suspension NISSAN ALMERA N16 2001 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1692 of 2493

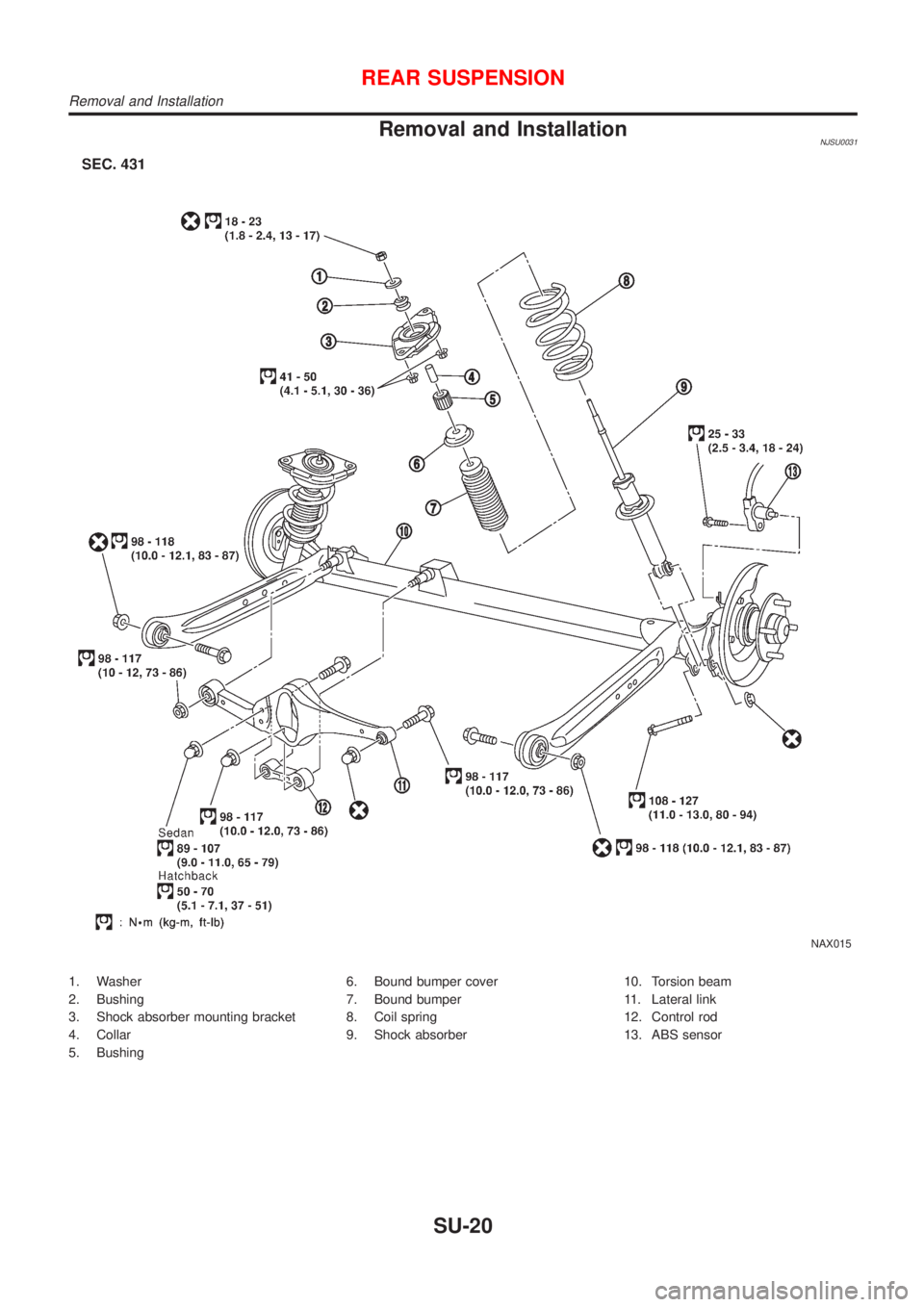

Removal and InstallationNJSU0031

NAX015

1. Washer

2. Bushing

3. Shock absorber mounting bracket

4. Collar

5. Bushing6. Bound bumper cover

7. Bound bumper

8. Coil spring

9. Shock absorber10. Torsion beam

11. Lateral link

12. Control rod

13. ABS sensor

REAR SUSPENSION

Removal and Installation

SU-20

Page 1693 of 2493

SRA695A

SSU038

REMOVALNJSU0031S01CAUTION:

+Before removing the rear suspension assembly, discon-

nect the ABS wheel sensor from the assembly. Failure to

do so may result in damage to the sensor wires and the

sensor becoming inoperative.

+Remove suspension assembly.

1. Disconnect brake hydraulic lines and parking brake cable at

toggle lever. (Models with drum brakes.)

+Drain brake fluid before disconnecting brake lines.

2. Disconnect parking brake cable from caliper and remove brake

caliper and rotor. (Models with disc brakes.)

Suspend caliper assembly with wire so as not to stretch

brake hose.

Be careful not to depress brake pedal, or piston will pop

out.

Make sure brake hose is not twisted.

