jump start NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 397 of 1701

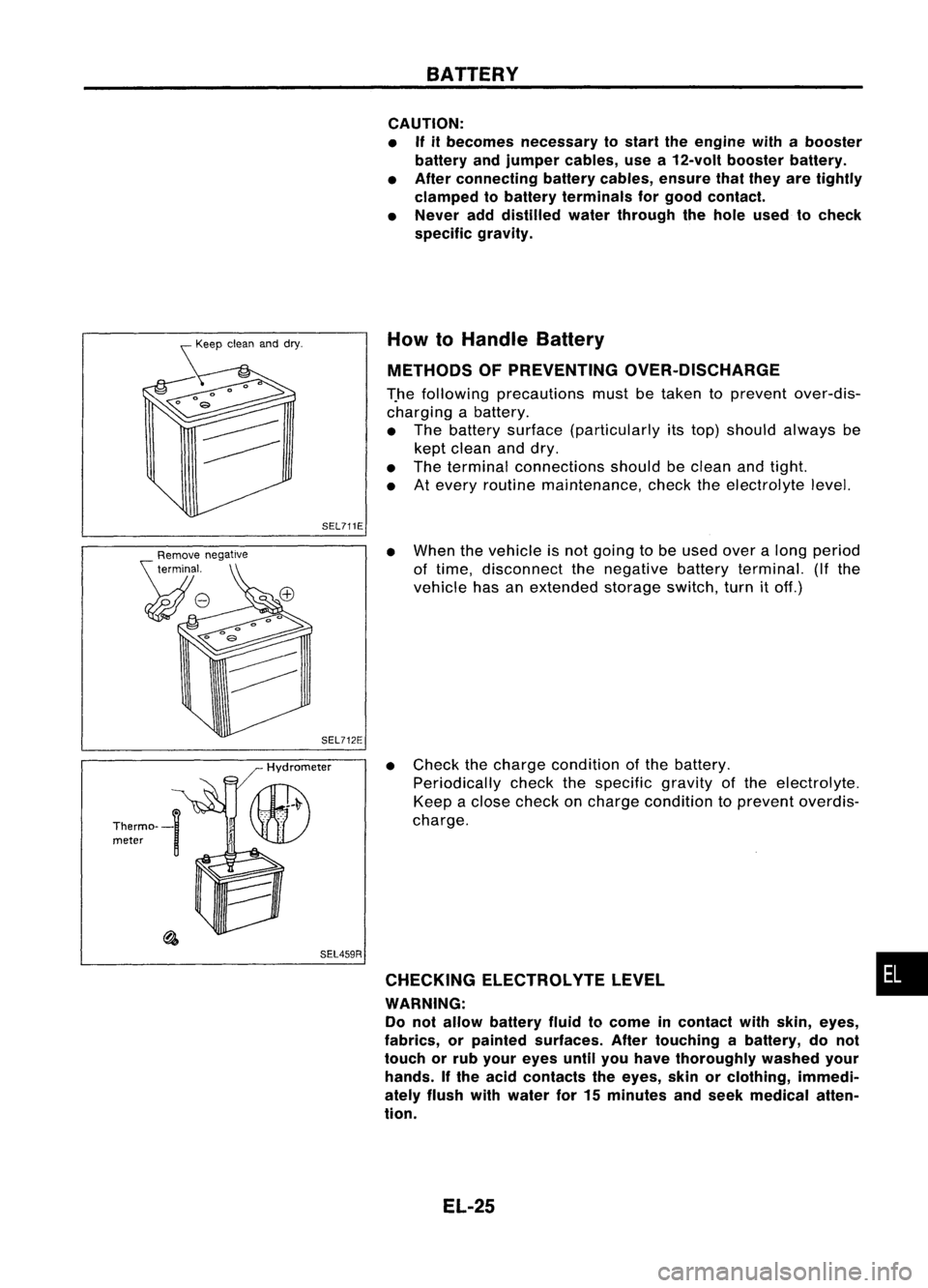

SEL711EBATTERY

CAUTION:

• If

itbecomes necessary tostart theengine withabooster

battery andjumper cables, usea12-volt booster battery.

• After connecting batterycables, ensurethatthey aretightly

clamped tobattery terminals forgood contact.

• Never adddistilled waterthrough thehole used tocheck

specific gravity.

How toHandle Battery

METHODS OFPREVENTING OVER-DISCHARGE

T.he following precautions mustbetaken toprevent over-dis-

charging abattery.

