brake NISSAN ALMERA N16 2001 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 898 of 2493

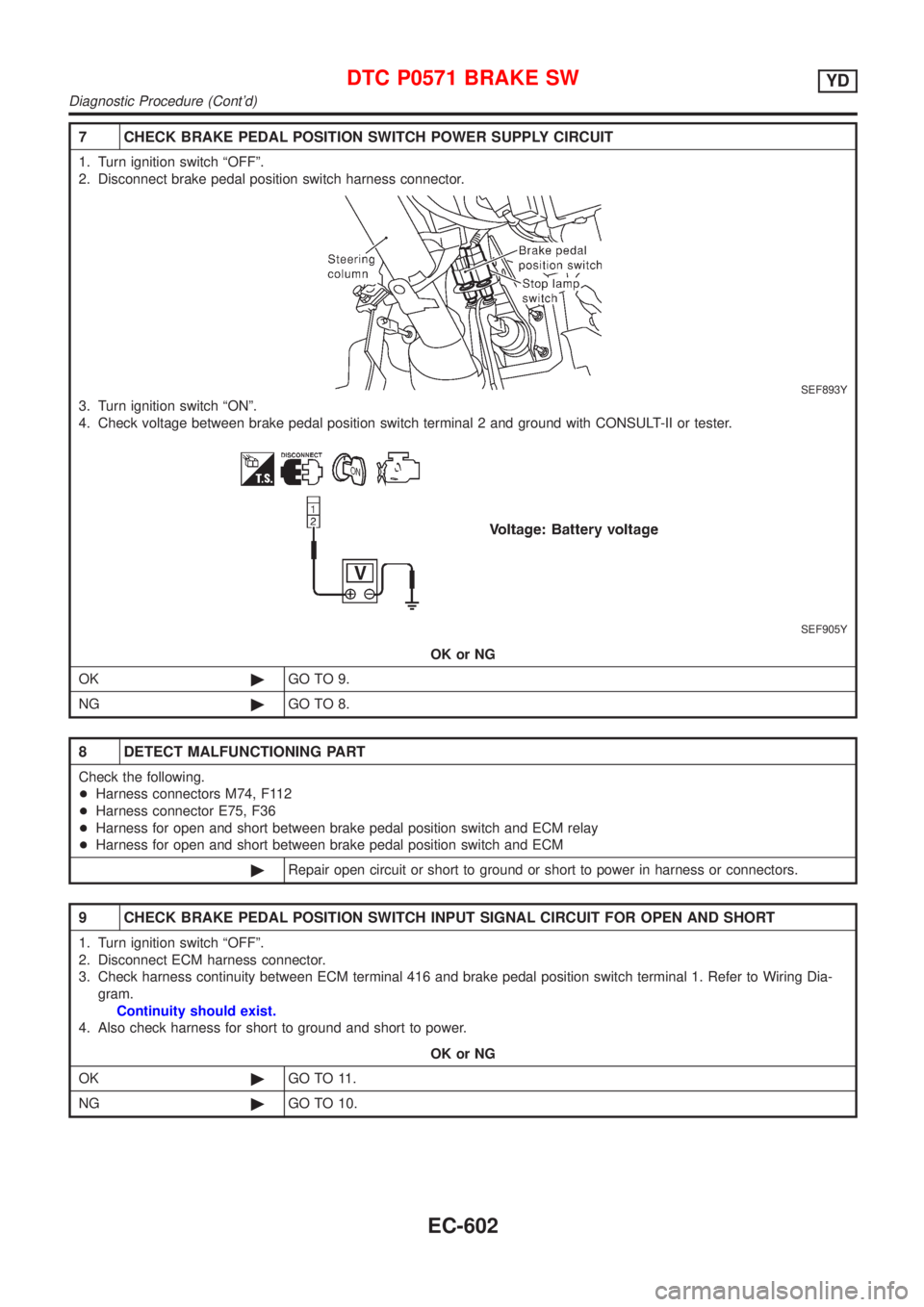

7 CHECK BRAKE PEDAL POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect brake pedal position switch harness connector.

SEF893Y

3. Turn ignition switch ªONº.

4. Check voltage between brake pedal position switch terminal 2 and ground with CONSULT-II or tester.

SEF905Y

OK or NG

OK©GO TO 9.

NG©GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M74, F112

+Harness connector E75, F36

+Harness for open and short between brake pedal position switch and ECM relay

+Harness for open and short between brake pedal position switch and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

9 CHECK BRAKE PEDAL POSITION SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 416 and brake pedal position switch terminal 1. Refer to Wiring Dia-

gram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 11.

NG©GO TO 10.

DTC P0571 BRAKE SWYD

Diagnostic Procedure (Cont'd)

EC-602

Page 899 of 2493

10 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M74, F112

+Harness for open or short between ECM and brake pedal position switch

©Repair open circuit or short to ground or short to power in harness or connectors.

