Color NISSAN ALMERA N15 1995 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1286 of 1701

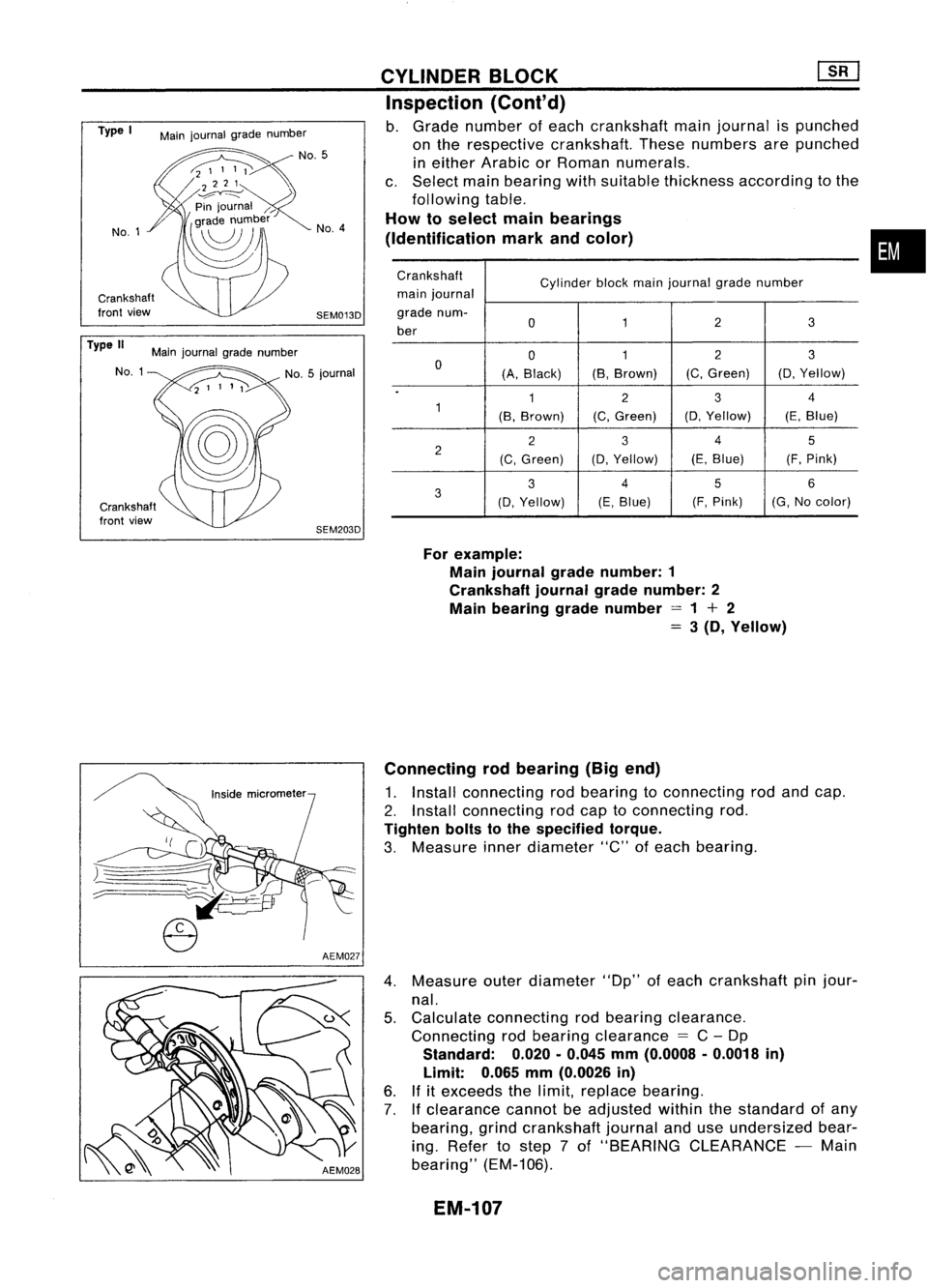

Crankshaft

front view

Crankshaft

front view

•

Crankshaft

Cylinderblockmainjournal gradenumber

main journal

grade num-

0 12

3

ber

012

3

0

(A,Black) (B,

Brown) (C,

Green) (0,Yellow)

.

12

3

4

1

(B,Brown) (C,Green) (0,

Yellow) (E,Blue)

2

3

4

5

2

(C,Green) (0,

Yellow) (E,Blue) (F,Pink)

3

4

5

6

3

(0,Yellow) (E,

Blue) (F,

Pink) (G,Nocolor)

For example:

Main journal gradenumber: 1

Crankshaft journalgradenumber: 2

Main bearing gradenumber =1+ 2

=

3(D, Yellow)

CYLINDER

BLOCK ~

Inspection (Conl'd)

b. Grade number ofeach crankshaft mainjournal ispunched

on the respective crankshaft. Thesenumbers arepunched

in either Arabic orRoman numerals.

c. Select mainbearing withsuitable thickness according tothe

following table.

How toselect mainbearings

(Identification markandcolor)

SEM013D No.

4

SEM203D

Main

journal gradenumber

No.5

Main journal gradenumber

NO.1

Type

I

No.1

Type II

Connectingrodbearing (Bigend)

1. Install connecting rodbearing toconnecting rodand cap.

2. Install connecting rodcap toconnecting rod.

Tighten boltstothe specified torque.

3. Measure innerdiameter "C"ofeach bearing.

4. Measure outerdiameter "Dp"ofeach crankshaft pinjour-

nal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Dp

Standard:

0.020.0.045

mm

(0.0008 .0.0018

in)

Limit:

0.065

mm

(0.0026

in)

6. Ifitexceeds thelimit, replace bearing.

7.

If

clearance cannotbeadjusted withinthestandard ofany

bearing, grindcrankshaft journalanduseundersized bear-

ing. Refer tostep 7of "BEARING CLEARANCE -Main

bearing" (EM-106).