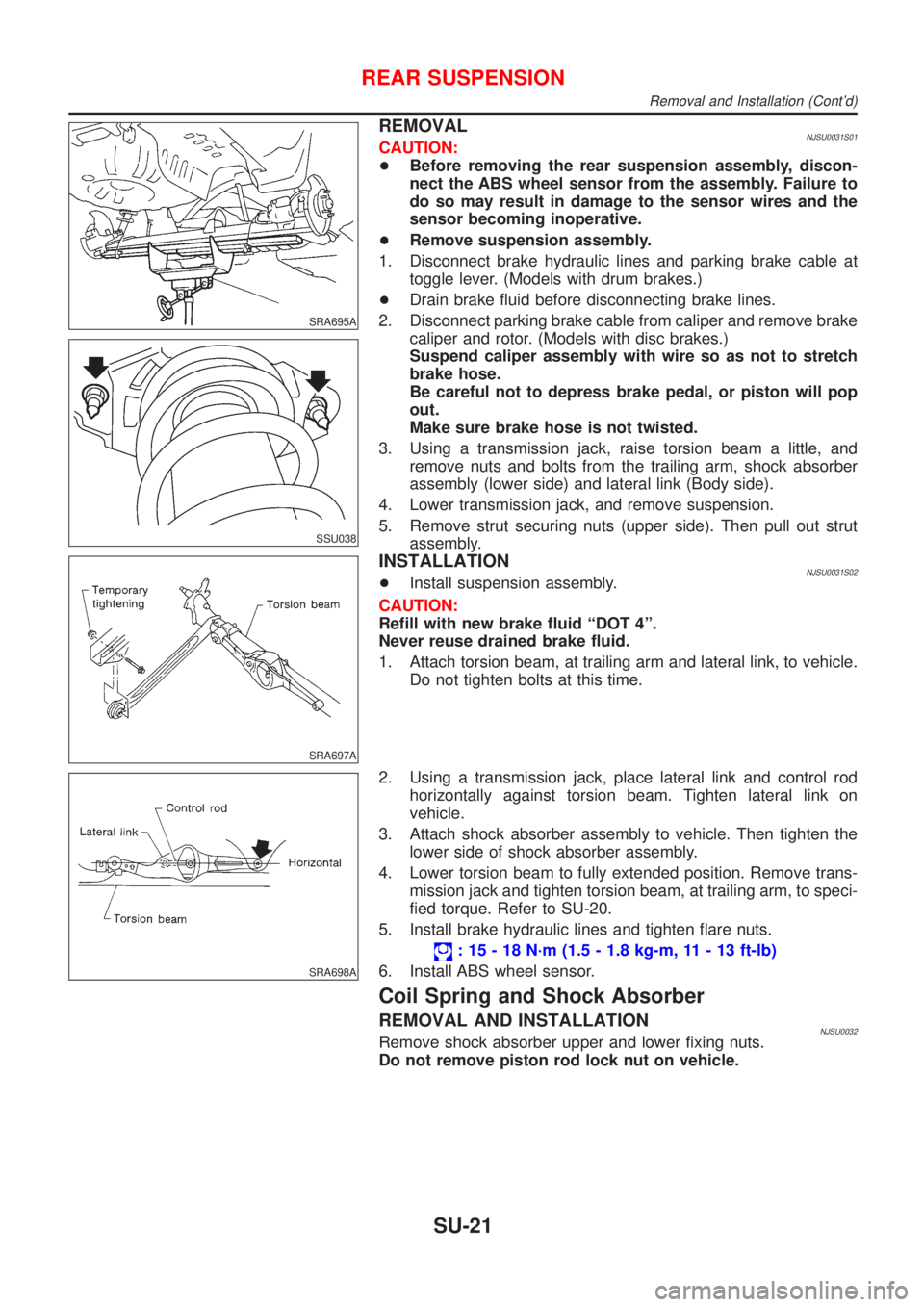

3. Using a transmission jack, raise torsion beam a little, and

remove nuts and bolts from the trailing arm, shock absorber

assembly (lower side) and lateral link (Body side).

4. Lower transmission jack, and remove suspension.

5. Remove strut securing nuts (upper side). Then pull out strut

assembly.

SRA697A

INSTALLATIONNJSU0031S02+Install suspension assembly.

CAUTION:

Refill with new brake fluid ªDOT 4º.

Never reuse drained brake fluid.

1. Attach torsion beam, at trailing arm and lateral link, to vehicle.

Do not tighten bolts at this time.

SRA698A

2. Using a transmission jack, place lateral link and control rod

horizontally against torsion beam. Tighten lateral link on

vehicle.

3. Attach shock absorber assembly to vehicle. Then tighten the

lower side of shock absorber assembly.

4. Lower torsion beam to fully extended position. Remove trans-

mission jack and tighten torsion beam, at trailing arm, to speci-

fied torque. Refer to SU-20.

5. Install brake hydraulic lines and tighten flare nuts.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

6. Install ABS wheel sensor.

Coil Spring and Shock Absorber

REMOVAL AND INSTALLATIONNJSU0032Remove shock absorber upper and lower fixing nuts.

