coolant NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1121 of 1701

TROUBLEDIAGNOSES ~

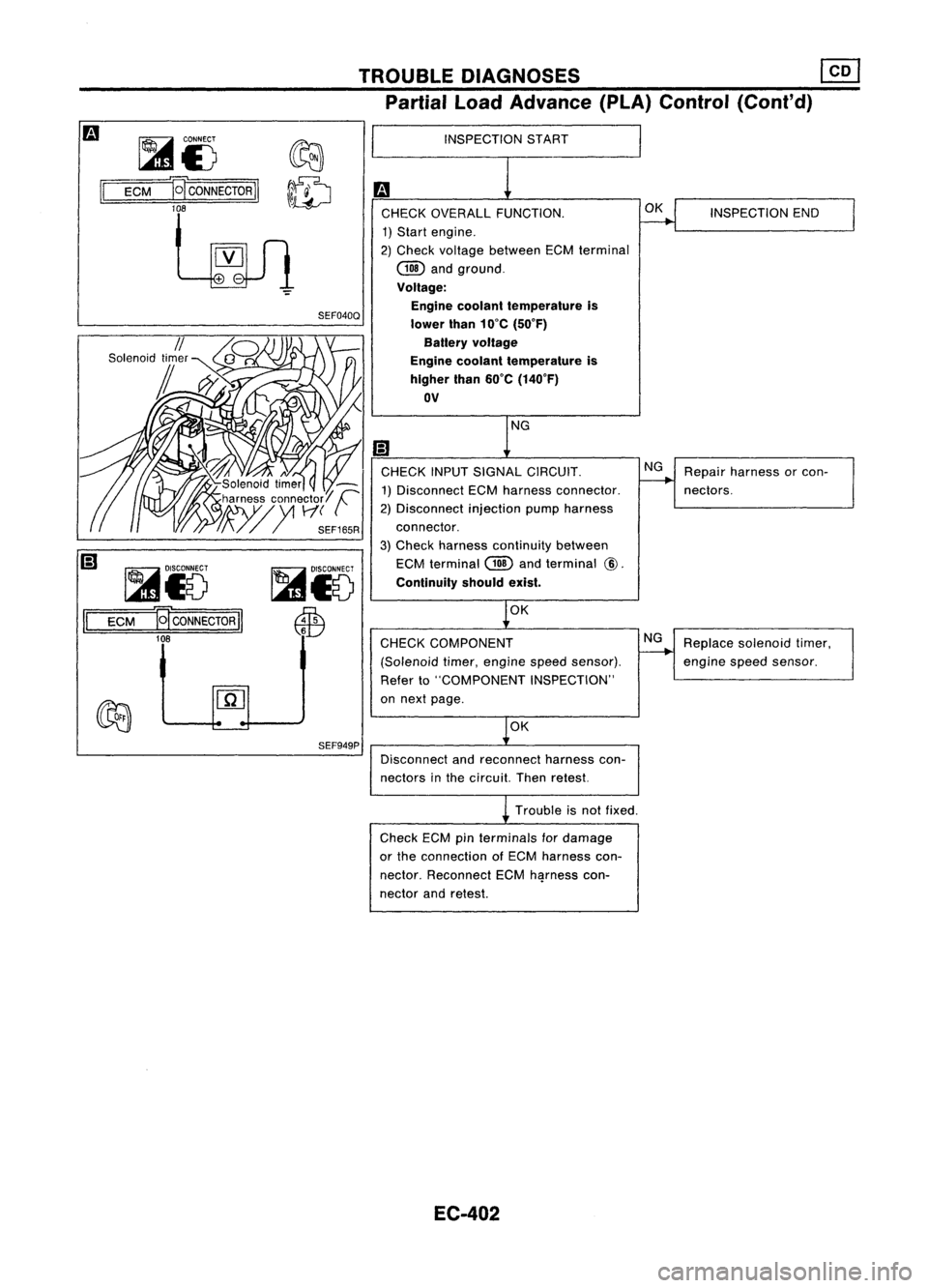

Partial LoadAdvance (PLA)Control (Cont'd)

II

~i5

D~CONNECTORII

lOB

~i5

ECM

M

CONNECTOR

II

10B

SEF040Q

SEF949P

INSPECTION

START

CHECK OVERALL FUNCTION.

1) Start engine.

2) Check voltage between ECMterminal

COO

andground.

Voltage: Engine coolant temperature is

lower than10'C (50'F)

Battery voltage

Engine coolant temperature is

higher than60'C (140'F)

OV

CHECK INPUTSIGNAL CIRCUIT.

1) Disconnect ECMharness connector.

2) Disconnect injectionpumpharness

connector.

3) Check harness continuity between

ECM terminal

COO

andterminal

@.

Continuity shouldexist.

OK

CHECK COMPONENT

(Solenoid timer,engine speedsensor).

Refer to"COMPONENT INSPECTION"

on next page.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpin

terminals

fordamage

or the connection ofECM harness con-

nector. Reconnect ECMh~rness con-

nector andretest.

EC-402 OK

NG

NG

INSPECTION

END

Repair harness orcon-

nectors.

Replace solenoid timer,

engine

speedsensor.

