NISSAN ALMERA N16 2001 Electronic Repair Manual

ALMERA N16 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57351/w960_57351-0.png

NISSAN ALMERA N16 2001 Electronic Repair Manual

Trending: wiper fluid, transmission oil, air conditioner, high beam, gas type, heater, battery

Page 1621 of 2493

SAT356D

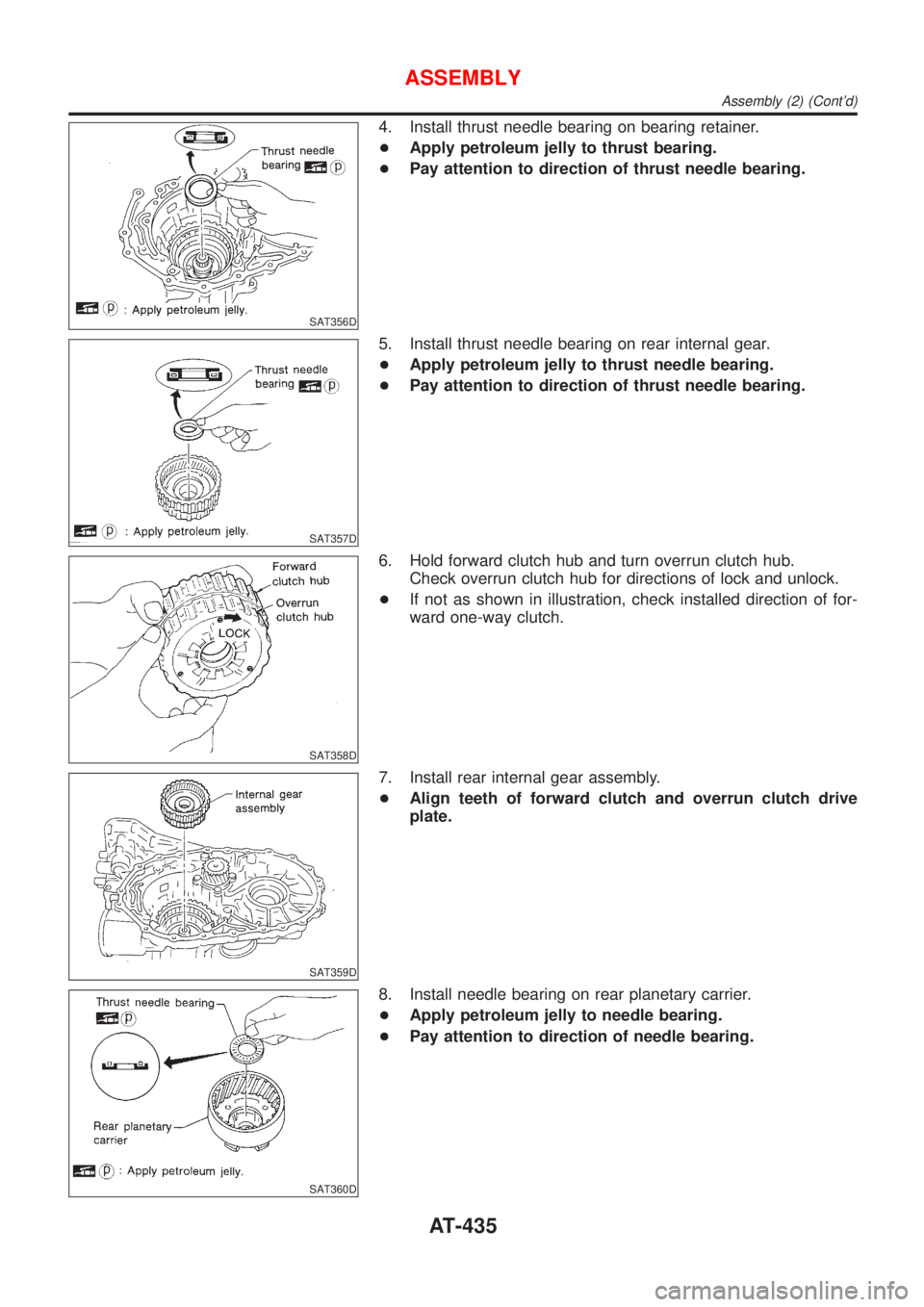

4. Install thrust needle bearing on bearing retainer.

+Apply petroleum jelly to thrust bearing.

+Pay attention to direction of thrust needle bearing.

SAT357D

5. Install thrust needle bearing on rear internal gear.

+Apply petroleum jelly to thrust needle bearing.

+Pay attention to direction of thrust needle bearing.

SAT358D

6. Hold forward clutch hub and turn overrun clutch hub.

Check overrun clutch hub for directions of lock and unlock.

+If not as shown in illustration, check installed direction of for-

ward one-way clutch.

SAT359D

7. Install rear internal gear assembly.

+Align teeth of forward clutch and overrun clutch drive

plate.

SAT360D

8. Install needle bearing on rear planetary carrier.

+Apply petroleum jelly to needle bearing.

+Pay attention to direction of needle bearing.

