ECU NISSAN ALMERA N16 2001 Electronic Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 644 of 2493

SEF174Y

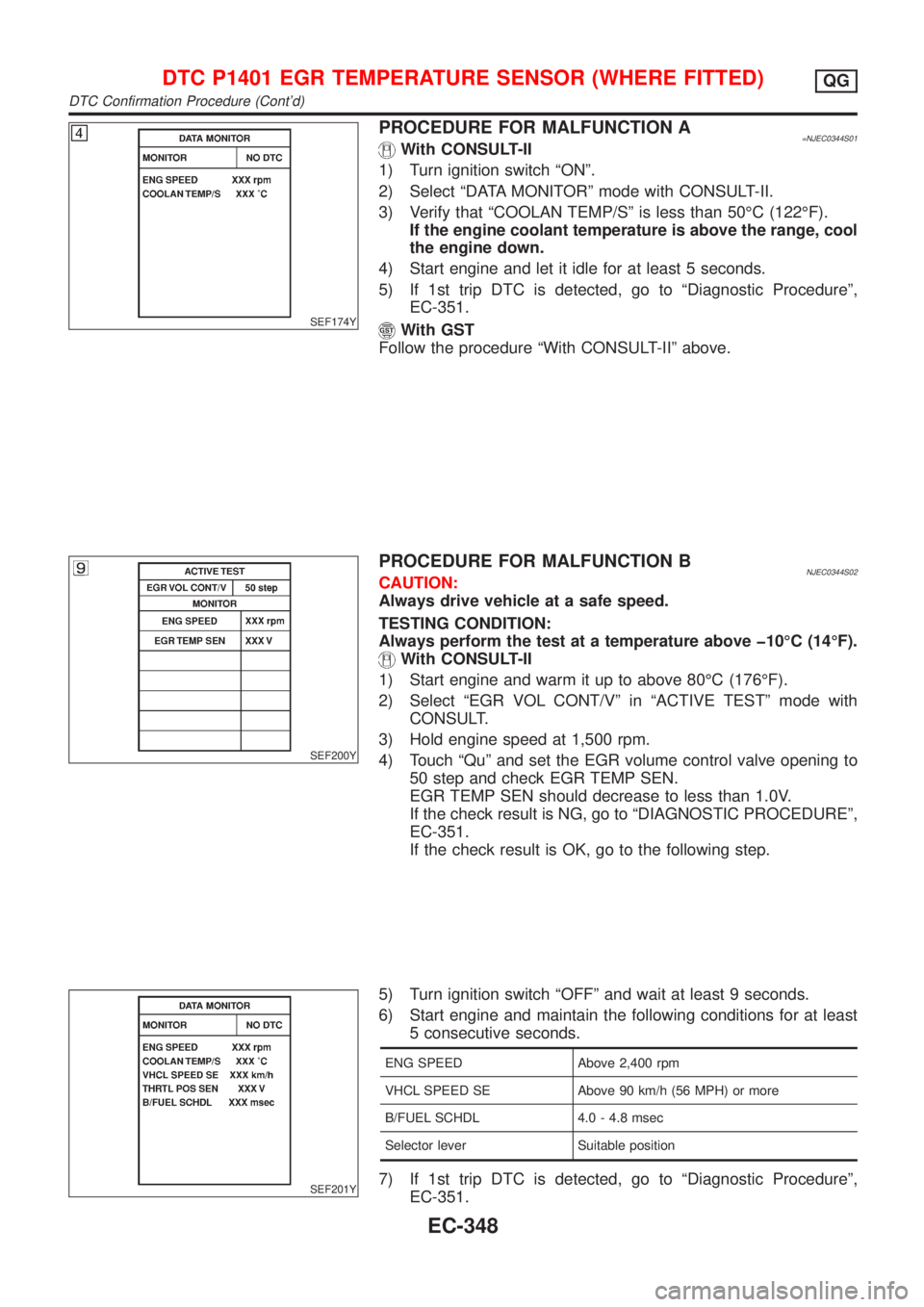

PROCEDURE FOR MALFUNCTION A=NJEC0344S01With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Verify that ªCOOLAN TEMP/Sº is less than 50ÉC (122ÉF).

If the engine coolant temperature is above the range, cool

the engine down.

4) Start engine and let it idle for at least 5 seconds.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-351.

With GST

Follow the procedure ªWith CONSULT-IIº above.