Page 1123 of 1701

TROUBLEDIAGNOSES

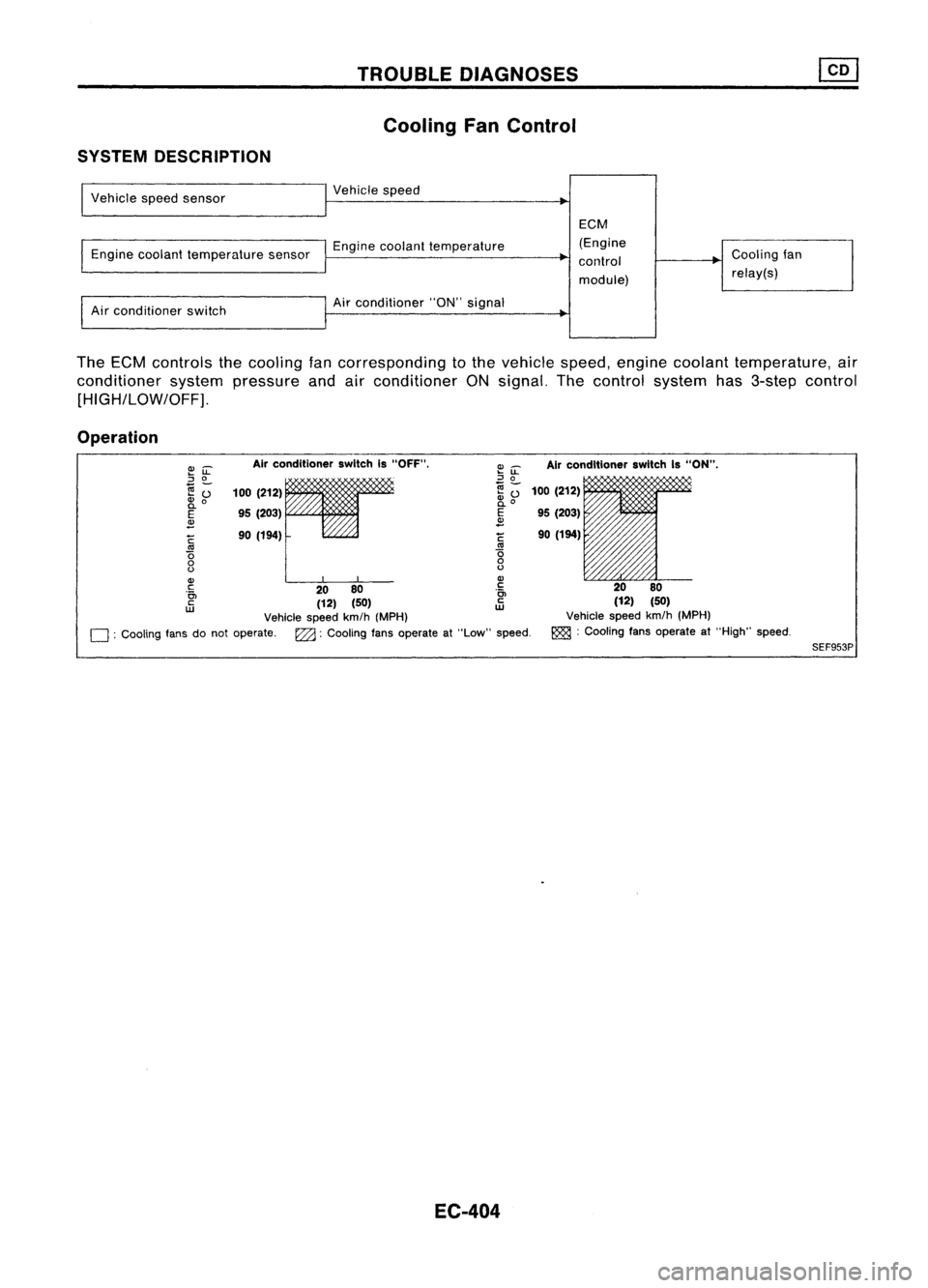

Cooling FanControl

SYSTEM DESCRIPTION

Vehicle speedsensor Vehicle

speed

Engine coolant temperature sensorEngine

coolant temperature

ECM

(Engine

control module) Cooling

fan

relay(s)

Air conditioner switch Air

conditioner "ON"signal

The ECM controls thecooling fancorresponding tothe vehicle speed,engine coolant temperature, air

conditioner systempressure andairconditioner ONsignal. Thecontrol system has3-step control

[HIGH/LOW/OFF].

Operation

SEF953P

20

80

(12) (50)

Vehicle speedkmfh(MPH)

~ :Cooling fansoperate at"High" speed.

Air

conditioner switchIs"ON".

100 (212)

95 (203)

90 (194)

~LL

:J

0

eZ;

~o

E

2

C

'"

'0

o

U

Q>

c

'5>

c

w

Air

conditioner switchIs"OFF".

100 (212)

95 (203)

90 (194)

Q>

-

... LL

:J

0

~~

~o

E

2

c

'"

'0

o

U

Q>

c

'5>

c:

w 20

80

(12) (50)

Vehicle speedkmfh(MPH)

o :

Cooling fansdonot operate.

1222l:

Cooling fansoperate at"Low" speed.

