transmission NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 15 of 1701

DESCRIPTION

Shift Mechanism (Cont'd)

OPERATION OFCLUTCH ANDBRAKE

Bandservo

ForwardLow

Low

&

Shift posi- Reverse

HighForward

Overrun

Lock-upRemarks

tion clutch clutchclutchclutch 2nd

3rd4thone-way

one-way reverse

apply release

applyclutch

clutch brake

P PARK

POSITION

0 0REVERSE

POSI-

R TION

N NEUTRAL

POSI-

TION

1st 0'10

••

D 2nd

0'10

0

•

Automatic

shift

'4 00'10

'2@

@

•

1<-->2<-->3<-->4

3rd

4th 0@ '3@

@0

0

1st 00

••

Automatic

shift

2 1<-->2

2nd 00 0

•

1st 00

•

•

0

Locks

(heldsta-

1 tionary)

in1st

2nd 00 0

•

speed

1

<--

2

'1 Operates whenoverdrive switchissel to"OFF".

'2 Oilpressure isapplied toboth 2nd"apply" sideand3rd"release" sideofband servo piston. However, brakebanddoes notcontract

because oilpressure areaonthe "release" sideisgreater thanthatonthe "apply" side.

'3 Oilpressure isapplied to4th "apply" sideincondition '2above, andbrake bandcontracts.

'4 AIT

will notshift to4th when overdrive switchisset to"OFF" position.

o

Operates.

• Operates. During"progressive" acceleration.

@ Operates butdoes notaffect power transmission.

Control System

CONTROL SYSTEM

Engine

AIT

•

Lock-up cancel

solenoid'1

Overdrive

control switch

1:1

Governor valve

I

11

1

I

1

1

OD cancel solenoid :

; I

L

J

AT-15

'1:

Equipped onmodel

34X69, 34X70and34X80

: Electrical signal

.... :Hydraulic pressure

SAT985HA

Page 17 of 1701

Fluidleakage TROUBLE

DIAGNOSES

Preliminary Check(PriortoRoad Testing)

AIT FLUID CHECK

Fluid leakage check

1. Clean areasuspected ofleaking, -for example, mating

surface ofconverter housingandtransmission case.

2. Start engine, applyfootbrake, placeselector leverin"0"

position andwait afew minutes.

3. Stop engine.

4. Check forfresh leakage.

SAT288G

Fluidcondition check

Fluid levelcheck -Refer toMA section (CHASSIS AND

BODY MAINTENANCE).

Fluid

color

Oark orblack withburned odor

Milky pink

Varnished fluid,lighttodark brown

and tacky Suspected

problem

Wear offrictional material

Water contamination

- Road water entering through

filler tubeorbreather

Oxidation

- Over orunder filling

- Overheating

•

Road Testing

Perform roadtests using "Symptom" chart.Refertopage

AT-20.

"P"

POSITION

1. Place selector leverin"P" position andstart engine. Stop

engine andrepeat theprocedure inall positions, including

neutral position.

2. Stop vehicle onaslight upgrade andplace selector leverin

"P" position. Releaseparkingbraketomake surevehicle

remains locked.

"R"

POSITION

1. Manually moveselector leverfrom"P"to"R", andnote

shift quality.

2. Drive vehicle inreverse longenough todetect slippage or

other abnormalities.

"N"

POSITION

1. Manually moveselector leverfrom"R"and"0"to"N" and

note shift quality.

2. Release parkingbrakewithselector leverin"N" position.

Lightly depress accelerator pedaltomake surevehicle

does notmove. (When vehicle isnew orsoon afterclutches

have been replaced, vehiclemaymove slightly. Thisisnot

a problem.)

