NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1971 of 2493

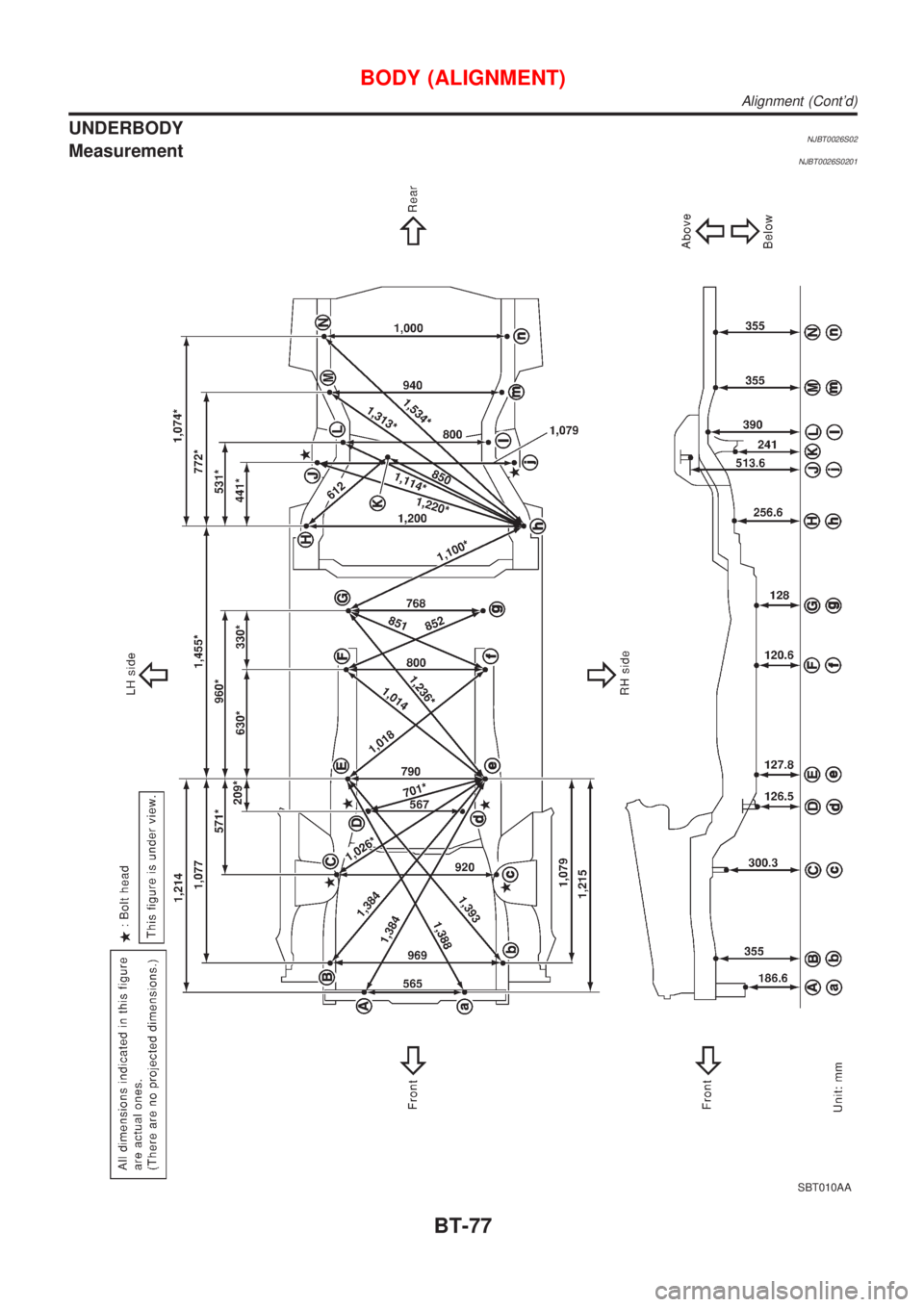

UNDERBODYNJBT0026S02MeasurementNJBT0026S0201

SBT010AA

BODY (ALIGNMENT)

Alignment (Cont'd)

