brake NISSAN ALMERA N16 2001 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 789 of 2493

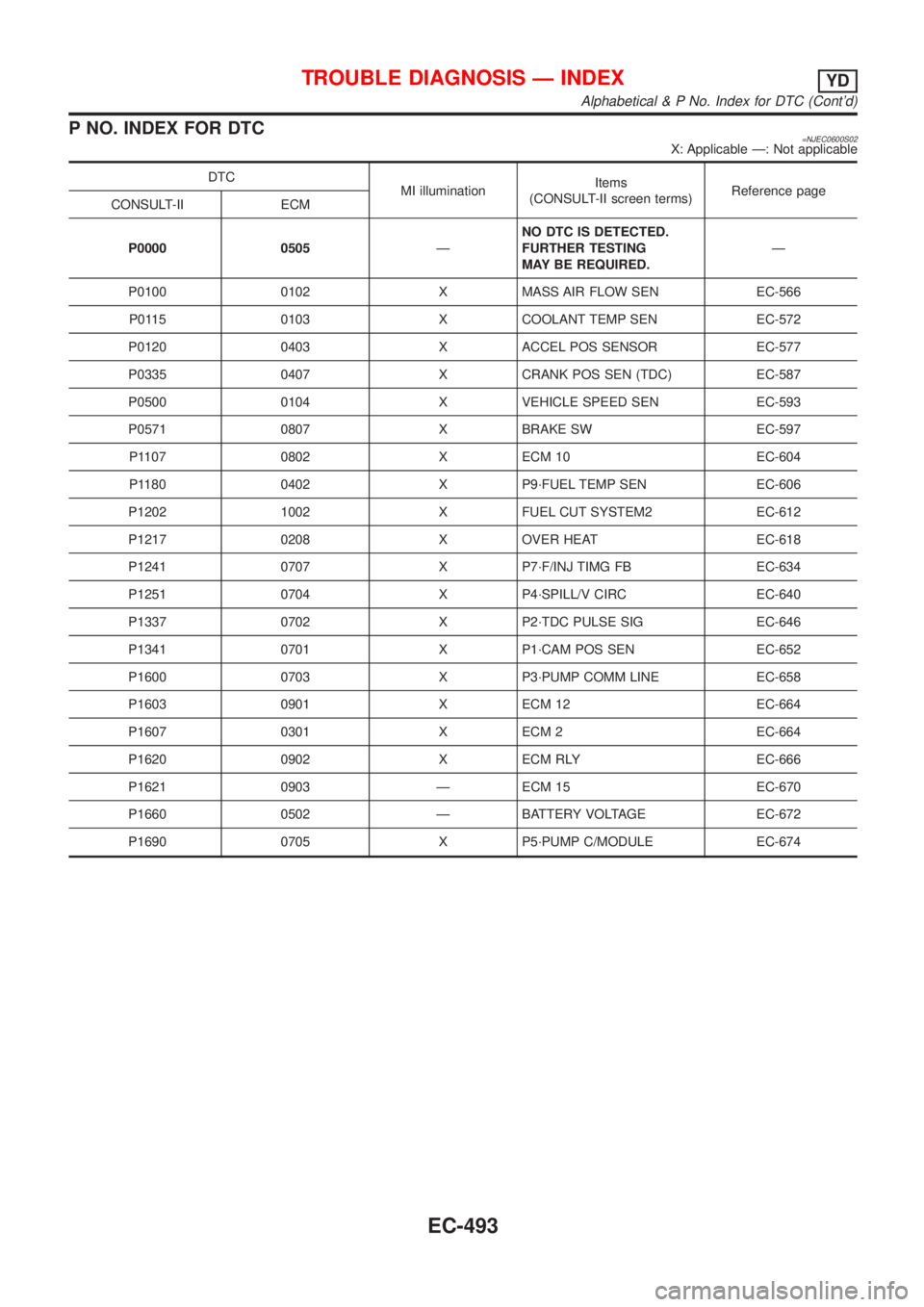

P NO. INDEX FOR DTC=NJEC0600S02X: Applicable Ð: Not applicable

DTC

MI illuminationItems

(CONSULT-II screen terms)Reference page

CONSULT-II ECM

P0000 0505ÐNO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.Ð

P0100 0102 X MASS AIR FLOW SEN EC-566

P0115 0103 X COOLANT TEMP SEN EC-572

P0120 0403 X ACCEL POS SENSOR EC-577

P0335 0407 X CRANK POS SEN (TDC) EC-587

P0500 0104 X VEHICLE SPEED SEN EC-593

P0571 0807 X BRAKE SW EC-597

P1107 0802 X ECM 10 EC-604

P1180 0402 X P9´FUEL TEMP SEN EC-606

P1202 1002 X FUEL CUT SYSTEM2 EC-612

P1217 0208 X OVER HEAT EC-618

P1241 0707 X P7´F/INJ TIMG FB EC-634

P1251 0704 X P4´SPILL/V CIRC EC-640

P1337 0702 X P2´TDC PULSE SIG EC-646

P1341 0701 X P1´CAM POS SEN EC-652

P1600 0703 X P3´PUMP COMM LINE EC-658

P1603 0901 X ECM 12 EC-664

P1607 0301 X ECM 2 EC-664

P1620 0902 X ECM RLY EC-666

P1621 0903 Ð ECM 15 EC-670

P1660 0502 Ð BATTERY VOLTAGE EC-672

P1690 0705 X P5´PUMP C/MODULE EC-674

TROUBLE DIAGNOSIS Ð INDEXYD

Alphabetical & P No. Index for DTC (Cont'd)

