Color NISSAN ALMERA N15 1995 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1003 of 1701

![NISSAN ALMERA N15 1995 Owners Manual TROUBLEDIAGNOSIS -General Description

[]:KJ

ECM Terminals andReference Value(Cont'd)

*Data arereference values.

TERMINAL WIRE

ITEM CONDITION *

DATA

NO. COLOR

/Ignitionswitch"ON'"

t NISSAN ALMERA N15 1995 Owners Manual TROUBLEDIAGNOSIS -General Description

[]:KJ

ECM Terminals andReference Value(Cont'd)

*Data arereference values.

TERMINAL WIRE

ITEM CONDITION *

DATA

NO. COLOR

/Ignitionswitch"ON'"

t](/img/5/57349/w960_57349-1002.png)

TROUBLEDIAGNOSIS -General Description

[]:KJ

ECM Terminals andReference Value(Cont'd)

*Data arereference values.

TERMINAL WIRE

ITEM CONDITION *

DATA

NO. COLOR

/Ignitionswitch"ON'"

t

"N" or"P" position

(A/T)

OV

35

G/OR

Neutral

position

Neutralposition

(M/T)

switch/lnhibitor switch

I'gnitionswitch"ON"I

BATTERYVOLTAGE

L

Except theabove gearposition (11

-14V)

I'gnition switch"OFF"I

OV

36 B/R Ignition

switch

Ilgnitionswitch"ON"I BATTERY

VOLTAGE

(11 -14V)

37 P/L Throttle

position sen-

pgnition switch"ON"I

Approximately5V

sor power supply

38 Powersupply forECM

Ilgnition switch"ON"I BATTERY

VOLTAGE

47 W/R

(11-14V)

39 B ECCSground IEngine

isrunning.1

Engineground

L

Idle speed

IEngine isrunning.!

L

Both airconditioner switchandblower fanApproximately

OV

41 G Air

conditioner switch switch

are"ON".

IEngine isrunning.1

BATTERYVOLTAGE

L

Airconditioner switchis"OFF". (11

-14V)

IEngine isrunning.1

OV

Power steering oil

L

Steering wheelisbeing turned.

43 PUlW

pressureswitch

IEngineisrunning.1

L

Steering wheelisnot being turned. 7

-9V

46 W/L Power

supply

I'gnitionswitch

"0FFj

BATTERY

VOLTAGE

(Back-up) (11-14V)

48 B ECCSground IEngine

isrunning.1

Engineground

L

Idle speed

109 W/L Currentreturn

Ilgnitionswitch"OFF"I BATTERY

VOLTAGE

(11 -14V)

101 RIB InjectorNo.1

103

G/B

InjectorNo.3

BATTERYVOLTAGE

110 Y/B InjectorNO.2 IEngine

isrunning.1

(11-14V)

112 LIB InjectorNO.4

EC-284

Page 1004 of 1701

![NISSAN ALMERA N15 1995 Owners Manual TROUBLEDIAGNOSIS -General Description

[]K]

ECM Terminals andReference Value(Cont'd)

'Data arereference values.

TERMINAL WIRE

ITEM CONDITION

'DATA

NO. COLOR

Ilgnitionswitch"ON"I

NISSAN ALMERA N15 1995 Owners Manual TROUBLEDIAGNOSIS -General Description

[]K]

ECM Terminals andReference Value(Cont'd)

'Data arereference values.

TERMINAL WIRE

ITEM CONDITION

'DATA

NO. COLOR

Ilgnitionswitch"ON"I](/img/5/57349/w960_57349-1003.png)

TROUBLEDIAGNOSIS -General Description

[]K]

ECM Terminals andReference Value(Cont'd)

'Data arereference values.

TERMINAL WIRE

ITEM CONDITION

'DATA

NO. COLOR

Ilgnitionswitch"ON"I

L

For 5seconds afterturning ignition switch

"ON" Approximately

OV

104 B/P Fuelpump relay !Engine

isrunning.1

Ilgnition switch"ON"I

BATTERY VOLTAGE

L

5seconds afterturning ignitionswitch

(11-14V)

"ON" andthereafter

IEngine isrunning.1

0.6-0.8V

EGR valve

&

EVAP

.L

Engine speedis4,000 rpm.

105 P canisterpurgecontrol

solenoid valve IEngine

isrunning.1

BATTERYVOLTAGE

L

Idle speed (11

-14V)

107 IEngine

isrunning.j

B/Y ECCSground

L

Engine

ground

108 Idlespeed

!Engine isrunning.1

Approximately0.2V

L

Engine speedisbelow 3,200rpm.