BT-77

Page 1972 of 2493

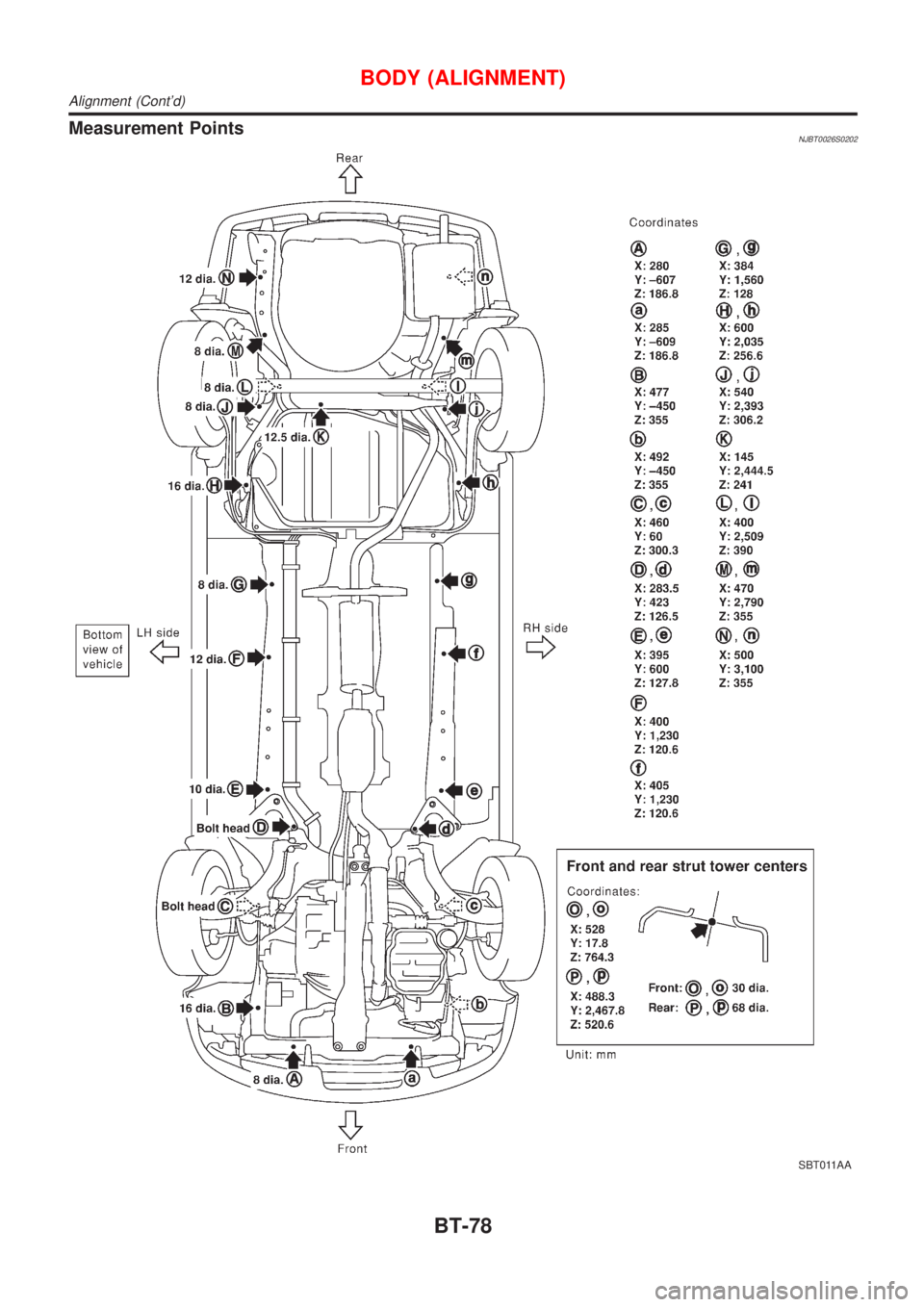

Measurement PointsNJBT0026S0202

SBT011AA

BODY (ALIGNMENT)

Alignment (Cont'd)

BT-78

Page 1973 of 2493

HEATER &

AIR CONDITIONER

SECTION

HA

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Precautions for Working with HFC-134a (R-134a) .....2

General Refrigerant Precautions .................................2

Precautions for Refrigerant Connection ......................3

Precautions for Servicing Compressor ........................5

Precautions for Service Equipment .............................6

Wiring Diagrams and Trouble Diagnosis .....................8

PREPARATION...............................................................9

Special Service Tools ..................................................9

HFC-134a (R-134a) Service Tools and

Equipment .................................................................. 11

DESCRIPTION...............................................................13

Refrigeration System .................................................13

CSV613 Variable Displacement Compressor............14

Component Layout ....................................................18

Control Operation ......................................................19

Discharge Air Flow.....................................................20

System Description ....................................................21

TROUBLE DIAGNOSES................................................22

Component Location..................................................22

Wiring Diagram - Heater............................................24

Circuit Diagram - Air Conditioner...............................26

Wiring Diagram - A/C, M - .........................................27

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................39

Operational Check .....................................................40

Intake Door ................................................................42

Mode Door .................................................................46Air Mix Door ...............................................................48

Max Hot Door (For Scandinavia and Cold Spec

Models) ......................................................................50

Blower Motor..............................................................54

Magnet Clutch............................................................61

Insufficient Cooling ....................................................74

Insufficient Heating ....................................................82

Noise ..........................................................................83

