coolant NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1160 of 1701

A16-21

N.m ~/

(1.6 •2.1 kg-m,

12 -15

ft.lb)

ENGINE

COOLING SYSTEM

Cooling SystemInspection (Cont'd)

Pull thenegative pressure valvetoopen it.

Check thatitcloses completely whenreleased.

CHECKING COOLINGSYSTEMFORLEAKS

To check forleakage, applypressure tothe cooling systemwith

a tester.

Testing pressure:

157 kPa (1.57 bar,1.6kg/cm

2,

23psi)

CAUTION:

Higher thanthespecified pressuremaycause radiator damage.

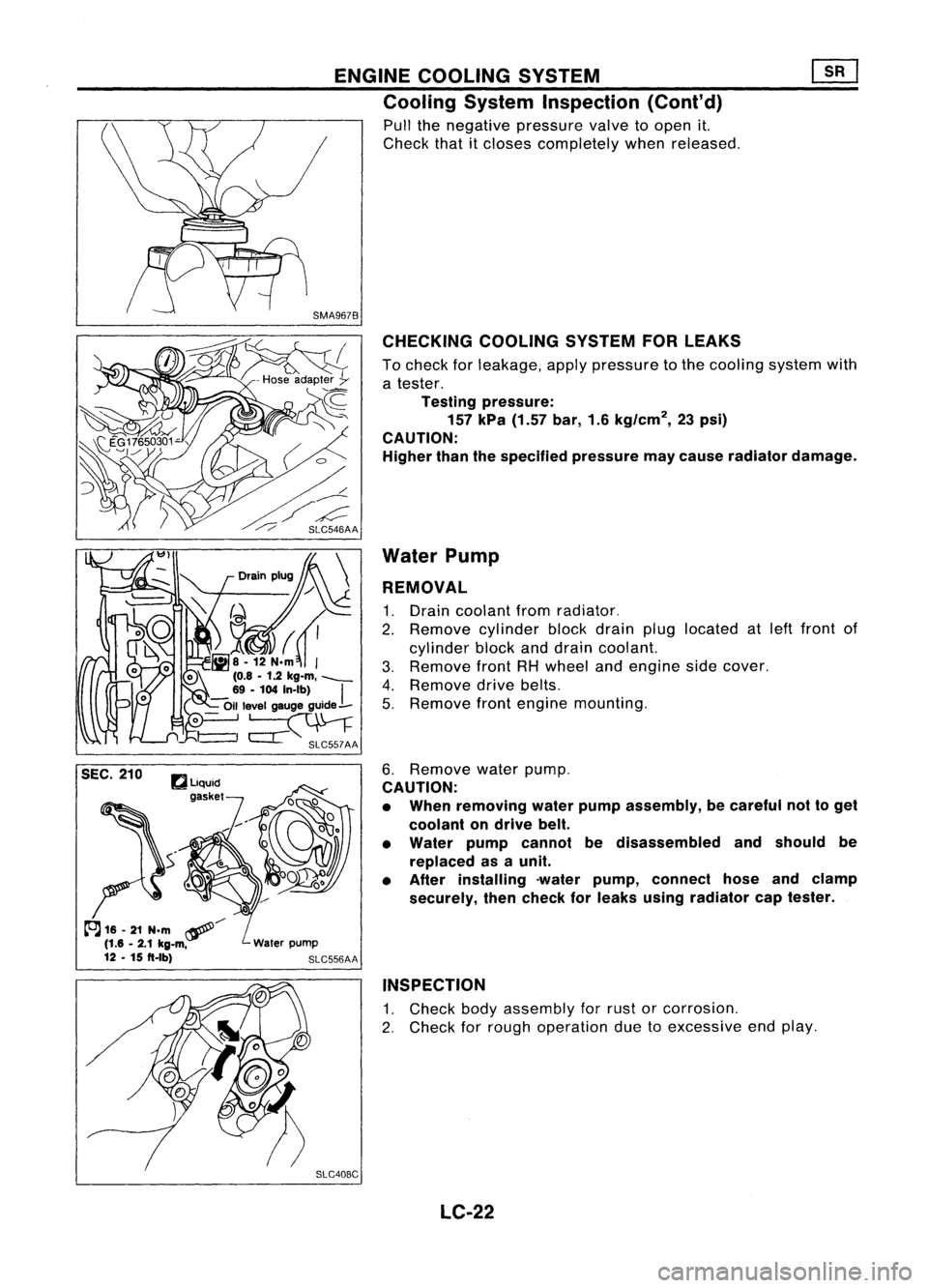

Water Pump

REMOVAL

1. Drain coolant fromradiator.

2. Remove cylinderblockdrain pluglocated atleft front of

cylinder blockanddrain coolant.

3. Remove frontRHwheel andengine sidecover.

4. Remove drivebelts.

5. Remove frontengine mounting.

6. Remove waterpump.

CAUTION:

• When removing waterpumpassembly, becareful nottoget

coolant ondrive belt.

• Water pumpcannot bedisassembled andshould be

replaced asaunit.

• After installing -waterpump, connect hoseandclamp

securely, thencheck forleaks using radiator captester.