EC-404

Page 1125 of 1701

TROUBLEDIAGNOSES

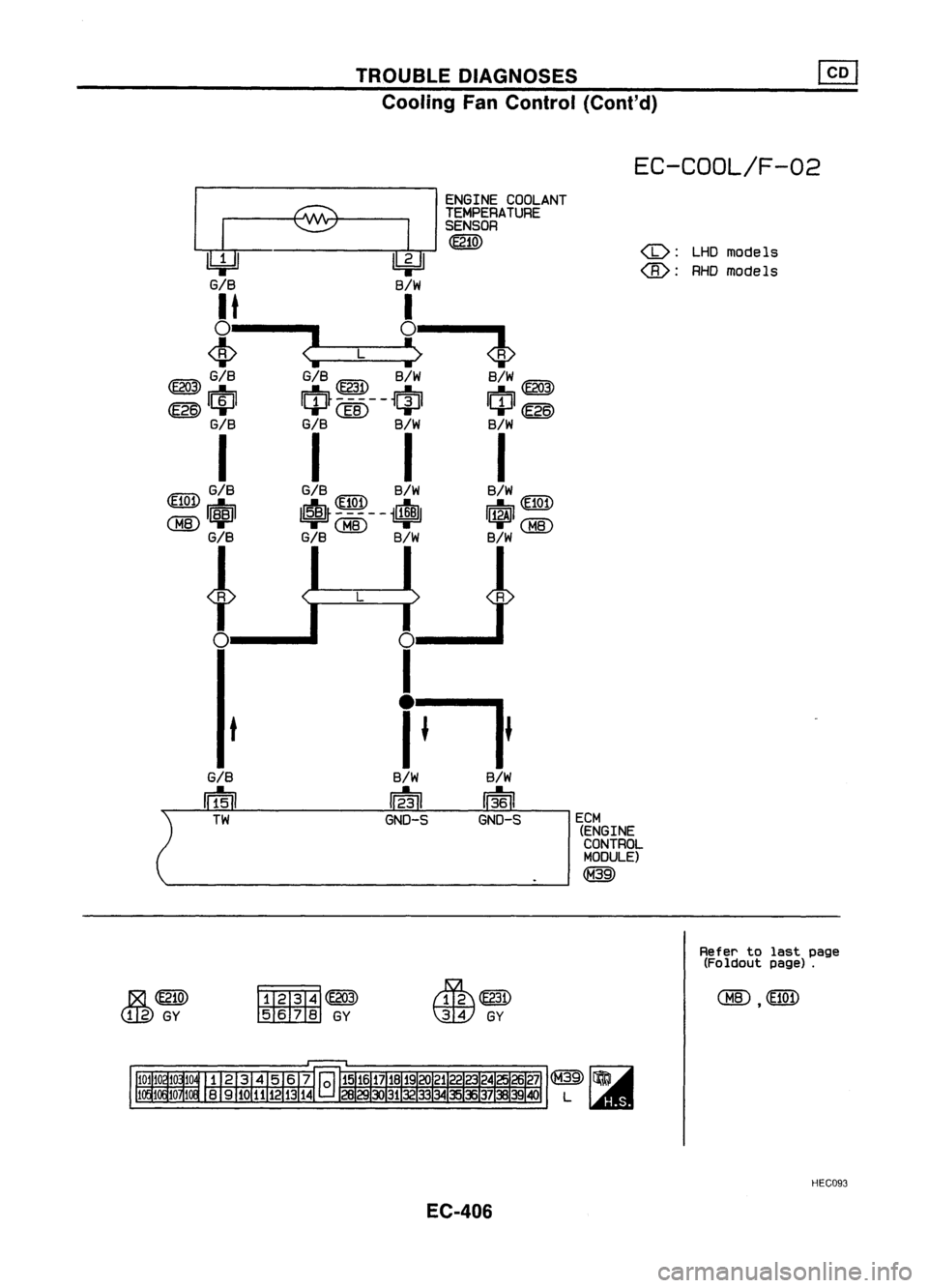

Cooling FanControl (Cont'd)

EC-COOL/F-02

LHDmodels

RHO models

(6):

(B):

I

EeM

(ENGINE

CONTROLMODULE)

@

S/W ~

IciJl

S/W

I

S/W

I~I@QD

;,:@

o

I

iTlJ

S/W S/W

1l@1

100'

GND-S GND-S

L

iJ

ENGINE COOLANT

_ TEMPERATURE

SENSOR

~

lLj:U

S/W

I

~ L

:>

GIS ~

S/W

d!b:. ~ d!b:.

Icpt

(ES-)-

-1~1

GIS

S/W

I I

GIS

t'ETr\'i\

S/W

db ~

,.,.b

1~~-M8--~

GIS

@

S/W

t

GIS

I@I

TW

GIS

It

o

(E203) ~

~11lJ1

GIS

I

@QD~

<:BID

I~I

GIS

t

o

~~

@GY

~(E203)

rnmz:mI

GY

~~

~GY

Refer

tolast page

(Foldout page).

HEC093

EC-406

Page 1127 of 1701

TROUBLEDIAGNOSES

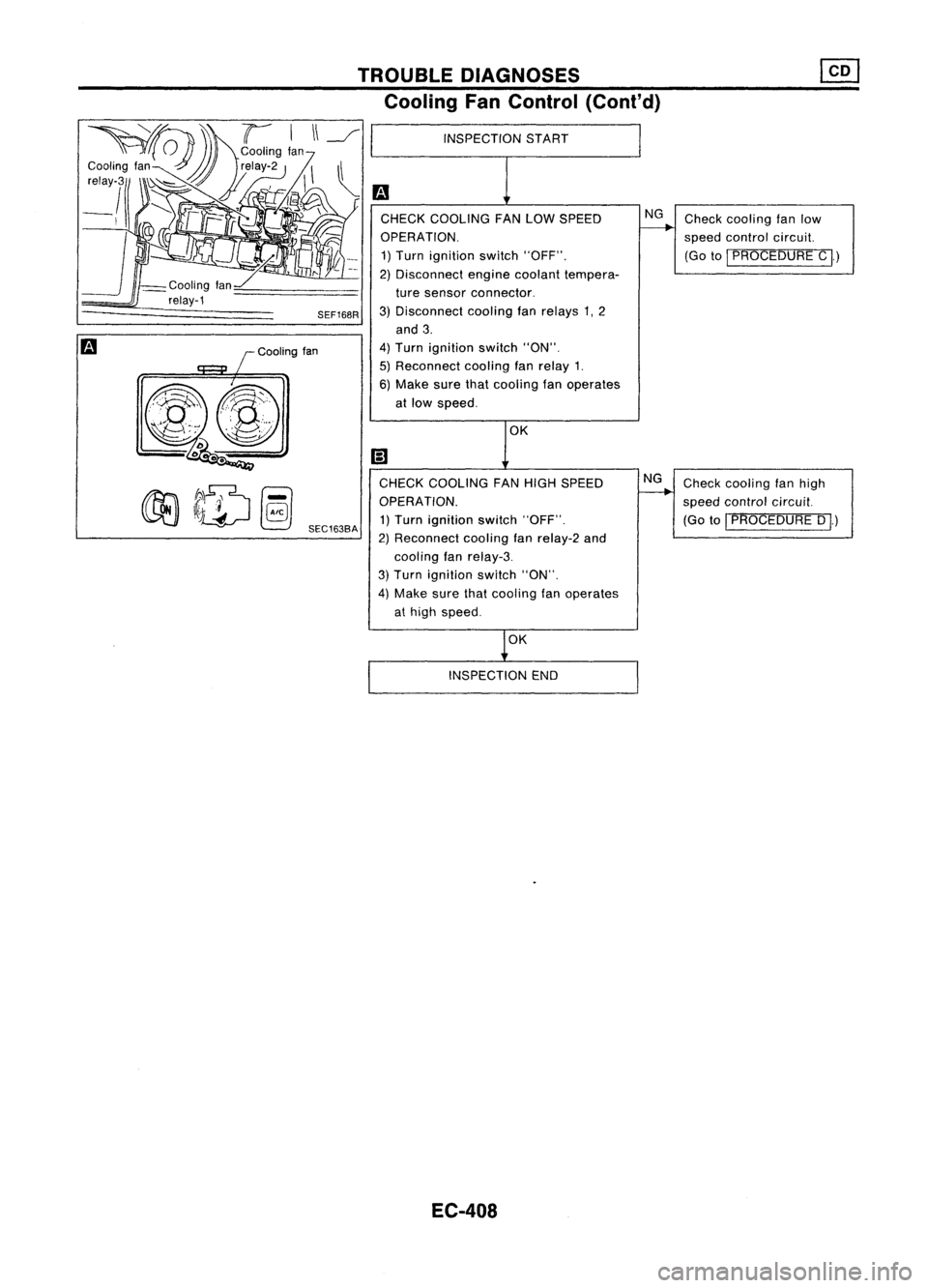

Cooling FanControl (Cont'd)

Checkcooling fanlow

speed control circuit.

(Go to

I

PROCEDURE C

P

Check cooling fanhigh

speed control circuit.

(Go to

I

PROCEDURE D

I.)

NG

NG

INSPECTION

START

OK

CHECK COOLING FANHIGH SPEED

OPERATION. 1) Turn ignition switch"OFF".

