jack points NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 688 of 1701

ON-VEHICLESERVICE

Front Wheel Alignment

Before checking frontwheel alignment, besure tomake apre-

liminary inspection (Unladen*).

*: Fuel, radiator coolantandengine oilfull. Spare tire,jack,

hand tools andmats indesignated positions.

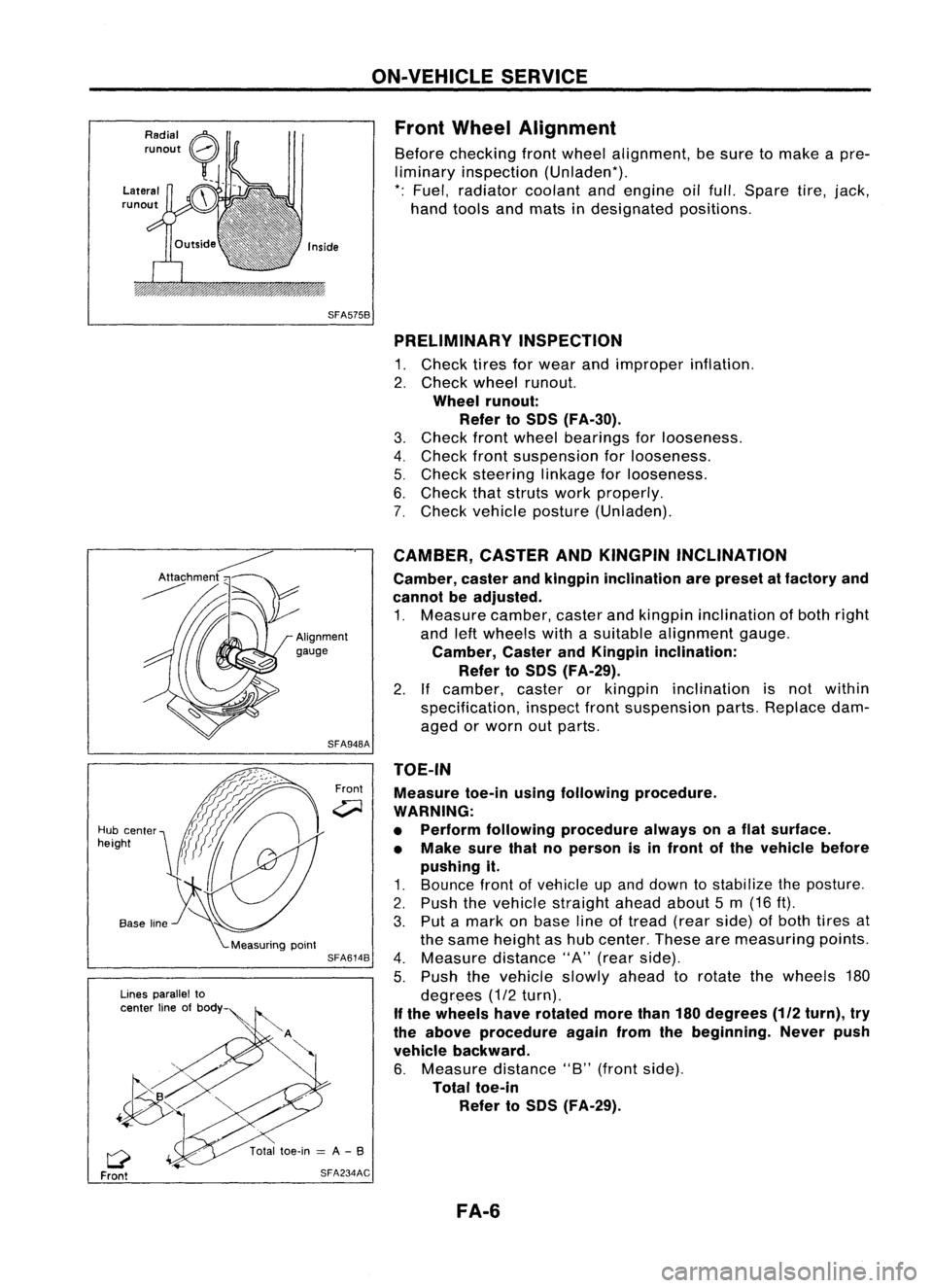

SFA575B PRELIMINARY INSPECTION

1. Check tiresforwear andimproper inflation.

2. Check wheelrunout.

Wheel runout:

Refer toSOS (FA-30).

