sensor NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1368 of 1701

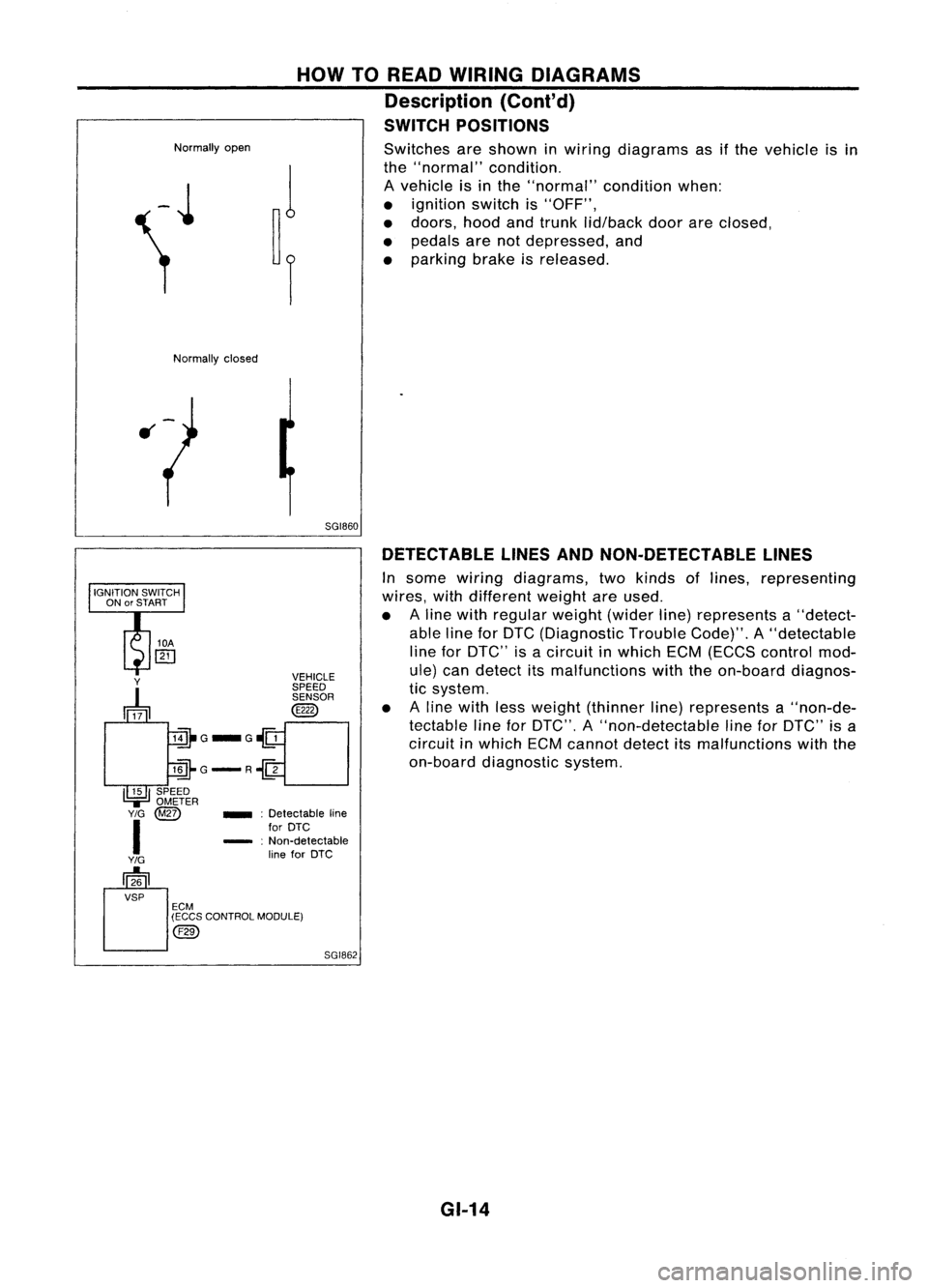

Normallyopen

HOW

TOREAD WIRING DIAGRAMS

Description (Cont'd)

SWITCH POSITIONS

Switches areshown inwiring diagrams asifthe vehicle isin

the "normal" condition.

A vehicle isin the "normal" conditionwhen:

• ignition switchis"OFF",

• doors, hoodandtrunk lid/back doorareclosed,

• pedals arenotdepressed, and

• parking brakeisreleased.

Normally closed

5GI860DETECTABLE LINESANDNON-DETECTABLE LINES

In some wiring diagrams, twokinds oflines, representing

wires, withdifferent weightareused.

• Aline with regular weight(widerline)represents a"detect-

able lineforDTC (Diagnostic TroubleCode)".A"detectable

line forDTC" isacircuit inwhich ECM(ECCS control mod-

ule) candetect itsmalfunctions withtheon-board diagnos-

tic system.

• Aline with lessweight (thinner line)represents a"non-de-

tectable lineforDTC", A"non-detectable lineforDTC" isa

circuit inwhich ECMcannot detectitsmalfunctions withthe

on-board diagnostic system.

SGI862

_

:Detectable line

for DTC

- :Non-detectable

line forDTC

Y

~ VEHICLE

SPEED SENSOR

@

lill-G_G~

llli-G-R~

I~I

SPEED

.,=

OMETER

Y/G

@Z)

I

Y/G

[]26

VSP ECM

(ECCS CONTROL MODULE)

@)

