engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 764 of 1701

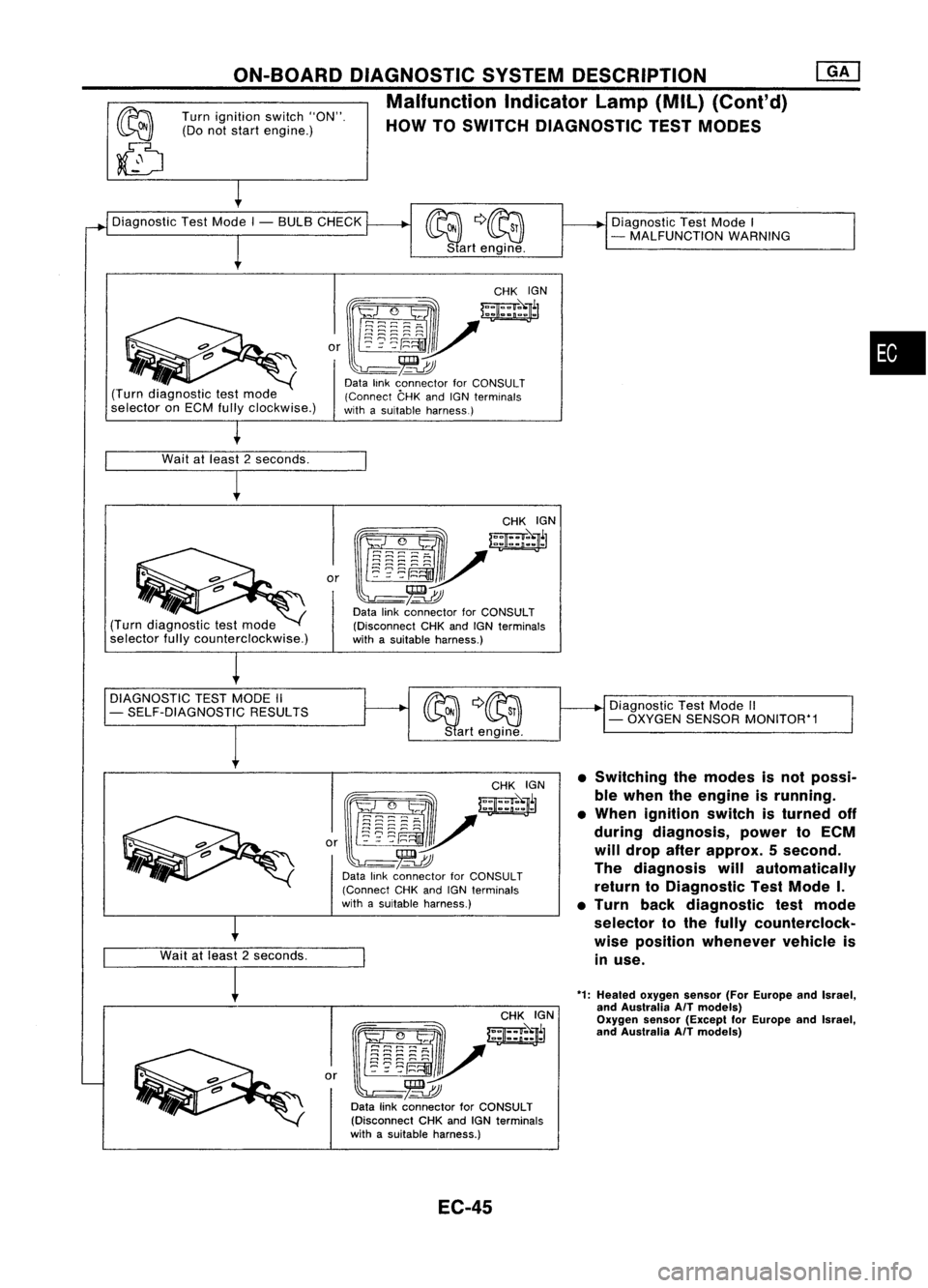

Turnignition switch"ON".

(Do notstart engine.)

ON-BOARD

DIAGNOSTIC SYSTEMDESCRIPTION

Malfunction Indicatorlamp(Mil)(Cont'd)

HOW TOSWITCH DIAGNOSTIC TESTMODES

Diagnostic TestMode I- BULB CHECK

DiagnosticTestMode I

- MALFUNCTION WARNING

(Turn diagnostic testmode

selector onECM fullyclockwise.)

o,~yr;;~N

~-~

Data linkconnector forCONSULT

(Connect CHKandIGNterminals

with asuitable harness.)

•

Wait atleast 2seconds.

(Turn diagnostic testmode

selector fullycounterclockwise.)

O,~/~N

~-~

Data linkconnector forCONSULT

(Disconnect CHKandIGNterminals

with asuitable harness.)

DIAGNOSTIC TESTMODE II ~

Q~

- SELF-DIAGNOSTIC RESULTS ON~

S art engine. Diagnostic

TestMode II

- OXYGEN SENSOR MONITOR*1

Wait atleast 2seconds.

1

*1:

Heated oxygen sensor(ForEurope andIsrael,

and Australia AfTmodels)

Oxygen sensor(Except forEurope andtsrael,

and Australia AfTmodels)

•

Switching themodes isnot possi-

ble when theengine isrunning.

• When ignition switchisturned off

during diagnosis, powertoECM

will drop afterapprox. 5second.

The diagnosis willautomatically

return toDiagnostic TestMode I.

• Turn backdiagnostic testmode

selector tothe fully counterclock-

wise position whenever vehicleis

in use.