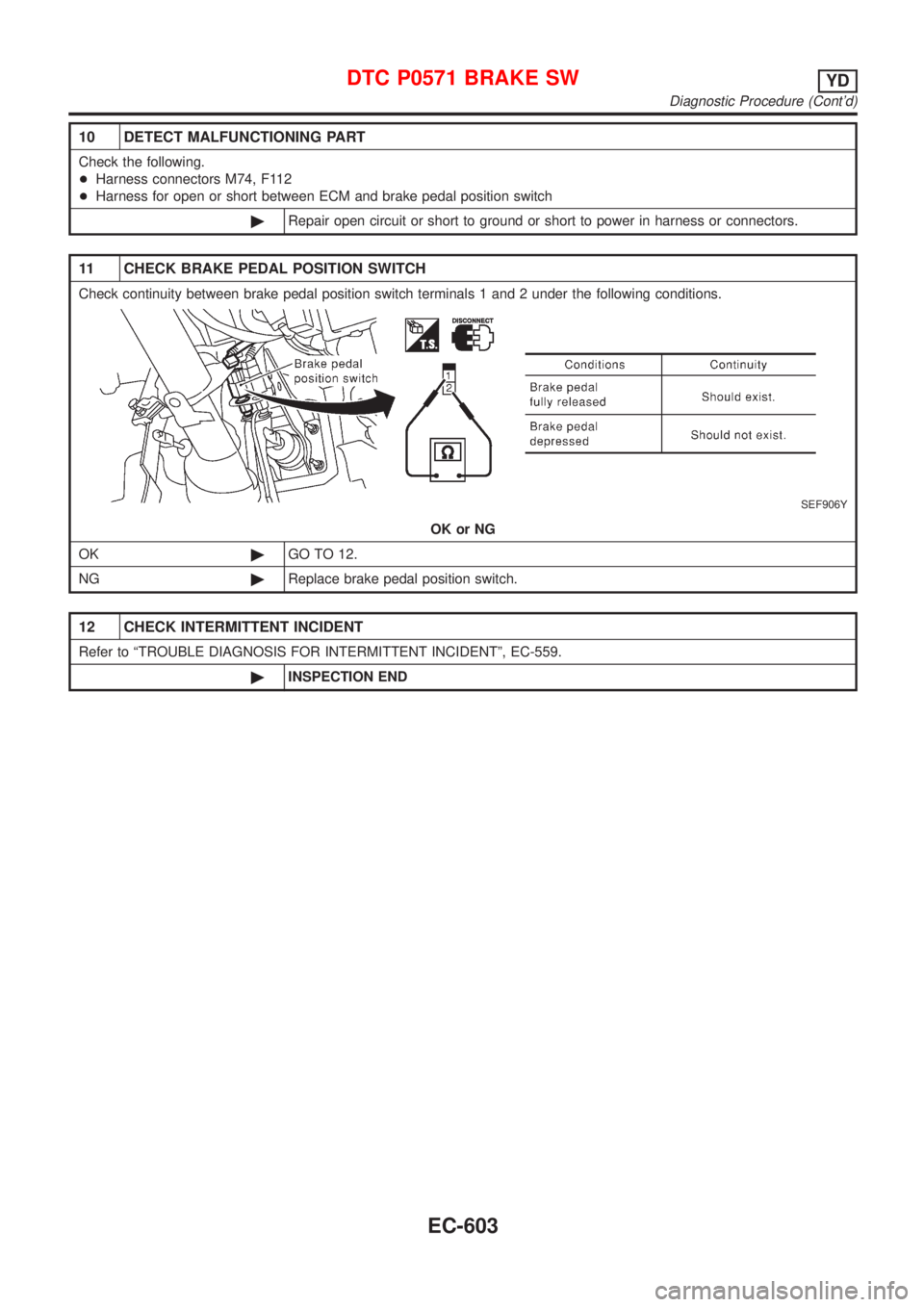

11 CHECK BRAKE PEDAL POSITION SWITCH

Check continuity between brake pedal position switch terminals 1 and 2 under the following conditions.

SEF906Y

OK or NG

OK©GO TO 12.

NG©Replace brake pedal position switch.

12 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-559.

©INSPECTION END

DTC P0571 BRAKE SWYD

Diagnostic Procedure (Cont'd)

EC-603

Page 1028 of 2493

SBR820BA

PrecautionsNJCL0001+Recommended fluid is brake fluid ªDOT 3º or ªDOT 4º

(Europe). Refer to MA-20, ªFluid and Lubricantsº.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+When removing and installing clutch piping, use Tool.

+Use new brake fluid to clean or wash all parts of master

cylinder and operating cylinder.

+Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not

use compressed air.

PRECAUTIONS

Precautions

CL-2

Page 1036 of 2493

CLUTCH PEDAL ADJUSTMENTNJCL0006S04Pedal StrokeNJCL0006S04011. Loosen the pedal stopper bolt completely (so there is no con-

tact between pedal and stopper bolt).

2. Adjust pedal stroke to the specified value with the master cyl-

inder push rod.

3. Adjust the pedal stopper bolt until it is just in contact with the

pedal, then tighten the lock nut.

4. Once stroke is set to specification, adjust clutch pedal free

play.

Pedal stroke ªSº.

Refer to ªSDSº, CL-24.

Pedal Free PlayNJCL0006S04021. Adjust pedal free play to the specified value with the master

cylinder push rod.

2. Tighten lock nut of the master cylinder push rod.

+Push on the clutch pedal until resistance is felt, and check the

distance the pedal moves.

Pedal free play ªAº.

Refer to ªSDSº, CL-24.