GI-14

Page 1371 of 1701

HOWTOREAD WIRING DIAGRAMS

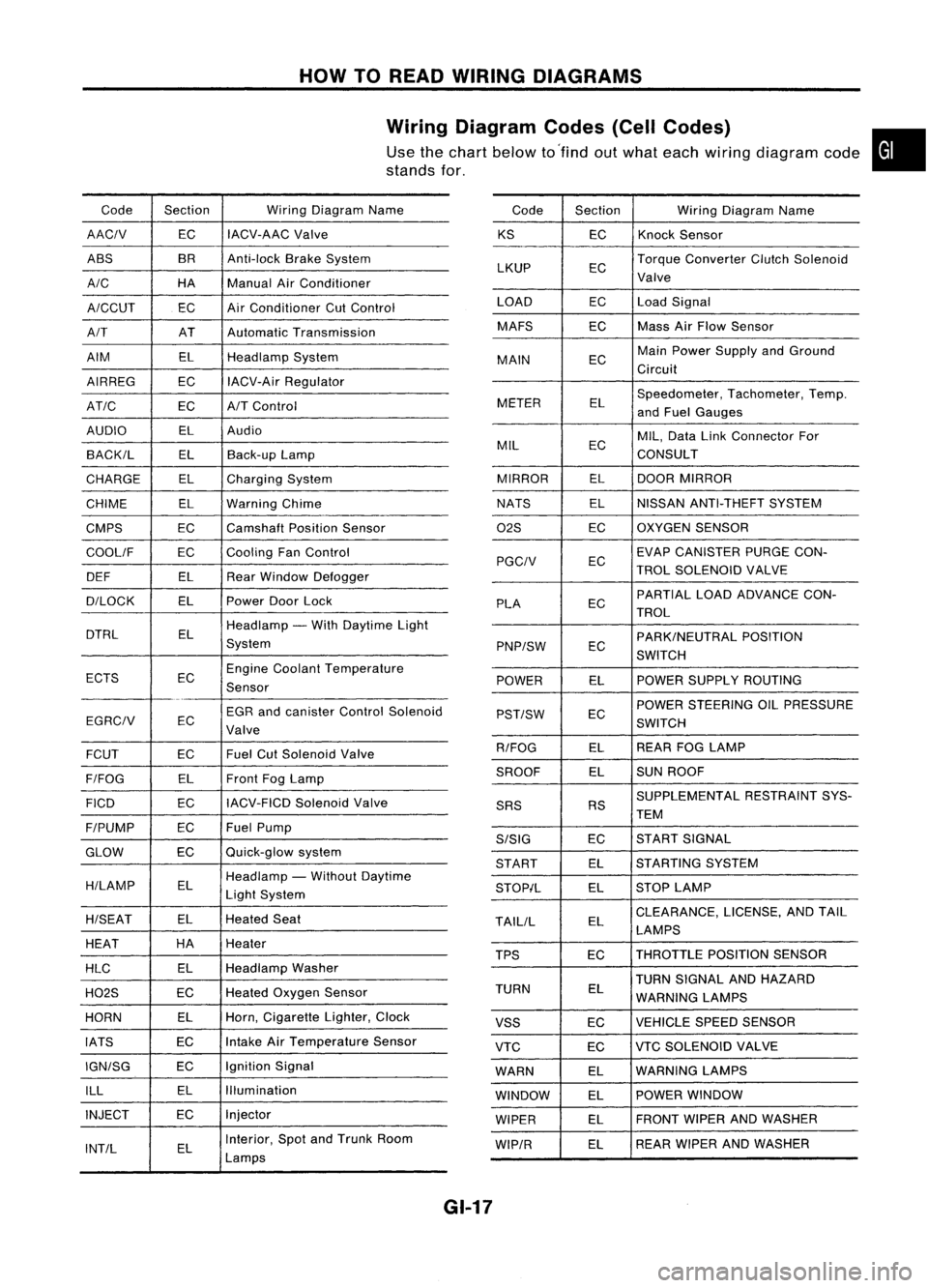

Wiring Diagram Codes(CellCodes)

Use thechart below to'find outwhat each wiring diagram code•

stands for,

Code Section WiringDiagram Name

AACIV ECIACV-AAC

Valve

ABS BR

Anti-lock BrakeSystem

A/C HAManualAirConditioner

A/CCUT ECAir

Conditioner CutControl

A/T ATAutomatic Transmission

AIM ELHeadlamp System

AIRREG ECIACV-Air Regulator

AT/C ECA/TControl

AUDIO ELAudio

BACK/L ELBack-up Lamp

CHARGE ELCharging System

CHIME ELWarning Chime

CMPS EC

Camshaft PositionSensor

COOllF ECCooling

FanControl

DEF ELRearWindow Defogger

D/LOCK ELPowerDoorLock

DTRL ELHeadlamp

-With Daytime Light

System

ECTS ECEngine

Coolant Temperature

Sensor

EGR andcanister ControlSolenoid

EGRCIV EC

Valve

FCUT ECFuel

CutSolenoid Valve

F/FOG ELFront

FogLamp

FICO ECIACV-FICD

SolenoidValve

F/PUMP ECFuel

Pump

GLOW ECQuick-glow

system

H/LAMP ELHeadlamp

-Without Daytime

Light System

H/SEAT ELHeated

Seat

HEAT HA

Heater

HLC ELHeadlamp

Washer

H02S ECHeated

Oxygen Sensor

HORN ELHorn,

Cigarette Lighter,Clock

IATS ECIntake

AirTemperature Sensor

IGN/SG ECIgnition

Signal

ILL ELIllumination

INJECT ECInjector

INT/L ELInterior,

SpotandTrunk Room

Lamps Code

Section WiringDiagram Name

KS ECKnock

Sensor

LKUP ECTorque

Converter ClutchSolenoid

Valve

LOAD ECLoadSignal

MAFS ECMass

AirFlow Sensor

MAIN ECMain

Power Supply andGround

Circuit

METER ELSpeedometer,

Tachometer,Temp.

and Fuel Gauges

MIL ECMIL,

Data LinkConnector For

CONSULT

MIRROR ELDOOR

MIRROR

NATS ELNISSAN

ANTI-THEFT SYSTEM

02S ECOXYGEN

SENSOR

EC EVAP

CANISTER PURGECON-

PGCIV TROLSOLENOID VALVE

PLA ECPARTIAL

LOADADVANCE CON-

TROL

EC PARK/NEUTRAL

POSITION

PNP/SW SWITCH

POWER ELPOWER

SUPPLY ROUTING

POWER STEERING OILPRESSURE

PST/SW EC

SWITCH

R/FOG ELREAR

FOGLAMP

SROOF ELSUN

ROOF

SUPPLEMENTAL RESTRAINTSYS-

SRS RS

TEM

S/SIG ECST

ART SIGNAL

START ELSTARTING

SYSTEM

STOP/L ELSTOP

LAMP

TAllIL ELCLEARANCE,

LICENSE,ANDTAIL

LAMPS

TPS ECTHROTTLE

POSITIONSENSOR

TURN SIGNAL ANDHAZARD

TURN EL

WARNING LAMPS

VSS ECVEHICLE

SPEEDSENSOR

VTC ECVTC

SOLENOID VALVE

WARN ELWARNING

LAMPS

WINDOW ELPOWER

WINDOW

WIPER ELFRONT

WIPERANDWASHER

WIP/R ELREAR

WIPER ANDWASHER

GI-17

Page 1373 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests

INTRODUCTION

Sometimes thesymptom isnot present whenthevehicle isbrought infor service.

If

possible, re-create

the conditions presentatthe time ofthe incident. Doingsomay help avoid aNo Trouble FoundDiag-

nosis. Thefollowing sectionillustrates waystosimulate theconditionslenvironment underwhich the

owner experiences anelectrical incident.