ASSEMBLY

Assembly (2) (Cont'd)

AT-435

Page 1622 of 2493

SAT052D

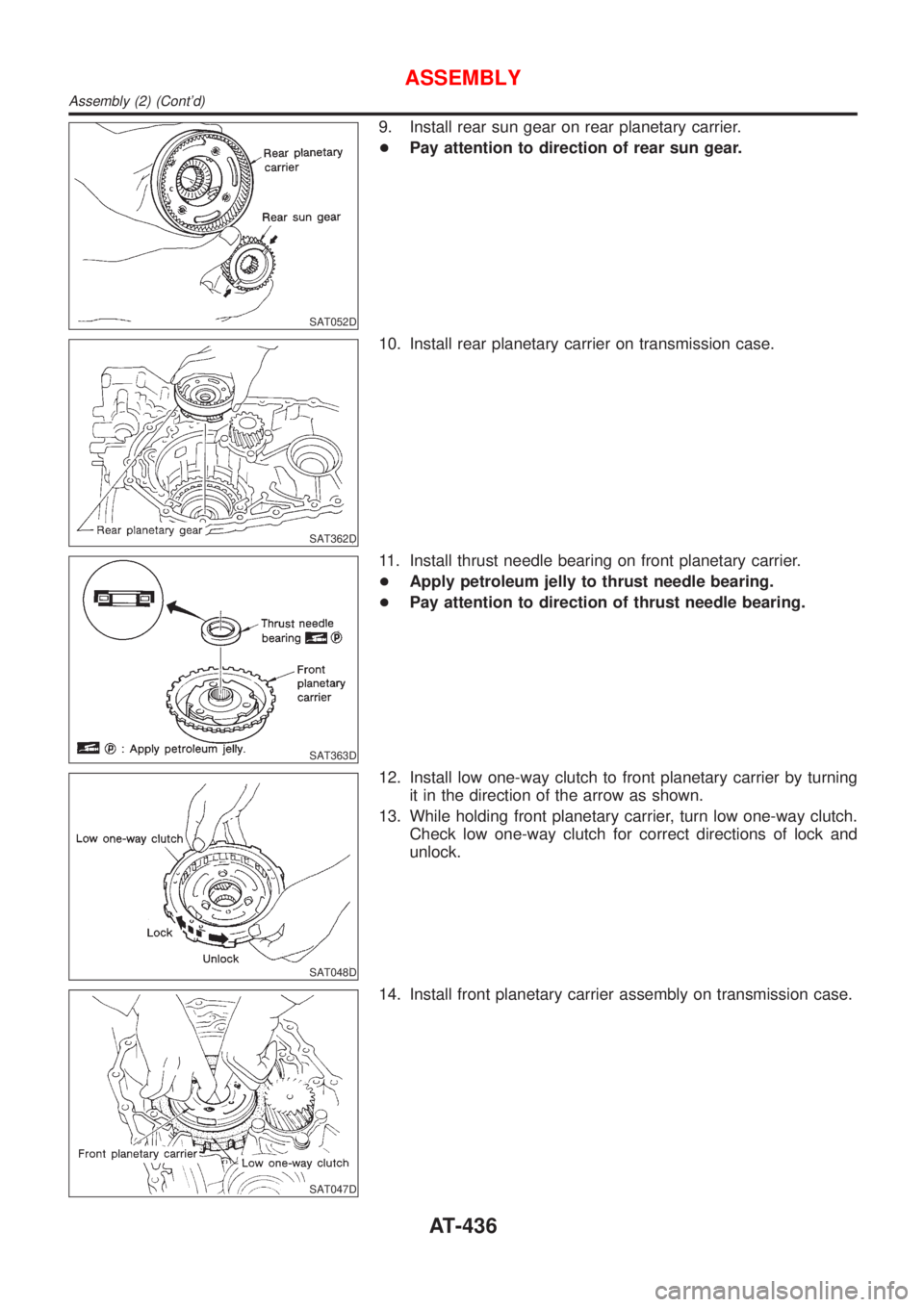

9. Install rear sun gear on rear planetary carrier.

+Pay attention to direction of rear sun gear.

SAT362D

10. Install rear planetary carrier on transmission case.

SAT363D

11. Install thrust needle bearing on front planetary carrier.

+Apply petroleum jelly to thrust needle bearing.

+Pay attention to direction of thrust needle bearing.

SAT048D

12. Install low one-way clutch to front planetary carrier by turning

it in the direction of the arrow as shown.

13. While holding front planetary carrier, turn low one-way clutch.

Check low one-way clutch for correct directions of lock and

unlock.

SAT047D

14. Install front planetary carrier assembly on transmission case.

ASSEMBLY

Assembly (2) (Cont'd)