~~Ol

W:jr

g2g~E;V

~~~;::

or

-~

Data linkconnector forCONSULT

(Disconnect CHKandIGNterminals

with asuitable harness.)

[gJ~~~~~~

~~r

0'

~!~~:V

-~

Data linkconnector forCONSULT

(Connect CHKandIGNterminals

with asuitable harness.)

EC-45

Page 765 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION @KJ

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE I-BULB CHECK

In this mode, theMALFUNCTION INDICATORLAMPonthe instrument panelshould stayON.Ifitremains

OFF, check thebulb. Refer toEL section ("WARNING LAMPSANDCHIME") orsee EC-223.

DIAGNOSTIC TESTMODE I-MALFUNCTION WARNING

MALFUNCTION INDICATORLAMP

ON

OFF Condition

Engine coolant temperature sensorcircuitmalfunction oroverheating isdetected, or

the ECM's CPUismalfunctioning.

No malfunction.

• These Diagnostic TroubleCodeNumbers areclarified inDiagnostic TestMode II(SELF-DIAGNOS-

TIC RESULTS).

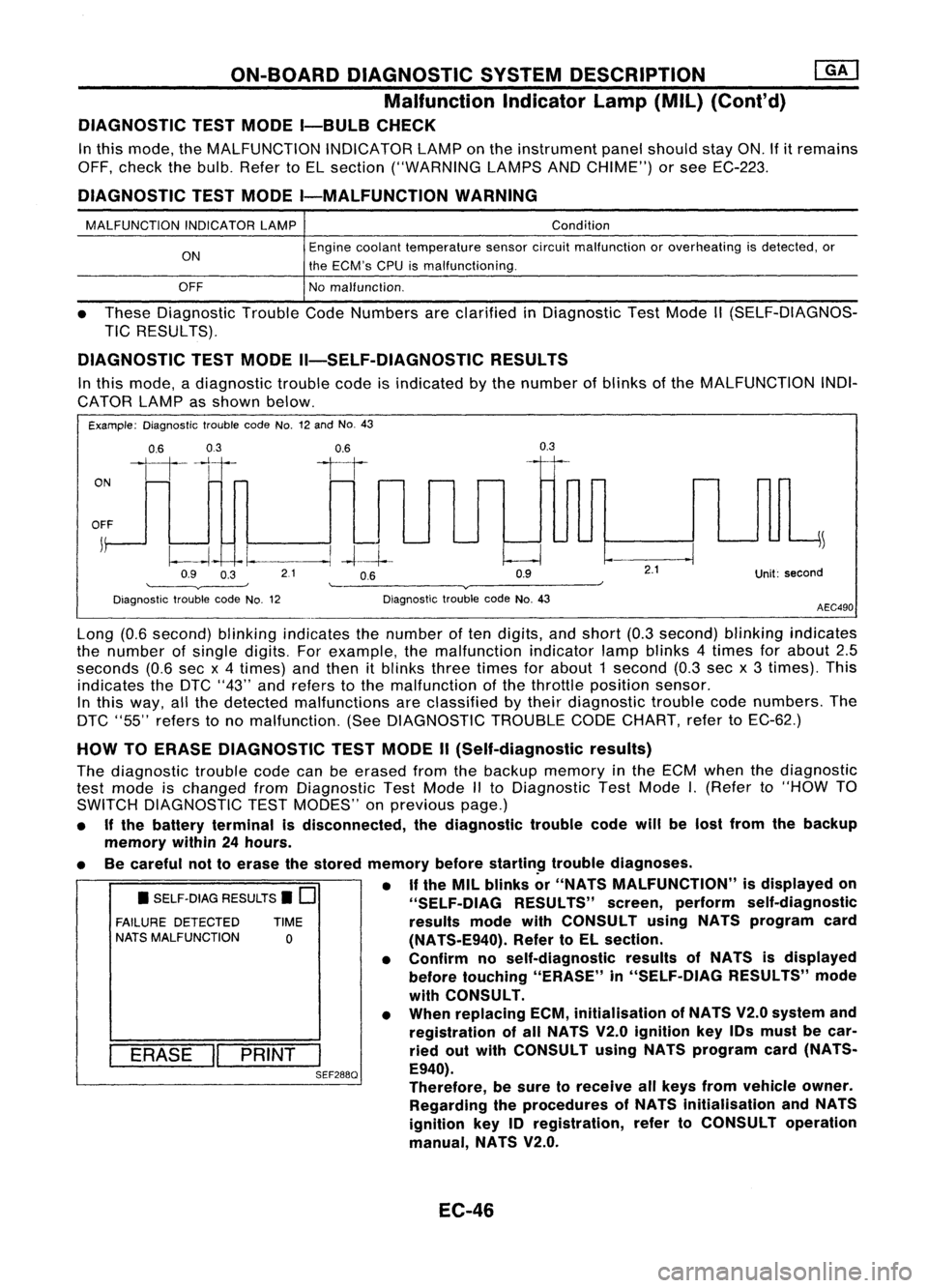

DIAGNOSTIC TESTMODE II-SELF-DIAGNOSTIC RESULTS

In this mode, adiagnostic troublecodeisindicated bythe number ofblinks ofthe MALFUNCTION INDI-

CATOR LAMPasshown below.

Example: Diagnostic troublecodeNo.12and No.43

ON

0.6

03

111-'1

0.6

II

0.3

OFF

j

~

~~ -I.

--.1

-4--1--

Q9 O~ 21 OB Q9

'--------v----' '--------v------~

Diagnostic troublecodeNo.12 DiagnostictroublecodeNo.43

2.1

Unit:second

AEC490

• SELF-DIAG RESULTS.

0

FAILURE DETECTED TIME

NATS MALFUNCTION

0

I

ERASE

II

PRINT

I

SEF288Q

Long

(0.6second) blinkingindicates thenumber often digits, andshort (0.3second) blinkingindicates

the number ofsingle digits. Forexample, themalfunction indicatorlampblinks 4times forabout 2.5

seconds (0.6secx4 times) andthen itblinks threetimes forabout 1second (0.3secx3 times). This

indicates theDTC "43" andrefers tothe malfunction ofthe throttle position sensor.

In this way, allthe detected malfunctions areclassified bytheir diagnostic troublecodenumbers. The

DTC "55" refers tono malfunction. (SeeDIAGNOSTIC TROUBLECODECHART, refertoEC-62.)

HOW TOERASE DIAGNOSTIC TESTMODE II(Self-diagnostic results)

The diagnostic troublecodecanbeerased fromthebackup memory inthe ECM when thediagnostic

test mode ischanged fromDiagnostic TestMode IIto Diagnostic TestMode

I.

(Refer to"HOW TO

SWITCH DIAGNOSTIC TESTMODES" onprevious page.)

• Ifthe battery terminal isdisconnected, thediagnostic troublecodewillbelost from thebackup

memory within24hours.

• Becareful nottoerase thestored memory before

startin~

troublediagnoses.

• If

the MIL blinks or"NATS MALFUNCTION" isdisplayed on

"SELF-OIAG RESULTS"screen,perform self-diagnostic

results modewithCONSULT usingNATS program card

(NATS-E940). RefertoEL section.

• Confirm noself-diagnostic resultsofNATS isdisplayed

before touching "ERASE" in"SELF-DIAG RESULTS"mode

with CONSULT.