Do not remove piston rod lock nut on vehicle.

REAR SUSPENSION

Removal and Installation (Cont'd)

SU-21

Page 1694 of 2493

SRA806A

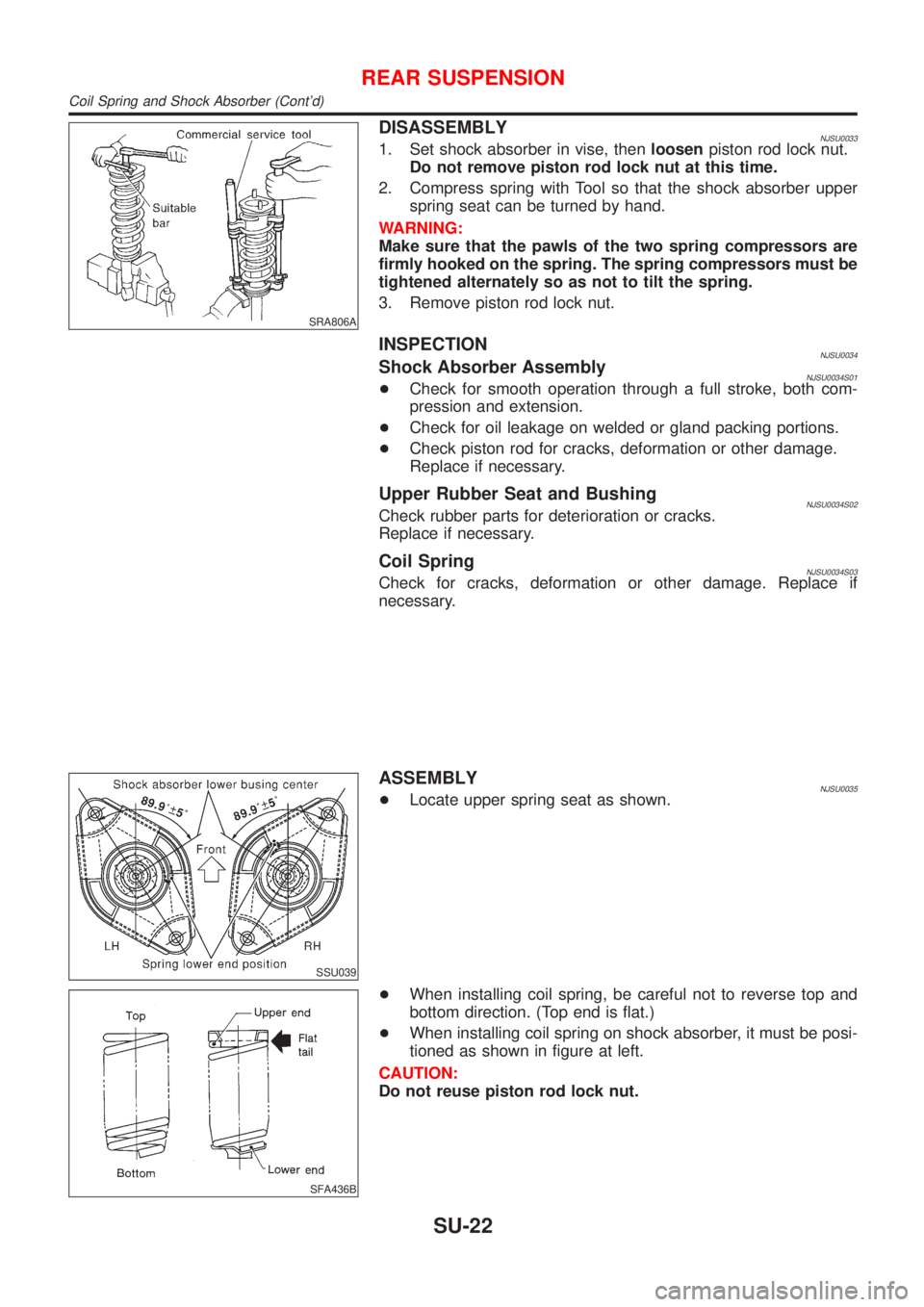

DISASSEMBLYNJSU00331. Set shock absorber in vise, thenloosenpiston rod lock nut.

Do not remove piston rod lock nut at this time.

2. Compress spring with Tool so that the shock absorber upper

spring seat can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are

firmly hooked on the spring. The spring compressors must be

tightened alternately so as not to tilt the spring.

3. Remove piston rod lock nut.

INSPECTIONNJSU0034Shock Absorber AssemblyNJSU0034S01+Check for smooth operation through a full stroke, both com-

pression and extension.

+Check for oil leakage on welded or gland packing portions.

+Check piston rod for cracks, deformation or other damage.

Replace if necessary.

Upper Rubber Seat and BushingNJSU0034S02Check rubber parts for deterioration or cracks.

Replace if necessary.

Coil SpringNJSU0034S03Check for cracks, deformation or other damage. Replace if

necessary.

SSU039

ASSEMBLYNJSU0035+Locate upper spring seat as shown.

SFA436B

+When installing coil spring, be careful not to reverse top and

bottom direction. (Top end is flat.)

