check engine light NISSAN ALMERA N15 1995 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1492 of 1701

GENERALMAINTENANCE

General maintenance includesthoseitemswhich should bechecked duringthenormal day-to-day

operation ofthe vehicle. Theyareessential ifthe vehicle isto continue operating properly.Theowners

can perform thechecks andinspections themselves orthey canhave theirNISSAN dealersdothem.

Item

OUTSIDE THEVEHICLE

The maintenance itemslistedhereshould beperformed fromtimetotime, unless oth-

erwise specified.

Tires

Check thepressure withagauge periodically whenataservice station, including

the spare, andadjust tothe specified pressureifnecessary. Checkcarefully fordamage,

cuts orexcessive wear.

Windshield wiperblades

Checkforcracks orwear ifthey donot wipe properly.

Doors andengine hood

Check thatalldoors, theengine hood,thetrunk lidand back

door operate properly. Alsoensure thatalllatches locksecurely. Lubricate hinges,

latches, rollersandlinks ifnecessary. Makesurethatthesecondary latchkeeps thehood

from opening whentheprimary latchisreleased.

When driving inareas usingroadsaltorother corrosive materials, checkforlubrication

frequently.

Tire rotation

Tiresshould berotated every

10,000

km

(6,000

miles).

INSIDE THEVEHICLE

The maintenance itemslistedhereshould bechecked onaregular basis,suchaswhen

performing periodicmaintenance, cleaningthevehicle, etc.

Lights

Makesurethattheheadlights, stoplights, taillights, turnsignal lights,andother

lights arealloperating properlyandinstalled securely. Alsocheck headlight aim.

Warning lightsandbuzzers/chimes

Makesurethatallwarning lightsandbuzzers/chimes

are operating properly.

Steering wheel

Check forchange inthe steering conditions, suchasexcessive freeplay,

hard steering orstrange noises.

Free play: Lessthan35mm (1.38 in)

Seat belts

Check thatallparts ofthe seat beltsystem (e.g.buckles, anchors, adjusters

and retractors) operateproperly andsmoothly, andareinstalled securely. Checkthebelt

webbing forcuts, fraying, wearordamage.

UNDER THEHOOD ANDVEHICLE

The maintenance itemslisted hereshould bechecked periodically e.g.each timeyou

check theengine oilorrefuel.

Windshield washerfluid

Check thatthere isadequate fluidinthe tank.

Engine coolant level

Check thecoolant levelwhen theengine iscold.

Engine oillevel

Check thelevel afterparking thevehicle onalevel spotandturning off

the engine.

Brake andclutch fluidlevels

Makesurethatthebrake andclutch fluidlevels arebetween

the "MAX" and"MIN" linesonthe reservoir.

Battery

Checkthefluid level ineach cell.Itshould bebetween the"MAX" and"MIN"

lines.