AT-17

Page 31 of 1701

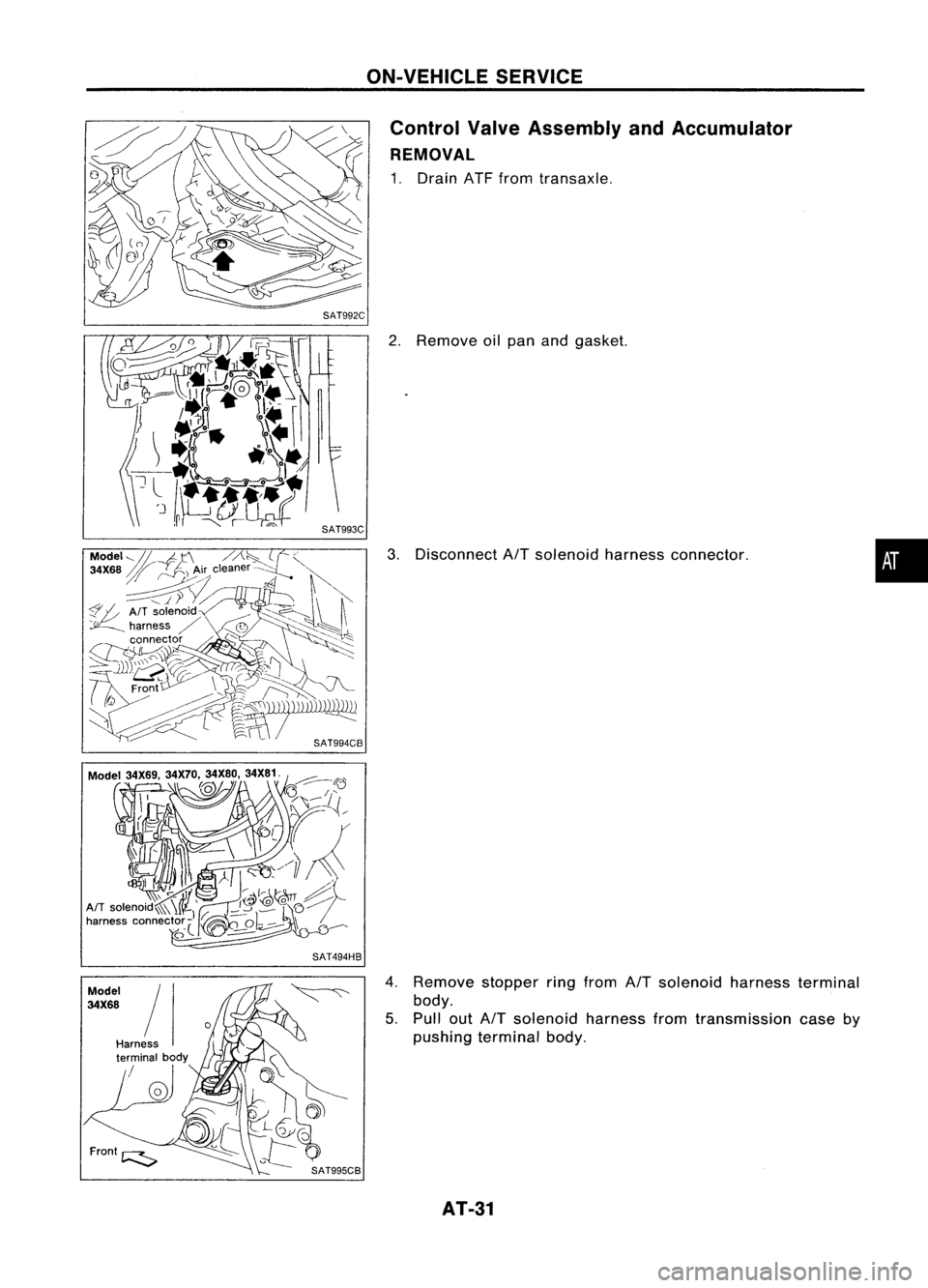

ON-VEHICLESERVICE

SAT494HB

Model

34X68 Control

ValveAssembly andAccumulator

REMOVAL

1. Drain ATFfrom transaxle.

2. Remove oilpan andgasket.

3. Disconnect

AfT

solenoid harnessconnector.

4. Remove stopperringfrom

AfT

solenoid harnessterminal

body.

5. Pull out

AfT

solenoid harnessfromtransmission caseby

pushing terminal body.