The section isbroken intothesixfollowing topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold orhot start up

Get athorough description ofthe incident fromthecustomer. Itis important forsimulating thecondi-

tions ofthe problem.

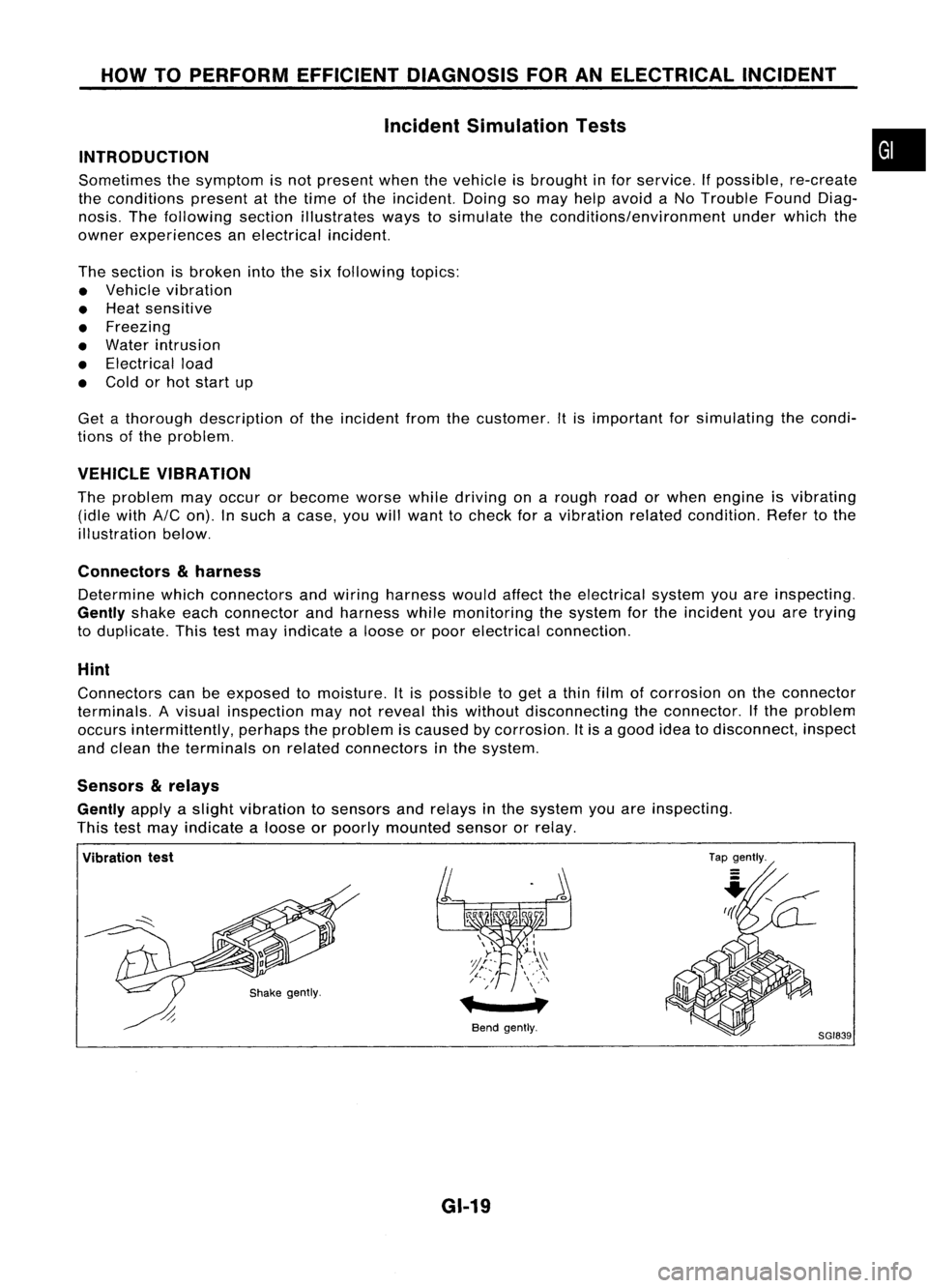

VEHICLE VIBRATION

The problem mayoccur orbecome worsewhiledriving onarough roadorwhen engine isvibrating

(idle with

AIC

on). Insuch acase, youwillwant tocheck foravibration relatedcondition. Refertothe

illustration below.

Connectors

&

harness

Determine whichconnectors andwiring harness wouldaffecttheelectrical systemyouareinspecting.

Gently

shakeeachconnector andharness whilemonitoring thesystem forthe incident youaretrying

to duplicate. Thistestmay indicate aloose orpoor electrical connection.

Hint

Connectors canbeexposed tomoisture. Itis possible toget athin film ofcorrosion onthe connector

terminals. Avisual inspection maynotreveal thiswithout disconnecting theconnector. Ifthe problem

occurs intermittently, perhapstheproblem iscaused bycorrosion. Itis agood ideatodisconnect, inspect

and clean theterminals onrelated connectors inthe system.

Sensors

&

relays

Gently

applyaslight vibration tosensors andrelays inthe system youareinspecting.

This testmay indicate aloose orpoorly mounted sensororrelay.

•

Vibration test

Bendgently.

GI-19

Tap

gently.