MA-6

Reference

pages

MA-51

MA-50

MA-19,38

MA-24, 33,41

MA-45,47

Page 1511 of 1701

ENGINEMAINTENANCE ~

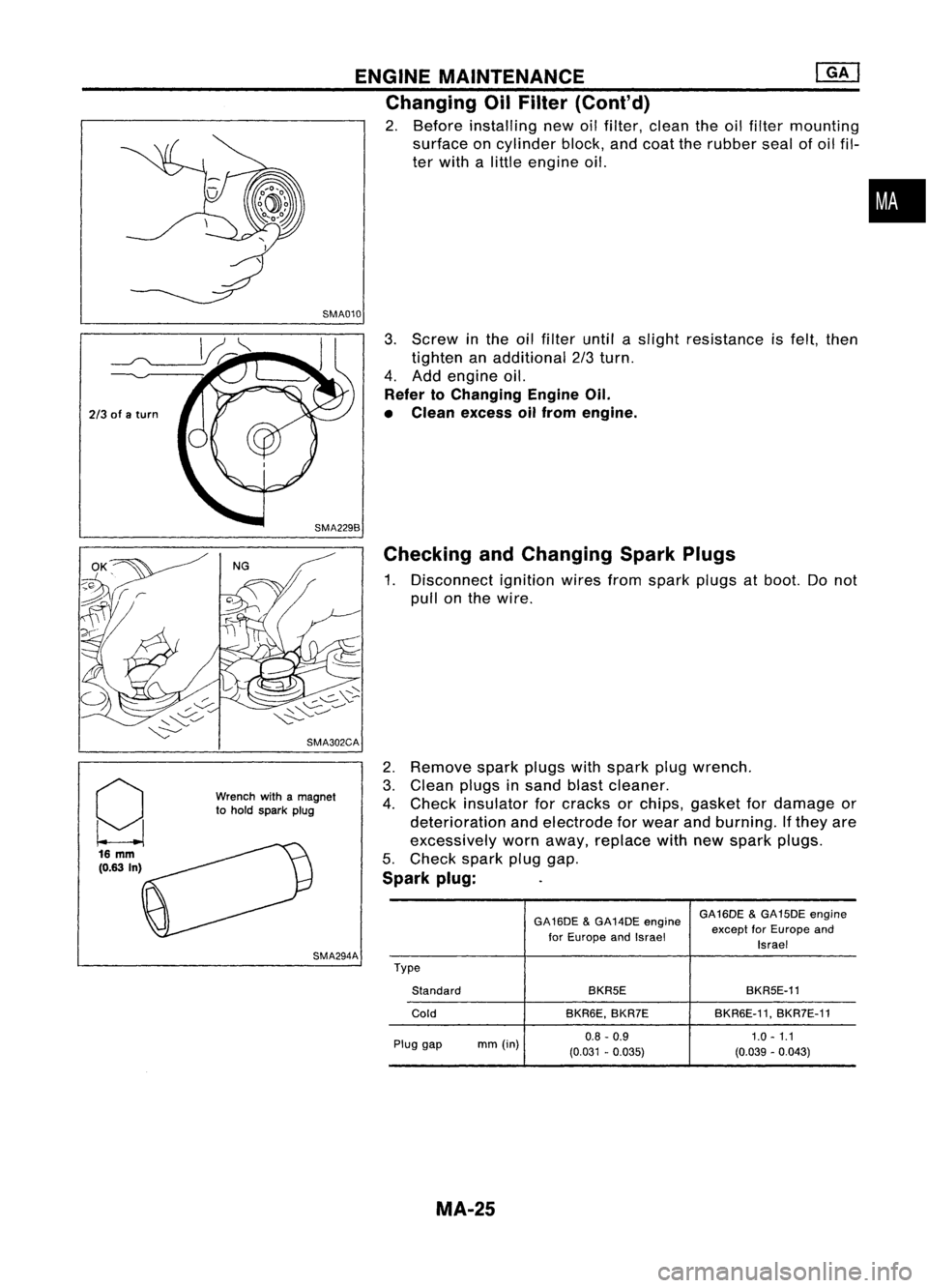

Changing OilFilter (Cont'd)

2. Before installing newoilfilter, clean theoilfilter mounting

surface oncylinder block,andcoat therubber sealofoil fil-

ter with alittle engine oil.

SMA010

•

2/3 ofaturn

g 16

mm

(0.63 In) SMA302CA

Wrench withamagnet

to hold spark plug

SMA294A

3.

Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

Checking andChanging SparkPlugs

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

2. Remove sparkplugswithspark plugwrench.

3. Clean plugsinsand blastcleaner.

4. Check insulator forcracks orchips, gasket fordamage or

deterioration andelectrode forwear andburning. Ifthey are

excessively wornaway, replace withnewspark plugs.

5. Check sparkpluggap.

Spark plug:

GA16DE&GA14DE engine GA16DE

&GA15DE engine

for Europe andIsrael except

forEurope and

Israel

Type Standard BKR5E

BKR5E-11

Cold BKR6E,BKR7E BKR6E-11,

BKR7E-11

Plug gap mm(in) 0.8

-0.9 1.0-1.1

(0.031 -0.035) (0.039-0.043)

MA-25

Page 1520 of 1701

![NISSAN ALMERA N15 1995 Owners Guide ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After NISSAN ALMERA N15 1995 Owners Guide ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After](/img/5/57349/w960_57349-1519.png)

ENGINEMAINTENANCE [}[]

Changing EngineOil(Cont'd)

4. Check oillevel.

5. Start engine andcheck areaaround drainplugandoilfilter

for oilleakage.

6. Run engine forafew minutes, thenturnitoff. After several

minutes, checkoillevel.

Refill oil10this

"H" level.

Do not overfill.

SMA390C

Changing OilFilter

1. Remove oilfilter withTool.

WARNING:

Be careful nottoburn yourself, asthe engine andtheengine

oil are hot.

2. Clean oilfilter mounting surfaceoncylinder block.Coat

rubber sealofnew oilfilter withengine oil.

2/3

ofaturn

-------

OK SMA010

3.Screw inthe oilfilter untilaslight resistance isfelt, then

tighten anadditional 2/3turn.

4. Add engine oil.

Refer toChanging EngineOil.

• Clean excess oilfrom engine.

Changing SparkPlugs(Platinum-tipped type)

1. Disconnect ignitionwiresfromspark plugsatboot. Donot

pull onthe wire.