AT-436

Page 1623 of 2493

SAT046D

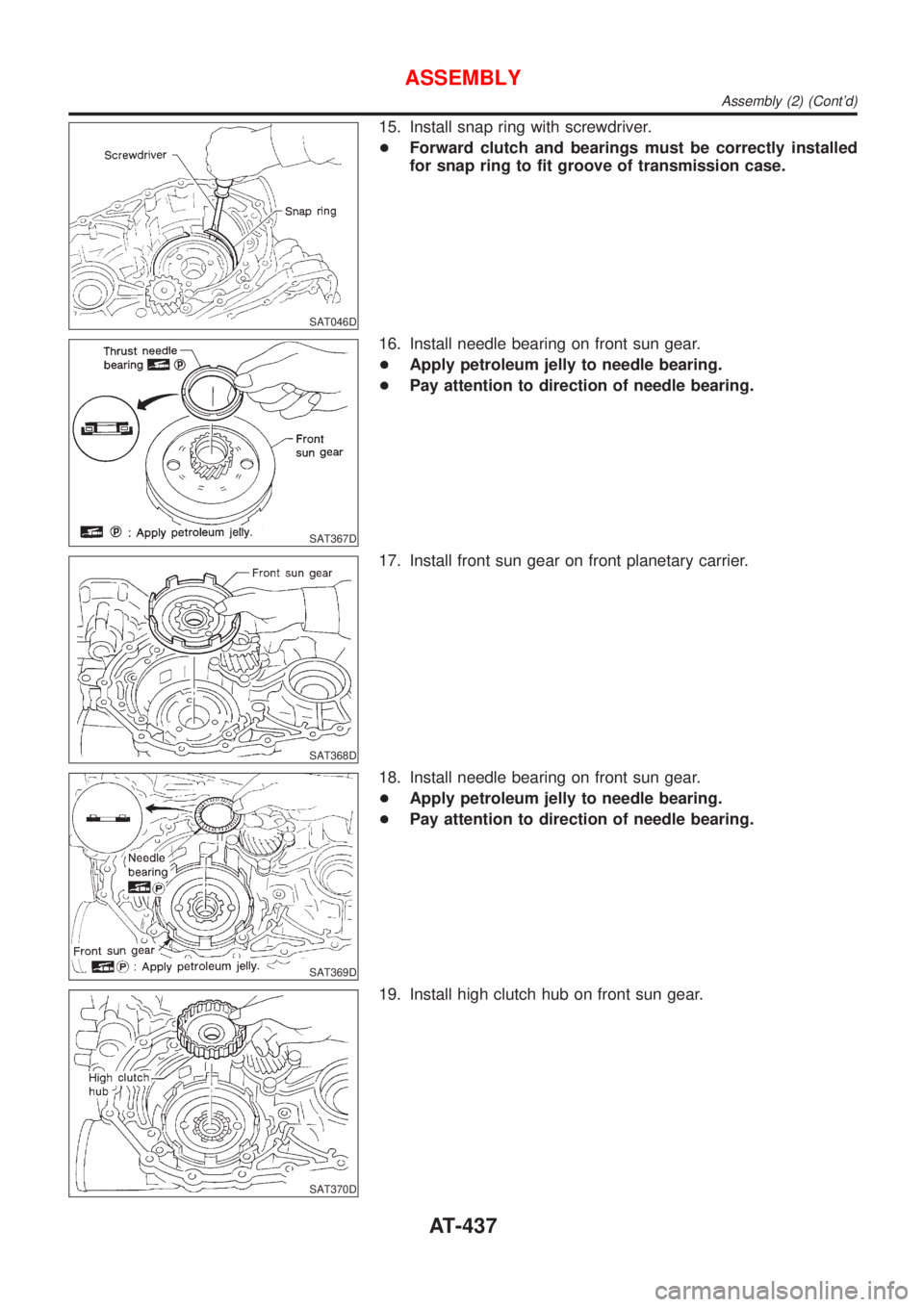

15. Install snap ring with screwdriver.

+Forward clutch and bearings must be correctly installed

for snap ring to fit groove of transmission case.

SAT367D

16. Install needle bearing on front sun gear.

+Apply petroleum jelly to needle bearing.

+Pay attention to direction of needle bearing.

SAT368D

17. Install front sun gear on front planetary carrier.

SAT369D

18. Install needle bearing on front sun gear.

+Apply petroleum jelly to needle bearing.

+Pay attention to direction of needle bearing.

SAT370D

19. Install high clutch hub on front sun gear.

ASSEMBLY

Assembly (2) (Cont'd)

AT-437

Page 1624 of 2493

SAT371D

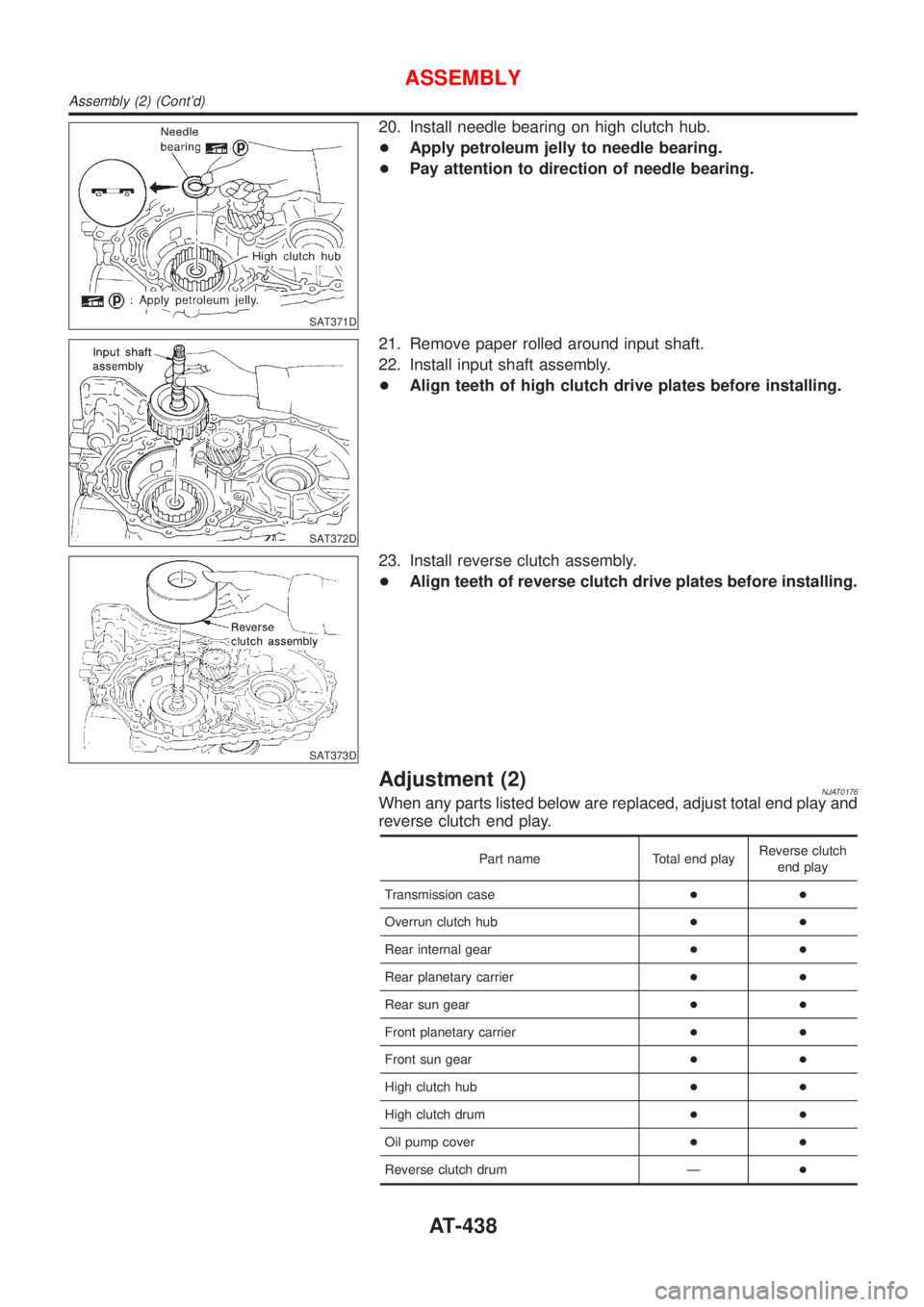

20. Install needle bearing on high clutch hub.

+Apply petroleum jelly to needle bearing.