Heated oxygen sensor

111 OR

heater IEngineisrunning.1

BATTERY VOLTAGE

L

Engine speedisabove 3,200rpm. (11

-14V)

IEngine isrunning.\

11-14V

L

Idle speed

113 SB IACV-AAC

valve lEngine

isrunning.1

~ Sle«;ng wheel;,be;ng I"med

2-11V

Air conditioner isoperating.

Rear window defogger switchis"ON".

Lighting switchis"ON".

!Engine isrunning.1

ApproximatelyOV

Torque converter

L

Idle speed

115 P/B clutch

solenoid valve

IEngineisrunning.1 (Warm-up condition)

(A/T

models)

L

Vehicle speedis60 km/h (37MPH) or BA

TTERY VOLTAGE

(11 -14V)

more in"D" position

116 BIY ECCS

ground IEngine

isrunning.1

Engineground

L

Idle speed

EC-285

•

Page 1096 of 1701

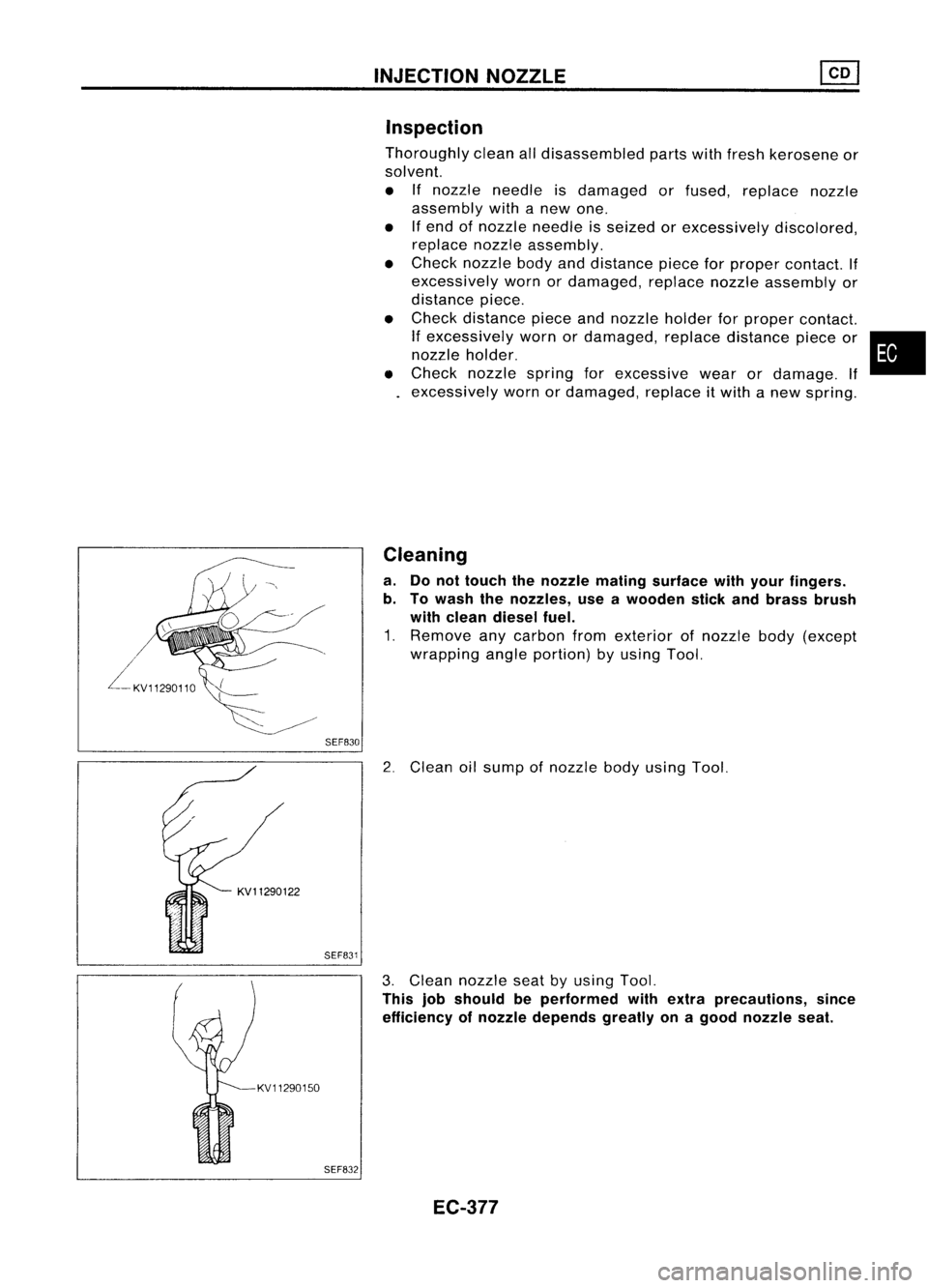

SEF830INJECTION

NOZZLE

Inspection

Thoroughly cleanalldisassembled partswithfresh kerosene or

solvent.