INSPECTION

1. Check bodyassembly forrust orcorrosion.

2. Check forrough operation duetoexcessive endplay.

SLC408C LC-22

Page 1162 of 1701

ENGINECOOLING SYSTEM ~

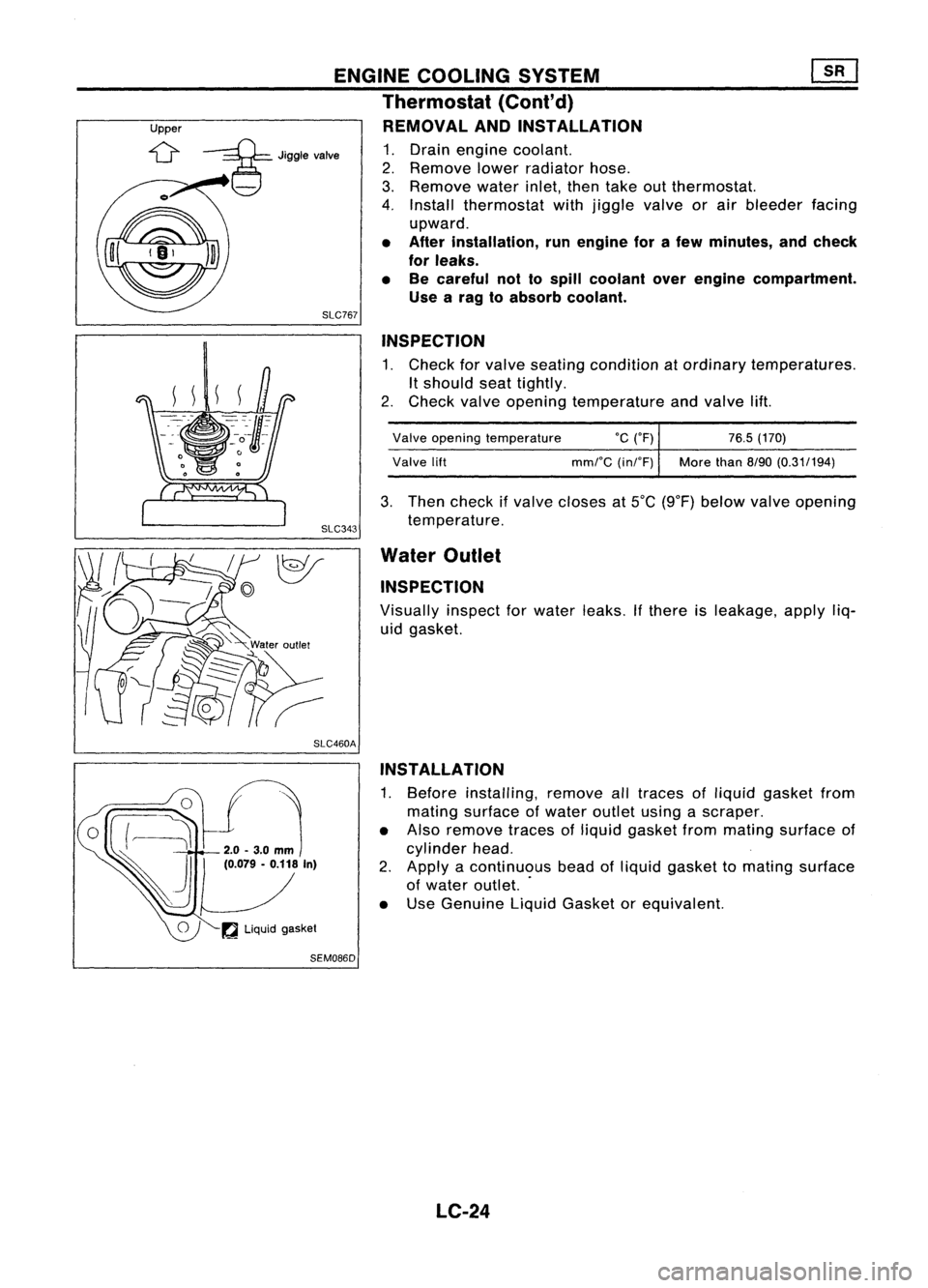

Thermostat

(Cont'd)

Upper REMOVALANDINSTAllATION

;::g=

Jigglevalve

1.Drain engine coolant.

2. Remove lowerradiator hose.

3. Remove waterinlet,thentake outthermostat.

4. Install thermostat withjiggle valveorair bleeder facing

upward.

• After installation, runengine forafew minutes, andcheck

for leaks.

• Becareful nottospill coolant overengine compartment.

Use arag toabsorb coolant.

SLC767

INSPECTION

1. Check forvalve seating condition atordinary temperatures.

It

should seattightly.

2. Check valveopening temperature andvalve lift.

Valve opening temperature

°c

(OF) 76.5(170)

Valve lift mmrC(inrF) Morethan

8/90(0.31/194)

3. Then check ifvalve closes at5°C (9°F) below valveopening

temperature.

Water Outlet

INSPECTION

Visually inspectforwater leaks.

If

there isleakage, applyliq-

uid gasket.

SLC460A INSTAllATION

1. Before installing, removealltraces ofliquid gasket from

mating surface ofwater outlet usingascraper.

• Also remove tracesofliquid gasket frommating surface of

cylinder head.

2. Apply acontinuous beadofliquid gasket tomating surface

of water outlet. .

• Use Genuine LiquidGasket orequivalent.

