set clock NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 305 of 1701

SBR646REAR

DISCBRAKE

Assembly (Cont'd)

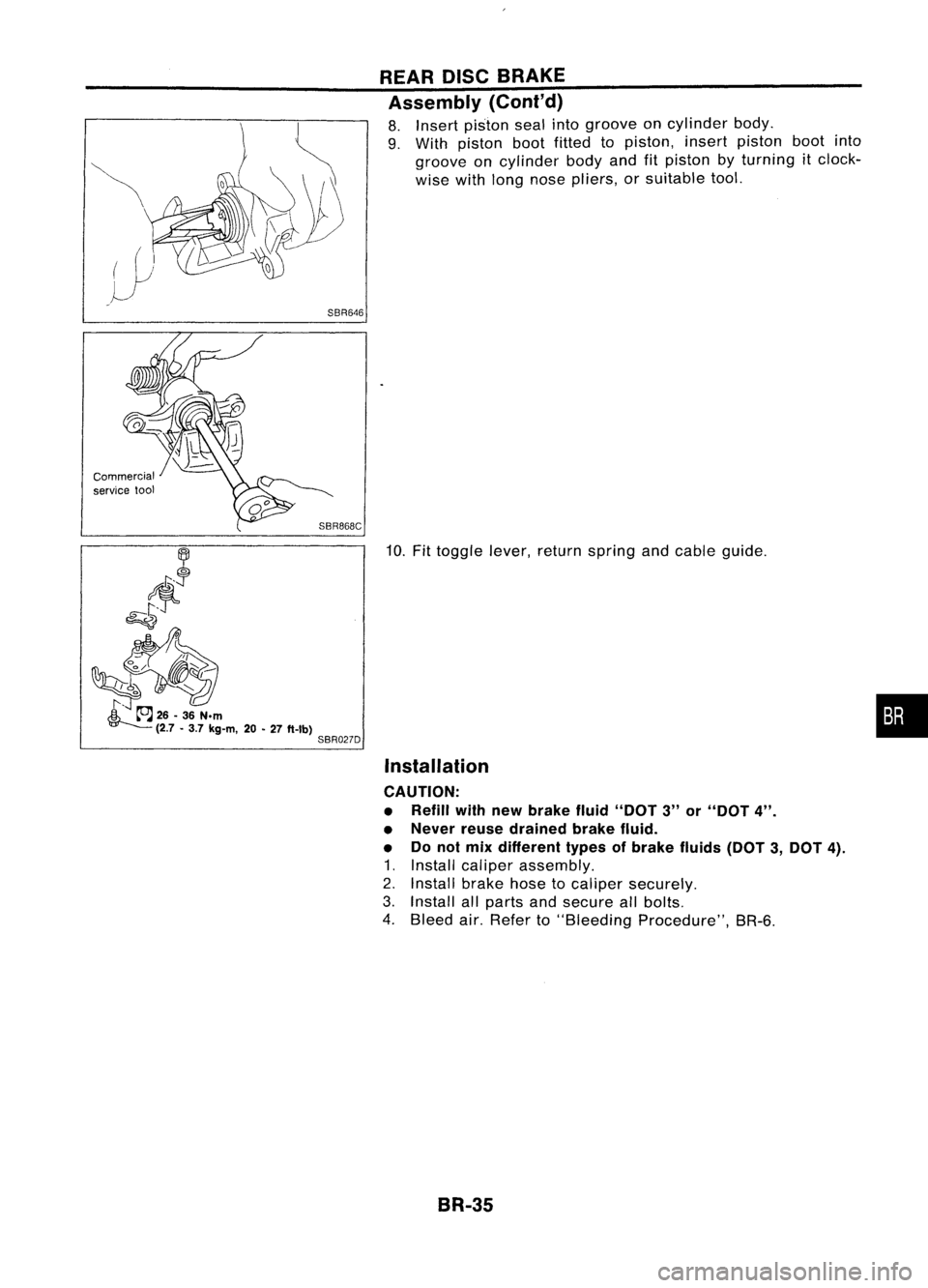

8. Insert piston sealintogroove oncylinder body.

9. With piston bootfitted topiston, insertpiston bootinto

groove oncylinder bodyandfitpiston byturning itclock-

wise withlong nose pliers, orsuitable tool.