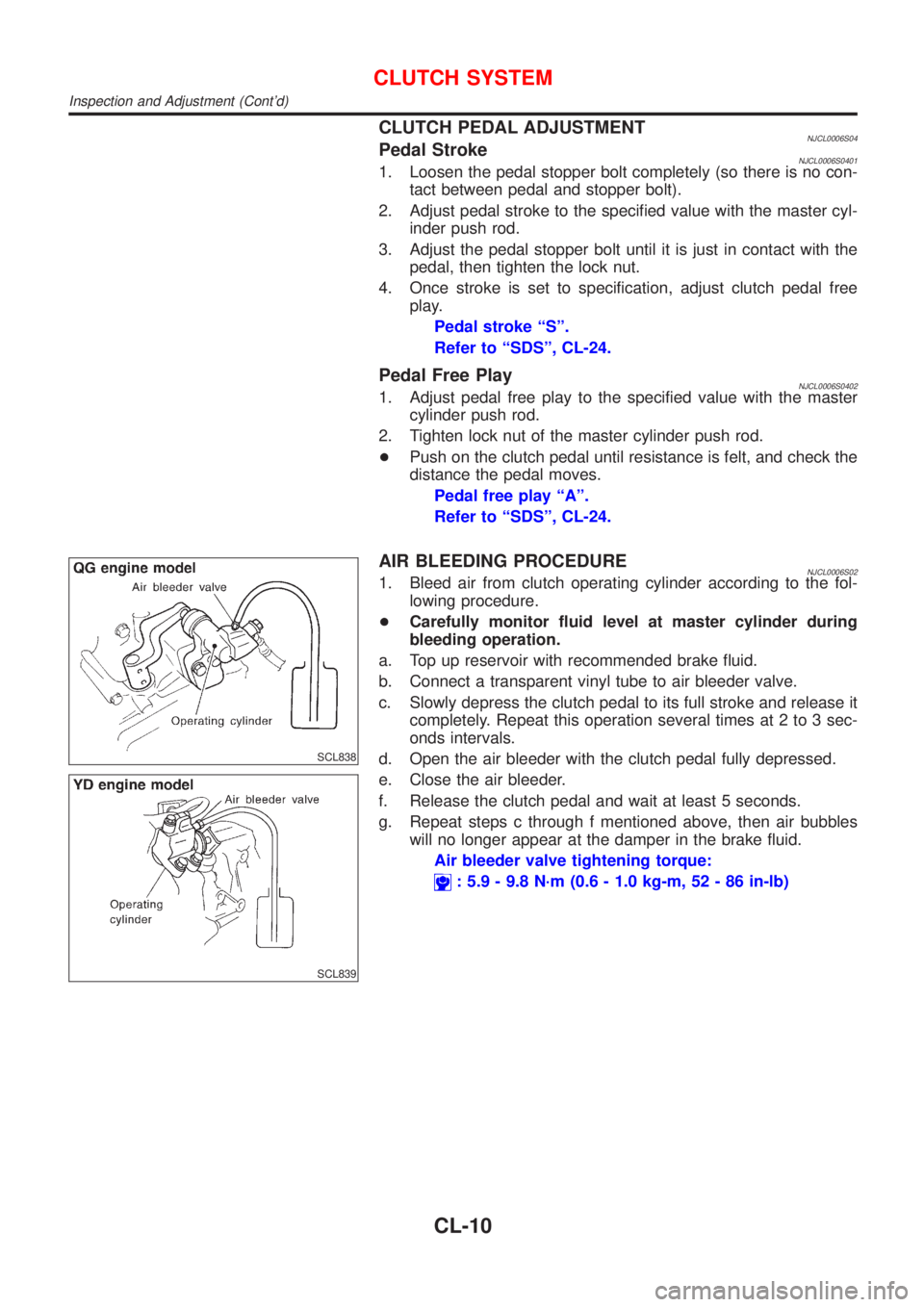

SCL838

SCL839

AIR BLEEDING PROCEDURENJCL0006S021. Bleed air from clutch operating cylinder according to the fol-

lowing procedure.

+Carefully monitor fluid level at master cylinder during

bleeding operation.

a. Top up reservoir with recommended brake fluid.

b. Connect a transparent vinyl tube to air bleeder valve.

c. Slowly depress the clutch pedal to its full stroke and release it

completely. Repeat this operation several times at 2 to 3 sec-

onds intervals.

d. Open the air bleeder with the clutch pedal fully depressed.

e. Close the air bleeder.

f. Release the clutch pedal and wait at least 5 seconds.

g. Repeat steps c through f mentioned above, then air bubbles

will no longer appear at the damper in the brake fluid.

Air bleeder valve tightening torque:

: 5.9 - 9.8 N´m (0.6 - 1.0 kg-m, 52 - 86 in-lb)

CLUTCH SYSTEM

Inspection and Adjustment (Cont'd)

CL-10

Page 1038 of 2493

RemovalNJCL00081. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

2. Remove clutch tube using a flare nut wrench.

3. Remove snap pin between clutch pedal and push rod, and

remove clevis pin.

4. Unscrew master cylinder assembly mounting nuts and remove

master cylinder assembly from vehicle.

InstallationNJCL00091. Connect clutch tube to master cylinder assembly, and hand-

tighten flare nut.

2. Install master cylinder assembly to vehicle, and tighten mount-

ing nuts to the specified torque.

: 11 - 14 N´m (1.1 - 1.5 kg-m,8-10ft-lb)

3. Tighten clutch tube flare nut using a flare nut torque wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

4. After installing clevis pin, install snap pin to connect clutch

pedal to push rod.

5. After finishing the operation, bleed air from clutch piping con-

nector and operating cylinder. (Refer to ªAir Bleeding

Procedureº, CL-10.)