3. Check frontwheel bearings forlooseness.

4. Check frontsuspension forlooseness.

5. Check steering linkageforlooseness.

6. Check thatstruts workproperly.

7. Check vehicle posture (Unladen).

TOE-IN Measure toe-inusingfollowing procedure.

WARNING:

• Perform following procedure alwaysonaflat surface.

• Make surethatnoperson isin front ofthe vehicle before

pushing it.

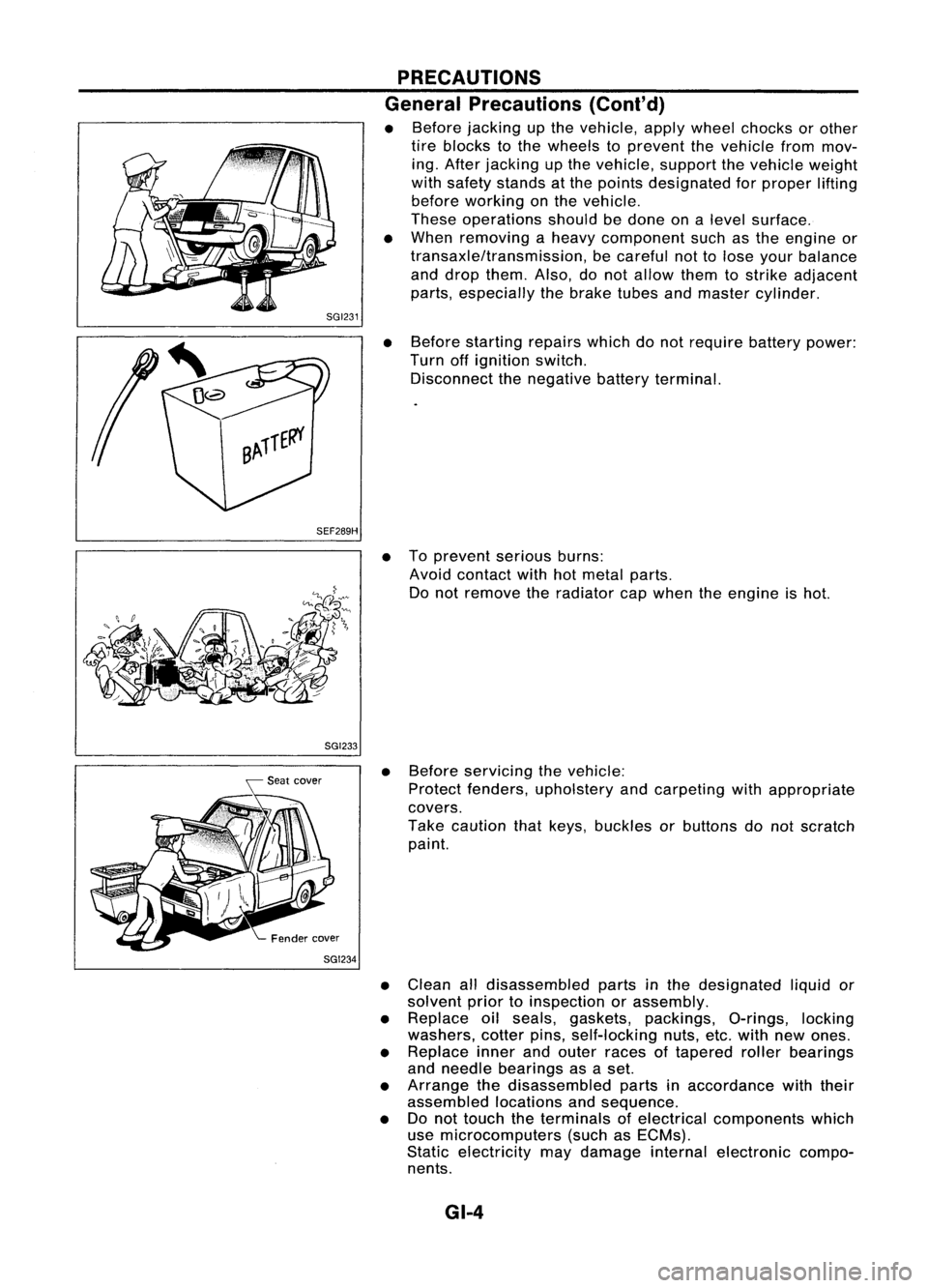

1. Bounce frontofvehicle upand down tostabilize theposture.

2. Push thevehicle straight aheadabout5m (16 ft).

3. Put amark onbase lineoftread (rearside) ofboth tires at

the same height ashub center. Thesearemeasuring points.