Commercial

service

1001

SBR868C

10.Fittoggle lever,return spring andcable guide.

Installation

CAUTION:

• Refill withnewbrake fluid"DOT 3"or"DOT

4".

• Never reusedrained brakefluid.

• Donot mix different typesofbrake fluids(DOT3,DOT

4).

1. Install caliper assembly.

2. Install brakehosetocaliper securely.

3. Install allparts andsecure allbolts.

4. Bleed air.Refer to"Bleeding Procedure", BR-6.

BR-35

•

Page 447 of 1701

Bulbcover

SEL995K HEADLAMP

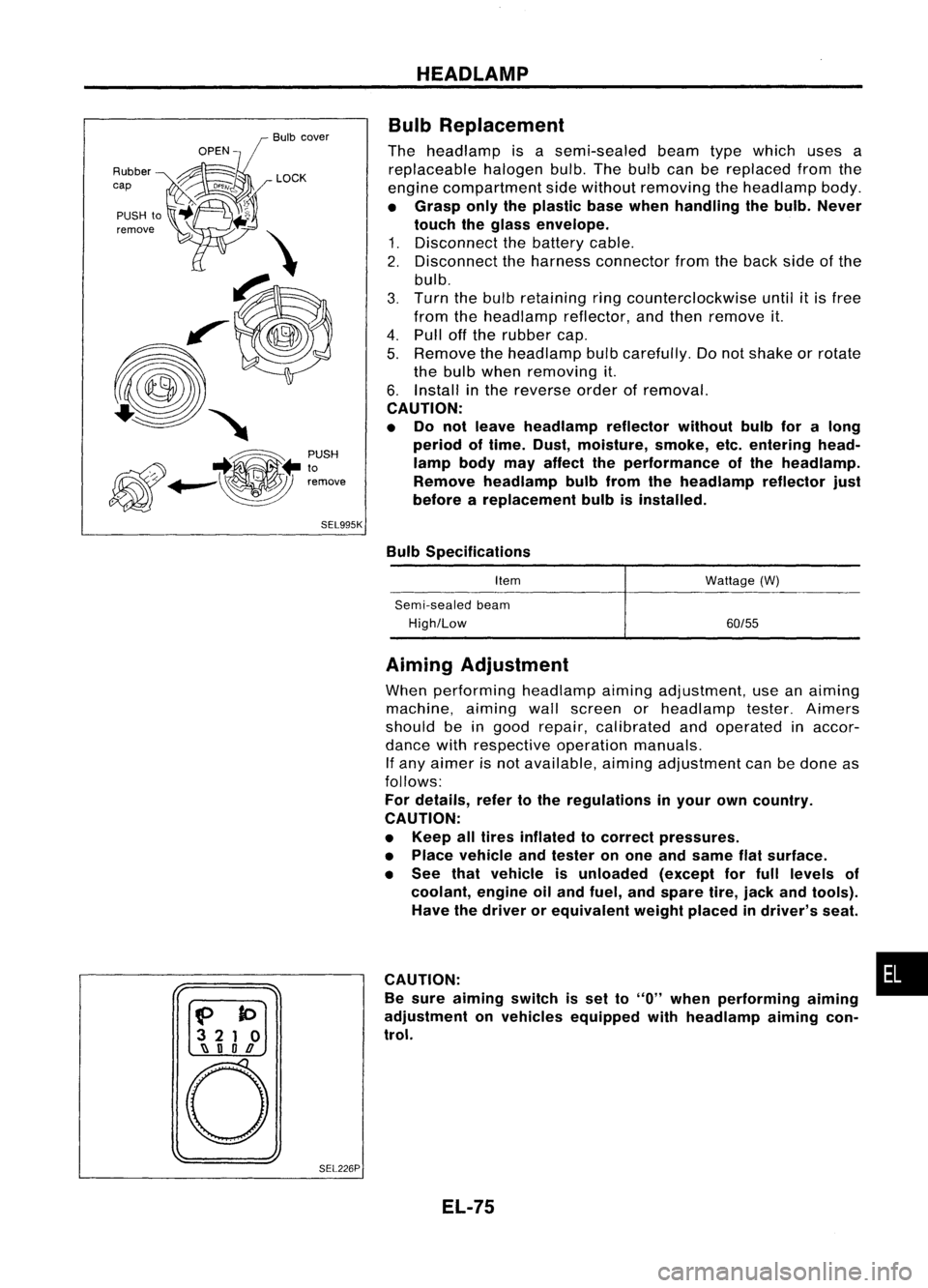

Bulb Replacement

The headlamp isasemi-sealed beamtypewhich usesa

replaceable halogenbulb.Thebulb canbereplaced fromthe

engine compartment sidewithout removing theheadlamp body.

• Grasp onlytheplastic basewhen handling thebulb. Never

touch theglass envelope.

1. Disconnect thebattery cable.

2. Disconnect theharness connector fromtheback sideofthe

bulb.

3. Turn thebulb retaining ringcounterclockwise until

it

is free

from theheadlamp reflector,andthen remove it.

4. Pull offthe rubber cap.

5. Remove theheadlamp bulbcarefully. Donot shake orrotate

the bulb when removing it.

6. Install inthe reverse orderofremoval.

CAUTION:

• Do not leave headlamp reflector withoutbulbforalong

