ECU NISSAN ALMERA N16 2001 Electronic Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1386 of 2493

Diagnostic ProcedureNJAT0278

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self- diagnostic results) for engine control. Check ignition signal circuit condition.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Check ignition signal circuit for engine control. Refer to EC-451, ªIGNITION SIGNALº.

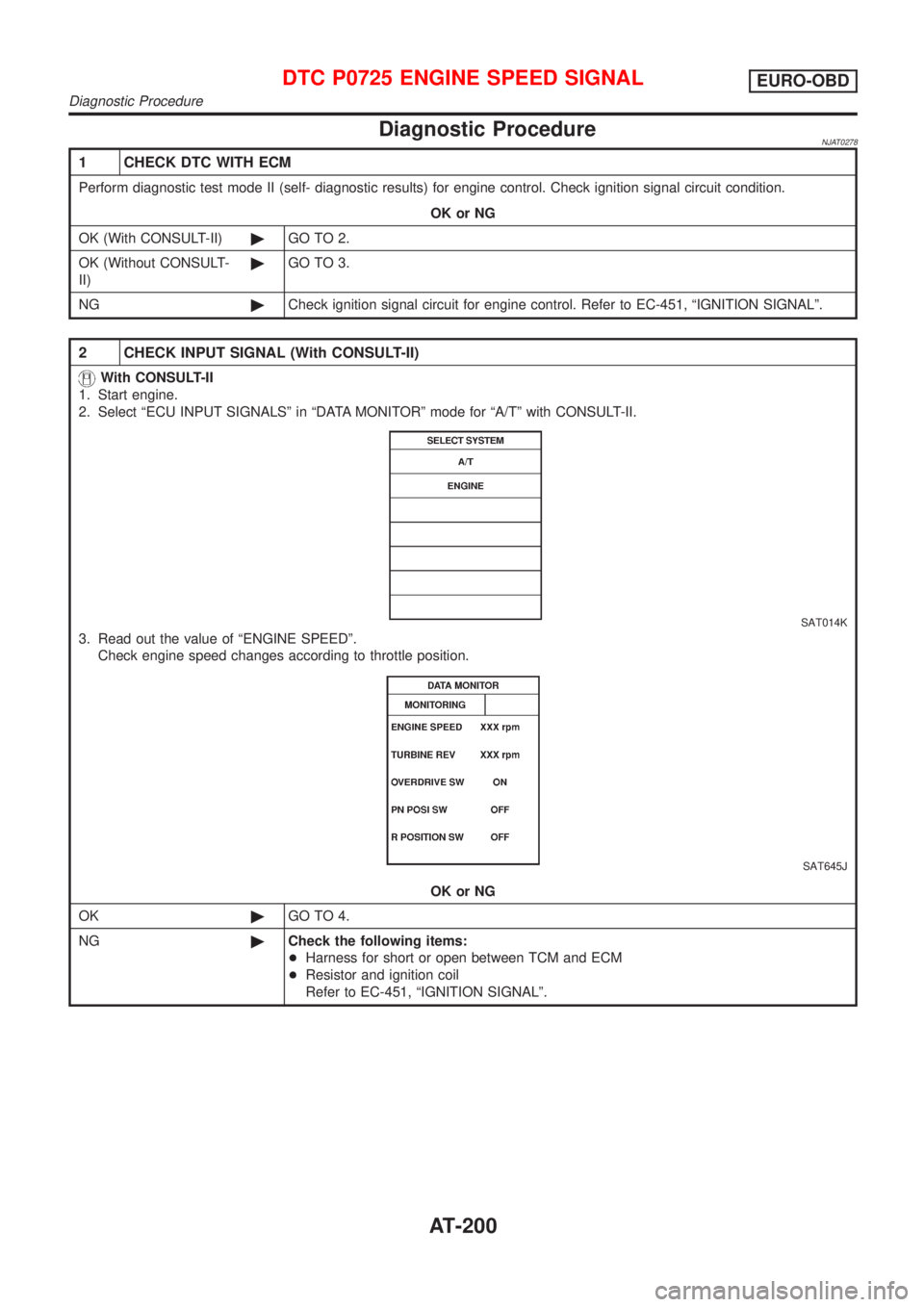

2 CHECK INPUT SIGNAL (With CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

SAT014K

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes according to throttle position.

SAT645J

OK or NG

OK©GO TO 4.

NG©Check the following items:

+Harness for short or open between TCM and ECM

+Resistor and ignition coil

Refer to EC-451, ªIGNITION SIGNALº.

DTC P0725 ENGINE SPEED SIGNALEURO-OBD

Diagnostic Procedure

AT-200

Page 1443 of 2493

ON BOARD DIAGNOSIS LOGICNJAT0311S03

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: TP SEN/CIRC A/T

TCM receives an excessively low or high

voltage from the sensor.+Harness or connectors

(The sensor circuit is open or shorted.)

+Throttle position sensor

+Throttle position switch

: P1705

SAT014K

SAT971J

SAT014K

SAT020K

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0311S04CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