+Pay attention to direction of needle bearing.

SAT372D

21. Remove paper rolled around input shaft.

22. Install input shaft assembly.

+Align teeth of high clutch drive plates before installing.

SAT373D

23. Install reverse clutch assembly.

+Align teeth of reverse clutch drive plates before installing.

Adjustment (2)NJAT0176When any parts listed below are replaced, adjust total end play and

reverse clutch end play.

Part name Total end playReverse clutch

end play

Transmission case++

Overrun clutch hub++

Rear internal gear++

Rear planetary carrier++

Rear sun gear++

Front planetary carrier++

Front sun gear++

High clutch hub++

High clutch drum++

Oil pump cover++

Reverse clutch drum Ð+

ASSEMBLY

Assembly (2) (Cont'd)

AT-438

Page 1625 of 2493

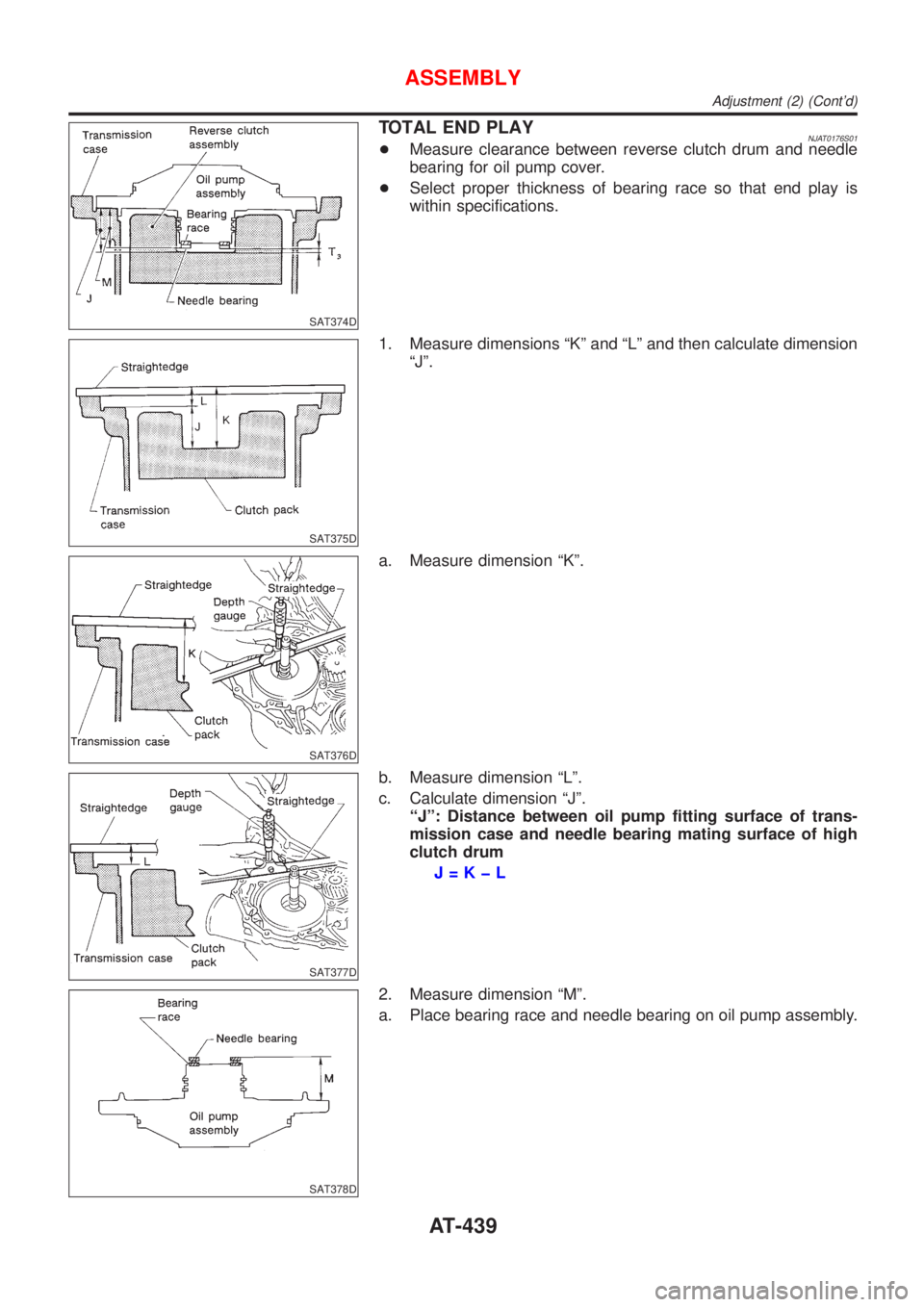

SAT374D

TOTAL END PLAYNJAT0176S01+Measure clearance between reverse clutch drum and needle

bearing for oil pump cover.

+Select proper thickness of bearing race so that end play is

within specifications.

SAT375D

1. Measure dimensions ªKº and ªLº and then calculate dimension

ªJº.

SAT376D

a. Measure dimension ªKº.

SAT377D

b. Measure dimension ªLº.

c. Calculate dimension ªJº.