EC-493

Page 816 of 2493

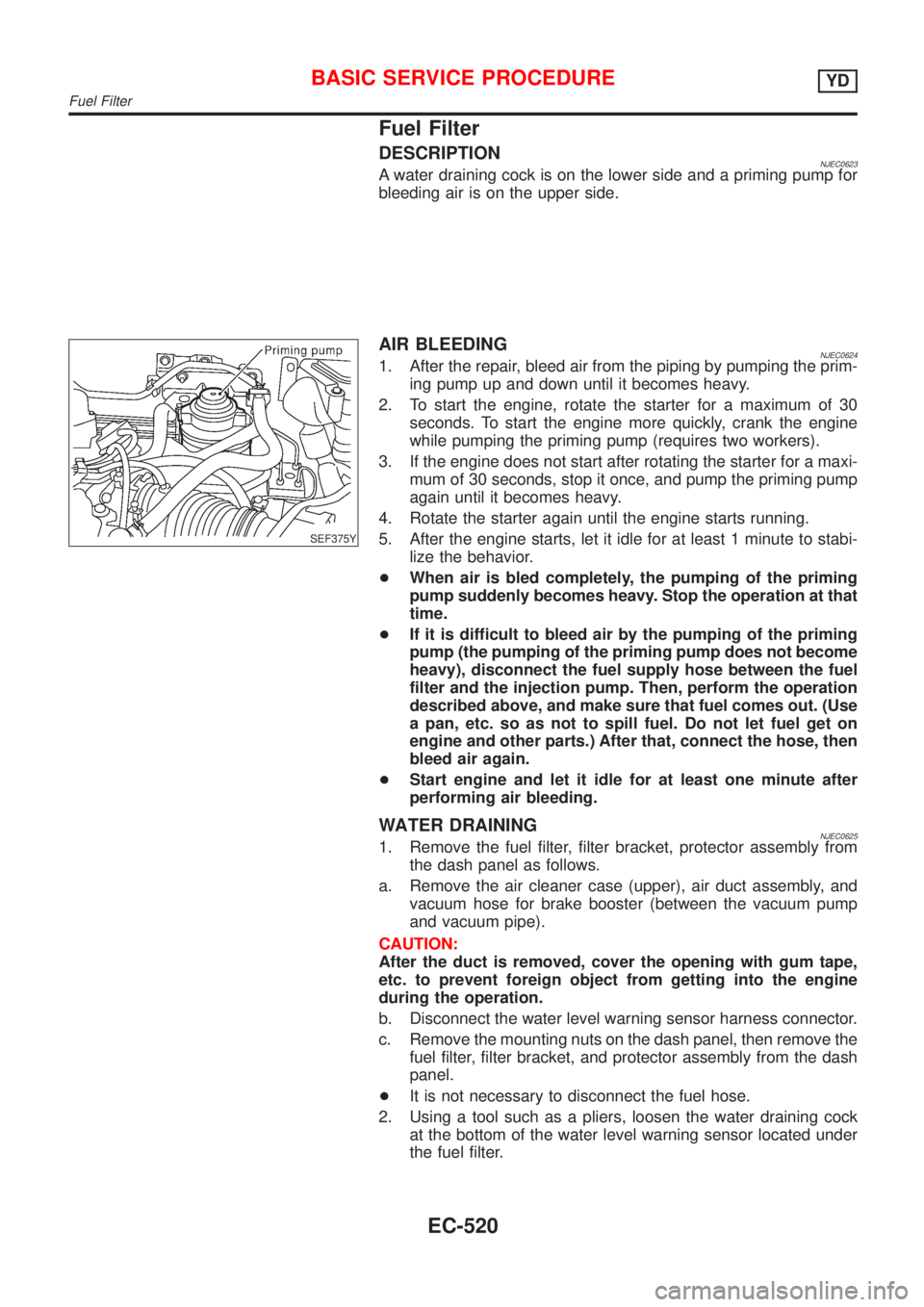

Fuel Filter

DESCRIPTIONNJEC0623A water draining cock is on the lower side and a priming pump for

bleeding air is on the upper side.

SEF375Y

AIR BLEEDINGNJEC06241. After the repair, bleed air from the piping by pumping the prim-

ing pump up and down until it becomes heavy.