AT-31

•

Page 38 of 1701

Converterhousingside(RHS)

Transmission caseside(LHS)

SAT259EA ON-VEHICLE

SERVICE

Differential SideOilSeal Replacement (Cont'd)

3. Install oilseals.

• Apply ATFtooil seal surface beforeinstalling.

Converter housing

side •

Install oilseals sothat dimensions

"A"

and

"8"

arewithin

specifications.

Transmission

case side

B

Oil

seal Oil

seal

A

SAT639D

A

5.5 -6.5 (0.217 -0.256)

4. Reinstall anypart removed.

AT-38

Unit:

mm(in)

B

0.5 (0.020)

or

less

Page 52 of 1701

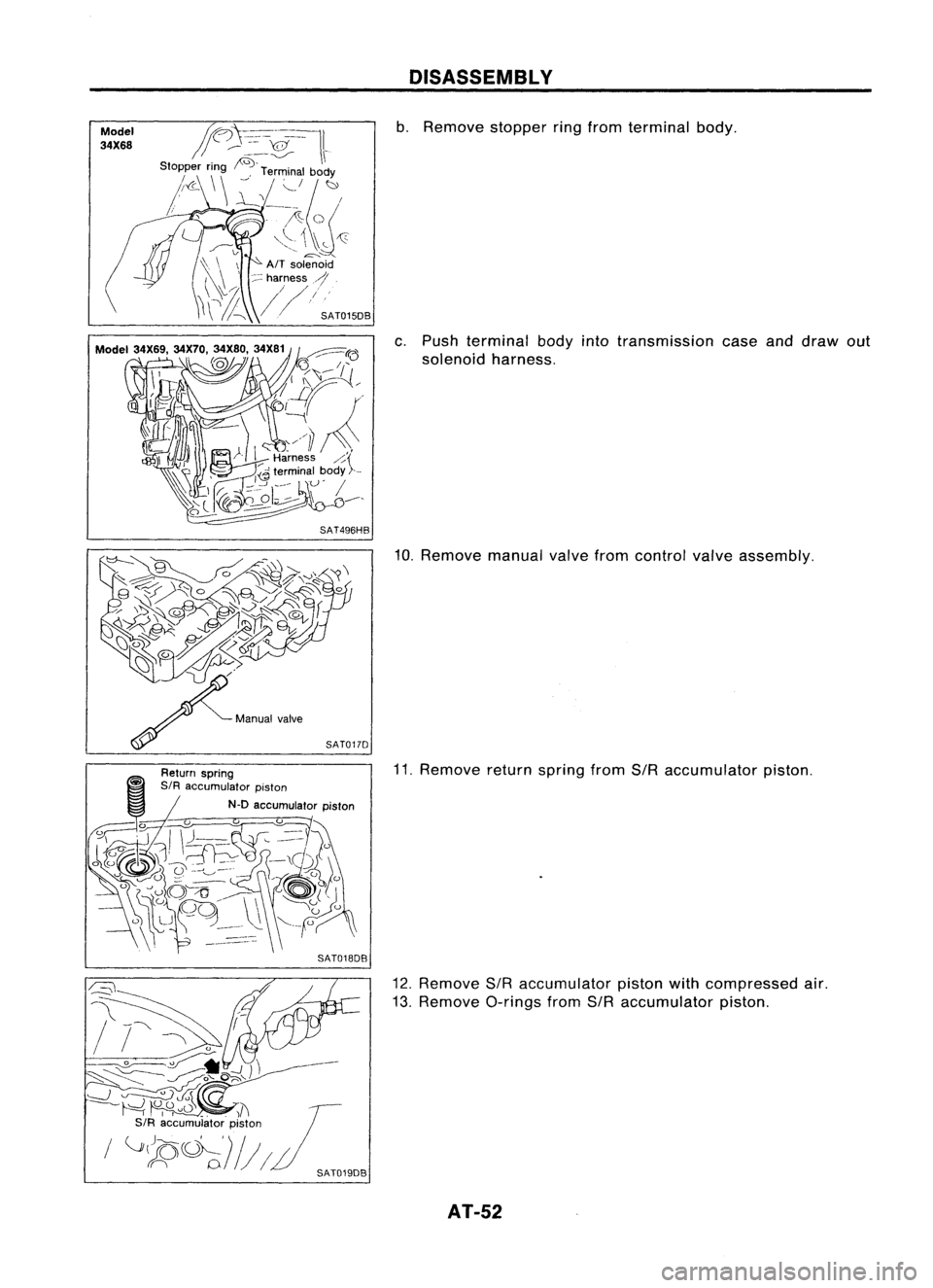

Model

34X68

SAT496HB

SAT0170

DISASSEMBL

Y

b. Remove stopperringfrom terminal body.

c. Push terminal bodyintotransmission caseanddraw out

solenoid harness.

10. Remove manualvalvefromcontrol valveassembly.

11. Remove returnspring fromSIRaccumulator piston.

12. Remove SIRaccumulator pistonwithcompressed air.

13. Remove O-ringsfromSIRaccumulator piston.

AT-52

Page 54 of 1701

DISASSEMBLV

21. Remove throttlewirefrom throttle lever.

22. Remove throttlewiremounting bolt.

23. Draw outthrottle wirefrom transmission case.

- All models -

24. Remove converter housingaccording tothe following pro-

cedures.

a. Remove converter housingmounting bolts@and

CID.

b. Remove converter housing.

c. Remove O-ringfromdifferential oilport.