• Ifnozzle needle isdamaged orfused, replace nozzle

assembly withanew one.

• Ifend ofnozzle needle isseized orexcessively discolored,

replace nozzleassembly.

• Check nozzle bodyanddistance pieceforproper contact. If

excessively wornordamaged, replacenozzleassembly or

distance piece.

• Check distance pieceandnozzle holderforproper contact.

If

excessively wornordamaged, replacedistance pieceor•

nozzle holder.

• Check nozzle springforexcessive wearordamage. If

excessively wornordamaged, replaceitwith anew spring.

Cleaning

a. Donot touch thenozzle mating surface withyour fingers.

b. Towash thenozzles, useawooden stickandbrass brush

with clean diesel fuel.

1. Remove anycarbon fromexterior ofnozzle body(except

wrapping angleportion) byusing Tool.

2. Clean oilsump ofnozzle bodyusing Tool.

KV11290150 SEF831

SEF832

3.

Clean nozzle seatbyusing Tool.

This jobshould beperformed withextra precautions, since

efficiency ofnozzle depends greatlyonagood nozzle seat.

EC-377

Page 1202 of 1701

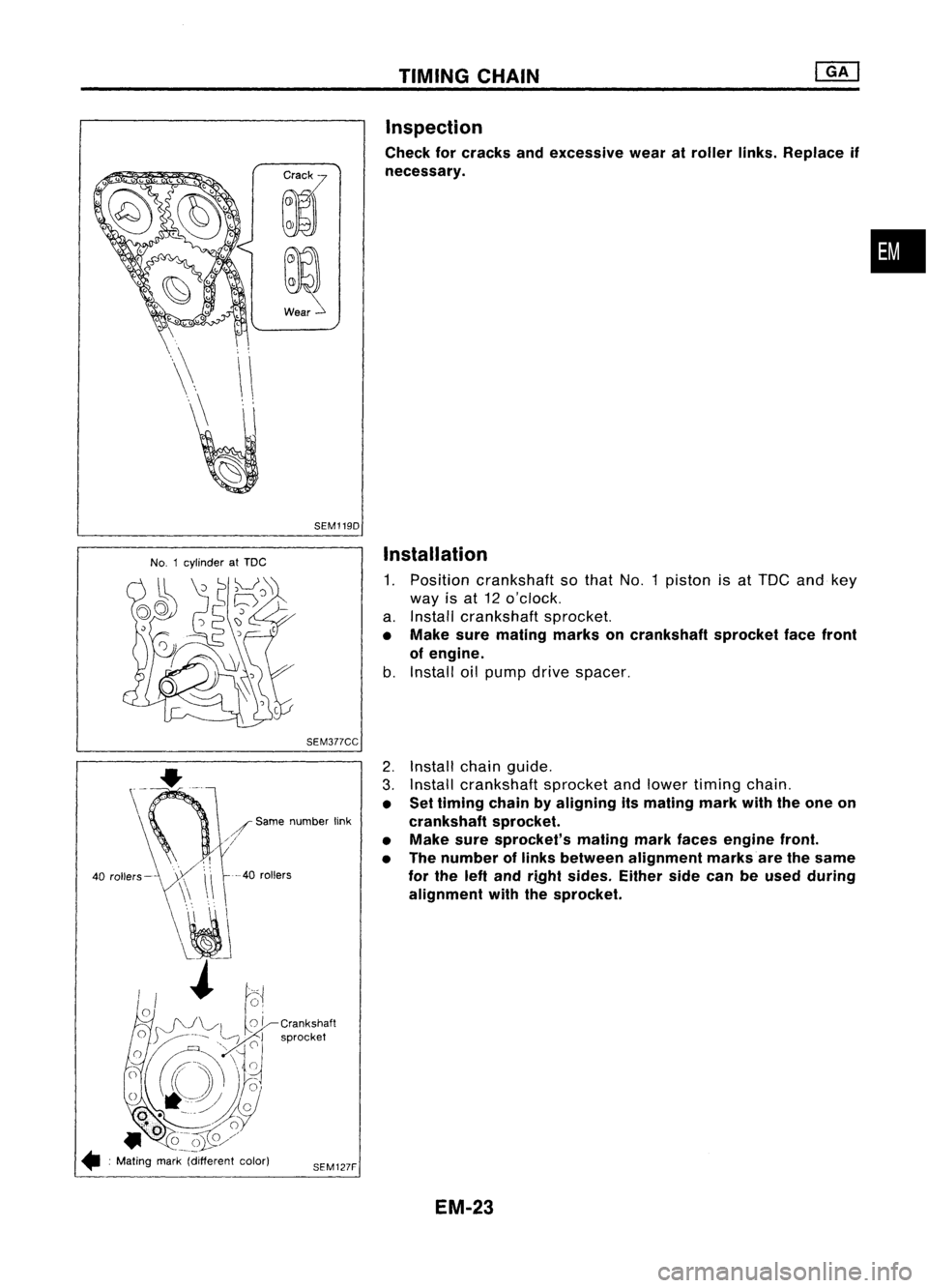

TIMINGCHAIN

Inspection

Check forcracks andexcessive wearatroller links.Replace if

necessary.

•

SEM1190

No. 1cylinder atTDC

Installation

1. Position crankshaft sothat No.1piston isat TOC andkey

way isat 12 o'clock.

a. Install crankshaft sprocket.

• Make suremating marksoncrankshaft sprocketfacefront

of engine.

b. Install oilpump drivespacer.

SEM377CC

--40

rollers

2.

Install chainguide.

3. Install crankshaft sprocketandlower timing chain.

• Settiming chainbyaligning itsmating markwiththeone on

crankshaft sprocket.

• Make suresprocket's matingmarkfaces engine front.

• The number oflinks between alignment marksare thesame

for the leftand ri.Qht sides. Eithersidecanbeused during

alignment withthesprocket.

SEM127F

/

Same number link

///

40 rollers-

• :Mating mark(different color)