SCL725

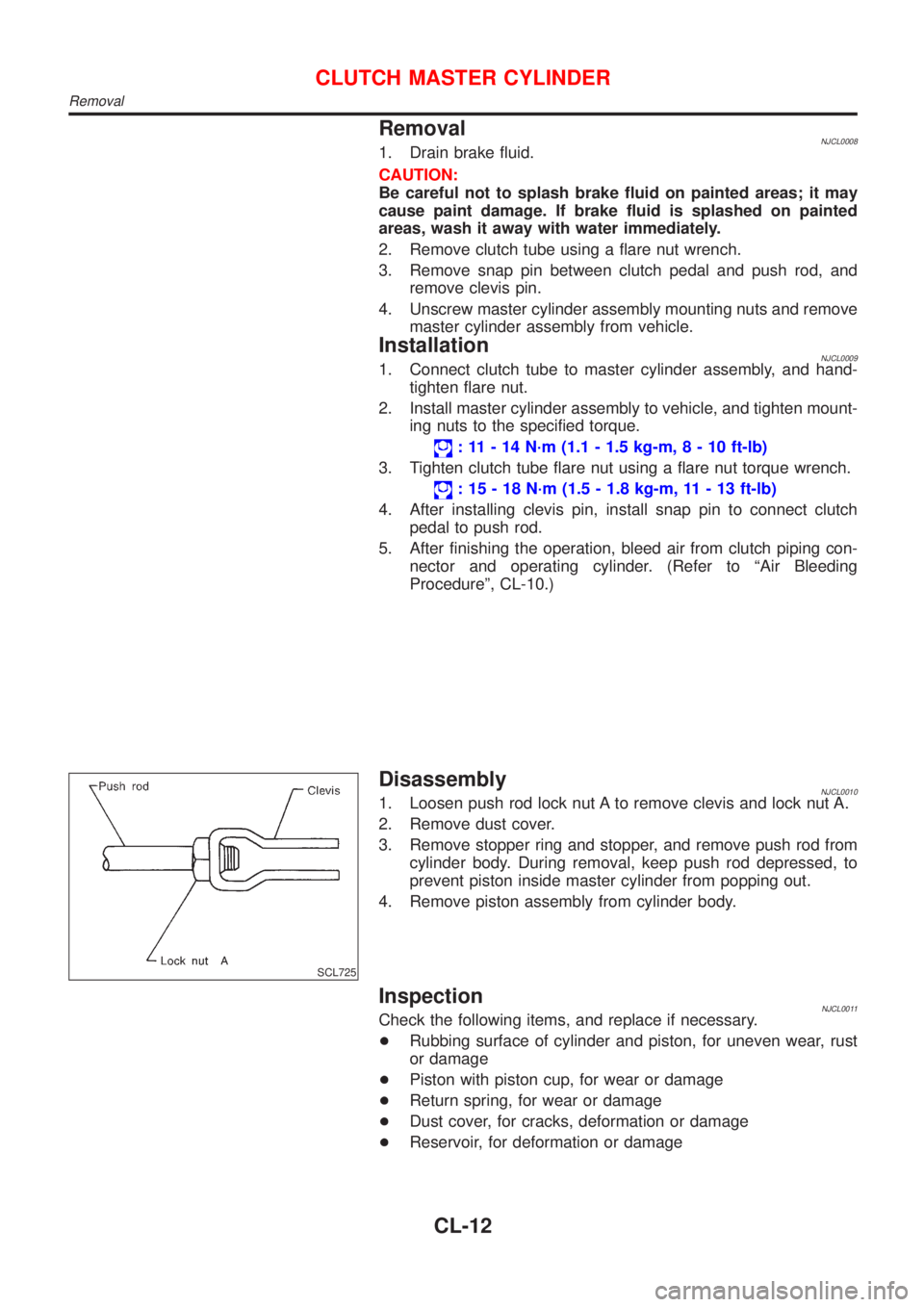

DisassemblyNJCL00101. Loosen push rod lock nut A to remove clevis and lock nut A.

2. Remove dust cover.

3. Remove stopper ring and stopper, and remove push rod from

cylinder body. During removal, keep push rod depressed, to

prevent piston inside master cylinder from popping out.

4. Remove piston assembly from cylinder body.

InspectionNJCL0011Check the following items, and replace if necessary.

