check engine light NISSAN ALMERA N15 1995 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 978 of 1701

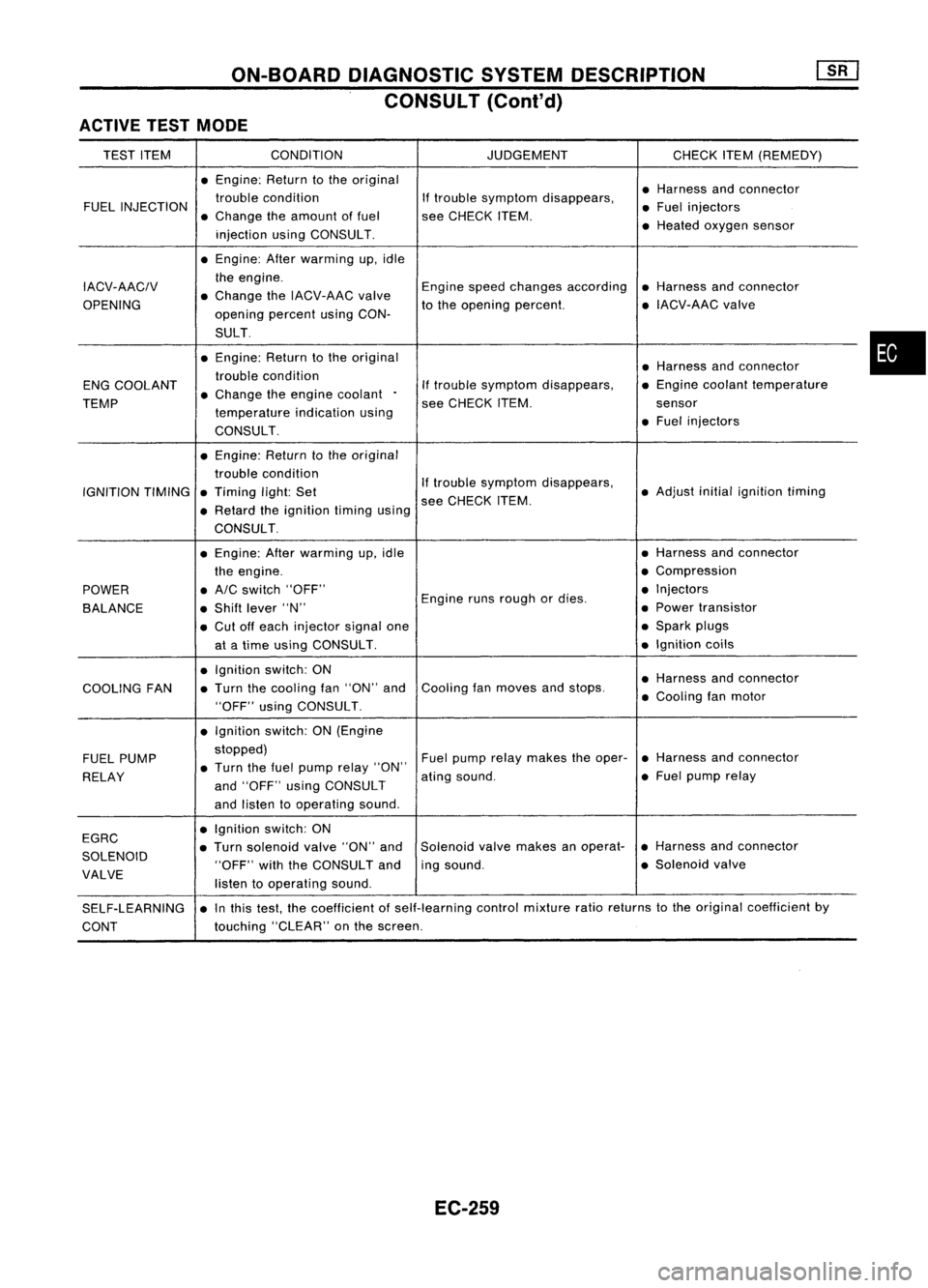

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Conl'd)

ACTIVE TESTMODE

TEST ITEM CONDITION JUDGEMENTCHECKITEM(REMEDY)

• Engine: Returntothe original

•Harness andconnector

FUEL INJECTION trouble

condition

Iftrouble symptom disappears,

•Fuel injectors

• Change theamount offuel

seeCHECK ITEM.

•Heated oxygen sensor

injection usingCONSULT .

• Engine: Afterwarming up,idle

IACV-AACIV the

engine.

Enginespeedchanges according •Harness andconnector

OPENING •

Change theIACV-AAC valve

tothe opening percent. •

IACV-AAC valve

opening percentusingCON-

SULT.

• Engine: Returntothe original

•Harness andconnector

ENG COOLANT trouble

condition

Iftrouble symptom disappears, •

Engine coolant temperature

• Change theengine coolant

.

TEMP see

CHECK ITEM. sensor

temperature indicationusing

•Fuel injectors

CONSULT .

• Engine: Returntothe original

trouble condition

Iftrouble symptom disappears,

IGNITION TIMING•Timing light:Set •

Adjust initialignition timing

• Retard theignition timingusingsee

CHECK ITEM.

CONSULT.

• Engine: Afterwarming up,idle •

Harness andconnector

the engine. •

Compression

POWER

•

AIC

switch "OFF"

Enginerunsrough ordies. •

Injectors

BALANCE •

Shift lever "N" •

Power transistor

• Cut offeach injector signalone •

Spark plugs

at atime using CONSULT . •

Ignition coils

• Ignition switch:ON

•Harness andconnector

COOLING FAN•

Turn thecooling fan"ON" andCooling

fanmoves andstops.

•Cooling fanmotor

"OFF" usingCONSULT .

• Ignition switch:ON(Engine

FUEL PUMP stopped)

Fuelpump relaymakes theoper- •

Harness andconnector

RELAY •

Turn thefuel pump relay"ON"

atingsound. •

Fuel pump relay

and "OFF" usingCONSULT

and listen tooperating sound.

EGRC •

Ignition switch:ON

• Turn solenoid valve"ON"and Solenoid

valvemakes anoperat- •

Harness andconnector

SOLENOID "OFF"withtheCONSULT andingsound. •

Solenoid valve

VALVE listentooperating sound.

SELF-LEARNING •

In this test, thecoefficient ofself-learning controlmixture ratioreturns tothe original coefficient by

CONT touching

"CLEAR" onthe screen.