2) Reconnect coolingfanrelay-2 and

cooling fanrelay-3.

3) Turn ignition switch"ON".

4) Make surethatcooling fanoperates

at high speed.

CHECK

COOLING FANLOW SPEED

OPERATION. 1) Turn ignition switch"OFF".

2) Disconnect enginecoolant tempera-

ture sensor connector.

SEF168R

3)Disconnect coolingfanrelays 1,2

and 3.

4) Turn ignition switch"ON".

5) Reconnect coolingfanrelay 1.

6) Make surethatcooling fanoperates

at low speed.

SEC163BA OK

INSPECTION END

EC-408

Page 1132 of 1701

TROUBLEDIAGNOSES

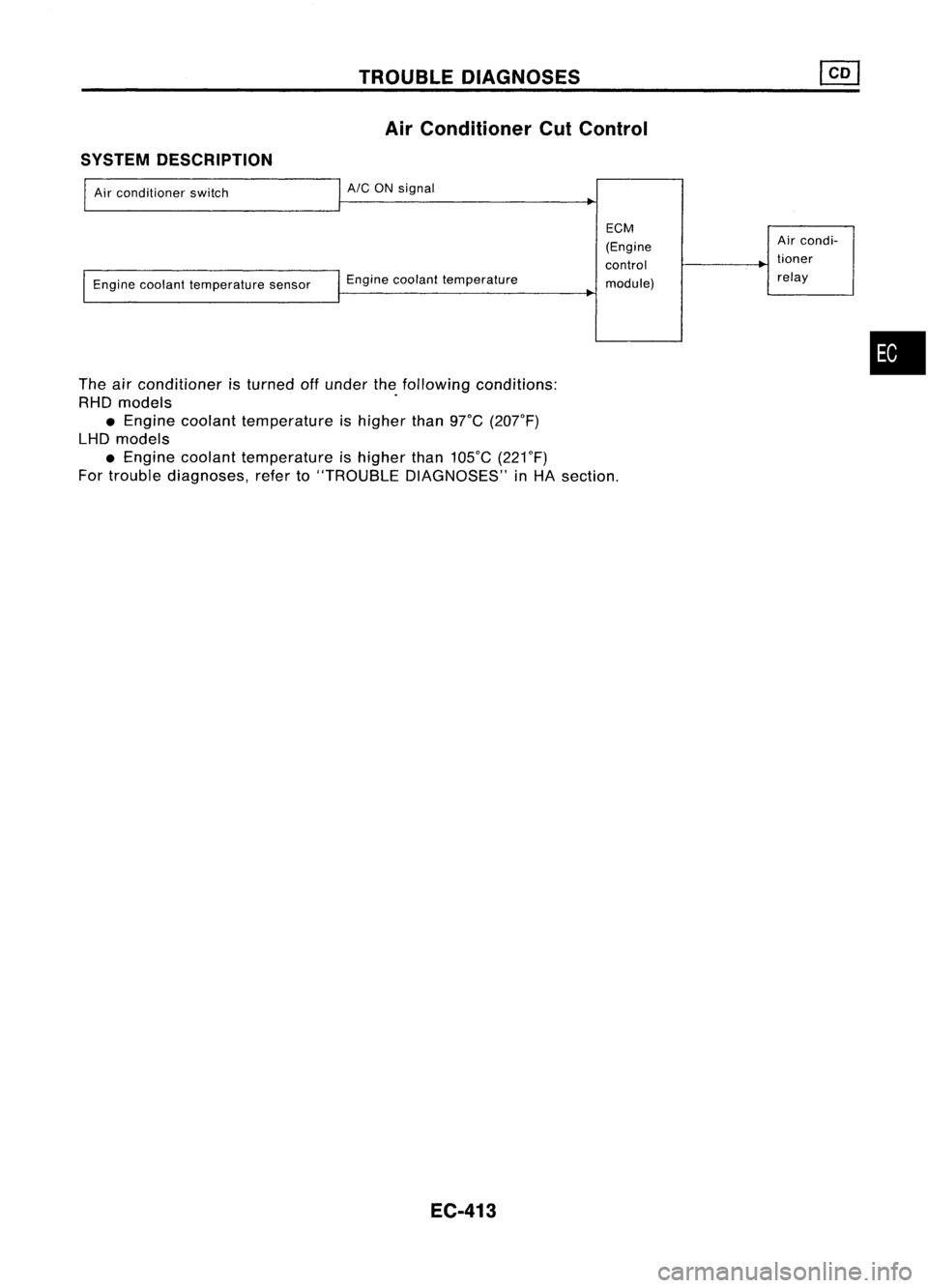

Air Conditioner CutControl

SYSTEM DESCRIPTION

The airconditioner isturned offunder thefollowing conditions:

RHO models .

• Engine coolant temperature ishigher than

grC

(20rF)

LHD models

• Engine coolant temperature ishigher than105°C (221°F)

For trouble diagnoses, referto"TROUBLE DIAGNOSES" inHA section.