~ Liquid gasket

SEM086D

LC-24

Page 1163 of 1701

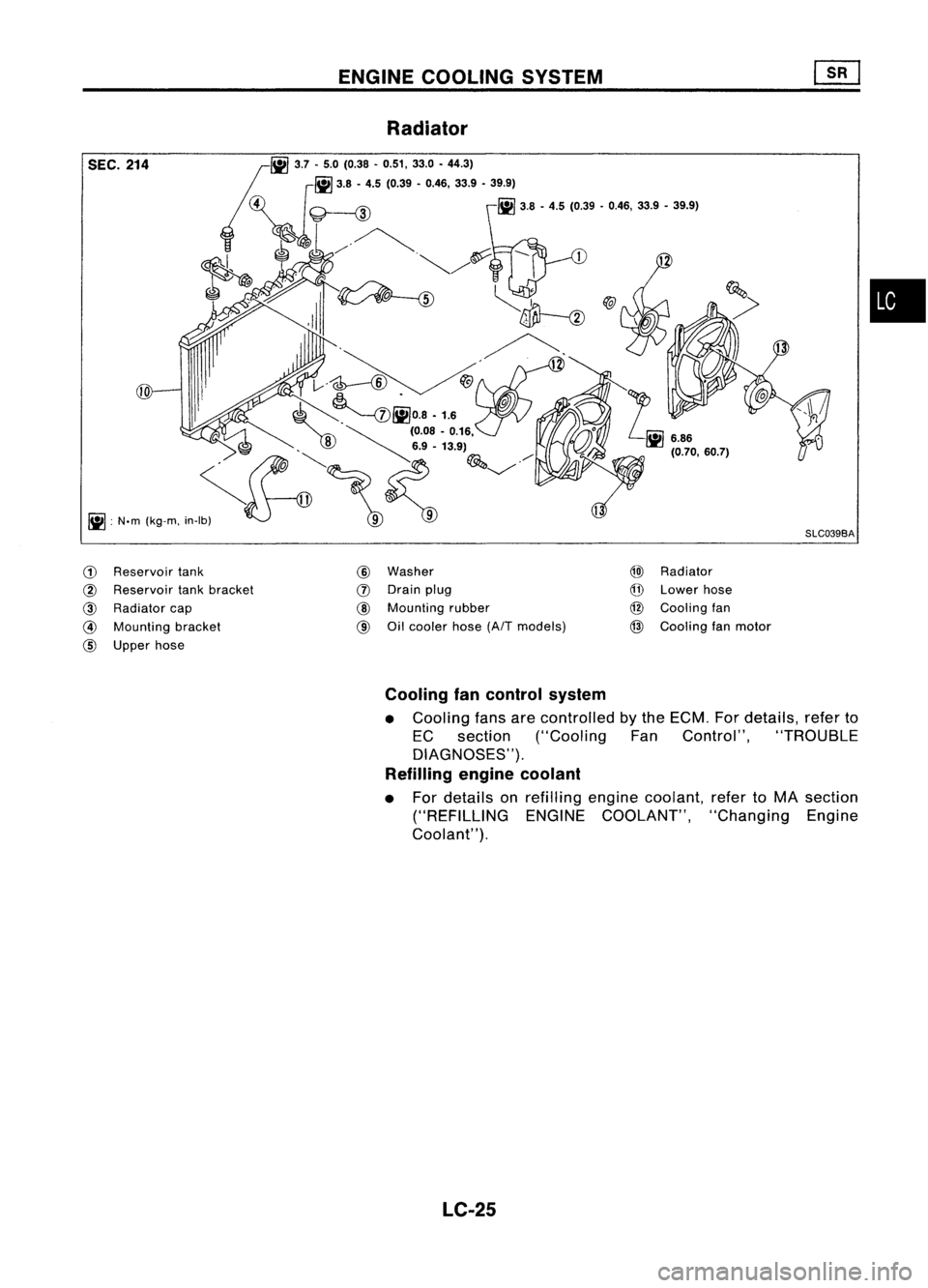

SEC.214

10

ENGINE

COOLING SYSTEM

Radiator

SLC039BA

•

CD

Reservoir tank

@

Reservoir tankbracket

@

Radiator cap

@

Mounting bracket

CID

Upper hose

@

Washer

(J)

Drain plug

CID

Mounting rubber

@

Oilcooler hose

(AfT

models)

@)

Radiator

@

Lower hose

@

Cooling fan

@

Cooling fanmotor

Cooling fancontrol system

• Cooling fansarecontrolled bythe ECM. Fordetails, referto

EC section ("Cooling FanControl", "TROUBLE

DIAGNOSES").

Refilling enginecoolant

• For details onrefilling enginecoolant, refertoMA section

("REFILLING ENGINECOOLANT", "ChangingEngine

Coolant").