EC-259

•

Page 980 of 1701

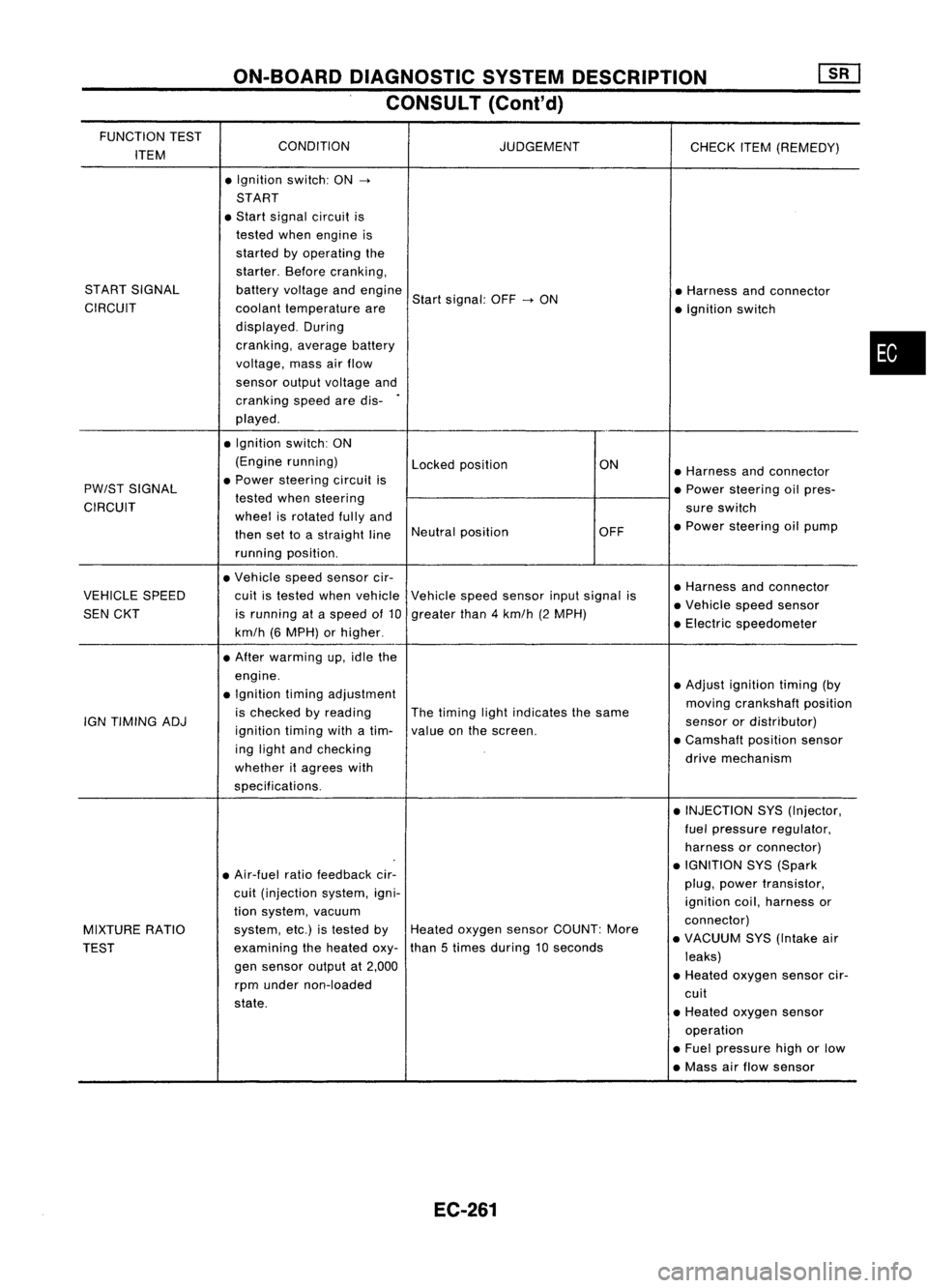

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

CONSULT (Cont'd)

FUNCTION TEST

CONDITION

ITEM JUDGEMENT

CHECKITEM(REMEDY)

• Ignition switch:ON

->

START

• Start signal circuit is

tested whenengine is

started byoperating the

starter. Beforecranking,

START SIGNAL batteryvoltage andengine

Startsignal: OFF

->

ON •

Harness andconnector

CIRCUIT coolanttemperature are

•Ignition switch

displayed. During

cranking, averagebattery

voltage, massairflow

sensor outputvoltage and

cranking speedaredis-

.

played .

• Ignition switch:ON

(Engine running)

Lockedposition ON

•Harness andconnector

PW/ST SIGNAL •

Power steering circuitis

•Power steering oilpres-

CIRCUIT tested

whensteering

sureswitch

wheel isrotated fullyand

•Power steering oilpump

then settoastraight lineNeutral

position OFF

running position.

• Vehicle speedsensor cir-

•Harness andconnector

VEHICLE SPEED cuitistested whenvehicle Vehiclespeedsensor inputsignal is

•Vehicle speedsensor

SEN CKT isrunning ataspeed of10 greater than4km/h (2MPH)

•Electric speedometer

km/h (6MPH) orhigher .

• After warming up,idle the

engine. •Adjust ignition timing(by

• Ignition timingadjustment

movingcrankshaft position

is checked byreading Thetiming lightindicates thesame

IGN TIMING ADJ

ignitiontimingwithatim- valueonthe screen. sensor

ordistributor)

ing light andchecking •

Camshaft positionsensor

whether itagrees with drive

mechanism

specifications. •INJECTION SYS(Injector,

fuel pressure regulator,

harness orconnector)

• Air-fuel ratiofeedback cir- •

IGNITION SYS(Spark

cuit (injection system,igni- plug,

power transistor,

ignition coil,harness or

tion system, vacuum

connector)

MIXTURE RATIO system,

etc.)istested byHeated oxygen sensorCOUNT: More

•VACUUM SYS(Intake air

TEST examining

theheated oxy-than

5times during 10seconds

leaks)

gen sensor outputat2,000

•Heated oxygen sensorcir-

rpm under non-loaded

cuit

state. •Heated oxygen sensor

operation

• Fuel pressure highorlow

• Mass airflow sensor

EC-261

•

Page 990 of 1701

TROUBLEDIAGNOSIS -General Descrip_ti_on

1S_R_'

Basic Inspection

Precaution:

Perform BasicInspection withoutelectrical ormechanical loads

applied;

• Headlamp switchisOFF,

• Air conditioner switchisOFF,

• Rear defogger switchisOFF,

• Steering wheelisinthe straight-ahead position,etc.

m

BEFORE STARTING

1. Check service records forany recent •

repairs thatmay indicate arelated

problem, orthe current needfor

scheduled maintenance.