MA-34

Page 1529 of 1701

![NISSAN ALMERA N15 1995 Owners Guide

2/3

ofaturn

ENGINE

MAINTENANCE @Q]

Changing EngineOilFilter (Cont'd)

3. Screw oilfilter onuntil aslight resistance isfelt, then tighten

an additional 2/3turn.

4. Warm upengine andcheck oillevel NISSAN ALMERA N15 1995 Owners Guide

2/3

ofaturn

ENGINE

MAINTENANCE @Q]

Changing EngineOilFilter (Cont'd)

3. Screw oilfilter onuntil aslight resistance isfelt, then tighten

an additional 2/3turn.

4. Warm upengine andcheck oillevel](/img/5/57349/w960_57349-1528.png)

2/3

ofaturn

ENGINE

MAINTENANCE @Q]

Changing EngineOilFilter (Cont'd)

3. Screw oilfilter onuntil aslight resistance isfelt, then tighten

an additional 2/3turn.

4. Warm upengine andcheck oillevel.

5. Adjust oillevel ifnecessary. •

Refer toStep 4in "Changing EngineOil",MA-42.

i

• Clean excess oilfrom engine.

SMA229B Checking InjectionNozzle

1. Remove injection deliverytubesandfuel spill tube.

2. Remove nozzlewithasuitable tool[span 27mm (1.06 in)].

WARNING:

When usingnozzle tester,becareful nottoallow diesel fuel

sprayed fromnozzle tocome intocontact withyour hand or

body, andmake surethatyour eyes areproperly protected.

3. Clean andcheck nozzles.

4. Install nozzle toinjection nozzletesterandbleed airfrom

flare nut.

5. Check initialinjection pressure bypumping testerhandle

one time persecond.

EF791A

6.Install injector topressure tester.

7. Check initialinjection pressure bypumping testerhandle

slowly (onetime persecond).

Injection pressure:

12,749 kPa(127.5 bar,130kg/cm

2,

1,849psi)

• Always checkinitialinjection pressure beforeinstalling new

nozzle.

Good

\

I

,

,

I

Wrong SEF672A

8.Check fuelspray pattern bypumping testerhandle quickly

(4 or 6times persecond).

9. Ifinitial injection pressure orinjection nozzleisnot normal,

adjust orclean injection nozzleorreplace it.

Refer toEC section forinjection pressure adjustment.

10. Install allinjection nozzlesandsecurely connectfuelspill

tube anddelivery tubes.

11. Bleed airfrom fuelsystem andcheck forfuel leakage with

engine running.

