NISSAN ALMERA N16 2001 Electronic Repair Manual

ALMERA N16 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57351/w960_57351-0.png

NISSAN ALMERA N16 2001 Electronic Repair Manual

Trending: timing belt, Hand break, Electric control injection, sunroof, warning light, fuel pressure, Cooling system

Page 1361 of 2493

SAT580J

SAT824H

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENJAT0061S05After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINJAT0061S05011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with CONSULT-

II.

3) With brake pedal depressed, shift the lever from ªPº®ªNº®

ªDº®ªNº®ªPº positions.

Without CONSULT-IINJAT0061S05021) Start engine.

2) With brake pedal depressed, shift the lever from ªPº®ªNº®

ªDº®ªNº®ªPº positions.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-42.

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Description (Cont'd)

AT-175

Page 1362 of 2493

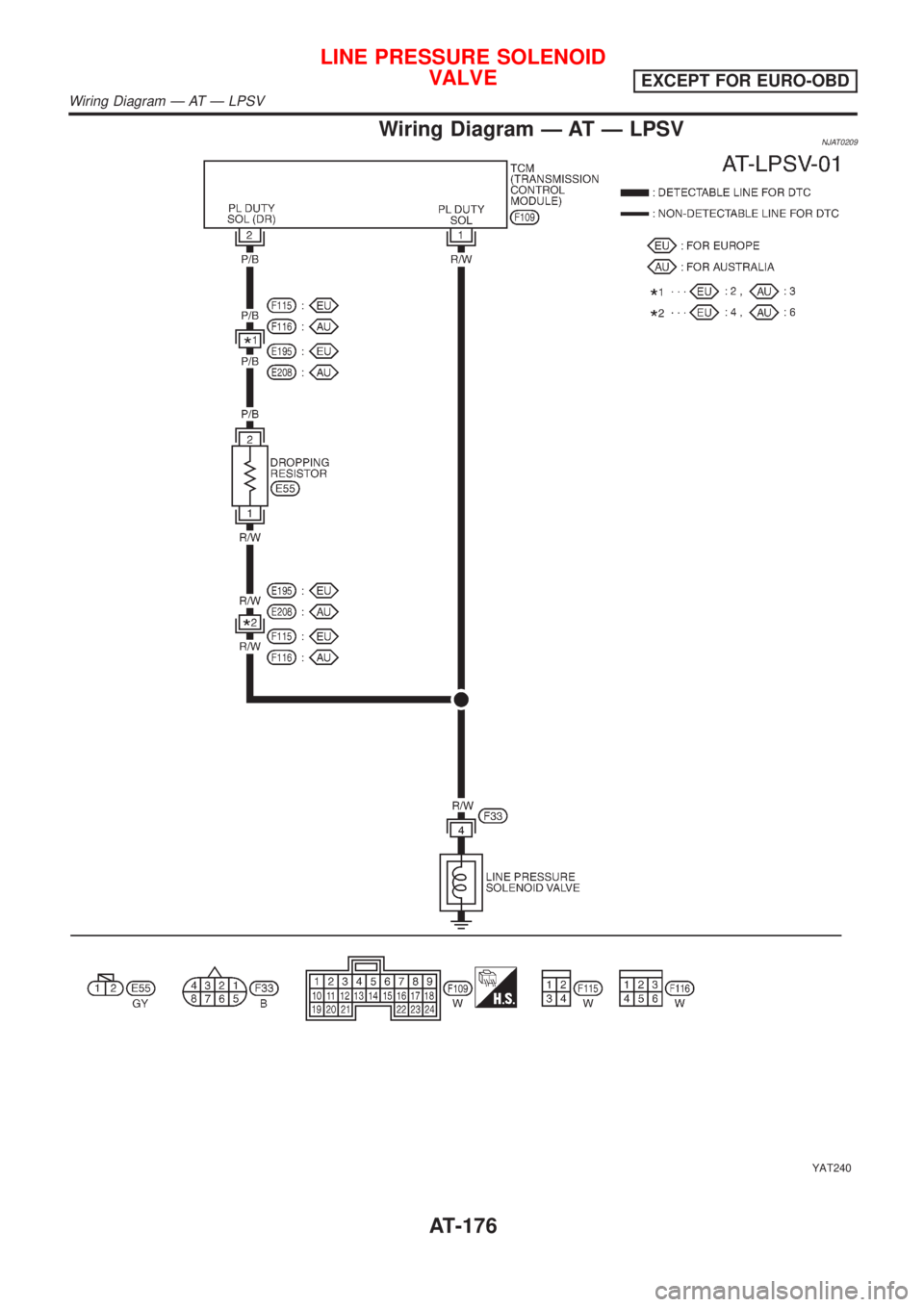

Wiring Diagram Ð AT Ð LPSVNJAT0209

YAT240

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Wiring Diagram Ð AT Ð LPSV

AT-176

Page 1363 of 2493

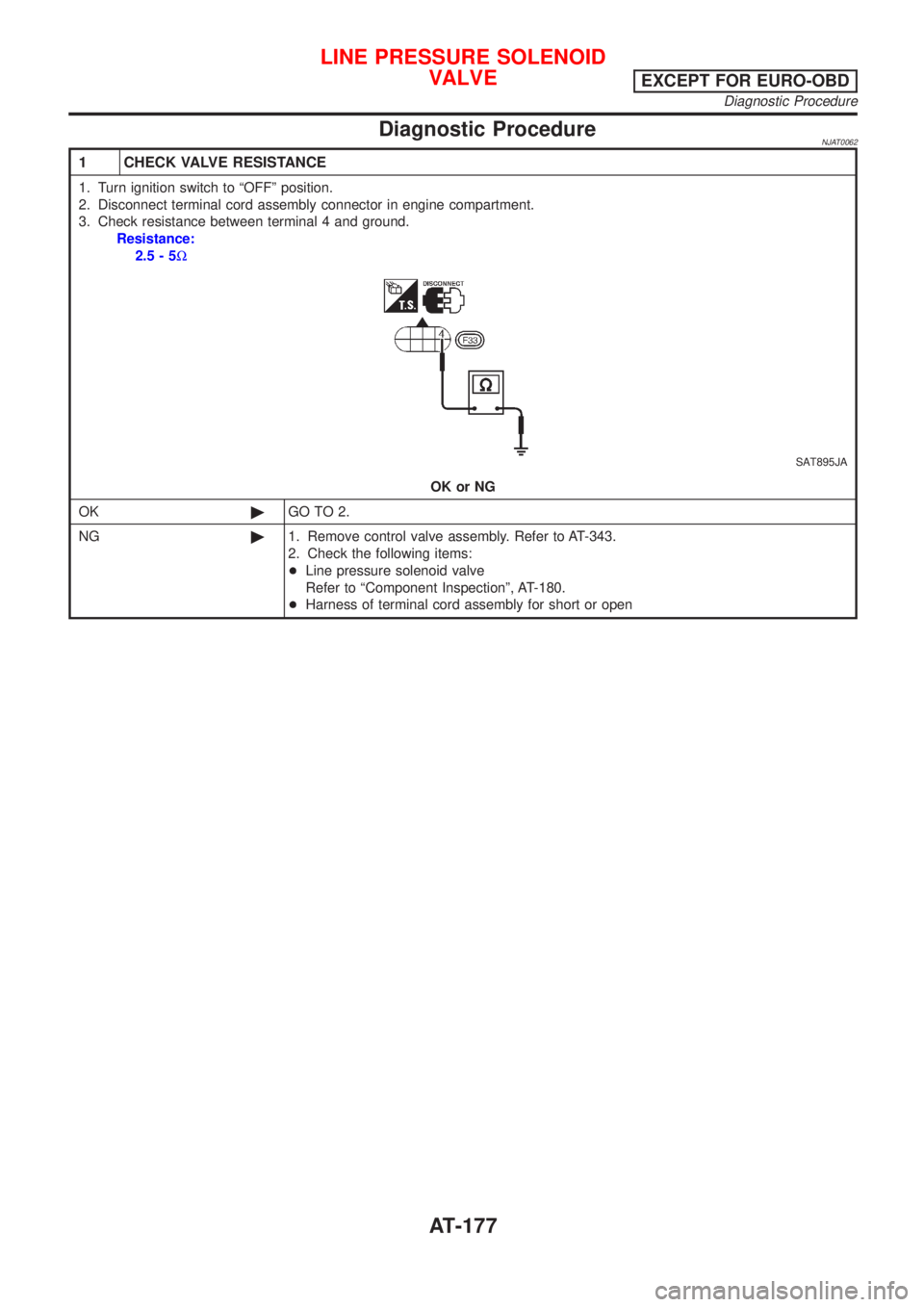

Diagnostic ProcedureNJAT0062

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector in engine compartment.

3. Check resistance between terminal 4 and ground.

Resistance:

2.5-5W

SAT895JA

OK or NG

OK©GO TO 2.

NG©1. Remove control valve assembly. Refer to AT-343.

2. Check the following items:

+Line pressure solenoid valve

Refer to ªComponent Inspectionº, AT-180.