8GI839

Page 1383 of 1701

HOWTOFOLLOW FLOWCHART INTROUBLE DIAGNOSES

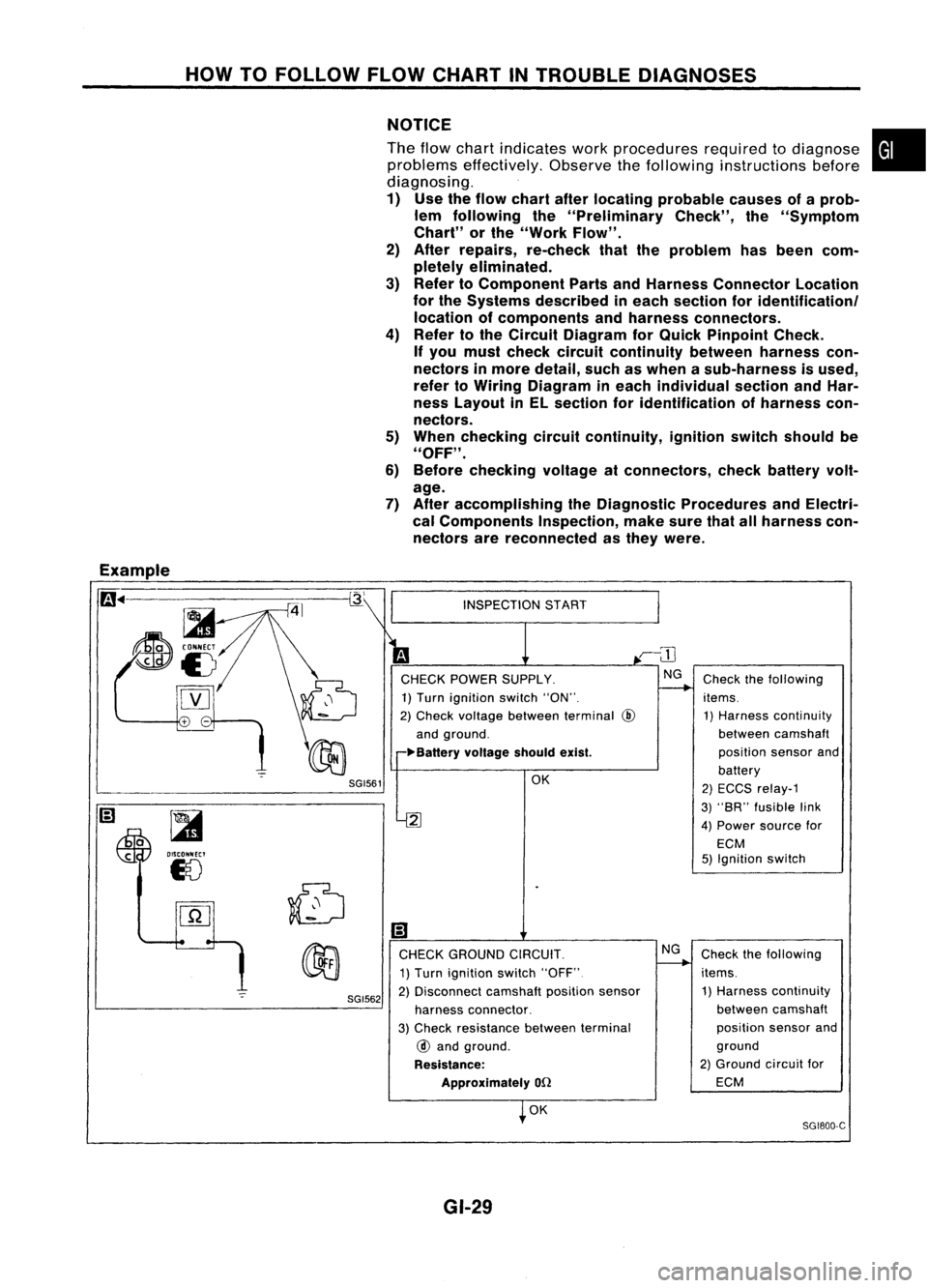

NOTICE

The flow chart indicates workprocedures requiredtodiagnose

problems effectively. Observethefollowing instructions before

diagnosing.

1) Use theflow chart afterlocating probable causesofaprob-

lem following the"Preliminary Check",the"Symptom

Chart" orthe "Work Flow".

2) After repairs, re-check thattheproblem hasbeen com-

pletely eliminated.

3) Refer toComponent PartsandHarness Connector Location

for the Systems described ineach section foridentificationl

location ofcomponents andharness connectors.

4) Refer tothe Circuit Diagram forQuick Pinpoint Check.

If you must check circuit continuity betweenharnesscon-

nectors inmore detail, suchaswhen asub-harness isused,

refer toWiring Diagram ineach individual sectionandHar-

ness Layout inEL section foridentification ofharness con-

nectors.

5) When checking circuitcontinuity, ignitionswitchshould be

"OFF" .

6) Before checking voltageatconnectors, checkbattery volt-

age.

7) After accomplishing theDiagnostic Procedures andElectri-

cal Components Inspection,makesurethatallharness con-

nectors arereconnected asthey were.

•

Example

m ..

-=-=~-----------~

~

~i5

[YJ

SGI561

~

OISCONNECT

18

SGI562

INSPECTION

START

CHECK POWER SUPPLY.

1) Turn ignition switch"ON".

2) Check voltage between terminal

@

and ground.

~Ba"ery voltageshouldexist.

OK

2

Ii)

CHECK GROUND CIRCUIT.

1) Turn ignition switch"OFF"

2) Disconnect camshaftpositionsensor

harness connector.

3) Check resistance betweenterminal

@

and ground.