4. Measure distance"A"(rear side).

5. Push thevehicle slowlyaheadtorotate thewheels 180

degrees (1/2turn).

If the wheels haverotated morethan180degrees

(112

turn), try

the above procedure againfromthebeginning. Neverpush

vehicle backward.

6. Measure distance"B"(front side).

Total toe-in

Refer toSOS (FA-29).

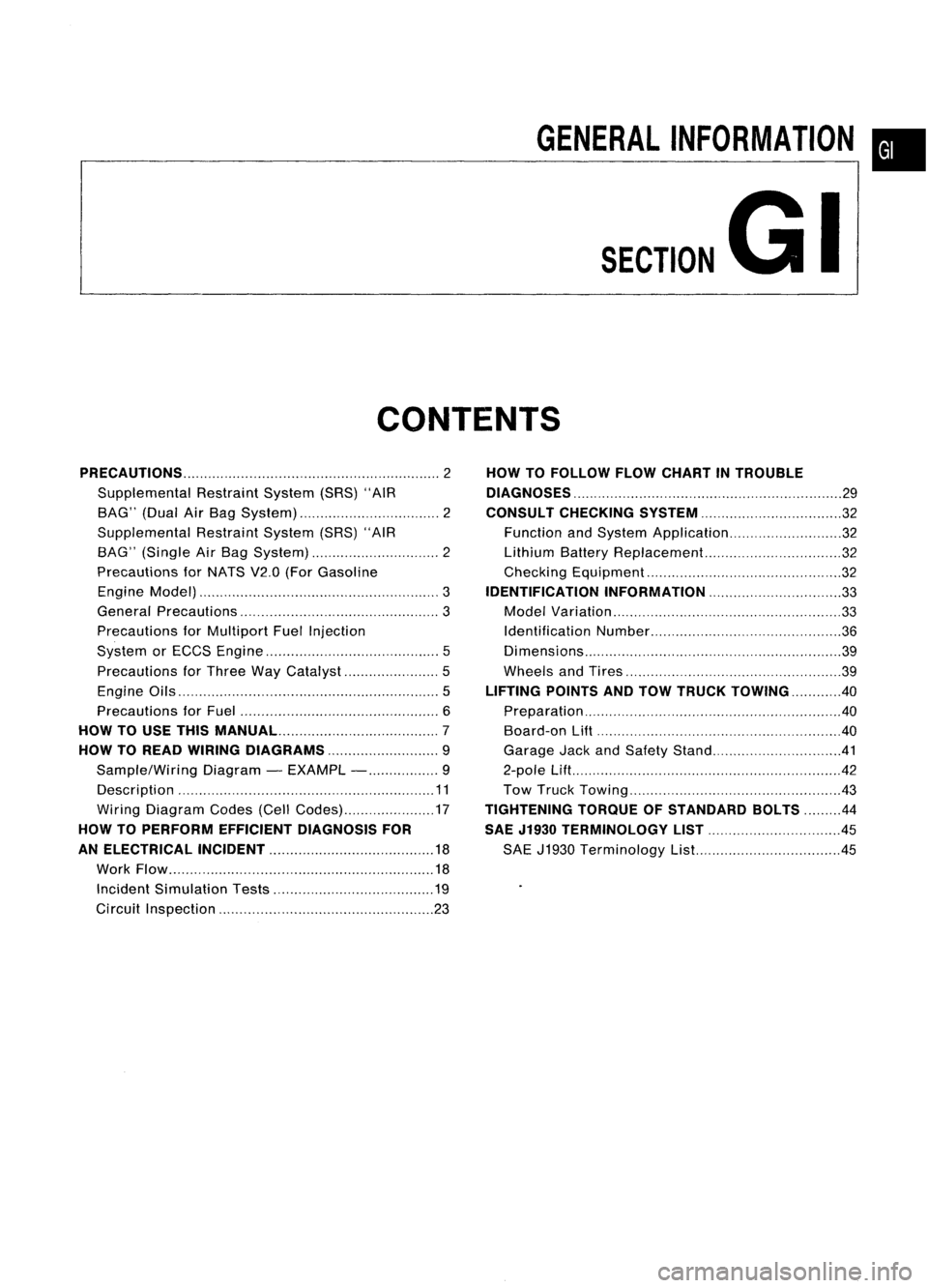

CAMBER,

CASTERANDKINGPIN INCLINATION

Camber, casterandkingpin inclination arepreset atfactory and

cannot beadjusted.