• The battery surface (particularly itstop) should always be

kept clean anddry.

• The terminal connections shouldbeclean andtight.

• Atevery routine maintenance, checktheelectrolyte level.

SEL459R

•

When thevehicle isnot going tobe used overalong period

of time, disconnect thenegative batteryterminal. (Ifthe

vehicle hasanextended storageswitch,turnitoff.)

• Check thecharge condition ofthe battery.

Periodically checkthespecific gravityofthe electrolyte.

Keep aclose check oncharge condition toprevent overdis-

charge.

CHECKING ELECTROLVTELEVEL •

WARNING: Do not allow battery fluidtocome incontact withskin, eyes,

fabrics, orpainted surfaces. Aftertouching abattery, donot

touch orrub your eyes untilyouhave thoroughly washedyour

hands. Ifthe acid contacts theeyes, skinorclothing, immedi-

ately flush withwater for15minutes andseek medical atten-

tion.

EL-25

Page 760 of 1701

•

oxygen

sen-

Europe and

nd Australia

els)

sensor

for Europe

el, and Aus-

T models)

@

II

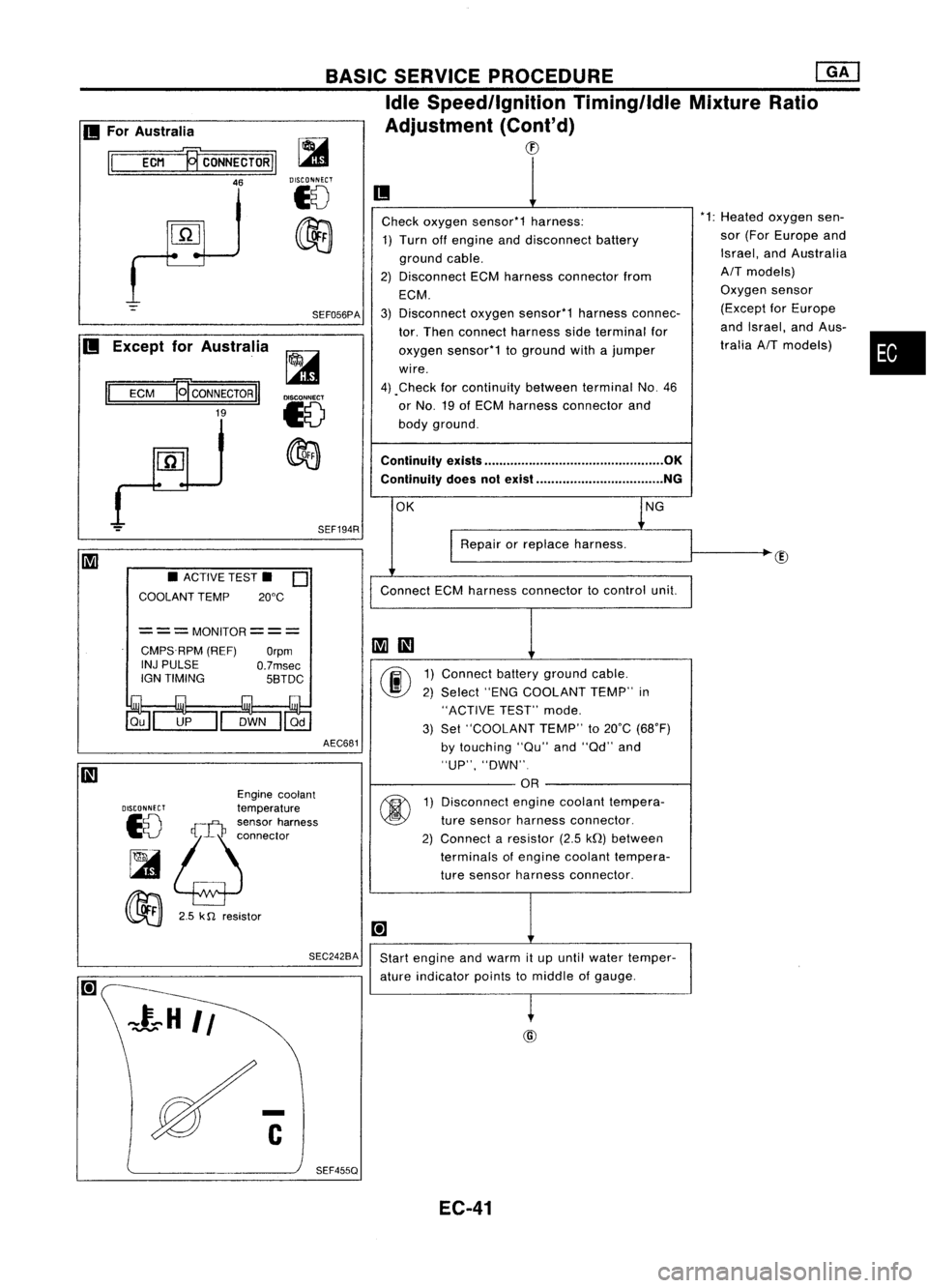

Check oxygen sensor*1 harness: *1:

Heated

1) Turn offengine anddisconnect battery sor

(For

ground cable. Israel,

a

2) Disconnect ECMharness connector from

AIT

mod

ECM. Oxygen

3) Disconnect oxygensensor*1 harnessconnec- (Except