LC-25

Page 1165 of 1701

ENGINELUBRICATION SYSTEM

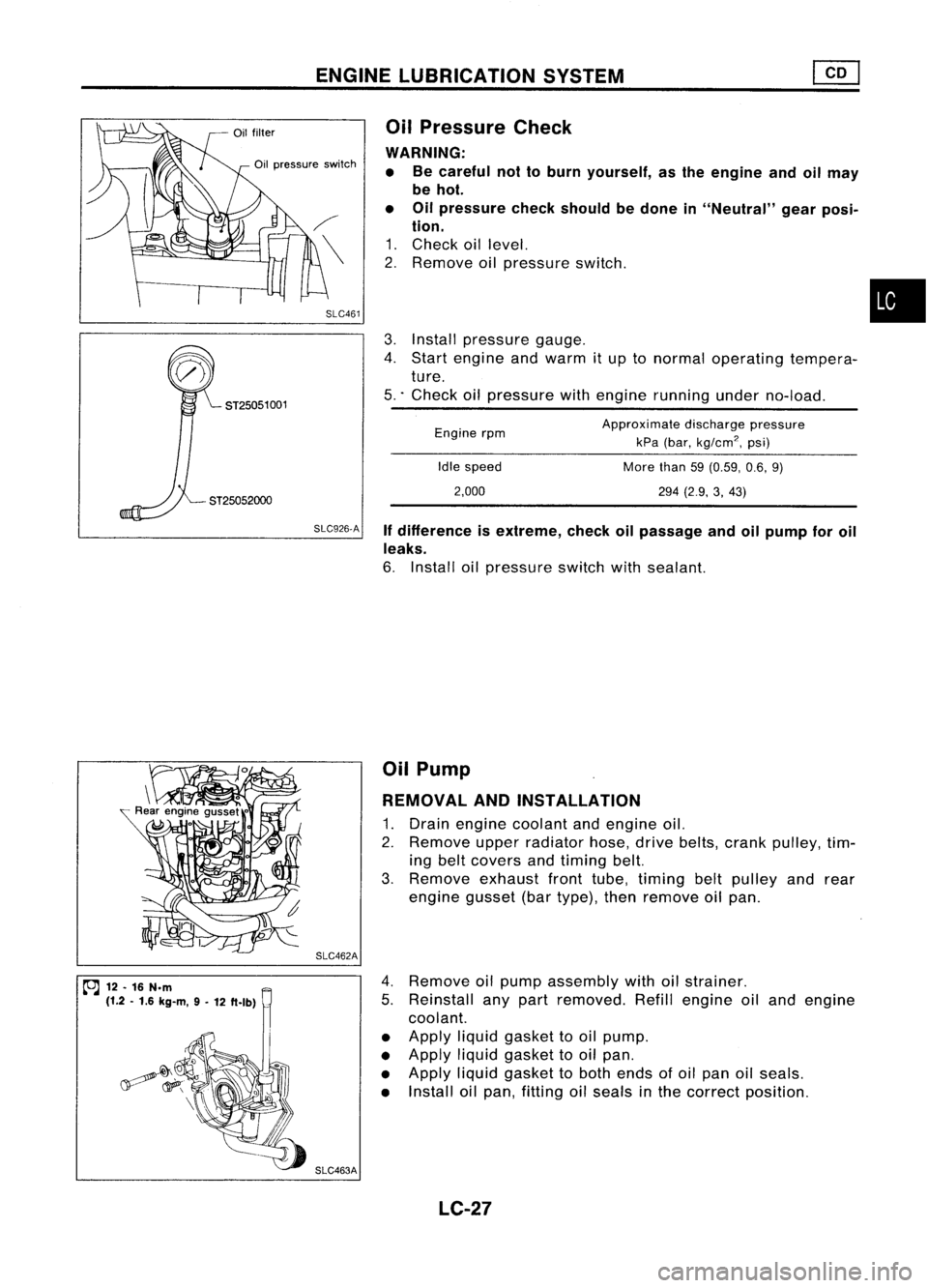

SLC926.A Ifdifference isextreme, checkoilpassage andoilpump foroil

leaks.

6. Install oilpressure switchwithsealant.

ST25052000

3.

Install pressure gauge.

4. Start engine andwarm itup tonormal operating tempera-

ture.

5 .. Check oilpressure withengine running underno-load.

•

Approximate dischargepressure

kPa (bar,

kg/cm

2,

psi)

More than59(0.59, 0.6,9)

294 (2.9, 3,43)

Idle

speed

2,000

Engine

rpm

Oil

Pressure Check

WARNING: • Becareful nottoburn yourself, asthe engine andoilmay

be hot.

• Oilpressure checkshould bedone in"Neutral" gearposi-

tion.

1. Check oillevel.

2. Remove oilpressure switch.

SLC461

Oil

pressure switch

ST25051 001

~ 12.16 N.m

(1.2 .1.6 kg-m, 9-

12 ft.lb) SLC462A

SLC463A Oil

Pump

REMOVAL ANDINSTAllATION

1. Drain engine coolant andengine oil.

2. Remove upperradiator hose,drivebelts, crank pulley, tim-

ing belt covers andtiming belt.

3. Remove exhaustfronttube, timing beltpulley andrear

engine gusset(bartype), thenremove oilpan.

4. Remove oilpump assembly withoilstrainer.

5. Reinstall anypart removed. Refillengine oiland engine

coolant.

• Apply liquidgasket tooil pump.

• Apply liquidgasket tooil pan.

• Apply liquidgasket toboth ends ofoil pan oilseals.

• Install oilpan, fitting oilseals inthe correct position.