+Rubbing surface of cylinder and piston, for uneven wear, rust

or damage

+Piston with piston cup, for wear or damage

+Return spring, for wear or damage

+Dust cover, for cracks, deformation or damage

+Reservoir, for deformation or damage

CLUTCH MASTER CYLINDER

Removal

CL-12

Page 1040 of 2493

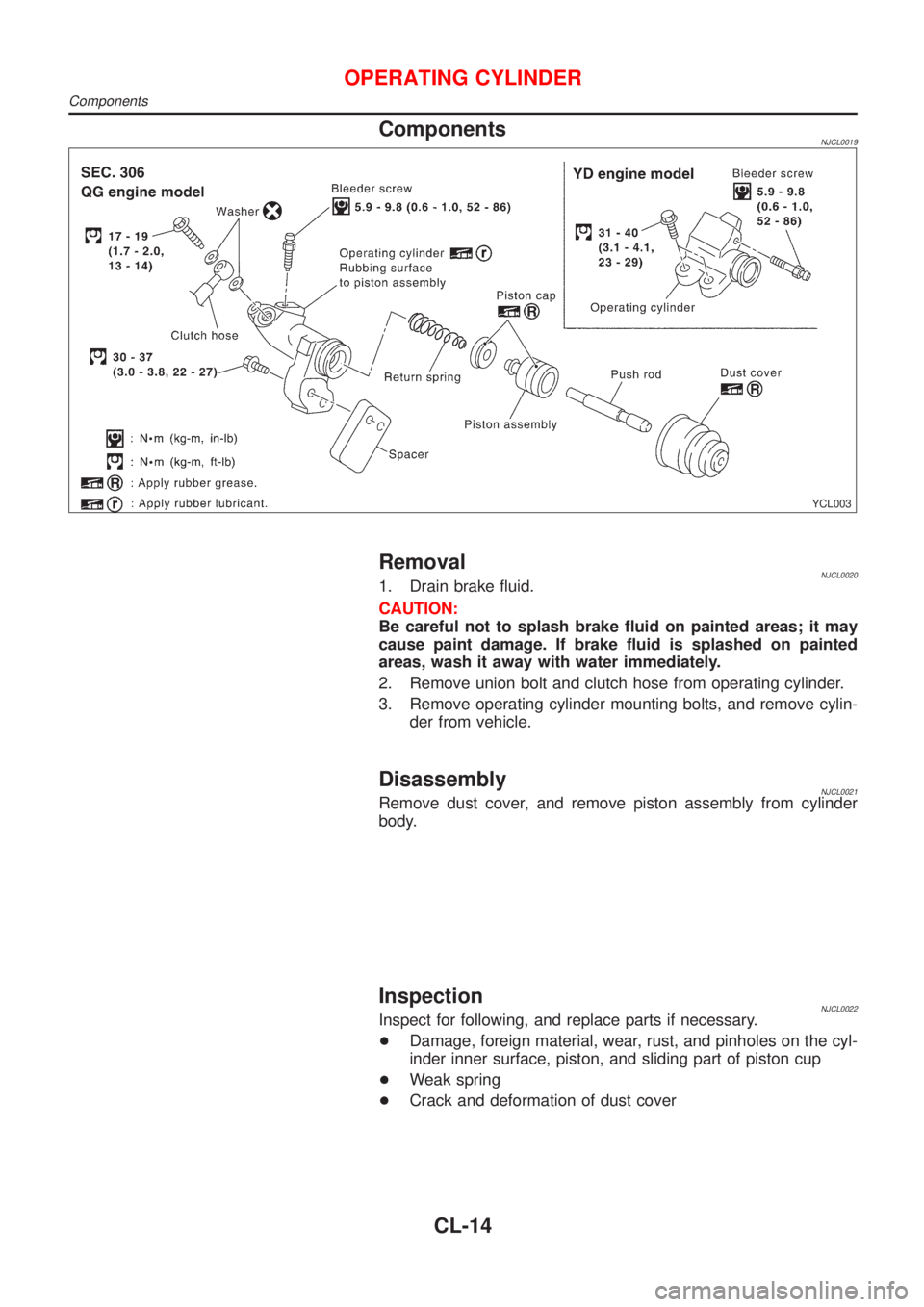

ComponentsNJCL0019

YCL003

RemovalNJCL00201. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

2. Remove union bolt and clutch hose from operating cylinder.

3. Remove operating cylinder mounting bolts, and remove cylin-

der from vehicle.

DisassemblyNJCL0021Remove dust cover, and remove piston assembly from cylinder

body.

InspectionNJCL0022Inspect for following, and replace parts if necessary.

+Damage, foreign material, wear, rust, and pinholes on the cyl-

inder inner surface, piston, and sliding part of piston cup

+Weak spring

+Crack and deformation of dust cover

OPERATING CYLINDER

Components

CL-14

Page 1042 of 2493

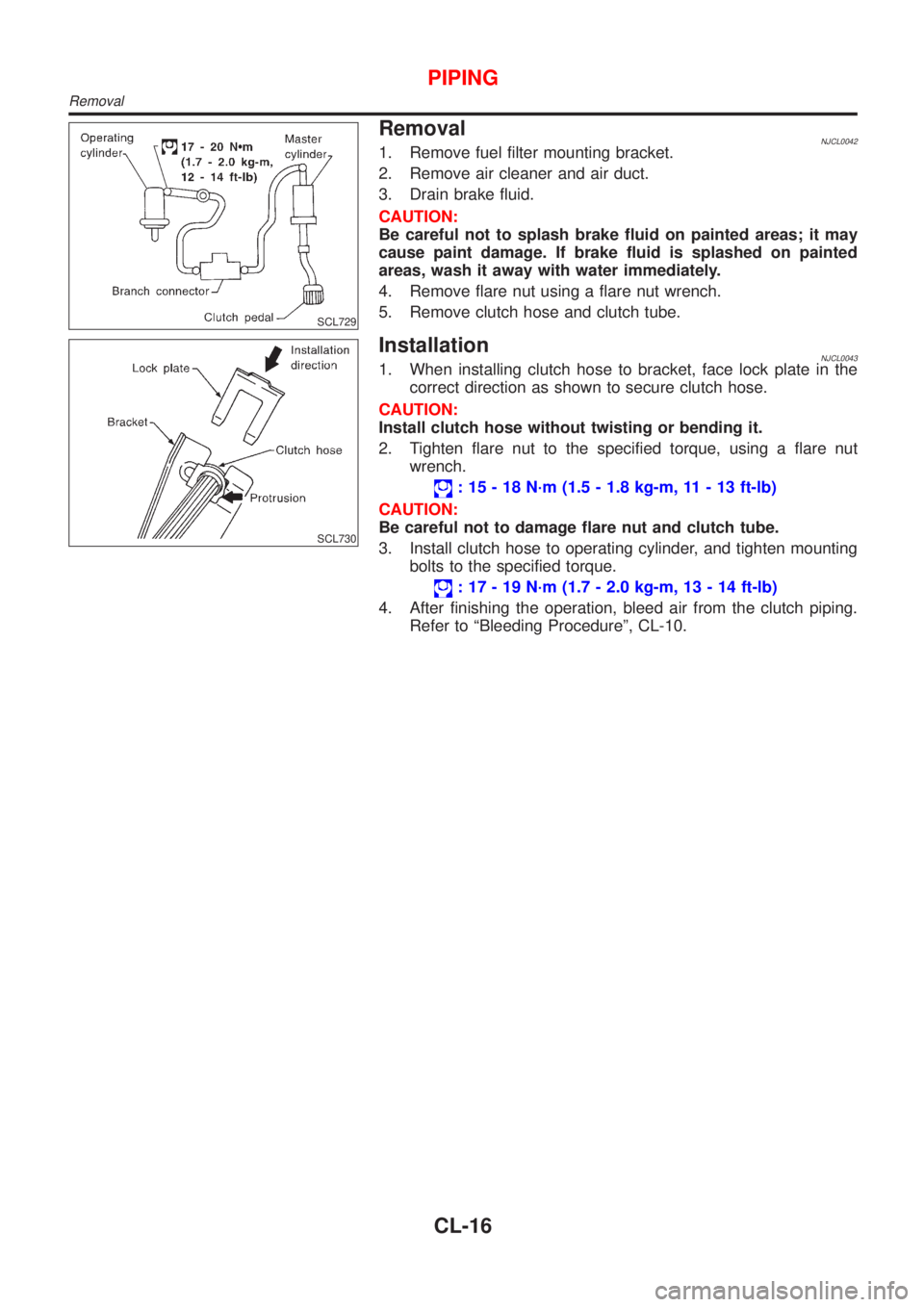

SCL729

RemovalNJCL00421. Remove fuel filter mounting bracket.

2. Remove air cleaner and air duct.

3. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

4. Remove flare nut using a flare nut wrench.

5. Remove clutch hose and clutch tube.

SCL730

InstallationNJCL00431. When installing clutch hose to bracket, face lock plate in the

correct direction as shown to secure clutch hose.

CAUTION:

Install clutch hose without twisting or bending it.

2. Tighten flare nut to the specified torque, using a flare nut

wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

CAUTION:

Be careful not to damage flare nut and clutch tube.

3. Install clutch hose to operating cylinder, and tighten mounting

bolts to the specified torque.