EM-23

Page 1203 of 1701

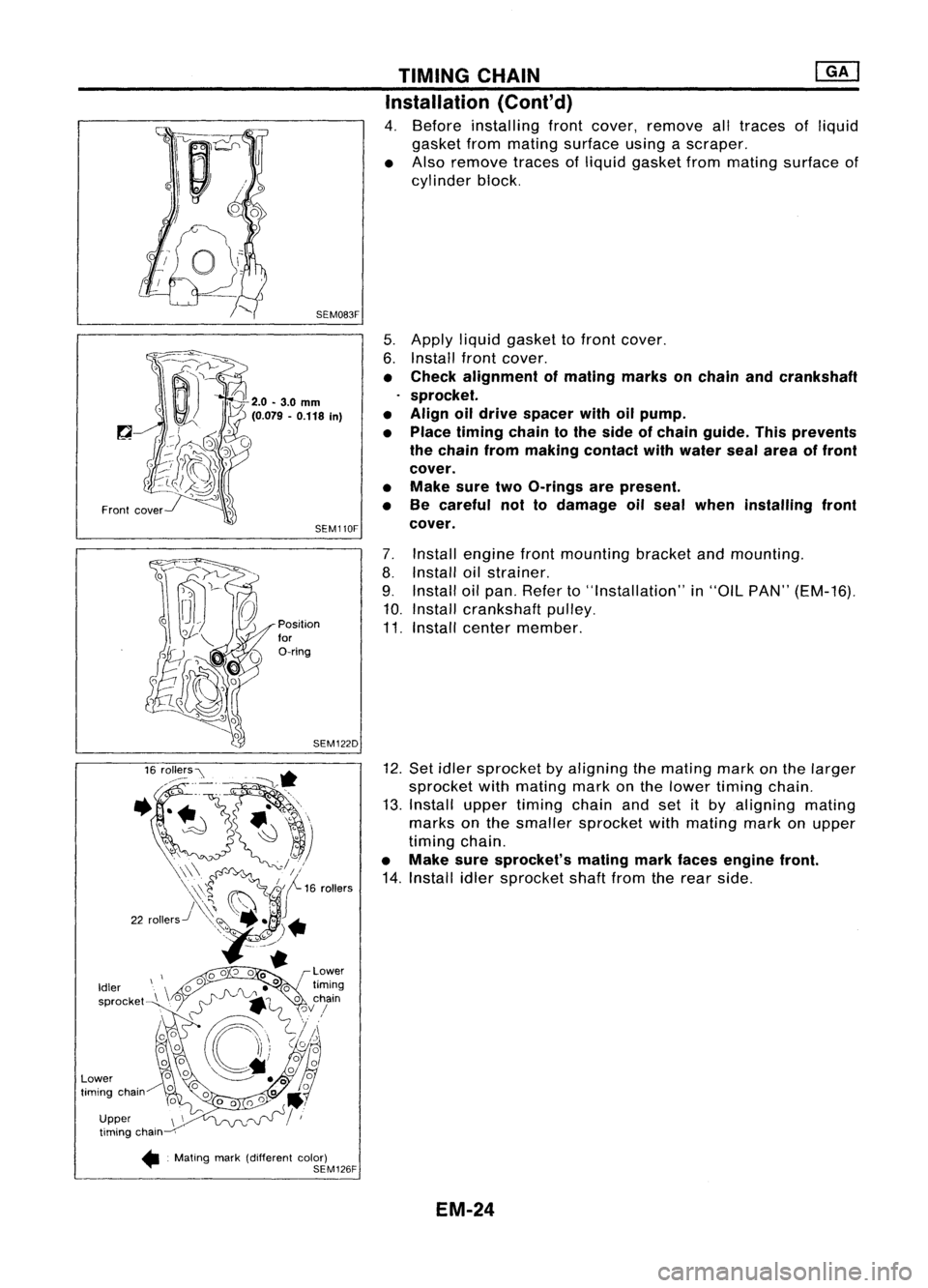

TIMINGCHAIN ~

Installation (Cont'd)

4. Before installing frontcover, remove alltraces ofliquid

gasket frommating surface usingascraper.

• Also remove tracesofliquid gasket frommating surface of

cylinder block.

5. Apply liquidgasket tofront cover.

6. Install frontcover.

• Check alignment ofmating marksonchain andcrankshaft

sprocket.

• Align oildrive spacer withoilpump.

• Place timing chaintothe side ofchain guide. Thisprevents

the chain frommaking contact withwater sealarea offront

cover.

• Make suretwoO-rings arepresent.

• Be careful nottodamage oilseal when installing front

cover.

7. Install engine frontmounting bracketandmounting.

8. Install oilstrainer.

9. Install oilpan. Refer to"Installation" in"OIL PAN" (EM-16).

10. Install crankshaft pulley.

11. Install center member.

12. Set idler sprocket byaligning themating markonthe larger

sprocket withmating markonthe lower timing chain.

13. Install uppertiming chainandsetitby aligning mating

marks onthe smaller sprocket withmating markonupper

timing chain.

• Make suresprocket's matingmarkfaces engine front.

14. Install idlersprocket shaftfromtherear side.

SEM083F

SEM110F

SEM122D

Position

for

O-ring

Front

cover

Upper timing chain

•. Mating mark(different color)

SEM126F

Idler

sprocket

Lower

timing chain

EM-24

Page 1206 of 1701

![NISSAN ALMERA N15 1995 Owners Manual

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

cam NISSAN ALMERA N15 1995 Owners Manual

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

cam](/img/5/57349/w960_57349-1205.png)

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

camshaft sprockets.

• Make suresprocket's matingmarksfaceengine front.

20. Install camshaft sprocketbolts.

• Apply newengine oiltobolt threads andseat surface .

•

SEM657D

2.0.3.0

mm

(0.079 -0.118 In)

21.

Install upperchaintensioner.

• Before installing chaintensioner, insertasuitable pininto

pin hole ofchain tensioner.

• After installing chaintensioner, removethepin.

22. Install lowerchaintensioner.

CAUTION:

• Check noproblems occurwhenengine isrotated.

• Make surethatNo.1piston isset atTOC onitscompres-

sion stroke.

• Make sureofthe direction ofthe gasket beforeinstalling

lower chaintensioner.

23. Apply liquidgasket tothermostat housing.

• Use Genuine LiquidGasket orequivalent.