SERVICE PROCEDURE................................................84

HFC-134a (R-134a) Service Procedure ....................84

Maintenance of Lubricant Quantity in

Compressor ...............................................................86

Compressor ...............................................................89

Compressor Clutch - CSV613 (CALSONIC

make) .........................................................................90

Heater & Cooling Unit (Heater Core) ........................94

A/C Evaporator ..........................................................94

Blower Unit ................................................................95

Refrigerant Lines .......................................................97

Belt ...........................................................................101

Idle Air Control Valve (IACV) - Auxiliary Air

Control (AAC) Valve ................................................102

Ventilation Air Filter ..................................................102

SERVICE DATA AND SPECIFICATIONS (SDS).......103

Compressor .............................................................103

Lubricant ..................................................................103

Refrigerant ...............................................................103

Engine Idling Speed (When A/C is On)...................103

Belt Tension .............................................................103

Page 1974 of 2493

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NJHA0190The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL N16 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Working with HFC-134a

(R-134a)

NJHA0113WARNING:

+CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. These refrigerants

must never be mixed, even in the smallest amounts. If the refrigerants are mixed, compressor fail-

ure is likely to occur.

+Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor failure is likely to occur.

+The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

a) When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

b) When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as pos-

sible to minimize the entry of moisture into system.

c) Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

d) Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose

and throat. Remove R-134a from the A/C system, using certified service equipment meeting

requirements of R-134a recycling equipment, or R-134a recovery equipment. If accidental system

discharge occurs, ventilate work area before resuming service. Additional health and safety

information may be obtained from refrigerant and lubricant manufacturers.

e) Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

General Refrigerant PrecautionsNJHA0114WARNING:

+Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

+Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

HA-2

Page 1975 of 2493

+Do not store or heat refrigerant containers above 52ÉC (125ÉF).

+Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

+Do not intentionally drop, puncture, or incinerate refrigerant containers.

+Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

+Refrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

+Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and R-134a have been

shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional health and safety information may be obtained from refrigerant manu-

facturers.