: 17 - 19 N´m (1.7 - 2.0 kg-m, 13 - 14 ft-lb)

4. After finishing the operation, bleed air from the clutch piping.

Refer to ªBleeding Procedureº, CL-10.

PIPING

Removal

CL-16

Page 1189 of 2493

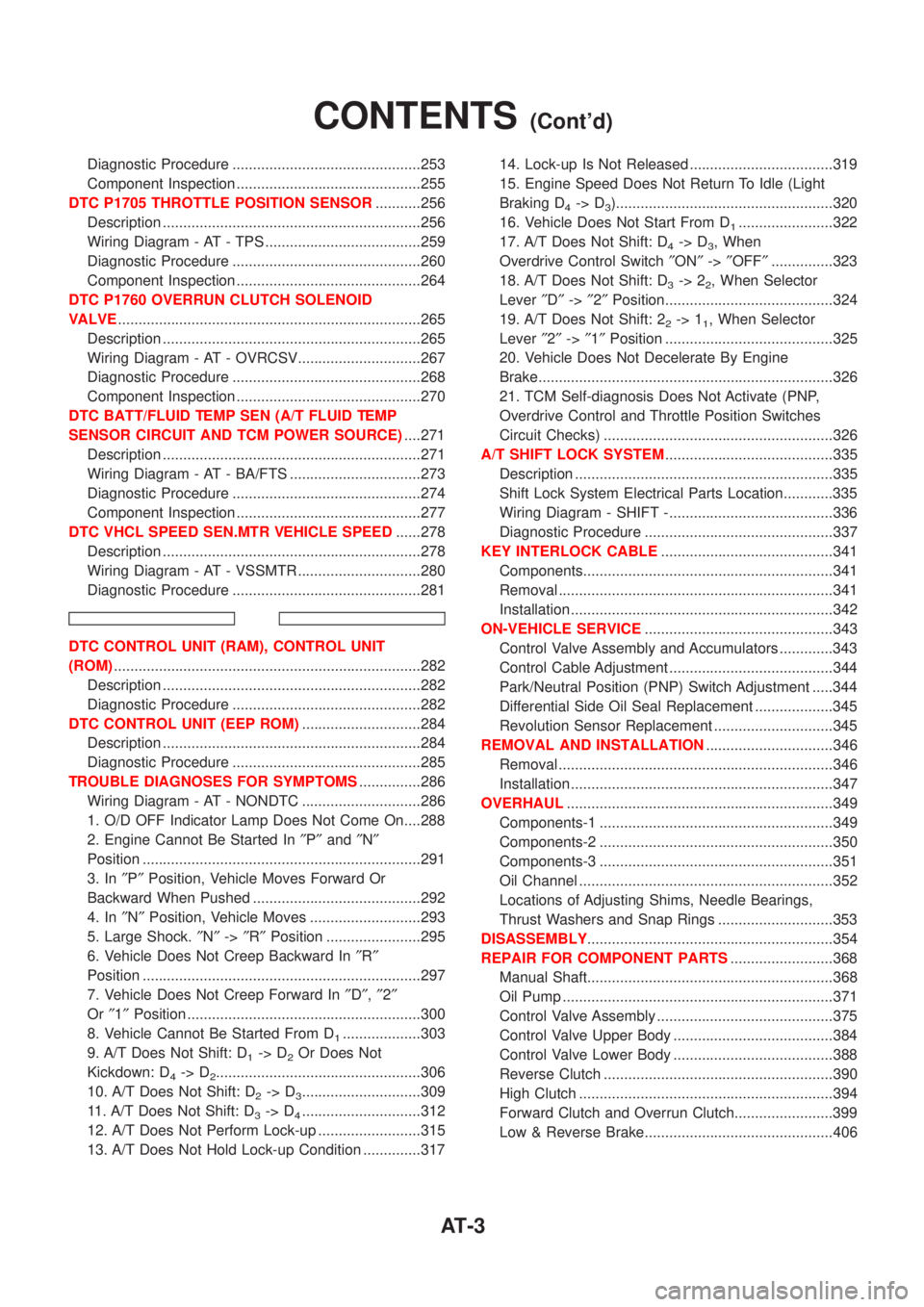

Diagnostic Procedure ..............................................253

Component Inspection .............................................255

DTC P1705 THROTTLE POSITION SENSOR...........256

Description ...............................................................256

Wiring Diagram - AT - TPS ......................................259

Diagnostic Procedure ..............................................260

Component Inspection .............................................264

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE..........................................................................265

Description ...............................................................265

Wiring Diagram - AT - OVRCSV..............................267

Diagnostic Procedure ..............................................268

Component Inspection .............................................270

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....271

Description ...............................................................271

Wiring Diagram - AT - BA/FTS ................................273

Diagnostic Procedure ..............................................274

Component Inspection .............................................277

DTC VHCL SPEED SEN.MTR VEHICLE SPEED......278

Description ...............................................................278

Wiring Diagram - AT - VSSMTR ..............................280

Diagnostic Procedure ..............................................281

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM)...........................................................................282

Description ...............................................................282

Diagnostic Procedure ..............................................282

DTC CONTROL UNIT (EEP ROM).............................284

Description ...............................................................284

Diagnostic Procedure ..............................................285

TROUBLE DIAGNOSES FOR SYMPTOMS...............286

Wiring Diagram - AT - NONDTC .............................286

1. O/D OFF Indicator Lamp Does Not Come On....288

2. Engine Cannot Be Started In²P²and²N²

Position ....................................................................291

3. In²P²Position, Vehicle Moves Forward Or

Backward When Pushed .........................................292

4. In²N²Position, Vehicle Moves ...........................293

5. Large Shock.²N²->²R²Position .......................295

6. Vehicle Does Not Creep Backward In²R²

Position ....................................................................297

7. Vehicle Does Not Creep Forward In²D²,²2²

Or²1²Position .........................................................300

8. Vehicle Cannot Be Started From D

1...................303

9. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................306

10. A/T Does Not Shift: D

2-> D3.............................309

11. A/T Does Not Shift: D

3-> D4.............................312

12. A/T Does Not Perform Lock-up .........................315

13. A/T Does Not Hold Lock-up Condition ..............31714. Lock-up Is Not Released ...................................319