Air

conditioner switch

Engine coolant temperature sensor

A/C

ONsignal

Engine coolant temperature

ECM

(Engine

control module) Air

condi-

tioner relay

•

EC-413

Page 1136 of 1701

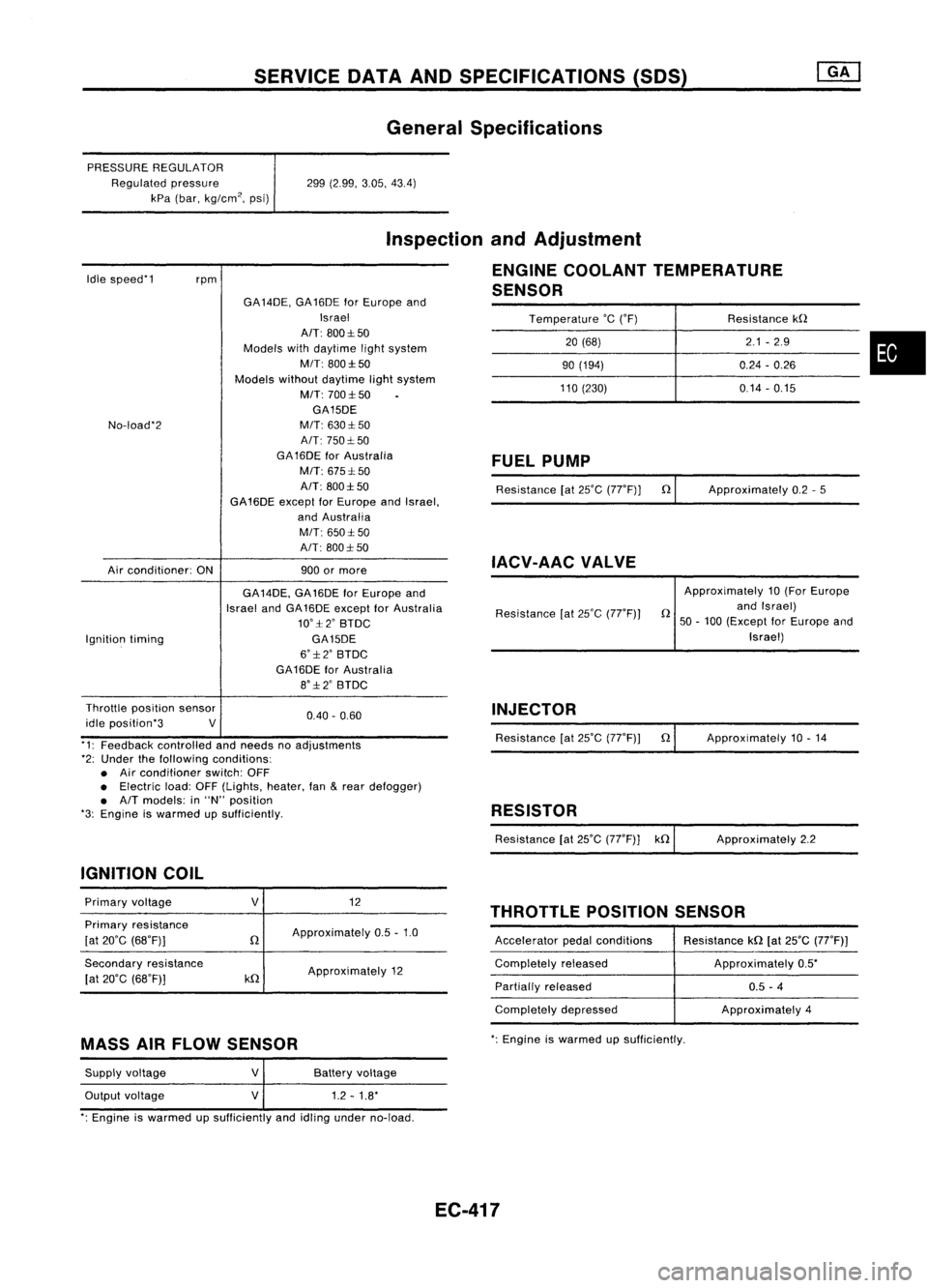

SERVICEDATAANDSPECIFICATIONS (SOS)

General Specifications

PRESSURE REGULATOR

Regulated pressure

kPa (bar, kg/cm

2,

psi) 299

(2.99, 3.05,43.4)

Idle speed'1

rpm

Inspection

andAdjustment

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature

'c

('F) Resistancekn

20 (68) 2.1

-2.9

•

90

(194) 0.24-0.26

110 (230) 0.14-0.15

No-load'2

Air conditioner: ONGA

14DE, GA16DE forEurope and

Israel

AIT: 800:1:50

Models withdaytime lightsystem

MIT: 800:1:50

Models withoutdaytime lightsystem

M/T: 700:1:50

GA15DE

M/T: 630:1: 50

A/T: 750:1: 50

GA 16DE forAustralia

M/T: 675:1: 50

A/T: 800:1:50

GA16DE exceptforEurope andIsrael,

and Australia

M/T: 650:1:50

A/T: 800:1: 50

900 ormore

FUEL

PUMP

Resistance [at25'C (77'F)] n

IACV-AAC VALVE

Approximately

0.2-5

Ignition timing GA

14DE, GA16DE forEurope and

Israel andGA16DE except forAustralia

10':1:2' BTDC

GA15DE

6':1:2' BTDC

GA16DE forAustralia

8':1:2' BTDC Resistance

[at25'C (77'F)) Approximately

10(For Europe

n andIsrael)

50 -100 (Except forEurope and

Israel)

0.40. 0.60

Throttle

position sensor

idle position'3 V

'1: Feedback controlled andneeds noadjustments

'2: Under thefollowing conditions:

• Air conditioner switch:OFF

• Electric load:OFF(Lights, heater,fan

&

rear defogger)

• A/T models: in"N" position

'3: Engine iswarmed upSUfficiently.

IGNITION COIL INJECTOR

Resistance [at25'C (77'F)) n

RESISTOR

Resistance [at25'C (77'F)] kn Approximately

10.14

Approximately 2.2

THROTTLE POSITIONSENSOR

Primary

voltage

Primary resistance

[at 20'C (68'F)]

Secondary resistance

[at 20'C (68'F)]

V

n

kn

12

Approximately 0.5-1.0

Approximately 12 Accelerator

pedalconditions

Completely released

Partially released

Completely depressed Resistance

kn[at25'C (77'F))

Approximately 0.5'

0.5 -4

Approximately 4

MASS AIRFLOW SENSOR

':

Engine iswarmed upsufficiently.

Supply voltage

Output voltage

V

V

Battery

voltage

1.2 -1.8'

': Engine iswarmed upSUfficiently andidling under no-load.