period oftime. Dust,moisture, smoke,etc.entering head-

lamp bodymayaffect theperformance ofthe head lamp.

Remove headlamp bulbfrom thehead lamp reflector just

before areplacement bulbisinstalled.

Bulb Specifications

Item

Semi-sealed beam

High/Low Wattage

(W)

60/55

f>

to

3 21 0

~ nOD

o

SEL226PAiming

Adjustment

When performing headlamp aiming adjustment, useanaiming

machine, aimingwallscreen orheadlamp tester.Aimers

should beingood repair, calibrated andoperated inaccor-

dance withrespective operationmanuals.

If any aimer isnot available, aimingadjustment canbedone as

follows:

For details, refertothe regulations inyour owncountry.

CAUTION:

• Keep alltires inflated tocorrect pressures.

• Place vehicle andtester onone and same flatsurface.

• See thatvehicle isunloaded (exceptforfull levels of

coolant, engineoiland fuel, andspare tire,jack andtools).

Have thedriver orequivalent weightplaced indriver's seat.

CAUTION: •

Be sure aiming switchisset to

"0"

when performing aiming

adjustment onvehicles equipped withheadlamp aiming con-

trol.

EL-75

Page 1093 of 1701

VE-TYPE INJECTION PUMP

SEF779A

Adjustment

INJECTION TIMINGADJUSTMENT (Plunger

lift

adjustment)