AT-54

Page 55 of 1701

KV381054S0SAT030D

SAT132E

SAT840DB

SAT133E DISASSEMBL

V

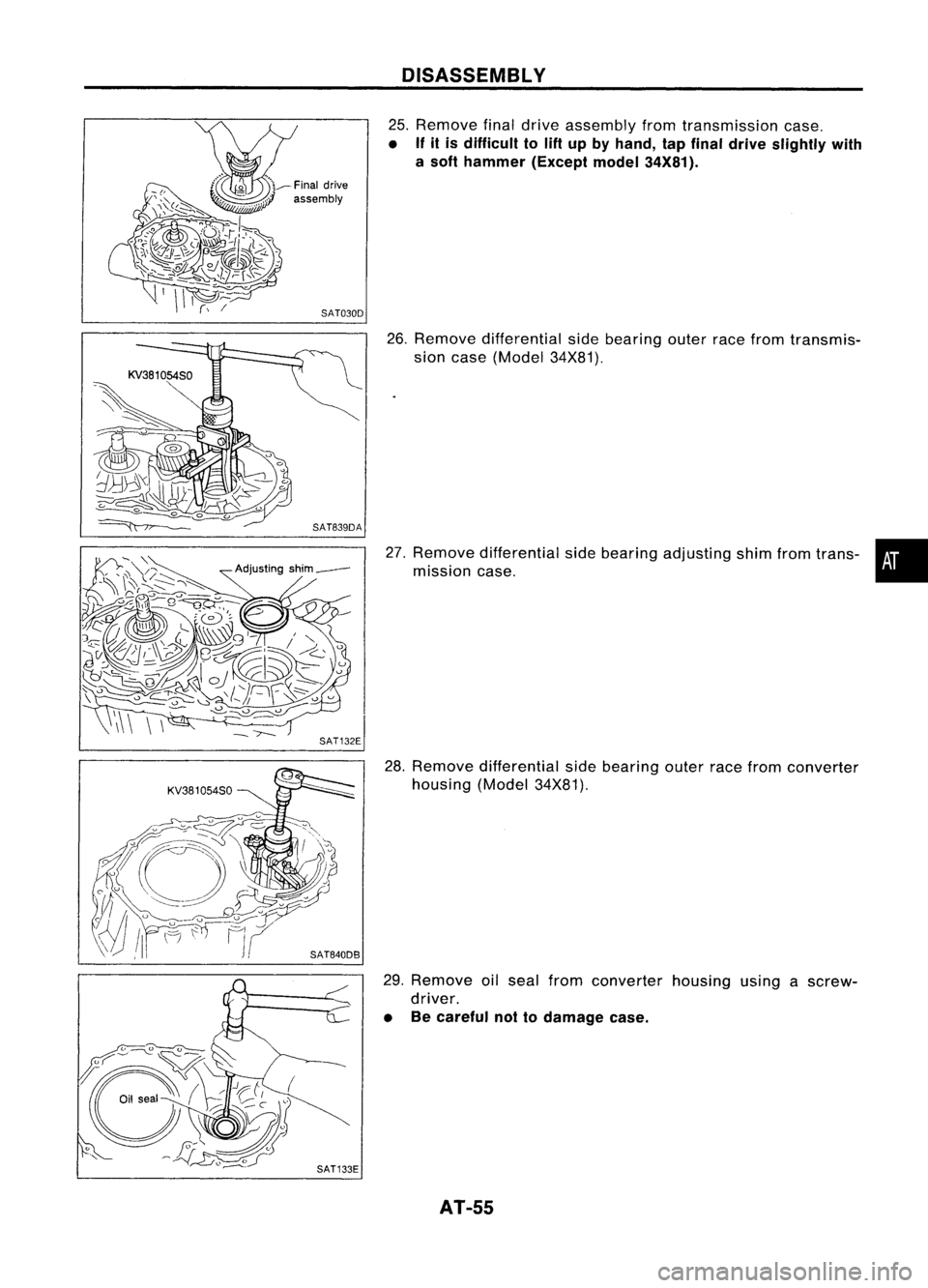

25. Remove finaldrive assembly fromtransmission case.

• If

it is difficult to

lift

up byhand, tapfinal drive slightly with

a soft hammer (Exceptmodel34X81).

26. Remove differential sidebearing outerracefrom transmis-

sion case (Model 34X81).

27. Remove differential sidebearing adjusting shimfromtrans- •

mission case.

28. Remove differential sidebearing outerracefrom converter

housing (Model34X81).

29. Remove oilseal from converter housingusingascrew-

driver.

• Becareful nottodamage case.