EM-107

Page 1287 of 1701

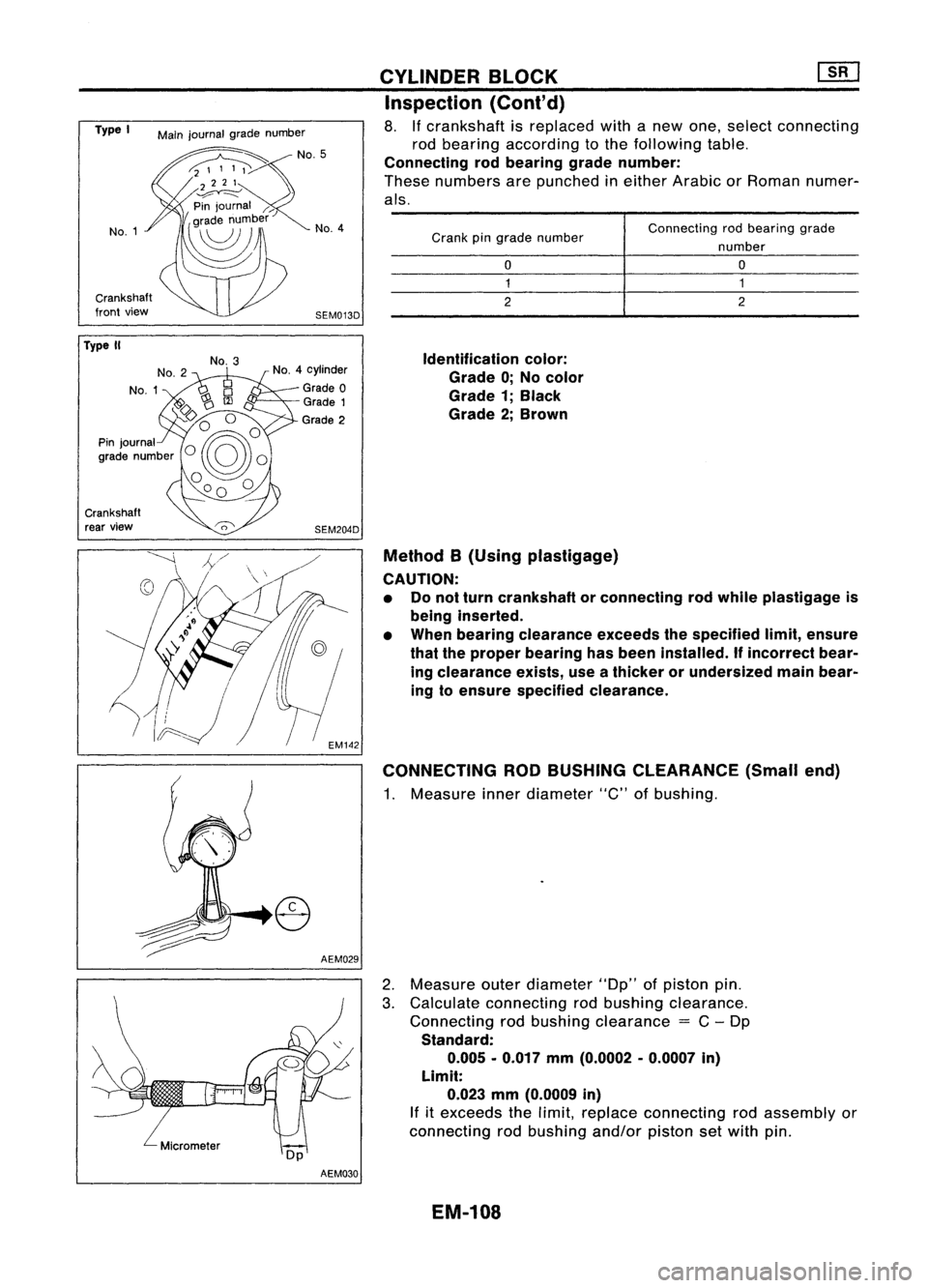

Connectingrodbearing grade

number

o

1

2

o

1

2

Crank

pingrade number

Identification color:

Grade 0;No color

Grade 1;Black

Grade 2;Brown

Method B(Using plastigage)

CAUTION: • Donot turn crankshaft orconnecting rodwhile plastigage is

being inserted.

• When bearing clearance exceedsthespecified limit,ensure

that theproper bearing hasbeen installed.

If

incorrect bear-

ing clearance exists,useathicker orundersized mainbear-

ing toensure specified clearance.

CONNECTING RODBUSHING CLEARANCE (Smallend)

1. Measure innerdiameter "C"ofbushing.

CYLINDER

BLOCK ~

Inspection (Cont'd)

8. Ifcrankshaft isreplaced withanew one, select connecting

rod bearing according tothe following table.

Connecting rodbearing gradenumber:

These numbers arepunched ineither Arabic orRoman numer-

als.

AEM029

SEM013D

No.

4

SEM204D

No.

4cylinder

Grade 0

Grade 1

Grade 2

No.

3

Main

journal gradenumber

No.1

Crankshaft

front view

Type

I

Crankshaft rear view

Type

II

2.Measure outerdiameter "Dp"ofpiston pin.

3. Calculate connecting rodbushing clearance.

Connecting rodbushing clearance

=

C-Dp

Standard: 0.005 -0.017 mm(0.0002 -0.0007 in)

Limit: 0.023 mm(0.0009 in)

If

itexceeds thelimit, replace connecting rodassembly or

connecting rodbushing and/orpistonsetwith pin.

AEM030

EM-108

Page 1326 of 1701

![NISSAN ALMERA N15 1995 Owners Guide CYLINDERBLOCK

@[]

Inspection (Cont'd)

• Ifeither bearing, crankshaft orcylinder blockisreplaced

with anew one, select mainbearing according tothe fol-

lowing table.These numbers arepunched in NISSAN ALMERA N15 1995 Owners Guide CYLINDERBLOCK

@[]

Inspection (Cont'd)

• Ifeither bearing, crankshaft orcylinder blockisreplaced

with anew one, select mainbearing according tothe fol-

lowing table.These numbers arepunched in](/img/5/57349/w960_57349-1325.png)

CYLINDERBLOCK

@[]

Inspection (Cont'd)

• Ifeither bearing, crankshaft orcylinder blockisreplaced

with anew one, select mainbearing according tothe fol-

lowing table.These numbers arepunched ineither Arabic

or Roman numerals.

Mainbearing housing gradenumber

0 1

2

Main bearing gradenumber

0 0 12

Crankshaft mainjour-

1

1

2

3

nal grade number

22

3

4

•

~NO'1 mainjournal gradenumber

NO.2 No.4

"" No. 3/ No.5

~'S"bci~

0000 "')N1

~ o.

- Counterweight

"\ /i

SEM706DAIdentification

color:

Grade 0

Grade 1

Grade 2

Grade 3

Grade 4 Yellow

Green

Brown

BlackBlue

No. 1journal gradenumber

~No.5

Q

Front

0

SEM706A

For

example:

Main journal gradenumber: 1

Crankshaft journalgradenumber: 2

Main bearing gradenumber

=

1

+

2

Main bearing thickness:

Refer toSOS (EM-175).