Resistance: Approximately

on

OK

GI-29 NG

Check

thefollowing

items. 1) Harness continuity

between camshaft

position sensorand

battery

2) ECCS relay-1

3) "SR" fusible link

4) Power source for

ECM

5) Ignition switch

Check thefollowing

items. 1) Harness continuity

between camshaft

position sensorand

ground

2) Ground circuitfor

ECM

SG1800-C

Page 1399 of 1701

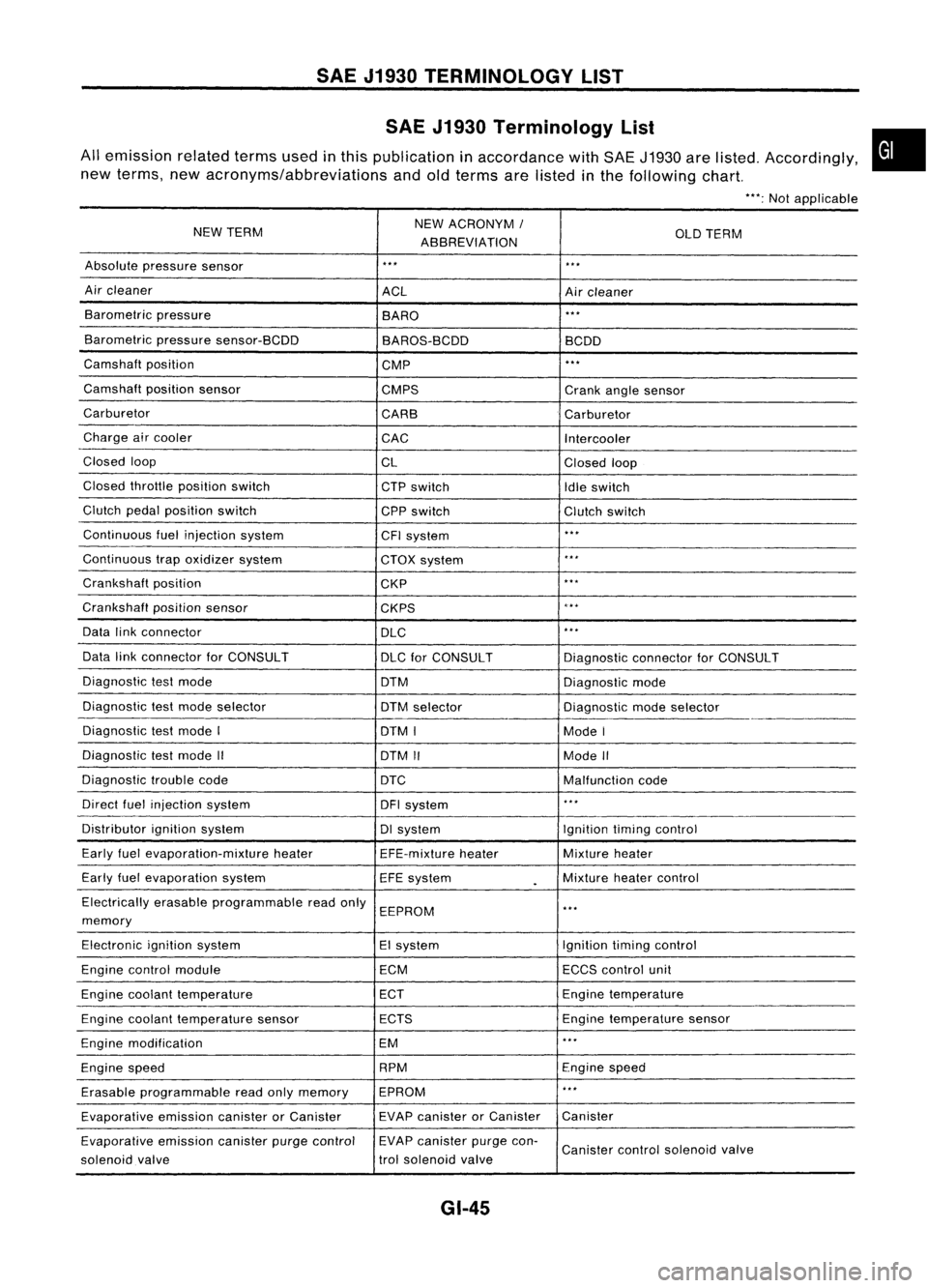

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List

All emission relatedtermsusedinthis publication inaccordance withSAE J1930 arelisted. Accordingly,

new terms, newacronyms/abbreviations andoldterms arelisted inthe following chart.

"':Not applicable

NEW TERM NEW

ACRONYM /

ABBREVIATION OLD

TERM

Absolute pressure sensor

'" '"

Air cleaner

ACLAircleaner

Barometric pressure

BARO

."

Barometric pressuresensor-BCDD

BAROS-BCDD BCDD

Camshaft position

CMP

'"

Camshaft positionsensor

CMPS Crankanglesensor

Carburetor CARBCarburetor

Charge aircooler

CACIntercooler

Closed loop

CLClosedloop

Closed throttle position switch

CTPswitch

Idleswitch

Clutch pedalposition switch

CPPswitch Clutchswitch

Continuous fuelinjection system

CFIsystem

'"

Continuous trapoxidizer system

CTOXsystem

...

Crankshaft position

CKP

'"

Crankshaft positionsensor

CKPS

~.**

Data linkconnector

DLC

,

..

Data linkconnector forCONSULT

DLCforCONSULT DiagnosticconnectorforCONSULT

Diagnostic testmode

DTMDiagnosticmode

Diagnostic testmode selector

DTMselector Diagnosticmodeselector

Diagnostic testmode I

DTMI ModeI

Diagnostic testmode II

DTMII ModeII

Diagnostic troublecode

DTC Malfunctioncode

Direct fuelinjection system

DFIsystem

..

,

Distributor ignitionsystem DIsystem Ignitiontimingcontrol

Early fuelevaporation-mixture heater

EFE-mixtureheater Mixture

heater

Early fuelevaporation system

EFEsystem

.

Mixture

heatercontrol

Electrically erasableprogrammable readonly

EEPROM

'"

memory

Electronic ignitionsystem EIsystem Ignitiontimingcontrol

Engine control module ECMECCScontrol unit

Engine coolant temperature ECTEngine

temperature

Engine coolant temperature sensor ECTS Engine

temperature sensor

Engine modification EM

'"

Engine speed RPM

Enginespeed

Erasable programmable readonlymemory EPROM

'"