15. Engine Speed Does Not Return To Idle (Light

Braking D

4-> D3).....................................................320

16. Vehicle Does Not Start From D

1.......................322

17. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch²ON²->²OFF²...............323

18. A/T Does Not Shift: D

3-> 22, When Selector

Lever²D²->²2²Position.........................................324

19. A/T Does Not Shift: 2

2-> 11, When Selector

Lever²2²->²1²Position .........................................325

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................326

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................326

A/T SHIFT LOCK SYSTEM.........................................335

Description ...............................................................335

Shift Lock System Electrical Parts Location............335

Wiring Diagram - SHIFT -........................................336

Diagnostic Procedure ..............................................337

KEY INTERLOCK CABLE..........................................341

Components.............................................................341

Removal ...................................................................341

Installation ................................................................342

ON-VEHICLE SERVICE..............................................343

Control Valve Assembly and Accumulators .............343

Control Cable Adjustment ........................................344

Park/Neutral Position (PNP) Switch Adjustment .....344

Differential Side Oil Seal Replacement ...................345

Revolution Sensor Replacement .............................345

REMOVAL AND INSTALLATION...............................346

Removal ...................................................................346

Installation ................................................................347

OVERHAUL.................................................................349

Components-1 .........................................................349

Components-2 .........................................................350

Components-3 .........................................................351

Oil Channel ..............................................................352

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ............................353

DISASSEMBLY............................................................354

REPAIR FOR COMPONENT PARTS.........................368

Manual Shaft............................................................368

Oil Pump ..................................................................371

Control Valve Assembly ...........................................375

Control Valve Upper Body .......................................384

Control Valve Lower Body .......................................388

Reverse Clutch ........................................................390

High Clutch ..............................................................394

Forward Clutch and Overrun Clutch........................399

Low & Reverse Brake..............................................406

CONTENTS(Cont'd)

AT-3

Page 1190 of 2493

Rear Internal Gear, Forward Clutch Hub and

Overrun Clutch Hub .................................................410

Output Shaft, Idler Gear, Reduction Pinion Gear

and Bearing Retainer...............................................414

Band Servo Piston Assembly ..................................419

Final Drive................................................................424

ASSEMBLY..................................................................428

Assembly (1) ............................................................428

Adjustment (1) .........................................................429

Assembly (2) ............................................................434

Adjustment (2) .........................................................438

Assembly (3) ............................................................442

Assembly (4) ............................................................444

SERVICE DATA AND SPECIFICATIONS (SDS).......449

General Specifications .............................................449

Shift Schedule..........................................................449

Stall Revolution ........................................................450

Line Pressure...........................................................450

Control Valves..........................................................450Clutch and Brakes ...................................................451

Clutch and Brake Return Springs............................452

Oil Pump ..................................................................453

Input Shaft ...............................................................453

Planetary Carrier......................................................453

Final Drive................................................................453

Reduction Pinion Gear ............................................455

Output Shaft.............................................................456

Bearing Retainer ......................................................457

Total End Play..........................................................457

Reverse Clutch End Play ........................................457

Accumulator .............................................................457

Band Servo ..............................................................458

Removal and Installation .........................................458

Shift Solenoid Valves ...............................................458

Resistance ...............................................................458

ATF Temp. Sensor ...................................................458

Revolution Sensor ...................................................458

Dropping Resistor ....................................................458

CONTENTS(Cont'd)