2. Open engine hoodandcheck thefol-

lowing:

• Harness connectors forimproper con-

nections

• Vacuum hosesforsplits, kinks,or

improper connections

• Wiring forimproper connections,

pinches, orcuts

Goto

(I.

No

CONNECT

CONSULTTOTHE VEHICLE.

Connect "CONSULT" tothe data link

connector forCONSULT andselect

"ENGINE" fromthemenu. Referto

EC-254.

DOES ENGINE START?

\\

~

~ SEF1421

START

•

IGN TIMING ADJ.

0

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR.

SEF555N

Yes

CHECK IGNITION TIMING.

(ij\

1.Warm upengine sufficiently.

~ 2.Select "IGNTIMING ADJ"in

"WORK SUPPORT" mode.

3. Touch "START".

4. Check ignition timingatidle

using timing light.

Ignition timing:

15°::f:2° BTDC

~ 1Warm upengine sufficiently.

~ 2:

Stop engine anddisconnect

throttle position sensorhar-

ness connector.

3. Start engine.

4. Check ignition timingatidle

using timing light.

Ignition timing:

15°::f:2° BTDC

OK

(Go to

@

onnext page.) Adjust

ignition timingby

turning distributor.

EC-271

Page 991 of 1701

![NISSAN ALMERA N15 1995 Owners Manual

I!]

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

---..

RPM.

turningidleadjusting

00

1.

Select "IGNTIMING ADJ"in screw.

"WORK SUPPORT" mode.

2. When touching "STAR NISSAN ALMERA N15 1995 Owners Manual

I!]

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

---..

RPM.

turningidleadjusting

00

1.

Select "IGNTIMING ADJ"in screw.

"WORK SUPPORT" mode.

2. When touching "STAR](/img/5/57349/w960_57349-990.png)

I!]

CHECK IDLEADJ. SCREW INITIALSET

NG

Adjust engine speedby

---..

RPM.

turningidleadjusting

00

1.

Select "IGNTIMING ADJ"in screw.

"WORK SUPPORT" mode.

2. When touching "START",

does engine speedfallto

750:!: 50rpm

(AfT

in

"N"

posi-

tion)?

OR

00

Does

engine runat750:!: 50rpm

(AfT

In

"N"

position)?

OK

Reconnect throttleposition sensorhar-

ness connector.

Ii

CHECK THROTTLE POSITIONSENSOR

NG

Adjust outputvoltage to

IDLE POSITION.

---..

0.50Vbyrotating throttle

00

1.

Perform ''THRTLPOSSEN

positionsensorbody.

ADJ" in"WORK SUPPORT"

1

mode.

2. Check thatoutput voltage of

RESETIDLEPOSITION

throttle position sensoris

MEMORY.

approx. 0.35to0.65V (Throttle

1.Warm upengine suffi-

valve fullycloses.) and"CLSD ciently.

2. Turn ignition switch

THLIPOSI" stays"ON".

"OFF"andwait at

OR least5seconds.

00

Measure

outputvoltage ofthrot- 3.

Disconnect throttle

position sensorhar-

tie position sensorusing

nessconnector.

voltmeter, andcheck thatitis

4.

Start engine andwait

approx. 0.35toO.65V. (Throttle at

least 5seconds in

"N" position.

valve fullyclosed.)

5.Reconnect throttle

OK • position

sensorhar-

ness connector while

running engine.

~

1

,

THRTL

POSSEN O,52V

SEF165P

•••

ADJMONITOR •••

TROUBLE

DIAGNOSIS -General Description

Basic Inspection (Cont'd)

@

========

MONITOR

========

CMPS.RPM (REF)Orpm

CLSDTHUP ON

Ii

•

THRTL POSSENADJ

.0

I!]

•IGN TIMING ADJ.

0

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR

I

START

I

SEF546N

CID

(Go tonext page)