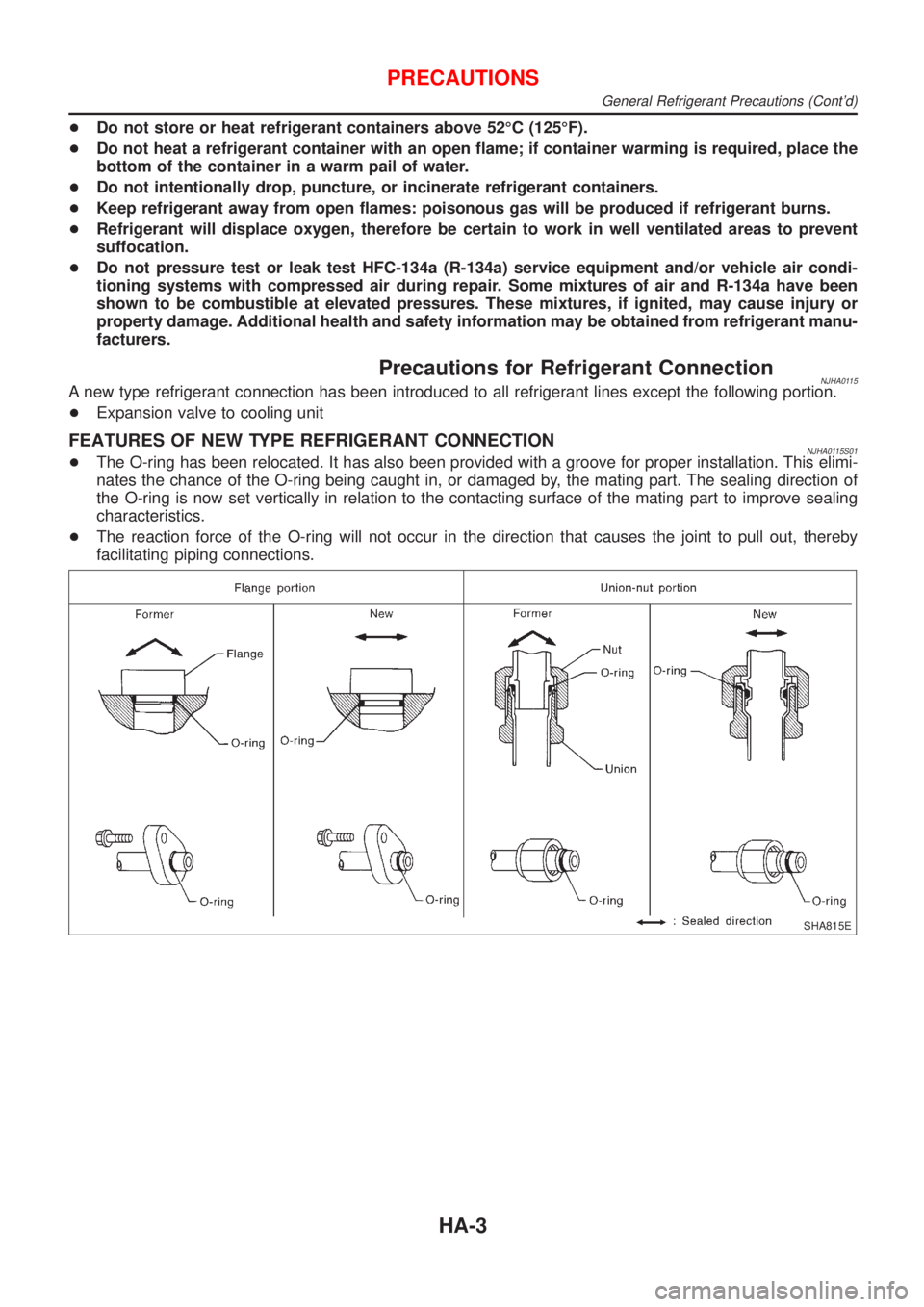

Precautions for Refrigerant ConnectionNJHA0115A new type refrigerant connection has been introduced to all refrigerant lines except the following portion.

+Expansion valve to cooling unit

FEATURES OF NEW TYPE REFRIGERANT CONNECTIONNJHA0115S01+The O-ring has been relocated. It has also been provided with a groove for proper installation. This elimi-

nates the chance of the O-ring being caught in, or damaged by, the mating part. The sealing direction of

the O-ring is now set vertically in relation to the contacting surface of the mating part to improve sealing

characteristics.

+The reaction force of the O-ring will not occur in the direction that causes the joint to pull out, thereby

facilitating piping connections.

SHA815E

PRECAUTIONS

General Refrigerant Precautions (Cont'd)