SEF200Y

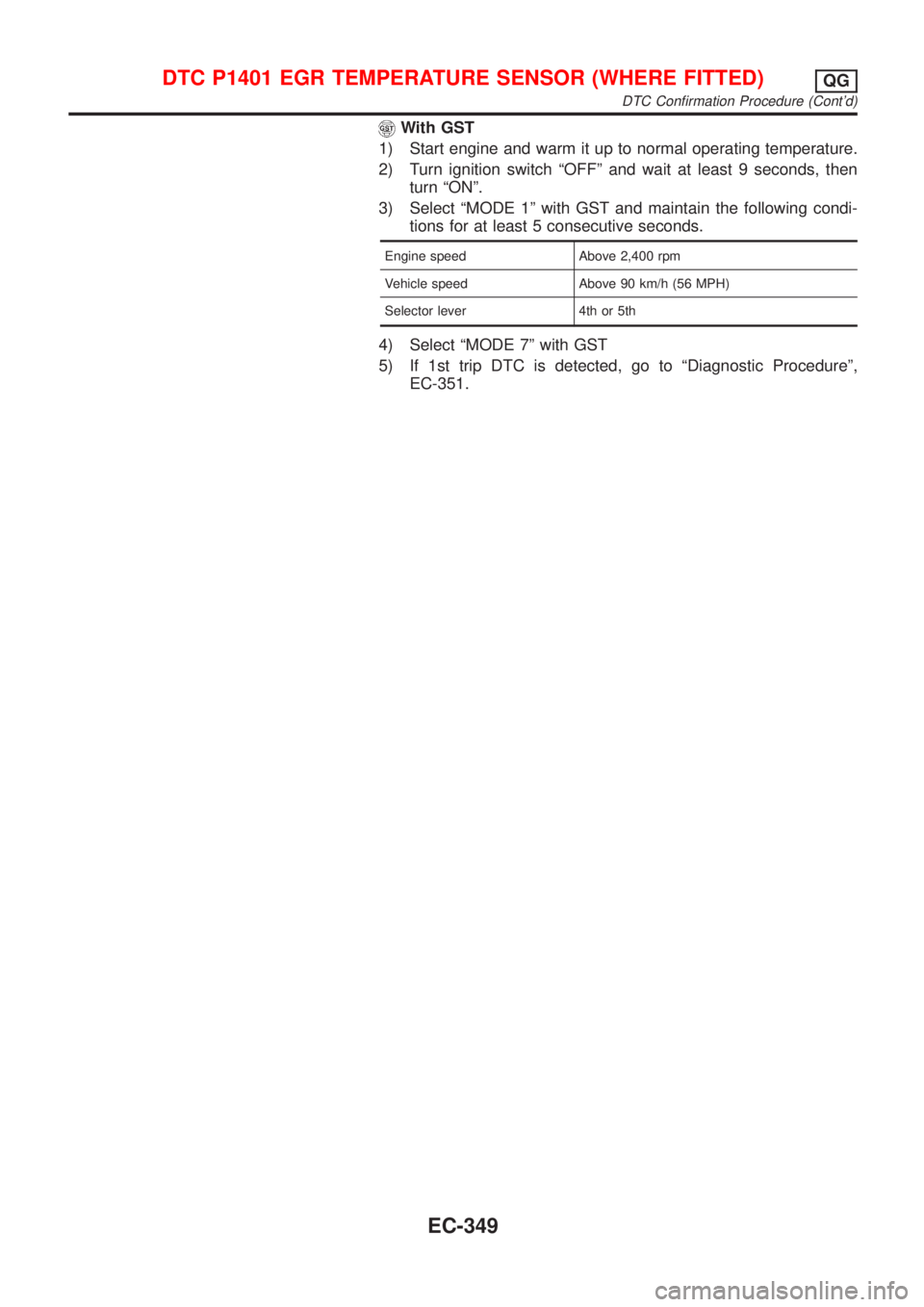

PROCEDURE FOR MALFUNCTION BNJEC0344S02CAUTION:

Always drive vehicle at a safe speed.

TESTING CONDITION:

Always perform the test at a temperature above þ10ÉC (14ÉF).

With CONSULT-II

1) Start engine and warm it up to above 80ÉC (176ÉF).

2) Select ªEGR VOL CONT/Vº in ªACTIVE TESTº mode with

CONSULT.

3) Hold engine speed at 1,500 rpm.

4) Touch ªQuº and set the EGR volume control valve opening to

50 step and check EGR TEMP SEN.

EGR TEMP SEN should decrease to less than 1.0V.

If the check result is NG, go to ªDIAGNOSTIC PROCEDUREº,

EC-351.

If the check result is OK, go to the following step.

SEF201Y

5) Turn ignition switch ªOFFº and wait at least 9 seconds.

6) Start engine and maintain the following conditions for at least

5 consecutive seconds.

ENG SPEED Above 2,400 rpm

VHCL SPEED SE Above 90 km/h (56 MPH) or more

B/FUEL SCHDL 4.0 - 4.8 msec

Selector lever Suitable position

7) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-351.

DTC P1401 EGR TEMPERATURE SENSOR (WHERE FITTED)QG

DTC Confirmation Procedure (Cont'd)

EC-348

Page 645 of 2493

With GST

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds, then

turn ªONº.

3) Select ªMODE 1º with GST and maintain the following condi-

tions for at least 5 consecutive seconds.

Engine speed Above 2,400 rpm

Vehicle speed Above 90 km/h (56 MPH)

Selector lever 4th or 5th

4) Select ªMODE 7º with GST

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-351.

DTC P1401 EGR TEMPERATURE SENSOR (WHERE FITTED)QG

DTC Confirmation Procedure (Cont'd)