AT-55

Page 56 of 1701

SAT134EDISASSEMBL

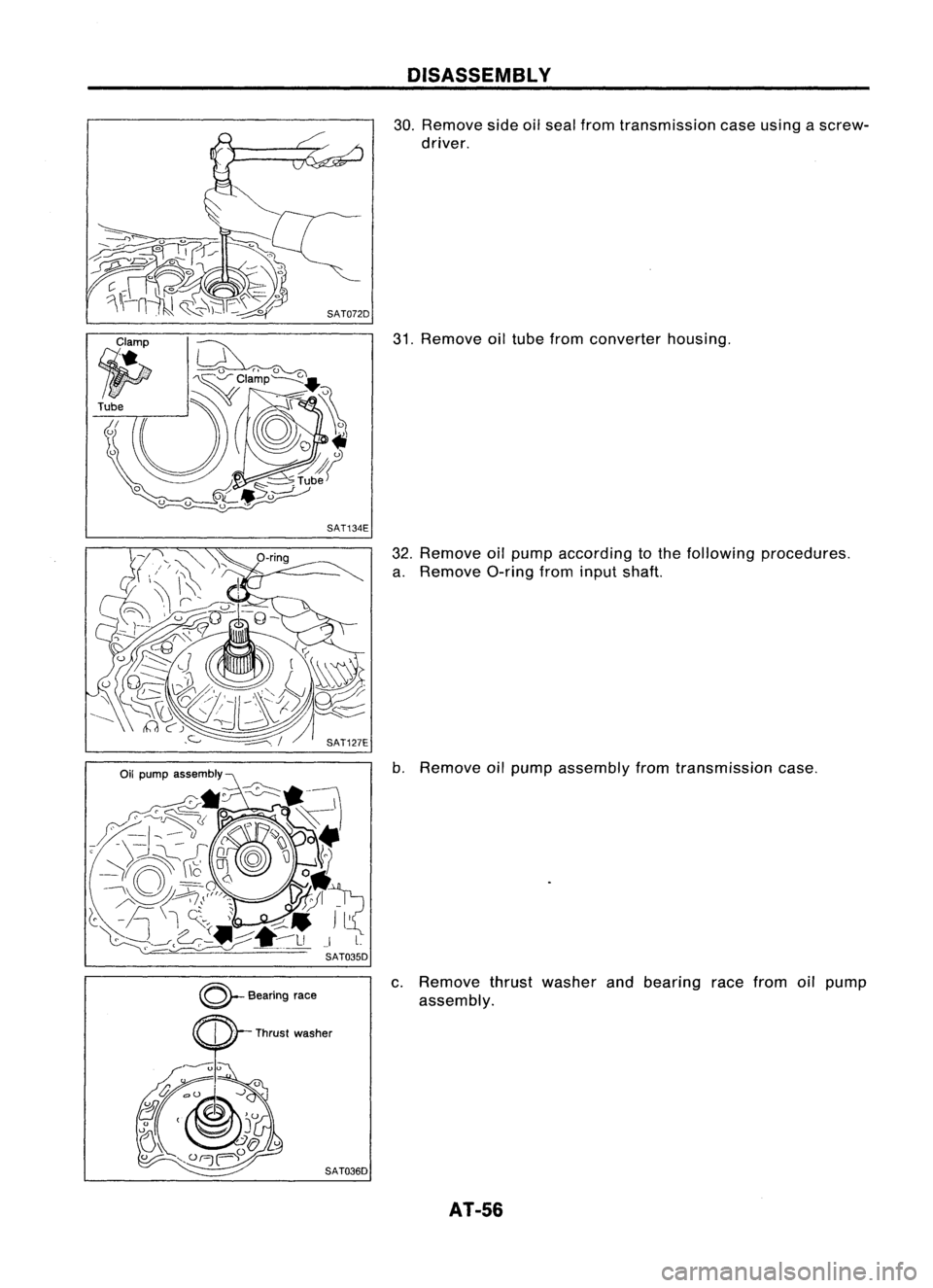

Y

30. Remove sideoilseal from transmission caseusing ascrew-

driver.

31. Remove oiltube from converter housing.

32. Remove oilpump according tothe following procedures.

a. Remove O-ringfrominput shaft.

b. Remove oilpump assembly fromtransmission case.

c. Remove thrustwasher andbearing racefrom oilpump

assembly.

AT-56

Page 57 of 1701

l~~

.

_~

Unit:mm(in)