HA-3

Page 1976 of 2493

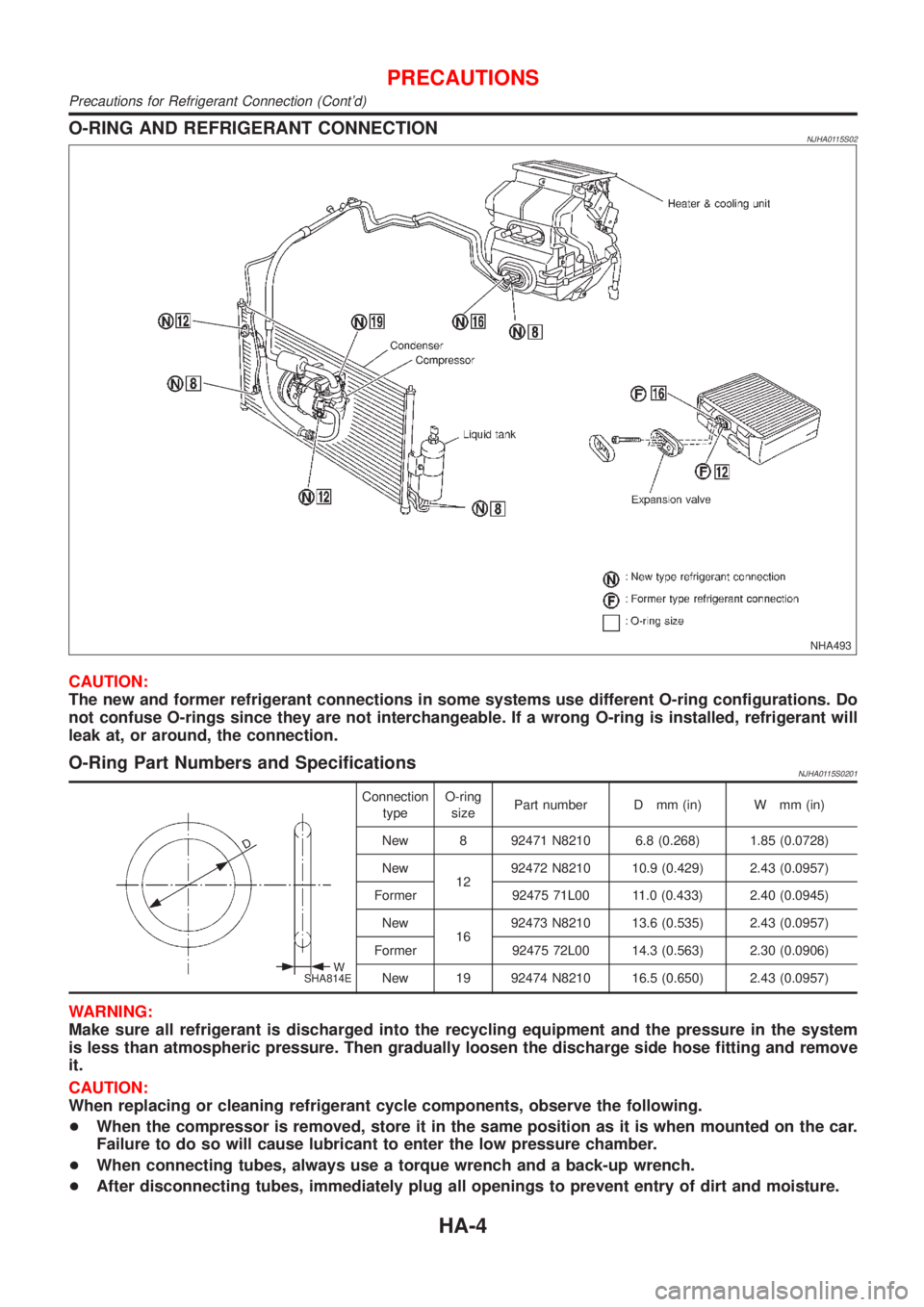

O-RING AND REFRIGERANT CONNECTIONNJHA0115S02

NHA493

CAUTION:

The new and former refrigerant connections in some systems use different O-ring configurations. Do

not confuse O-rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will

leak at, or around, the connection.

O-Ring Part Numbers and SpecificationsNJHA0115S0201

SHA814E

Connection

typeO-ring

sizePart number D mm (in) W mm (in)

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

New

1292472 N8210 10.9 (0.429) 2.43 (0.0957)

Former 92475 71L00 11.0 (0.433) 2.40 (0.0945)

New

1692473 N8210 13.6 (0.535) 2.43 (0.0957)

Former 92475 72L00 14.3 (0.563) 2.30 (0.0906)

New 19 92474 N8210 16.5 (0.650) 2.43 (0.0957)

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system

is less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove

it.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

+When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

+When connecting tubes, always use a torque wrench and a back-up wrench.