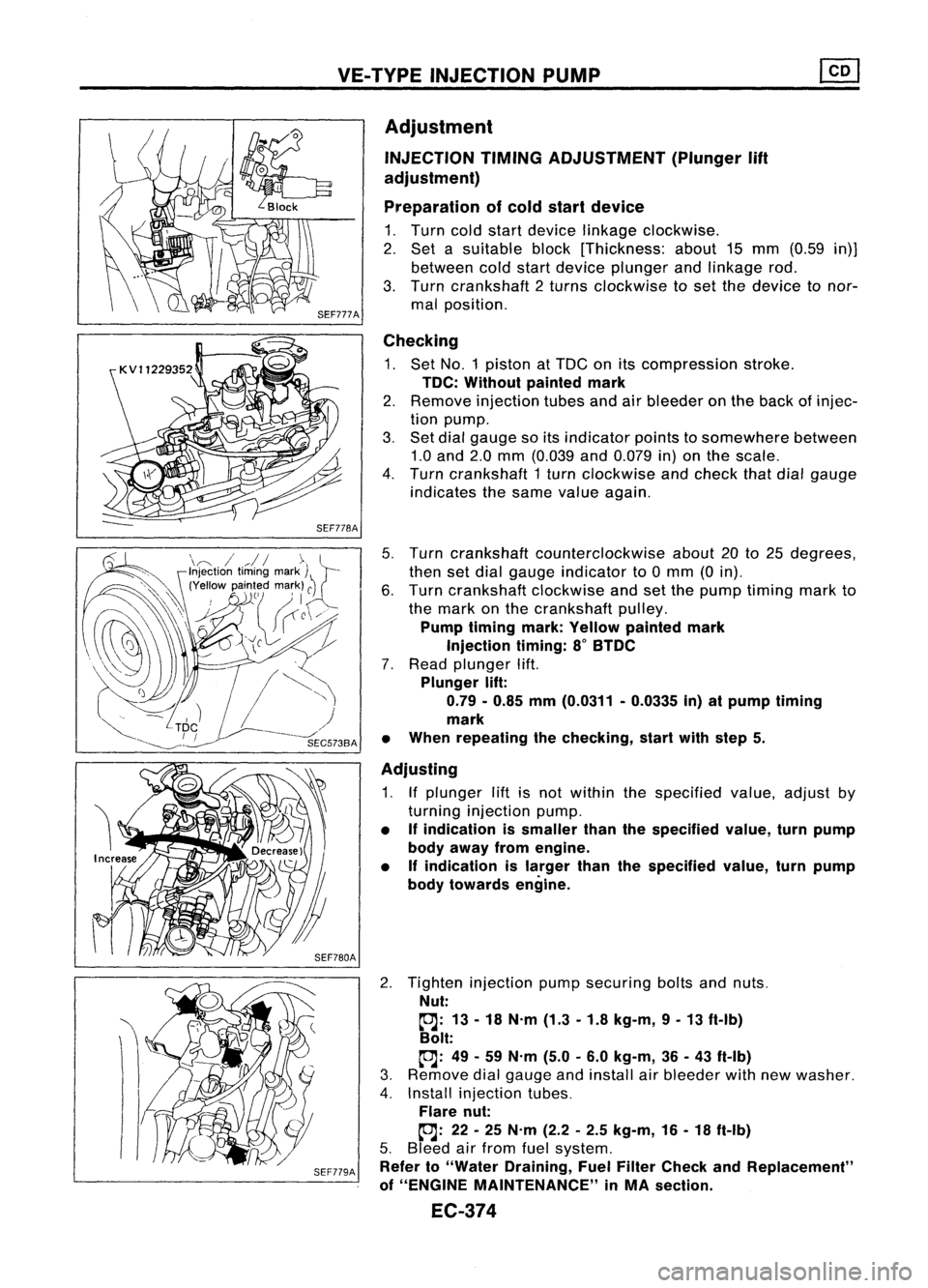

Preparation ofcold start device

1. Turn coldstart device linkage clockwise.

2. Set asuitable block[Thickness: about15mm (0.59 in)]

between coldstart device plunger andlinkage rod.

3. Turn crankshaft 2turns clockwise toset the device tonor-

mal position.

Checking

1. Set NO.1 piston atTDC onitscompression stroke.

TDC: Without paintedmark

2. Remove injection tubesandairbleeder onthe back ofinjec-

tion pump.

3. Set dial gauge soitsindicator pointstosomewhere between

1.0 and 2.0mm (0.039 and0.079 in)onthe scale.

4. Turn crankshaft 1turn clockwise andcheck thatdialgauge

indicates thesame value again.

5. Turn crankshaft counterclockwise about20to25 degrees,

then setdial gauge indicator to0mm (0in).

6. Turn crankshaft clockwiseandsetthe pump timing markto

the mark onthe crankshaft pulley.

Pump timing mark:Yellow painted mark

Injection timing:8

0

BTDC

7. Read plunger lift.

Plunger lift:

0.79 -0.85 mm(0.0311 -0.0335 in)atpump timing

mark

• When repeating thechecking, startwithstep 5.

Adjusting

1. Ifplunger liftisnot within thespecified value,adjust by

turning injection pump.

• Ifindication issmaller thanthespecified value,turnpump

body away fromengine.

• Ifindication islarger thanthespecified value,turnpump

body towards engine.