• When replacing ECM,initialisation ofNATS V2.0system and

registration ofall NATS V2.0ignition key10smust becar-

ried outwith CONSULT usingNATS program card(NATS-

E940).

Therefore, besure toreceive allkeys from vehicle owner.

Regarding theprocedures ofNATS initialisation andNATS

ignition key10registration, refertoCONSULT operation

manual, NATS V2.0.

EC-46

Page 766 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[QKJ

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-OXYGEN SENSOR*1MONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays thecondition ofthe fuel mixture (leanor

rich) which ismonitored bythe oxygen sensor*1.

MALFUNCTION INDICATORLAMPFuelmixture condition inthe exhaust gas

Airfuel ratio feedback controlcondition

ON Lean

OFF RichClosed

loopsystem

*2 Remains ONorOFF Anycondition

Openloopsystem

*2: Maintains conditions justbefore switching toopen loop.

To check theoxygen sensor*1 function,startengine inDiagnostic TestMode II.Then warm itup until

engine coolant temperature indicatorpointstomiddle ofgauge. •

Next runengine atabout 2,000rpmforabout 2minutes underno-load conditions. Makesurethatthe

MALFUNCTION INDICATORLAMPcomes ONmore than5times within 10seconds withengine running

at 2,000 rpmunder no-load. .

*1: Heated oxygen sensor(ForEurope andIsrael, andAustralia

AfT

models)

Oxygen sensor(Except forEurope andIsrael, andAustralia

AfT

models)

EC-47

Page 767 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

for

CONSULT

E3==/

NISSAN

CONSULT

EE940

+

I !DiI

I

START

I

SUB

MODE

I

SEF253Q

~ SELECT~S_Y_S_T_EM

I

ENGINE----~

SEFS95K

~ SELECT DIAGMODE

lill

WORK SUPPORT

I

SELF-DIAG RESULTS

I

DATA MONITOR

I

ACTIVE TEST

I

ECM PART NUMBER

I

FUNCTION TEST

SEF136PCONSULT

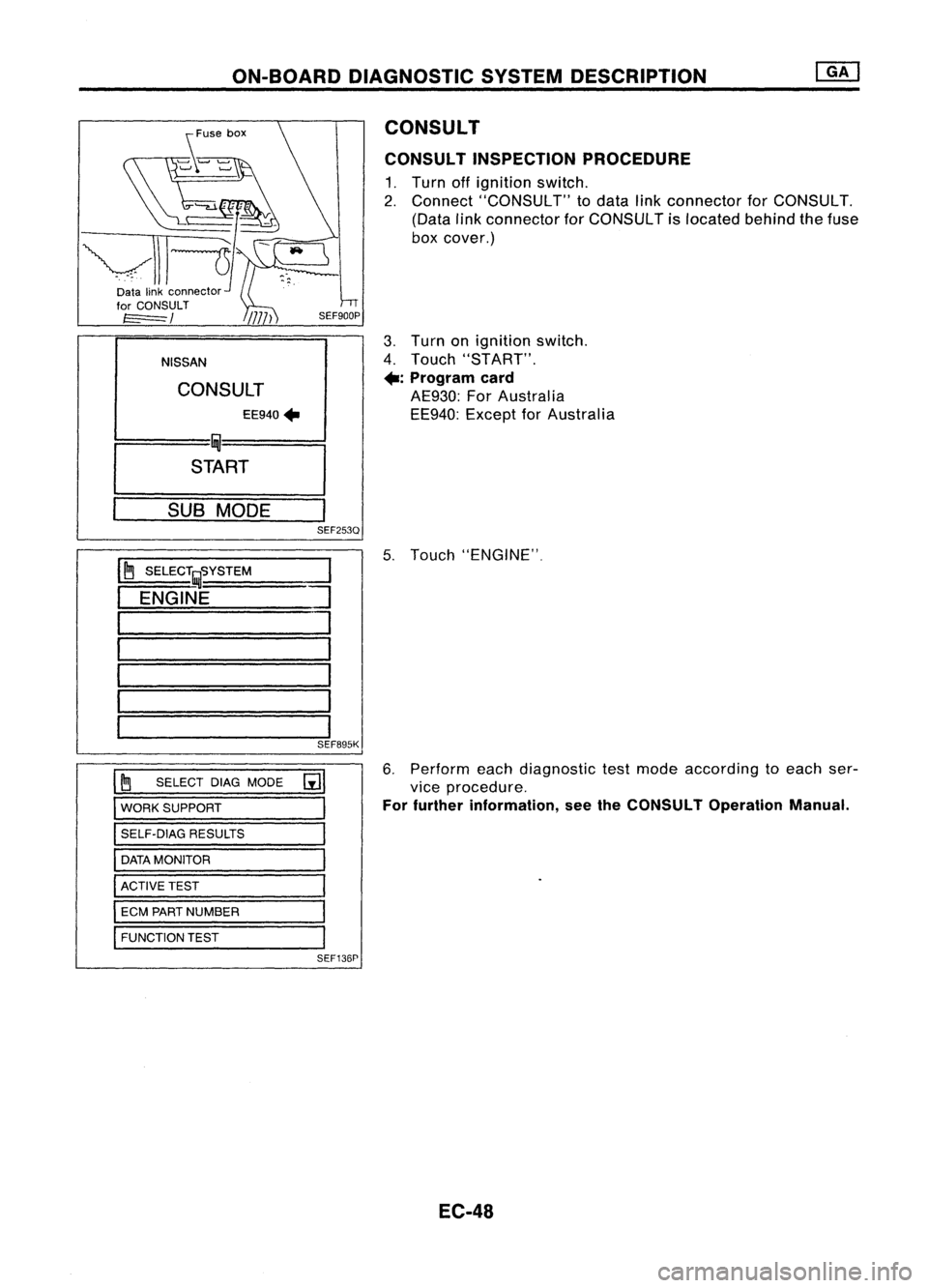

CONSULT INSPECTION PROCEDURE

1. Turn offignition switch.

2. Connect "CONSULT" todata linkconnector forCONSULT.

(Data linkconnector forCONSULT islocated behindthefuse

box cover.)

3. Turn onignition switch.

4. Touch "START".

+:

Program card

AE930: ForAustralia

EE940: ExceptforAustralia

5. Touch "ENGINE".

6. Perform eachdiagnostic testmode according toeach ser-

vice procedure.

For further information, seetheCONSULT OperationManual.

EC-48

Page 768 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

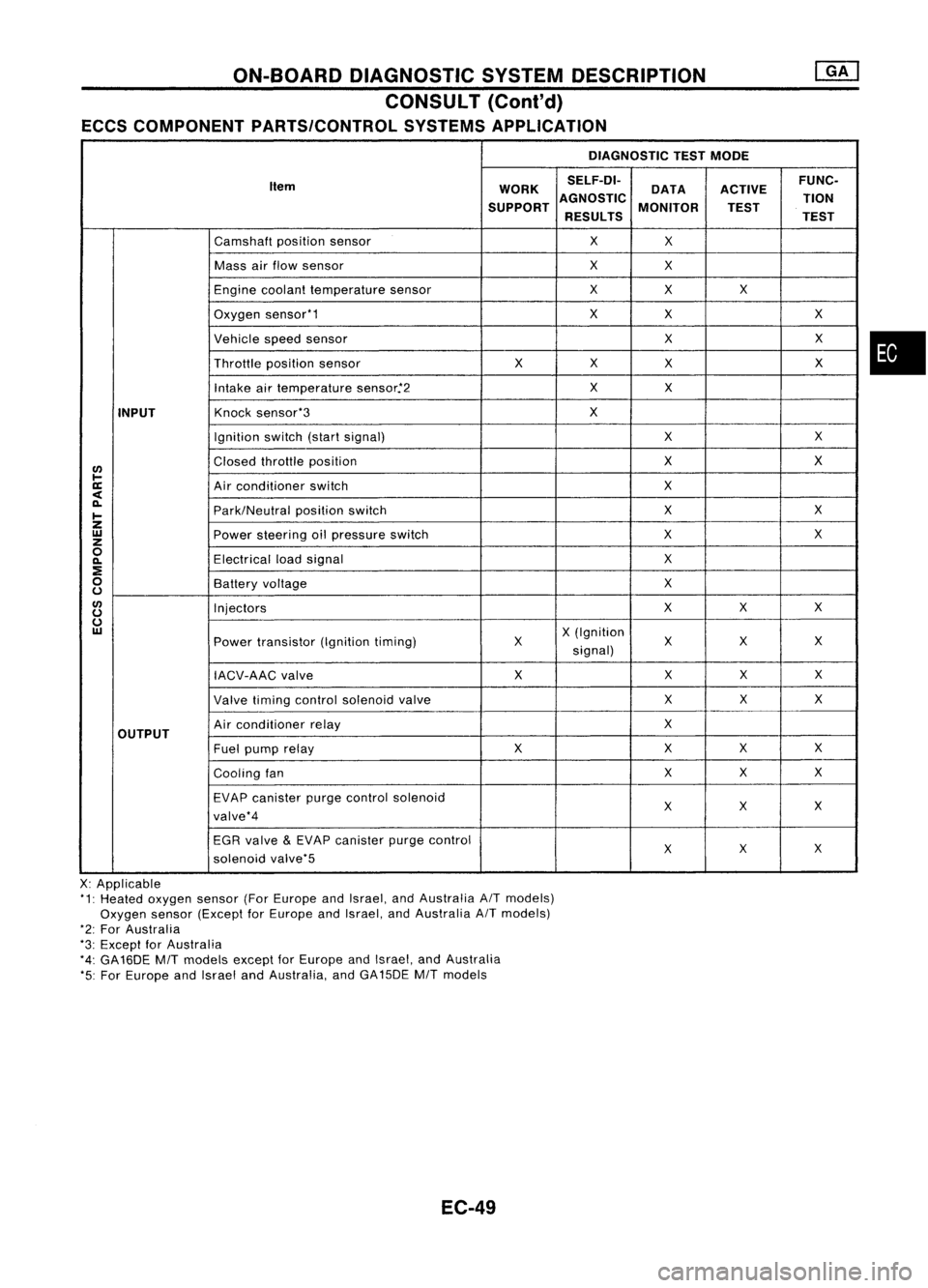

ECCS COMPONENT PARTS/CONTROL SYSTEMSAPPLICATION

DIAGNOSTICTESTMODE

Item WORKSELF-DI-

ACTIVEFUNC-

DATA

SUPPORT AGNOSTIC

MONITOR TION

TEST

RESULTS TEST

Camshaft positionsensor

X

X

Mass airflow sensor

X

X

Engine coolant temperature sensor

X

X X

Oxygen sensor'1

X

X X

Vehicle speedsensor

XX

Throttle positionsensor

XX

X X

Intake airtemperature sensor.'2

X

X

INPUT

Knock

sensor'3

X

Ignition switch(startsignal)

XX