EC-349

Page 661 of 2493

SEF213Y

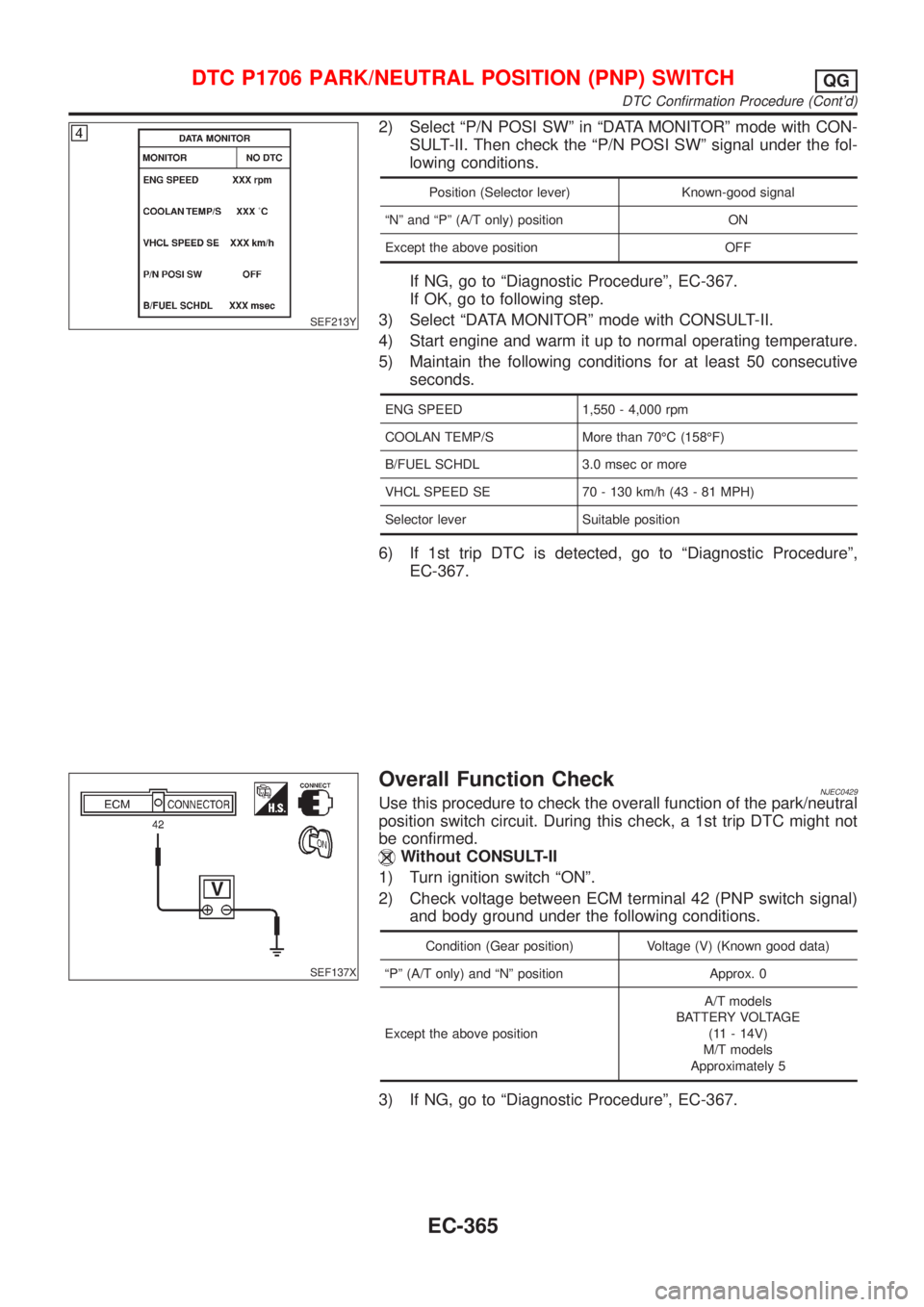

2) Select ªP/N POSI SWº in ªDATA MONITORº mode with CON-

SULT-II. Then check the ªP/N POSI SWº signal under the fol-

lowing conditions.

Position (Selector lever) Known-good signal

ªNº and ªPº (A/T only) position ON

Except the above position OFF

If NG, go to ªDiagnostic Procedureº, EC-367.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Start engine and warm it up to normal operating temperature.

5) Maintain the following conditions for at least 50 consecutive

seconds.

ENG SPEED 1,550 - 4,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.0 msec or more

VHCL SPEED SE 70 - 130 km/h (43 - 81 MPH)

Selector lever Suitable position

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-367.

SEF137X

Overall Function CheckNJEC0429Use this procedure to check the overall function of the park/neutral

position switch circuit. During this check, a 1st trip DTC might not

be confirmed.

Without CONSULT-II

1) Turn ignition switch ªONº.

2) Check voltage between ECM terminal 42 (PNP switch signal)

and body ground under the following conditions.

Condition (Gear position) Voltage (V) (Known good data)

ªPº (A/T only) and ªNº position Approx. 0

Except the above positionA/T models

BATTERY VOLTAGE

(11 - 14V)

M/T models

Approximately 5

3) If NG, go to ªDiagnostic Procedureº, EC-367.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG

DTC Confirmation Procedure (Cont'd)

