wiring NISSAN ALMERA N16 2001 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 347 of 2493

21 CHECK HEATED OXYGEN SENSOR 1 (FRONT) SIGNAL

With CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. See ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode.

6. Running engine at 2,000 rpm under no-load (engine is warmed up to normal operating temperature.), check that the

monitor fluctuates between ªLEANº and ªRICHº more than 5 times during 10 seconds.

1 time: RICH®LEAN®RICH

2 times: RICH®LEAN®RICH®LEAN®RICH

Without CONSULT-II

1. Stop engine.

2. Replace heated oxygen sensor 1 (front).

3. Start engine and warm it up to normal operating temperature.

4. Run engine at approx. 2,000 rpm for approx. 2 minutes under no-load.

5. Set voltmeter probe between ECM terminal 62 and ground.

6. Make sure that the voltage fluctuates between 0 to 0.3V and 0.6 to 1.0V more than 5 times during 10 seconds at 2,000

rpm.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0 - 0.3V

OK or NG

OK©INSPECTION END

NG©GO TO 22.

22 DETECT MALFUNCTIONING PART

Check the following.

1. Check fuel pressure regulator. Refer to EC-39.

2. Check mass air flow sensor and its circuit. Refer to EC-152.

3. Check injector and its circuit. Refer to EC-446.

Clean or replace if necessary.

4. Check engine coolant temperature sensor and its circuit. Refer to EC-163.

5. Check ECM function by substituting another known-good ECM.

(ECM may be the cause of a problem, but this is rarely the case.)

©GO TO 3.

23 CHECK HEATED OXYGEN SENSOR 1 (FRONT) HARNESS

1. Turn off engine and disconnect battery ground cable.

2. Disconnect ECM harness connector.

3. Disconnect heated oxygen sensor 1 (front) harness connector.

4. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 1.

Refer to Wiring Diagram, EC-176.

Continuity should exist.

OK or NG

OK©GO TO 25.

NG©GO TO 24.

24 REPAIR OR REPLACE

Repair or replace harness between ECM and heated oxygen sensor 1 (front).

©GO TO 3.

BASIC SERVICE PROCEDUREQG

Inspection Procedure (Cont'd)