2. To start the engine, rotate the starter for a maximum of 30

seconds. To start the engine more quickly, crank the engine

while pumping the priming pump (requires two workers).

3. If the engine does not start after rotating the starter for a maxi-

mum of 30 seconds, stop it once, and pump the priming pump

again until it becomes heavy.

4. Rotate the starter again until the engine starts running.

5. After the engine starts, let it idle for at least 1 minute to stabi-

lize the behavior.

+When air is bled completely, the pumping of the priming

pump suddenly becomes heavy. Stop the operation at that

time.

+If it is difficult to bleed air by the pumping of the priming

pump (the pumping of the priming pump does not become

heavy), disconnect the fuel supply hose between the fuel

filter and the injection pump. Then, perform the operation

described above, and make sure that fuel comes out. (Use

a pan, etc. so as not to spill fuel. Do not let fuel get on

engine and other parts.) After that, connect the hose, then

bleed air again.

+Start engine and let it idle for at least one minute after

performing air bleeding.

WATER DRAININGNJEC06251. Remove the fuel filter, filter bracket, protector assembly from

the dash panel as follows.

a. Remove the air cleaner case (upper), air duct assembly, and

vacuum hose for brake booster (between the vacuum pump

and vacuum pipe).

CAUTION:

After the duct is removed, cover the opening with gum tape,

etc. to prevent foreign object from getting into the engine

during the operation.

b. Disconnect the water level warning sensor harness connector.

c. Remove the mounting nuts on the dash panel, then remove the

fuel filter, filter bracket, and protector assembly from the dash

panel.

+It is not necessary to disconnect the fuel hose.

2. Using a tool such as a pliers, loosen the water draining cock

at the bottom of the water level warning sensor located under

the fuel filter.

BASIC SERVICE PROCEDUREYD

Fuel Filter

EC-520

Page 825 of 2493

![NISSAN ALMERA N16 2001 Electronic Owners Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT NISSAN ALMERA N16 2001 Electronic Owners Manual Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT](/img/5/57351/w960_57351-824.png)

Monitored item

[Unit]ECM

input

signalsMain

signalsDescription Remarks

SPILL/V [ÉCA]

j+The control position of spill valve (sent

from electronic control fuel injection

pump) is displayed.

BATTERY VOLT [V]

jj+The power supply voltage of ECM is

displayed.

P/N POSI SW*1

[ON/OFF] (where

fitted)jj+Indicates [ON/OFF] condition from the

park/neutral position switch signal.

START SIGNAL

[ON/OFF]jj+Indicates [ON/OFF] condition from the

starter signal.+After starting the engine, [OFF] is dis-

played regardless of the starter signal.

BRAKE SW

[ON/OFF]jj+Indicates [ON/OFF] condition from the

stop lamp switch signal.

BRAKE SW2

[ON/OFF]jj+Indicates [ON/OFF] condition from the

brake pedal position switch signal.

IGN SW

[ON/OFF]jj+Indicates [ON/OFF] condition from igni-

tion switch signal.

MAS AIR/FL SE [V]

jj+The signal voltage of the mass air flow

sensor is displayed.+When the engine is stopped, a certain

value is indicated.

INT/A VOLUME [mg/]+The intake air volume computed from

the mass air flow sensor signal is dis-

played.

F/CUT SIGNAL

[ON/OFF]

j+The [ON/OFF] condition from decelera-

tion fuel cut signal (sent from electronic

control fuel injection pump) is displayed.

OFF´´´Fuel is cut off.

ON´´´Fuel is not cut off.

GLOW RLY

[ON/OFF]j+The glow relay control condition (deter-

mined by ECM according to the input

signal) is displayed.

COOLING FAN

[LOW/HI/OFF]

j+Indicates the control condition of the

cooling fans (determined by ECM

according to the input signal).

+LOW ... Operates at low speed.

HI ... Operates at high speed.

OFF ... Stopped.

BARO SEN [kPa]

jj+The barometric pressure (determined

by the signal voltage from the baromet-

ric pressure sensor built into the ECM)

is displayed.

EGR VOL CON/V

[step]

j+Indicates the EGR volume control value

computed by the ECM according to the

input signals.

+The opening becomes larger as the

value increases.

*1: On models not equipped with park/neutral position (PNP) switch, ªOFFº is always displayed regardless of gear shift position.