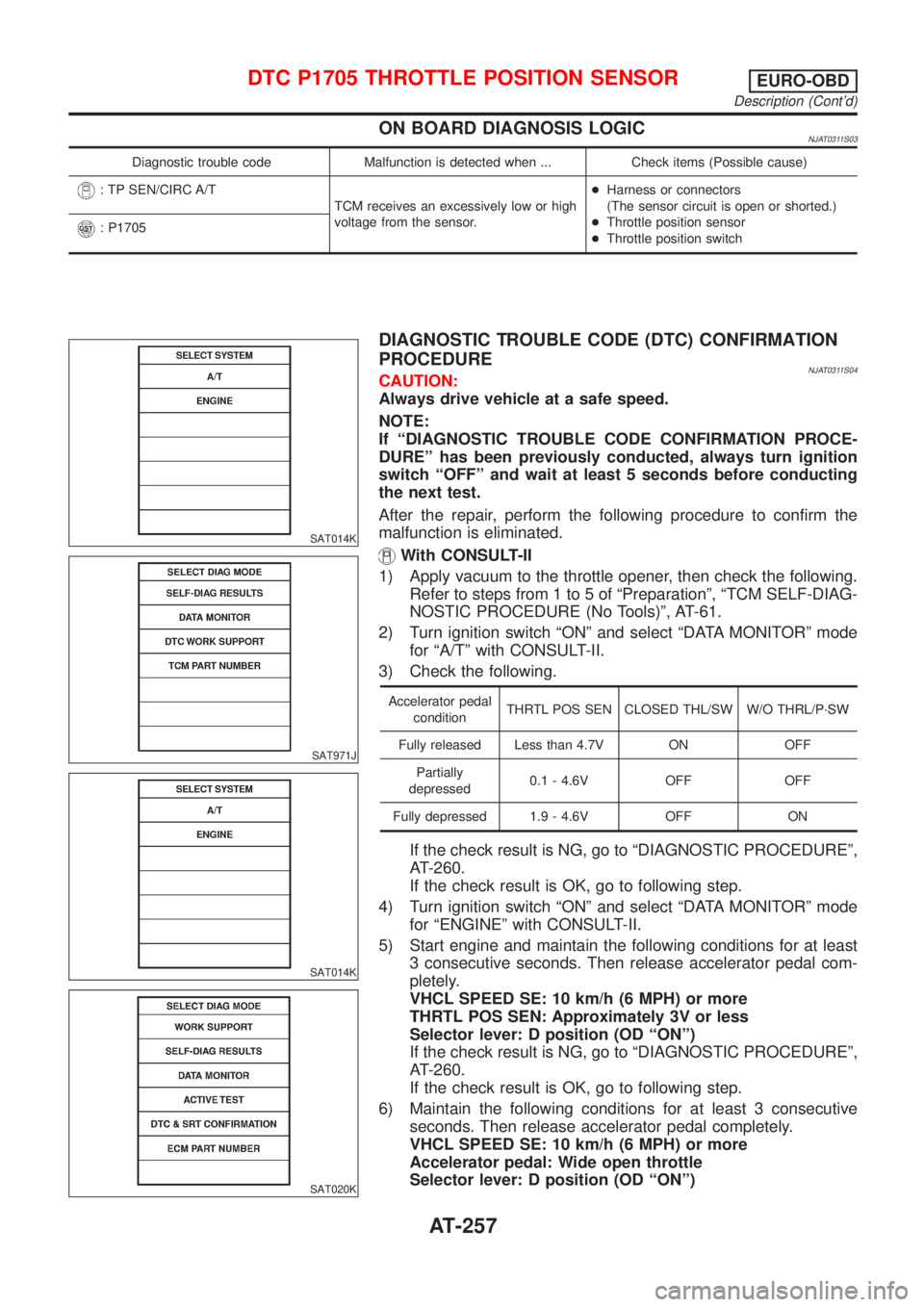

With CONSULT-II

1) Apply vacuum to the throttle opener, then check the following.

Refer to steps from 1 to 5 of ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-61.

2) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªA/Tº with CONSULT-II.

3) Check the following.

Accelerator pedal

conditionTHRTL POS SEN CLOSED THL/SW W/O THRL/P´SW

Fully released Less than 4.7V ON OFF

Partially

depressed0.1 - 4.6V OFF OFF

Fully depressed 1.9 - 4.6V OFF ON

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-260.

If the check result is OK, go to following step.

4) Turn ignition switch ªONº and select ªDATA MONITORº mode

for ªENGINEº with CONSULT-II.

5) Start engine and maintain the following conditions for at least

3 consecutive seconds. Then release accelerator pedal com-

pletely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: Approximately 3V or less

Selector lever: D position (OD ªONº)

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

AT-260.

If the check result is OK, go to following step.

6) Maintain the following conditions for at least 3 consecutive

seconds. Then release accelerator pedal completely.

VHCL SPEED SE: 10 km/h (6 MPH) or more

Accelerator pedal: Wide open throttle

Selector lever: D position (OD ªONº)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Description (Cont'd)

AT-257

Page 1446 of 2493

Diagnostic ProcedureNJAT0313

1 CHECK DTC WITH ECM

Perform diagnostic test mode II (self-diagnostic results) for engine control.

Refer to EC-72, ªMalfunction Indicator (MI)º.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 3.

NG©Check throttle position sensor circuit for engine control. Refer to EC-168, ªDTC P0120

THROTTLE POSITION SENSORº.