LC-27

Page 1168 of 1701

ENGINELUBRICATION SYSTEM

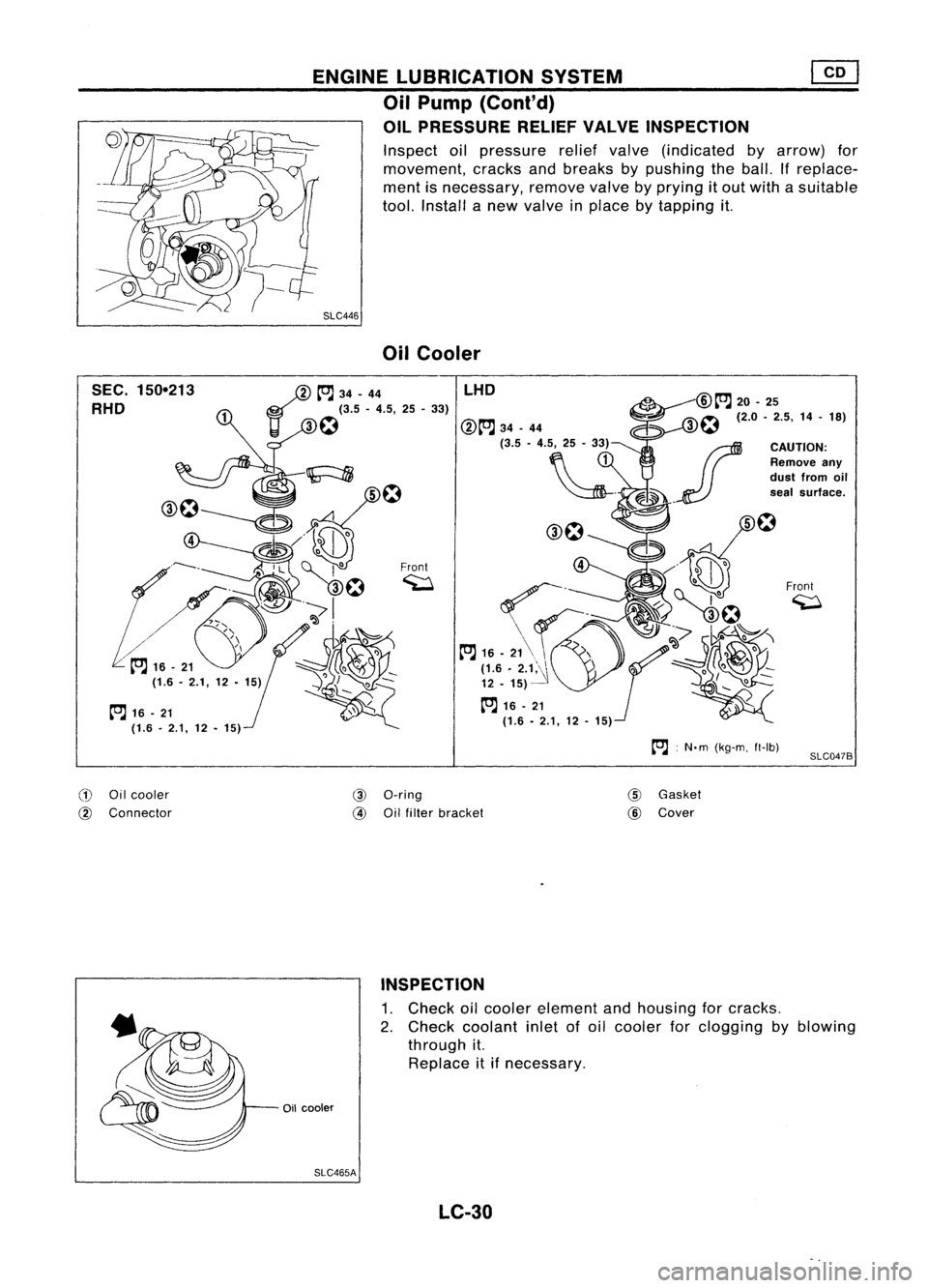

Oil Pump (Cont'd)

OIL PRESSURE RELIEFVALVEINSPECTION

Inspect oilpressure reliefvalve (indicated byarrow) for

movement, cracksandbreaks bypushing theball. Ifreplace-

ment isnecessary, removevalvebyprying itout with asuitable

tool. Install anew valve inplace bytapping it.

SLC446 OilCooler

SEC. 150-213

RHO

tOJ

16-21

(1.6. 2.1,12•15)

/

tOJ

34-44

11 ~

f:1

(3.5 -4.5, 25-33)

Front ~ LHO

:N.m (kg-m, ft-Ib)

Front

~

SLC047B

CD

Oilcooler

@

Connector

@

a-ring

@

Oilfilter bracket

@

Gasket

@

Cover

INSPECTION

1. Check oilcooler element andhousing forcracks.

2. Check coolant inletofoil cooler forclogging byblowing

through it.

Replace itifnecessary.

Oil cooler

SLC465A LC-30

Page 1171 of 1701

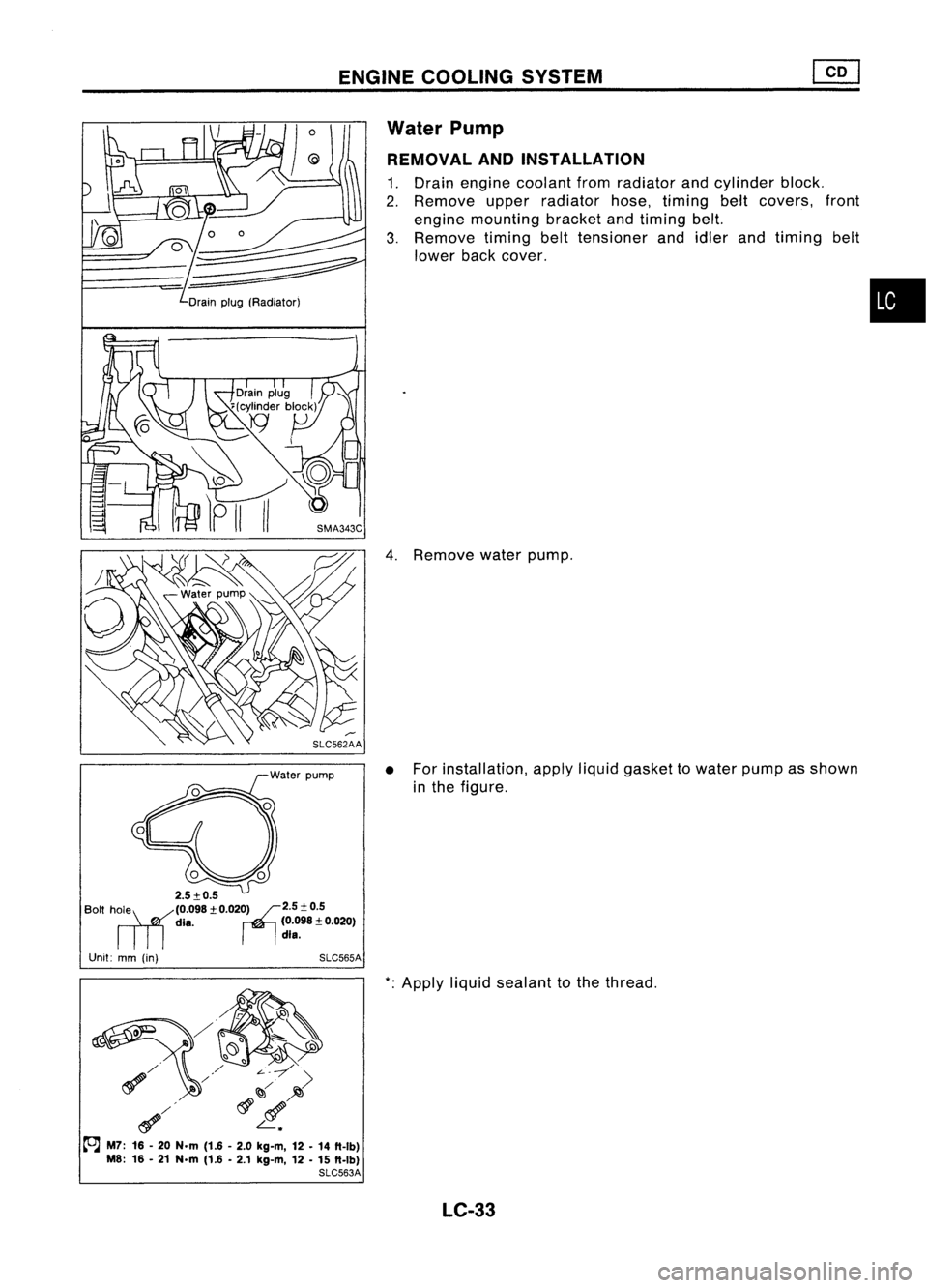

ENGINECOOLING SYSTEM

Water Pump

REMOVAL ANDINSTALLATION

1. Drain engine coolant fromradiator andcylinder block.

2. Remove upperradiator hose,timing beltcovers, front

engine mounting bracketandtiming belt.