tor. Then connect harness sideterminal for and

Isra

oxygen sensor*1 toground withajumper tralia

AI

wire.

4) .Check forcontinuity betweenterminalNo.46

or No. 19ofECM harness connector and

body ground.

Continuity exists................................................ OK

Continuity doesnotexist .................................. NG

OK lNG

I

Repair orreplace harness.

Connect ECMharness connector tocontrol unit.

~

III

00

1)

Connect batteryground cable.

2) Select "ENGCOOLANT TEMP"in

"ACTIVE TEST"mode.

3) Set "COOLANT TEMP"to20°C (68°F)

by touching "au"and"ad" and

"UP", "DWN".

OR

@

1)

Disconnect enginecoolant tempera-

ture sensor harness connector.

2) Connect aresistor (2.5kQ)between

terminals ofengine coolant tempera-

ture sensor harness connector.

[+]

Start engine andwarm itup until water temper-

ature indicator pointstomiddle ofgauge.

~

BASIC

SERVICE PROCEDURE ~

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

CD

SEF194R

SEF056PA

~

DISCONNECT

18

~

AEC681

===MONITOR===

CMPS.RPM (REF)

Orpm

INJ PULSE

O.7msec

IGN TIMING 5BTDC

SEC242BA

•

ACTIVE TEST.

0

COOLANT TEMP 20°C

Engine coolant

DISCONNECT

temperature

10

!;j:~:~~'~";"'"

~

00

2.5k

n

resistor

II

ECM

19'