2. Tighten injection pumpsecuring boltsandnuts.

Nut:

~: 13-18 N.m (1.3-1.8 kg-m, 9-13 ft-Ib)

Bolt:

~: 49-59 N.m (5.0-6.0 kg-m, 36-43 ft-Ib)

3. Remove dialgauge andinstall airbleeder withnewwasher.

4. Install injection tubes.

Flare nut:

~: 22-25 N.m (2.2-2.5 kg-m, 16-18 ft-Ib)

5. Bleed airfrom fuelsystem.

Refer to"Water Draining, FuelFilter Check andReplacement"

of "ENGINE MAINTENANCE" inMA section.

EC-374

Page 1202 of 1701

TIMINGCHAIN

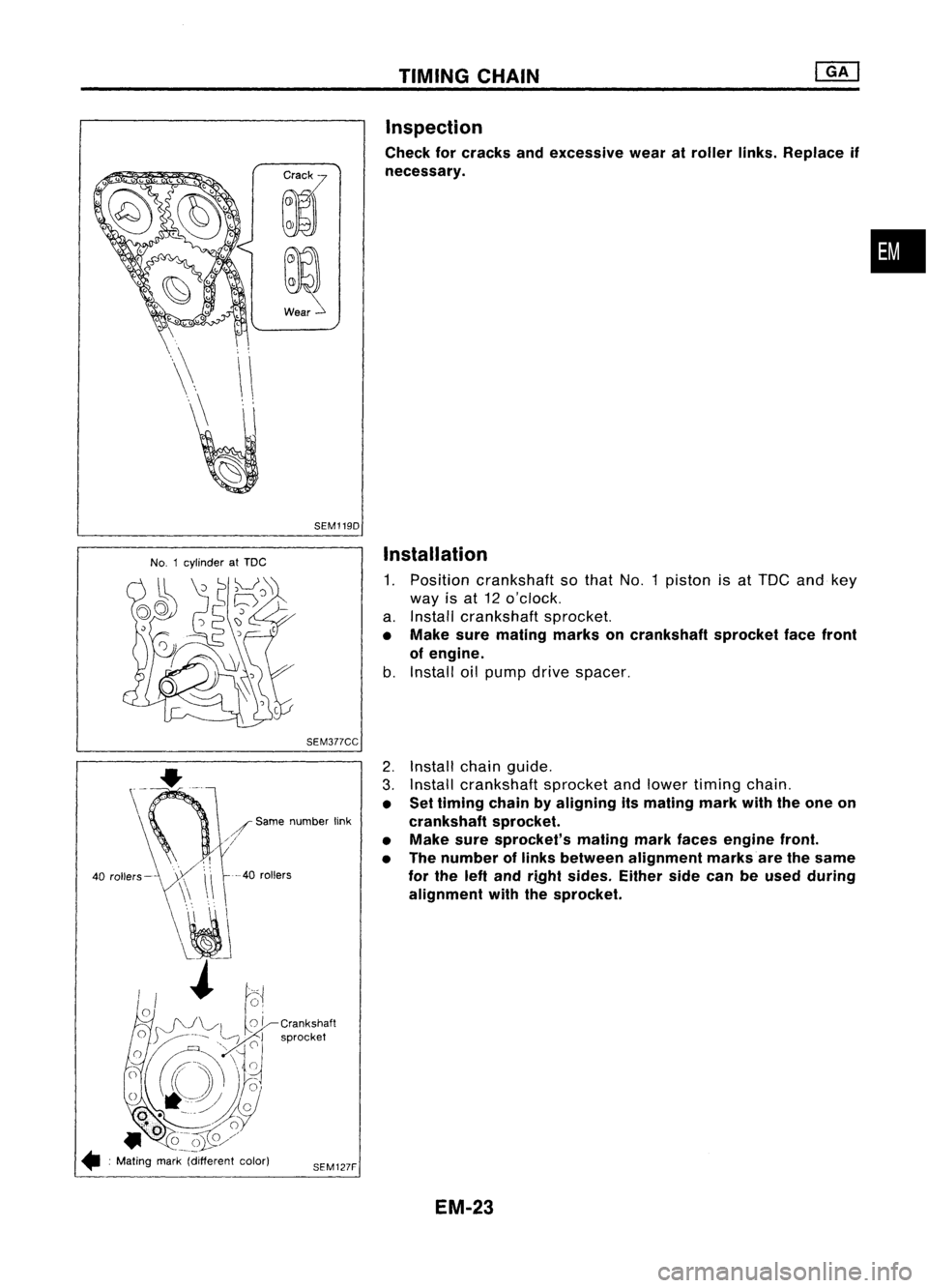

Inspection

Check forcracks andexcessive wearatroller links.Replace if

necessary.