EC-272

Page 996 of 1701

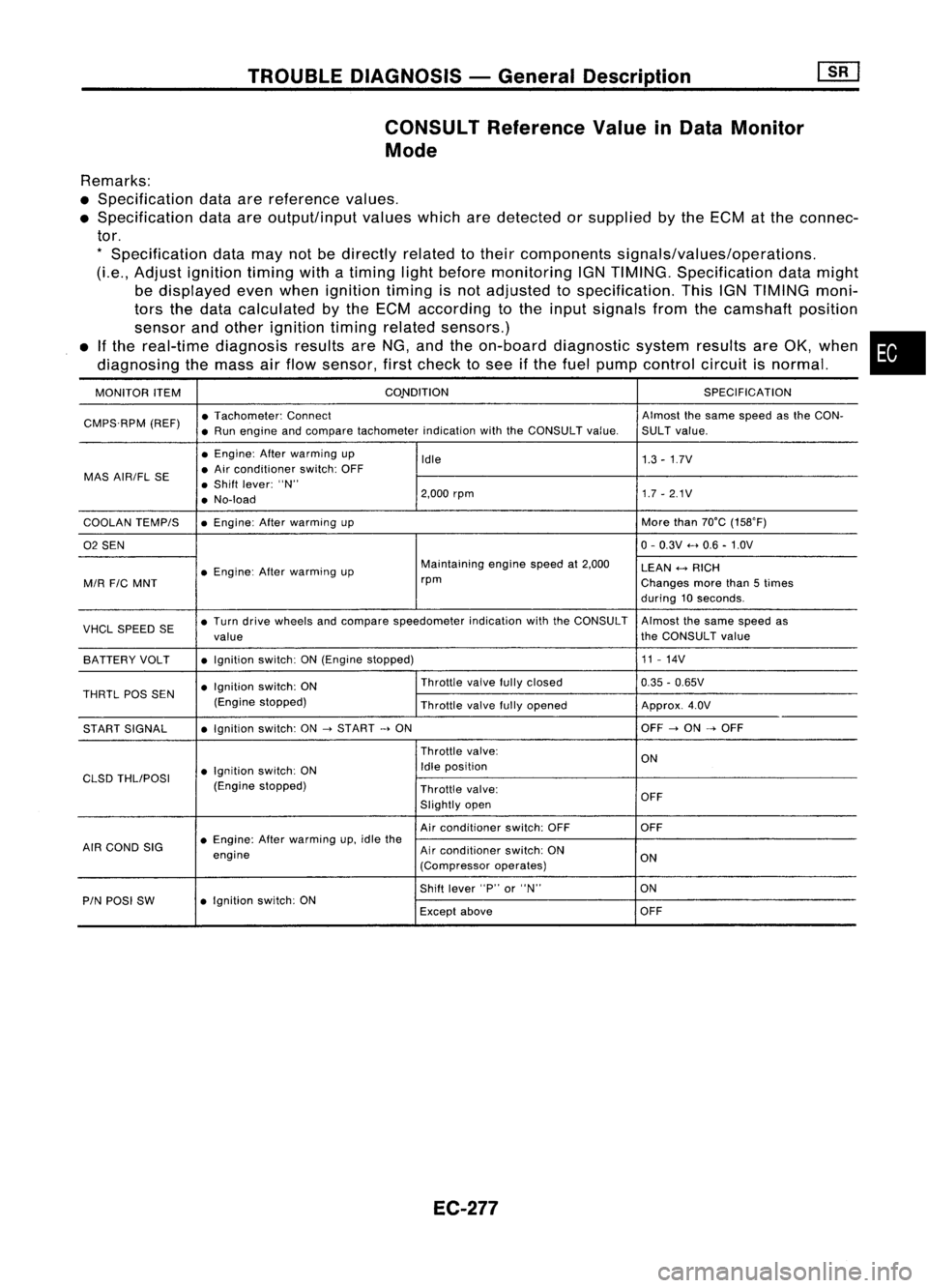

TROUBLEDIAGNOSIS -General Description

CONSULT Reference ValueinData Monitor

Mode

Remarks:

• Specification dataarereference values.

• Specification dataareoutput/input valueswhicharedetected orsupplied bythe ECM atthe connec-

tor.

*

Specification datamaynotbedirectly relatedtotheir components signals/values/operations.

(Le., Adjust ignition timingwithatiming lightbefore monitoring IGNTIMING. Specification datamight

be displayed evenwhen ignition timingisnot adjusted tospecification. ThisIGNTIMING moni-

tors thedata calculated bythe ECM according tothe input signals fromthecamshaft position

sensor andother ignition timingrelated sensors.)

• Ifthe real-time diagnosis resultsareNG, andtheon-board diagnostic systemresultsareOK, when •

diagnosing themass airflow sensor, firstcheck tosee ifthe fuel pump control circuitisnormal.

MONITOR ITEM CONDITION

SPECIFICATION

CMPS.RPM (REF)•

Tachometer: Connect Almostthesame speed asthe CON-

• Run engine andcompare tachometer indicationwiththeCONSULT value.SULTvalue.

• Engine: Afterwarming up

Idle 1.3-1.7V

MAS AIR/FL SE •

Air conditioner switch:OFF

• Shift lever: "N"

• No-load 2,000

rpm 1.7-2.1V

COOLAN TEMPIS •

Engine: Afterwarming up More

than70°C (15S0F)

02 SEN 0-

0.3V .....0.6 -1.0V

• Engine: Afterwarming up Maintaining

enginespeedat2,000

LEAN

+-->

RICH

MIR

FIC

MNT rpm

Changesmorethan5times

during 10seconds.

VHCL SPEED SE•

Turn drive wheels andcompare speedometer indicationwiththeCONSULT Almostthesame speed as

value the

CONSULT value

BATTERY VOLT •

Ignition switch:ON(Engine stopped) 11

-14V

• Ignition switch:ON Throttle

valvefullyclosed

0.35-0.65V

THRTL

pas

SEN

(Enginestopped)

Throttlevalvefullyopened Approx.4.0V

START SIGNAL •

Ignition switch:ON

->

START

->

ON OFF

->

ON

->

OFF

Throttle valve:

ON

• Ignition switch:ON Idle

position

CLSD THLIPOSI

(Enginestopped)

Throttlevalve:

Slightly open OFF

Air conditioner switch:OFF OFF

AIR COND SIG •

Engine: Afterwarming up,idle the

engine Air

conditioner switch:ON

ON

(Compressor operates)