EC-365

Page 681 of 2493

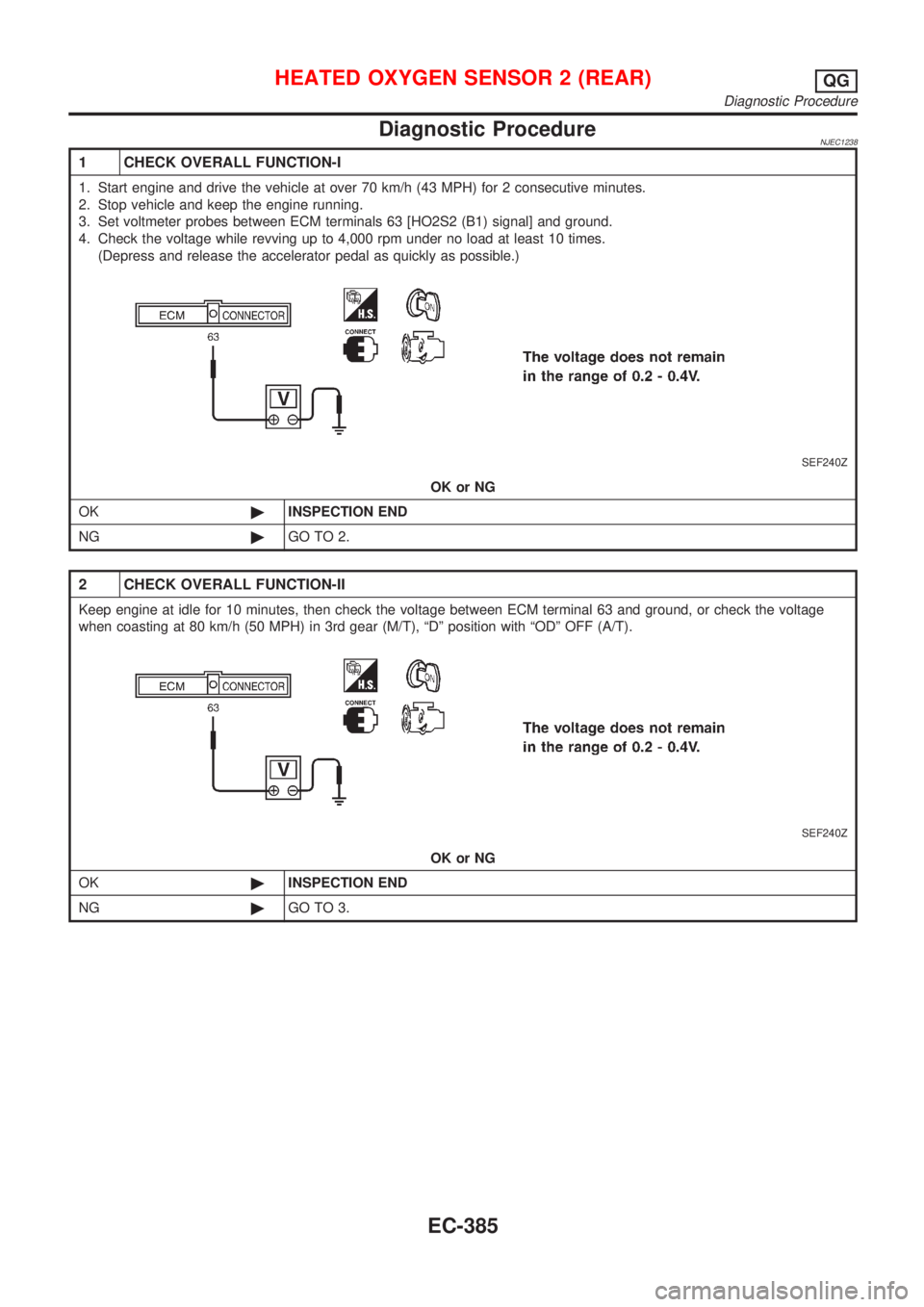

Diagnostic ProcedureNJEC1238

1 CHECK OVERALL FUNCTION-I

1. Start engine and drive the vehicle at over 70 km/h (43 MPH) for 2 consecutive minutes.

2. Stop vehicle and keep the engine running.

3. Set voltmeter probes between ECM terminals 63 [HO2S2 (B1) signal] and ground.

4. Check the voltage while revving up to 4,000 rpm under no load at least 10 times.

(Depress and release the accelerator pedal as quickly as possible.)

SEF240Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK OVERALL FUNCTION-II

Keep engine at idle for 10 minutes, then check the voltage between ECM terminal 63 and ground, or check the voltage

when coasting at 80 km/h (50 MPH) in 3rd gear (M/T), ªDº position with ªODº OFF (A/T).

SEF240Z

OK or NG

OK©INSPECTION END

NG©GO TO 3.

HEATED OXYGEN SENSOR 2 (REAR)QG

Diagnostic Procedure

EC-385

Page 683 of 2493

6 CHECK GROUND CIRCUIT

1. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 4 and body ground.

Refer to wiring diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

7 CHECK HEATED OXYGEN SENSOR 2 (REAR)

Refer to ªComponent Inspectionº, EC-387.

OK or NG

OK©GO TO 8.

NG©Replace heated oxygen sensor 2 (rear).