3

SEM507A CONNECTING

RODBEARING CLEARANCE (Bigend)

1. Install connecting rodbearing toconnecting rodand cap.

2. Install connecting rodcap with bearing toconnecting rod.

Apply oiltothe thread portion ofbolts andseating surface of

nuts.

toJ:

37-45 N'm (3.8-4.6 kg-m, 27-33 ft-Ib)

3. Measure insidediameter "C"ofbearing.

EM-147

Page 1327 of 1701

![NISSAN ALMERA N15 1995 Owners Guide CYLINDERBLOCK [][]

Inspection (Cont'd)

4. Measure outsidediameter "Dp"ofcrankshaft pinjournal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Op

Standa NISSAN ALMERA N15 1995 Owners Guide CYLINDERBLOCK [][]

Inspection (Cont'd)

4. Measure outsidediameter "Dp"ofcrankshaft pinjournal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Op

Standa](/img/5/57349/w960_57349-1326.png)

CYLINDERBLOCK [][]

Inspection (Cont'd)

4. Measure outsidediameter "Dp"ofcrankshaft pinjournal.

5. Calculate connecting rodbearing clearance.

Connecting rodbearing clearance

=

C-Op

Standard:

0.031 -0.055

mm

(0.0012 -0.0022

in)

• Ifitexceeds thelimit, replace thebearing.

• Ifcrankshaft pinjournal isworn orshows anyabnormality,

regrind crankpinand useundersized bearingstomaintain

the specified oilclearance.

• Refer toSOS forregrinding diameterofcrankshaft pinand

available serviceparts(EM-174).

• When regrinding crankshaft pin,donot grind fillet-roll.

Pin

jOUrnal~

Maintain morethan0.13mm(0.0051 in)

SEM361D

~NO' 1pin journal gradenumber

~NO' 2No.3

__ NO.4

,/

o

J

0 0 ~ NO.1

~ C,"'''ffl.;ghl

SEM705D

Selective

connecting rodbearing

• Ifeither bearings orcrankshaft arebeing replaced withnew

ones, select connecting rodbearings according tothe fol-

lowing table.Grade numbers arepunched ineither Arabic

or Roman numerals.

Crankshaftpinjournal gradenumber

0 1

2

Connecting rodbaring gradenum-

0 12

ber

Identification color

Grade 0:Black

Grade 1:Yellow

Grade 2:Blue

CONNECTING RODANDPISTON PINCLEARANCE

(Small end)

Clearance

(0-

d):

0.025 -0.044

mm

(0.0010 -0.0017

in)

• Ifclearance exceedsthespecifications, replacethebearing.

Clearance

=

0 -d

SEM575B

EM-148

Page 1341 of 1701

CRANKSHAFT SERVICE

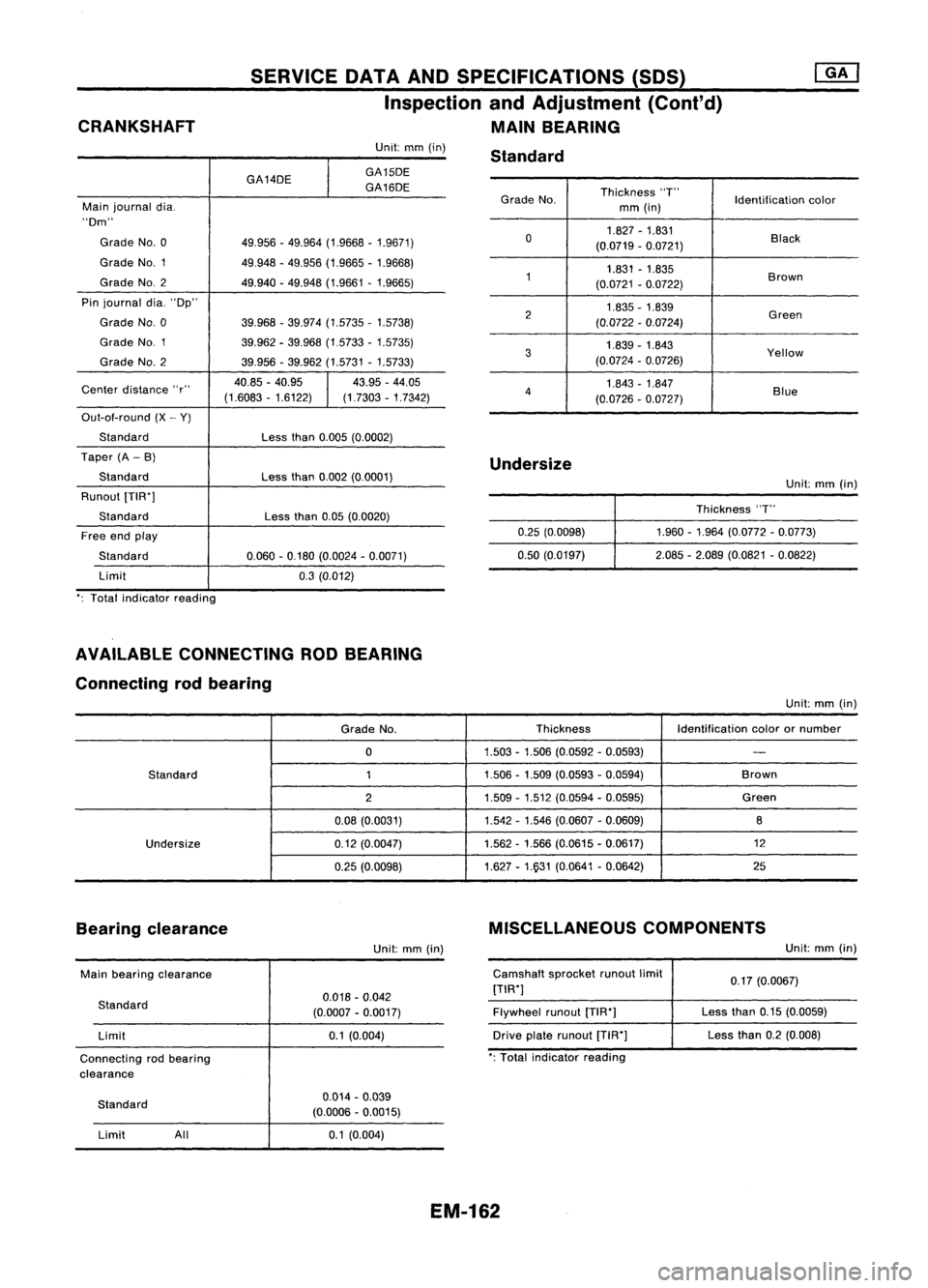

DATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

MAIN BEARING

Grade No. Thickness

"T"

Identificationcolor

mm (in)

0 1.827

-1.831

Black

(0.0719 -0.0721)

1 1.831

-1.835

Brown

(0.0721 -0.0722)

2 1.835

-1.839

Green

(0.0722 -0.0724)

3 1.839

-1.843

Yellow

(0.0724 -0.0726)

4 1.843

-1.847

Blue

(0.0726 -0.0727)

Unit:

mm(in)

GA14DE

I

GA15DE

GA16DE

Main journal dia.