I/)

Closed

throttle position

X

X

l-

ll:

Airconditioner switch

X

<

~

Park/Neutralpositionswitch

X

X

I-

Z

UJ

Powersteering oilpressure switch

XX

z

0

Electricalloadsignal

X

~

:E

0

Batteryvoltage

X

u

I/)

Injectors

XX

X

u

u

UJ

X(Ignition

Power transistor (Ignitiontiming) X X

XX

signal)

IACV-AAC valve X

XX

X

Valve timing control solenoid valve XX

X

OUTPUT

Air

conditioner relay

X

Fuel pump relay XX

XX

Cooling fan XX

X

EVAP canister purgecontrol solenoid

XX X

valve'4

EGR valve

&

EVAP canister purgecontrol

XX

X

solenoid valve'5

X: Applicable

'1: Heated oxygen sensor(ForEurope andIsrael, andAustralia AITmodels)

Oxygen sensor(Except forEurope andIsrael, andAustralia AITmodels)

'2: For Australia

'3: Except forAustralia

'4: GA16DE

MIT

models exceptforEurope andIsrael, andAustralia

'5: For Europe andIsrael andAustralia, andGA15DE

MIT

models

EC-49

•

Page 769 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

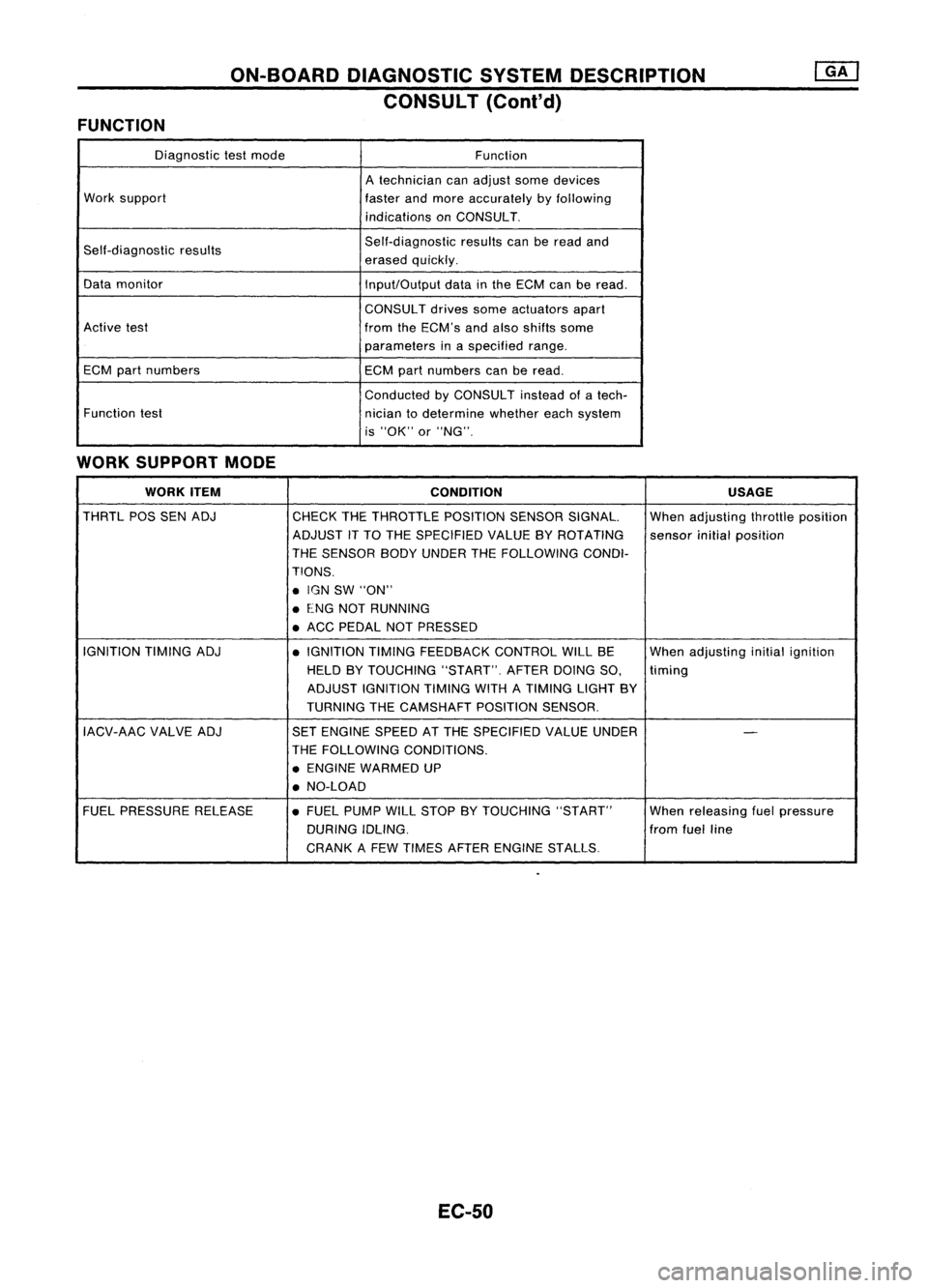

FUNCTION

Diagnostictestmode

Function

A technician canadjust somedevices

Work support

fasterandmore accurately byfollowing

indications onCONSULT.

Self-diagnostic results Self-diagnostic

resultscanberead and

erased quickly.

Data monitor

Input/Outputdatainthe ECM canberead.

CONSUL Tdrives someactuators apart

Active test

fromtheECM's andalso shifts some

parameters inaspecified range.

ECM partnumbers ECMpartnumbers canberead.

Conducted byCONSULT insteadofatech-

Function test

niciantodetermine whethereachsystem

is "OK" or"NG".

WORK SUPPORT MODE

WORK ITEM

CONDITION USAGE

THRTL POSSENADJ

CHECKTHETHROTTLE POSITIONSENSORSIGNAL. Whenadjusting throttleposition

ADJUST iTTO THE SPECIFIED VALUEBYROTATING

sensorinitialposition

THE SENSOR BODYUNDER THEFOLLOWiNG CONDI-

TIONS .

• IGN SW"ON"

• ENG NOTRUNNING

• ACC PEDAL NOTPRESSED

IGNITION TIMINGADJ

•IGNITION TIMINGFEEDBACK CONTROLWILLBE Whenadjusting initialignition

HELD BYTOUCHING "START".AFTERDOINGSO,

timing

ADJUST IGNITION TIMINGWITHATIMING LIGHTBY

TURNING THECAMSHAFT POSITIONSENSOR.

IACV-AAC VALVEADJ SETENGINE SPEEDATTHE SPECIFIED VALUEUNDER

-

THE FOllOWING CONDITIONS.

• ENGINE WARMED UP

• NO-LOAD

FUEL PRESSURE RELEASE •FUEL PUMP WillSTOP BYTOUCHING "START" Whenreleasing fuelpressure

DURING IDLING. fromfuelline

CRANK AFEW TIMES AFTER ENGINE STALLS.

EC-50

Page 770 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (ConI'd)

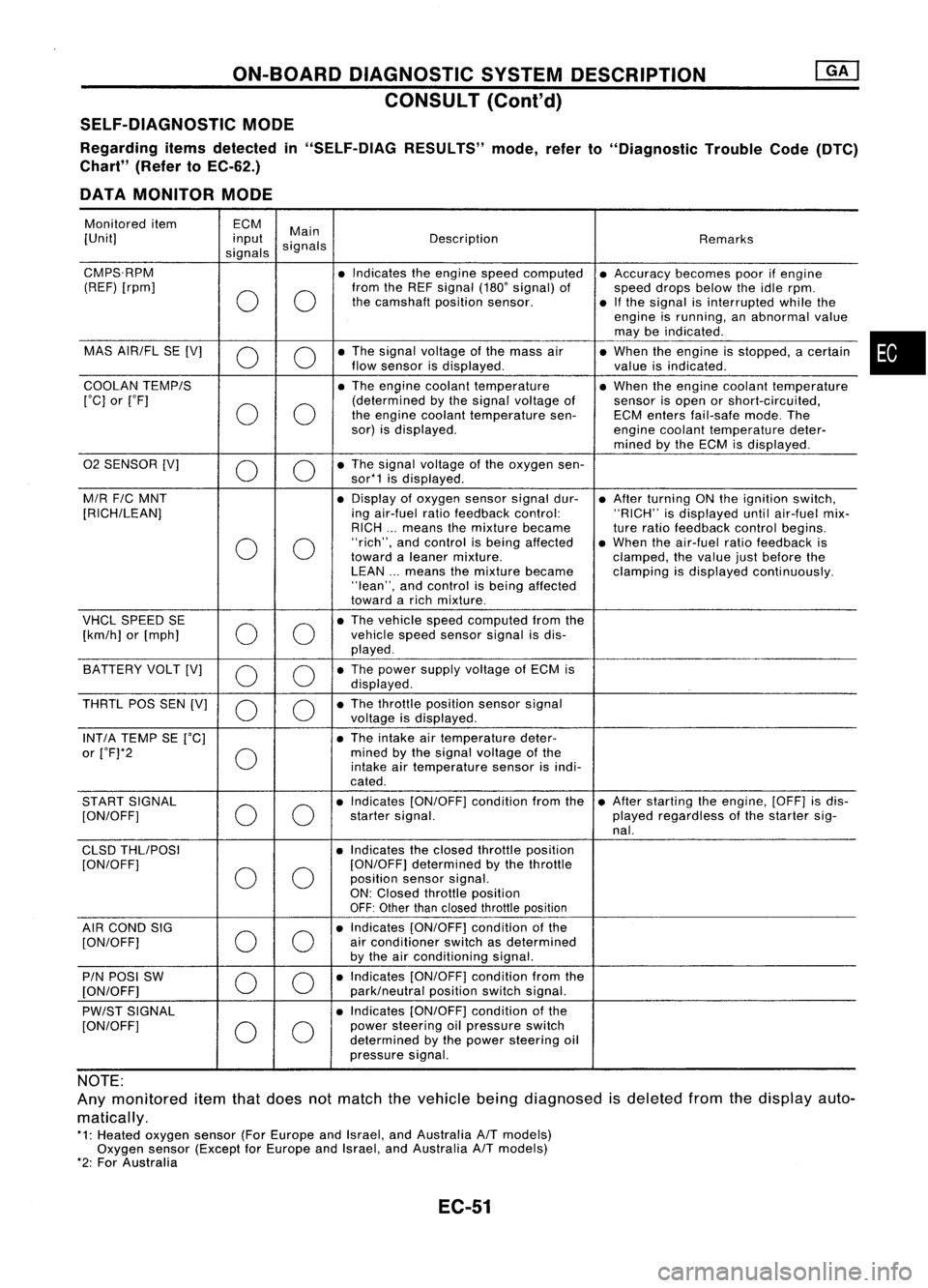

SELF-DIAGNOSTIC MODE

Regarding itemsdetected in"SELF-DIAG RESULTS"mode,referto"Diagnostic TroubleCode(DTC)

Chart" (RefertoEC-62.)

DATA MONITOR MODE

Monitored item ECM

Main

[Unit] input

signals Description

Remarks

signals

CMPS.RPM •Indicates theengine speedcomputed •Accuracy becomespoorifengine