Shift lever "P"or"N" ON

PIN POSI SW •

Ignition switch:ON

Exceptabove OFF

EC-277

Page 1008 of 1701

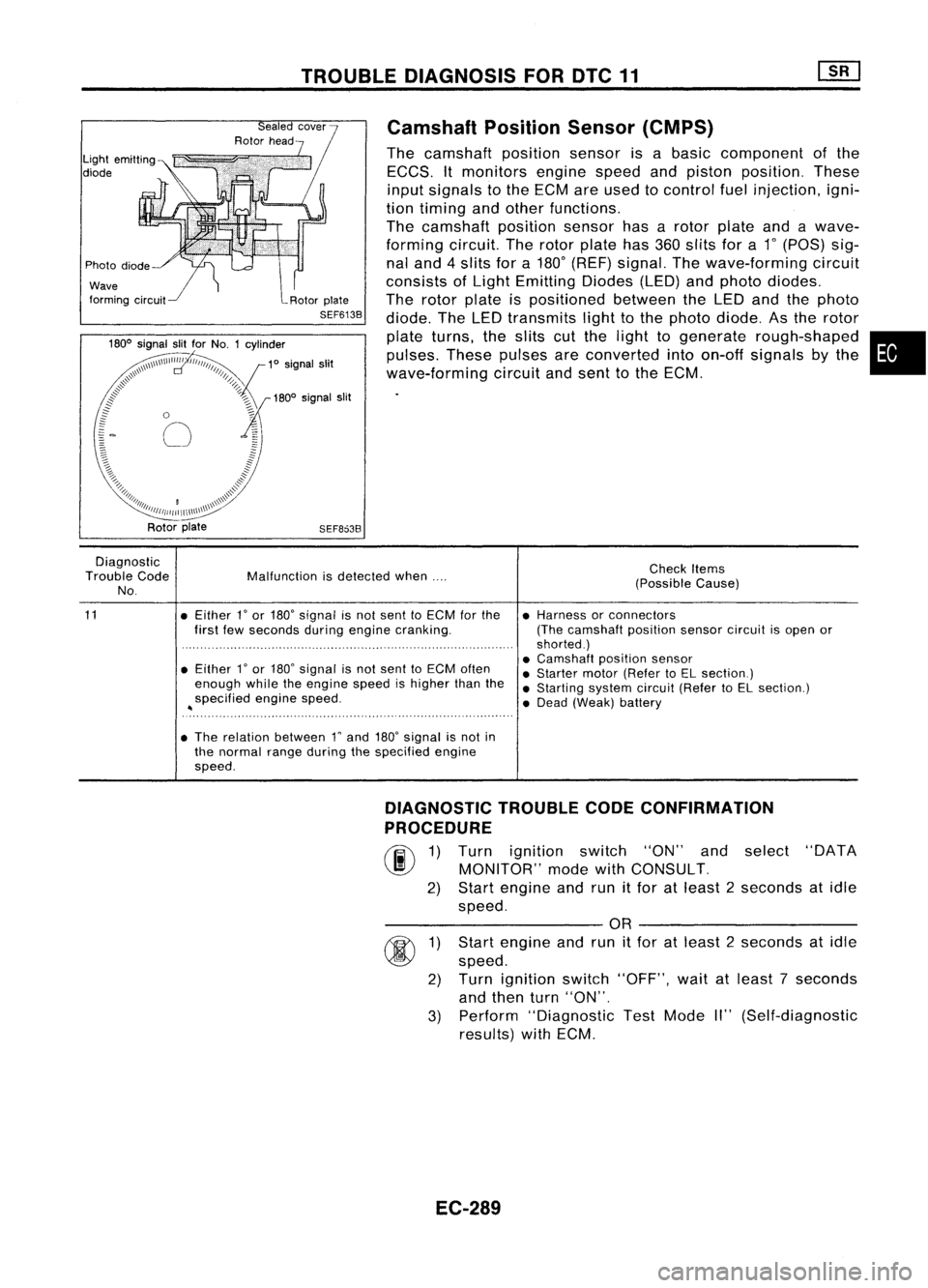

TROUBLEDIAGNOSIS FOROTC11

Rotor plate

SEF6138

180

0

signal slitfor NO.1 cylinder

\\\\""I"~'11111

1

0

signal slit

\\\\\ d'"

/11;

:£

';\'0\

I//..;:

#'

/%

$ ~

180

0

signal slit

f

0

%

o

Camshaft

PositionSensor(CMPS)

The camshaft positionsensorisabasic component ofthe

ECCS. Itmonitors enginespeedandpiston position. These

input signals tothe ECM areused tocontrol fuelinjection, igni-

tion timing andother functions.

The camshaft positionsensorhasarotor plate andawave-

forming circuit.Therotor plate has360slits fora

1"

(POS) sig-

nal and 4slits fora180

0

(REF) signal. Thewave-forming circuit

consists ofLight Emitting Diodes(LED)andphoto diodes.

The rotor plate ispositioned betweentheLED andthephoto

diode. TheLED transmits lighttothe photo diode. Asthe rotor

plate turns, theslits cutthe light togenerate rough-shaped •

pulses. Thesepulses areconverted intoon-off signals bythe

wave-forming circuitandsent tothe ECM.

Rotor plate

SEF8638

Diagnostic

Trouble Code

No.

11

Malfunction

isdetected when....

• Either 1

0

or 180

0

signal isnot sent toECM forthe

first fewseconds duringengine cranking.

• Either

r

or 180" signal isnot sent toECM often

enough whiletheengine speedishigher thanthe

specified enginespeed.

~

• The relation between rand180

0

signal isnot in

the normal rangeduring thespecified engine

speed. Check

Items

(Possible Cause)

• Harness orconnectors

(The camshaft positionsensorcircuitisopen or

shorted.)

• Camshaft positionsensor

• Starter motor(Refer toEL section.)

• Starting systemcircuit(RefertoEL section.)

• Dead (Weak) battery

3)

@

1)

2)

DIAGNOSTIC

TROUBLECODECONFIRMATION

PROCEDURE

rif\

1)Turn ignition switch"ON"andselect "DATA

~ MONITOR" modewithCONSULT.

2) Start engine andrunitfor atleast 2seconds atidle

speed.

---------- OR----------

Start engine andrunitfor atleast 2seconds atidle

speed.

Turn ignition switch"OFF", waitatleast 7seconds

and then turn"ON".

Perform "Diagnostic TestMode II"(Self-diagnostic

results) withECM.

EC-289

Page 1274 of 1701

![NISSAN ALMERA N15 1995 Owners Manual CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

S NISSAN ALMERA N15 1995 Owners Manual CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

S](/img/5/57349/w960_57349-1273.png)

CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

SEM085D•

Always usenew valve oilseal.

Refer toOIL SEAL REPLACEMENT.

• Before installing valveoilseal, install valvespring seat.

.' Install valvespring (uneven pitchtype) withitsnarrow

pitched sidetoward cylinder headside(paint mark).

• After installing valvecomponent parts,tapvalve stemtip

with plastic hammer toassure aproper fit.

11. Check hydraulic lashadjusters.

a. Push rocker armathydraulic lashadjuster location, andsee

if rocker armmoves. Ifitmoves atleast 1mm (0.04 in),it

indicates thatthere isair inthe high pressure chamber.

Noise willbeemitted fromhydraulic lashadjuster ifengine

is started without bleeding air.

b. Remove hydraulic lashadjuster anddipinacontainer filled

with engine oil.While pushing plungerasshown infigure,

lightly pushcheck ballusing athin rod. Airiscompletely

bled when plunger nolonger moves.

Air cannot bebled from thistype oflash adjuster byrunning the

engine.

SEM093D

• rEngine oil

- - , t-=1=i

Proper

rod

SEM772C

Rocker arm9UVide

Rock~rarm

Shim

Hydraulic

I

.,h

.dj"'"

i\\ j

12.

Install rocker arms,shims, rockerarmguides andhydrau-

lic lash adjusters.

CAUTION: Install allparts intheir original positions.

SEM202D EM-95

Page 1373 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests

INTRODUCTION

Sometimes thesymptom isnot present whenthevehicle isbrought infor service.