"Dm"

Grade No.0 49.956-49.964 (1.9668 -1.9671)

Grade NO.1 49.948-49.956 (1.9665 -1.9668)

Grade NO.2

49.940-49.948 (1.9661 -1.9665)

Pin journal dia."Dp"

Grade No.0 39.968-39.974 (1.5735 -1.5738)

Grade NO.1

39.962-39.968 (1.5733 -1.5735)

Grade No.2 39.956-39.962 (1.5731 -1.5733)

Center distance "r" 40.85

-40.95

I

43.95

-44.05

(1.6083 -1.6122) (1.7303-1.7342)

Out-ot-round (X-Y)

Standard Lessthan0.005 (0.0002)

Taper (A-B)

Standard Lessthan0.002 (0.0001)

Runout [TIW]

Standard Lessthan0.05(0.0020)

Free endplay

Standard 0.060-0.180 (0.0024 -0.0071)

Limit 0.3(0.012)

': Total indicator reading Standard

Undersize 0.25(0.0098)

0.50 (0.0197) Unit:

mm(in)

Thickness "T"

1.960 -1.964 (0.0772 -0.0773)

2.085 -2.089 (0.0821 -0.0822)

AVAILABLE CONNECTING RODBEARING

Connecting rodbearing

Unit:mm(in)

Grade No. Thickness

Identificationcolorornumber

0 1.503

-1.506 (0.0592 -0.0593)

-

Standard 11.506-1.509 (0.0593 -0.0594) Brown

2 1.509

-1.512 (0.0594 -0.0595) Green

0.08 (0.0031) 1.542

-1.546 (0.0607 -0.0609)

8

Undersize 0.12(0.0047) 1.562

-1.566 (0.0615 -0.0617) 12

0.25 (0.0098) 1.627

-1.931 (0.0641 -0.0642) 25

Bearing clearance

Unit:mm(in) MISCELLANEOUS

COMPONENTS

Unit:mm(in)

Main bearing clearance

Standard Limit

Connecting rodbearing

clearance 0.018

-0.042

(0.0007 -0.0017)

0.1 (0.004) Camshaft

sprocketrunoutlimit

[TIW]

Flywheel runout[TIW]

Drive platerunout [T1R']

': Total indicator reading 0.17

(0.0067)

Less than0.15(0.0059)

Less than0.2(0.008)

Standard Limit All 0.014

-0.039

(0.0006 -0.0015)

0.1 (0.004)

EM-162

Page 1349 of 1701

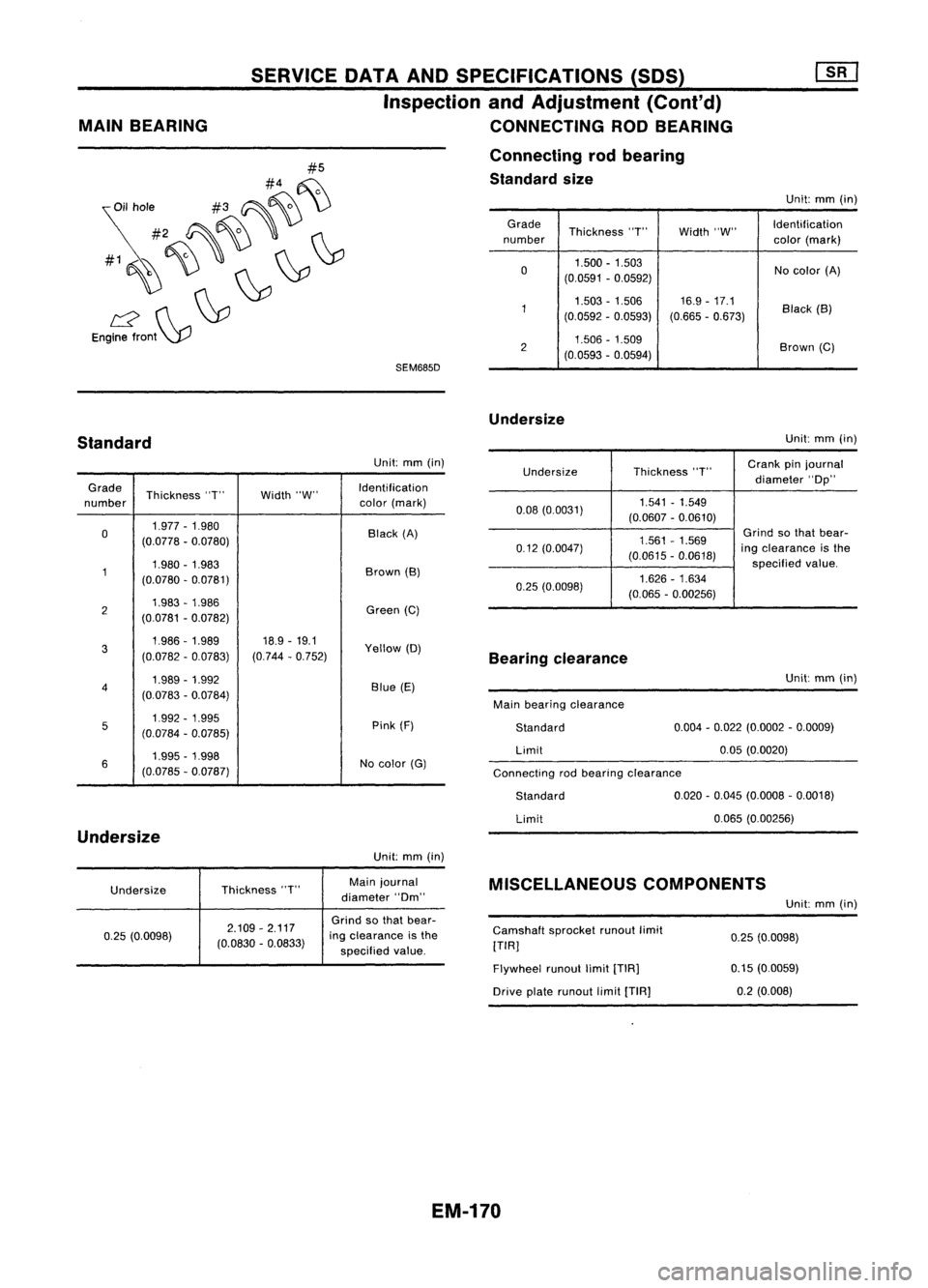

SEM685D

#5

#4 ~

~il hole #3~~ \)

#2 ~~'

#1~~~ ~~

L2 ~~

Engine front~

MAIN

BEARING SERVICE

DATAANDSPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

CONNECTING RODBEARING

Connecting rodbearing

Standard size

Unit:mm(in)

Grade Thickness"T"Width"W" Identification

number color(mark)

0 1.500

-1.503

Nocolor (A)

(0.0591 -0.0592)

1 1.503

-1.506 16.9-17.1

Black(B)

(0.0592 -0.0593) (0.665-0.673)

2 1.506

-1.509

Brown(C)

(0.0593 -0.0594)

Undersize

Standard

Unit:

mm(in)

Connecting rodbearing clearance

Undersize

Thickness

"T"

Crank

pinjournal

diameter "Op"

0.08 (0.0031) 1.541

-1.549

(0.0607 -0.0610)

1.561 -1.569

Grind

sothat bear-

0.12 (0.0047)

(0.0615-0.0618)

ing

clearance isthe

specified value.