EF794A

MA.43

Page 1530 of 1701

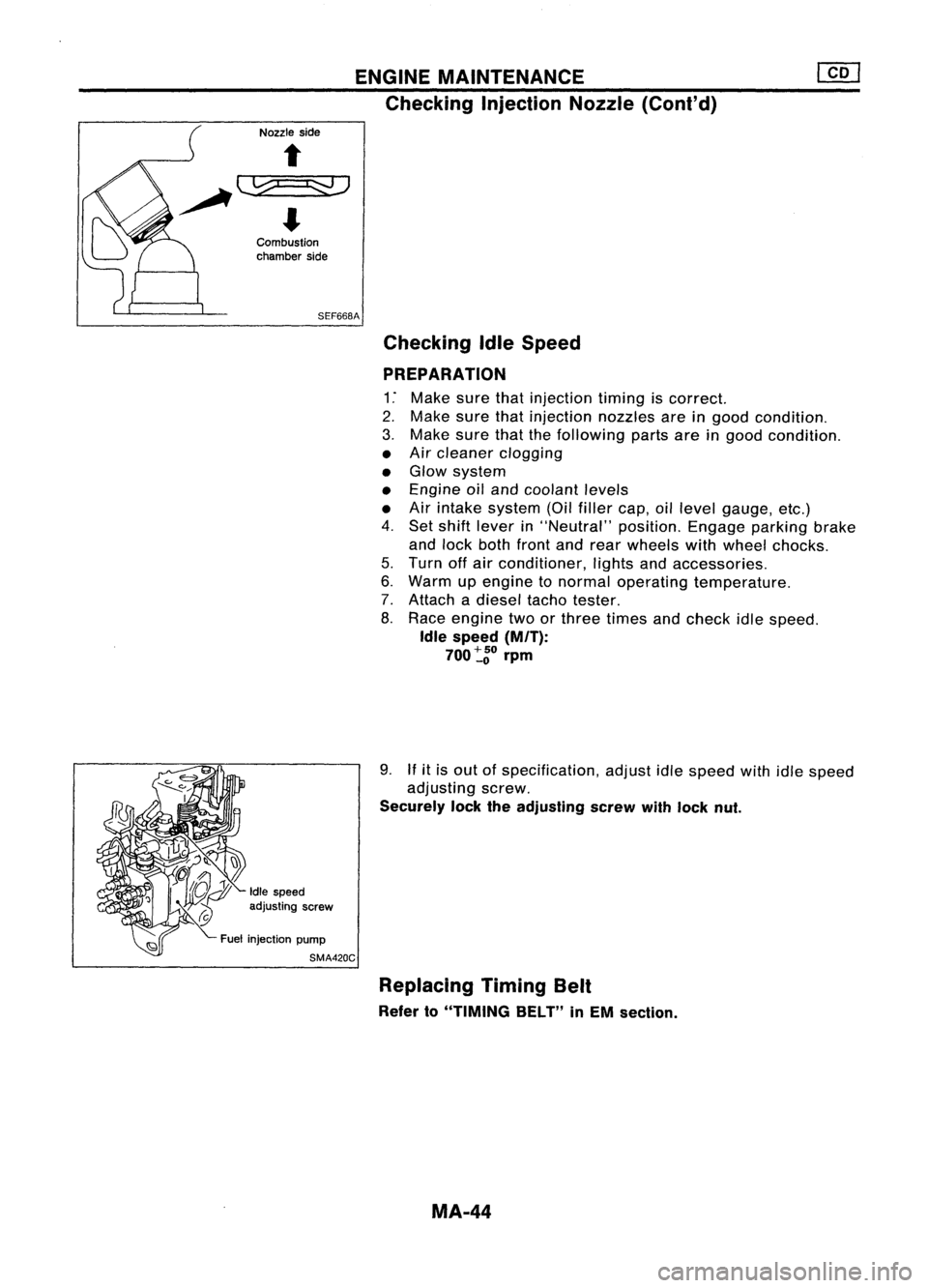

ENGINEMAINTENANCE

Checking InjectionNozzle(Cont'd)

Nozzle side

Combustion

chamber side

SEF668A Checking IdleSpeed

PREPARATION

1: Make surethatinjection timingiscorrect.

2. Make surethatinjection nozzlesareingood condition.

3. Make surethatthefollowing partsareingood condition.

• Air cleaner clogging

• Glow system

• Engine oiland coolant levels

• Air intake system (Oilfiller cap,oillevel gauge, etc.)

4. Set shift lever in"Neutral" position.Engageparkingbrake

and lock both front andrear wheels withwheel chocks.

5. Turn offair conditioner, lightsandaccessories.

6. Warm upengine tonormal operating temperature.

7. Attach adiesel tachotester.

8. Race engine twoorthree times andcheck idlespeed.

Idle speed (M/T):

700~go rprn

9.

If

itis out ofspecification, adjustidlespeed withidlespeed

adjusting screw.

Securely locktheadjusting screwwithlock nut.

Idle speed

adjusting screw

Fuel injection pump

SMA420C

Replacing TimingBelt

Refer to"TIMING BELT"inEM section.