Evaporative emissioncanisterorCanister EVAP

canister orCanister Canister

Evaporative emissioncanisterpurgecontrol EVAP

canister purgecon-

Canister controlsolenoid valve

solenoid valve trol

solenoid valve

GI-45

•

Page 1400 of 1701

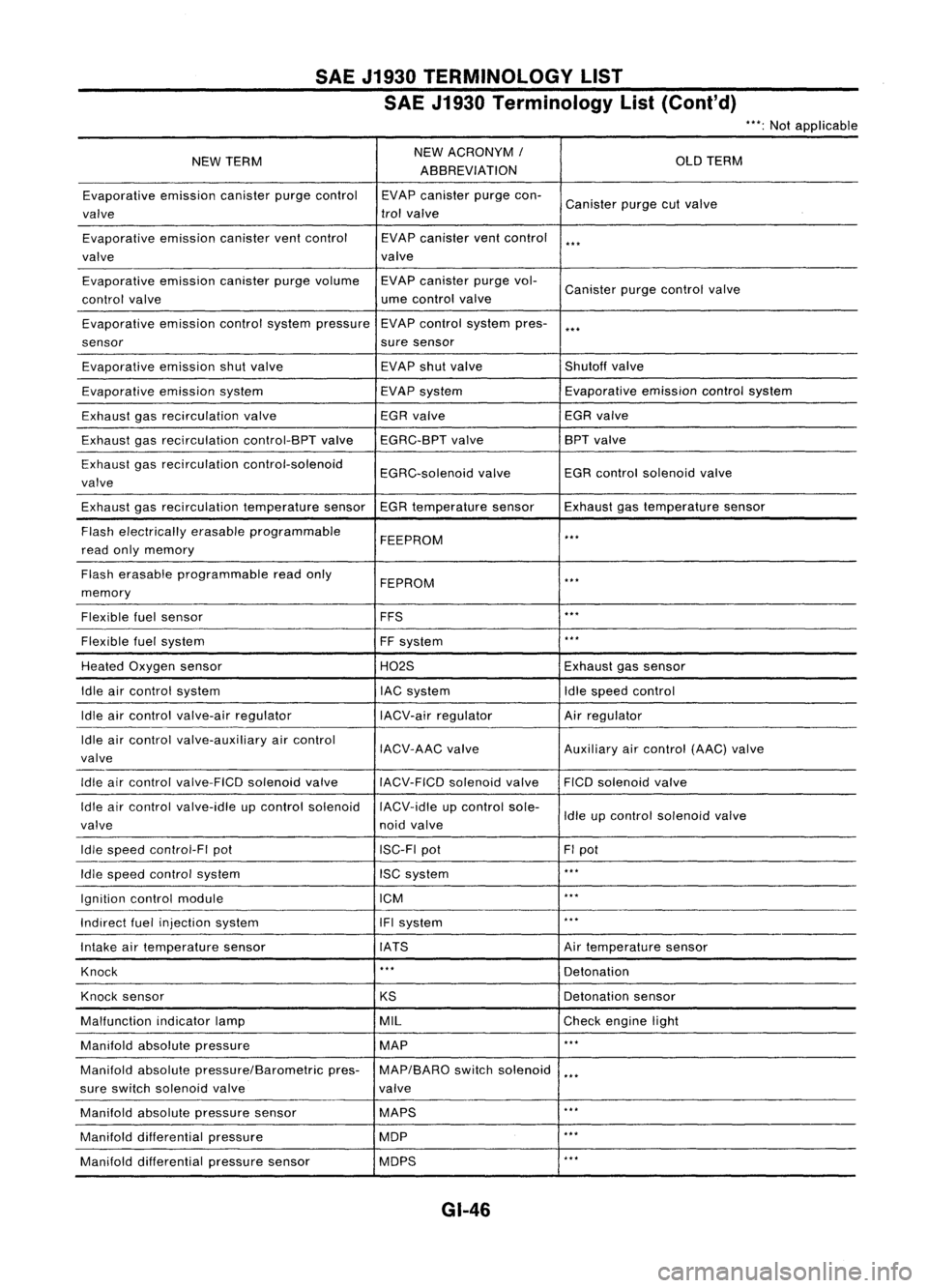

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

***:

Not applicable

NEW TERM NEW

ACRONYM /

OLDTERM

ABBREVIATION

Evaporative emissioncanisterpurgecontrol EVAPcanister purgecon-

Canister purgecutvalve

valve trol

valve

Evaporative emissioncanisterventcontrol EVAPcanister ventcontrol

***

valve valve

Evaporative emissioncanisterpurgevolume EVAPcanister purgevol-

Canister purgecontrol valve

control valve ume

control valve

Evaporative emissioncontrolsystem pressure EVAP

control system pres-

***

sensor suresensor

Evaporative emissionshutvalve EVAP

shutvalve Shutoffvalve

Evaporative emissionsystem EVAPsystem Evaporative

emissioncontrolsystem

Exhaust gasrecirculation valve EGR

valve EGRvalve

Exhaust gasrecirculation control-BPTvalveEGRC-BPT valve BPT

valve

Exhaust gasrecirculation control-solenoid

EGRC-solenoidvalveEGR

control solenoid valve

valve

Exhaust gasrecirculation temperaturesensorEGRtemperature sensorExhaustgastemperature sensor