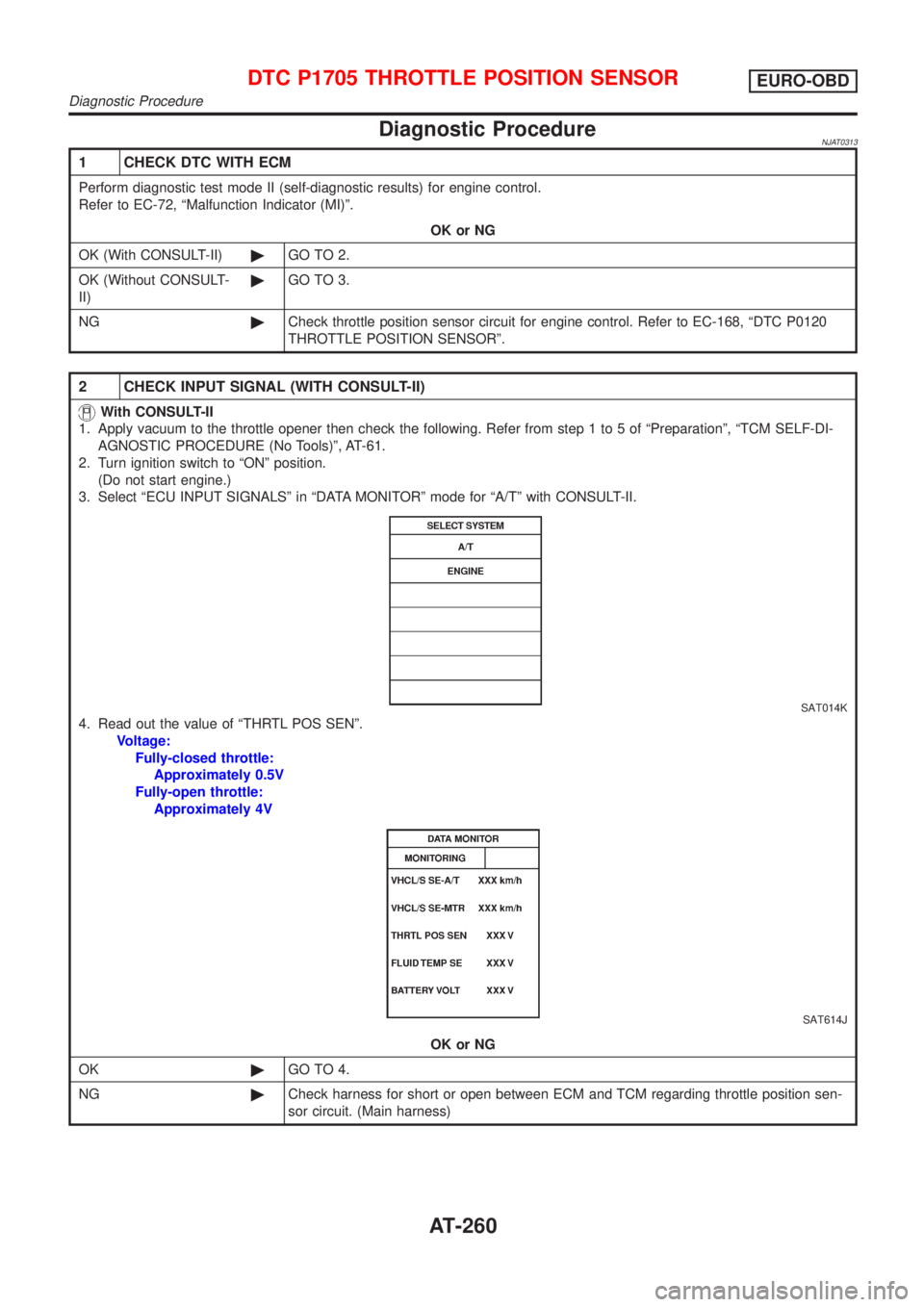

2 CHECK INPUT SIGNAL (WITH CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener then check the following. Refer from step 1 to 5 of ªPreparationº, ªTCM SELF-DI-

AGNOSTIC PROCEDURE (No Tools)º, AT-61.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

SAT014K

4. Read out the value of ªTHRTL POS SENº.

Voltage:

Fully-closed throttle:

Approximately 0.5V

Fully-open throttle:

Approximately 4V

SAT614J

OK or NG

OK©GO TO 4.

NG©Check harness for short or open between ECM and TCM regarding throttle position sen-

sor circuit. (Main harness)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Diagnostic Procedure