+Harness of terminal cord assembly for short or open

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Diagnostic Procedure

AT-177

Page 1364 of 2493

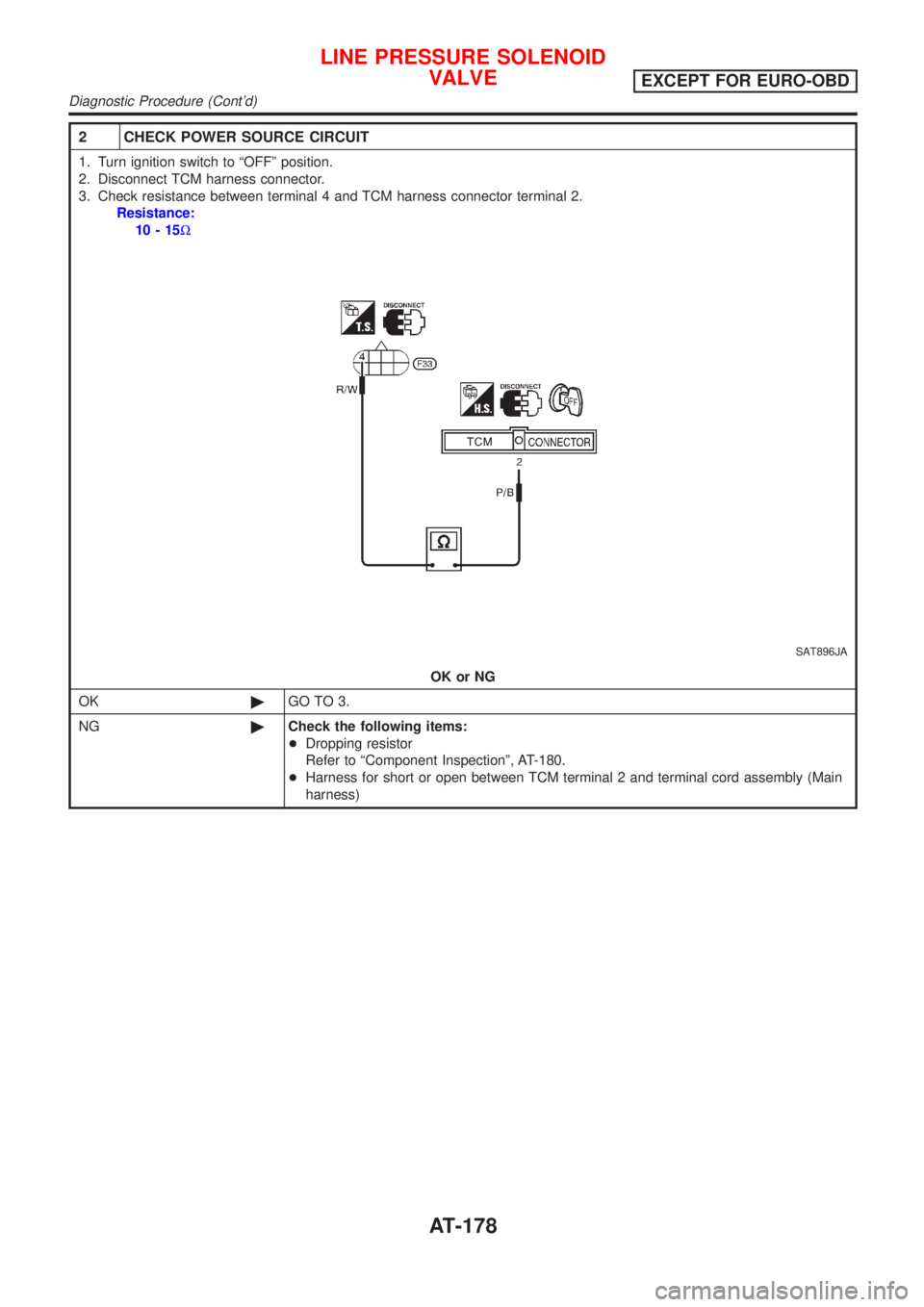

2 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 4 and TCM harness connector terminal 2.

Resistance:

10-15W

SAT896JA

OK or NG

OK©GO TO 3.

NG©Check the following items:

+Dropping resistor

Refer to ªComponent Inspectionº, AT-180.

+Harness for short or open between TCM terminal 2 and terminal cord assembly (Main

harness)

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-178

Page 1365 of 2493

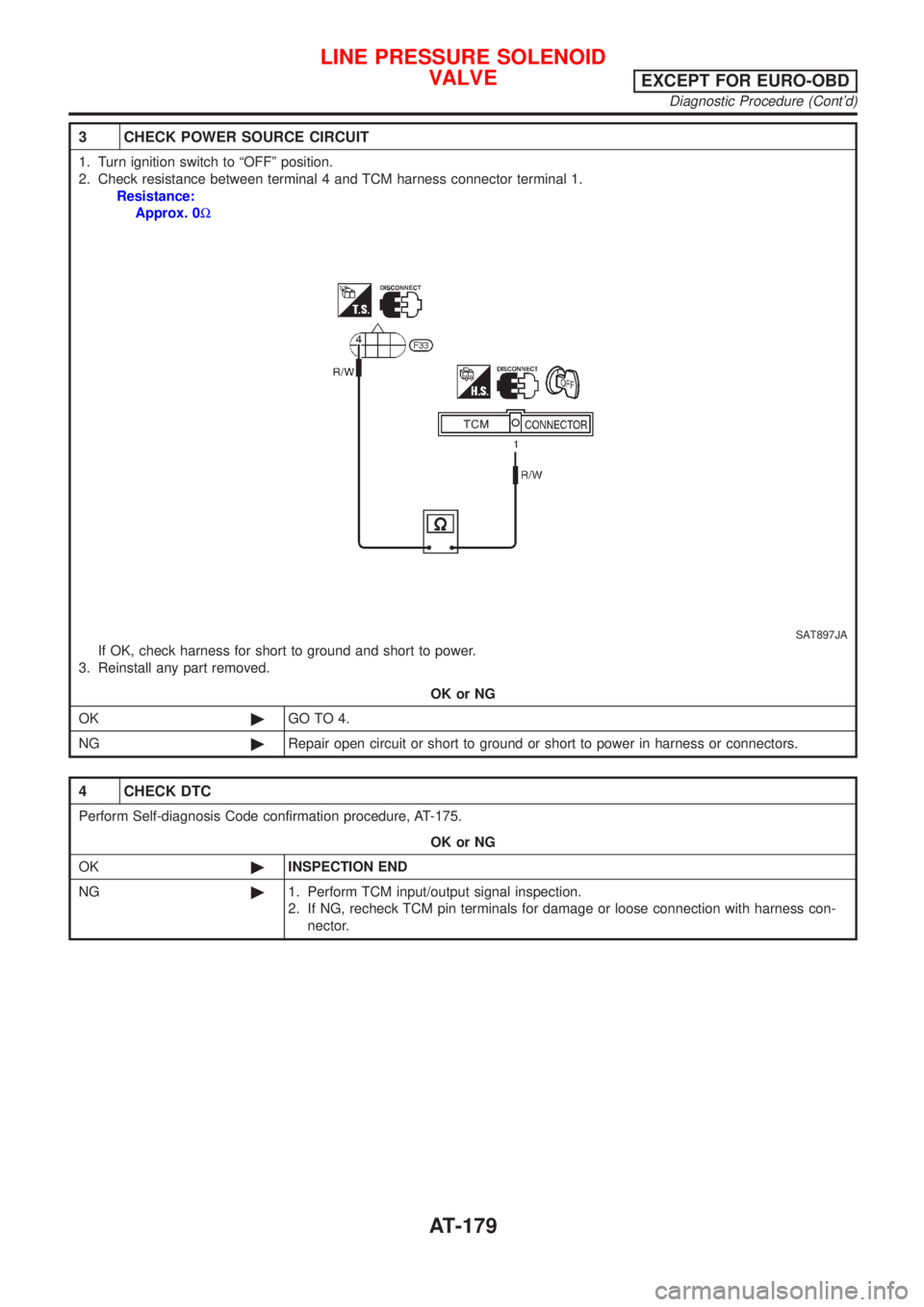

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Check resistance between terminal 4 and TCM harness connector terminal 1.