EC-51

Page 390 of 2493

MEF036D

SEF233G

SEF234G

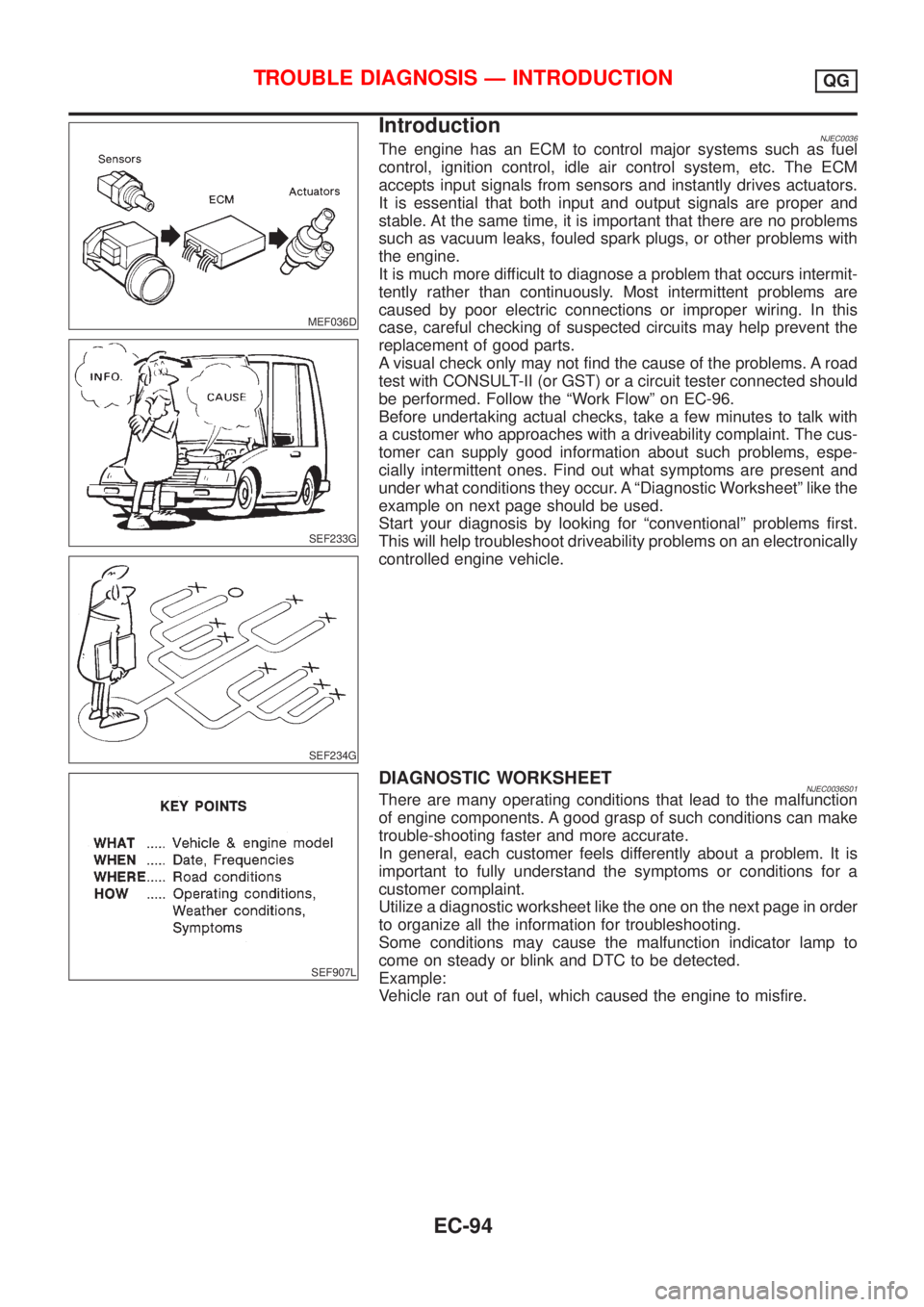

IntroductionNJEC0036The engine has an ECM to control major systems such as fuel

control, ignition control, idle air control system, etc. The ECM

accepts input signals from sensors and instantly drives actuators.

It is essential that both input and output signals are proper and

stable. At the same time, it is important that there are no problems

such as vacuum leaks, fouled spark plugs, or other problems with

the engine.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or improper wiring. In this

case, careful checking of suspected circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems. A road

test with CONSULT-II (or GST) or a circuit tester connected should

be performed. Follow the ªWork Flowº on EC-96.

Before undertaking actual checks, take a few minutes to talk with

a customer who approaches with a driveability complaint. The cus-

tomer can supply good information about such problems, espe-

cially intermittent ones. Find out what symptoms are present and

under what conditions they occur. A ªDiagnostic Worksheetº like the

example on next page should be used.

Start your diagnosis by looking for ªconventionalº problems first.

This will help troubleshoot driveability problems on an electronically

controlled engine vehicle.

SEF907L

DIAGNOSTIC WORKSHEETNJEC0036S01There are many operating conditions that lead to the malfunction

of engine components. A good grasp of such conditions can make

trouble-shooting faster and more accurate.

In general, each customer feels differently about a problem. It is

important to fully understand the symptoms or conditions for a

customer complaint.

Utilize a diagnostic worksheet like the one on the next page in order

to organize all the information for troubleshooting.

Some conditions may cause the malfunction indicator lamp to

come on steady or blink and DTC to be detected.

Example:

Vehicle ran out of fuel, which caused the engine to misfire.

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG

EC-94

Page 393 of 2493

DESCRIPTION FOR WORK FLOWNJEC0563S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using

the ªDIAGNOSTIC WORK SHEETº, EC-95.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or GST) the (1st trip) DTC

and the (1st trip) freeze frame data, then erase the DTC and the data. (Refer to EC-68, EC-71.) The (1st trip)

DTC and the (1st trip) freeze frame data can be used when duplicating the incident at STEP III & IV.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The ªSymptom Matrix Chartº will be useful. See EC-124.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) DTC by driving in (or performing) the ªDTC Confirmation Procedureº. Check and read

the (1st trip) DTC and (1st trip) freeze frame data by using CONSULT-II or GST.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

In case the ªDTC Confirmation Procedureº is not available, perform the ªOverall Function Checkº instead. The

(1st trip) DTC cannot be displayed by this check, however, this simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOverall Function Checkº is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed refer to ªBASIC INSPECTIONº, EC-98. If CONSULT-II is available, per-

form ªDATA MONITOR (SPEC)º mode with CONSULT-II and proceed to the ªTROUBLE DIAGNOSIS Ð SPECI-

FICATION VALUEº. (Refer to EC-140.) (If malfunction is detected, proceed to ªREPAIR/REPLACEº.) Then per-

form inspections according to the Symptom Matrix Chart. (Refer to EC-124.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-132.

The ªDiagnostic Procedureº in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI section

(ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº, ªCircuit Inspectionº).

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº,

EC-144.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDTC Confirmation Procedureº and confirm the normal code [DTC No. P0000] is detected. If the

incident is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM and TCM (Transmission control module). (Refer to EC-68, EC-71.)