3. Remove timingbelttensioner andidler andtiming belt

lower backcover.

~

Drain plug(Radiator)

4.Remove waterpump.

• For installation, applyliquidgasket towater pumpasshown

in the figure.

2.5:!:0.5

Bolt hRille (0.098:!:0.020r12.5:!: 0.5

die. (0.098:!:0.020)

dIe.

Unit: mm(in) SLC565A

*:

Apply liquidsealant tothe thread.

~/ ~~;>

~/ ~l!.

to.J

M7: 16-20 N.m (1.6-2.0 kg-m, 12-14 ft-Ib)

M8: 16-21 N.m (1.6-2.1 kg-m, 12-15 ft-Ib)

SLC563A

LC-33

•

Page 1174 of 1701

ENGINECOOLING SYSTEM

@J

Radiator (Cont'd)

Cooling fancontrol system

• Cooling fansarecontrolled bythe ECM. Fordetails, referto

EC section

("Cooling

FanControl", "TROUBLE

DIAGNOSES").

Refilling enginecoolant

• For details onrefilling enginecoolant, refertoMA section

("REFILLING ENGINECOOLANT", "ChangingEngine

Coolant").

LC-36

Page 1182 of 1701

Innerside

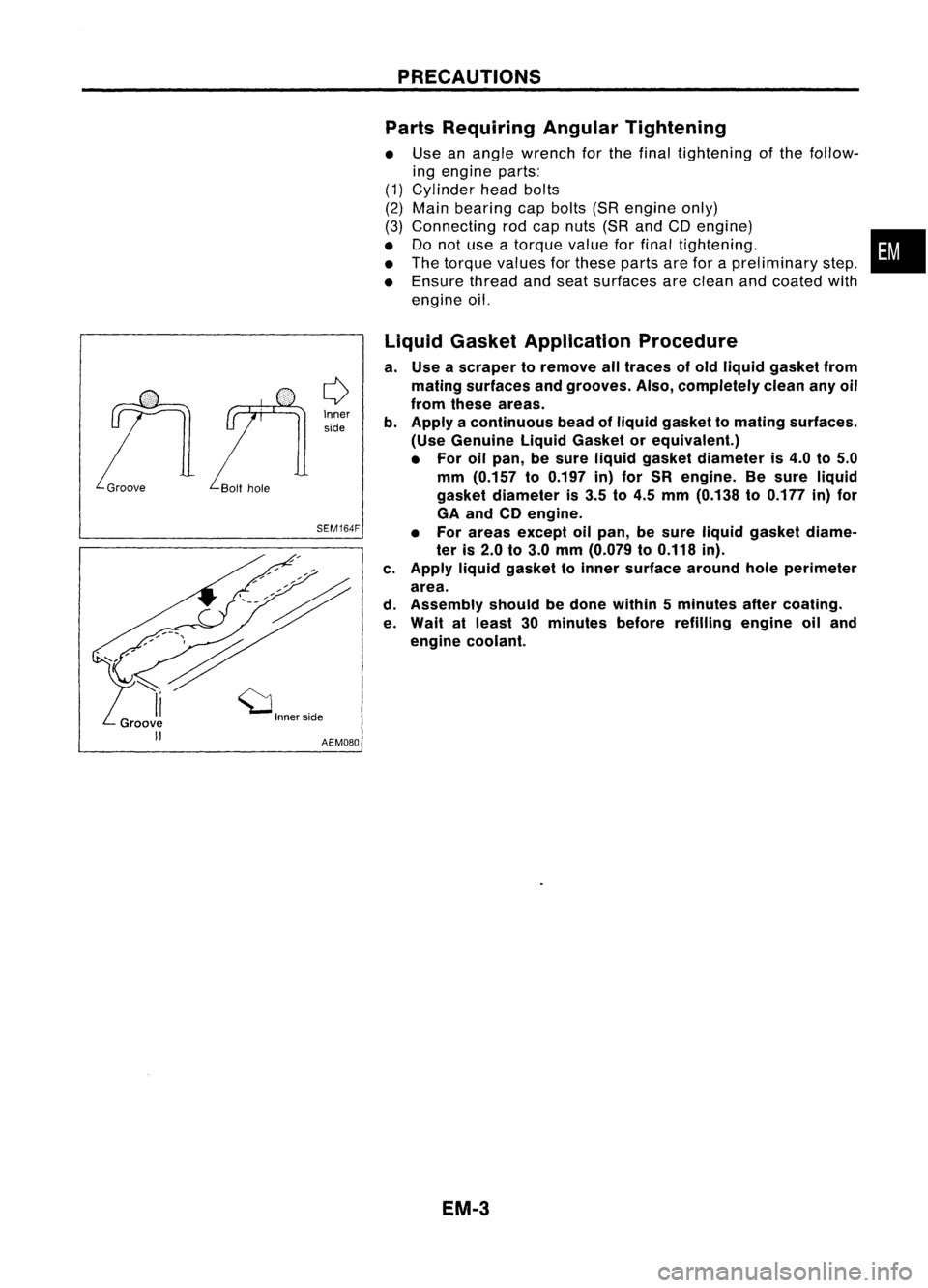

SEM164F PRECAUTIONS

Parts Requiring AngularTightening

• Use anangle wrench forthe final tightening ofthe follow-

ing engine parts:

(1) Cylinder headbolts

(2) Main bearing capbolts (SRengine only)

(3) Connecting rodcap nuts (SRand CDengine)

• Donot use atorque valueforfinal tightening. •

• The torque values forthese partsareforapreliminary step.