Resistance:

Approx. 0W

SAT897JA

If OK, check harness for short to ground and short to power.

3. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Self-diagnosis Code confirmation procedure, AT-175.

OK or NG

OK©INSPECTION END

NG©1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness con-

nector.

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Diagnostic Procedure (Cont'd)

AT-179

Page 1366 of 2493

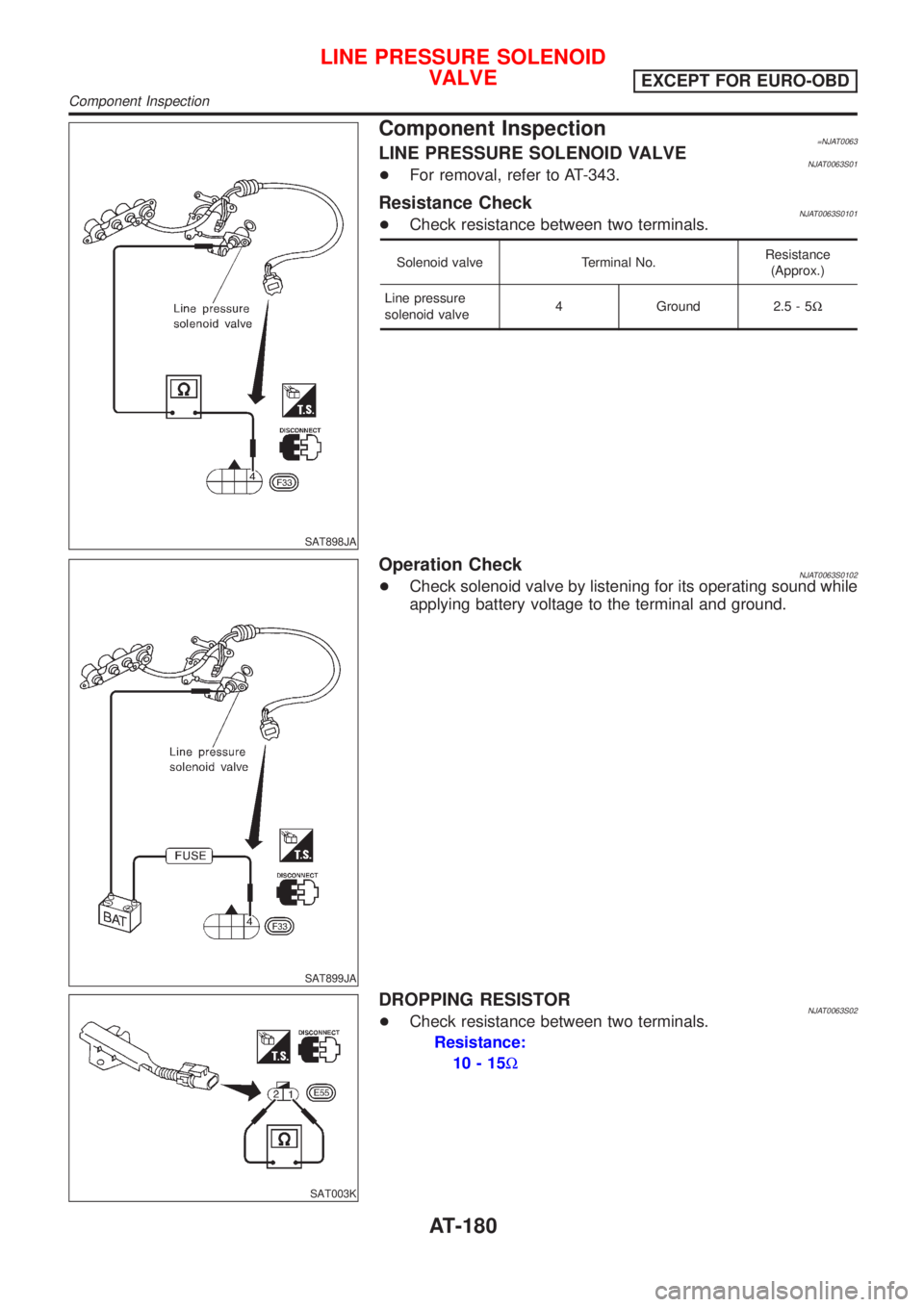

SAT898JA

Component Inspection=NJAT0063LINE PRESSURE SOLENOID VALVENJAT0063S01+For removal, refer to AT-343.

Resistance CheckNJAT0063S0101+Check resistance between two terminals.

Solenoid valve Terminal No.Resistance

(Approx.)

Line pressure

solenoid valve4 Ground 2.5 - 5W

SAT899JA

Operation CheckNJAT0063S0102+Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground.

SAT003K

DROPPING RESISTORNJAT0063S02+Check resistance between two terminals.