TROUBLE DIAGNOSIS Ð INTRODUCTIONQG

Work Flow (Cont'd)

EC-97

Page 394 of 2493

Basic InspectionNJEC1785MODELS WITH THROTTLE POSITION SWITCHNJEC1785S01Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

On vehicle equipped with daytime light systems, set lighting

switch to the 1st position to light only small lamps.

+Air conditioner switch is OFF,

+Rear window defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

+Harness connectors for improper connections

+Vacuum hoses for splits, kinks and improper connections

+Wiring for improper connections, pinches and cuts

+Air cleaner clogging

+Hoses and ducts for leaks

SEF983U

©GO TO 2.

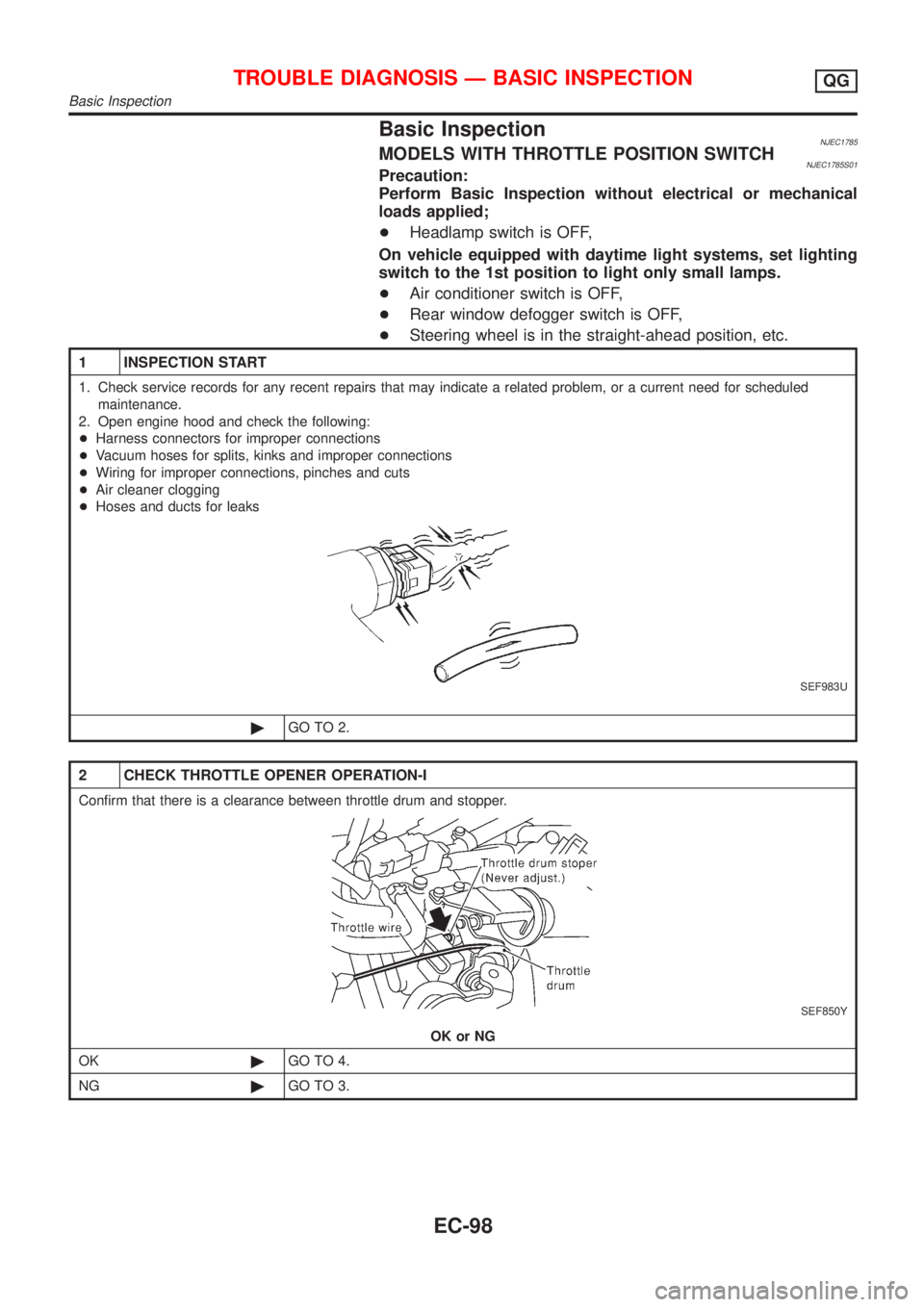

2 CHECK THROTTLE OPENER OPERATION-I

Confirm that there is a clearance between throttle drum and stopper.