24. Install thermostat housing.

25. Install waterpump pulley.

EM-27

Page 1219 of 1701

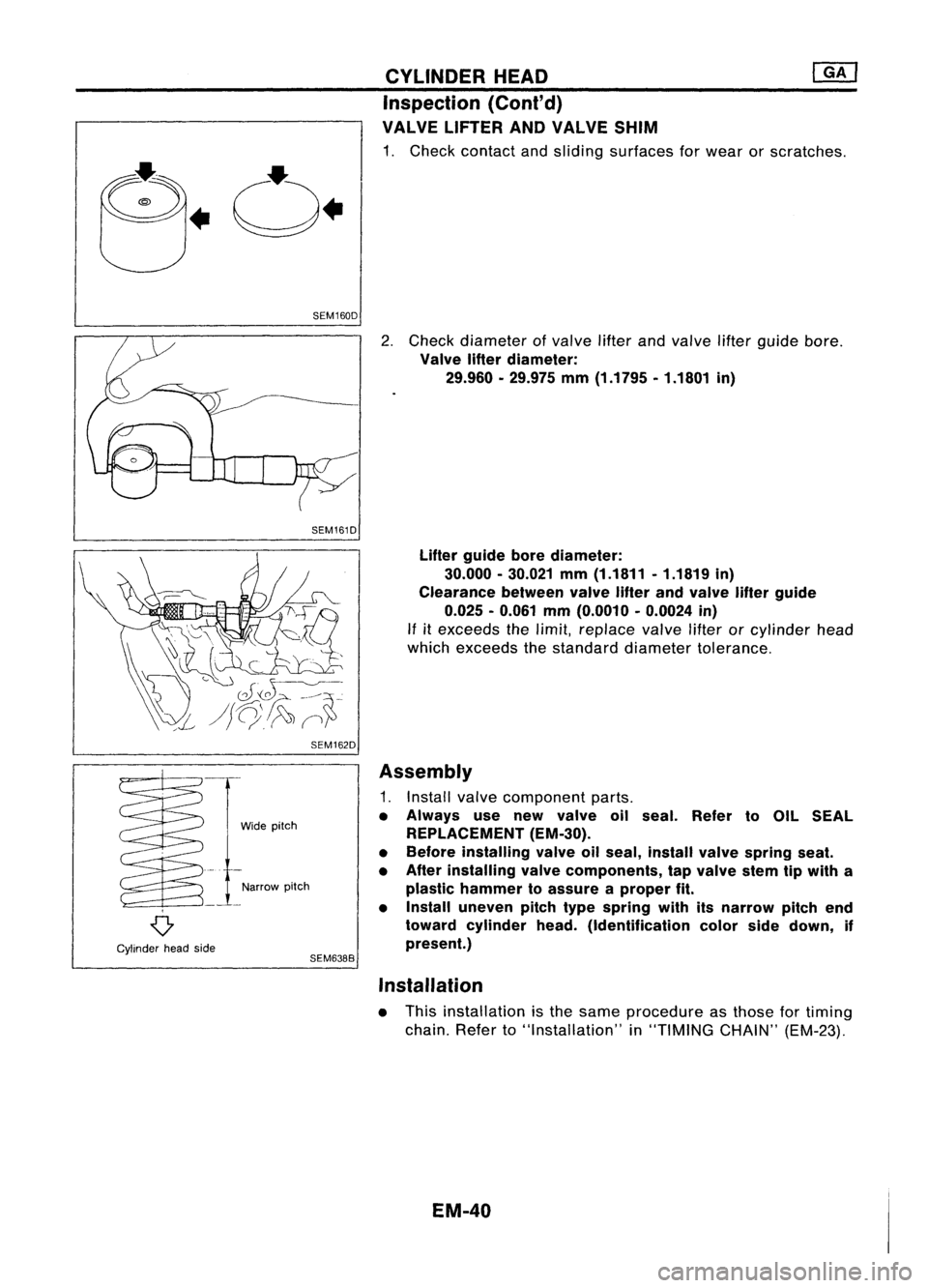

SEM160DCYLINDER

HEAD

Inspection (Cont'd)

VALVE LIFTER ANDVALVE SHIM

1. Check contact andsliding surfaces forwear orscratches.

SEM161D

SEM162D

2.

Check diameter ofvalve lifterandvalve lifterguide bore.

Valve lifterdiameter:

29.960 •29.975 mm(1.1795 •1.1801 in)

Lifter guide borediameter:

30.000 -30.021 mm(1.1811 .1.1819 in)

Clearance betweenvalvelifterandvalve lifterguide

0.025 -0.061 mm(0.0010 -0.0024 in)

If

it

exceeds thelimit, replace valvelifterorcylinder head

which exceeds thestandard diameter tolerance.

o

Cylinder headside Wide

pitch

Narrow pitch

SEM638B

Assembly

1. Install valvecomponent parts.

• Always usenew valve oilseal. Refer toOIL SEAL

REPLACEMENT (EM-30).

• Before installing valveoilseal, install valvespring seat.

• After installing valvecomponents, tapvalve stemtipwith a

plastic hammer toassure aproper fit.

• Install uneven pitchtypespring withitsnarrow pitchend

toward cylinder head.(Identification colorsidedown, if

present.)

Installation

• This installation isthe same procedure asthose fortiming

chain. Referto"Installation" in"TIMING CHAIN"(EM-23).