NOTE:

Any monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONYD

CONSULT-II (Cont'd)

EC-529

Page 847 of 2493

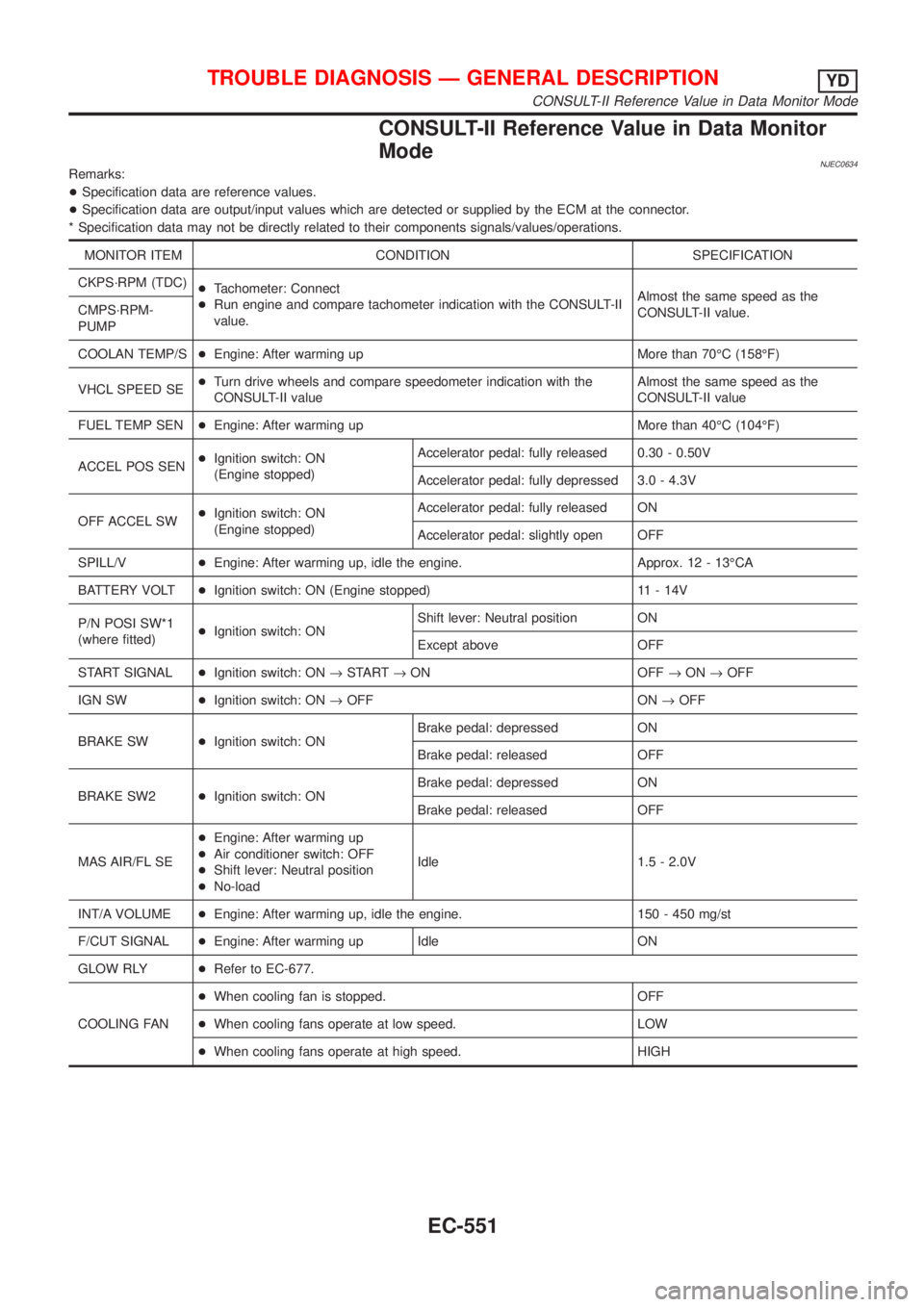

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0634Remarks:

+Specification data are reference values.

+Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPS´RPM (TDC)

+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value. CMPS´RPM-

PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the

CONSULT-II valueAlmost the same speed as the

CONSULT-II value

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.30 - 0.50V

Accelerator pedal: fully depressed 3.0 - 4.3V

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/V+Engine: After warming up, idle the engine. Approx. 12 - 13ÉCA

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW*1

(where fitted)+Ignition switch: ONShift lever: Neutral position ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

IGN SW+Ignition switch: ON®OFF ON®OFF

BRAKE SW+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

BRAKE SW2+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: Neutral position

+No-loadIdle 1.5 - 2.0V

INT/A VOLUME+Engine: After warming up, idle the engine. 150 - 450 mg/st

F/CUT SIGNAL+Engine: After warming up Idle ON

GLOW RLY+Refer to EC-677.

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fans operate at low speed. LOW

+When cooling fans operate at high speed. HIGH

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

CONSULT-II Reference Value in Data Monitor Mode

EC-551

Page 852 of 2493

![NISSAN ALMERA N16 2001 Electronic Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

337

338

350

351W/L

PU/W

GY

OR/BEGR volume control

valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

(Voltage sig NISSAN ALMERA N16 2001 Electronic Owners Manual TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

337

338

350

351W/L

PU/W

GY

OR/BEGR volume control

valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

(Voltage sig](/img/5/57351/w960_57351-851.png)

TERMI-

NAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and Pulse

Signal)

337

338

350

351W/L

PU/W

GY

OR/BEGR volume control

valve[Engine is running]

+Warm-up condition

+Idle speed0.1 - 14V

(Voltage signals of each ECM

terminals differ according to the

control position of EGR volume

control valve.)