SEF850Y

OK or NG

OK©GO TO 4.

NG©GO TO 3.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection

EC-98

Page 409 of 2493

35 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 31.

OK or NG

OK©GO TO 37.

NG©GO TO 36.

36 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-27, ªInstallationº.

OK or NG

OK©GO TO 34.

NG©1. Repair the timing chain installation.

2. GO TO 32.

37 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM and TCM (Transmission control module).

Refer to ªHow to Erase Emission-Related Diagnostic Informationº, EC-68 or EC-75 and AT-50, ªHOW TO ERASE DTCº.

OK or NG

©INSPECTION END

MODELS WITHOUT THROTTLE POSITION SWITCHNJEC1785S02Precaution:

Perform Basic Inspection without electrical or mechanical

loads applied;

+Headlamp switch is OFF,

On vehicle equipped with daytime light system, set lighting

switch to the 1st position to light only small lamps.

+Air conditioner switch is OFF,

+Rear window defogger switch is OFF,

+Steering wheel is in the straight-ahead position, etc.

1 INSPECTION START

1. Check service records for any recent repairs that may indicate a related problem, or a current need for scheduled

maintenance.

2. Open engine hood and check the following:

+Harness connectors for improper connections

+Vacuum hoses for splits, kinks and improper connections

+Wiring for improper connections, pinches and cuts

+Air cleaner clogging

+Hoses and ducts for leaks

SEF983U

©GO TO 2.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONQG

Basic Inspection (Cont'd)