1. Measure camber,casterandkingpin inclination ofboth right

and leftwheels withasuitable alignment gauge.

Camber, CasterandKingpin inclination:

Refer toSOS (FA-29).

2. Ifcamber, casterorkingpin inclination isnot within

specification, inspectfrontsuspension parts.Replace dam-

aged orworn outparts.

Front

SFA948A

SFA614B

SFA234AC

Lines

parallel to

center lineofbody

Q

Front

Hub

center

height

FA-6

Page 1355 of 1701

GENERALINFORMATION •

SECTION

G

I

CONTENTS

PRECAUTIONS 2

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 2

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 2

Precautions forNATS V2.0(ForGasoline

Engine Model) 3

General Precautions 3

Precautions forMultiport FuelInjection

System orECCS Engine 5

Precautions forThree WayCatalyst 5

Engine Oils 5

Precautions forFuel 6

HOW TOUSE THIS

MANUAL 7

HOW TOREAD WIRING DIAGRAMS 9

Sample/Wiring Diagram-EXAMPL - 9

Description 11

Wiring Diagram Codes(CellCodes) 17

HOW TOPERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT 18

Work Flow 18

Incident Simulation Tests 19

Circuit Inspection 23

HOW

TOFOLLOW FLOWCHART INTROUBLE

DIAGNOSES 29

CONSULT CHECKING SYSTEM

32

Function andSystem Application 32

Lithium BatteryReplacement.. 32

Checking Equipment 32

IDENTIFICATION INFORMATION 33

Model Variation 33

Identification Number 36

Di mens ions 39

Wheels andTires 39

LIFTING POINTSANDTOW TRUCK TOWING ..40

Preparation 40

Board-on

Lift

40

Garage JackandSafety Stand 41

2-pole Lift 42

Tow Truck Towing 43

TIGHTENING TORQUEOFSTANDARD BOLTS

44

SAE J1930 TERMINOLOGY LIST 45

SAE J1930 Terminology List.. 45

Page 1358 of 1701

SEF289HSGI233

SGI234 PRECAUTIONS

General Precautions (Cont'd)

• Before jacking upthe vehicle, applywheel chocks orother

tire blocks tothe wheels toprevent thevehicle frommov-

ing. After jacking upthe vehicle, supportthevehicle weight

with safety stands atthe points designated forproper lifting

before working onthe vehicle.

These operations shouldbedone onalevel surface.

• When removing aheavy component suchasthe engine or

transaxle/transmission, becareful nottolose your balance

and drop them. Also,donot allow themtostrike adjacent

parts, especially thebrake tubesandmaster cylinder.

• Before starting repairswhichdonot require batterypower:

Turn offignition switch.

Disconnect thenegative batteryterminal.

• Toprevent seriousburns:

Avoid contact withhotmetal parts.

Do not remove theradiator capwhen theengine ishot.

• Before servicing thevehicle:

Protect fenders, upholstery andcarpeting withappropriate

covers.

Take caution thatkeys, buckles orbuttons donot scratch

paint.

• Clean alldisassembled partsinthe designated liquidor

solvent priortoinspection orassembly.

• Replace oilseals, gaskets, packings, O-rings,locking

washers, cotterpins,self-locking nuts,etc.with newones.

• Replace innerandouter races oftapered rollerbearings

and needle bearings asaset.

• Arrange thedisassembled partsinaccordance withtheir

assembled locationsandsequence.

• Donot touch theterminals ofelectrical components which

use microcomputers (suchasECMs).

Static electricity maydamage internalelectronic compo-

nents.