+When installing coil spring on shock absorber, it must be posi-

tioned as shown in figure at left.

CAUTION:

Do not reuse piston rod lock nut.

REAR SUSPENSION

Coil Spring and Shock Absorber (Cont'd)

SU-22

Page 1695 of 2493

Torsion Beam, Lateral Link and Control Rod

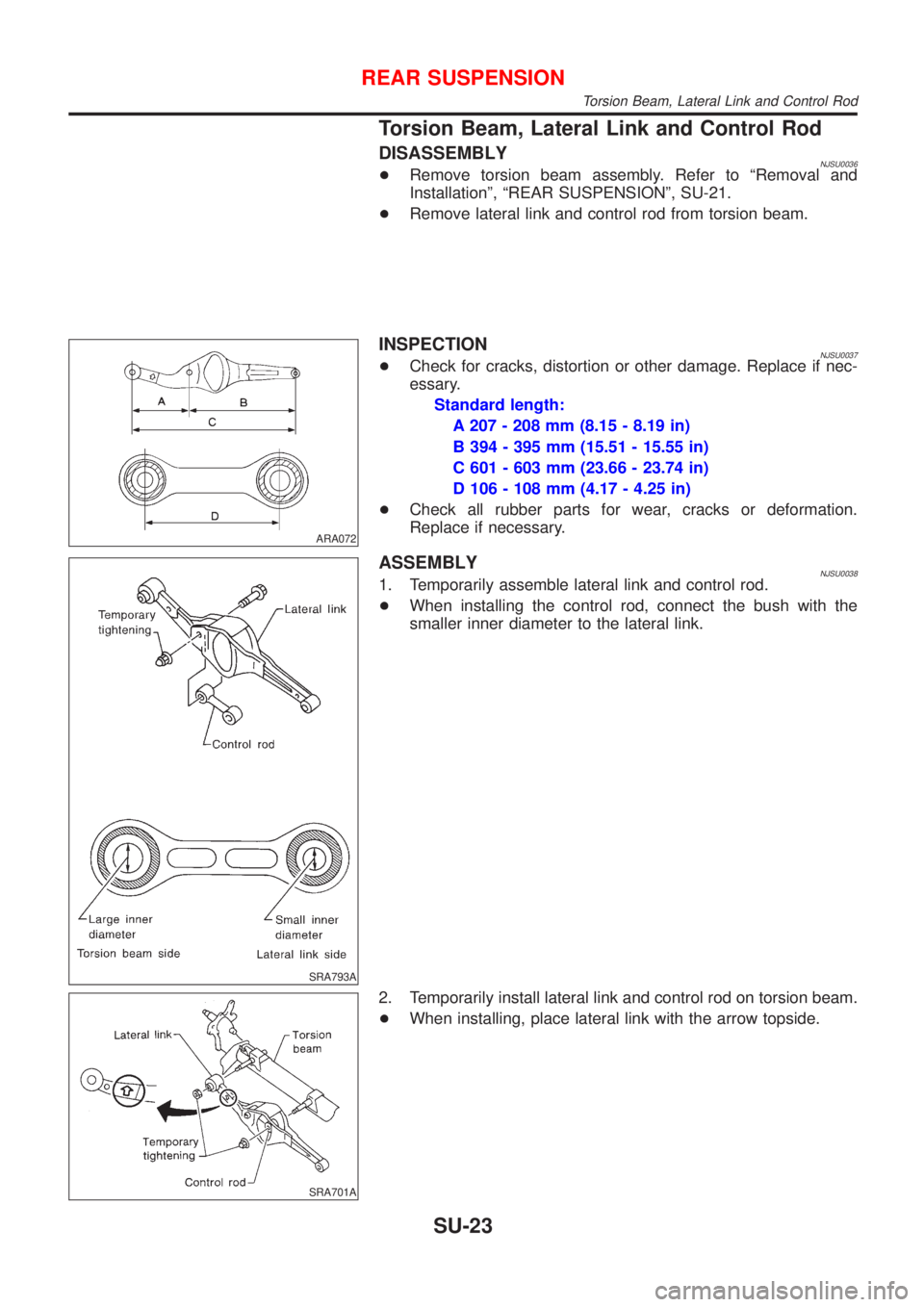

DISASSEMBLYNJSU0036+Remove torsion beam assembly. Refer to ªRemoval and

Installationº, ªREAR SUSPENSIONº, SU-21.

+Remove lateral link and control rod from torsion beam.

ARA072

INSPECTIONNJSU0037+Check for cracks, distortion or other damage. Replace if nec-

essary.

Standard length:

A 207 - 208 mm (8.15 - 8.19 in)

B 394 - 395 mm (15.51 - 15.55 in)

C 601 - 603 mm (23.66 - 23.74 in)

D 106 - 108 mm (4.17 - 4.25 in)

+Check all rubber parts for wear, cracks or deformation.

Replace if necessary.

SRA793A

ASSEMBLYNJSU00381. Temporarily assemble lateral link and control rod.

+When installing the control rod, connect the bush with the

smaller inner diameter to the lateral link.

SRA701A

2. Temporarily install lateral link and control rod on torsion beam.

+When installing, place lateral link with the arrow topside.