(REF) [rpm]

00

from

theREF signal (180'signal) of

speeddropsbelow theidle rpm.

the camshaft positionsensor.

•Ifthe signal isinterrupted whilethe

engine isrunning, anabnormal value

may beindicated .

MAS AIR/FL SE[V]

0 0

•

The signal voltage ofthe mass air

•When theengine isstopped, acertain

flow sensor isdisplayed .

valueisindicated.

COOLAN TEMP/S

•The engine coolant temperature •When theengine coolant temperature

['C] or['F]

00

(determined

bythe signal voltage of

sensorisopen orshort-circuited,

the engine coolant temperature sen-ECMenters fail-safe mode.The

sor) isdisplayed.

enginecoolant temperature deter-

mined bythe ECM isdisplayed .

02 SENSOR [V]

00

•

The signal voltage ofthe oxygen sen-

sor*1 isdisplayed .

M/R F/CMNT •

Display ofoxygen sensorsignaldur-

•After turning ONthe ignition switch,

[RICH/LEAN] ingair-fuel ratiofeedback control: "RICH"isdisplayed untilair-fuel mix-

RICH ...means themixture became

tureratio feedback controlbegins.

0 0

"rich",

andcontrol isbeing affected •When theair-fuel ratiofeedback is

toward aleaner mixture.

clamped,thevalue justbefore the

LEAN ...means themixture became clampingisdisplayed continuously.

"lean", andcontrol isbeing affected

toward arich mixture .

VHCL SPEED SE

00

•

The vehicle speedcomputed fromthe

[km/h] or[mph] vehicle

speedsensor signalisdis-

played .

BATTERY VOLT[V]

0 0

•

The power supply voltage ofECM is

displayed .

THRTL POSSEN[V]

0 0

•

The throttle position sensorsignal

voltage isdisplayed.

INT/A TEMP SE['C] •The intake airtemperature deter-

or ['F]*2

0

mined

bythe signal voltage ofthe

intake airtemperature sensorisindi-

cated .

START SIGNAL

00

•

Indicates [ON/OFF] conditionfromthe•After starting theengine, [OFF]isdis-

[ON/OFF] startersignal. playedregardless ofthe starter sig-

nal.

CLSD THLIPOSI •Indicates theclosed throttle position

[ON/OFF]

00

[ON/OFF]

determined bythe throttle

position sensorsignal.

ON: Closed throttle position

OFF: Other thanclosed throttle position

AIR COND SIG

00

•

Indicates [ON/OFF] conditionofthe

[ON/OFF] air

conditioner switchasdetermined

by the airconditioning signal.

PIN POSI SW

00

•

Indicates [ON/OFF] conditionfromthe

[ON/OFF] park/neutralpositionswitchsignal.

PW/ST SIGNAL •

Indicates [ON/OFF] conditionofthe

[ON/OFF]

00

power

steering oilpressure switch

determined bythe power steering oil

pressure signal.

NOTE:

Any monitored itemthatdoes notmatch thevehicle beingdiagnosed isdeleted fromthedisplay auto-

matically.

*1: Heated oxygen sensor(ForEurope andIsrael, andAustralia A/Tmodels)

Oxygen sensor(Except forEurope andIsrael, andAustralia A/Tmodels)

*2: For Australia

EC-51

•

Page 771 of 1701

![NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Coni'd)

Monitored item