Resistance:

10-15W

LINE PRESSURE SOLENOID

VALVE

EXCEPT FOR EURO-OBD

Component Inspection

AT-180

Page 1367 of 2493

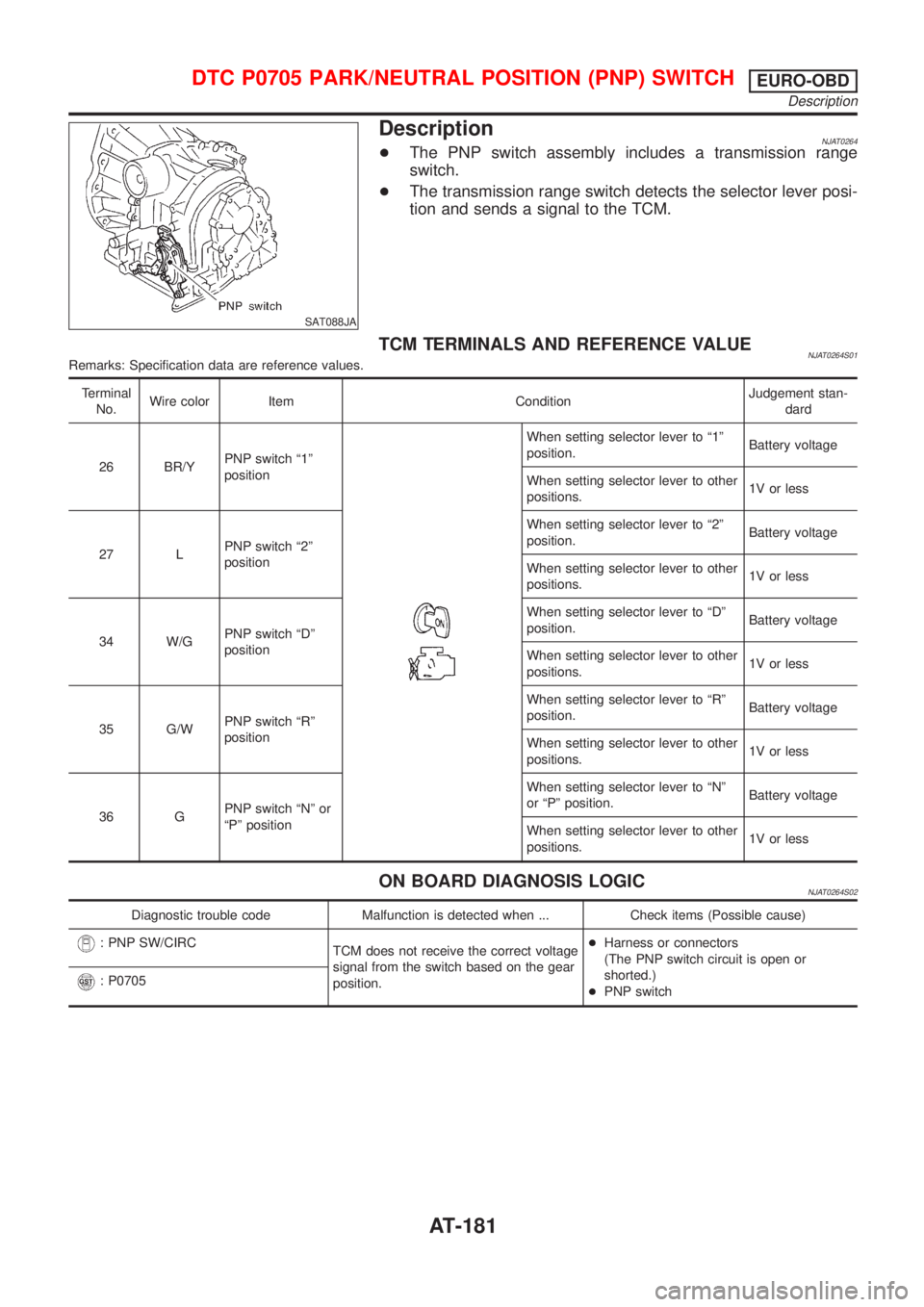

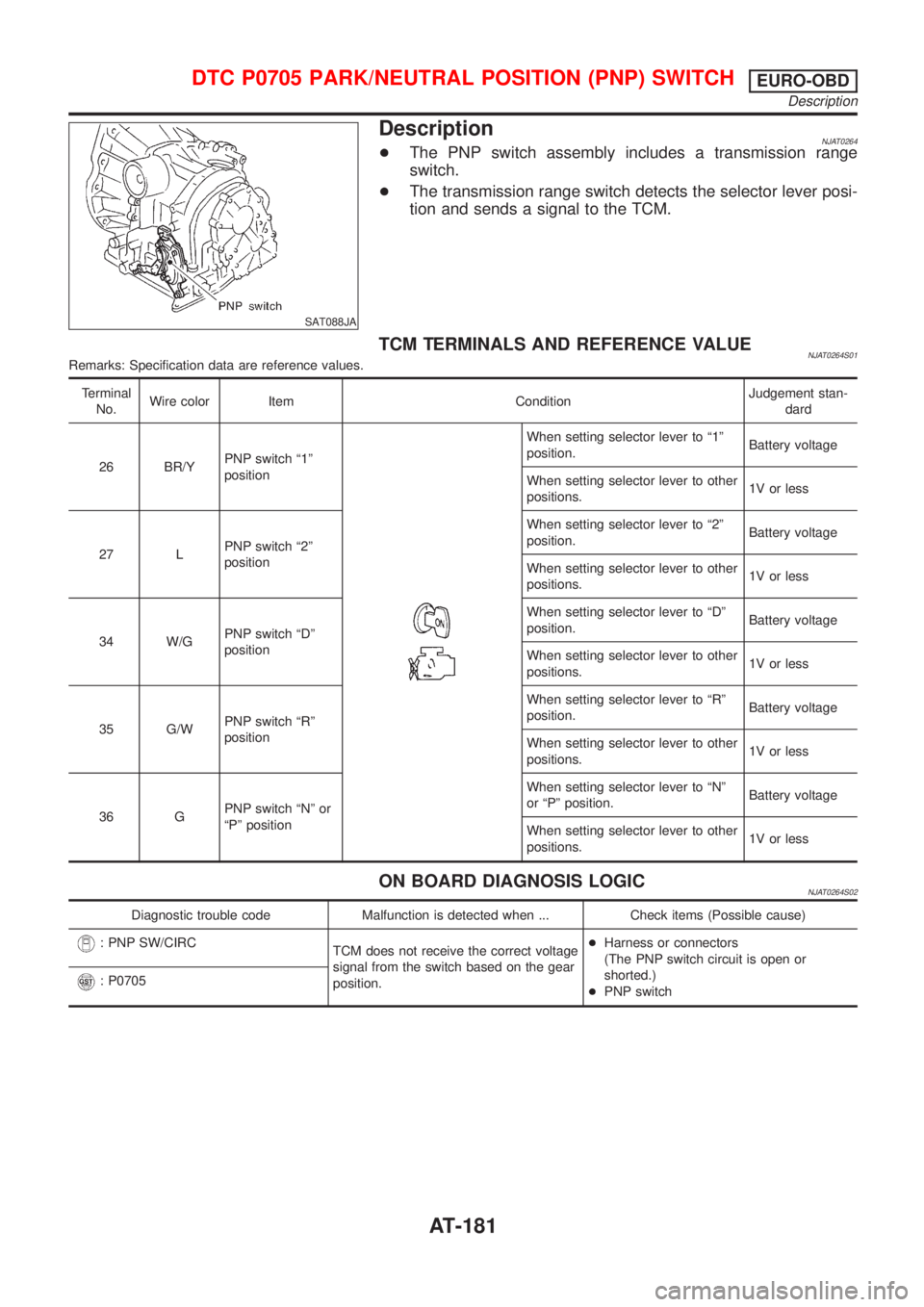

SAT088JA

DescriptionNJAT0264+The PNP switch assembly includes a transmission range

switch.

+The transmission range switch detects the selector lever posi-

tion and sends a signal to the TCM.

TCM TERMINALS AND REFERENCE VALUENJAT0264S01Remarks: Specification data are reference values.

Terminal

No.Wire color Item ConditionJudgement stan-

dard

26 BR/YPNP switch ª1º

position

When setting selector lever to ª1º

position.Battery voltage

When setting selector lever to other

positions.1V or less

27 LPNP switch ª2º

positionWhen setting selector lever to ª2º

position.Battery voltage

When setting selector lever to other

positions.1V or less

34 W/GPNP switch ªDº

positionWhen setting selector lever to ªDº

position.Battery voltage

When setting selector lever to other

positions.1V or less

35 G/WPNP switch ªRº

positionWhen setting selector lever to ªRº

position.Battery voltage

When setting selector lever to other

positions.1V or less

36 GPNP switch ªNº or

ªPº positionWhen setting selector lever to ªNº

or ªPº position.Battery voltage

When setting selector lever to other

positions.1V or less

ON BOARD DIAGNOSIS LOGICNJAT0264S02

Diagnostic trouble code Malfunction is detected when ... Check items (Possible cause)

: PNP SW/CIRC

TCM does not receive the correct voltage

signal from the switch based on the gear

position.+Harness or connectors

(The PNP switch circuit is open or

shorted.)