0.25 (0.0098) 1.626

-1.634

(0.065 -0.00256)

Unit:

mm(in)

Grade Thickness "T"Width"W" Identification

number color

(mark)

0 1.977

-1.980

Black(A)

(0.0778 -0.0780)

1 1.980

-1.983

Brown(B)

(0.0780 -0.0781)

2 1.983

-1.986

Green(C)

(0.0781 -0.0782)

3 1.986-1.989

18.9-19.1

Yellow(D)

(0.0782 -0.0783) (0.744

-0.752)

4 1.989

-1.992

Blue(E)

(0.0783 -0.0784)

5 1.992

-1.995

Pink(F)

(0.0784 -0.0785)

6 1.995

-1.998

Nocolor (G)

(0.0785 -0.Q787)

Undersize

Unit:mm(in)

Bearing

clearance

Main bearing clearance

Standard

Limit

Standard

Limit Unit:

mm(in)

0.004 -0.022 (0.0002 -0.0009)

0.05 (0.0020)

0.020 -0.045 (0.0008 -0.0018)

0.065 (0.00256)

Undersize Thickness

"T" Main

journal

diameter "Om"

MISCELLANEOUS

COMPONENTS

Unit:mm(in)

0.25 (0.0098) 2.109

-2.117

(0.0830 -0.0833)

Grind

sothat bear-

ing clearance isthe

specified value. Camshaft

sprocketrunoutlimit

[TIR]

Flywheel runoutlimit[TIR]

Drive platerunout limit[TIA]

0.25

(0.0098)

0.15 (0.0059)

0.2 (0.008)

EM-170

Page 1354 of 1701

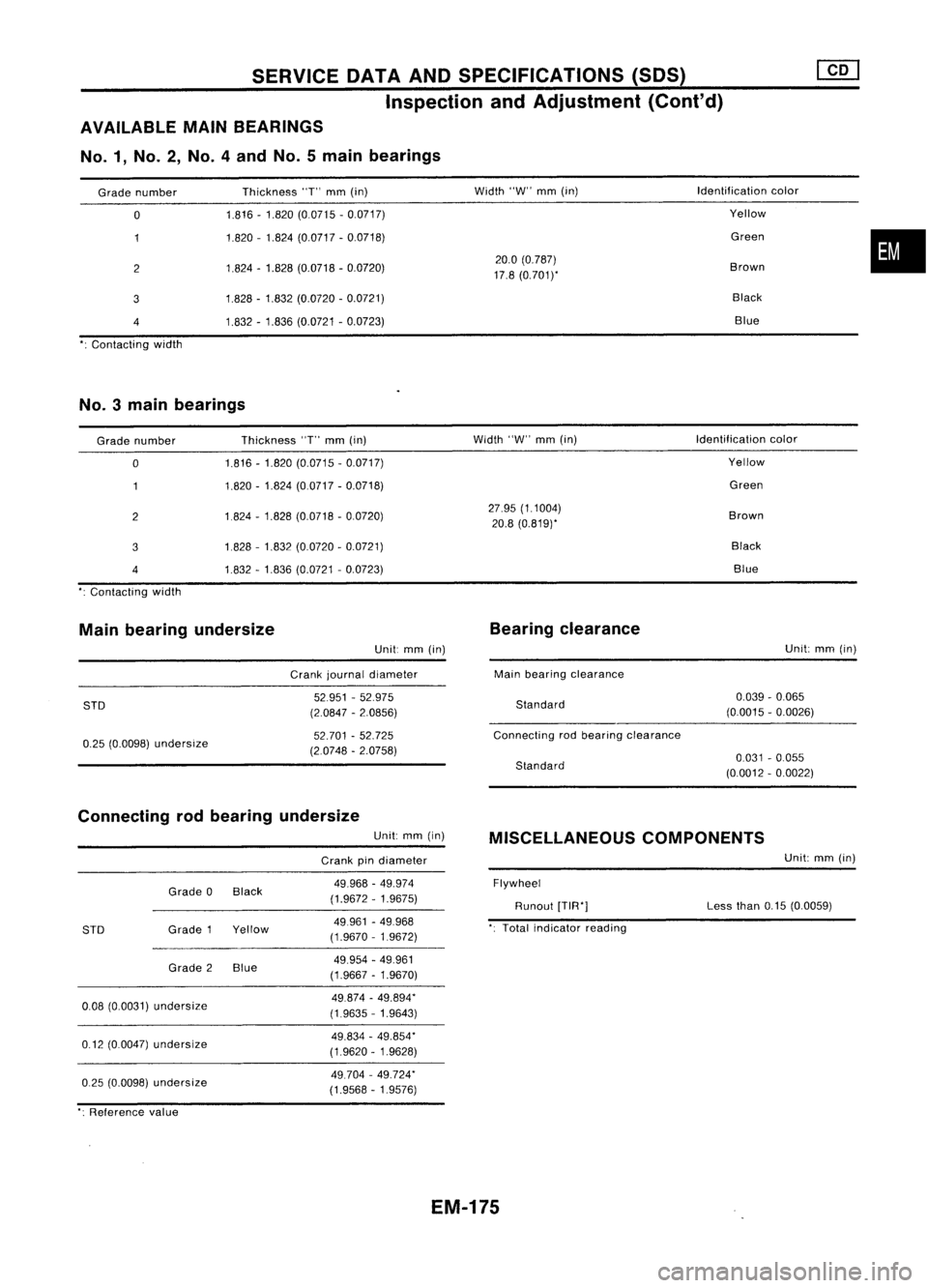

SERVICEOATAAND SPECIFICATIONS (SOS)

Inspection andAdjustment (Cont'd)

AVAILABLE MAINBEARINGS

No.1, No.2, No.4andNo.5main bearings

Grade number

o

2

3

4

Contacting width Thickness

"T"

mm

(in)

1.816 -1.820 (0.0715 -0.0717)

1.820 -1.824 (0.0717 -0.0718)

1.824 -1.828 (0.0718 -0.0720)

1.828 -1.832 (0.0720 -0.0721)

1.832 -1.836 (0.0721 -0.0723)

Width

"W"

mm

(in)

20.0 (0.787)

17.8 (0.7011'