ªJº: Distance between oil pump fitting surface of trans-

mission case and needle bearing mating surface of high

clutch drum

J=KþL

SAT378D

2. Measure dimension ªMº.

a. Place bearing race and needle bearing on oil pump assembly.

ASSEMBLY

Adjustment (2) (Cont'd)

AT-439

Page 1626 of 2493

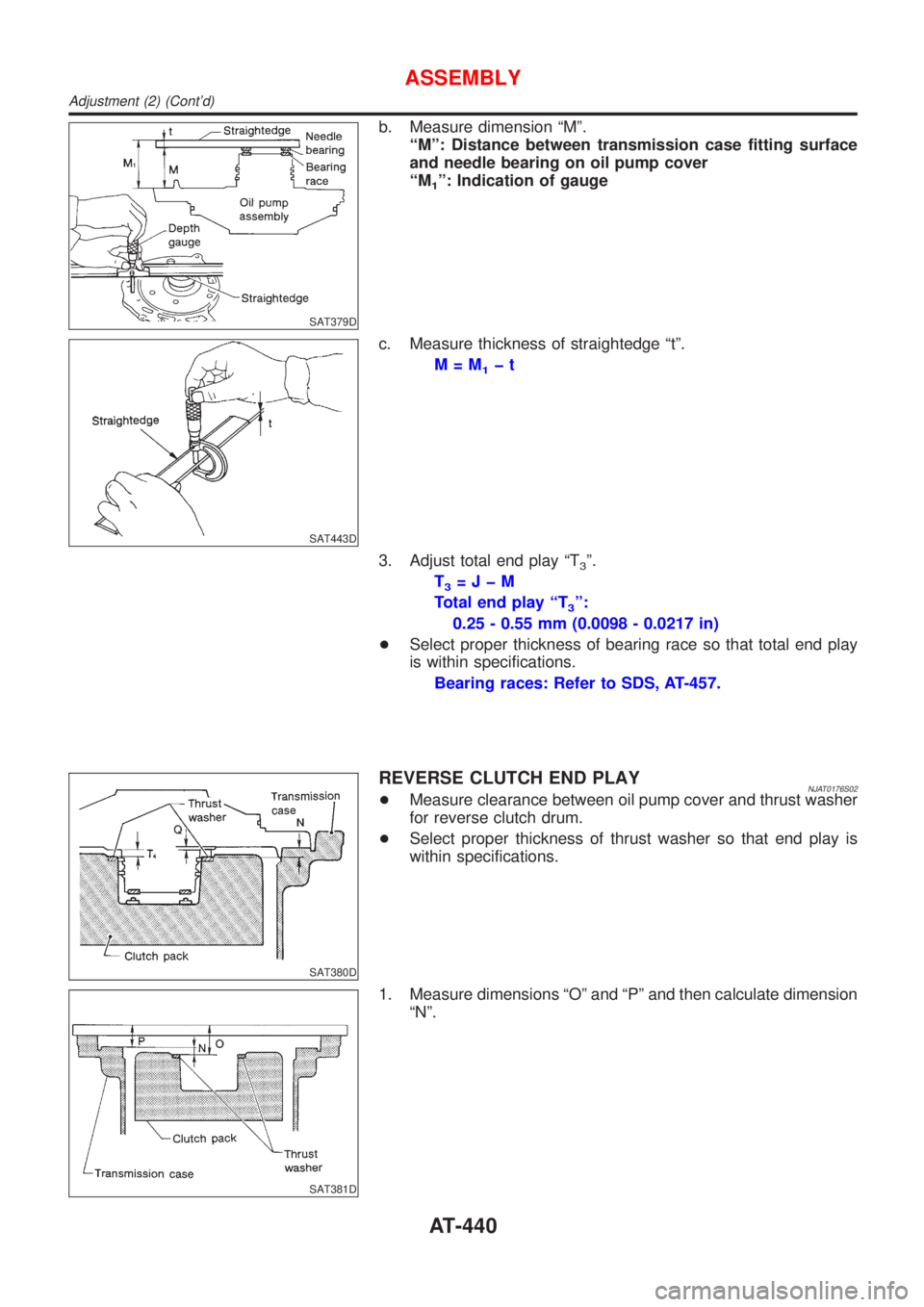

SAT379D

b. Measure dimension ªMº.

ªMº: Distance between transmission case fitting surface

and needle bearing on oil pump cover

ªM

1º: Indication of gauge

SAT443D

c. Measure thickness of straightedge ªtº.

M=M

1þt

3. Adjust total end play ªT

3º.

T

3=JþM

Total end play ªT

3º:

0.25 - 0.55 mm (0.0098 - 0.0217 in)

+Select proper thickness of bearing race so that total end play

is within specifications.

Bearing races: Refer to SDS, AT-457.

SAT380D

REVERSE CLUTCH END PLAYNJAT0176S02+Measure clearance between oil pump cover and thrust washer

for reverse clutch drum.

+Select proper thickness of thrust washer so that end play is

within specifications.

SAT381D

1. Measure dimensions ªOº and ªPº and then calculate dimension

ªNº.

ASSEMBLY

Adjustment (2) (Cont'd)