344 WCrankshaft position sen-

sor (TDC)[Engine is running]

+Warm-up condition

+Idle speedApproximately 0V

SEF333Y

[Engine is running]

+Warm-up condition

+Engine speed is 2,000 rpmApproximately 0V

SEF334Y

347 L/BEngine coolant tempera-

ture sensor[Engine is running]Approximately 0 - 4.8V

Output voltage varies with

engine coolant temperature

403 R/L Air conditioner switch[Engine is running]

+Air conditioner switch is ªOFFºBATTERY VOLTAGE

(11 - 14V)

[Engine is running]

+Both air conditioner switch and blower fan

switch are ªONº

(Compressor is operating)Approximately 0.1V

405 R/G Stop lamp switch[Ignition switch ªONº]

+Brake pedal fully releasedApproximately 0V

[Ignition switch ªONº]

+Brake pedal depressedBATTERY VOLTAGE

(11 - 14V)

416 Y/BBrake pedal position

switch[Ignition switch ªONº]

+Brake pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Brake pedal depressedApproximately 0V

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONYD

ECM Terminals and Reference Value (Cont'd)

EC-556

Page 893 of 2493

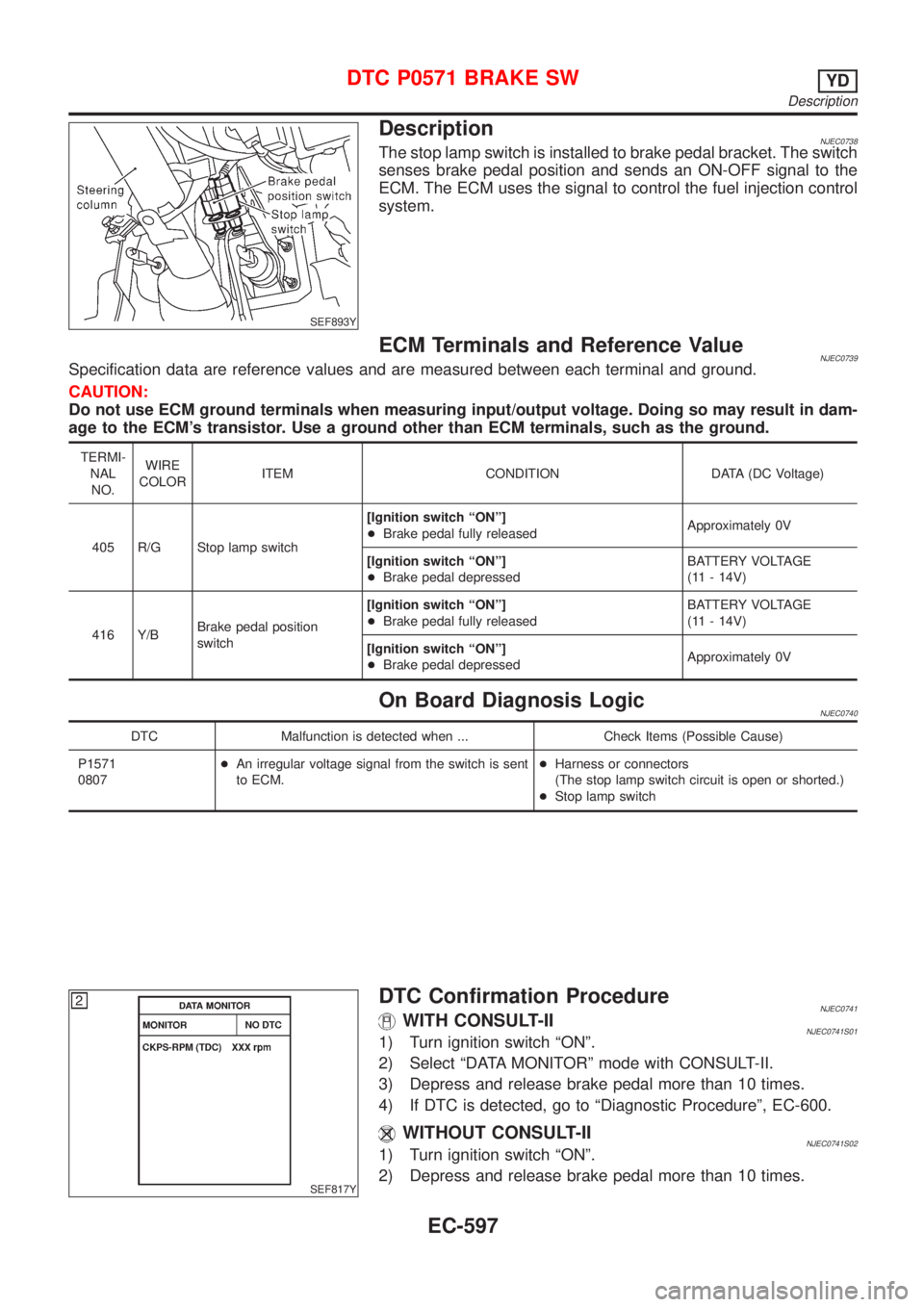

SEF893Y

DescriptionNJEC0738The stop lamp switch is installed to brake pedal bracket. The switch

senses brake pedal position and sends an ON-OFF signal to the

ECM. The ECM uses the signal to control the fuel injection control

system.