AT-260

Page 1448 of 2493

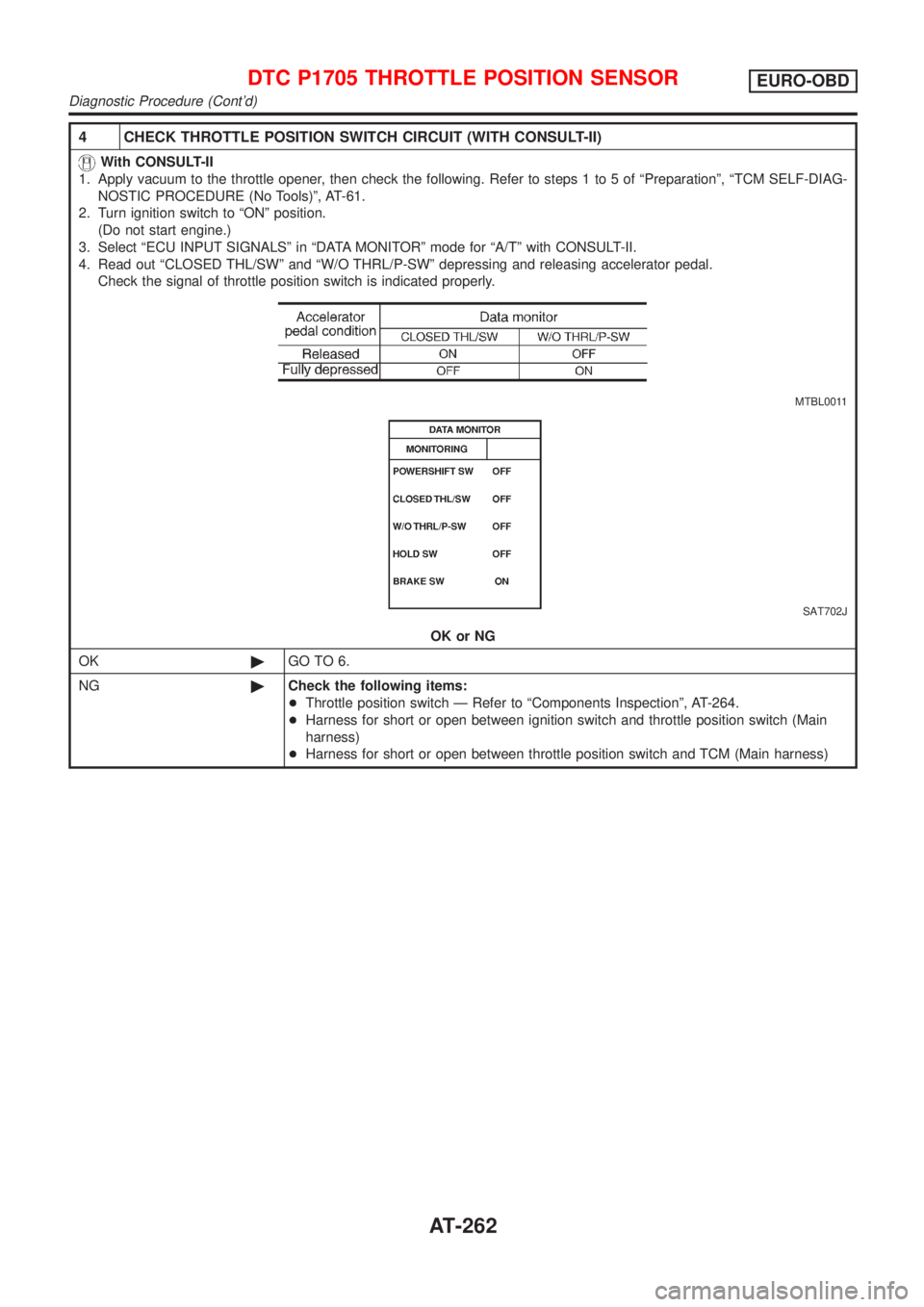

4 CHECK THROTTLE POSITION SWITCH CIRCUIT (WITH CONSULT-II)

With CONSULT-II

1. Apply vacuum to the throttle opener, then check the following. Refer to steps 1 to 5 of ªPreparationº, ªTCM SELF-DIAG-

NOSTIC PROCEDURE (No Tools)º, AT-61.

2. Turn ignition switch to ªONº position.

(Do not start engine.)

3. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

4. Read out ªCLOSED THL/SWº and ªW/O THRL/P-SWº depressing and releasing accelerator pedal.

Check the signal of throttle position switch is indicated properly.

MTBL0011

SAT702J

OK or NG

OK©GO TO 6.

NG©Check the following items:

+Throttle position switch Ð Refer to ªComponents Inspectionº, AT-264.

+Harness for short or open between ignition switch and throttle position switch (Main

harness)

+Harness for short or open between throttle position switch and TCM (Main harness)

DTC P1705 THROTTLE POSITION SENSOREURO-OBD

Diagnostic Procedure (Cont'd)

AT-262

Page 1461 of 2493

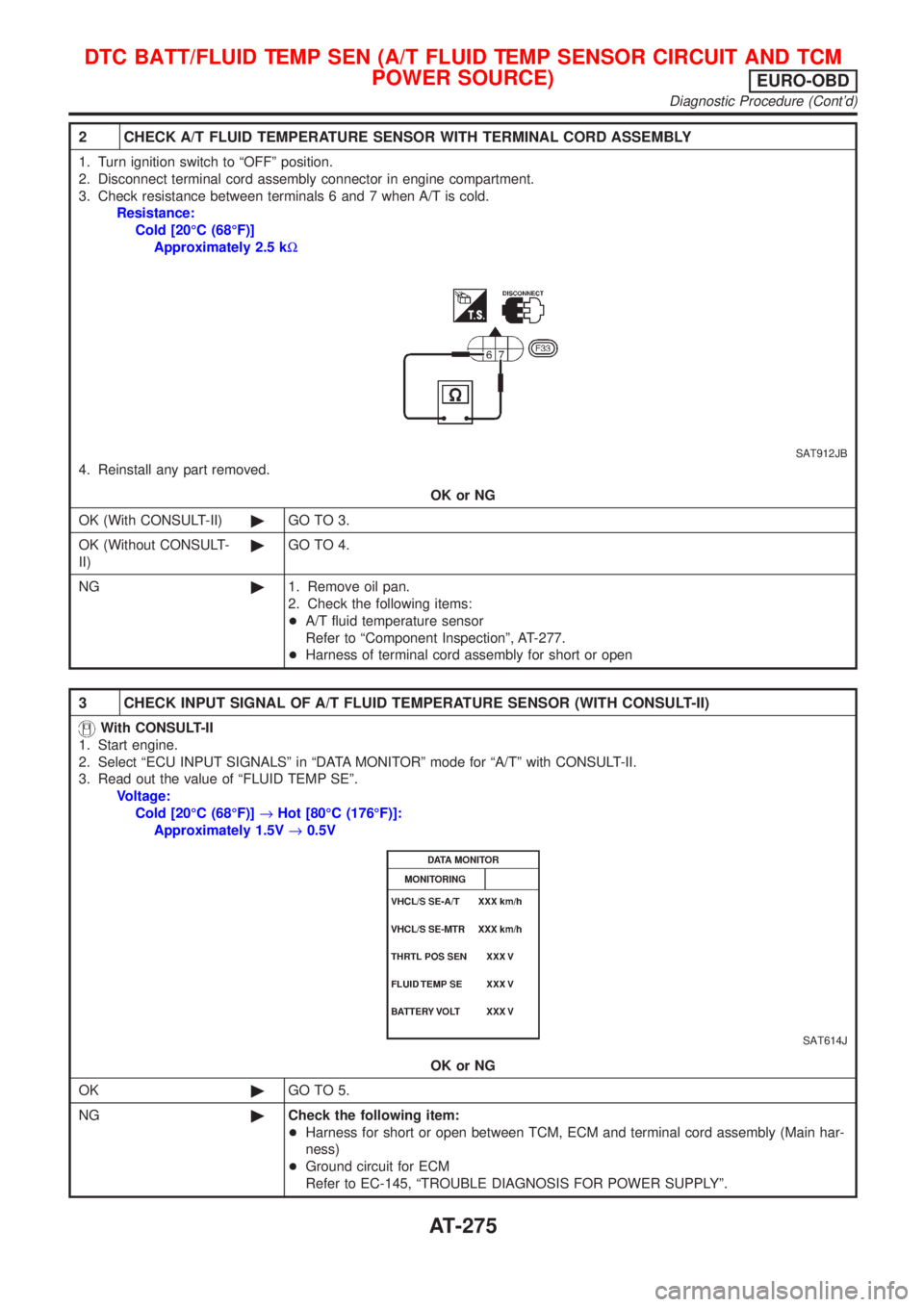

2 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminals 6 and 7 when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

SAT912JB

4. Reinstall any part removed.

OK or NG

OK (With CONSULT-II)©GO TO 3.