AT-440

Page 1627 of 2493

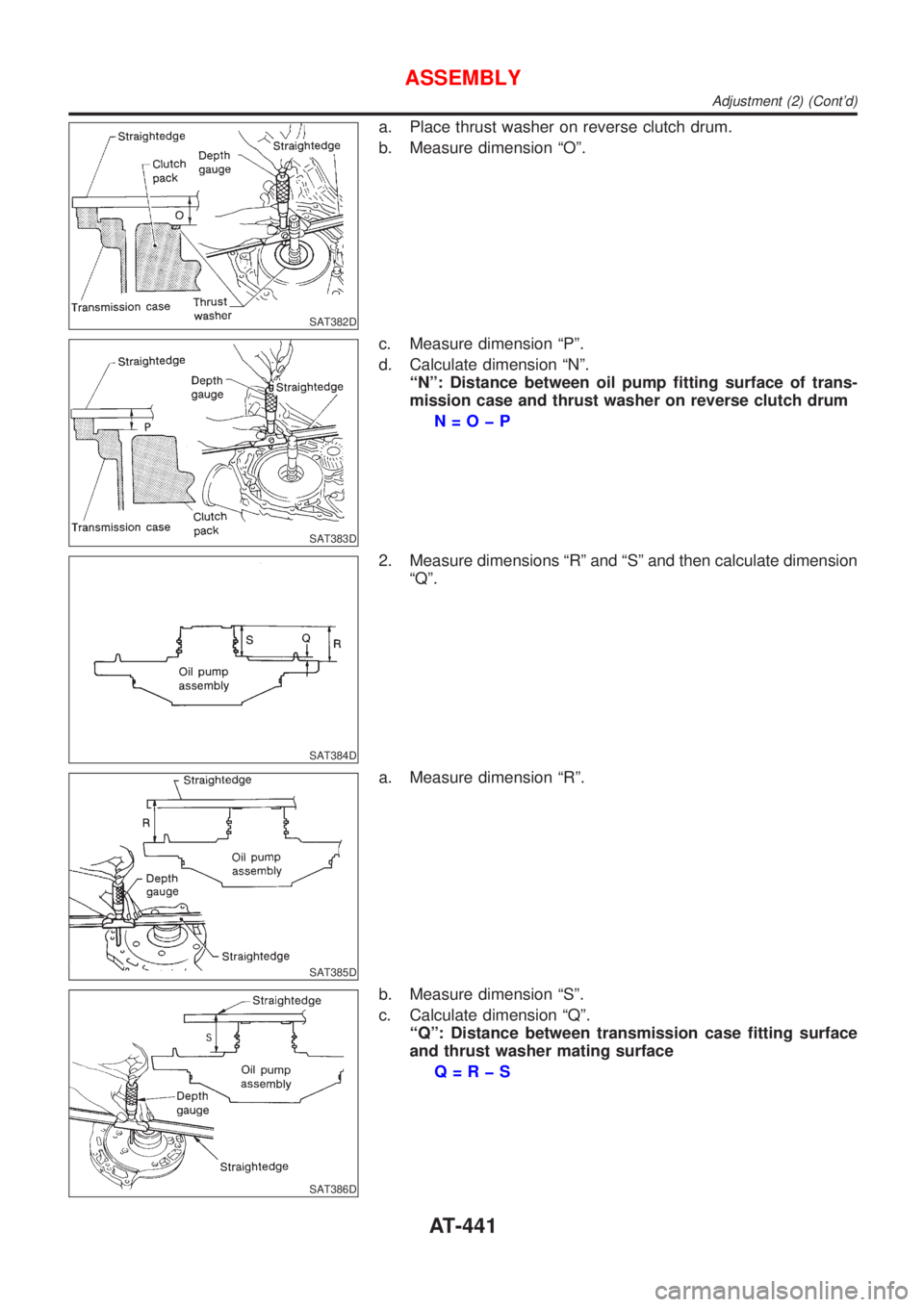

SAT382D

a. Place thrust washer on reverse clutch drum.

b. Measure dimension ªOº.

SAT383D

c. Measure dimension ªPº.

d. Calculate dimension ªNº.

ªNº: Distance between oil pump fitting surface of trans-

mission case and thrust washer on reverse clutch drum

N=OþP

SAT384D

2. Measure dimensions ªRº and ªSº and then calculate dimension

ªQº.

SAT385D

a. Measure dimension ªRº.

SAT386D

b. Measure dimension ªSº.

c. Calculate dimension ªQº.

ªQº: Distance between transmission case fitting surface

and thrust washer mating surface

Q=RþS

ASSEMBLY

Adjustment (2) (Cont'd)