SAT039D DISASSEMBLY

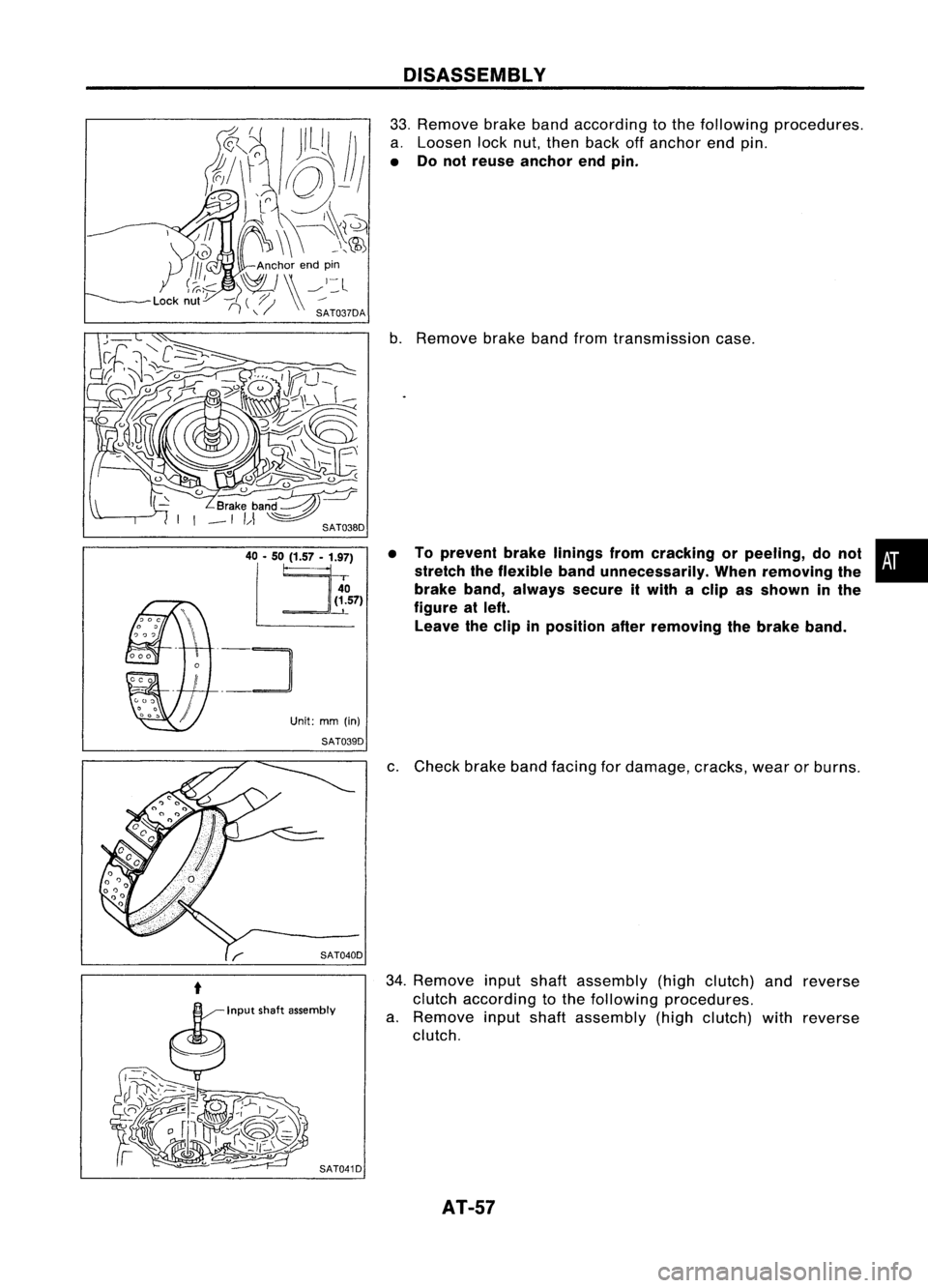

33. Remove brakebandaccording tothe following procedures.

a. Loosen locknut,then back offanchor endpin.

• Donot reuse anchor endpin.

b. Remove brakebandfromtransmission case.

• Toprevent brakelinings fromcracking orpeeling, donot •

stretch theflexible bandunnecessarily. Whenremoving the

i

brake band,always secureitwith aclip asshown inthe

figure atleft.

Leave theclip inposition afterremoving thebrake band.

c. Check brakebandfacing fordamage, cracks,wearorburns.

34. Remove inputshaftassembly (highclutch) andreverse

clutch according tothe following procedures.

a. Remove inputshaft assembly (highclutch) withreverse

clutch.