OK (Without CONSULT-

II)©GO TO 4.

NG©1. Remove oil pan.

2. Check the following items:

+A/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-277.

+Harness of terminal cord assembly for short or open

3 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªFLUID TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT614J

OK or NG

OK©GO TO 5.

NG©Check the following item:

+Harness for short or open between TCM, ECM and terminal cord assembly (Main har-

ness)

+Ground circuit for ECM

Refer to EC-145, ªTROUBLE DIAGNOSIS FOR POWER SUPPLYº.

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

EURO-OBD

Diagnostic Procedure (Cont'd)

AT-275

Page 1467 of 2493

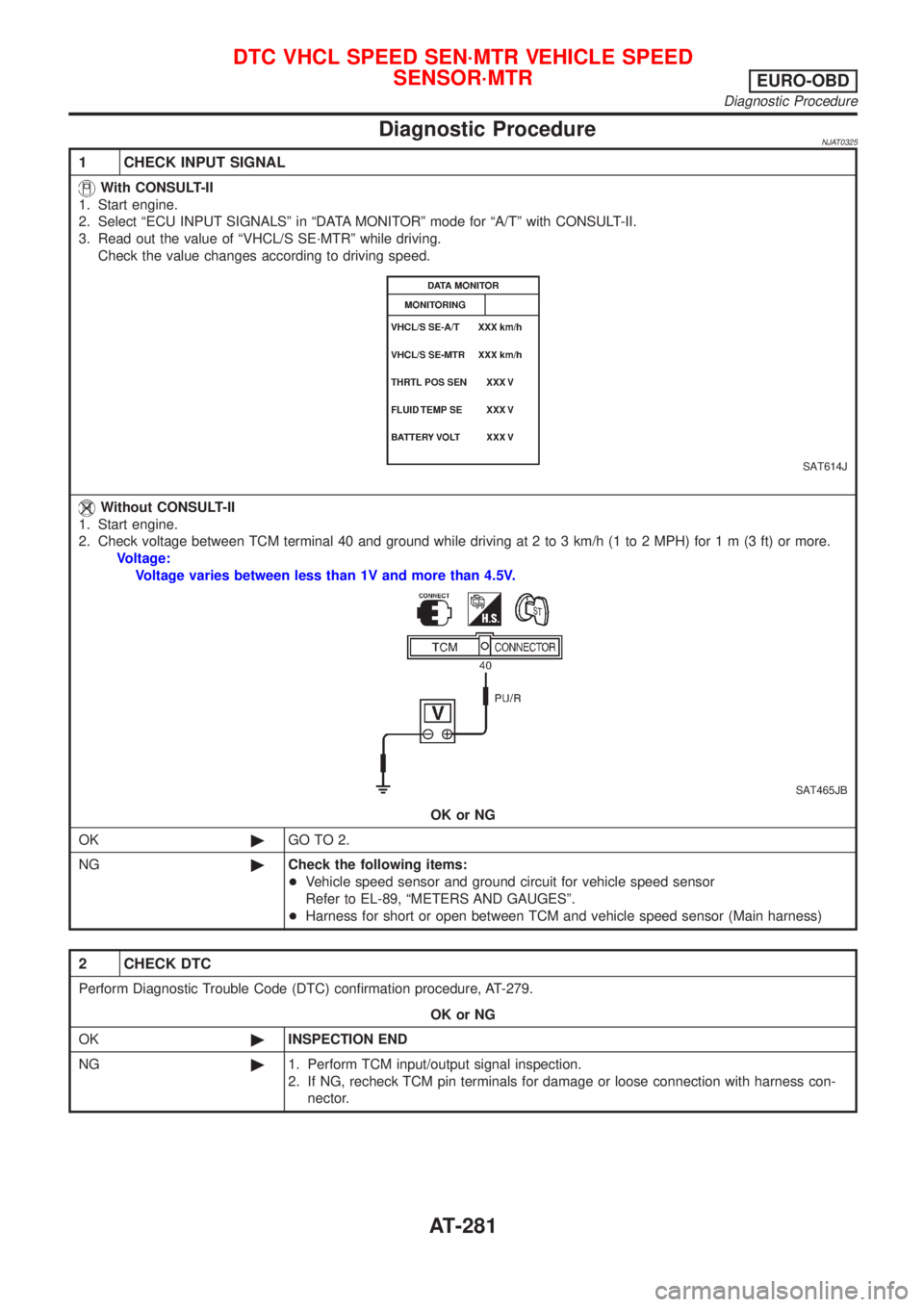

Diagnostic ProcedureNJAT0325

1 CHECK INPUT SIGNAL

With CONSULT-II

1. Start engine.

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªVHCL/S SE´MTRº while driving.

Check the value changes according to driving speed.

SAT614J

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 40 and ground while driving at 2 to 3 km/h (1 to 2 MPH) for1m(3ft)ormore.

Voltage:

Voltage varies between less than 1V and more than 4.5V.

SAT465JB

OK or NG

OK©GO TO 2.