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

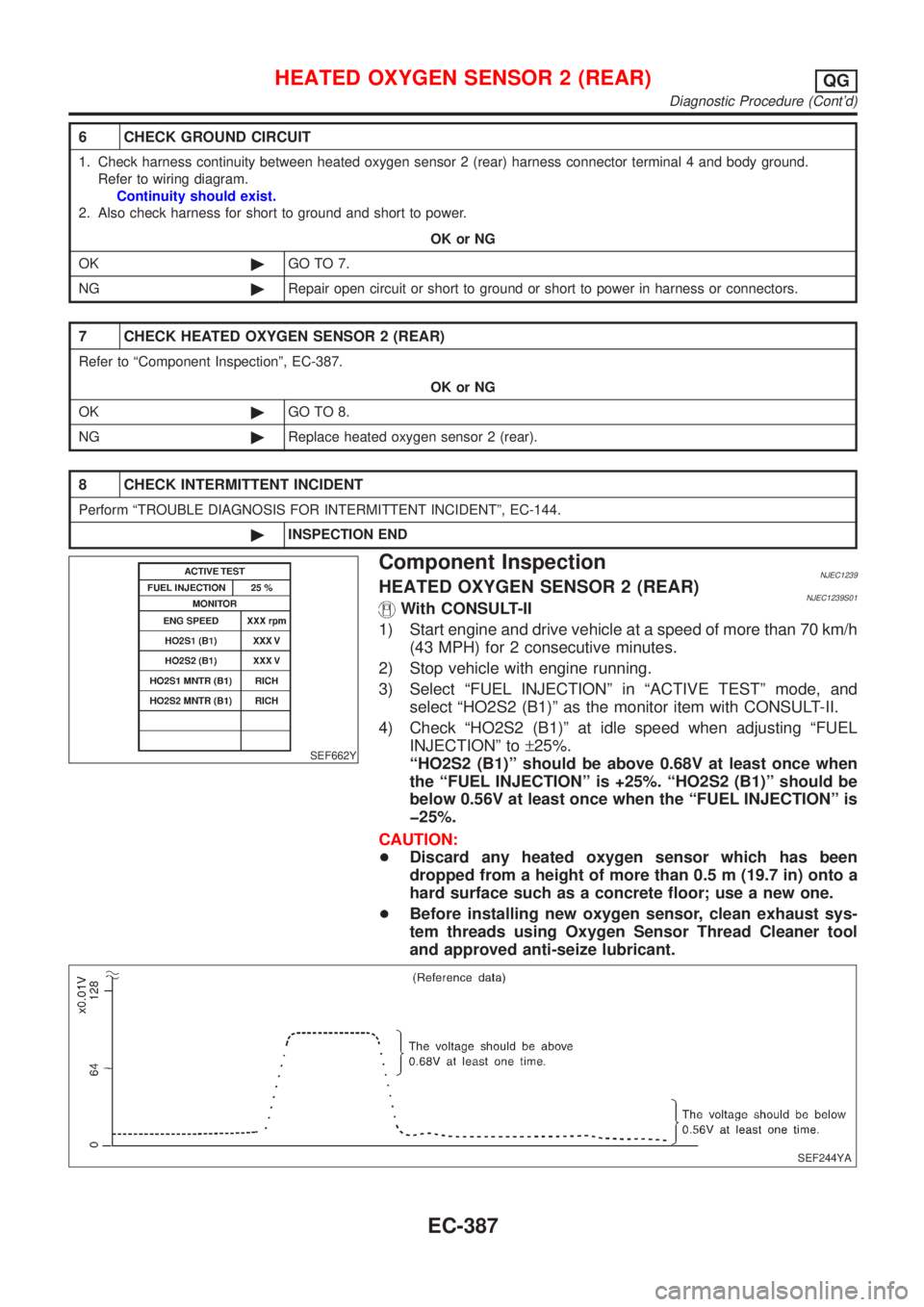

SEF662Y

Component InspectionNJEC1239HEATED OXYGEN SENSOR 2 (REAR)NJEC1239S01With CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Select ªFUEL INJECTIONº in ªACTIVE TESTº mode, and

select ªHO2S2 (B1)º as the monitor item with CONSULT-II.

4) Check ªHO2S2 (B1)º at idle speed when adjusting ªFUEL

INJECTIONº to±25%.

ªHO2S2 (B1)º should be above 0.68V at least once when

the ªFUEL INJECTIONº is +25%. ªHO2S2 (B1)º should be

below 0.56V at least once when the ªFUEL INJECTIONº is

þ25%.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

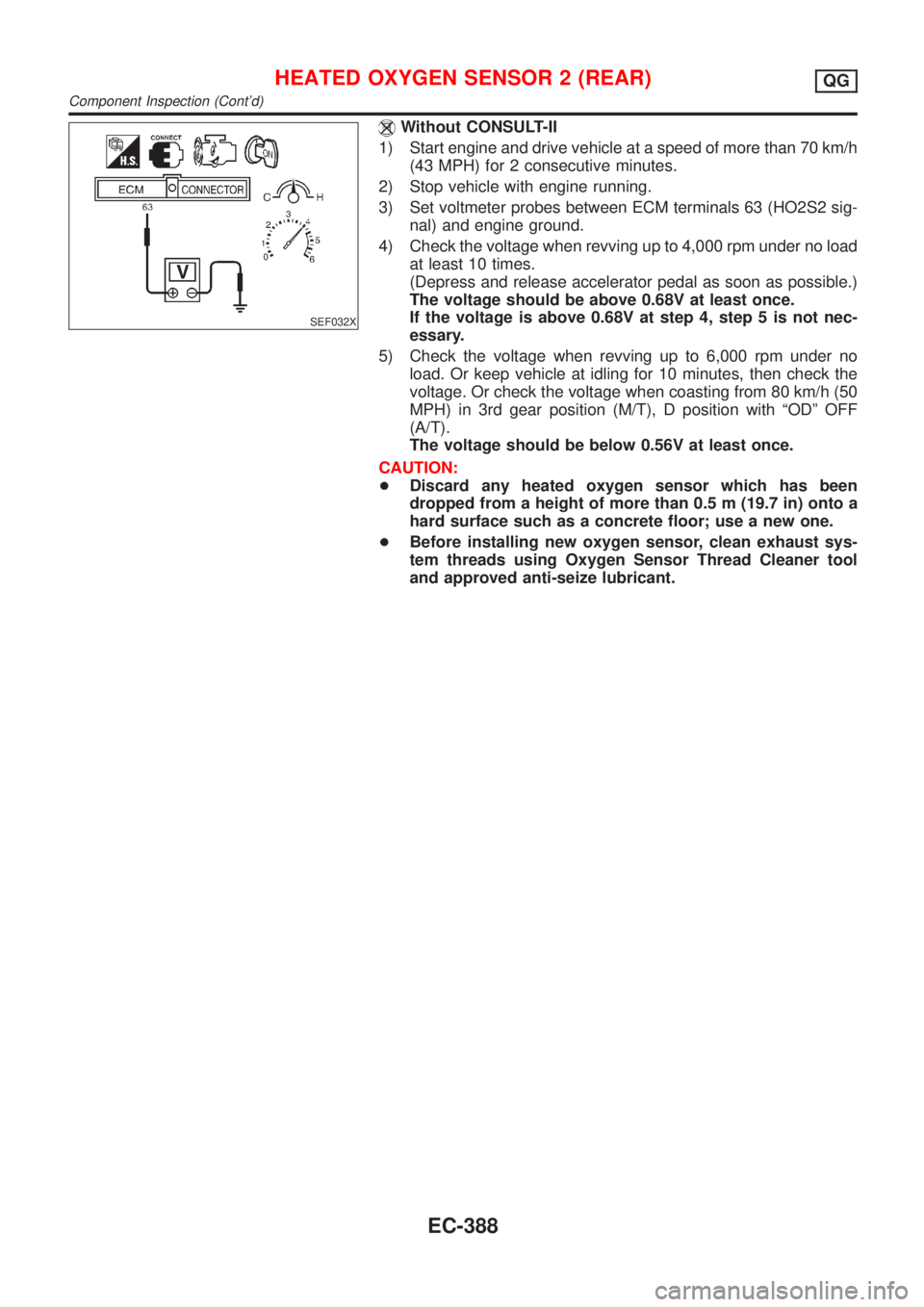

SEF244YA

HEATED OXYGEN SENSOR 2 (REAR)QG

Diagnostic Procedure (Cont'd)

EC-387

Page 684 of 2493

SEF032X

Without CONSULT-II

1) Start engine and drive vehicle at a speed of more than 70 km/h

(43 MPH) for 2 consecutive minutes.