EC-417

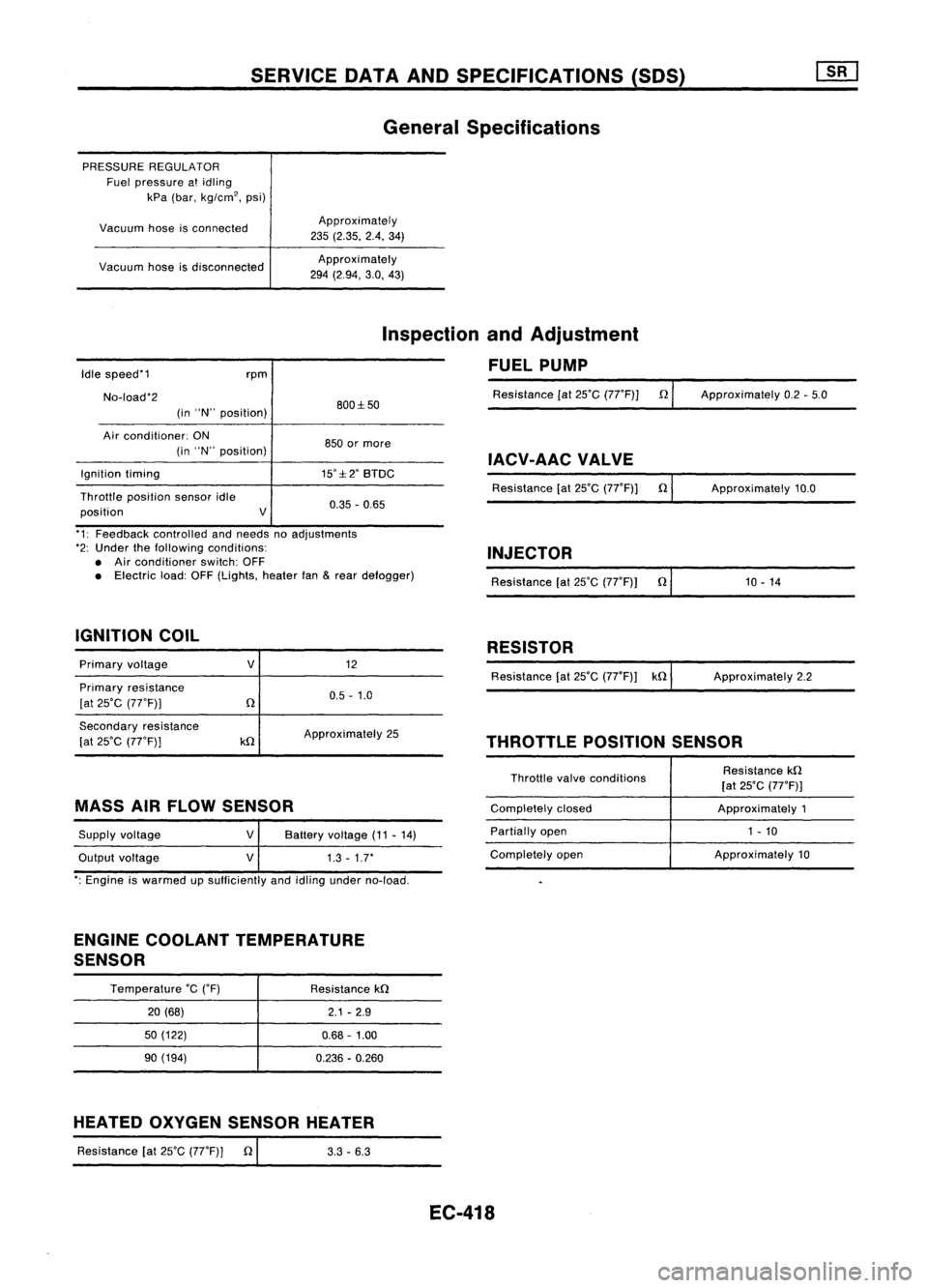

Page 1137 of 1701

SERVICEDATAANDSPECIFICATIONS (SOS)

General Specifications

PRESSURE REGULATOR

Fuel pressure atidling

kPa (bar, kg/cm

2,

psi)

Vacuum hoseisconnected

Vacuum hoseisdisconnected Approximately

235 (2.35. 2.4.34)

Approxi mately

294 (2.94, 3.0,43)

Idle speed'1

No-load'2 rpm

(in "N" position) 800:1:50

Inspection

andAdjustment

FUEL PUMP

Resistance [at25'C (77'F)] n

Approximately 0.2-5.0

Air conditioner: ON

(in "N" position)

Ignition timing

Throttle position sensoridle

position V850

ormore

IACV-AACVALVE

15':1:2' BTDC

Resistance[at25'C (77'F)] n

0.35 -0.65 Approximately

10.0

'1: Feedback controlled andneeds noadjustments

'2: Under thefollowing conditions:

• Air conditioner switch:OFF

• Electric load:OFF(Lights, heaterfan

&

rear defogger)

IGNITION COIL INJECTOR

Resistance [at25'C (77'F)) n'

1_0_-_1_4 _

RESISTOR

Primary voltage

Primary resistance

[at 25'C (77'F))

V

12

0.5 -1.0 Resistance

[at25'C (77'F)) kn ApproXimately 2.2

Secondary resistance

[at 25'C (77'F))

kn

Approximately

25

THROTTLEPOSITIONSENSOR

MASS AIRFLOW SENSOR

Supply voltage

Output voltage

V

V

Battery

voltage (11-14)

1.3 -1.7'

Throttle

valveconditions

Completely closed

Partially open

Completely open Resistance

kn

[at 25'C (77'F)]

Approximately 1

1 - 10

Approximately 10

': Engine iswarmed upsufficiently andidling under no-load.

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature

'c

('F)

20 (68)

50 (122)