•

SEM1190

No. 1cylinder atTDC

Installation

1. Position crankshaft sothat No.1piston isat TOC andkey

way isat 12 o'clock.

a. Install crankshaft sprocket.

• Make suremating marksoncrankshaft sprocketfacefront

of engine.

b. Install oilpump drivespacer.

SEM377CC

--40

rollers

2.

Install chainguide.

3. Install crankshaft sprocketandlower timing chain.

• Settiming chainbyaligning itsmating markwiththeone on

crankshaft sprocket.

• Make suresprocket's matingmarkfaces engine front.

• The number oflinks between alignment marksare thesame

for the leftand ri.Qht sides. Eithersidecanbeused during

alignment withthesprocket.

SEM127F

/

Same number link

///

40 rollers-

• :Mating mark(different color)

EM-23

Page 1253 of 1701

![NISSAN ALMERA N15 1995 Service Manual

@

~c

t':'

CO',

M''''',mwk

Mating markC

~!

56

coli'" ~

t..

coli."

CD

Mating mark

SEM500E TIMING

CHAIN

[]K]

Installation (Cont'd)

2. Positio NISSAN ALMERA N15 1995 Service Manual

@

~c

t':'

CO',

M''''',mwk

Mating markC

~!

56

coli'" ~

t..

coli."

CD

Mating mark

SEM500E TIMING

CHAIN

[]K]

Installation (Cont'd)

2. Positio](/img/5/57349/w960_57349-1252.png)

@

~c

t':'

CO',

M''''',mwk

Mating markC

~!

56

coli'" ~

t..

coli."

CD

Mating mark

SEM500E TIMING

CHAIN

[]K]

Installation (Cont'd)

2. Position crankshaft sothat No.1 piston isset atTOG andkey

way isat 12 o'clock. Fittiming chainoncrankshaft sprocket,

aligning themating marks.

• Mating markcolorontiming chain.

eD

Gold

@,

CID:

Silver

3. Install timing chainandtiming chainguides.

4. Before installing frontcover, remove alltraces ofliquid

gasket frommating surface usingascraper.

• Also remove tracesofliquid gasket frommating surface of

cylinder block.

5. Apply acontinuous beadofliquid gasket tomating surface

of front cover.

• Use Genuine LiquidGasket orequivalent.

• Besure toinstall newfront oilseal inthe right direction.

Refer toEM-82.