NG©Check the following items:

+Vehicle speed sensor and ground circuit for vehicle speed sensor

Refer to EL-89, ªMETERS AND GAUGESº.

+Harness for short or open between TCM and vehicle speed sensor (Main harness)

2 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-279.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

DTC VHCL SPEED SEN´MTR VEHICLE SPEED

SENSOR´MTR

EURO-OBD

Diagnostic Procedure

AT-281

Page 1477 of 2493

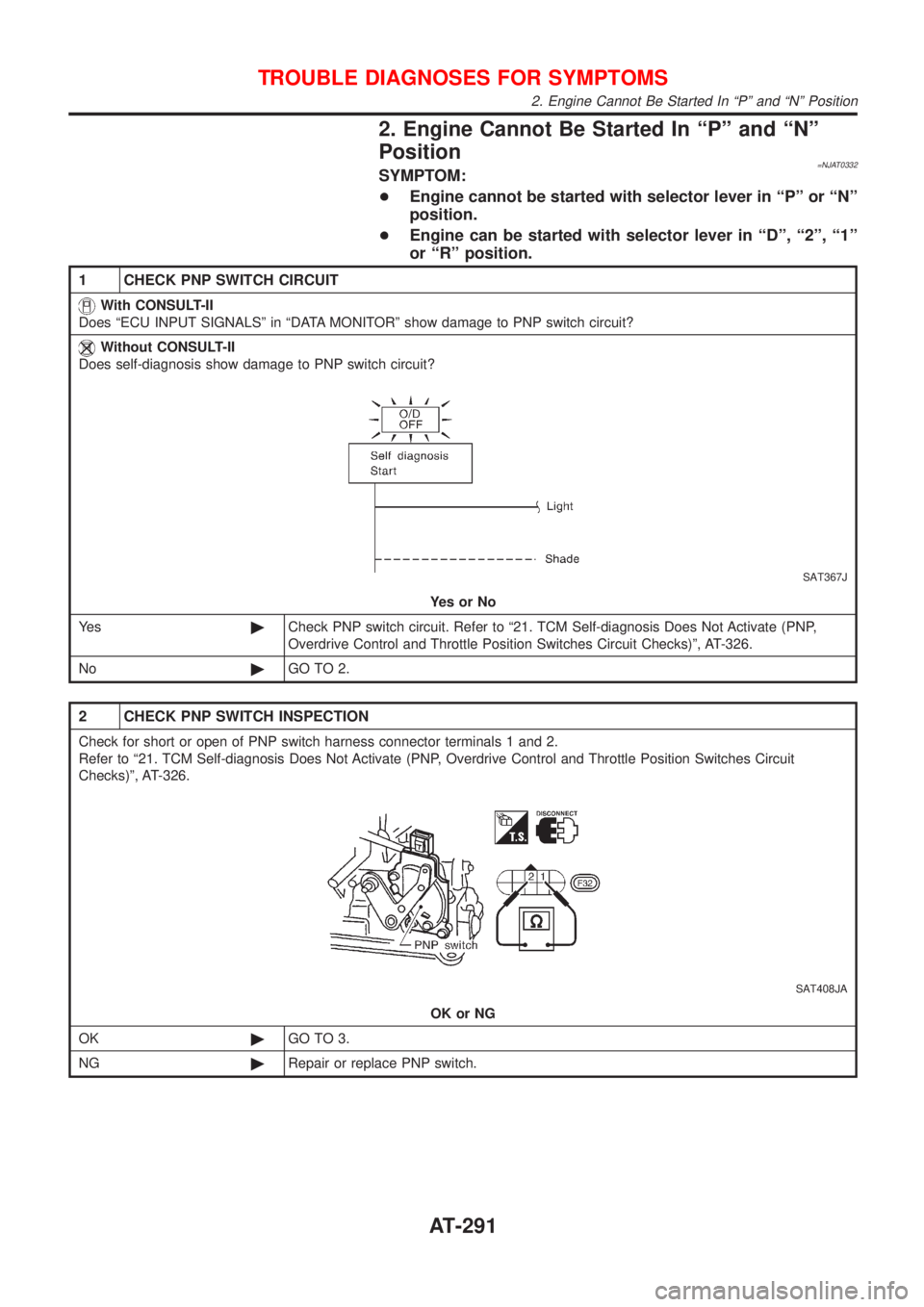

2. Engine Cannot Be Started In ªPº and ªNº

Position

=NJAT0332SYMPTOM:

+Engine cannot be started with selector lever in ªPº or ªNº

position.

+Engine can be started with selector lever in ªDº, ª2º, ª1º

or ªRº position.

1 CHECK PNP SWITCH CIRCUIT

With CONSULT-II

Does ªECU INPUT SIGNALSº in ªDATA MONITORº show damage to PNP switch circuit?

Without CONSULT-II

Does self-diagnosis show damage to PNP switch circuit?

SAT367J

YesorNo

Ye s©Check PNP switch circuit. Refer to ª21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches Circuit Checks)º, AT-326.

No©GO TO 2.

2 CHECK PNP SWITCH INSPECTION

Check for short or open of PNP switch harness connector terminals 1 and 2.

Refer to ª21. TCM Self-diagnosis Does Not Activate (PNP, Overdrive Control and Throttle Position Switches Circuit

Checks)º, AT-326.

SAT408JA

OK or NG

OK©GO TO 3.

NG©Repair or replace PNP switch.