2) Stop vehicle with engine running.

3) Set voltmeter probes between ECM terminals 63 (HO2S2 sig-

nal) and engine ground.

4) Check the voltage when revving up to 4,000 rpm under no load

at least 10 times.

(Depress and release accelerator pedal as soon as possible.)

The voltage should be above 0.68V at least once.

If the voltage is above 0.68V at step 4, step 5 is not nec-

essary.

5) Check the voltage when revving up to 6,000 rpm under no

load. Or keep vehicle at idling for 10 minutes, then check the

voltage. Or check the voltage when coasting from 80 km/h (50

MPH) in 3rd gear position (M/T), D position with ªODº OFF

(A/T).

The voltage should be below 0.56V at least once.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

HEATED OXYGEN SENSOR 2 (REAR)QG

Component Inspection (Cont'd)

EC-388

Page 687 of 2493

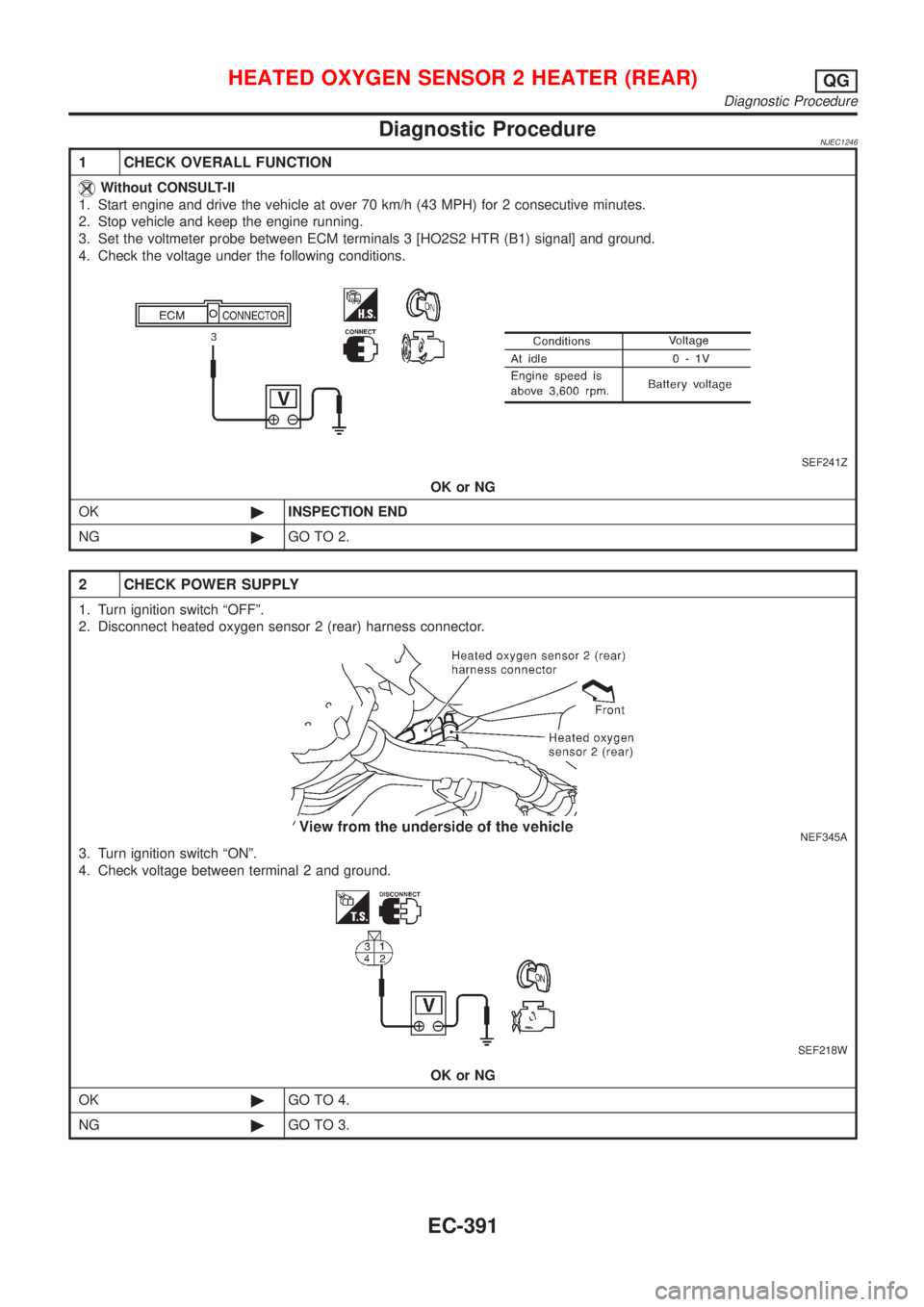

Diagnostic ProcedureNJEC1246

1 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine and drive the vehicle at over 70 km/h (43 MPH) for 2 consecutive minutes.

2. Stop vehicle and keep the engine running.

3. Set the voltmeter probe between ECM terminals 3 [HO2S2 HTR (B1) signal] and ground.

4. Check the voltage under the following conditions.

SEF241Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector.

NEF345A

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground.

SEF218W

OK or NG

OK©GO TO 4.

NG©GO TO 3.

HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Diagnostic Procedure

EC-391

Page 815 of 2493

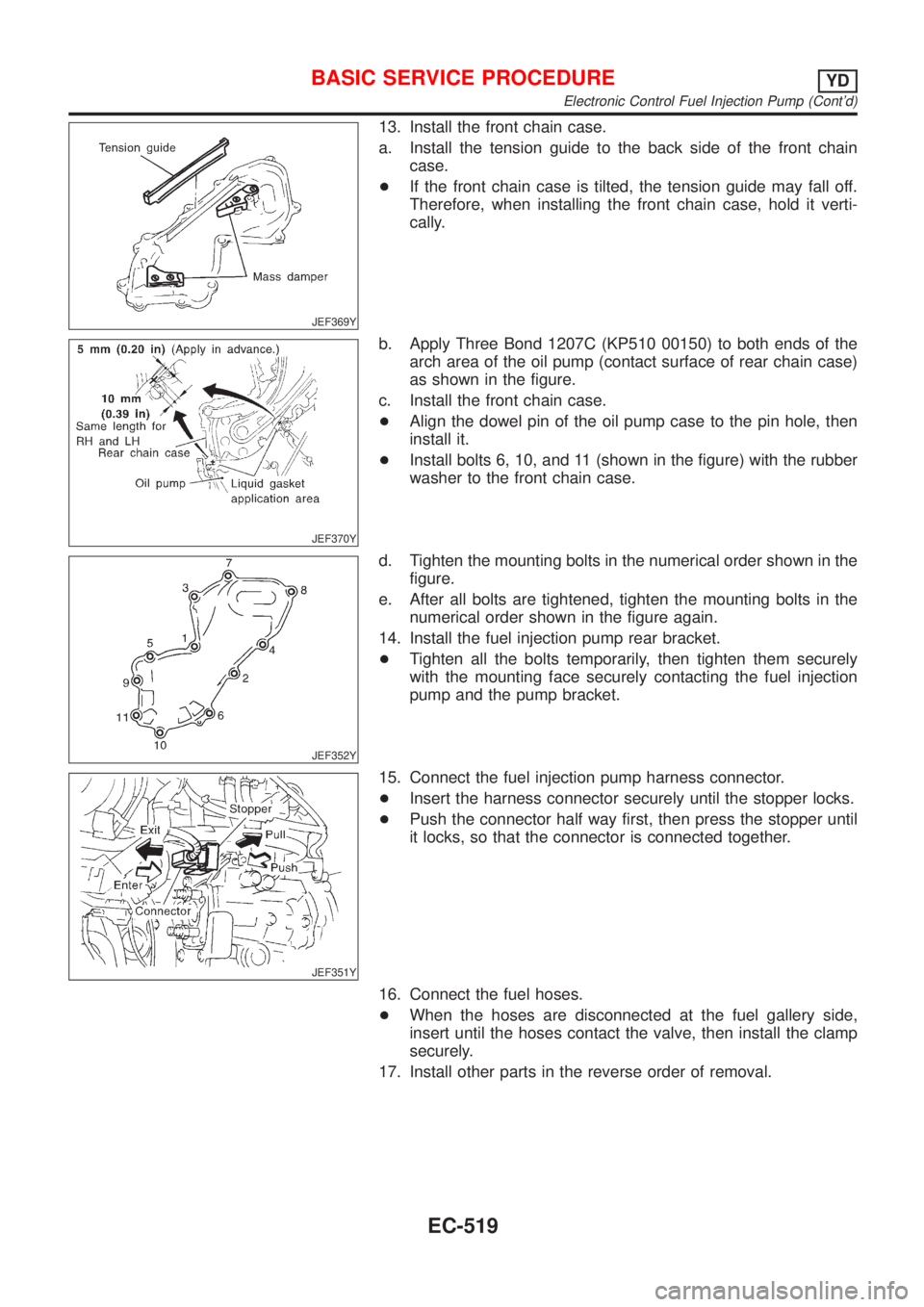

JEF369Y

13. Install the front chain case.

a. Install the tension guide to the back side of the front chain

case.

+If the front chain case is tilted, the tension guide may fall off.

Therefore, when installing the front chain case, hold it verti-

cally.

JEF370Y

b. Apply Three Bond 1207C (KP510 00150) to both ends of the

arch area of the oil pump (contact surface of rear chain case)

as shown in the figure.

c. Install the front chain case.

+Align the dowel pin of the oil pump case to the pin hole, then

install it.

+Install bolts 6, 10, and 11 (shown in the figure) with the rubber

washer to the front chain case.

JEF352Y

d. Tighten the mounting bolts in the numerical order shown in the

figure.

e. After all bolts are tightened, tighten the mounting bolts in the

numerical order shown in the figure again.

14. Install the fuel injection pump rear bracket.

+Tighten all the bolts temporarily, then tighten them securely

with the mounting face securely contacting the fuel injection

pump and the pump bracket.

JEF351Y

15. Connect the fuel injection pump harness connector.

+Insert the harness connector securely until the stopper locks.

+Push the connector half way first, then press the stopper until

it locks, so that the connector is connected together.

16. Connect the fuel hoses.

+When the hoses are disconnected at the fuel gallery side,

insert until the hoses contact the valve, then install the clamp

securely.