If

possible, re-create

the conditions presentatthe time ofthe incident. Doingsomay help avoid aNo Trouble FoundDiag-

nosis. Thefollowing sectionillustrates waystosimulate theconditionslenvironment underwhich the

owner experiences anelectrical incident.

The section isbroken intothesixfollowing topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold orhot start up

Get athorough description ofthe incident fromthecustomer. Itis important forsimulating thecondi-

tions ofthe problem.

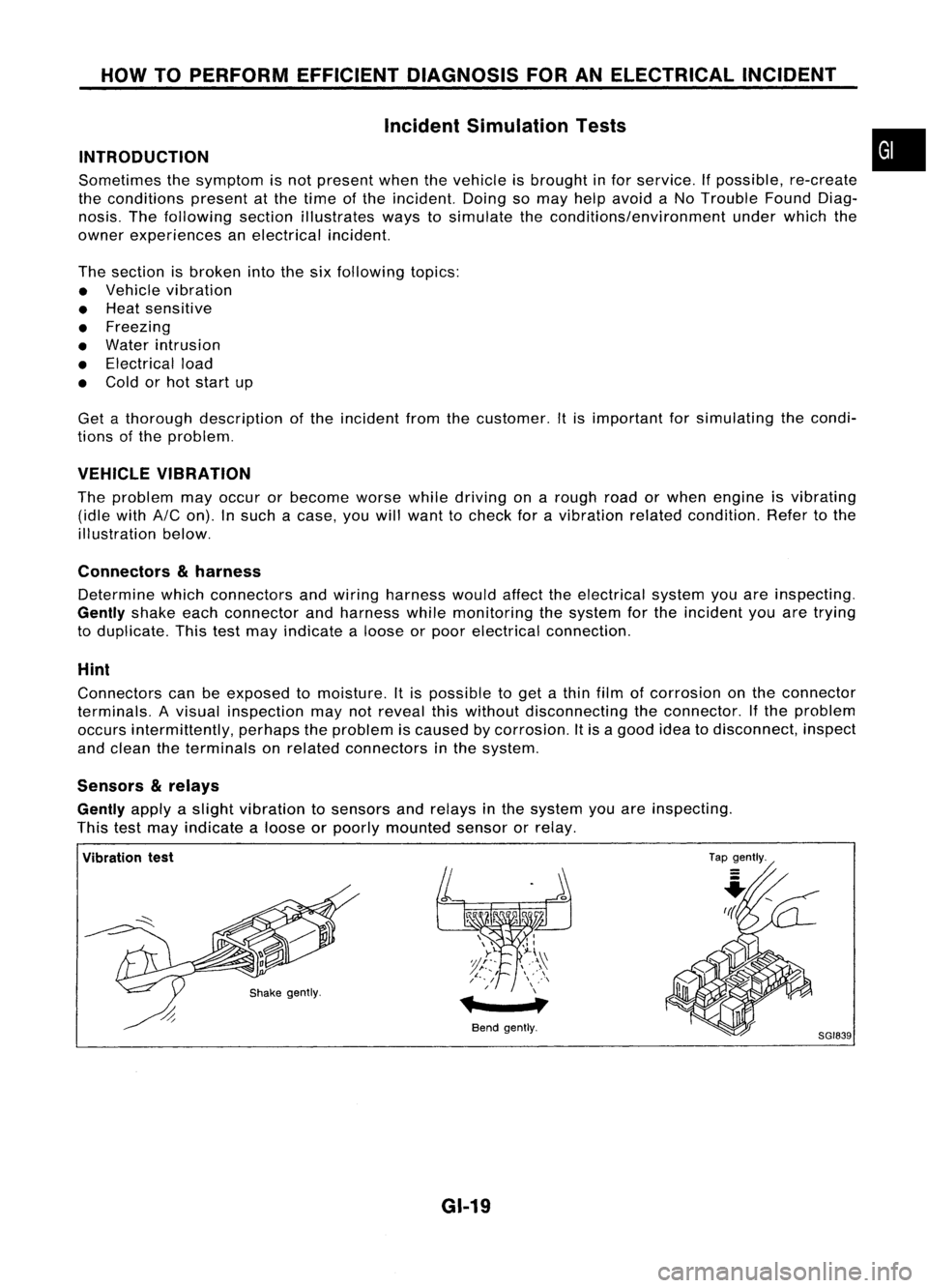

VEHICLE VIBRATION

The problem mayoccur orbecome worsewhiledriving onarough roadorwhen engine isvibrating

(idle with

AIC

on). Insuch acase, youwillwant tocheck foravibration relatedcondition. Refertothe

illustration below.

Connectors

&

harness

Determine whichconnectors andwiring harness wouldaffecttheelectrical systemyouareinspecting.

Gently

shakeeachconnector andharness whilemonitoring thesystem forthe incident youaretrying

to duplicate. Thistestmay indicate aloose orpoor electrical connection.

Hint

Connectors canbeexposed tomoisture. Itis possible toget athin film ofcorrosion onthe connector

terminals. Avisual inspection maynotreveal thiswithout disconnecting theconnector. Ifthe problem

occurs intermittently, perhapstheproblem iscaused bycorrosion. Itis agood ideatodisconnect, inspect

and clean theterminals onrelated connectors inthe system.

Sensors

&

relays

Gently

applyaslight vibration tosensors andrelays inthe system youareinspecting.

This testmay indicate aloose orpoorly mounted sensororrelay.

•

Vibration test

Bendgently.

GI-19

Tap

gently.