TROUBLE DIAGNOSES FOR SYMPTOMS

2. Engine Cannot Be Started In ªPº and ªNº Position

AT-291

Page 1479 of 2493

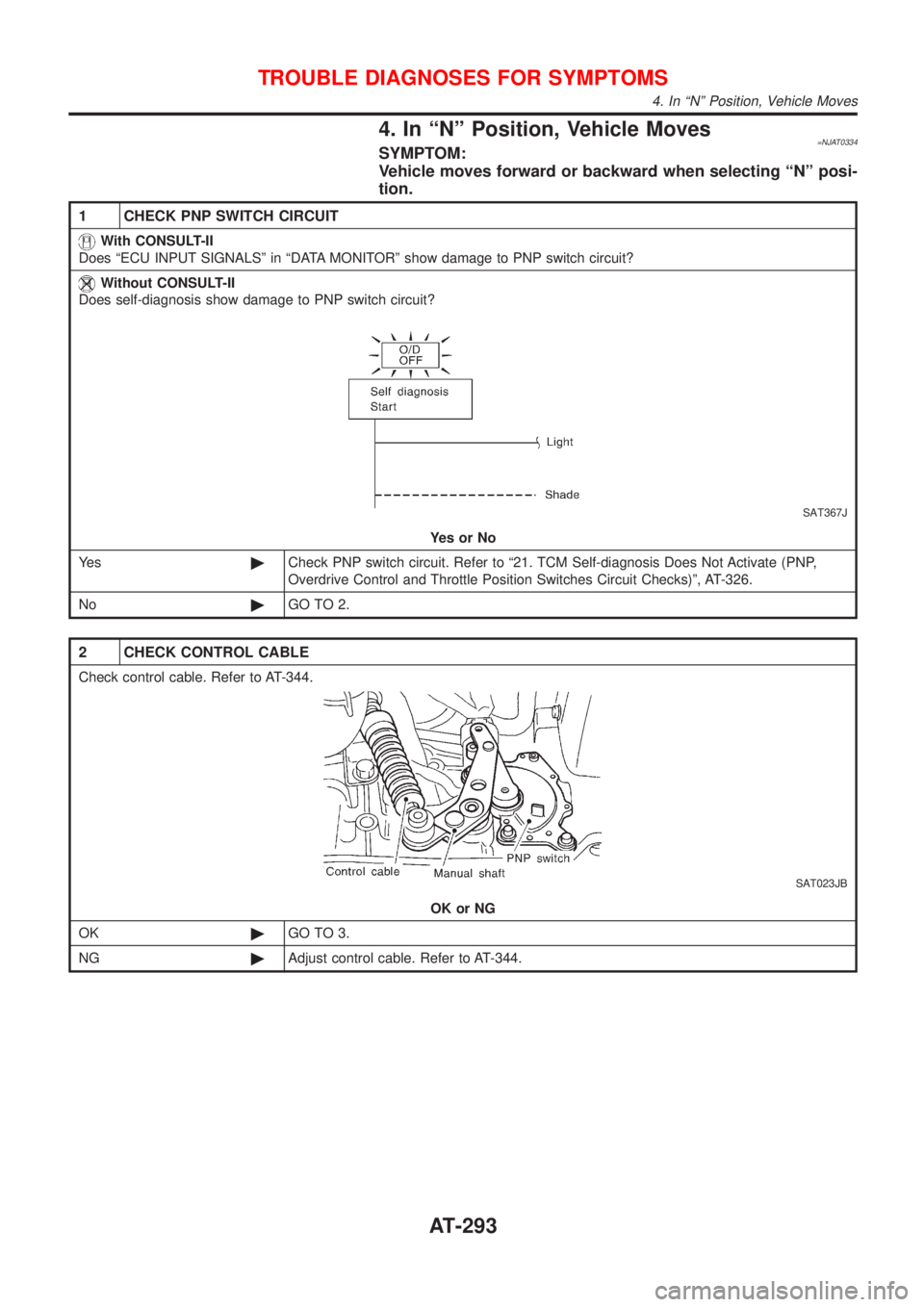

4. In ªNº Position, Vehicle Moves=NJAT0334SYMPTOM:

Vehicle moves forward or backward when selecting ªNº posi-

tion.

1 CHECK PNP SWITCH CIRCUIT

With CONSULT-II

Does ªECU INPUT SIGNALSº in ªDATA MONITORº show damage to PNP switch circuit?

Without CONSULT-II

Does self-diagnosis show damage to PNP switch circuit?

SAT367J

YesorNo

Ye s©Check PNP switch circuit. Refer to ª21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches Circuit Checks)º, AT-326.

No©GO TO 2.

2 CHECK CONTROL CABLE

Check control cable. Refer to AT-344.

SAT023JB

OK or NG

OK©GO TO 3.

NG©Adjust control cable. Refer to AT-344.

TROUBLE DIAGNOSES FOR SYMPTOMS

4. In ªNº Position, Vehicle Moves

AT-293

Page 1492 of 2493

9. A/T Does Not Shift: D1®D2Or Does Not

Kickdown: D

4®D2=NJAT0339SYMPTOM:

A/T does not shift from D

1to D2at the specified speed.

A/T does not shift from D

4to D2when depressing accelerator

pedal fully at the specified speed.

1 CHECK SYMPTOM

Are 7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position and 8. Vehicle Cannot Be Started From D1OK?

YesorNo

Ye s©GO TO 2.

No©Go to 7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position and 8. Vehicle Can-

not Be Started From D

1, AT-300, 303.

2 CHECK PNP SWITCH CIRCUIT

With CONSULT-II

Does ªECU INPUT SIGNALSº in ªDATA MONITORº show damage to PNP switch circuit?

Without CONSULT-II

Does self-diagnosis show damage to PNP switch circuit?

SAT367J

YesorNo

Ye s©Check PNP switch circuit. Refer to ª21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches Circuit Checks)º, AT-326.

No©GO TO 3.