+PNP switch

: P0705

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Description

AT-181

Page 1368 of 2493

SAT014K

SAT020K

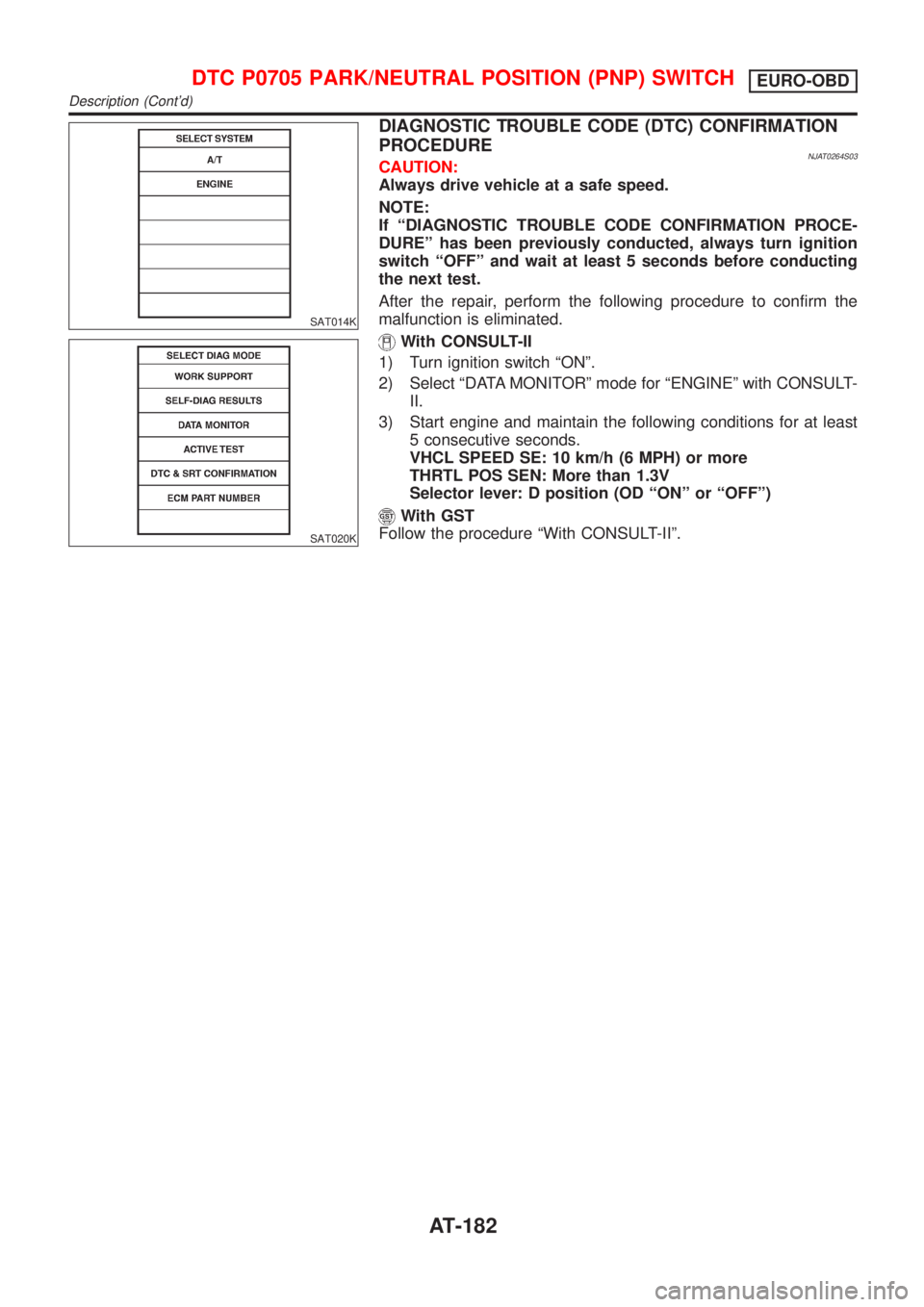

DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION

PROCEDURE

NJAT0264S03CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDIAGNOSTIC TROUBLE CODE CONFIRMATION PROCE-

DUREº has been previously conducted, always turn ignition

switch ªOFFº and wait at least 5 seconds before conducting

the next test.

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode for ªENGINEº with CONSULT-

II.

3) Start engine and maintain the following conditions for at least

5 consecutive seconds.

VHCL SPEED SE: 10 km/h (6 MPH) or more

THRTL POS SEN: More than 1.3V

Selector lever: D position (OD ªONº or ªOFFº)

With GST

Follow the procedure ªWith CONSULT-IIº.

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Description (Cont'd)