ECM

Main

[Unit] input

signals Description

Remarks

signals

LOAD SIGNAL •Indicates [ON/OFF] conditionfromthe

[ON/OFF] reardefo NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Coni'd)

Monitored item

ECM

Main

[Unit] input

signals Description

Remarks

signals

LOAD SIGNAL •Indicates [ON/OFF] conditionfromthe

[ON/OFF] reardefo](/img/5/57349/w960_57349-770.png)

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Coni'd)

Monitored item

ECM

Main

[Unit] input

signals Description

Remarks

signals

LOAD SIGNAL •Indicates [ON/OFF] conditionfromthe

[ON/OFF] reardefogger signaland/or lighting

switch.

0 0

ON:

Rear defogger isoperating

and/or lighting switchison.

OFF: Rear defogger isnot operating

and lighting switchisnot on.

INJ PULSE [msec]

0

•

Indicates theactual fuelinjection

•When theengine isstopped, acertain

pulse widthcompensated byECM computedvalueisindicated.

according tothe input signals.

IGN TIMING [BTDC]

0

•

Indicates theignition timingcomputed

by ECM according tothe input sig-

nals.

IACV-AACIV

[%]

•Indicates theidle aircontrol valve

0

(AAC

valve) control valuecomputed

by ECM according tothe input sig-

nals.

A/F ALPHA

[%]

•Indicates themean valueofthe air-

•When theengine isstopped, acertain

0

fuel

ratio feedback correction factor valueisindicated.

per cycle. •This data alsoincludes thedata for

the air-fuel ratiolearning control.

AIR COND RLY

0

•

Indicates theairconditioner relay

[ON/OFF] controlcondition (determined byECM

according tothe input signal).

COOLING FAN*2

•Indicates thecontrol condition ofthe

[ON/OFF] or[LOW/

coolingfans(determined byECM

HI/OFF]

0

according

tothe input signal).

ON ...Operating

LOW ...Operates atlow speed

HI ...Operates athigh speed

OFF ...Stopped

FUEL PUMP RLY

0

•

Indicates thefuel pump relaycontrol

[ON/OFF] conditiondetermined byECM accord-

ing tothe input signals.

VALVE TIMSOL*1

•The control condition ofthe valve tim-

[ON/OFF] ingsolenoid valve(determined by

ECM according tothe input signal) is

indicated.

ON ...VTC operating

OFF ...VTC notoperating

EGRC SOLIV (EVAP

•Indicates thecontrol condition ofthe

canister purgecon-

EVAPcanister purgecontrol solenoid

trol solenoid valve valveorEGR valve

&

EVAP canister

or EGR

&

EVAP can- purgecontrol solenoid valve(deter-

ister purge control

0

mined

byECM according tothe input

solenoid valve) signal).

[ON/OFF] ON'"EVAP canister purgeoperation

cut-off OFF ...EVAP canister purgeoperation

not cut-off

VOLTAGE •Voltage measured bythe voltage

[V] probe.

PULSE •Pulse width, frequency orduty cycle •Only "#"isdisplayed ifitem is

[msec] or[Hz] or measuredbythe pulse probe. unable

tobe measured .

[%]

•

Figures with"#"s aretemporary

ones. Theyarethesame figures as

an actual pieceofdata which wasjust