3 CHECK VEHICLE SPEED SENSOR´A/T (REVOLUTION SENSOR) AND CHECK VEHICLE SPEED

SENSOR´MTR CIRCUIT

Check vehicle speed sensor´A/T (revolution sensor) and vehicle speed sensor´MTR circuit. Refer to AT-124 (Except for

Euro-OBD), AT-193 (EURO-OBD) and AT-129 (Except for Euro-OBD), AT-278 (EURO-OBD).

OK or NG

OK©GO TO 4.

NG©Repair or replace vehicle speed sensor´A/T (revolution sensor) and vehicle speed

sensor´MTR circuits.

TROUBLE DIAGNOSES FOR SYMPTOMS

9. A/T Does Not Shift: D1®D2Or Does Not Kickdown: D4®D2

AT-306

Page 1495 of 2493

10. A/T Does Not Shift: D2®D3=NJAT0340SYMPTOM:

A/T does not shift from D

2to D3at the specified speed.

1 CHECK SYMPTOM

Are 7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position and 8. Vehicle Cannot Be Started From D1OK?

YesorNo

Ye s©GO TO 2.

No©Go to 7. Vehicle Does Not Creep Forward In ªDº, ª2º Or ª1º Position and 8. Vehicle Can-

not Be Started From D

1, AT-300, 303.

2 CHECK PNP SWITCH CIRCUIT

With CONSULT-II

Does ªECU INPUT SIGNALSº in ªDATA MONITORº show damage to PNP switch circuit?

Without CONSULT-II

Does self-diagnosis show damage to PNP switch circuit?

SAT367J

YesorNo

Ye s©Check PNP switch circuit. Refer to ª21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches Circuit Checks)º, AT-326.

No©GO TO 3.

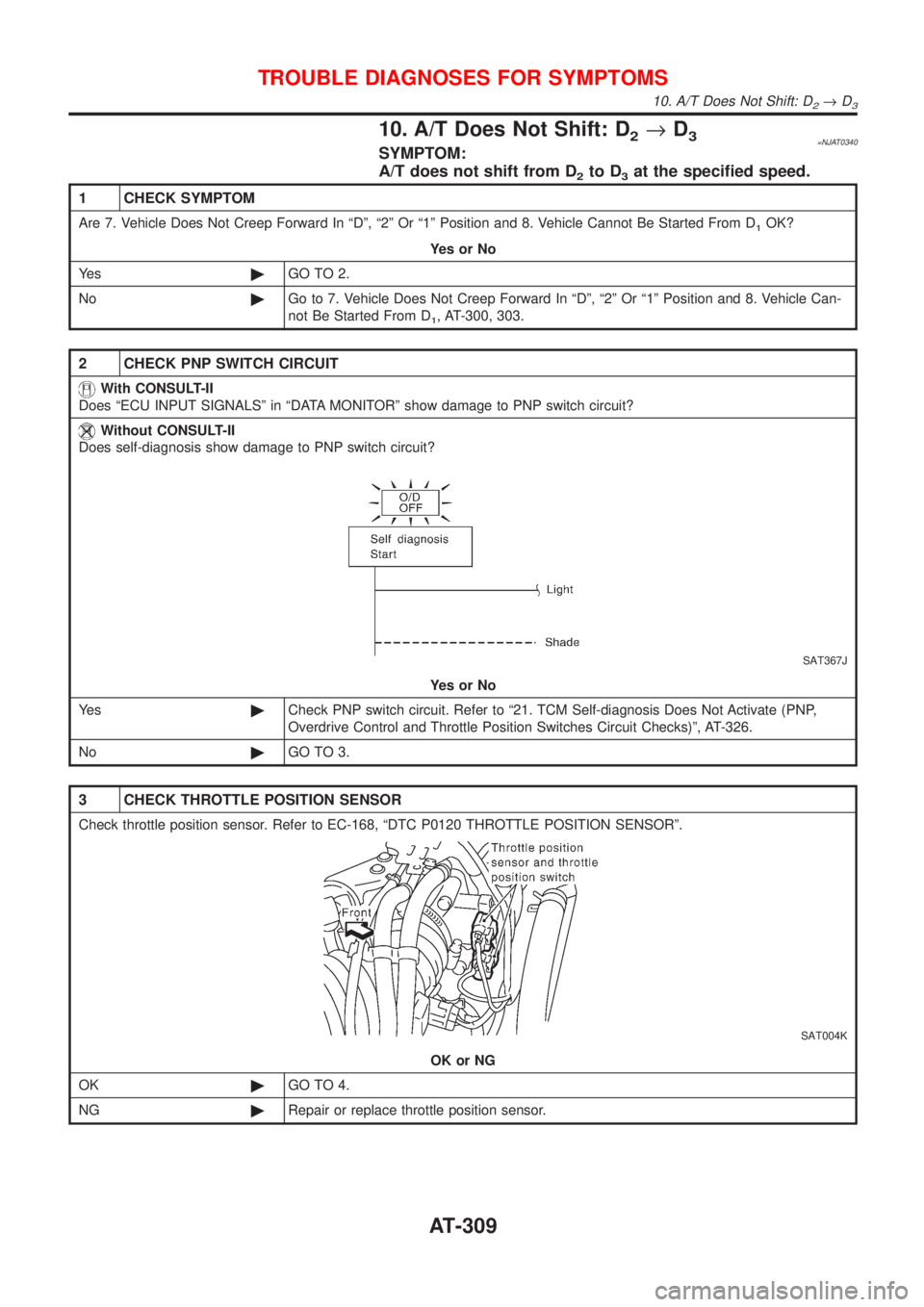

3 CHECK THROTTLE POSITION SENSOR

Check throttle position sensor. Refer to EC-168, ªDTC P0120 THROTTLE POSITION SENSORº.

SAT004K

OK or NG

OK©GO TO 4.

NG©Repair or replace throttle position sensor.

TROUBLE DIAGNOSES FOR SYMPTOMS

10. A/T Does Not Shift: D2®D3

AT-309