AT-182

Page 1369 of 2493

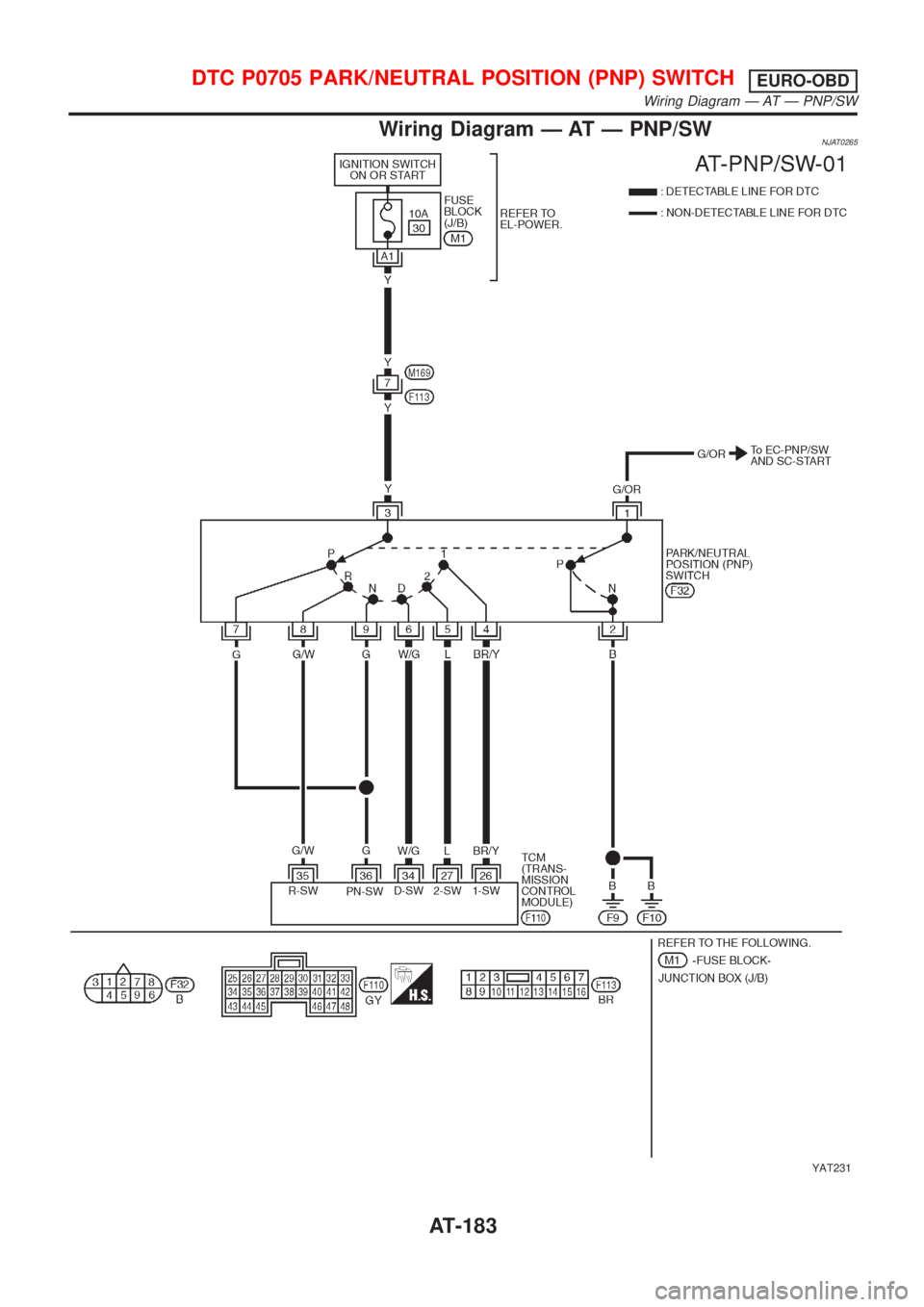

Wiring Diagram Ð AT Ð PNP/SWNJAT0265

YAT231

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Wiring Diagram Ð AT Ð PNP/SW

AT-183

Page 1370 of 2493

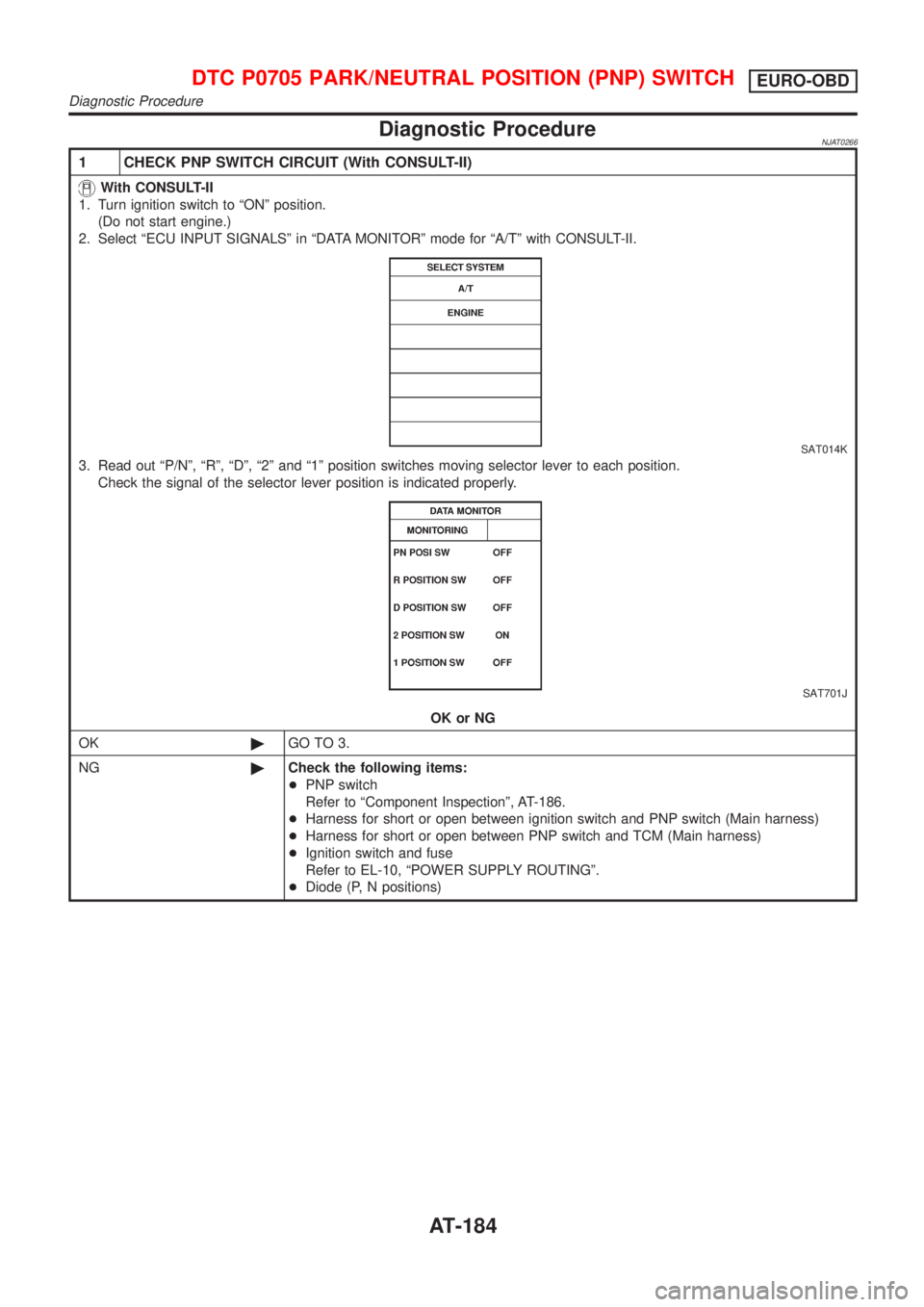

Diagnostic ProcedureNJAT0266

1 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªECU INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

SAT014K

3. Read out ªP/Nº, ªRº, ªDº, ª2º and ª1º position switches moving selector lever to each position.

Check the signal of the selector lever position is indicated properly.

SAT701J

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-186.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL-10, ªPOWER SUPPLY ROUTINGº.

+Diode (P, N positions)

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCHEURO-OBD

Diagnostic Procedure

AT-184

Trending: service reset, Blower, wiper fluid, instrument, rear lam, Headlamp aiming control, jump cable