REAR SUSPENSION

Torsion Beam, Lateral Link and Control Rod

SU-23

Page 1696 of 2493

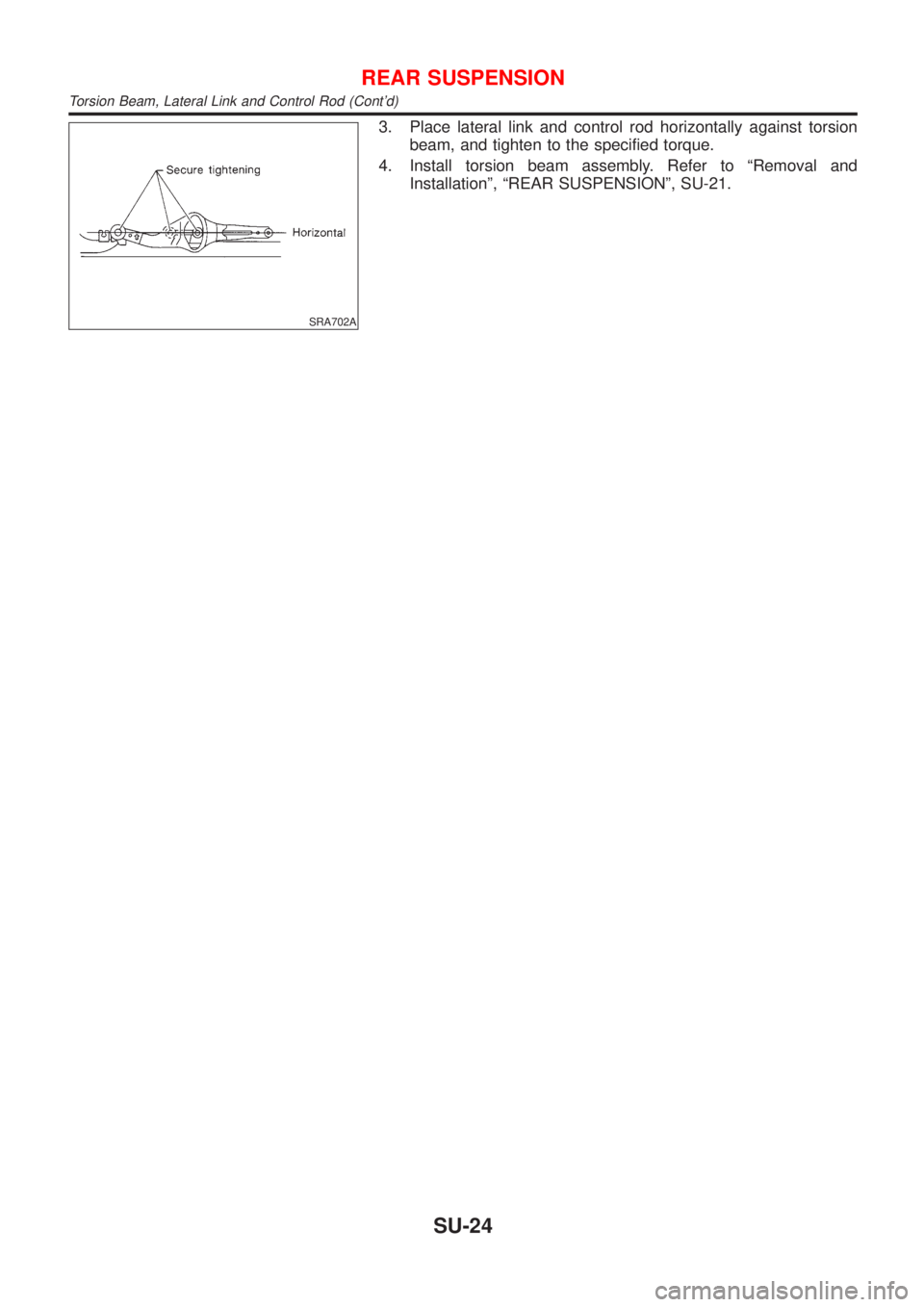

SRA702A

3. Place lateral link and control rod horizontally against torsion

beam, and tighten to the specified torque.

4. Install torsion beam assembly. Refer to ªRemoval and

Installationº, ªREAR SUSPENSIONº, SU-21.

REAR SUSPENSION

Torsion Beam, Lateral Link and Control Rod (Cont'd)