EM-74

Page 1300 of 1701

SEM520DSEM515D TIMING

BELT

em

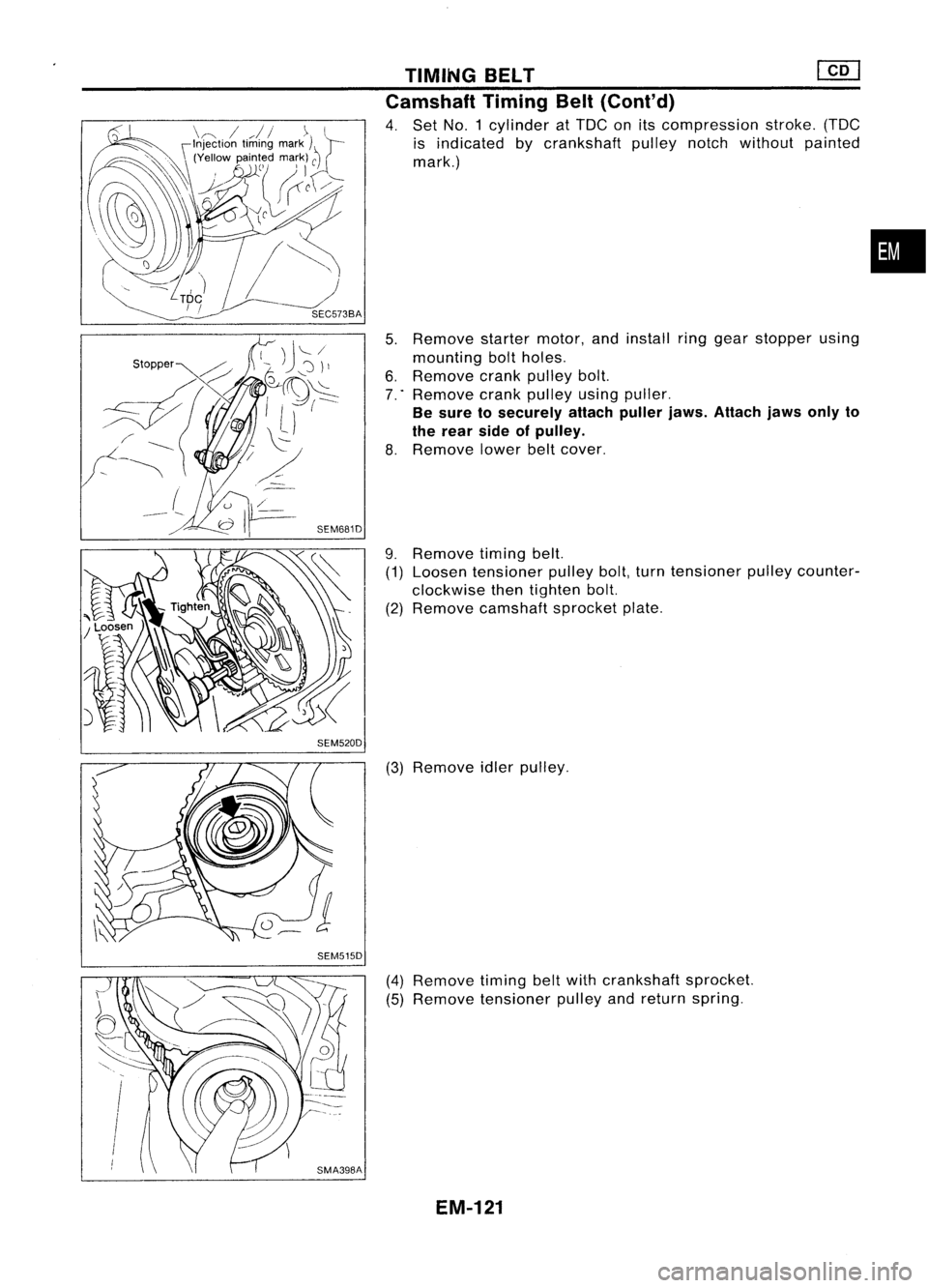

Camshaft TimingBelt(Cont'd)

4. Set NO.1 cylinder atTDC onitscompression stroke.(TDC

is indicated bycrankshaft pulleynotchwithout painted

mark.)

5. Remove startermotor,andinstall ringgear stopper using

mounting boltholes.

6. Remove crankpulley bolt.

7 .. Remove crankpulley usingpuller.

Be sure tosecurely attachpullerjaws.Attach jawsonlyto

the rear sideofpulley.

8. Remove lowerbeltcover.

9. Remove timingbelt.

(1) Loosen tensioner pulleybolt,turntensioner pulleycounter-

clockwise thentighten bolt.

(2) Remove camshaft sprocketplate.

(3) Remove idlerpulley.

(4) Remove timingbeltwith crankshaft sprocket.

(5) Remove tensioner pulleyandreturn spring.

EM-121

•

Page 1303 of 1701

![NISSAN ALMERA N15 1995 Service Manual TIMINGBELT

@[]

Camshaft TimingBelt(Cont'd)

5. Install timing beltwith crankshaft sprocket.

a. Align white linesontiming beltwith punchmarks oncam-

shaft sprocket andcrankshaft sprocket.

b. Poi NISSAN ALMERA N15 1995 Service Manual TIMINGBELT

@[]

Camshaft TimingBelt(Cont'd)

5. Install timing beltwith crankshaft sprocket.

a. Align white linesontiming beltwith punchmarks oncam-

shaft sprocket andcrankshaft sprocket.

b. Poi](/img/5/57349/w960_57349-1302.png)

TIMINGBELT

@[]

Camshaft TimingBelt(Cont'd)

5. Install timing beltwith crankshaft sprocket.

a. Align white linesontiming beltwith punchmarks oncam-

shaft sprocket andcrankshaft sprocket.

b. Point arrow ontiming belttoward beltcover.