Flash electrically erasableprogrammable

FEEPROM

***

read onlymemory

Flash erasable programmable readonly

FEPROM

**.

memory

Flexible fuelsensor FFS

***

Flexible fuelsystem

FFsystem

***

Heated Oxygen sensor H02SExhaustgassensor

Idle aircontrol system lACsystem Idlespeed control

Idle aircontrol valve-air regulator IACV-airregulator Airregulator

Idle aircontrol valve-auxiliary aircontrol

IACV-AACvalve Auxiliaryaircontrol (AAC)valve

valve

Idle aircontrol valve-FICO solenoidvalve

IACV-FICDsolenoidvalve FICOsolenoid valve

Idle aircontrol valve-idle upcontrol solenoid IACV-idleupcontrol sole-

Idleupcontrol solenoid valve

valve noidvalve

Idle speed control-FI pot ISC-FIpot FIpot

Idle speed control system ISCsystem

***

Ignition controlmodule ICM

***

Indirect fuelinjection system IFIsystem

***

Intake airtemperature sensor IATS Airtemperature sensor

Knock

***

Detonation

Knock sensor

KSDetonation

sensor

Malfunction indicatorlamp MIL

Checkengine light

Manifold absolutepressure MAP

***

Manifold absolutepressure/Barometric pres-MAP/BARO switchsolenoid

***

sure switch solenoid valve valve

Manifold absolutepressure sensor MAPS

**.

Manifold differential pressure MOP

***

Manifold differential pressuresensor MOPS

***

GI-46

Page 1401 of 1701

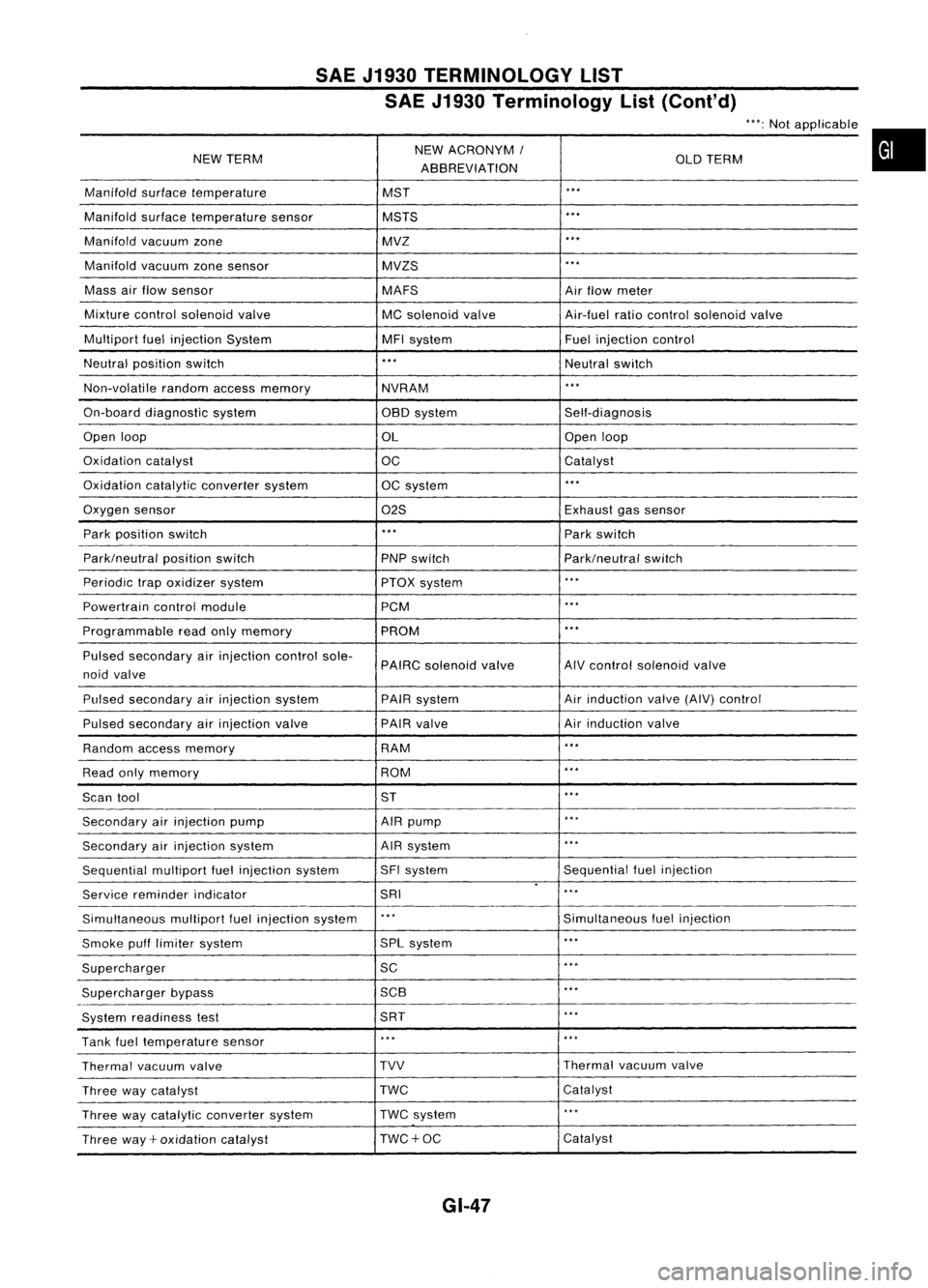

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

NEW TERM NEW

ACRONYM /

OLDTERM

ABBREVIATION

Manifold surfacetemperature MST

...

Manifold surfacetemperature sensor MSTS

...

Manifold vacuumzone MVZ

...

Manifold vacuumzonesensor MVZS

...

Mass airflow sensor

MAFSAirflow meter

Mixture controlsolenoid valve

MCsolenoid valve Air-fuelratiocontrol solenoid valve

Multipart fuelinjection System MFIsystem Fuelinjection control

Neutral position switch

...

Neutralswitch

Non-volatile randomaccessmemory

NVRAM

...

On-board diagnostic system OBOsystem Self-diagnosis

Open loop

OLOpen

loop

Oxidation catalyst

OCCatalyst

Oxidation catalyticconverter system OCsystem

...

Oxygen sensor

02SExhaust

gassensor

Park position switch

...

Parkswitch

Park/neutral positionswitch

PNPswitch Park/neutralswitch

Periodic trapoxidizer system

PTOXsystem

...

Powertrain controlmodule PCM

...

Programmable readonlymemory PROM

...

Pulsed secondary airinjection controlsole-

PAIRCsolenoid valve AIV

control solenoid valve

noid valve

Pulsed secondary airinjection system PAIRsystem Air

induction valve(AIV)control

Pulsed secondary airinjection valve PAIR

valve Airinduction valve

Random accessmemory RAM

...

Read onlymemory ROM

...

Scan tool ST

...

Secondary airinjection pump AIRpump

...

Secondary airinjection system AIR

system

...

Sequential multiportfuelinjection system SFI

system Sequentialfuelinjection

.

Service reminder indicator SRI

...

Simultaneous multipartfuelinjection system

...

Simultaneousfuelinjection

Smoke pufflimiter system SPL

system

...

Supercharger SC

...

Supercharger bypass 5CB

...

System readiness test 5RT

...

Tank fueltemperature sensor

...

...

Thermal vacuumvalve TVV

Thermal

vacuumvalve

Three waycatalyst TWC

Catalyst

Three waycatalytic converter system TWC

system

...