90 (194) Resistance

kn

2.1-2.9

0.68 -1.00

0.236 -0.260

HEATED OXYGEN SENSOR HEATER

Resistance [at25'C (77'F)] n

I

3.3-6.3

EC-418

Page 1140 of 1701

Inner

side

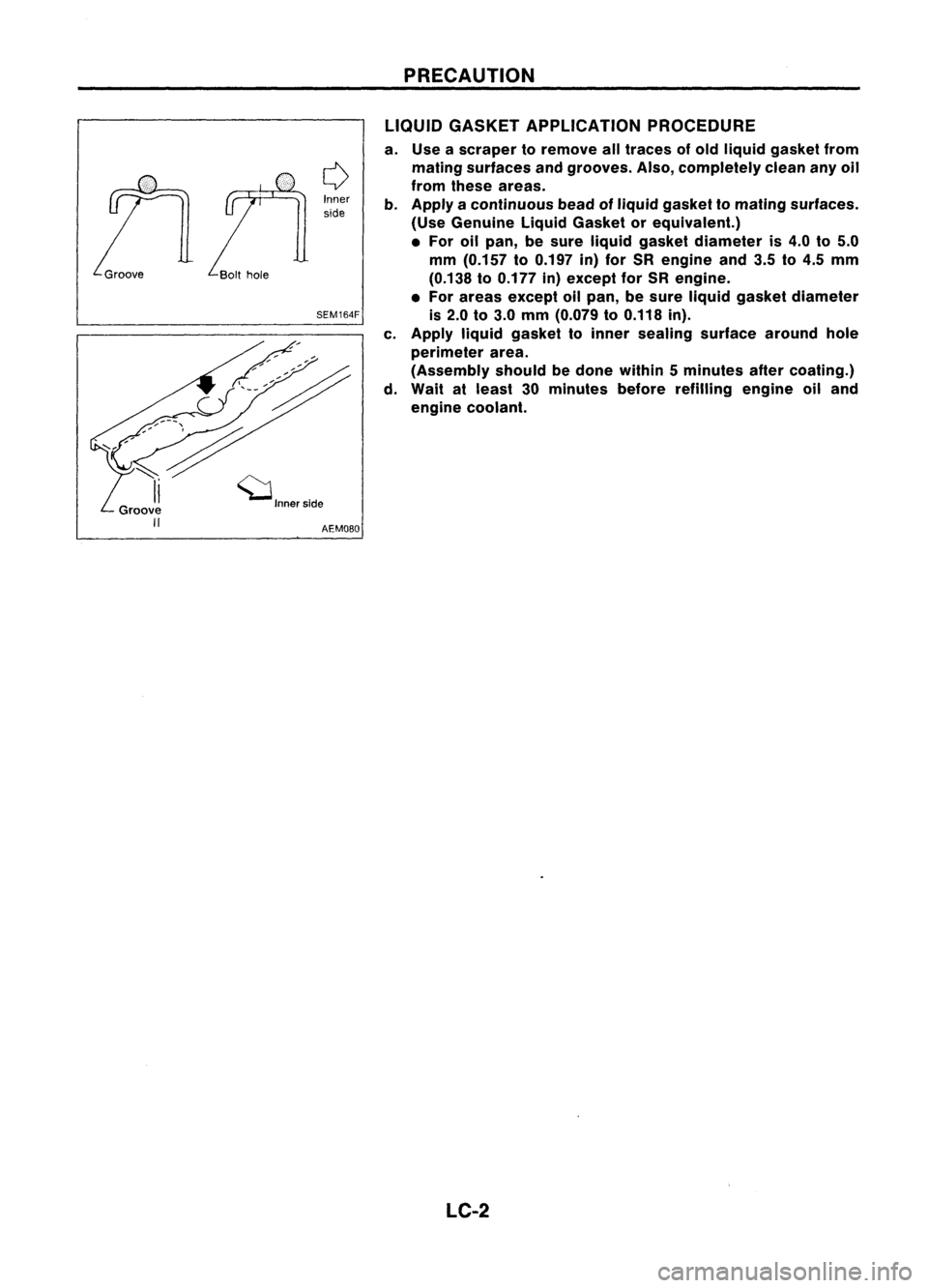

SEM164F PRECAUTION

LIQUID GASKET APPLICATION PROCEDURE

a. Use ascraper toremove alltraces ofold liquid gasket from

mating surfaces andgrooves. Also,completely cleananyoil

from these areas.

b. Apply acontinuous beadofliquid gasket tomating surfaces.

(Use Genuine LiquidGasket orequivalent.)

• For oilpan, besure liquid gasket diameter is4.0 to5.0

mm (0.157 to0.197 in)for SRengine and3.5to4.5 mm

(0.138 to0.177 in)except forSRengine.

• For areas except oilpan, besure liquid gasket diameter

is 2.0 to3.0 mm (0.079 to0.118 in).

c. Apply liquidgasket toinner sealing surface aroundhole

perimeter area.

(Assembly shouldbedone within 5minutes aftercoating.)

d. Wait atleast 30minutes beforerefilling engineoiland

engine coolant.

LC-2

Page 1151 of 1701

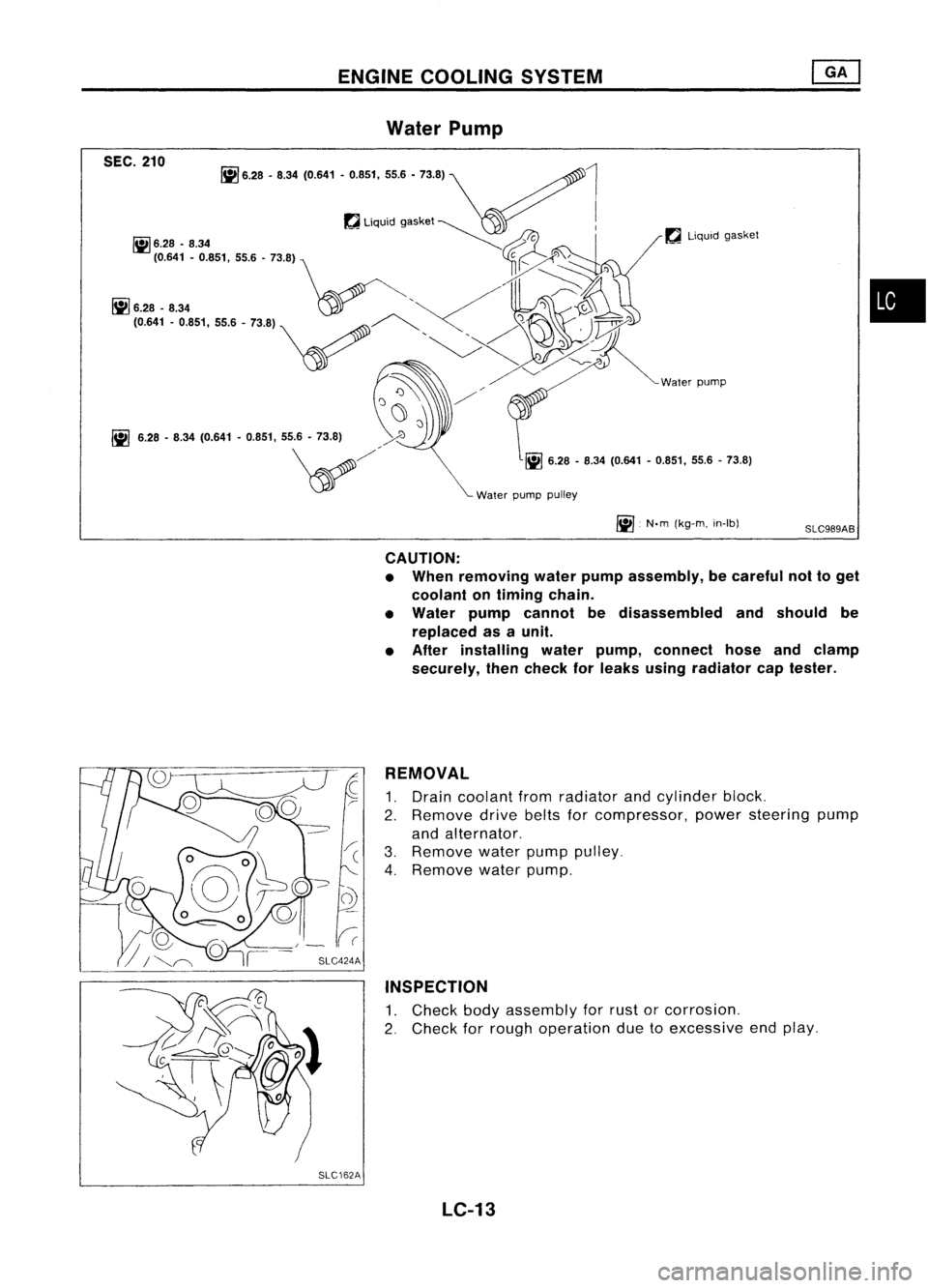

ENGINECOOLING SYSTEM

IiJ

6.28 -8.34 (0.641 -0.851, 55.6-73.8)

SEC.