+After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-4

Page 1977 of 2493

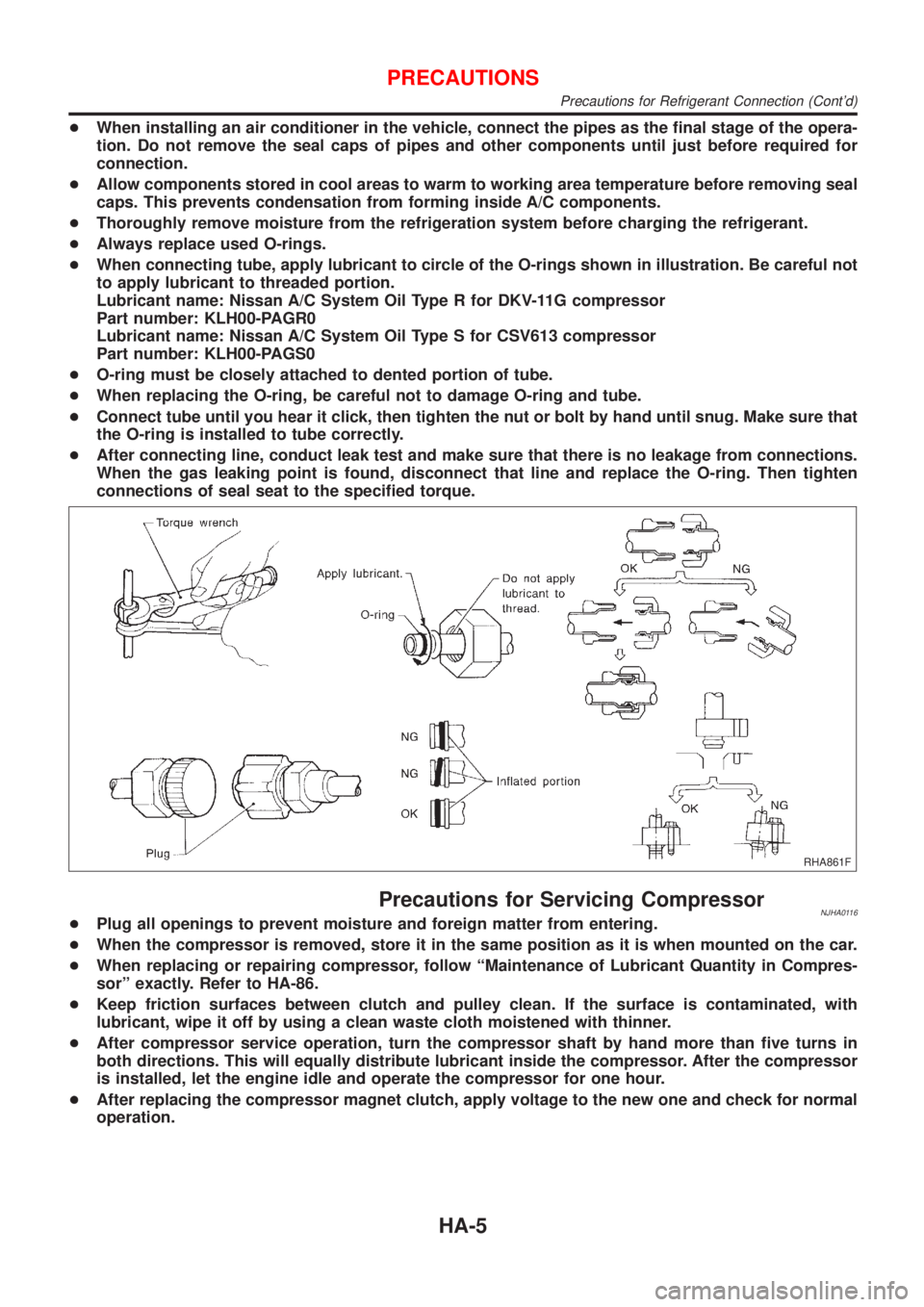

+When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

+Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

+Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

+Always replace used O-rings.

+When connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type R for DKV-11G compressor

Part number: KLH00-PAGR0

Lubricant name: Nissan A/C System Oil Type S for CSV613 compressor

Part number: KLH00-PAGS0

+O-ring must be closely attached to dented portion of tube.

+When replacing the O-ring, be careful not to damage O-ring and tube.

+Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

+After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNJHA0116+Plug all openings to prevent moisture and foreign matter from entering.

+When the compressor is removed, store it in the same position as it is when mounted on the car.

+When replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-86.

