (LED)andphoto diodes.

The rotor plate ispositioned' betweentheLED andthephoto

diode. TheLED transmits lighttothe photo diode. Asthe rotor

plate turns, theslits cutthe light togenerate rough-shaped

pulses. Thesepulses areconverted intoon-off signals bythe

wave-forming circuitandsent tothe EGM.

SEF653B

180

0

signal

Diagnostic

Trouble Code

No.

11

Malfunction

isdetected when....

• Either

l'

or 180' signal isnot entered toECM for

the first fewseconds duringengine cranking.

• Either

l'

or 180' signal isnot entered toECM often

enough whiletheengine speedishigher thanthe

specified enginespeed.

• The relation between

l'

and 180'signal isnot in

the normal rangeduring thespecified engine

speed.

EC-94

Check

Items

(Possible cause)

• Harness orconnectors

(The camshaft positionsensorcircuitisopen or

shorted.)

• Camshaft positionsensor

• Starter motor(Refer toEL section.)

• Starting systemcircuit(RefertoEL section.)

• Dead (Weak) battery

Page 818 of 1701

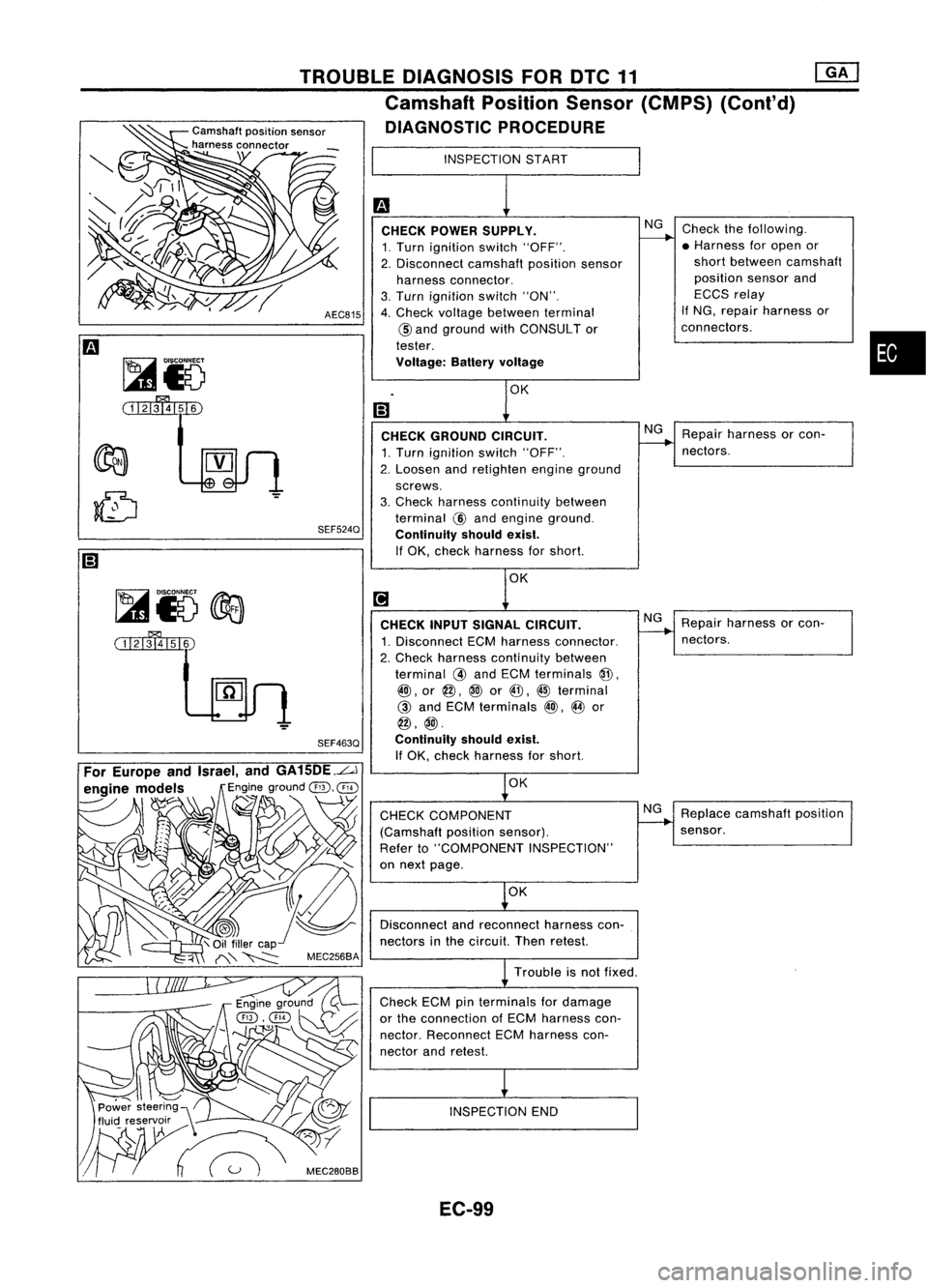

•

Repair harness orcon-

nectors.

Check

thefollowing.

• Harness foropen or

short between camshaft

position sensorand

ECCS relay

If NG, repair harness or

connectors .

NG

NG

CHECK

POWER SUPPLY.

1. Turn ignition switch"OFF".

2. Disconnect camshaftpositionsensor

harness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

@

and ground withCONSULT or

tester.

Voltage: Batteryvoltage

CHECK GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Loosen andretighten engineground

screws.

3. Check harness continuity between

terminal

@

and engine ground.

Continuity shouldexist.

If OK, check harness forshort.

AEC815

SEF524Q

TROUBLE

DIAGNOSIS FORDTC11 ~

Camshaft PositionSensor(CMPS) (Conl'd)

Camshaft positionsensor

DIAGNOSTIC PROCEDURE

harness connector

\ INSPECTIONSTART

Trouble isnot fixed.

~i5

@a

(i1'lmI51~ CHECK

INPUTSIGNAL CIRCUIT.

1. Disconnect ECMharness connector.

2. Check harness continuity between

terminal

@

and ECM terminals

@.

@),

or

@,

@

or

@, @

terminal

@

and ECM terminals

@),

@

or

@,@.

SEF463Q Continuityshouldexist.

If

OK, check harness forshort.

OK

CHECK COMPONENT

(Camshaft positionsensor).

Refer to"COMPONENT INSPECTION"

on next page.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

NG

Repair

harness orcon-

nectors.

Replace camshaft position

sensor.

EC-99