GI-4

Page 1395 of 1701

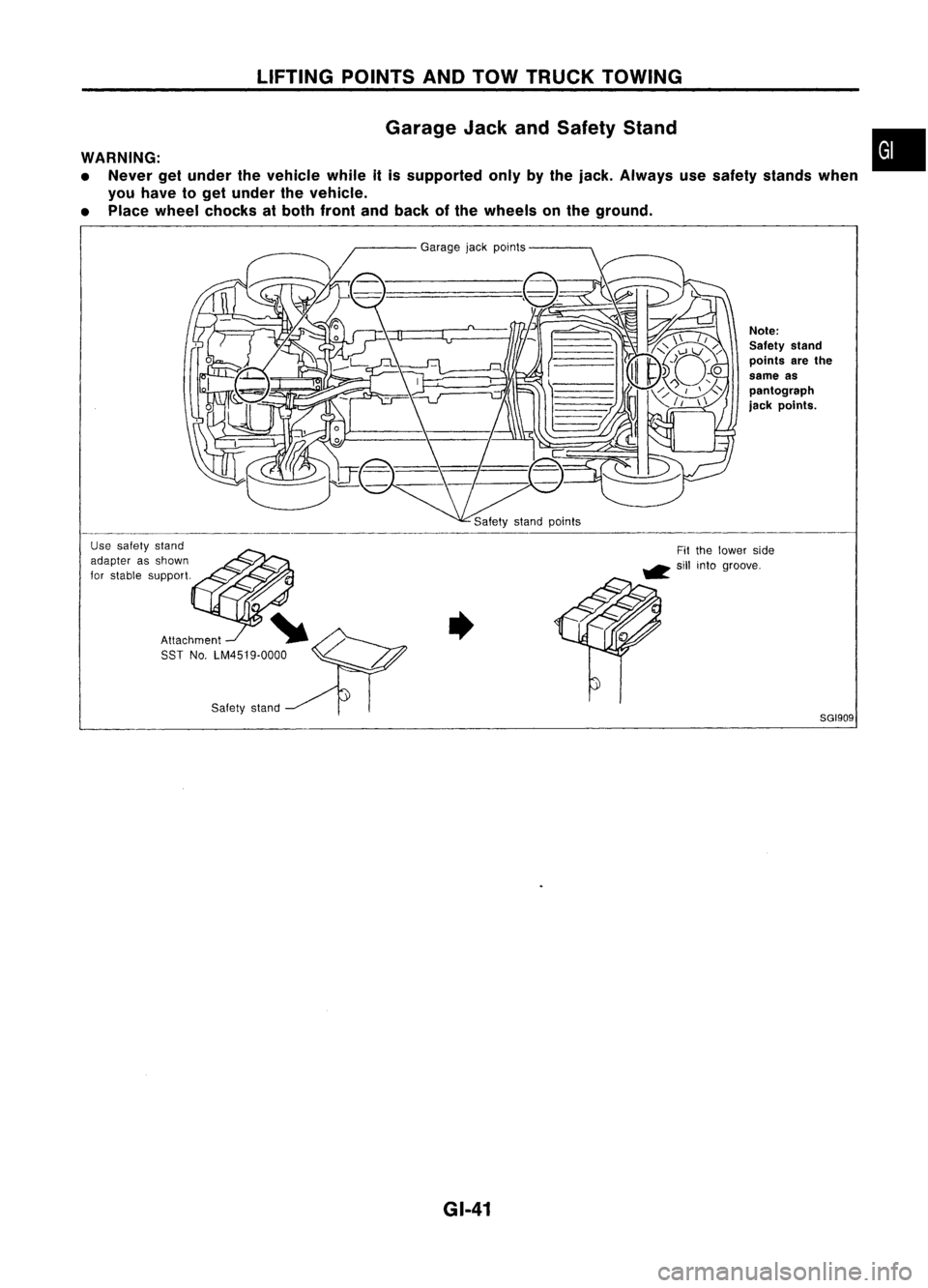

LIFTINGPOINTSANDTOW TRUCK TOWING

Garage JackandSafety Stand

WARNING:

• Never getunder thevehicle whileitis supported onlybythe jack. Always usesafety stands when

you have toget under thevehicle.

• Place wheel chocks atboth front andback ofthe wheels onthe ground.

•

Safety stand

8GI909

Note:

Safety stand

points arethe

same as

pantograph

jack points.

Garage

jackpoints

Attachment SST No.LM4519.0000

Use

safety stand

adapter asshown

for stable support.