8GI839

Page 1400 of 1701

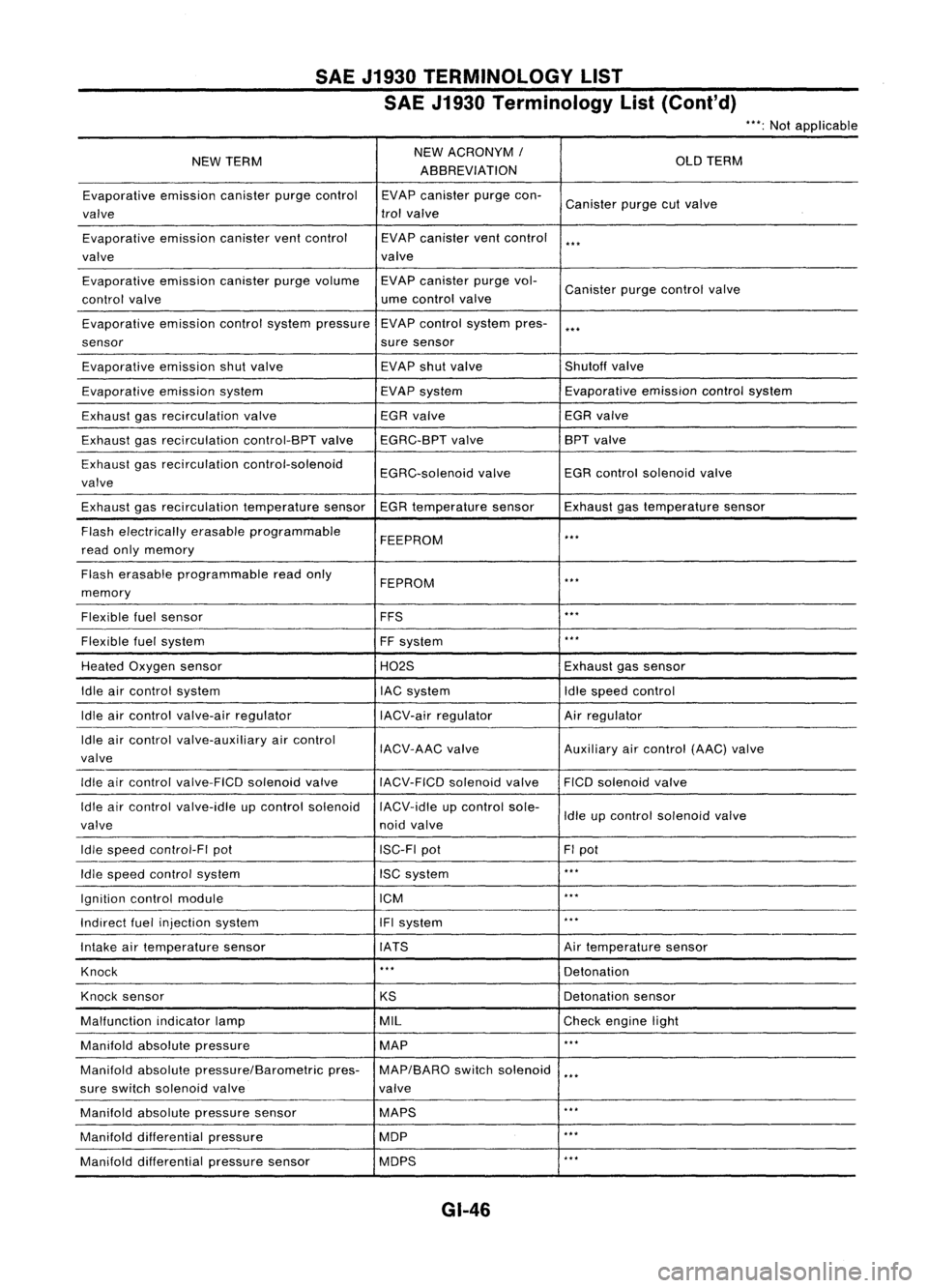

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

***:

Not applicable

NEW TERM NEW

ACRONYM /

OLDTERM

ABBREVIATION

Evaporative emissioncanisterpurgecontrol EVAPcanister purgecon-

Canister purgecutvalve

valve trol

valve

Evaporative emissioncanisterventcontrol EVAPcanister ventcontrol

***

valve valve

Evaporative emissioncanisterpurgevolume EVAPcanister purgevol-

Canister purgecontrol valve

control valve ume

control valve

Evaporative emissioncontrolsystem pressure EVAP

control system pres-

***

sensor suresensor

Evaporative emissionshutvalve EVAP

shutvalve Shutoffvalve

Evaporative emissionsystem EVAPsystem Evaporative

emissioncontrolsystem

Exhaust gasrecirculation valve EGR

valve EGRvalve

Exhaust gasrecirculation control-BPTvalveEGRC-BPT valve BPT

valve

Exhaust gasrecirculation control-solenoid

EGRC-solenoidvalveEGR

control solenoid valve

valve

Exhaust gasrecirculation temperaturesensorEGRtemperature sensorExhaustgastemperature sensor