SU-24

Page 1697 of 2493

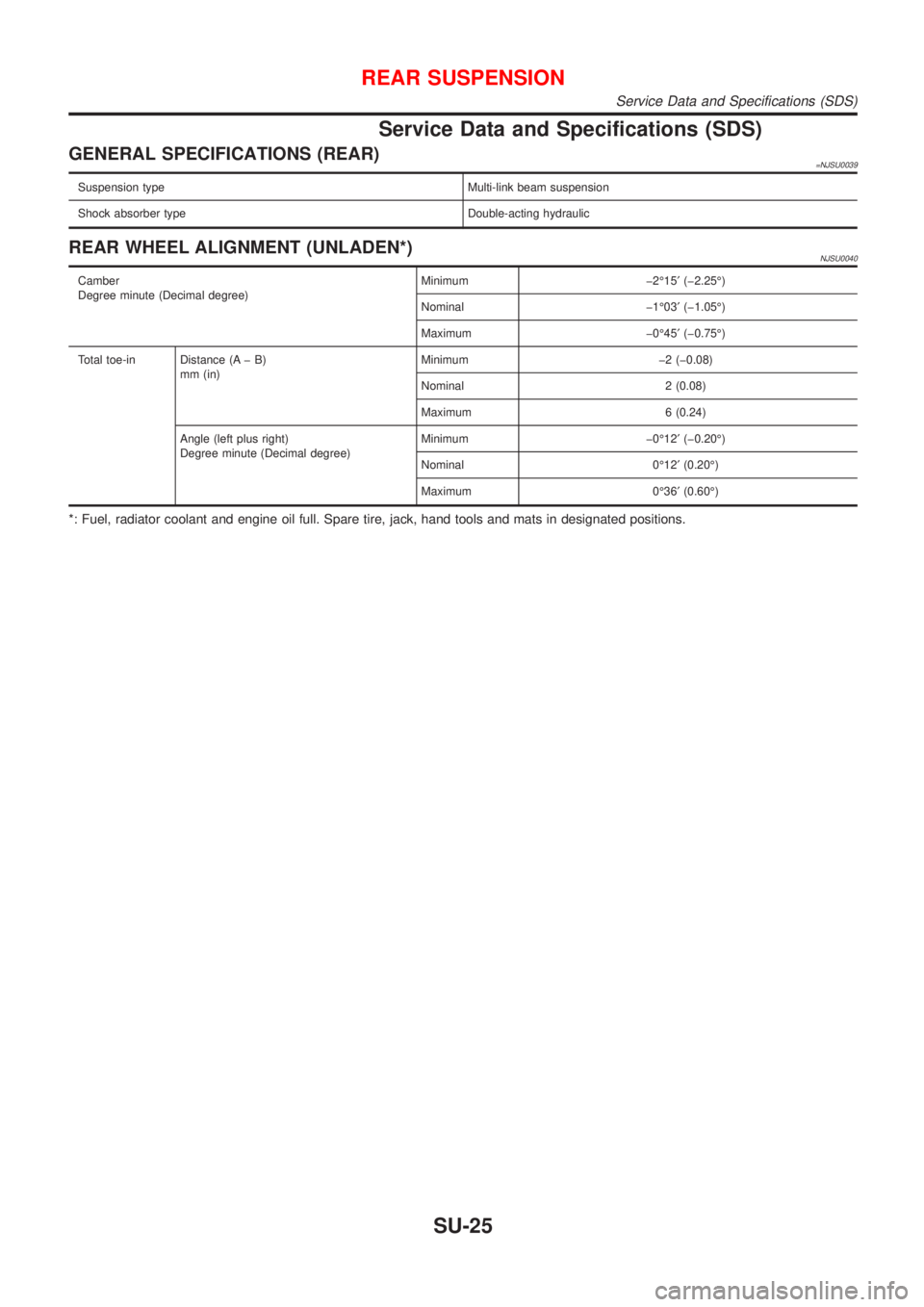

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (REAR)=NJSU0039

Suspension type Multi-link beam suspension

Shock absorber type Double-acting hydraulic

REAR WHEEL ALIGNMENT (UNLADEN*)NJSU0040

Camber

Degree minute (Decimal degree)Minimum þ2É15¢(þ2.25É)

Nominal þ1É03¢(þ1.05É)

Maximum þ0É45¢(þ0.75É)

Total toe-in Distance (A þ B)

mm (in)Minimum þ2 (þ0.08)

Nominal 2 (0.08)

Maximum 6 (0.24)

Angle (left plus right)

Degree minute (Decimal degree)Minimum þ0É12¢(þ0.20É)

Nominal 0É12¢(0.20É)

Maximum 0É36¢(0.60É)

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

REAR SUSPENSION

Service Data and Specifications (SDS)

SU-25

Page 1698 of 2493

REAR SUSPENSION

Service Data and Specifications (SDS) (Cont'd)