210 Water

Pump

~ 6.28 -8.34 (0.641 -0.851, 55.6-73.8)

WaterpumppUlley

l

~Liquid gasket

~ N.m(kg-m, in-Ib)

SLC989AB

•

CAUTION:

• When removing waterpumpassembly, becareful nottoget

coolant ontiming chain.

• Water pumpcannot bedisassembled andshould be

replaced asaunit.

• After installing waterpump, connect hoseandclamp

securely, thencheck forleaks using radiator captester.

REMOVAL

1. Drain coolant fromradiator andcylinder block.

2. Remove drivebeltsforcompressor, powersteering pump

and alternator.

3. Remove waterpumppulley.

4. Remove waterpump.

INSPECTION

1. Check bodyassembly forrust orcorrosion.

2. Check forrough operation duetoexcessive endplay.

SLC162A LC-13

Page 1154 of 1701

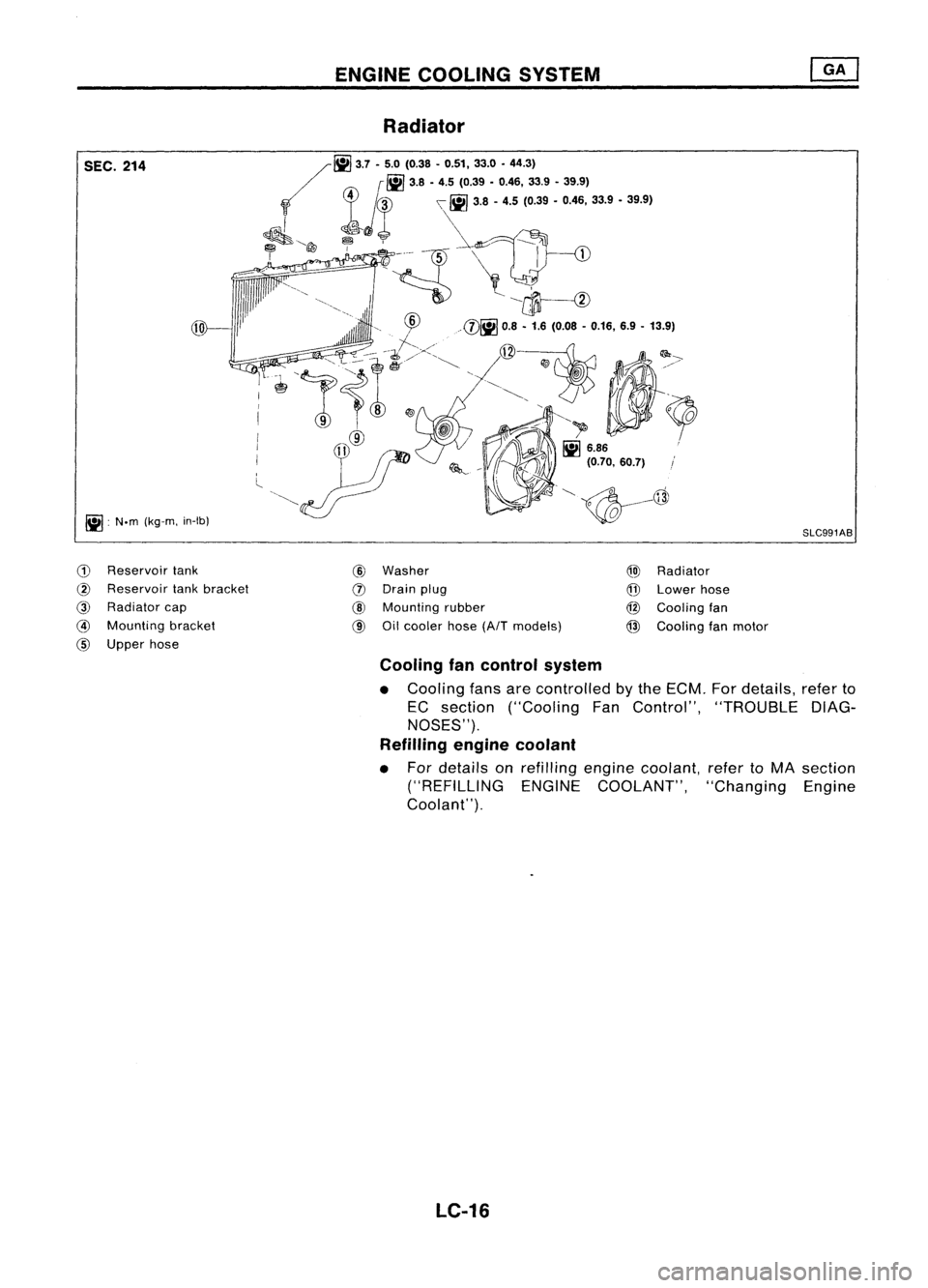

SEC.214

10

~ :N.m (kg-m, in-Ib)

ENGINE

COOLING SYSTEM

Radiator

~~ 3.7.5.0(0.38-0.51, 33.0•44.3)

~~ 3.8.4.5 (0.39 •0.46, 33.9.39.9)

. I

L!

\[jj

3.'-4.5 (0.39 -0.45,3>' -39.')

~,,~ 'fl

'~~WI-

I

--

5'\

,

),

"~

" It, -~ ~,.../ "---./"-- ~~

n.- /

i ~

r~ ~ ~'".~

i

@

'0)"

I

I

Jl~J)

1~~

6.86 •

~ "" <>!.

0

(0.70,60.7)

",,~~@

SLC991AB

G)

Reservoir tank

@

Reservoir tankbracket

@

Radiator cap

@

Mounting bracket

@

Upper hose

@

Washer

(J)

Drain plug

@

Mounting rubber

@

Oilcooler hose(AfTmodels)

@l

Radiator

@

Lower hose

@

Cooling fan

@

Cooling fanmotor

Cooling fancontrol system

• Cooling fansarecontrolled bythe ECM. Fordetails, referto

EC section ("Cooling FanControl", "TROUBLE DIAG-

NOSES").

Refilling enginecoolant

• For details onrefilling enginecoolant, refertoMA section

("REFILLING ENGINECOOLANT", "ChangingEngine

Coolant").

LC-16