AT-441

Page 1628 of 2493

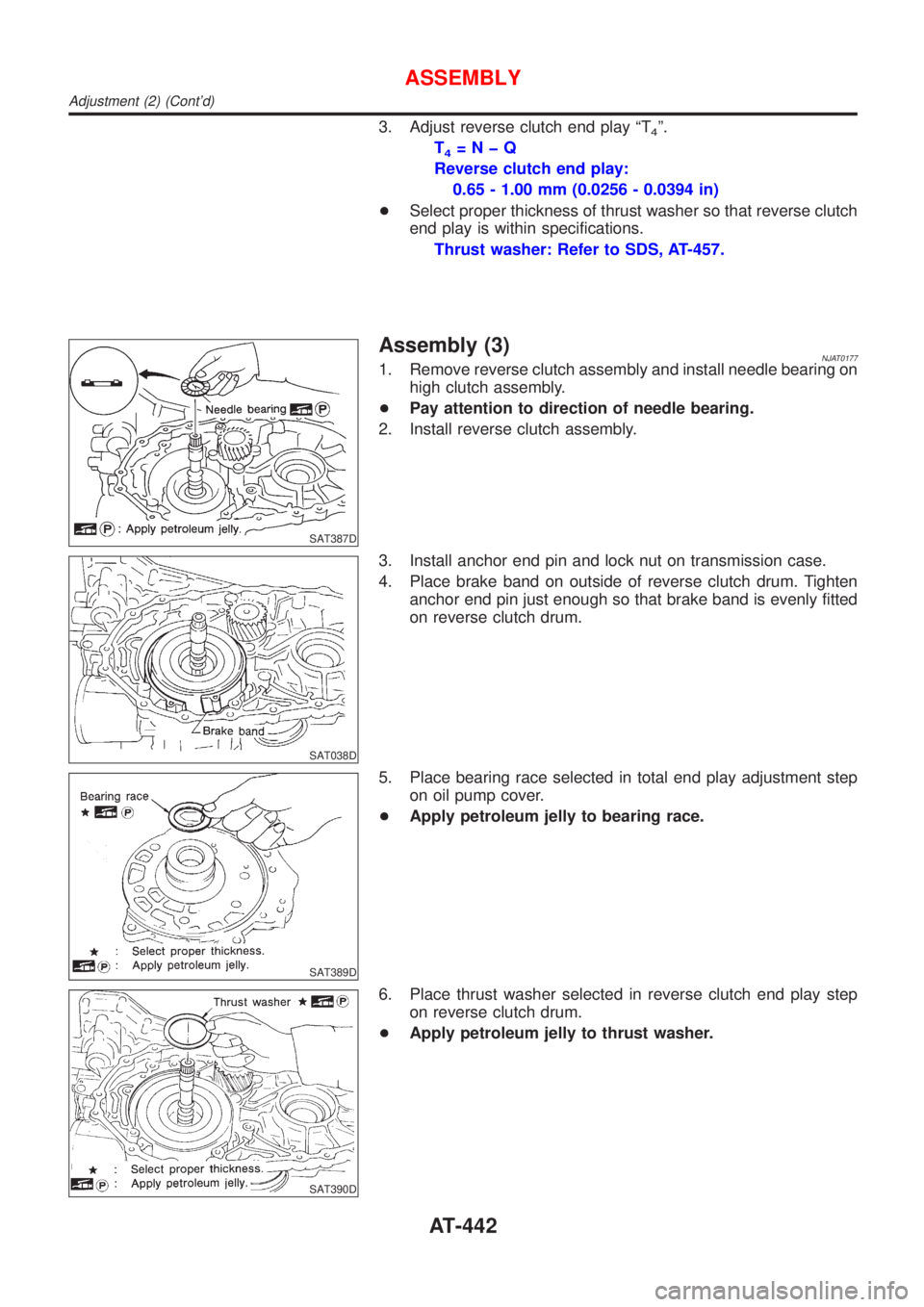

3. Adjust reverse clutch end play ªT4º.

T

4=NþQ

Reverse clutch end play:

0.65 - 1.00 mm (0.0256 - 0.0394 in)

+Select proper thickness of thrust washer so that reverse clutch

end play is within specifications.

Thrust washer: Refer to SDS, AT-457.

SAT387D

Assembly (3)NJAT01771. Remove reverse clutch assembly and install needle bearing on

high clutch assembly.

+Pay attention to direction of needle bearing.

2. Install reverse clutch assembly.

SAT038D

3. Install anchor end pin and lock nut on transmission case.

4. Place brake band on outside of reverse clutch drum. Tighten

anchor end pin just enough so that brake band is evenly fitted

on reverse clutch drum.

SAT389D

5. Place bearing race selected in total end play adjustment step

on oil pump cover.

+Apply petroleum jelly to bearing race.

SAT390D

6. Place thrust washer selected in reverse clutch end play step

on reverse clutch drum.

+Apply petroleum jelly to thrust washer.

ASSEMBLY

Adjustment (2) (Cont'd)