previously measured.

*1: GA16DE exceptforEurope andIsrael

*2: GA16DE engineA/Tmodels forEurope without heavydutykithave a2- step control [ON/OFF] system."LOW"and"HI"

are shown onCONSULT screentorepresent "ON"condition.

EC-52

Page 772 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

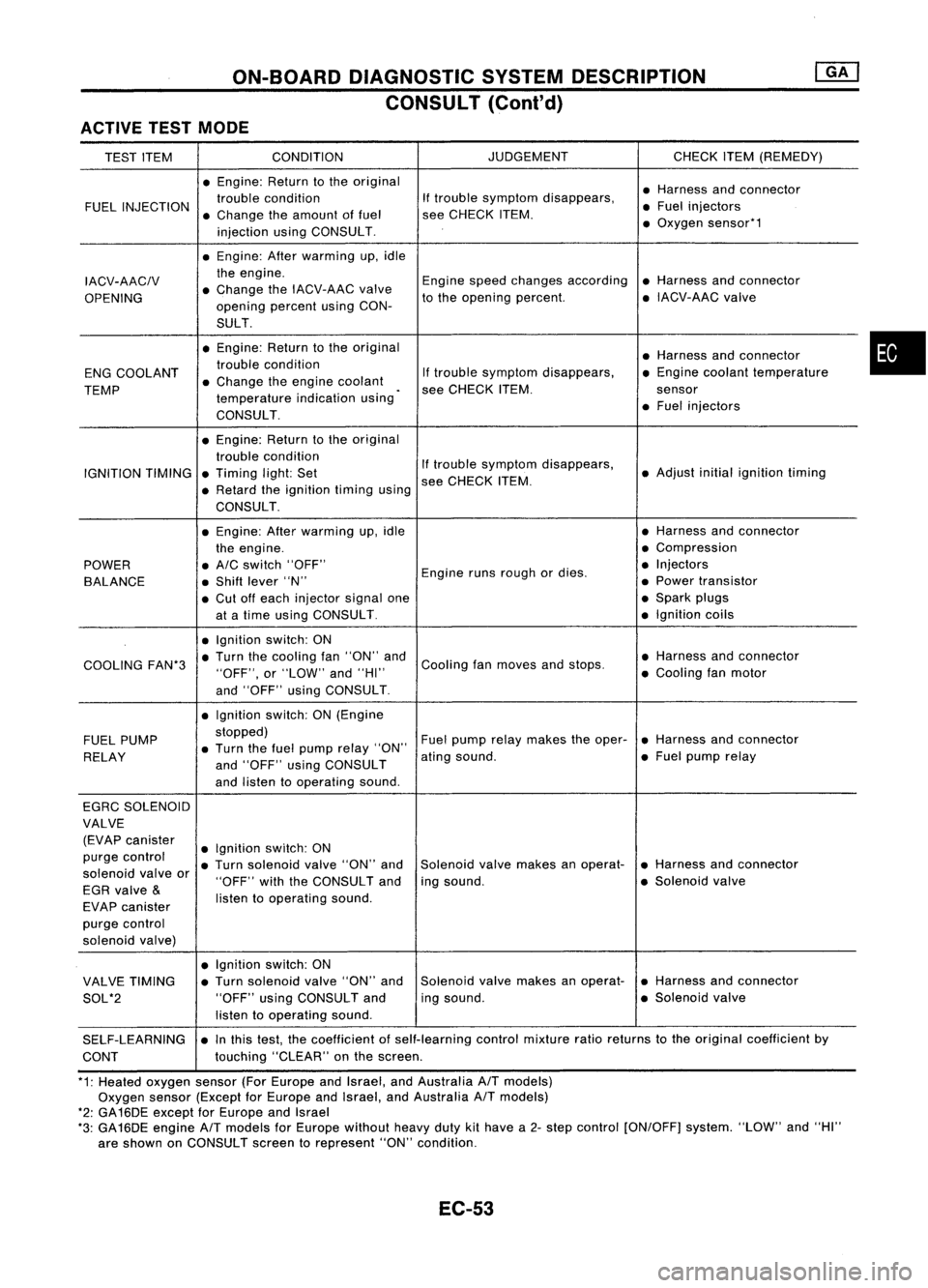

ACTIVE TESTMODE

TEST ITEM CONDITION JUDGEMENT

CHECKITEM(REMEDY)

• Engine: Returntothe original

•Harness andconnector

FUEL INJECTION trouble

condition If

trouble symptom disappears,

•Fuel injectors

• Change theamount offuel see

CHECK ITEM.

injection usingCONSULT . •

Oxygen sensor*1

• Engine: Afterwarming up,idle

IACV-AACIV the

engine.

Enginespeedchanges according •Harness andconnector

OPENING •

Change theIACV-AAC valve

tothe opening percent. •

IACV-AAC valve

opening percentusingCON-

SULT.

• Engine: Returntothe original

•Harness andconnector

ENG COOLANT trouble

condition

Iftrouble symptom disappears, •

Engine coolant temperature

TEMP •

Change theengine coolant

.

see CHECK ITEM. sensor

temperature indicationusing

•Fuel injectors

CONSULT.

• Engine: Returntothe original

trouble condition

Iftrouble symptom disappears,

IGNITION TIMING•

Timing light:Set •

Adjust initialignition timing

• Retard theignition timingusingsee

CHECK ITEM.

CONSULT .

• Engine: Afterwarming up,idle •

Harness andconnector

the engine. •

Compression

POWER •

A/C switch "OFF"

Enginerunsrough ordies . •

Injectors

BALANCE •

Shift lever "N" •

Power transistor

• Cut offeach injector signalone •

Spark plugs

at atime using CONSULT. •

Ignition coils

• Ignition switch:ON

COOLING FAN*3•

Turn thecooling fan"ON" and

Cooling fanmoves andstops. •

Harness andconnector

"OFF", or"LOW" and"HI" •

Cooling fanmotor

and "OFF" usingCONSULT .

• Ignition switch:ON(Engine

FUEL PUMP stopped)

Fuelpump relaymakes theoper- •Harness andconnector

• Turn thefuel pump relay"ON"

RELAY and"OFF" usingCONSULT ating

sound. •

Fuel pump relay

and listen tooperating sound.

EGRC SOLENOID

VALVE (EVAP canister

•Ignition switch:ON

purge control

•Turn solenoid valve"ON" and Solenoid

valvemakes anoperat- •

Harness andconnector

solenoid valveor

EGR valve

&

"OFF"

withtheCONSULT andingsound. •

Solenoid valve

EVAP canister listen

tooperating sound.

purge control

solenoid valve)

•Ignition switch:ON

VALVE TIMING •

Turn solenoid valve"ON" and Solenoid

valvemakes anoperat- •

Harness andconnector

SOL*2 "OFF"

usingCONSULT anding

sound. •

Solenoid valve

listen tooperating sound.

SELF-LEARNING •

Inthis test, thecoefficient ofself-learning controlmixture ratioreturns tothe original coefficient by

CONT touching

"CLEAR" onthe screen.

*1: Heated oxygen sensor(ForEurope andIsrael, andAustralia A/Tmodels)