Three way+oxidation catalyst TWC+OC Catalyst

GI-47

Page 1402 of 1701

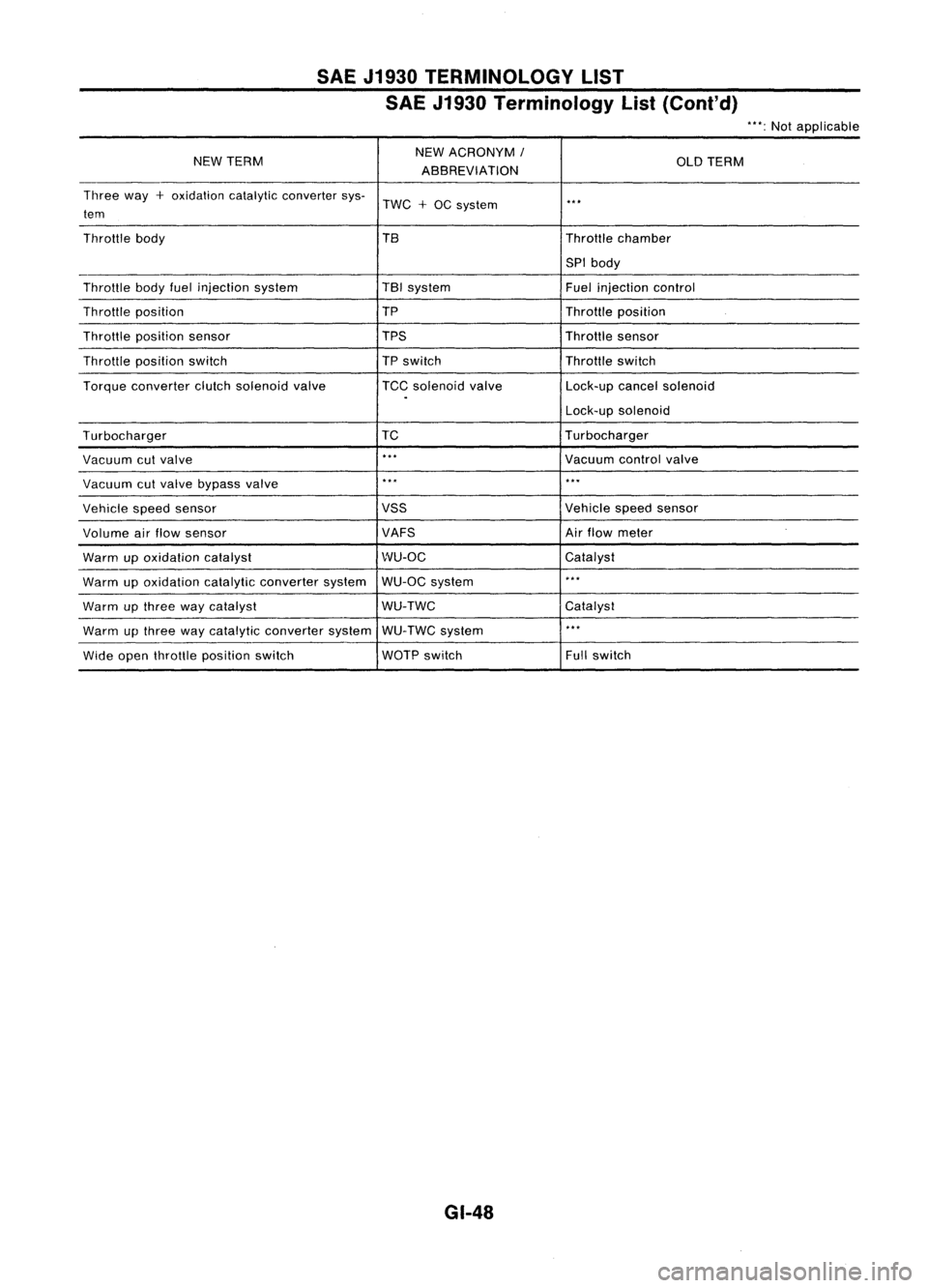

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

"':Not applicable

NEW TERM NEW

ACRONYM

I

OLDTERM

ABBREVIATION

Three way

+

oxidation catalyticconverter sys-

TWC

+

OC system

..

,

tem

Throttle body TBThrottlechamber

SPI body

Throttle bodyfuelinjection system TBI

system

Fuelinjection control

Throttle position TP

Throttleposition

Throttle position sensor TPSThrottlesensor

Throttle position switch

TP

switch Throttleswitch

Torque converter clutchsolenoid valve TCCsolenoid valve Lock-upcancelsolenoid

.

Lock-upsolenoid

Turbocharger TC

Turbocharger

Vacuum cutvalve

..

,

Vacuumcontrolvalve

Vacuum cutvalve bypass valve

..

,

...

Vehicle speedsensor VSS

Vehiclespeedsensor

Volume airflow sensor VAFSAir

flow meter

Warm upoxidation catalyst WU-OC

Catalyst

Warm upoxidation catalyticconverter systemWU-OC

system

..

,

Warm upthree waycatalyst WU-TWC

Catalyst

Warm upthree waycatalytic converter systemWU-TWC system

..

,

Wide open throttle position switch WOTP

switch Fullswitch

GI-48

Page 1404 of 1701

PRECAUTIONSANDPREPARATION

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System)

The Supplemental RestraintSystem"AirBag" usedalong withaseat belt,helps toreduce therisk or

severity ofinjury tothe driver andfront passenger inafrontal collision. TheSupplemental Restraint

System consists ofair bag modules (locatedinthe center ofthe steering wheelandonthe instrument

panel onthe passenger side),adiagnosis sensorunit,warning lamp,wiring harness andspiral cable.

Information necessarytoservice thesystem safelyisincluded inthe

RSsection

ofthis Service Manual.

WARNING:

• Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by an authorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual. SRSwiring harnesses arecovered withyellow insulation eitherjustbefore the

harness connectors orfor the complete harness,foreasy identification.

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System)

The Supplemental RestraintSystem"AirBag" andused along withaseat belt,helps toreduce therisk

or severity ofinjury tothe driver inafrontal collision. TheSupplemental RestraintSystemconsists of

an air bag module (located inthe center ofthe steering wheel),adiagnosis sensorunit,warning lamp,

wiring harness andspiral cable. Information necessarytoservice thesystem safelyisincluded inthe

RS section

ofthis Service Manual.

WARNING: • Toavoid rendering theSRS inoperative, whichcouldincrease therisk ofpersonal injuryordeath

in the event ofacollision whichwould resultinair bag inflation, allmaintenance mustbeperformed

by anauthorized NISSANdealer.

• Improper maintenance, includingincorrectremovalandinstallation ofthe SRS, canlead topersonal

injury caused byunintentional activationofthe system.

• Donot use electrical testequipment onany circuit related tothe SRS unless instructed tointhis

Service Manual.

HA-2

Page 1487 of 1701

SECTION

CONTENTS

MAINTENANCE

MA

•

PRECAUTIONS ANDPREPARATION

3

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 3

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 3

Special Service Tools 4

Commercial ServiceTool 4

PRE-DELIVERY INSPECTIONITEMS

5

GENERAL MAINTENANCE 6

PERIODIC MAINTENANCE (Exceptfor

Europe) 7

Engine andEmission ControlService 7

Chassis andBody Service 8

Maintenance UnderSevere DrivingConditions 9

PERIODIC MAINTENANCE (ForEurope) 10

Engine Oil

&

Minor Service 10

Engine andEmission ControlService 11

Chassis andBody Services 12

Maintenance UnderSevere Driving Conditions 13

RECOMMENDED LUBRICANTSANDFLUIDS 14

Lubricants andFluids 14

SAE Viscosity Number 15

Anti-freeze CoolantMixtureRatio 16

~ --ll

GA

I I

ENGINE MAINTENANCE 17

Checking DriveBelts 17

Changing EngineCoolant... 19

Checking CoolingSystem 21

Checking FuelLines 22

Changing FuelFilter 22

Cleaning andChanging AirCleaner Filter 23

Changing EngineOil 24

Changing OilFilter 24

Checking andChanging SparkPlugs 25

Checking IgnitionWires 26Changing

PositiveCrankcase Ventilation

(PCV) Filter 26

Checking EVAPVapor Lines 26

Checking OxygenSensor(02S)orHeated

Oxygen Sensor(H02S) 27

~ --ll

SR

I I

ENGINE MAINTENANCE 28

Checking DriveBelts 28

Changing EngineCoolant... 29

Checking CoolingSystem 31

Checking FuelLines 32

Changing FuelFilter 32

Changing AirCleaner Filter 33

Changing EngineOil 33

Changing OilFilter 34

Changing SparkPlugs(Platinum-tipped type)34

Checking IgnitionWires 35

Checking EVAPVapor

&

Purge Lines 36

Checking HeatedOxygen Sensor(H02S) 37

~_~ ..-JI

CD

I I

ENGINE MAINTENANCE

38

Manifold NutCheck 38

Checking DriveBelt 38

Changing EngineCoolant. 38

Checking CoolingSystem .40

Checking FuelLine .40

Changing AirCleaner Filter 41

Water Draining, FuelFilter Check and

Replacement 41

Changing EngineOil .41

Changing EngineOilFilter 42

Checking InjectionNozzle 43

Checking IdleSpeed .44

Replacing TimingBelt 44