EM-40

Page 1232 of 1701

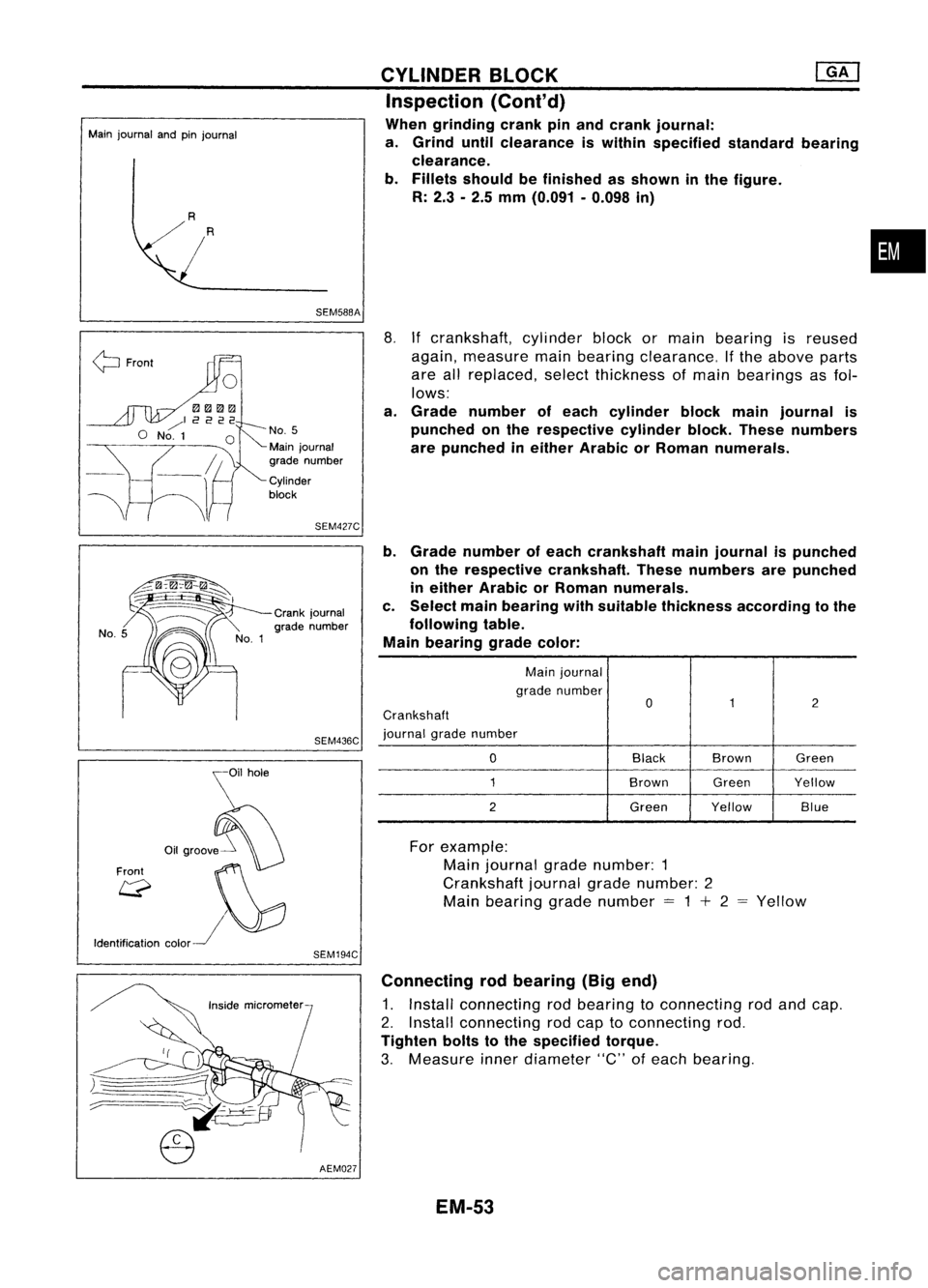

Mainjournal andpinjournal

R

SEM588ACYLINDER

BLOCK

[ill

Inspection (Conl'd)

When grinding crankpinand crank journal:

a. Grind untilclearance iswithin specified standardbearing

clearance.

b. Fillets should befinished asshown inthe figure.

R: 2.3 -2.5 mm (0.091 -0.098 in)

•

~ Front

No.5

Main journal

grade number

Cylinder

block

SEM427C

8.

Ifcrankshaft, cylinderblockormain bearing isreused

again, measure mainbearing clearance. Ifthe above parts

are allreplaced, selectthickness ofmain bearings asfol-

lows:

a. Grade number ofeach cylinder blockmainjournal is

punched onthe respective cylinderblock.These numbers

are punched ineither Arabic orRoman numerals.

b. Grade number ofeach crankshaft mainjournal ispunched

on the respective crankshaft. Thesenumbers arepunched

in either Arabic orRoman numerals.

c. Select mainbearing withsuitable thickness according tothe

following table.