+Keep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

+After compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

+After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-5

Page 1978 of 2493

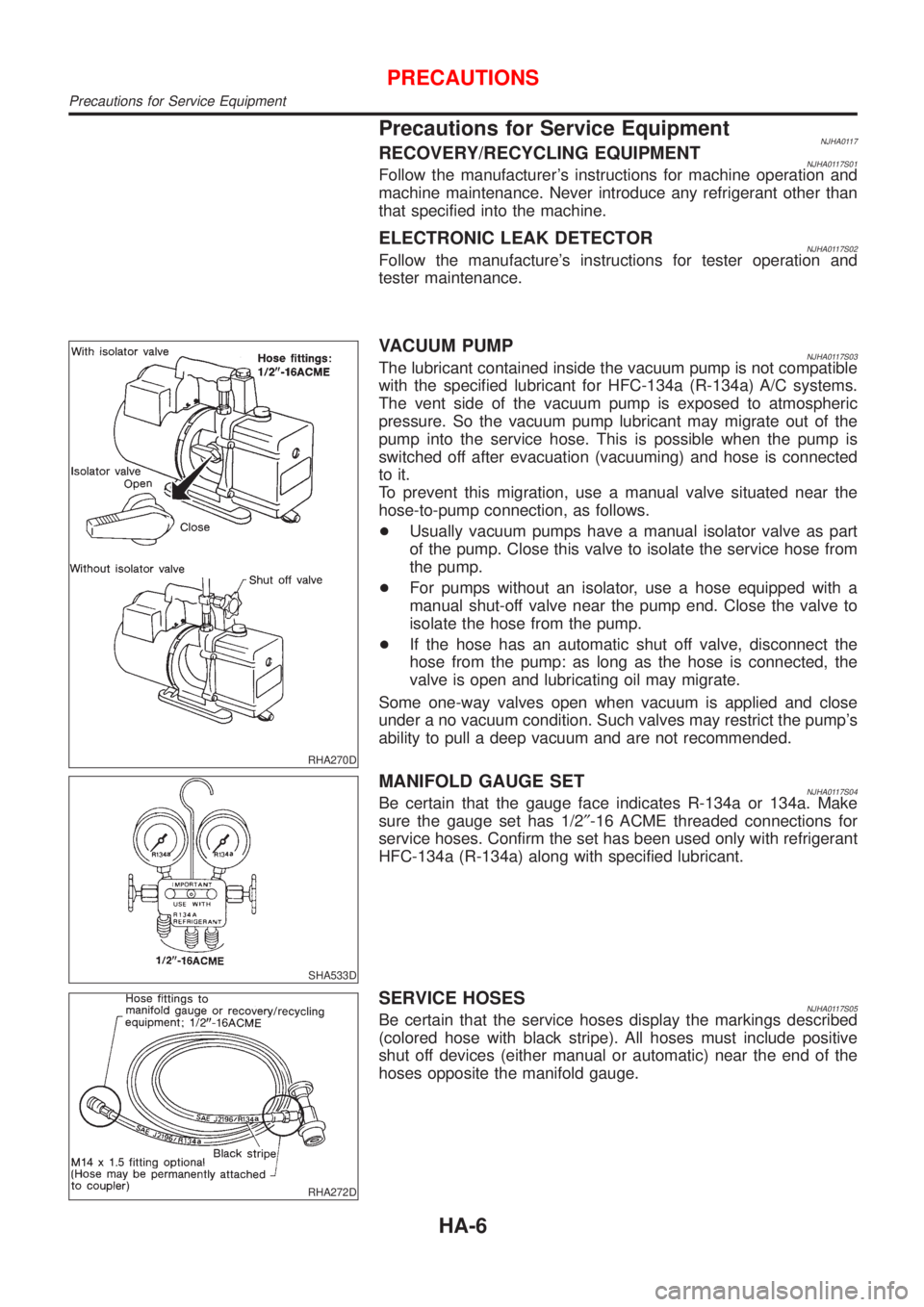

Precautions for Service EquipmentNJHA0117RECOVERY/RECYCLING EQUIPMENTNJHA0117S01Follow the manufacturer's instructions for machine operation and

machine maintenance. Never introduce any refrigerant other than

that specified into the machine.

ELECTRONIC LEAK DETECTORNJHA0117S02Follow the manufacture's instructions for tester operation and

tester maintenance.

RHA270D

VACUUM PUMPNJHA0117S03The lubricant contained inside the vacuum pump is not compatible

with the specified lubricant for HFC-134a (R-134a) A/C systems.

The vent side of the vacuum pump is exposed to atmospheric

pressure. So the vacuum pump lubricant may migrate out of the

pump into the service hose. This is possible when the pump is

switched off after evacuation (vacuuming) and hose is connected

to it.

To prevent this migration, use a manual valve situated near the

hose-to-pump connection, as follows.

+Usually vacuum pumps have a manual isolator valve as part

of the pump. Close this valve to isolate the service hose from

the pump.

+For pumps without an isolator, use a hose equipped with a

manual shut-off valve near the pump end. Close the valve to

isolate the hose from the pump.

+If the hose has an automatic shut off valve, disconnect the

hose from the pump: as long as the hose is connected, the

valve is open and lubricating oil may migrate.

Some one-way valves open when vacuum is applied and close

under a no vacuum condition. Such valves may restrict the pump's

ability to pull a deep vacuum and are not recommended.

SHA533D

MANIFOLD GAUGE SETNJHA0117S04Be certain that the gauge face indicates R-134a or 134a. Make

sure the gauge set has 1/2²-16 ACME threaded connections for

service hoses. Confirm the set has been used only with refrigerant

HFC-134a (R-134a) along with specified lubricant.

RHA272D

SERVICE HOSESNJHA0117S05Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive

shut off devices (either manual or automatic) near the end of the

hoses opposite the manifold gauge.