AT-57

Page 59 of 1701

Frontplanetary carrier

SAT049DDISASSEMBLY

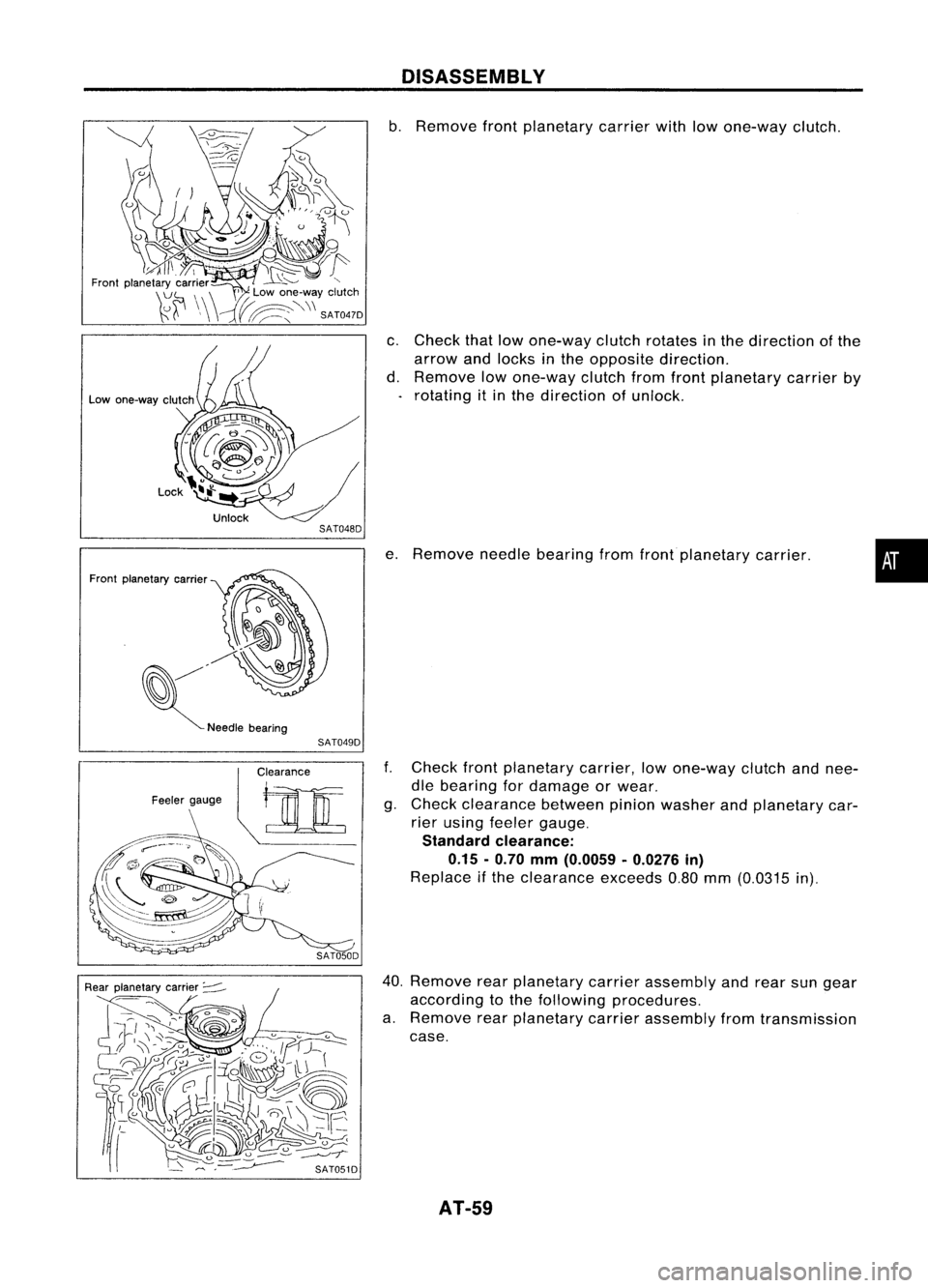

b. Remove frontplanetary carrierwithlowone-way clutch.

c. Check thatlowone-way clutchrotates inthe direction ofthe

arrow andlocks inthe opposite direction.

d. Remove lowone-way clutchfromfront planetary carrierby

rotating itin the direction ofunlock.

e. Remove needlebearing fromfrontplanetary carrier.

•

f. Check frontplanetary carrier,lowone-way clutchandnee-

dle bearing fordamage orwear.

g. Check clearance betweenpinionwasher andplanetary car-

rier using feeler gauge.

Standard clearance:

0.15 -0.70

mm

(0.0059 -0.0276

in)

Replace ifthe clearance exceeds0.80mm(0.0315 in).

40. Remove rearplanetary carrierassembly andrear sungear

according tothe following procedures.

a. Remove rearplanetary carrierassembly fromtransmission

case.

AT-59