Main bearing gradecolor:

Main journal

grade number

0

1

2

Crankshaft

journal gradenumber

0

Black

Brown Green

1

BrownGreenYellow

2

GreenYellow Blue

Crank

journal

grade number

SEM436C

\i1hOle

o,.",,!f0

Front ~~

Q

I\}:J

Identification color~

SEM194C

For

example:

Main journal gradenumber: 1

Crankshaft journalgradenumber: 2

Main bearing gradenumber

=

1

+

2 Yellow

)=====

.-:::::::======_ ..

;::..----

AEM027Connecting

rodbearing (Bigend)

1. Install connecting rodbearing toconnecting rodand cap.

2. Install connecting rodcap toconnecting rod.

Tighten boltstothe specified torque.

3. Measure innerdiameter "C"ofeach bearing.

EM-53

Page 1233 of 1701

![NISSAN ALMERA N15 1995 Owners Manual CYLINDERBLOCK .@K]

Inspection (Cont'd)

4. Measure outerdiameter "Op"ofeach crankshaft pinjour-

nal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Dp

St NISSAN ALMERA N15 1995 Owners Manual CYLINDERBLOCK .@K]

Inspection (Cont'd)

4. Measure outerdiameter "Op"ofeach crankshaft pinjour-

nal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Dp

St](/img/5/57349/w960_57349-1232.png)

CYLINDERBLOCK .@K]

Inspection (Cont'd)

4. Measure outerdiameter "Op"ofeach crankshaft pinjour-

nal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Dp

Standard:

0.014 -0.039 mm(0.0006 •0.0015 in)

Limit: 0.1mm (0.004 in)

6. Ifitexceeds thelimit, replace bearing.

7. Ifclearance cannotbeadjusted withinthestandard ofany

bearing, grindcrankshaft journalanduseundersized bear-

ing. Refer tostep 7of "BEARING CLEARANCE -Main

bearing" (EM-52).

CONNECTING RODBUSHING CLEARANCE (Smallend)

1. Measure innerdiameter "C"ofbushing.

8.

Ifbearing, crankshaft orconnecting rodisreplaced witha

new one, select connecting rodbearing according tothe

following table.

Connecting rodbearing gradenumber:

Grade numbers arepunched ineither Arabic orRoman numer-

als.

Method B(Using plastigage)

CAUTION:

• Donot turn crankshaft orconnecting rodwhile plastigage is

being inserted.

• When bearing clearance exceedsthespecified limit,ensure

that theproper bearing hasbeen installed. Thenifexces-

sive bearing clearance exists,useathicker mainbearing or

undersized bearingsothat thespecified bearingclearance

is obtained.

Brown

Green

Connecting

rodbearing

grade color

a

1

2

Crank

pingrade color

SEM437C

EM-54

Page 1253 of 1701

![NISSAN ALMERA N15 1995 Owners Manual

@

~c

t':'

CO',

M''''',mwk

Mating markC

~!

56

coli'" ~

t..

coli."

CD

Mating mark

SEM500E TIMING

CHAIN

[]K]

Installation (Cont'd)

2. Positio NISSAN ALMERA N15 1995 Owners Manual

@

~c

t':'

CO',

M''''',mwk

Mating markC

~!

56

coli'" ~

t..

coli."

CD

Mating mark

SEM500E TIMING

CHAIN

[]K]

Installation (Cont'd)

2. Positio](/img/5/57349/w960_57349-1252.png)

@

~c

t':'

CO',

M''''',mwk

Mating markC

~!

56

coli'" ~

t..

coli."

CD

Mating mark

SEM500E TIMING

CHAIN

[]K]

Installation (Cont'd)

2. Position crankshaft sothat No.1 piston isset atTOG andkey

way isat 12 o'clock. Fittiming chainoncrankshaft sprocket,

aligning themating marks.

• Mating markcolorontiming chain.

eD

Gold

@,

CID:

Silver

3. Install timing chainandtiming chainguides.

4. Before installing frontcover, remove alltraces ofliquid

gasket frommating surface usingascraper.

• Also remove tracesofliquid gasket frommating surface of

cylinder block.

5. Apply acontinuous beadofliquid gasket tomating surface

of front cover.

• Use Genuine LiquidGasket orequivalent.

• Besure toinstall newfront oilseal inthe right direction.

Refer toEM-82.

EM-74