• Ensure threadandseat surfaces areclean andcoated with

engine oil.

Liquid Gasket Application Procedure

a. Use ascraper toremove alltraces ofold liquid gasket from

mating surfaces andgrooves. Also,completely cleananyoil

from these areas.

b. Apply acontinuous beadofliquid gasket tomating surfaces.

(Use Genuine LiquidGasket orequivalent.)

• For oilpan, besure liquid gasket diameter is4.0 to5.0

mm (0.157 to0.197 in)for SR engine. Besure liquid

gasket diameter is3.5 to4.5 mm (0.138 to0.177 in)for

GA and CDengine.

• For areas except oilpan, besure liquid gasket diame-

ter is2.0 to3.0 mm (0.079 to0.118 in).

c. Apply liquidgasket toinner surface aroundholeperimeter

area.

d. Assembly shouldbedone within 5minutes aftercoating.

e. Wait atleast 30minutes beforerefilling engineoiland

engine coolant.

EM.3

Page 1189 of 1701

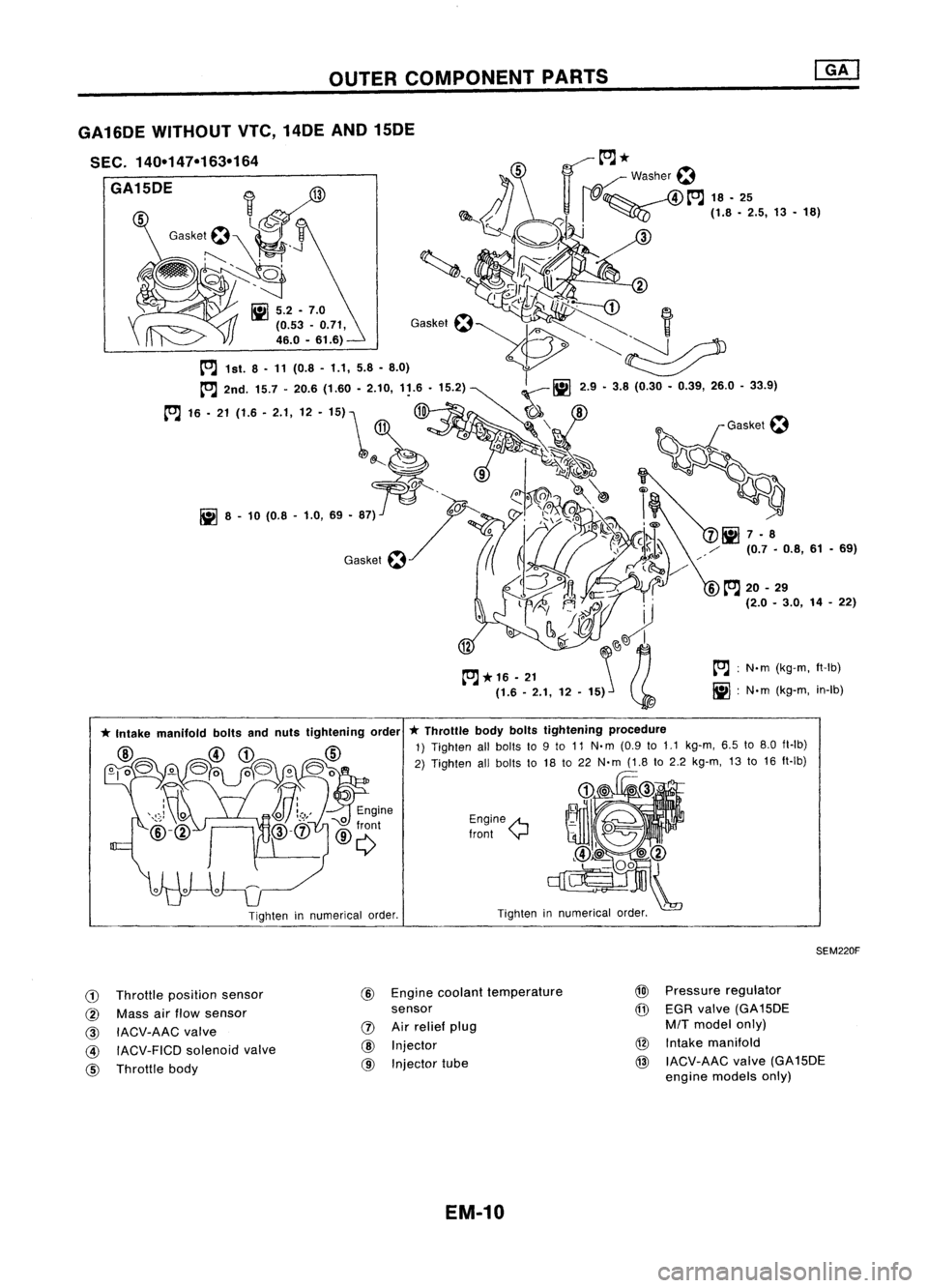

OUTERCOMPONENT PARTS

tOJ:

N.m (kg-m, ft-Ib)

iii :

N'm (kg-m, in-Ib)

Tighten innumerical order.

Engine

A

Iront

y

*

Throttle bodyboltstightening procedure

1) Tighten allbolts to9to 11 N.m (0.9 to

1.1

kg-m, 6.5to8.0 fl-Ib)

2) Tighten allbolts to18 to22 N'm (1.8to2.2 kg-m, 13to16 ft-Ib)

Tighten innumerical order.