Identification

color

Yellow

Green

Brown Black Blue

•

No.3 mainbearings

Grade number

o

2

3

4

Contacting width Thickness

"T"

mm

(in)

1.816 -1.820 (0.0715 -0.0717)

1.820 -1.824 (0.0717 -0.0718)

1.824 -1.828 (0.0718 -0.0720)

1828 -1.832 (0.0720 -0.0721)

1.832 -1.836 (0.0721 -0.0723)

Width

"W"

mm

(in)

27.95 (1.1004)

20.8 (0.819)'

Identification

color

Yellow

Green

Brown BlackBlue

Main bearing undersize

Unit:

mm

(in)

Crank journal diameter

Bearing

clearance

Main bearing clearance Unit:

mm

(in)

STD

0.25 (0.0098)

undersize

52951

-52.975

(2.0847 -2.0856)

52.701 -52.725

(2.0748 -2.0758)

Standard

Connecting rodbearing clearance

Standard

0.039

-0.065

(0.0015 -0.0026)

0.031 -0.055

(0.0012 -0.0022)

Connecting rodbearing undersize

Unit:

mm

(in)

Crank pindiameter

MISCELLANEOUS

COMPONENTS

Unit:

mm

(in)

0.25 (0.0098)

undersize

0.08

(0.0031)

undersize

0.12 (0.0047)

undersize

STD

Grade

0Black

Grade 1Yellow

Grade 2Blue

49.968

-49.974

(1.9672 -1.9675)

49961 -49.968

(1.9670 -1.9672)

49.954 -49.961

(1.9667 -1.9670)

49.874 -49.894"

(1.9635 -1.9643)

49.834 -49.854"

(1.9620 -1.9628)

49.704 -49.724"

(1.9568 -1.9576)

Flywheel

Runout

[TIR"]

Total indicator reading Less

than

0.15(0.0059)

": Reference value

EM-175

Page 1365 of 1701

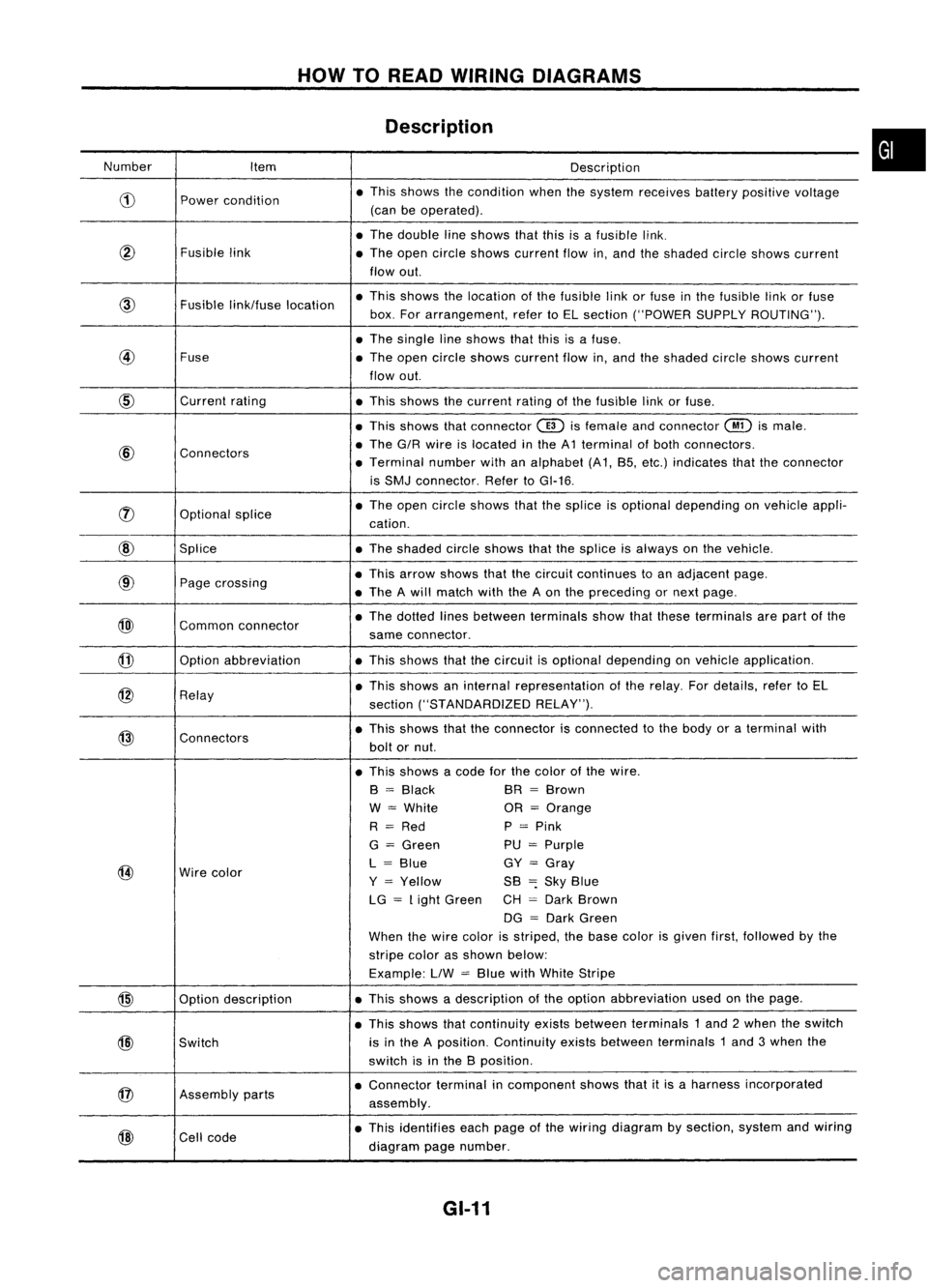

HOWTOREAD WIRING DIAGRAMS

Description

Number Item Description

CD

Power

condition •

This shows thecondition whenthesystem receives batterypositive voltage

(can beoperated) .

• The double lineshows thatthisisafusible link.

@

Fusiblelink

•The open circle shows current flowin,and theshaded circleshows current

flow out.

link/fuse location •

This shows thelocation ofthe fusible linkorfuse inthe fusible linkorfuse

box. Forarrangement, refertoEL section ("POWER SUPPLYROUTING") .

• The single lineshows thatthisisafuse.

@

Fuse

•The open circle shows current flowin,and theshaded circleshows current

flow out.

CID

Current

rating

•This shows thecurrent ratingofthe fusible linkorfuse .

• This shows thatconnector

@)

isfemale andconnector

@

ismale .

@

Connectors •

The G/R wire islocated inthe A1 terminal ofboth connectors.

• Terminal numberwithanalphabet (A1, B5, etc.) indicates thattheconnector

is SMJ connector. RefertoGI-16 .

rJ)

Optionalsplice •

The open circle shows thatthesplice isoptional depending onvehicle appli-

cation.