EC-113

Page 441 of 2493

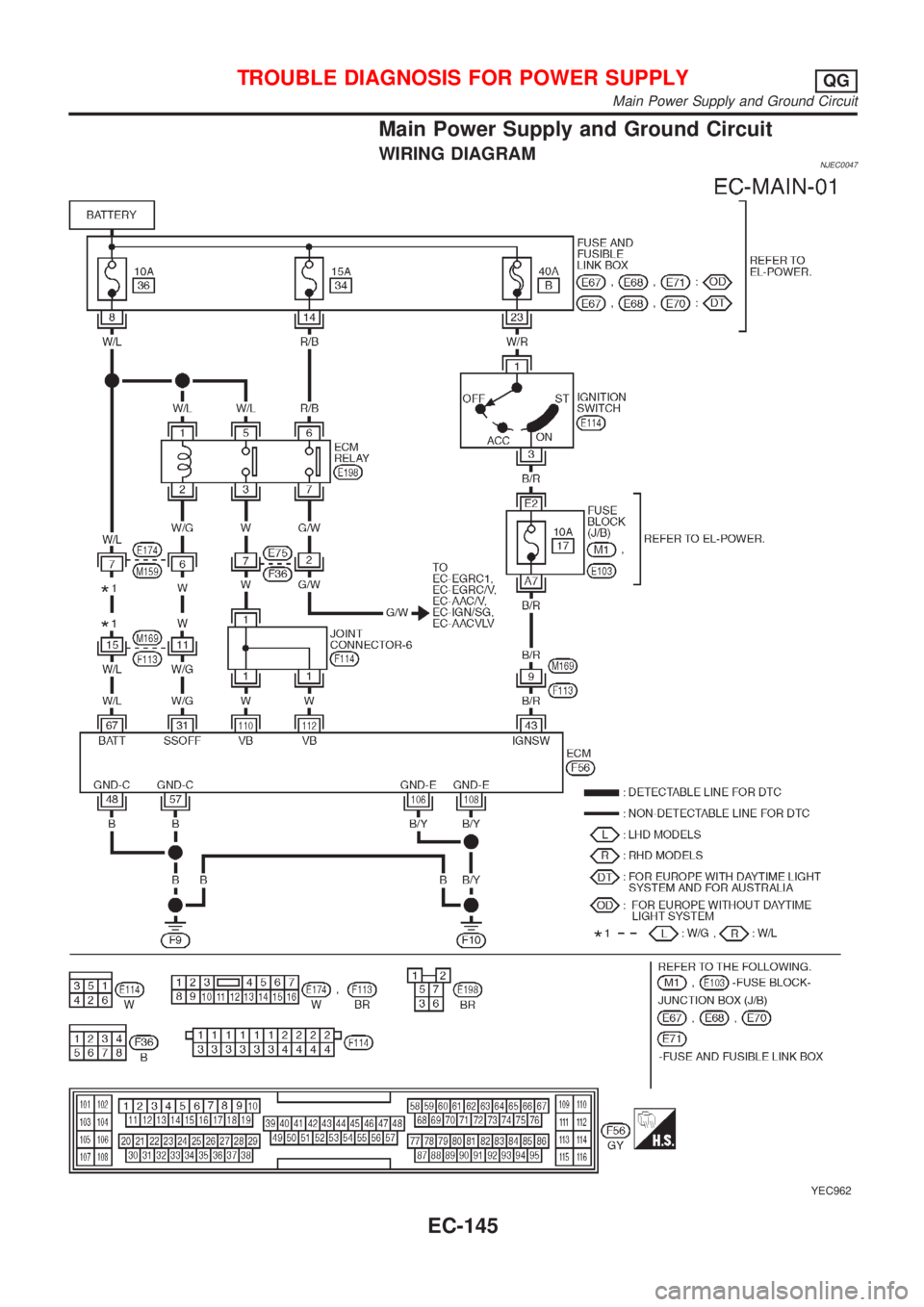

Main Power Supply and Ground Circuit

WIRING DIAGRAMNJEC0047

YEC962

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit

EC-145

Page 443 of 2493

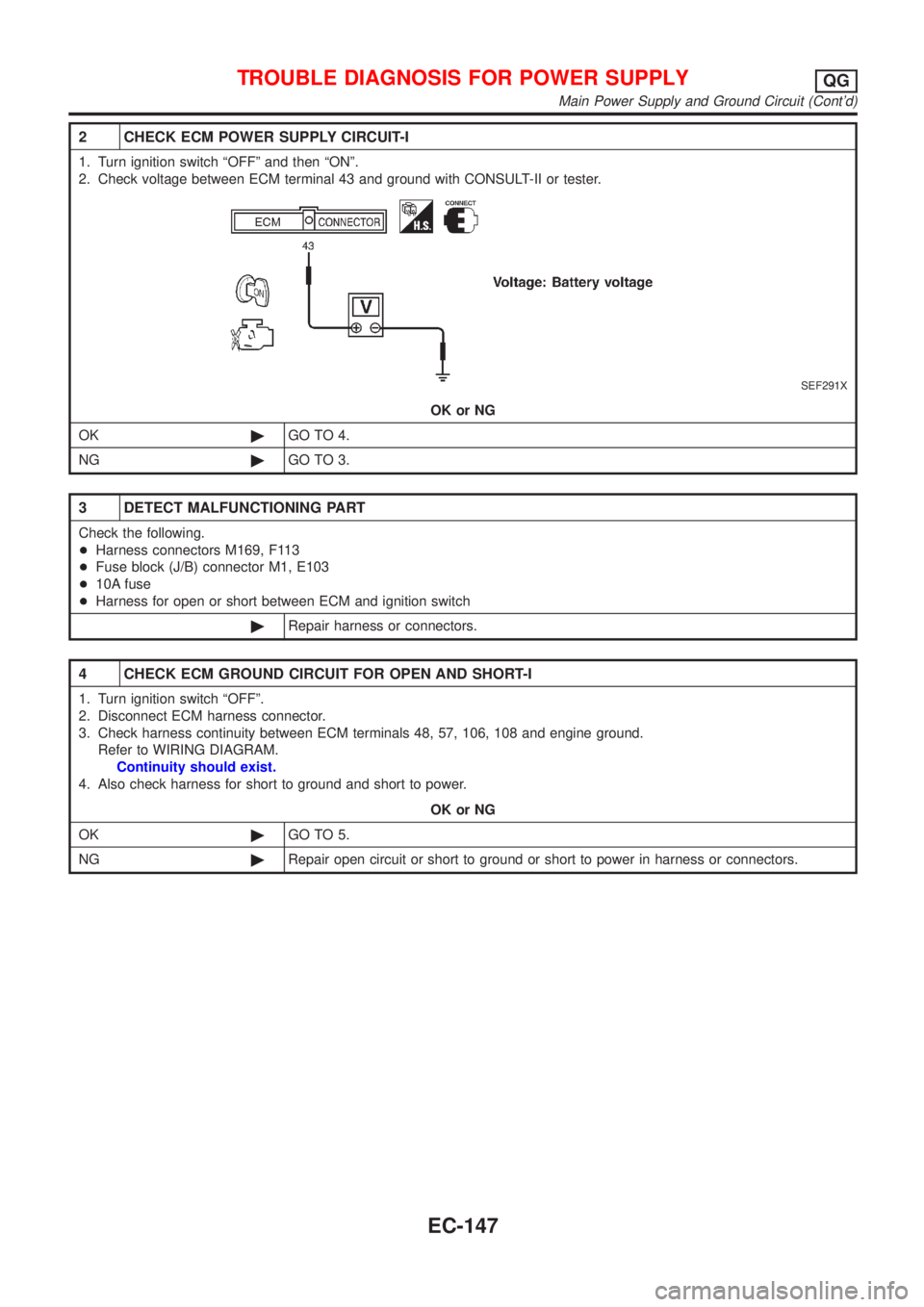

2 CHECK ECM POWER SUPPLY CIRCUIT-I

1. Turn ignition switch ªOFFº and then ªONº.

2. Check voltage between ECM terminal 43 and ground with CONSULT-II or tester.

SEF291X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M169, F113

+Fuse block (J/B) connector M1, E103

+10A fuse

+Harness for open or short between ECM and ignition switch

©Repair harness or connectors.