MA-44

Page 1673 of 1701

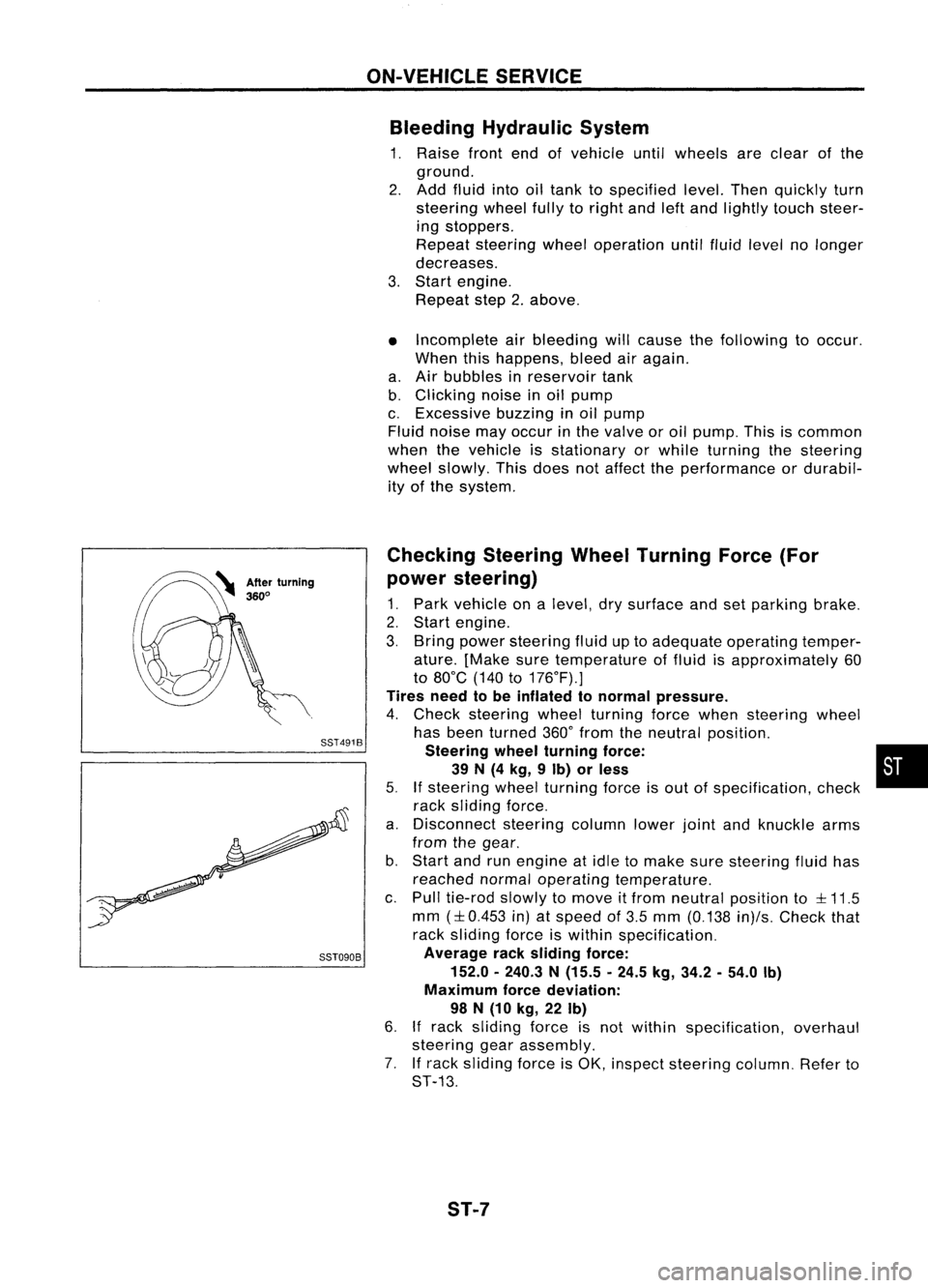

SST491B

SST090B ON-VEHICLE

SERVICE

Bleeding Hydraulic System

1. Raise frontendofvehicle untilwheels areclear ofthe

ground.

2. Add fluid intooiltank tospecified level.Thenquickly turn

steering wheelfullytoright andleftand lightly touchsteer-

ing stoppers.

Repeat steering wheeloperation untilfluid level nolonger

decreases.

3. Start engine.

Repeat step2.above.

• Incomplete airbleeding willcause thefollowing tooccur.

When thishappens, bleedairagain.

a. Air bubbles inreservoir tank

b. Clicking noiseinoil pump

c. Excessive buzzinginoil pump

Fluid noise mayoccur inthe valve oroil pump. Thisiscommon

when thevehicle isstationary orwhile turning thesteering

wheel slowly. Thisdoes notaffect theperformance ordurabil-

ity ofthe system.

Checking SteeringWheelTurning Force(For

power steering)

1. Park vehicle onalevel, drysurface andsetparking brake.

2. Start engine.

3. Bring power steering fluiduptoadequate operating temper-

ature. [Make suretemperature offluid isapproximately 60

to 80°C (140to176°F).]

Tires needtobe inflated tonormal pressure.

4. Check steering wheelturning forcewhen steering wheel

has been turned 360°from theneutral position.

Steering wheelturning force: •

39 N(4 kg, 9Ib) orless

5.

If

steering wheelturning forceisout ofspecification, check

rack sliding force.

a. Disconnect steeringcolumnlowerjointandknuckle arms

from thegear.

b. Start andrunengine atidle tomake suresteering fluidhas

reached normaloperating temperature.

c. Pull tie-rod slowlytomove itfrom neutral position to

::l::

11.5

mm

(::l::

0.453 in)atspeed of3.5 mm (0.138 in)/s.Check that

rack sliding forceiswithin specification.

Average racksliding force:

152.0 -240.3 N(15.5 -24.5 kg,34.2 -54.0 Ib)

Maximum forcedeviation:

98 N(10 kg, 22Ib)

6.

If

rack sliding forceisnot within specification, overhaul

steering gearassembly.

7. Ifrack sliding forceisOK, inspect steering column.Referto

ST-13.

ST-7