CONNECTOR

II

19

II

For Australia

II

ECM ~CONNECTORII

46

II

Except forAustralia

SEF455Q EC-41

Page 921 of 1701

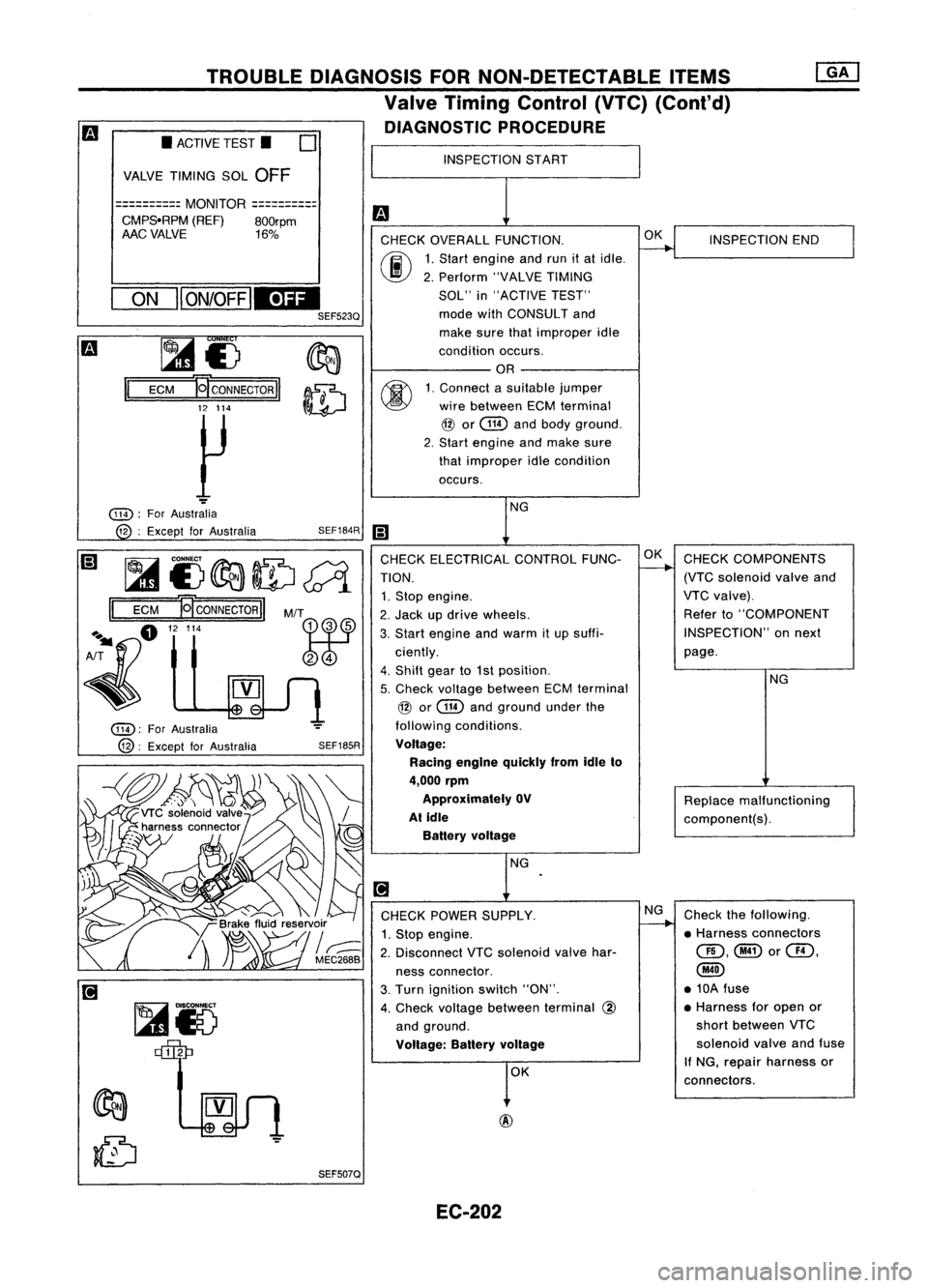

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Valve Timing Control (VTC)(Cant'd)

DIAGNOSTIC PROCEDURE

INSPECTION START

m

CHECK OVERALL FUNCTION.

~

INSPECTION

END

00

1.

Start engine andrunitat idle.

2. Perform "VALVETIMING

SOL" in"ACTIVE TEST"

mode withCONSULT and

make surethatimproper idle

condition occurs.

OR

00

1.

Connect asuitable jumper

wire between ECMterminal

@

or

@

andbody ground.

2. Start engine andmake sure

that improper idlecondition

occurs.

NG

iii

CHECK ELECTRICAL CONTROLFUNC-OK

CHECK COMPONENTS

TION.

-+

(VTCsolenoid valveand

1. Stop engine. VTC

valve).

2. Jack updrive wheels. Refer

to"COMPONENT

3. Start engine andwarm itup suffi- INSPECTION"

onnext

ciently. page.

4. Shift gearto1st position.

NG

5. Check voltage between ECMterminal

@

or

@

andground underthe

following conditions.

Voltage: Racing engine quickly fromidleto

4,000 rpm

Approximately OV

Replacemalfunctioning

At idle

component(s).

Battery voltage

NG

.

[!J

CHECK POWER SUPPLY. NG

Check thefollowing.

1. Stop engine.

~

•Harness connectors

2. Disconnect VTCsolenoid valvehar- QD,@or@,

ness connector.

@

3. Turn ignition switch"ON". •

10A fuse

4. Check voltage between terminal

@

•

Harness foropen or

and ground. short

between VTC

Voltage: Batteryvoltage

solenoid

valveandfuse

OK If

NG, repair harness or

connectors.

SEF185R

SEF507Q

SEF184R

M/T

~r5 ~

~£)

II

ECM

~CONNECTORII

12 114

~

ON

II

ON/OFF

IEDI

SEF523Q

•

ACTIVE TEST.