GI-41

Page 1396 of 1701

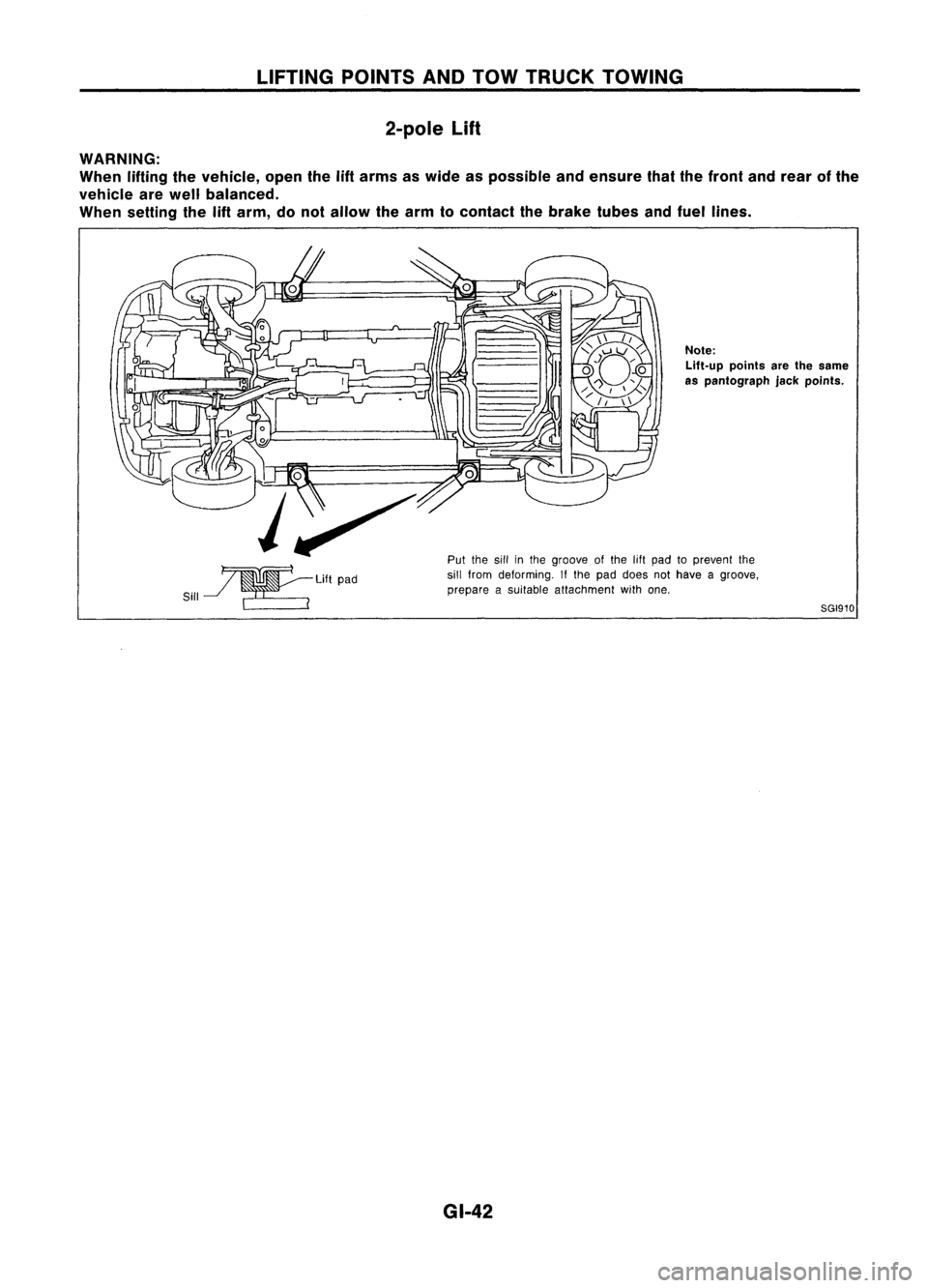

LIFTINGPOINTSANDTOW TRUCK TOWING

2-pole

Lift

WARNING:

When liftingthevehicle, openthe

lift

arms aswide aspossible andensure thatthefront andrear ofthe

vehicle arewell balanced.

When setting the

lift

arm, donot allow thearm tocontact thebrake tubesandfuel lines.

~LiftPad

Sill ~ ~__ ~ ~..

~---

Note:

Lift-up pointsarethesame

as pantograph jackpoints.

Put thesillinthe groove ofthe 11ftpad toprevent the

sill from deforming. Ifthe pad does nothave agroove,

prepare asuitable attachment withone.

8GI910

GI-42