4 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-147

Page 446 of 2493

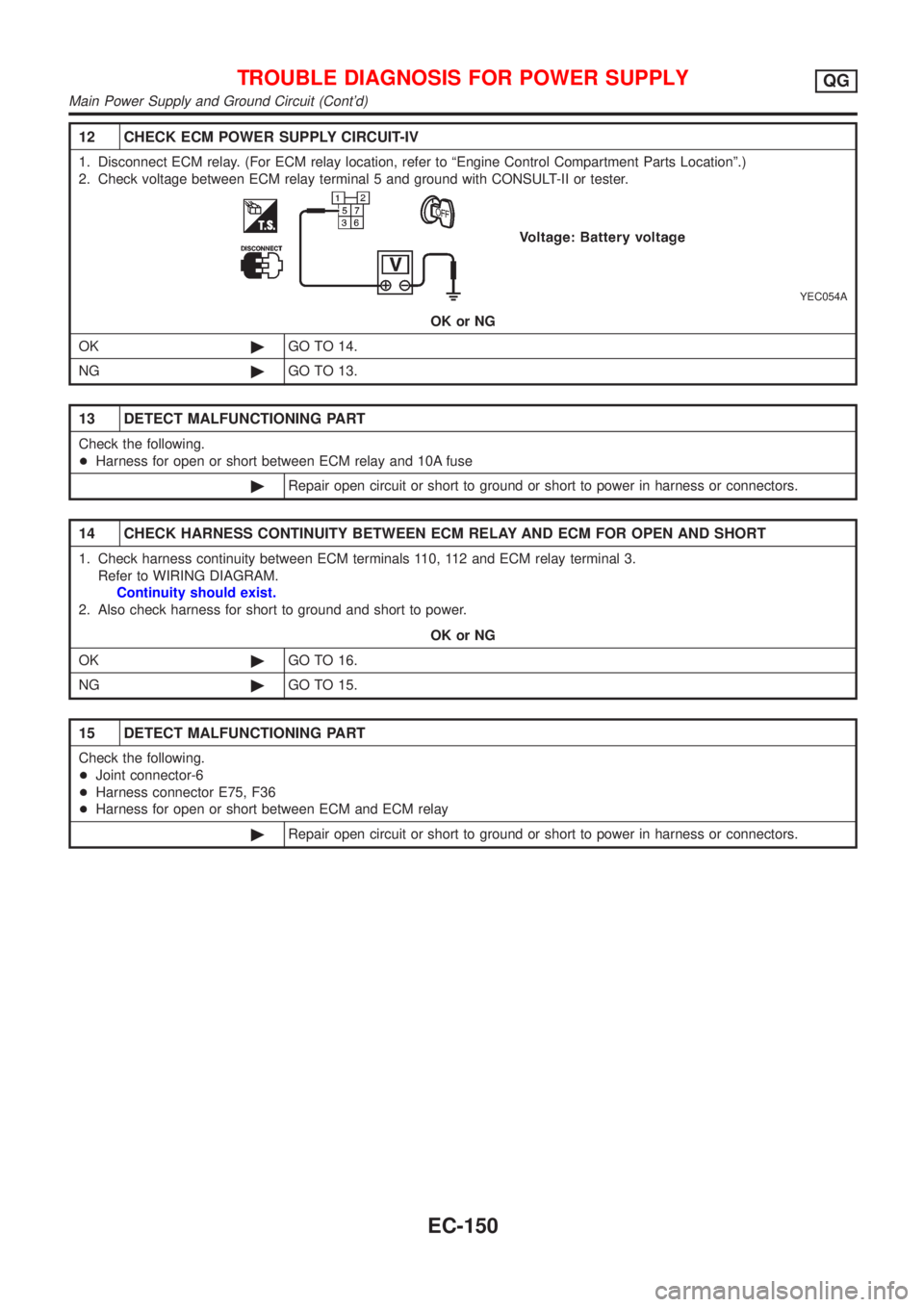

12 CHECK ECM POWER SUPPLY CIRCUIT-IV

1. Disconnect ECM relay. (For ECM relay location, refer to ªEngine Control Compartment Parts Locationº.)

2. Check voltage between ECM relay terminal 5 and ground with CONSULT-II or tester.

YEC054A

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 DETECT MALFUNCTIONING PART

Check the following.