0

VALVE TIMING SOL

OFF

==========

MONITOR

==========

CMPS.RPM (REF)800rpm

AAC VALVE 16%

@):

ForAustralia

@:

Except forAustralia

@):

ForAustralia

12 :Except forAustralia

~i)~ID~

II

ECM

NCONNECTORII

A~fl "'"

~

EC-202

Page 966 of 1701

![NISSAN ALMERA N15 1995 Service Manual Heatedoxygen sensor

harness connector BASIC

SERVICE PROCEDURE [][]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

II

MEF031DB

~io

ECM TIcoNNECTORl1

19

LEn

MEC712B

Check

NISSAN ALMERA N15 1995 Service Manual Heatedoxygen sensor

harness connector BASIC

SERVICE PROCEDURE [][]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

II

MEF031DB

~io

ECM TIcoNNECTORl1

19

LEn

MEC712B

Check](/img/5/57349/w960_57349-965.png)

Heatedoxygen sensor

harness connector BASIC

SERVICE PROCEDURE [][]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

II

MEF031DB

~io

ECM TIcoNNECTORl1

19

LEn

MEC712B

Check

heated oxygen sensorharness:

1. Turn offengine anddisconnect batteryground

cable.

2. Disconnect ECMharness connector fromECM.

3. Disconnect heatedoxygen sensorharness con-

nector. Thenconnect harness sideterminal for

heated oxygen sensortoground withajumper

wire.

4. Check forcontinuity betweenterminal

@

ofECM

harness connector andbody ground.

Continuity exists OK

Continuity doesnotexist NG

OK

Repairorreplace harness.

Connect ECMharness connector toECM .

•

OR

1.

Connect batteryground cable.

2. Select "ENGCOOLANT TEMP"in

"ACTIVE TEST"mode.

3. Set "COOLANT TEMP"to20"C (68"F) by

touching "Qu"and"Qd" and"UP",

"DWN".

Disconnect enginecoolant temperature

sensor harness connector.

2. Connect aresistor (2.5kQ)between termi-

nals ofengine coolant temperature sensor

harness connector.

3. Connect batteryground cable.

Ii

AEC681

•

ACTIVE TEST.

0

COOLANT TEMP 20°C

===MONITOR=== CMPS.RPM (REF)

Orpm

INJ PULSE

O.7msec

IGN TIMING 5BTDC

DISCONNFCT

Enginecoolant

10 temperature

sensor

harness connector

~ ~

00

2.5

k0 resistor

Start

engine andwarm itup until engine coolant

temperature indicatorpointstomiddle ofgauge.

(Be sure tostart engine aftersetting "COOLANT

'-- A_E_C6_8-l2

TEMP"orinstalling a2.5 kQresistor.)