Flash electrically erasableprogrammable

FEEPROM

***

read onlymemory

Flash erasable programmable readonly

FEPROM

**.

memory

Flexible fuelsensor FFS

***

Flexible fuelsystem

FFsystem

***

Heated Oxygen sensor H02SExhaustgassensor

Idle aircontrol system lACsystem Idlespeed control

Idle aircontrol valve-air regulator IACV-airregulator Airregulator

Idle aircontrol valve-auxiliary aircontrol

IACV-AACvalve Auxiliaryaircontrol (AAC)valve

valve

Idle aircontrol valve-FICO solenoidvalve

IACV-FICDsolenoidvalve FICOsolenoid valve

Idle aircontrol valve-idle upcontrol solenoid IACV-idleupcontrol sole-

Idleupcontrol solenoid valve

valve noidvalve

Idle speed control-FI pot ISC-FIpot FIpot

Idle speed control system ISCsystem

***

Ignition controlmodule ICM

***

Indirect fuelinjection system IFIsystem

***

Intake airtemperature sensor IATS Airtemperature sensor

Knock

***

Detonation

Knock sensor

KSDetonation

sensor

Malfunction indicatorlamp MIL

Checkengine light

Manifold absolutepressure MAP

***

Manifold absolutepressure/Barometric pres-MAP/BARO switchsolenoid

***

sure switch solenoid valve valve

Manifold absolutepressure sensor MAPS

**.

Manifold differential pressure MOP

***

Manifold differential pressuresensor MOPS

***

GI-46

Page 1491 of 1701

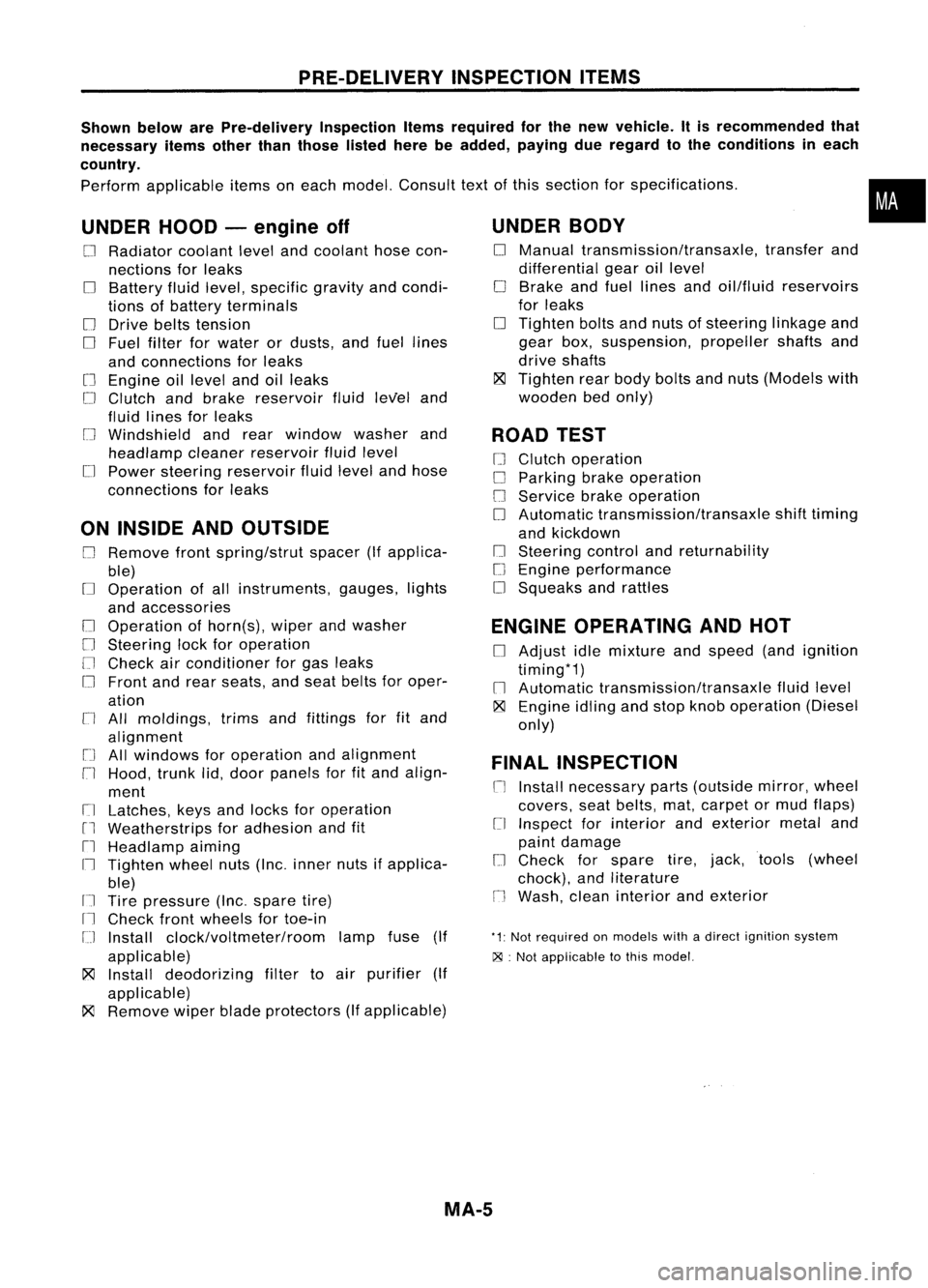

PRE-DELIVERYINSPECTIONITEMS

Shown belowarePre-delivery InspectionItemsrequired forthe new vehicle. Itis recommended that

necessary itemsotherthanthose listedherebeadded, payingdueregard tothe conditions ineach

country.

Perform applicable itemsoneach model. Consult textofthis section forspecifications .

UNDER HOOD-engine off

o

Radiator coolantlevelandcoolant hosecon-

nections forleaks

o

Battery fluidlevel, specific gravityandcondi-

tions ofbattery terminals

o

Drive beltstension

D

Fuel filter forwater ordusts, andfuel lines

and connections forleaks

[] Engine oillevel andoilleaks

D

Clutch andbrake reservoir fluidlevel and

fluid lines forleaks

o

Windshield andrear window washerand

headlamp cleanerreservoir fluidlevel

D

Power steering reservoir fluidlevel andhose

connections forleaks

ON INSIDE ANDOUTSIDE

D

Remove frontspring/strut spacer(Ifapplica-

ble)

D

Operation ofall instruments, gauges,lights

and accessories

o

Operation ofhorn(s), wiperandwasher

[] Steering lockforoperation

[] Check airconditioner forgas leaks

o

Front andrear seats, andseat belts foroper-

ation

n

All moldings, trimsandfittings forfitand

alignment

[J

Allwindows foroperation andalignment

n

Hood, trunklid,door panels forfitand align-

ment

[1

Latches, keysandlocks foroperation

rl

Weatherstrips foradhesion andfit

[l

Headlamp aiming

I~ Tighten wheelnuts(Inc. inner nutsifapplica-

ble)

IJ Tire pressure (Inc.spare tire)

Il

Check frontwheels fortoe-in

IJ Install clock/voltmeter/room lampfuse(If

applicable)

~ Install deodorizing filtertoair purifier (If

applicable)

~ Remove wiperbladeprotectors (Ifapplicable)

UNDER

BODY

o

Manual transmission/transaxle, transferand

differential gearoillevel

D

Brake andfuel lines andoil/fluid reservoirs

for leaks

D

Tighten boltsandnuts ofsteering linkageand

gear box,suspension, propellershaftsand

drive shafts

~ Tighten rearbody boltsandnuts (Models with

wooden bedonly)

ROAD TEST

D

Clutch operation

D

Parking brakeoperation

[J

Service brakeoperation

D

Automatic transmission/transaxle shifttiming

and kickdown

[] Steering controlandreturnability

o

Engine performance

D

Squeaks andrattles

ENGINE OPERATING ANDHOT

D

Adjust idlemixture andspeed (andignition

timing*1)

n

Automatic transmission/transaxle fluidlevel

~ Engine idlingandstop knob operation (Diesel

only)

FINAL INSPECTION

n

Install necessary parts(outside mirror,wheel

covers, seatbelts, mat,carpet ormud flaps)

[1

Inspect forinterior andexterior metaland

paint damage

[] Check forspare tire,jack, tools (wheel

chock), andliterature

n

Wash, cleaninterior andexterior

"1: Not required onmodels withadirect ignition system

~ :Not appiicable tothis model.

•

MA-5