+Harness for open or short between ECM relay and 10A fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

14 CHECK HARNESS CONTINUITY BETWEEN ECM RELAY AND ECM FOR OPEN AND SHORT

1. Check harness continuity between ECM terminals 110, 112 and ECM relay terminal 3.

Refer to WIRING DIAGRAM.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 16.

NG©GO TO 15.

15 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-6

+Harness connector E75, F36

+Harness for open or short between ECM and ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-150

Page 447 of 2493

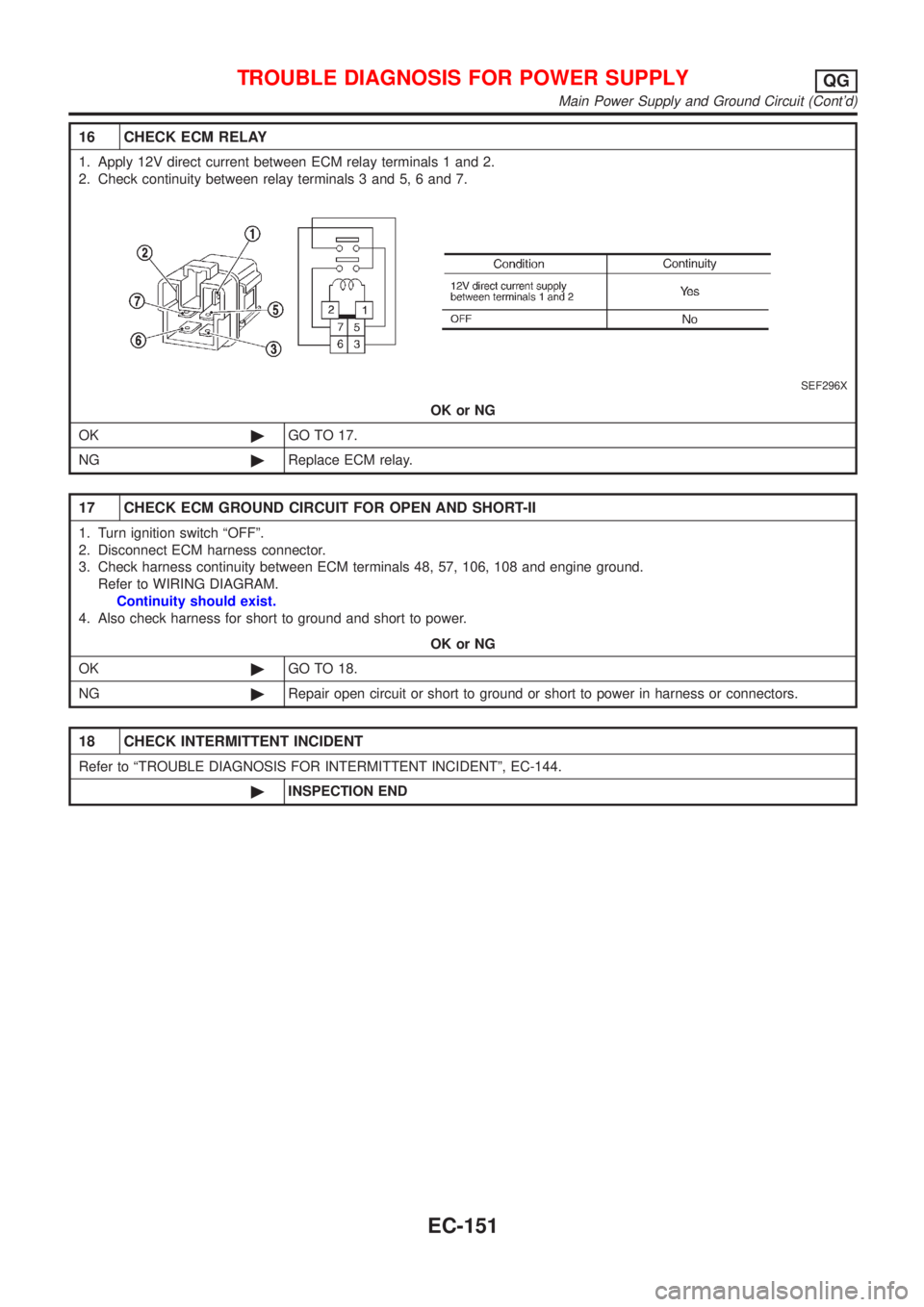

16 CHECK ECM RELAY

1. Apply 12V direct current between ECM relay terminals 1 and 2.

2. Check continuity between relay terminals 3 and 5, 6 and 7.

SEF296X

OK or NG

OK©GO TO 17.