17. Install other parts in the reverse order of removal.

BASIC SERVICE PROCEDUREYD

Electronic Control Fuel Injection Pump (Cont'd)

EC-519

Page 822 of 2493

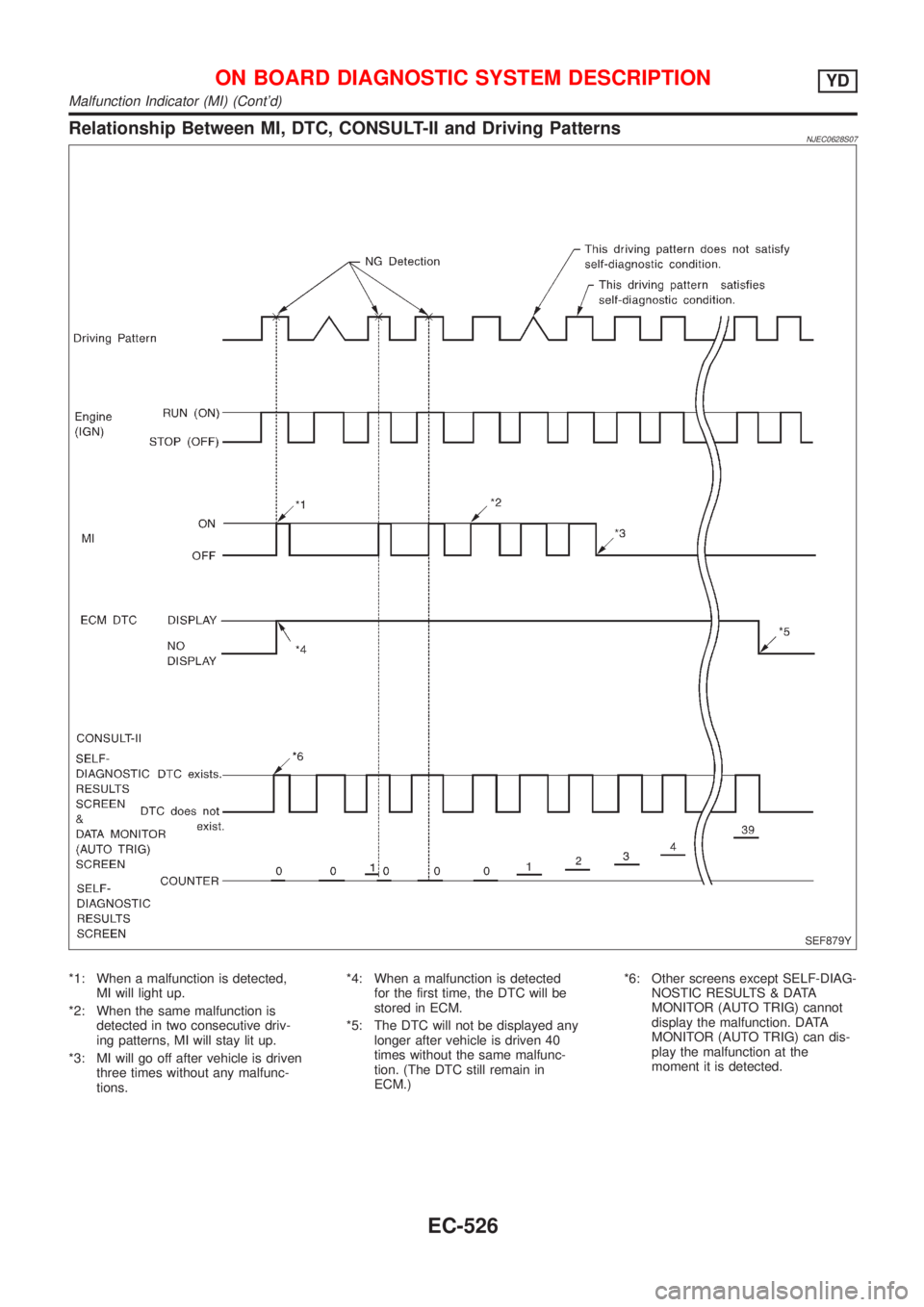

Relationship Between MI, DTC, CONSULT-II and Driving PatternsNJEC0628S07

SEF879Y

*1: When a malfunction is detected,

MI will light up.

*2: When the same malfunction is

detected in two consecutive driv-

ing patterns, MI will stay lit up.

*3: MI will go off after vehicle is driven

three times without any malfunc-

tions.*4: When a malfunction is detected

for the first time, the DTC will be

stored in ECM.

*5: The DTC will not be displayed any

longer after vehicle is driven 40

times without the same malfunc-

tion. (The DTC still remain in

ECM.)*6: Other screens except SELF-DIAG-

NOSTIC RESULTS & DATA

MONITOR (AUTO TRIG) cannot

display the malfunction. DATA

MONITOR (AUTO TRIG) can dis-

play the malfunction at the

moment it is detected.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

Malfunction Indicator (MI) (Cont'd)

EC-526

Page 855 of 2493

DescriptionNJEC0637Intermittent incidents (I/I) may occur. In many cases, the problem resolves itself (the part or circuit function

returns to normal without intervention). It is important to realize that the symptoms described in the custom-

er's complaint often do not recur on DTC visits. Realize also that the most frequent cause of I/I occurrences

is poor electrical connections. Because of this, the conditions under which the incident occurred may not be

clear. Therefore, circuit checks made as part of the standard diagnostic procedure may not indicate the spe-

cific problem area.

COMMON I/I REPORT SITUATIONSNJEC0637S01

STEP in Work Flow Situation

II The CONSULT-II is used. The SELF-DIAG RESULTS screen shows time data other than ª0º.

III The symptom described by the customer does not recur.

IV DTC does not appear during the DTC Confirmation Procedure.

VI The Diagnostic Procedure for XXXX does not indicate the problem area.

Diagnostic ProcedureNJEC0638

1 INSPECTION START

Erase DTCs. Refer to ªHOW TO ERASE DTCº, EC-522.

©GO TO 2.

2 CHECK GROUND TERMINALS

Check ground terminals for corroding or loose connection.

Refer to GI-22, ªGROUND INSPECTIONº.

OK or NG

OK©GO TO 3.

NG©Repair or replace.

3 SEARCH FOR ELECTRICAL INCIDENT

Perform GI-22, ªIncident Simulation Testsº.

OK or NG

OK©INSPECTION END

NG©Repair or replace.

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTYD

Description

EC-559