Ii

SEF455QEC-247

Page 1379 of 1701

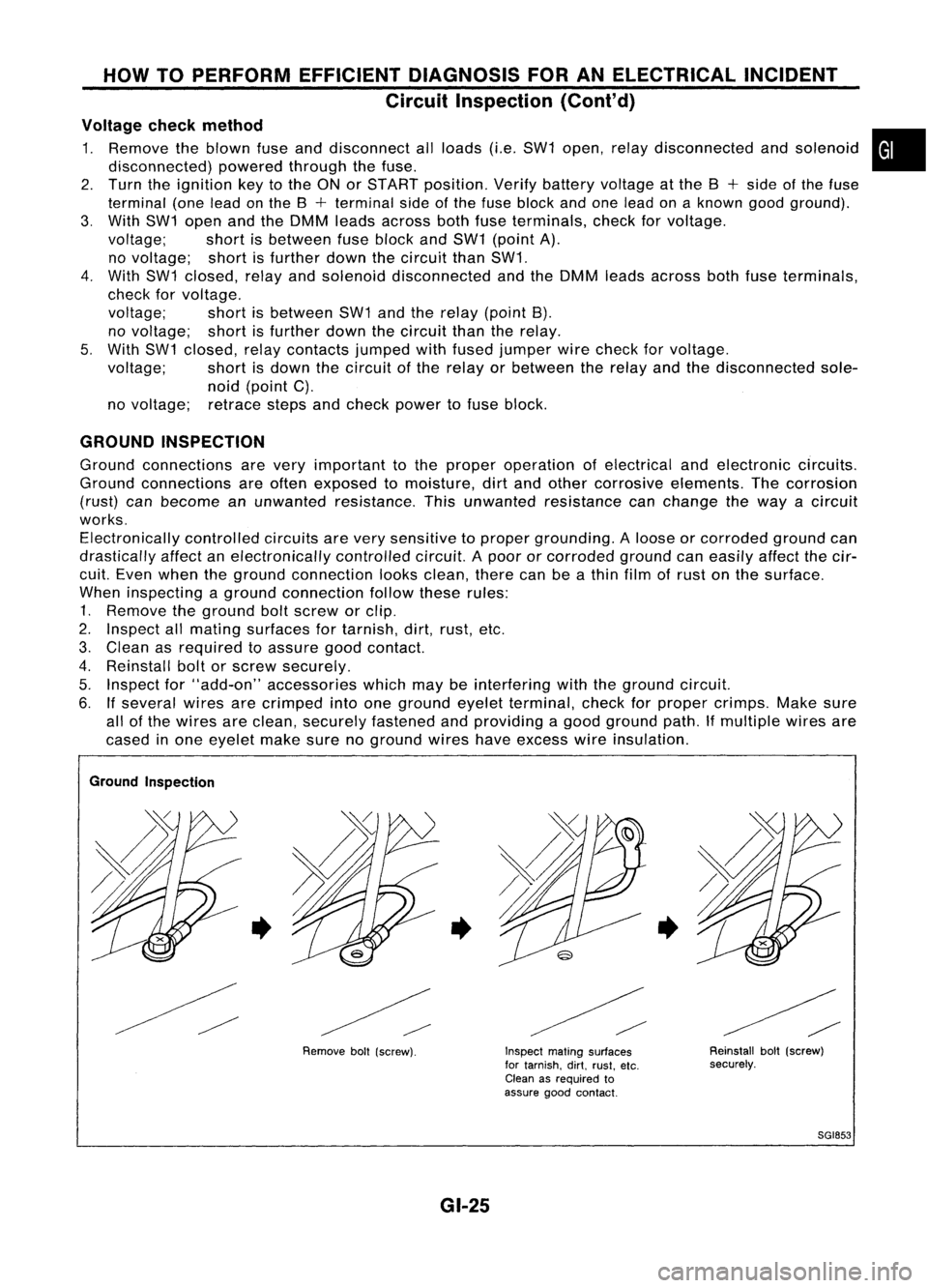

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Circuit Inspection (Cont'd)

Voltage checkmethod

1. Remove theblown fuseanddisconnect allloads (i.e.SW1 open, relaydisconnected andsolenoid •

disconnected) poweredthroughthefuse.

2. Turn theignition keytothe ONorSTART position. Verifybattery voltage atthe B

+

side ofthe fuse

terminal (oneleadonthe B

+

terminal sideofthe fuse block andone lead onaknown goodground).

3. With SW1 open andtheDMM leads across bothfuseterminals, checkforvoltage.

voltage; shortisbetween fuseblock andSW1 (point A).

no voltage; shortisfurther downthecircuit thanSW1.

4. With SW1 closed, relayandsolenoid disconnected andtheDMM leadsacross bothfuseterminals,

check forvoltage.

voltage; shortisbetween SW1andtherelay (point B).

no voltage; shortisfurther downthecircuit thantherelay.

5. With SW1 closed, relaycontacts jumpedwithfused jumper wirecheck forvoltage.

voltage; shortisdown thecircuit ofthe relay orbetween therelay andthedisconnected sole-

noid (point C).

no voltage; retracestepsandcheck power tofuse block.

GROUND INSPECTION

Ground connections arevery important tothe proper operation ofelectrical andelectronic circuits.

Ground connections areoften exposed tomoisture, dirtand other corrosive elements. Thecorrosion

(rust) canbecome anunwanted resistance. Thisunwanted resistance canchange theway acircuit

works. Electronically controlledcircuitsarevery sensitive toproper grounding. Aloose orcorroded groundcan

drastically affectanelectronically controlledcircuit.Apoor orcorroded groundcaneasily affectthecir-

cuit. Even when theground connection looksclean, therecanbeathin film ofrust onthe surface.

When inspecting aground connection followtheserules:

1. Remove theground boltscrew orclip.

2. Inspect allmating surfaces fortarnish, dirt,rust, etc.

3. Clean asrequired toassure goodcontact.

4. Reinstall boltorscrew securely.

5. Inspect for"add-on" accessories whichmaybeinterfering withtheground circuit.

6. Ifseveral wiresarecrimped intoone ground eyeletterminal, checkforproper crimps. Makesure

all ofthe wires areclean, securely fastened andproviding agood ground path.Ifmultiple wiresare

cased inone eyelet makesurenoground wireshaveexcess wireinsulation.

Ground Inspection

•

Removeboll(screw).

•

GI-25

Inspect

matingsurfaces

for tarnish. dirt.rust. etc.

Clean asrequired to

assure goodcontact.

•

Reinstallbolt(screw)

securely.

SGI853