SU-26

Page 1704 of 2493

NJBR0005

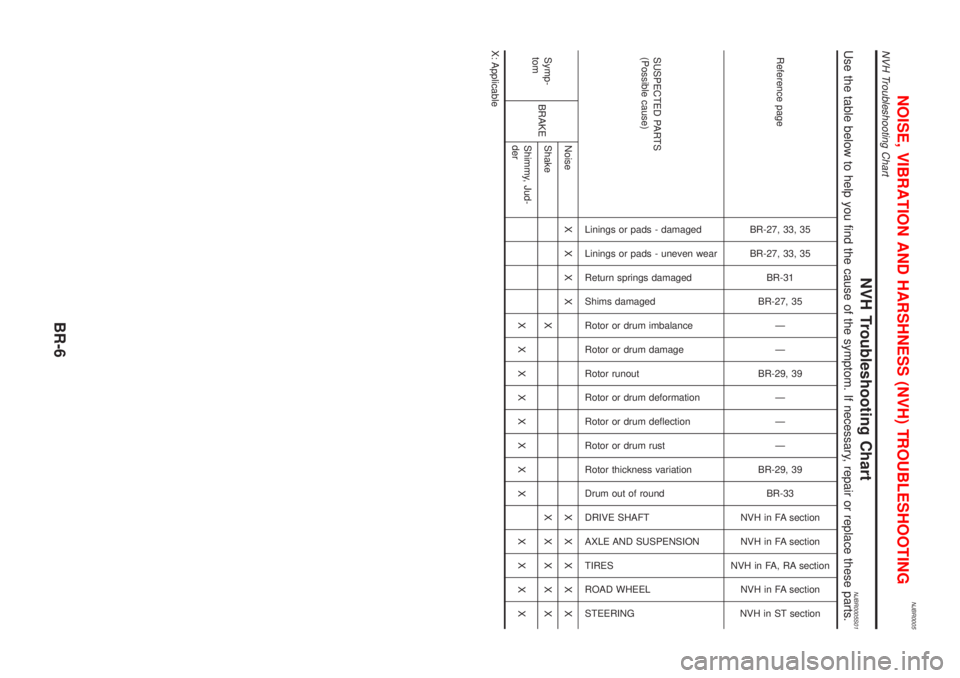

NVH Troubleshooting ChartNJBR0005S01Use the table below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

BR-27, 33, 35

BR-27, 33, 35

BR-31

BR-27, 35

Ð

Ð

BR-29, 39

Ð

Ð

Ð

BR-29, 39

BR-33

NVH in FA section

NVH in FA section

NVH in FA, RA section

NVH in FA section

NVH in ST section

SUSPECTED PARTS

(Possible cause)

Linings or pads - damaged

Linings or pads - uneven wear

Return springs damaged

Shims damaged

Rotor or drum imbalance

Rotor or drum damage

Rotor runout

Rotor or drum deformation

Rotor or drum deflection

Rotor or drum rust

Rotor thickness variation

Drum out of round

DRIVE SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

STEERING

Symp-

tomBRAKENoiseXXXX XXXXX

Shake XXXXXX

Shimmy, Jud-

derXXXXXXXX XXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

BR-6

Page 1795 of 2493

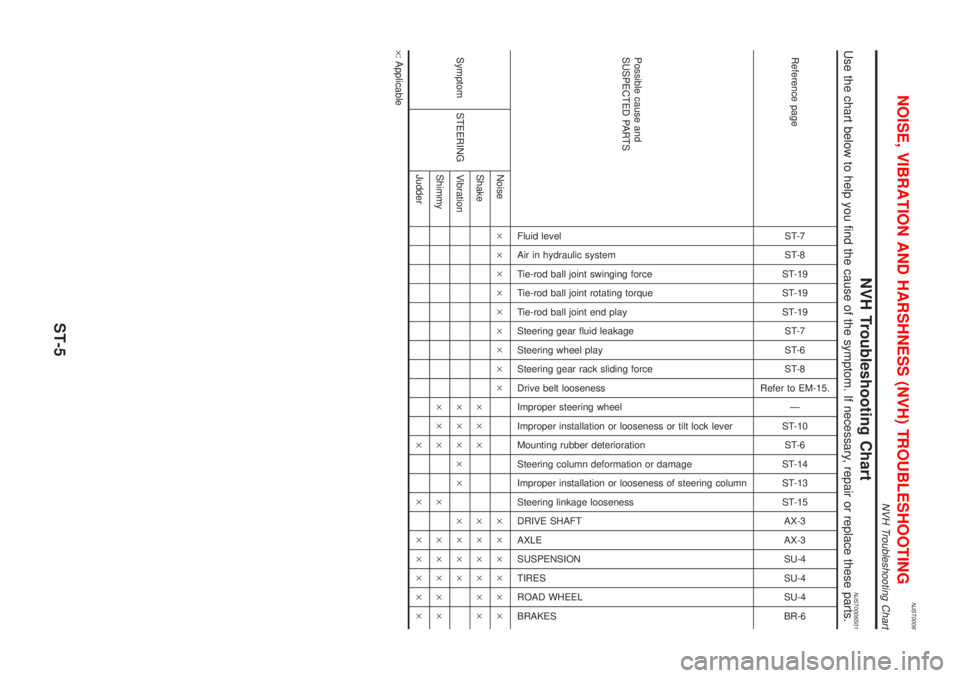

NJST0006

NVH Troubleshooting ChartNJST0006S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-7

ST-8

ST-19

ST-19

ST-19

ST-7

ST-6

ST-8

Refer to EM-15.