GA16DE

WITHOUT VTe,14DE AND15DE

SEC. 140-147-163-164

GA15DE

SEM220F

CD

Throttle position sensor

@ Mass airflow sensor

@

IACV-AAC valve

@ IACV-FICD solenoidvalve

@ Throttle body @

Engine coolant temperature

sensor

IJ)

Airrelief plug

@

Injector

@ Injector tube

@l

Pressure regulator

@

EGR valve (GA15DE

M/T

model only)

@ Intake manifold

@ IACV-AAC valve(GA15DE

engine models only)

EM-10

Page 1199 of 1701

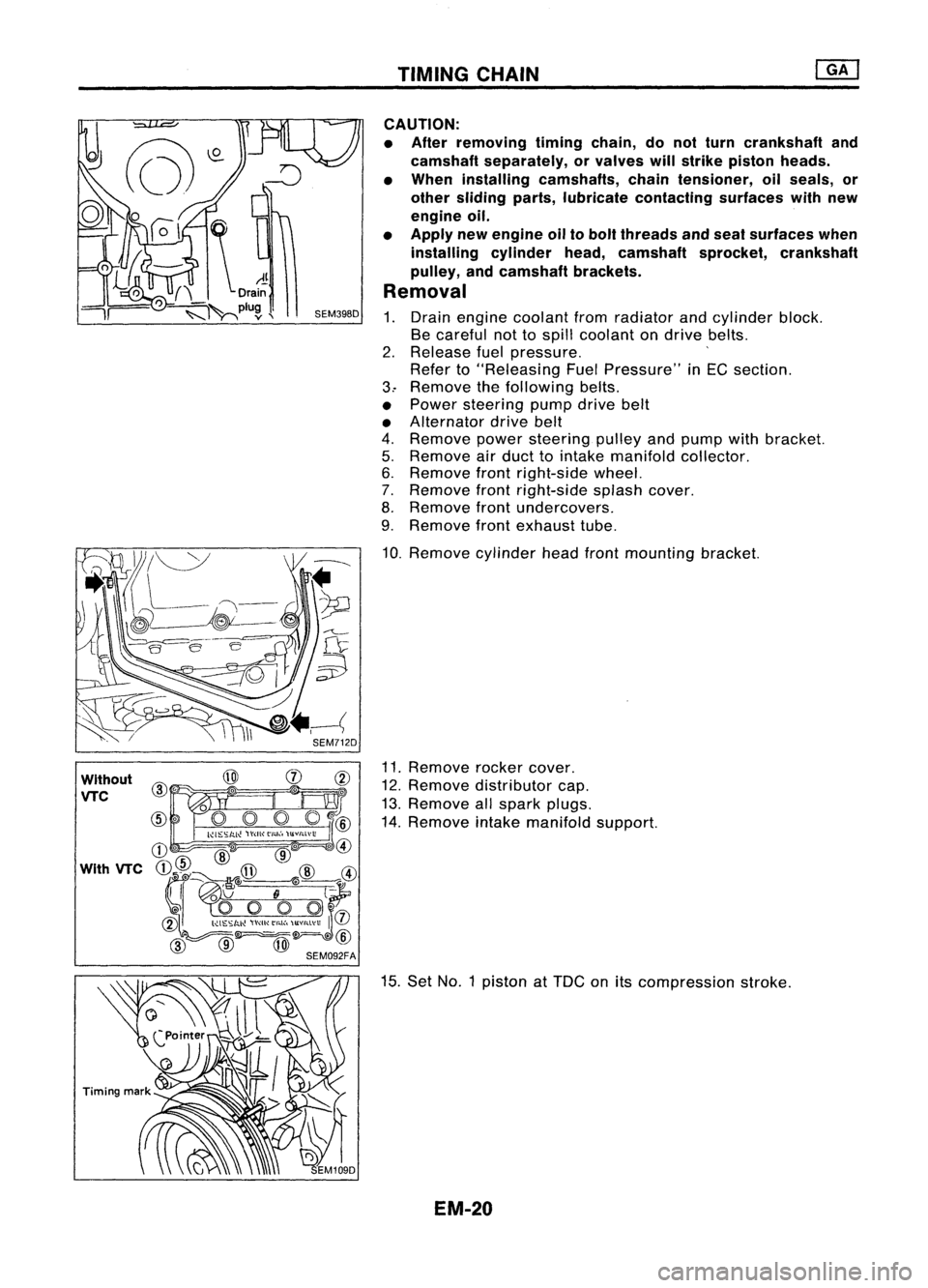

TIMINGCHAIN

Without

VTC

CAUTION:

• After removing timingchain,donot turn crankshaft and

camshaft separately, orvalves willstrike piston heads.

• When installing camshafts, chaintensioner, oilseals, or

other sliding parts,lubricate contacting surfaceswithnew

engine oil.

• Apply newengine oiltobolt threads andseat surfaces when

installing cylinderhead,camshaft sprocket,crankshaft

pulley, andcamshaft brackets.

Removal

1. Drain engine coolant fromradiator andcylinder block.

Be careful nottospill coolant ondrive belts.

2. Release fuelpressure. '

Refer to"Releasing FuelPressure" inEG section.

3.. Remove thefollowing belts.

• Power steering pumpdrivebelt

• Alternator drivebelt

4. Remove powersteering pulleyandpump withbracket.

5. Remove airduct tointake manifold collector.

6. Remove frontright-side wheel.

7. Remove frontright-side splashcover.

8. Remove frontundercovers.

9. Remove frontexhaust tube.

10. Remove cylinderheadfrontmounting bracket.

11. Remove rockercover.

12. Remove distributor cap.

13. Remove allspark plugs.

14. Remove intakemanifold support.

15. Set NO.1 piston at

TOG

onitscompression stroke.

EM-20