AT-4

Page 1201 of 2493

SMA827CA

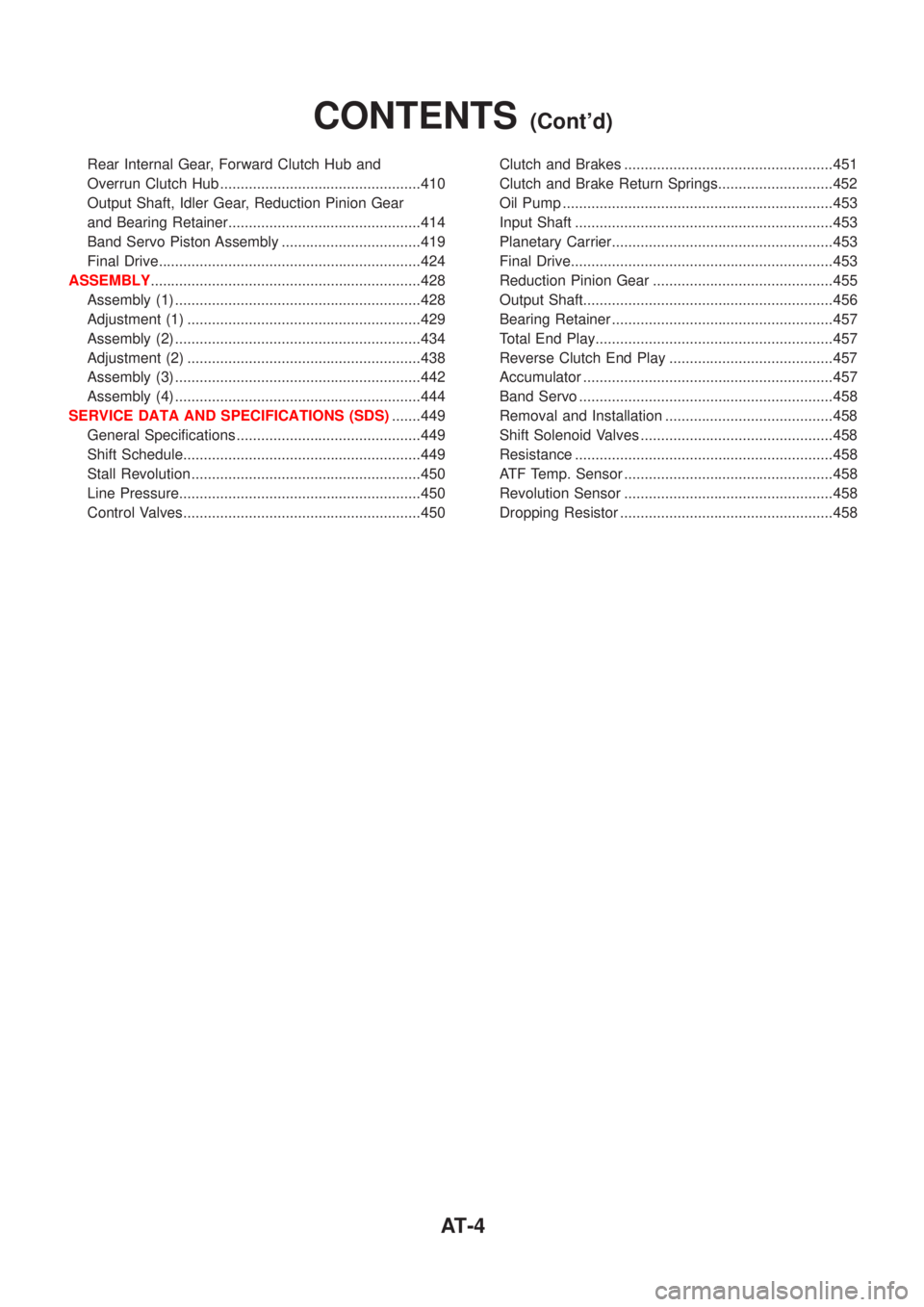

Checking A/T FluidNJAT02281. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of

range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

SMA853B

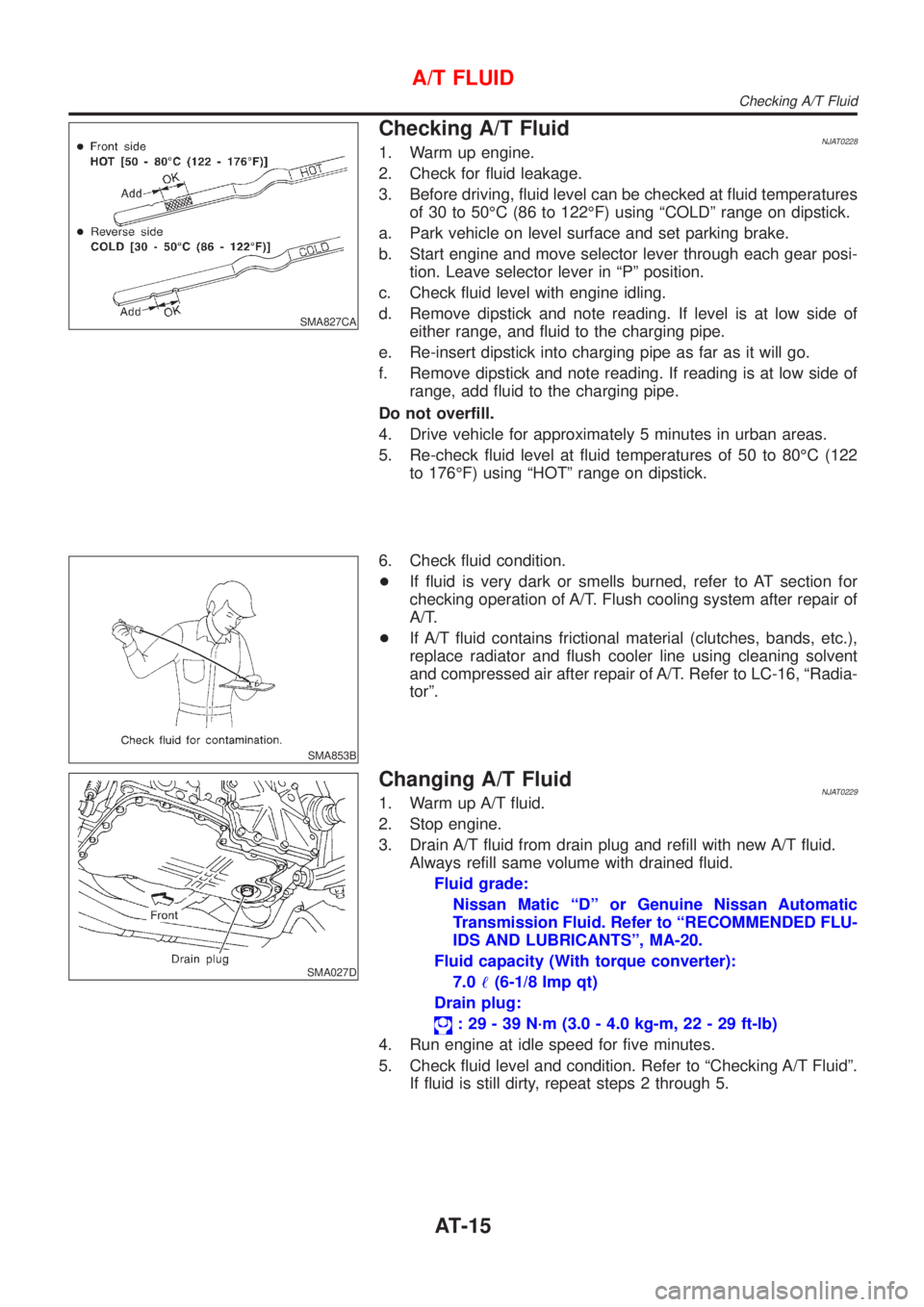

6. Check fluid condition.

+If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

+If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC-16, ªRadia-

torº.

SMA027D

Changing A/T FluidNJAT02291. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Nissan Matic ªDº or Genuine Nissan Automatic

Transmission Fluid. Refer to ªRECOMMENDED FLU-

IDS AND LUBRICANTSº, MA-20.

Fluid capacity (With torque converter):

7.0!(6-1/8 Imp qt)

Drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to ªChecking A/T Fluidº.

If fluid is still dirty, repeat steps 2 through 5.

A/T FLUID

Checking A/T Fluid

AT-15