@

Splice •The shaded circleshows thatthesplice isalways onthe vehicle.

@

Page

crossing •

This arrow shows thatthecircuit continues toan adjacent page.

• The Awill match withtheAon the preceding ornext page .

@)

Commonconnector •

The dotted linesbetween terminals showthatthese terminals arepart ofthe

same connector.

@

Option

abbreviation •This shows thatthecircuit isoptional depending onvehicle application.

@

Relay •

This shows aninternal representation ofthe relay. Fordetails, refertoEL

section ("STANDARDIZED RELAY").

@

Connectors •

This shows thattheconnector isconnected tothe body oraterminal with

bolt ornut.

• This shows acode forthe color ofthe wire.

B

=

Black BR

=

Brown

W

=

White OR

=

Orange

R

=

Red P

=

Pink

G

=

Green PU

=

Purple

@

Wire

color L

=

Blue GY

=

Gray

Y

=

Yellow SB

=:

Sky Blue

LG

=

Light Green CH

=

Dark Brown

DG

=

Dark Green

When thewire color isstriped, thebase color isgiven first,followed bythe

stripe colorasshown below:

Example: LlW

=

Blue withWhite Stripe

@

Optiondescription •

This shows adescription ofthe option abbreviation usedonthe page.

• This shows thatcontinuity existsbetween terminals 1and 2when theswitch

@)

Switch is

inthe Aposition. Continuity existsbetween terminals 1and 3when the

switch isinthe Bposition .

@

Assembly

parts •

Connector terminalincomponent showsthatitis aharness incorporated

assembly .

@

Cell

code •

This identifies eachpage ofthe wiring diagram bysection, systemandwiring

diagram pagenumber.

GI-11

•

Page 1366 of 1701

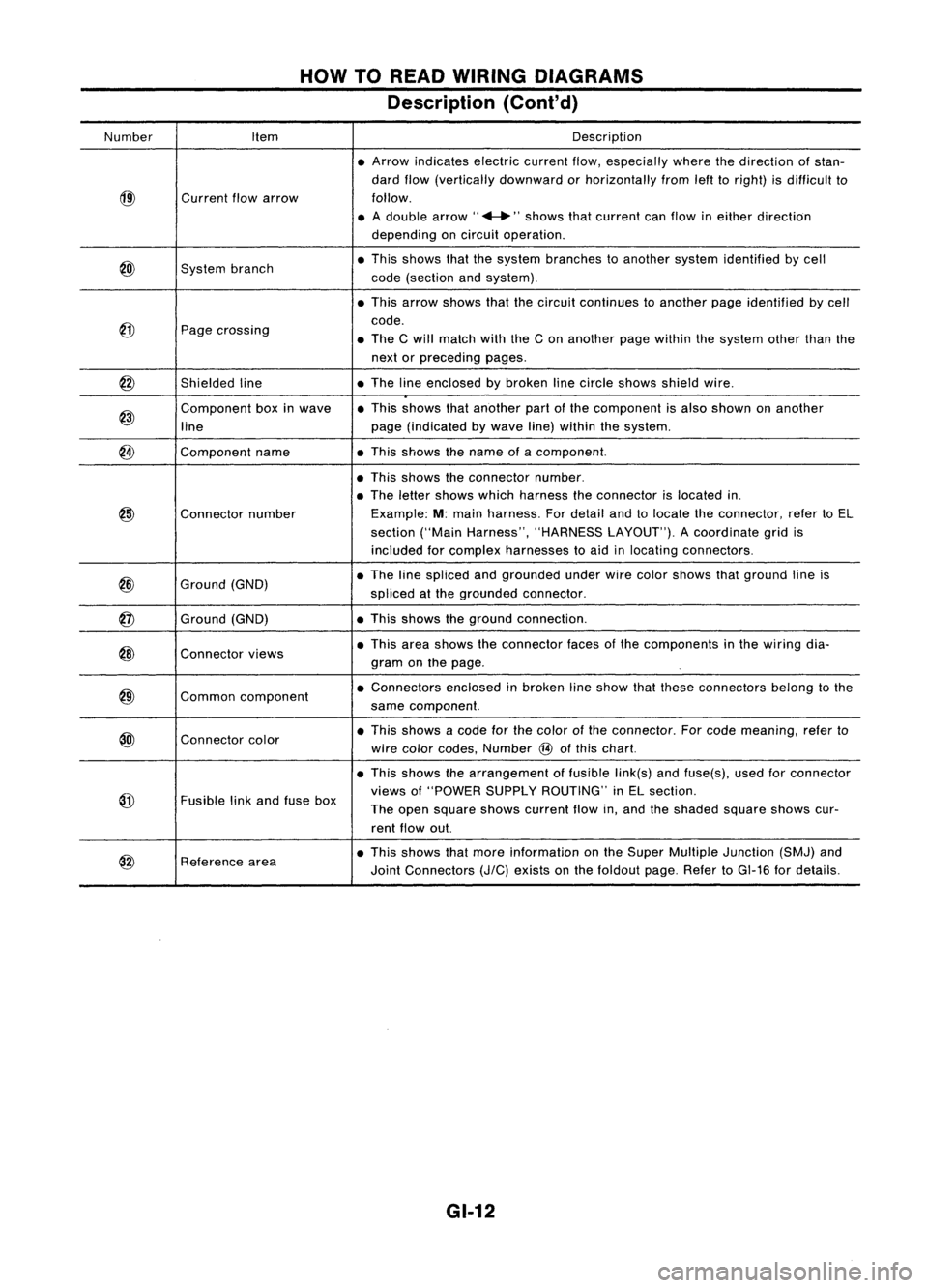

HOWTOREAD WIRING DIAGRAMS

Description (Cont'd)

Number Item Description

• Arrow indicates electriccurrentflow,especially wherethedirection ofstan-

dard flow(vertically downward orhorizontally fromlefttoright) isdifficult to

@)

Current

flowarrow follow.

• Adouble arrow" ...."shows thatcurrent canflow ineither direction

depending oncircuit operation .

@)

System

branch •

This shows thatthesystem branches toanother systemidentified bycell

code (section andsystem) .

• This arrow shows thatthecircuit continues toanother pageidentified bycell

@

code.

Page crossing

•The Cwill match withtheCon another pagewithin thesystem otherthanthe

next orpreceding pages.

@

Shieldedline •

The lineenclosed bybroken linecircle shows shieldwire.

@)

Component

boxinwave •

This shows thatanother partofthe component isalso shown onanother

line page

(indicated bywave line)within thesystem.

@

Component

name •This shows thename ofacomponent.

• This shows theconnector number.

• The letter shows whichharness theconnector islocated in.