ECM Terminals and Reference ValueNJEC0739Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

405 R/G Stop lamp switch[Ignition switch ªONº]

+Brake pedal fully releasedApproximately 0V

[Ignition switch ªONº]

+Brake pedal depressedBATTERY VOLTAGE

(11 - 14V)

416 Y/BBrake pedal position

switch[Ignition switch ªONº]

+Brake pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

[Ignition switch ªONº]

+Brake pedal depressedApproximately 0V

On Board Diagnosis LogicNJEC0740

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1571

0807+An irregular voltage signal from the switch is sent

to ECM.+Harness or connectors

(The stop lamp switch circuit is open or shorted.)

+Stop lamp switch

SEF817Y

DTC Confirmation ProcedureNJEC0741WITH CONSULT-IINJEC0741S011) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Depress and release brake pedal more than 10 times.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-600.

WITHOUT CONSULT-IINJEC0741S021) Turn ignition switch ªONº.

2) Depress and release brake pedal more than 10 times.

DTC P0571 BRAKE SWYD

Description

EC-597

Page 894 of 2493

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º with

ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-600.

DTC P0571 BRAKE SWYD

DTC Confirmation Procedure (Cont'd)

EC-598

Page 895 of 2493

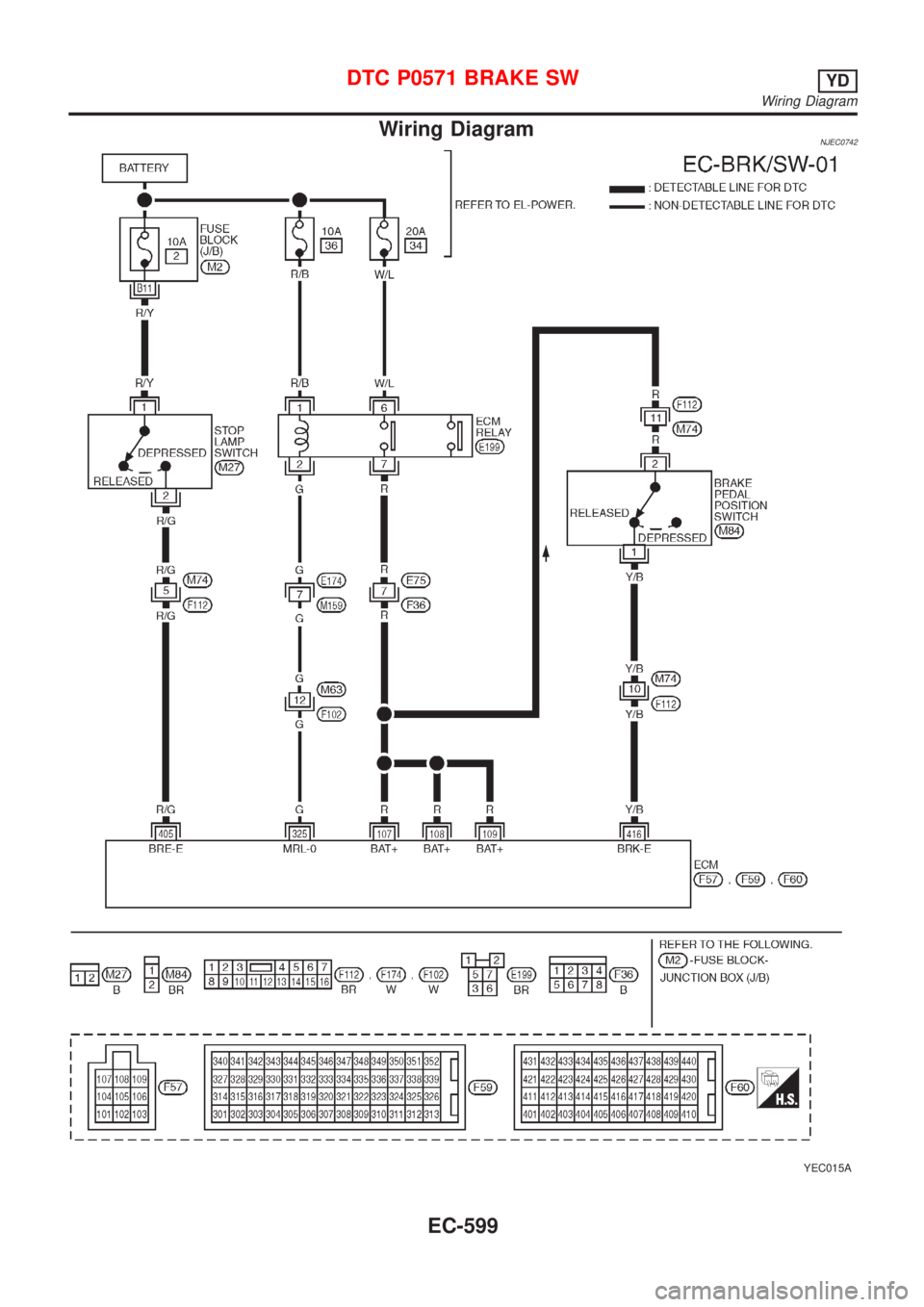

Wiring DiagramNJEC0742

YEC015A

DTC P0571 BRAKE SWYD

Wiring Diagram

EC-599

Page 896 of 2493

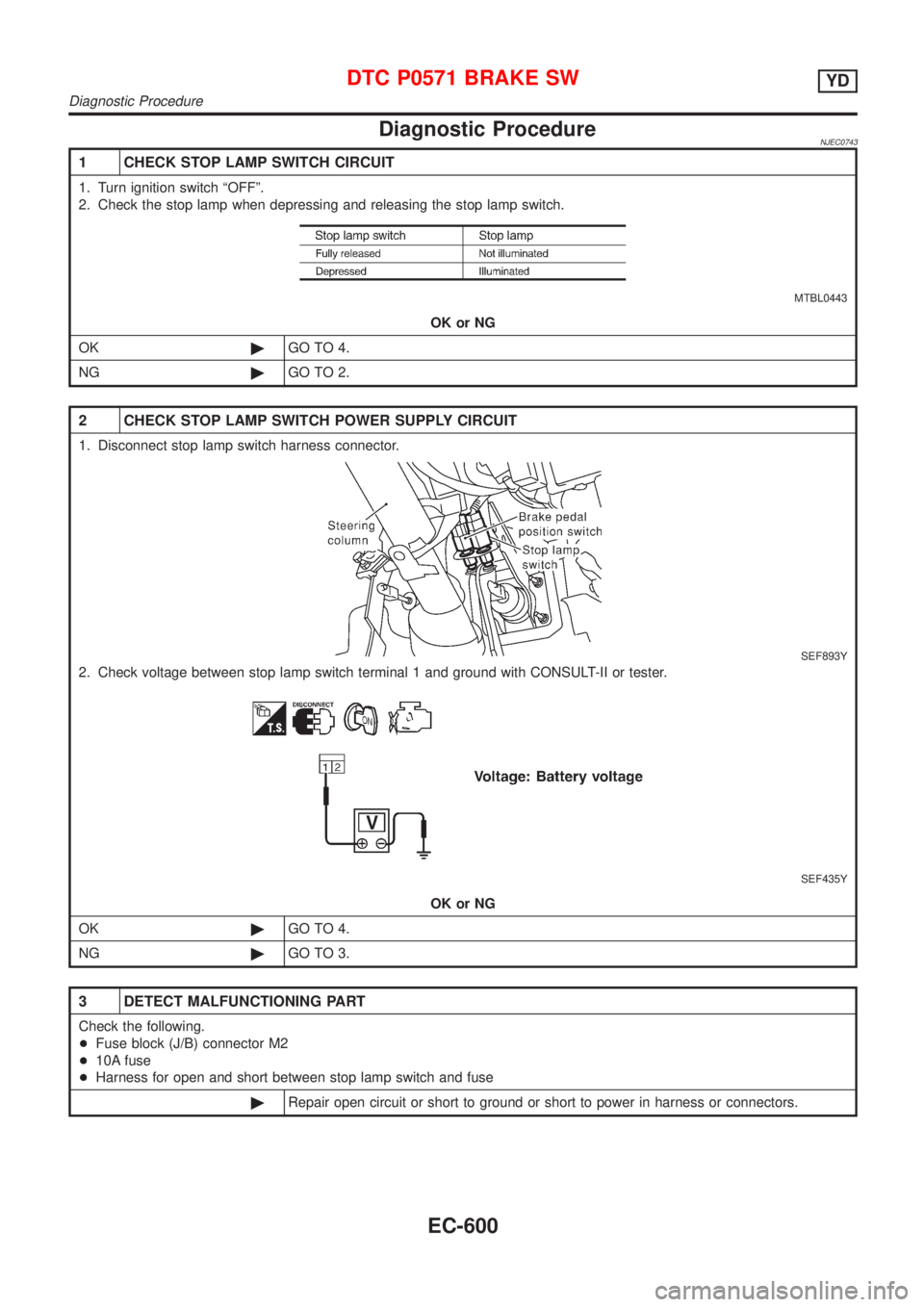

Diagnostic ProcedureNJEC0743

1 CHECK STOP LAMP SWITCH CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check the stop lamp when depressing and releasing the stop lamp switch.

MTBL0443

OK or NG

OK©GO TO 4.