PRECAUTIONS

Precautions for Service Equipment

HA-6

Page 1979 of 2493

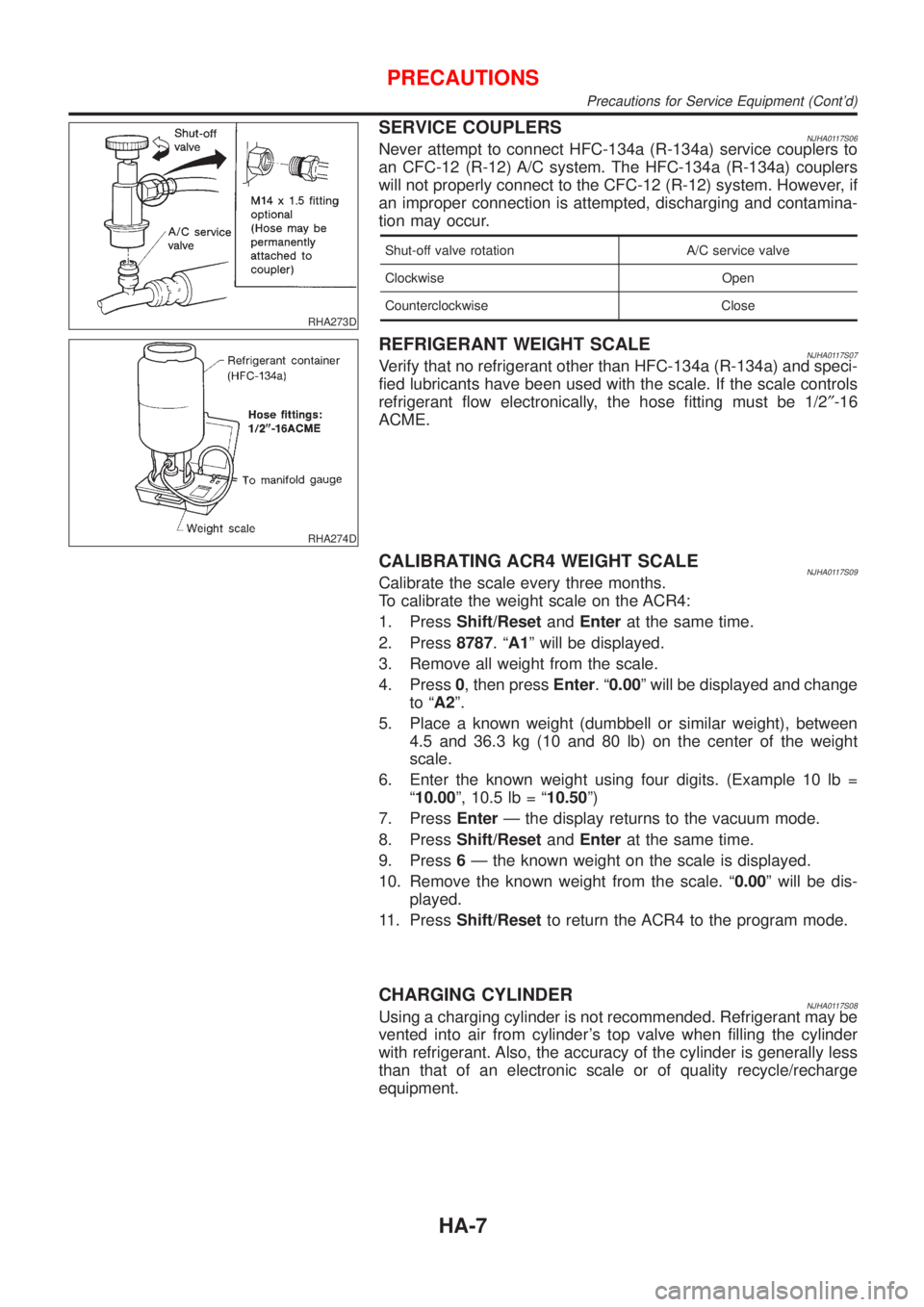

RHA273D

SERVICE COUPLERSNJHA0117S06Never attempt to connect HFC-134a (R-134a) service couplers to

an CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers

will not properly connect to the CFC-12 (R-12) system. However, if

an improper connection is attempted, discharging and contamina-

tion may occur.

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA274D

REFRIGERANT WEIGHT SCALENJHA0117S07Verify that no refrigerant other than HFC-134a (R-134a) and speci-

fied lubricants have been used with the scale. If the scale controls

refrigerant flow electronically, the hose fitting must be 1/2²-16

ACME.

CALIBRATING ACR4 WEIGHT SCALENJHA0117S09Calibrate the scale every three months.

To calibrate the weight scale on the ACR4:

1. PressShift/ResetandEnterat the same time.

2. Press8787.ªA1º will be displayed.

3. Remove all weight from the scale.

4. Press0, then pressEnter.ª0.00º will be displayed and change

to ªA2º.

5. Place a known weight (dumbbell or similar weight), between

4.5 and 36.3 kg (10 and 80 lb) on the center of the weight

scale.

6. Enter the known weight using four digits. (Example 10 lb =

ª10.00º, 10.5 lb = ª10.50º)

7. PressEnterÐ the display returns to the vacuum mode.

8. PressShift/ResetandEnterat the same time.

9. Press6Ð the known weight on the scale is displayed.

10. Remove the known weight from the scale. ª0.00º will be dis-

played.

11. PressShift/Resetto return the ACR4 to the program mode.

CHARGING CYLINDERNJHA0117S08Using a charging cylinder is not recommended. Refrigerant may be

vented into air from cylinder's top valve when filling the cylinder

with refrigerant. Also, the accuracy of the cylinder is generally less

than that of an electronic scale or of quality recycle/recharge

equipment.

PRECAUTIONS

Precautions for Service Equipment (Cont'd)

HA-7

Page 1980 of 2493

Wiring Diagrams and Trouble DiagnosisNJHA0118When you read wiring diagrams, refer to the following:

+GI-12, ªHOW TO READ WIRING DIAGRAMSº

+Sedan: EL-23 (QG), EL-0 (YD), Hatchback: EL-12, ªWiring

Diagram РPOWER к.

When you perform trouble diagnosis, refer to the following:

+GI-32, ªHOW TO FOLLOW TROUBLE DIAGNOSESº

+GI-21, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENTº

PRECAUTIONS

Wiring Diagrams and Trouble Diagnosis

HA-8