AT-442

Page 1629 of 2493

SAT391D

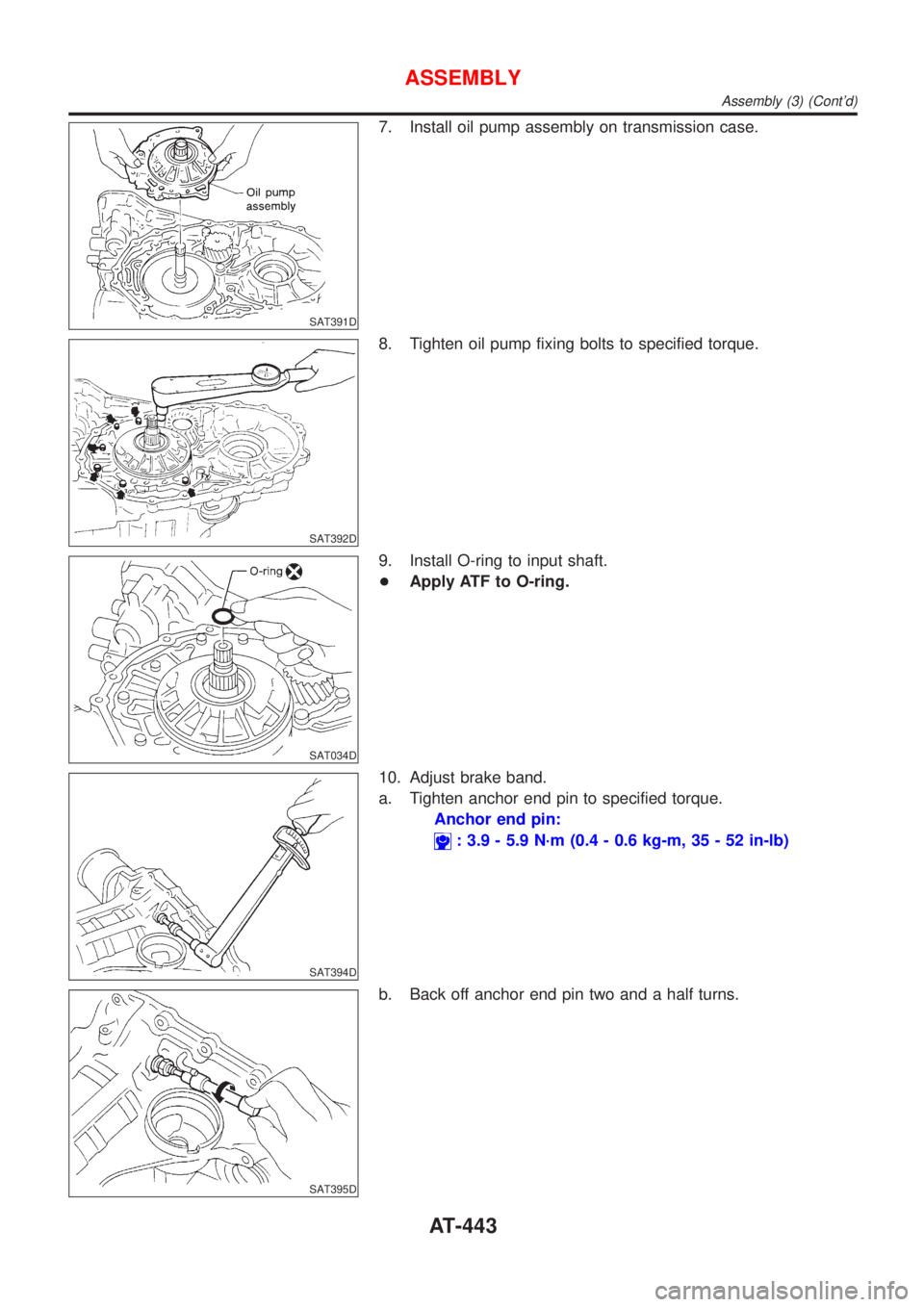

7. Install oil pump assembly on transmission case.

SAT392D

8. Tighten oil pump fixing bolts to specified torque.

SAT034D

9. Install O-ring to input shaft.

+Apply ATF to O-ring.

SAT394D

10. Adjust brake band.

a. Tighten anchor end pin to specified torque.

Anchor end pin:

: 3.9 - 5.9 N´m (0.4 - 0.6 kg-m, 35 - 52 in-lb)

SAT395D

b. Back off anchor end pin two and a half turns.

ASSEMBLY

Assembly (3) (Cont'd)

AT-443

Page 1630 of 2493

SAT396D

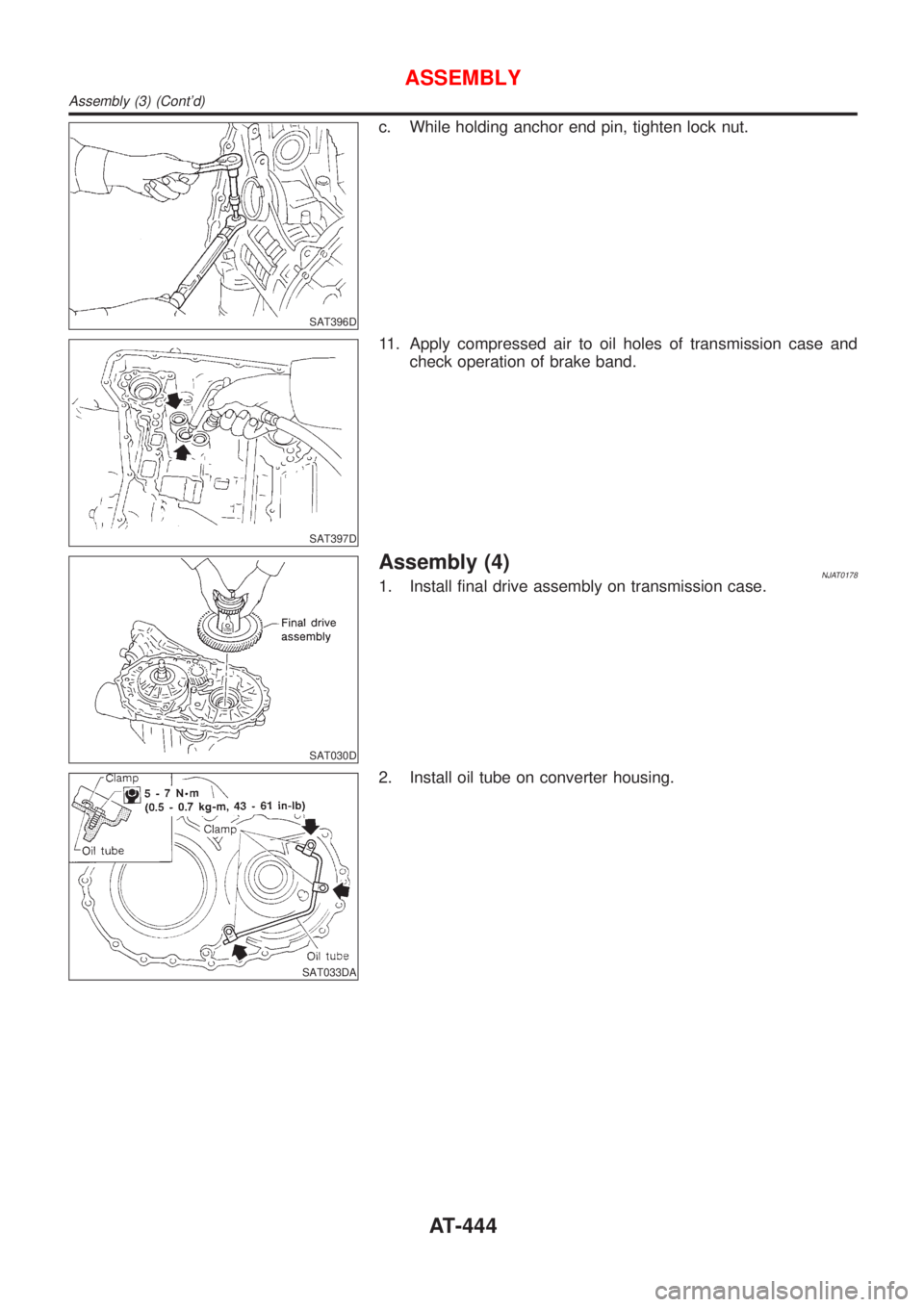

c. While holding anchor end pin, tighten lock nut.

SAT397D

11. Apply compressed air to oil holes of transmission case and

check operation of brake band.

SAT030D

Assembly (4)NJAT01781. Install final drive assembly on transmission case.

SAT033DA

2. Install oil tube on converter housing.

ASSEMBLY

Assembly (3) (Cont'd)

AT-444

Trending: Thermo, overheating, P1690, wiper size, EC-451, refrigerant type, Rad fan