6. Install camshaft sprocketplateandsecure screws withlock-

tite.

7. Adjust timing belttension.

1) Loosen tensioner lockbolttoapply tension totiming belt.

2) Rotate crankshaft clockwisetwoturns toapply thespecified

tension totiming belt.

3) Tighten tensioner lockboltwhile holding tensioner pUlley

with hexagon wrench. .

Belt tension:

147.1 :1:24.5 N(15:1:2.5 kg,33.1 :1:5.5 Ib)

SEM520D Injection PumpTiming Belt

~ .N'm (kg-m, in-Ib)

~ :N.m (kg-m, ft-Ib)

SEC.

130-135

~

-"~

.~\(~[-~~' c~1

Timingbelt

?\~-d

(~K.

c

'0

t£

Tensioner spring

J

J

N

0~lJ'00 ~/ Tensioner

t0

J

l\J~.~l:~

'Gl

~')U

r

r~/~

16-21 (1.6 -2.1,12 -15)

It

I

L~0--~ '

~htiJ

JD/~h~J/ "

'SP/

_-z,}) ~A

[/ ......., ....... InJeclion~

.... ~. -;;, pump@J_

• '~~ sprocket~

"fc;,~~-

@ ~

59-

69-.1

Rear camshaft sprocket .~(6.0•7.0,

1m

43-51)

[O;l

87•107

(8.9 -10.9, 64•79)

SEM225F

REMOVAL

1. Set NO.1 cylinder atTDC onitscompression stroke.(TDC

is indicated bycrankshaft pulleynotchwithout painted

mark.)

2. Remove airduct withresonator andtiming beltcover.

EM-124

Page 1304 of 1701

![NISSAN ALMERA N15 1995 Service Manual

InjectionpumppUlley

TIMING

BELT

[fQ]

Injection PumpTiming Belt(Cont'd)

3. Remove timingbelt.

1) Loosen tensioner locknutand turn tensioner clockwise to

free beltfrom tension. Thentemporarily NISSAN ALMERA N15 1995 Service Manual

InjectionpumppUlley

TIMING

BELT

[fQ]

Injection PumpTiming Belt(Cont'd)

3. Remove timingbelt.

1) Loosen tensioner locknutand turn tensioner clockwise to

free beltfrom tension. Thentemporarily](/img/5/57349/w960_57349-1303.png)

InjectionpumppUlley

TIMING

BELT

[fQ]

Injection PumpTiming Belt(Cont'd)

3. Remove timingbelt.

1) Loosen tensioner locknutand turn tensioner clockwise to

free beltfrom tension. Thentemporarily tightentensioner

nut.

2) Remove timingbelt.

INSTAllATION

1. Confirm thatNO.1 piston isset atTDC onitscompression

stroke. (TDCisindicated bycrankshaft pulleynotchwithout

painted mark.)

• Ifinjection pumppulley wasremoved, confirmthatitis

re-installed asillustrated.

Identification ofalignment:

Use mark "A"

2. Set timing belt.

a. Align white linesontiming beltwith punchmarks oncam-

shaft sprocket andinjection pumpsprocket.

b. Point arrow ontiming belttoward beltcover.

3. Adjust belttension.

1) Loosen tensioner locknuttoapply tension totiming belt.

2) Rotate crankshaft clockwisetwoturns.

Do not turn crankshaft bycamshaft sprockets.

3) Tighten tensioner locknutwhile holding tensioner witha

screwdriver.

Belt tension:

147:l:49 N(15:l:5 kg,33:l:11 Ib)

INSPECTION

Refer toINSPECTION in"Camshaft TimingBelt"(EM-122).

INJECTION TIMINGADJUSTMENT

Refer toEC section.

EM-125

•