Ð

ST-10

ST-6

ST-14

ST-13

ST-15

AX-3

AX-3

SU-4

SU-4

SU-4

BR-6

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symptom STEERINGNoise´´´´´´´´´ ´´´´´´

Shake´´´ ´´´´´´

Vibration´´´´´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-5

Page 1796 of 2493

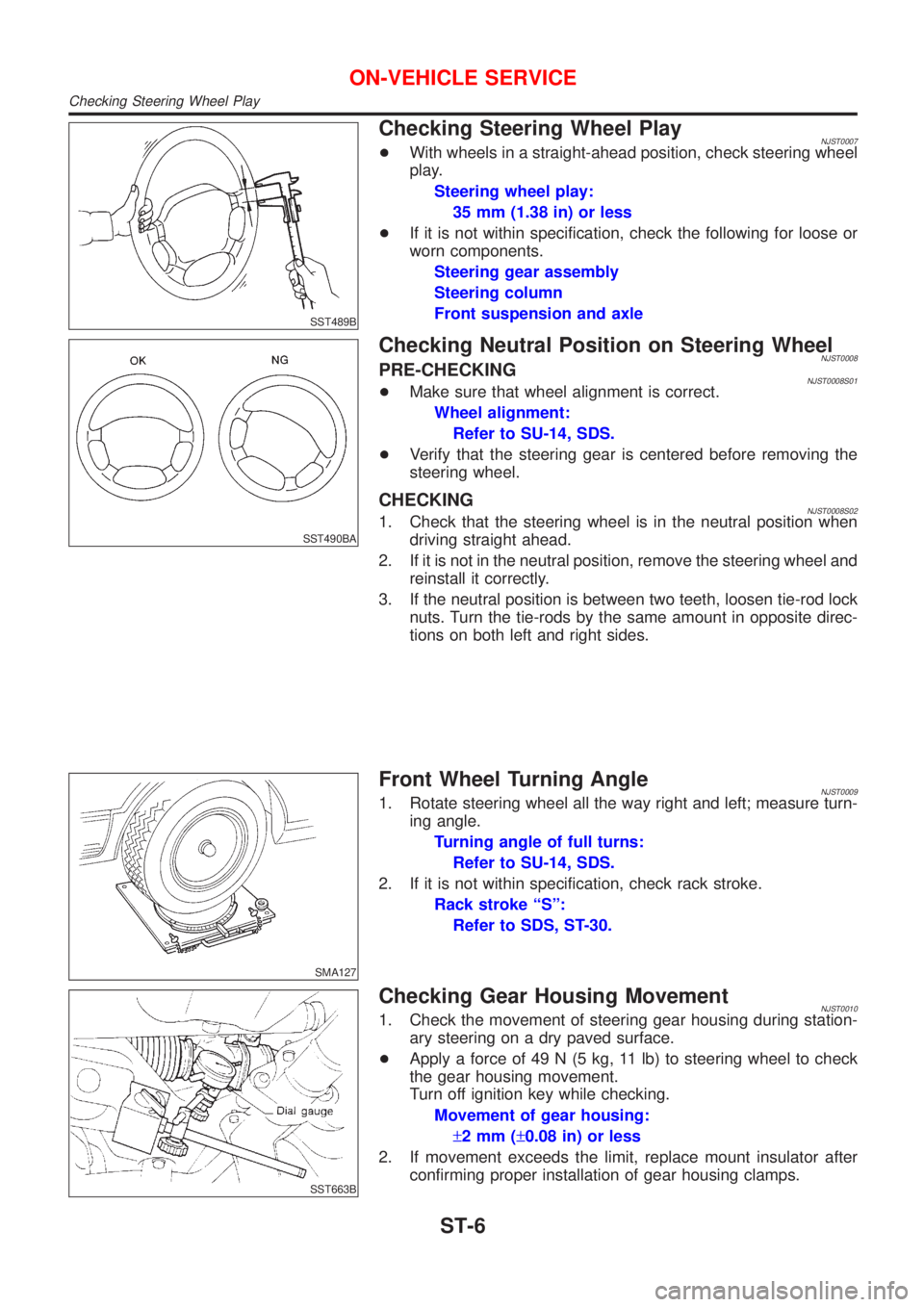

SST489B

Checking Steering Wheel PlayNJST0007+With wheels in a straight-ahead position, check steering wheel

play.

Steering wheel play:

35 mm (1.38 in) or less

+If it is not within specification, check the following for loose or

worn components.

Steering gear assembly

Steering column

Front suspension and axle

SST490BA

Checking Neutral Position on Steering WheelNJST0008PRE-CHECKINGNJST0008S01+Make sure that wheel alignment is correct.

Wheel alignment:

Refer to SU-14, SDS.

+Verify that the steering gear is centered before removing the

steering wheel.

CHECKINGNJST0008S021. Check that the steering wheel is in the neutral position when

driving straight ahead.

2. If it is not in the neutral position, remove the steering wheel and

reinstall it correctly.

3. If the neutral position is between two teeth, loosen tie-rod lock

nuts. Turn the tie-rods by the same amount in opposite direc-

tions on both left and right sides.

SMA127

Front Wheel Turning AngleNJST00091. Rotate steering wheel all the way right and left; measure turn-

ing angle.

Turning angle of full turns:

Refer to SU-14, SDS.

2. If it is not within specification, check rack stroke.

Rack stroke ªSº:

Refer to SDS, ST-30.

SST663B

Checking Gear Housing MovementNJST00101. Check the movement of steering gear housing during station-

ary steering on a dry paved surface.

+Apply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

ON-VEHICLE SERVICE

Checking Steering Wheel Play

ST-6