NG©Replace ECM relay.

17 CHECK ECM GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminals 48, 57, 106, 108 and engine ground.

Refer to WIRING DIAGRAM.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 18.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

18 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

TROUBLE DIAGNOSIS FOR POWER SUPPLYQG

Main Power Supply and Ground Circuit (Cont'd)

EC-151

Page 450 of 2493

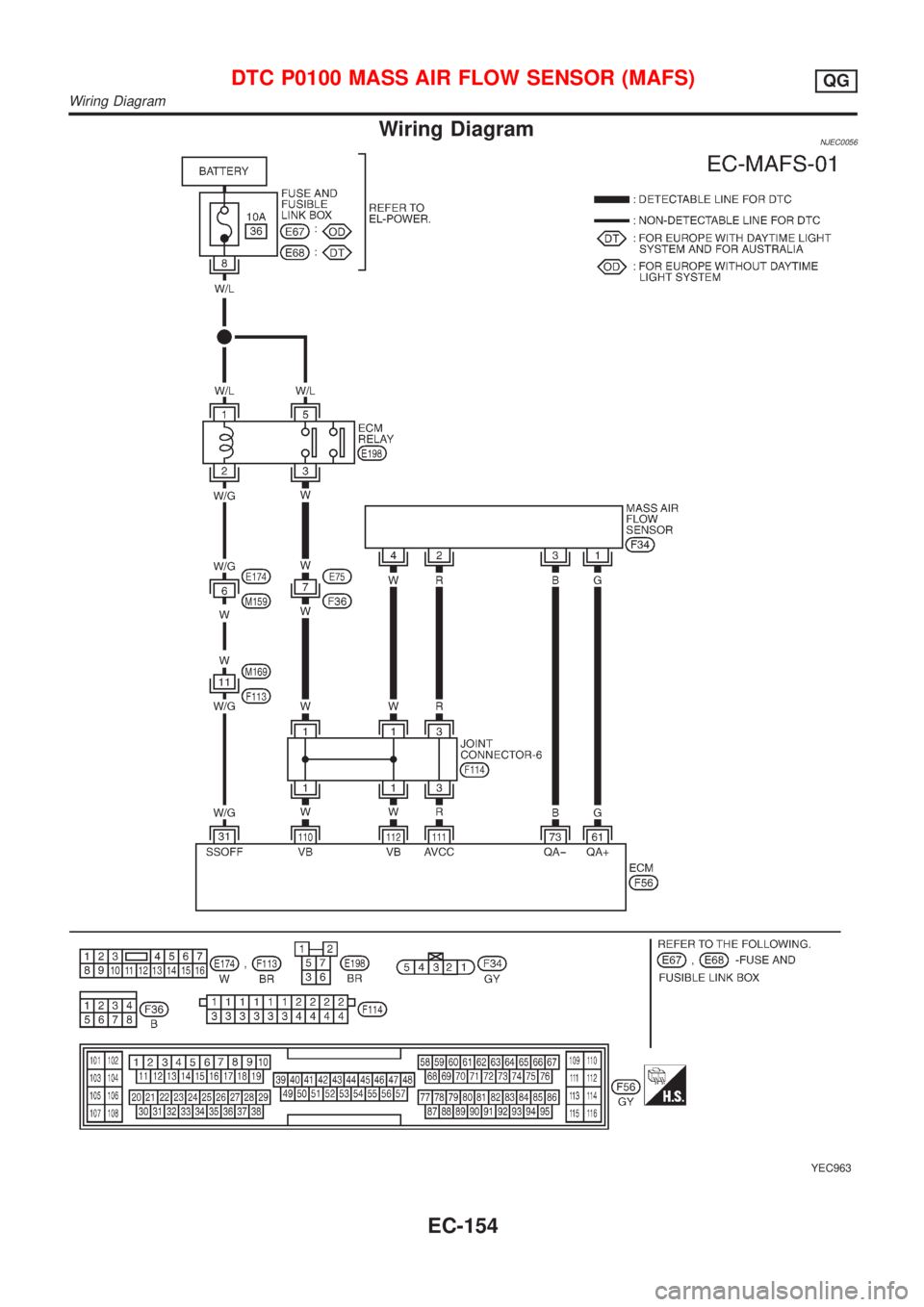

Wiring DiagramNJEC0056

YEC963

DTC P0100 MASS AIR FLOW SENSOR (MAFS)QG

Wiring Diagram

EC-154