@)

Connector

number Example:

M:main harness. Fordetail andtolocate theconnector, refertoEL

section ("MainHarness", "HARNESS LAYOUT").Acoordinate gridis

included forcomplex harnesses toaid inlocating connectors .

@

Ground

(GND) •

The linespliced andgrounded underwirecolor shows thatground lineis

spliced atthe grounded connector.

@

Ground

(GND) •

This shows theground connection.

@)

Connector

views •

This area shows theconnector facesofthe components inthe wiring dia-

gram onthe page .

@)

Common

component •

Connectors enclosedinbroken lineshow thatthese connectors belongtothe

same component.

@l

Connector

color •

This shows acode forthe color ofthe connector. Forcode meaning, referto

wire color codes, Number

@

ofthis chart.

• This shows thearrangement offusible link(s)andfuse(s), usedforconnector

@

views

of"POWER SUPPLYROUTING" inEL section.

Fusible linkand fuse box

Theopen square showscurrent flowin,and theshaded squareshowscur-

rent flow out.

@

Reference

area •

This shows thatmore information onthe Super Multiple Junction (SMJ)and

Joint Connectors

(J/C)

exists onthe foldout page.RefertoGI-16 fordetails.

GI-12

Page 1392 of 1701

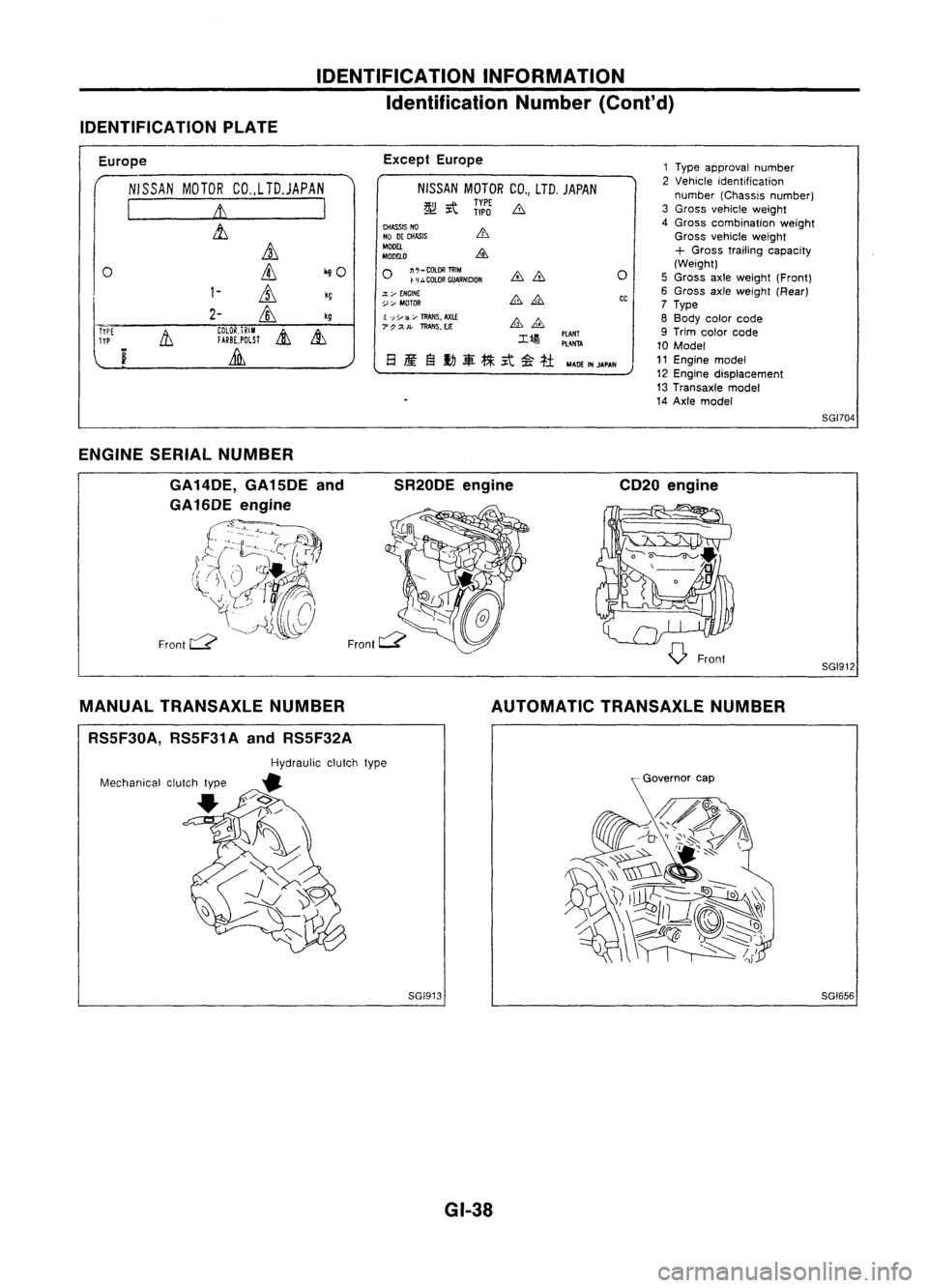

IDENTIFICATIONINFORMATION

Identification Number(Cont'd)

IDENTIFICATION PLATE

Europe

NISSAN MOTORCO.,LTD.JAPAN

I

It

I

&,

it

0

ill

iliO

1-

ill

kg

2-

&,

kg

Tri'[

11

COlOR.iRIM

&

&,

TYP

fARBE,POLSl

i

Lilli

Except

Europe

NISSAN MOTORCO.,LTD. JAPAN

~ it

ii:J

b

CHASS~ NO

NO DECHASIS

MODEL

MDDELO

o

~;::~:~~NlctDN

.:t;..-

ENGINE

~:,... MOTOR

~ ';;Y

3;..-

TRANS~

AXl.£

7P;;<'.

ll!AIIS.EJt:

M4DEINJAPAN

o

CC

1

Type approval number

2 Vehicle identification

number (Chassis number)

3 Gross vehicle weight

4 Gross combination weight

Gross vehicle weight

+

Gross trailing capacity

(Weight)

5 Gross axleweight (Front)

6 Gross axleweight (Rear)

7 Type

8 Body colorcode

9 Trim color code

10 Model

11 Engine model

12 Engine displacement

13 Transaxle model

14 Axle model

SGI704

ENGINE SERIALNUMBER

GA 14DE, GA15DE and

GA16DE engine

£~b-=~~rrf~)

(J~~~6

Front

c:::?

SR20DE

engine CD20engine

SGI912

MANUAL TRANSAXLE NUMBER

RS5F30A, RS5F31AandRS5F32A AUTOMATIC

TRANSAXLE NUMBER

SGI913 GI-38 SGI656