Oxygen sensor(Except forEurope andIsrael, andAustralia A/Tmodels)

*2: GA16DE except forEurope andIsrael

*3: GA16DE engine A/Tmodels forEurope without heavydutykithave a2- step control [ON/OFF] system."LOW"and"HI"

are shown onCONSULT screentorepresent "ON"condition.

EC-53

•

Page 773 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

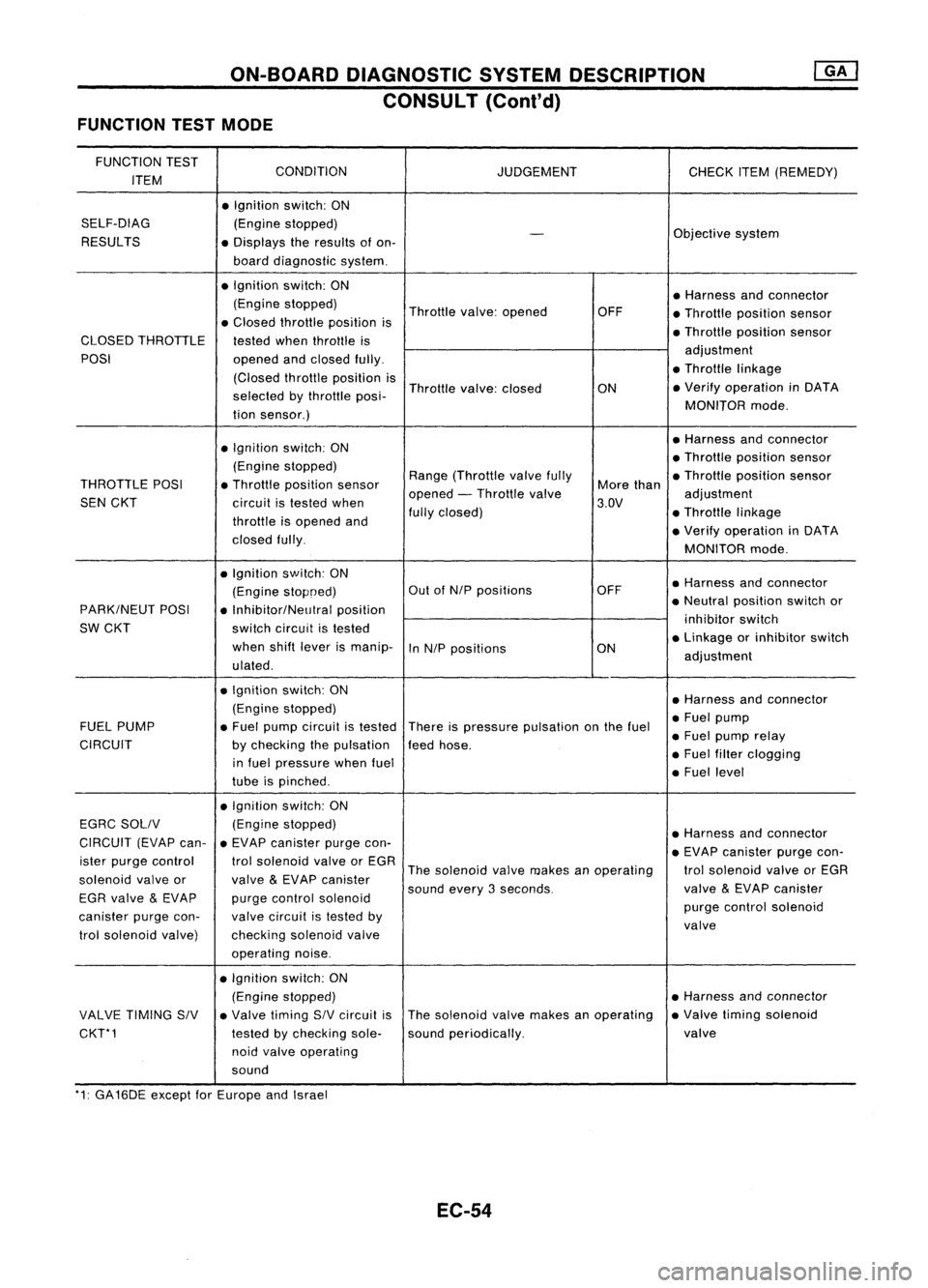

FUNCTION TESTMODE

FUNCTION TEST

CONDITION

ITEM JUDGEMENT

CHECKITEM(REMEDY)

• Ignition switch:ON

SELF-DIAG (Enginestopped)

RESULTS

-

Objective

system

• Displays theresults ofon-

board diagnostic system.

• Ignition switch:ON

•Harness andconnector

(Engine stopped)

Throttlevalve:opened OFF

•Throllle position sensor

• Closed throllle position is

•Throllie position sensor

CLOSED THROTTLE

testedwhenthrottle is

POSI openedandclosed fully. adjustment

(Closed throllieposition is •

Throttle linkage

selected bythrottle posi- Throttle

valve:closed

ON•

Verify operation inDATA

tion sensor.) MONITOR

mode.

• Ignition switch:ON •

Harness andconnector

(Engine stopped) •

Throttle position sensor

THROTTLE POSI•Throllle position sensor Range

(Throllle valvefully

Morethan •

Throllle position sensor

SEN CKT

circuitistested when opened

-Throllle valve

3.DV adjustment

throllie isopened and fully

closed) •Throllie linkage

closed fully. •

Verify operation inDATA

MONITOR mode.

• Ignition switch:ON

•Harness andconnector

(Engine stopoed) Out

ofNIP positions OFF

PARK/NEUT POSI

•Inhibitor/NelJlral position •

Neutral position switchor

SW CKT switchcircuit istested inhibitor

switch

when shiftlever ismanip-

InNIP positions ON•

Linkage orinhibitor switch

ulated . adjustment

• Ignition switch:ON

•Harness andconnector

(Engine stopped)

•Fuel pump

FUEL PUMP •Fuel pump circuit istested

Thereispressure pulsation onthe fuel

•Fuel pump relay

CIRCUIT bychecking thepulsation feedhose.

in fuel pressure whenfuel •

Fuel filter clogging

tube ispinched . •

Fuel level

• Ignition switch:ON

EGRC SOllV (Engine

stopped)

•Harness andconnector

CIRCUIT (EVAPcan-•EVAP canister purgecon-

•EVAP canister purgecon-

ister purge control trolsolenoid valveorEGR

Thesolenoid valvemakes anoperating trolsolenoid valveorEGR

solenoid valveor

valve

&

EVAP canister

soundevery3seconds. valve

&

EVAP canister

EGR valve

&

EVAP purgecontrol solenoid

purgecontrol solenoid

canister purgecon- valvecircuit istested by

valve

trol solenoid valve) checkingsolenoidvalve

operating noise.

• Ignition switch:ON

(Engine stopped) •

Harness andconnector

VALVE TIMING SIV•Valve timing SIVcircuit isThe

solenoid valvemakes anoperating •

Valve timing solenoid

CKT*1 testedbychecking sole-soundperiodically. valve

noid valve operating

sound

'1: GA16DE exceptforEurope andIsrael

EC-54