NG©GO TO 2.

2 CHECK STOP LAMP SWITCH POWER SUPPLY CIRCUIT

1. Disconnect stop lamp switch harness connector.

SEF893Y

2. Check voltage between stop lamp switch terminal 1 and ground with CONSULT-II or tester.

SEF435Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Fuse block (J/B) connector M2

+10A fuse

+Harness for open and short between stop lamp switch and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0571 BRAKE SWYD

Diagnostic Procedure

EC-600

Page 897 of 2493

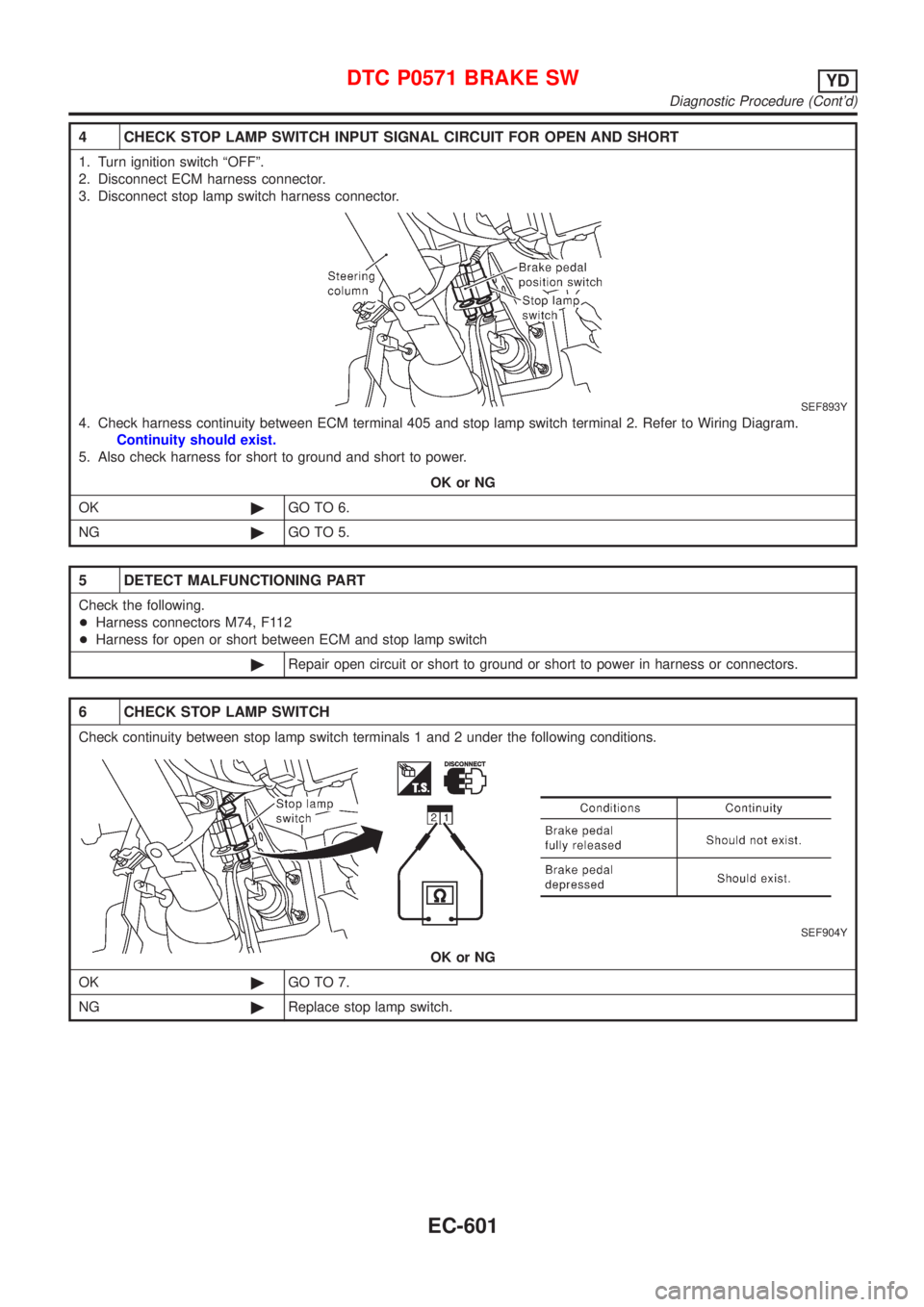

4 CHECK STOP LAMP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect stop lamp switch harness connector.

SEF893Y

4. Check harness continuity between ECM terminal 405 and stop lamp switch terminal 2. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M74, F112

+Harness for open or short between ECM and stop lamp switch

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK STOP LAMP SWITCH

Check continuity between stop lamp switch terminals 1 and 2 under the following conditions.

SEF904Y

OK or NG

OK©GO TO 7.

NG©Replace stop lamp switch.

DTC P0571 BRAKE SWYD

Diagnostic Procedure (Cont'd)

EC-601