NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 541 of 2493

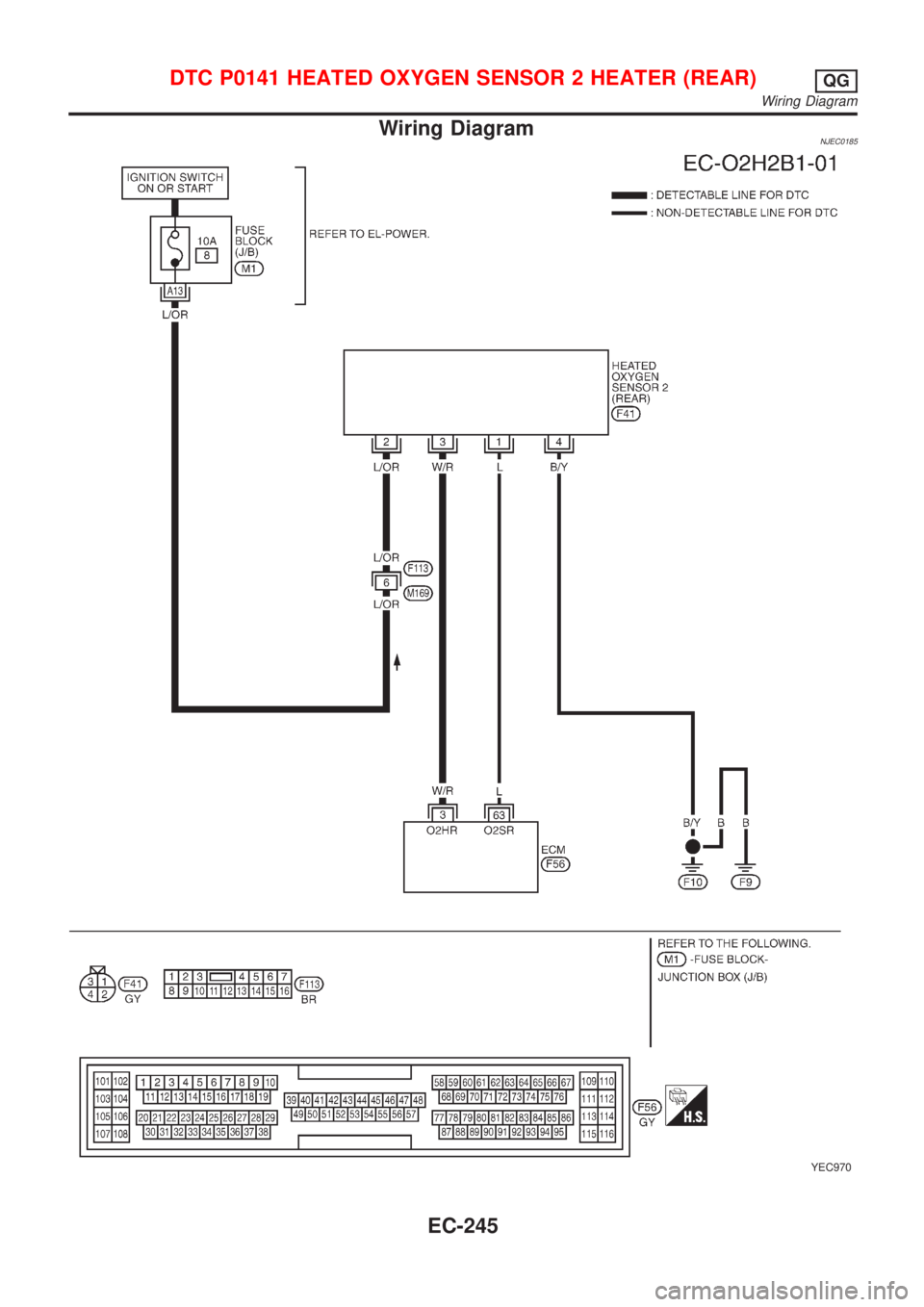

Wiring DiagramNJEC0185

YEC970

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Wiring Diagram

EC-245

Page 542 of 2493

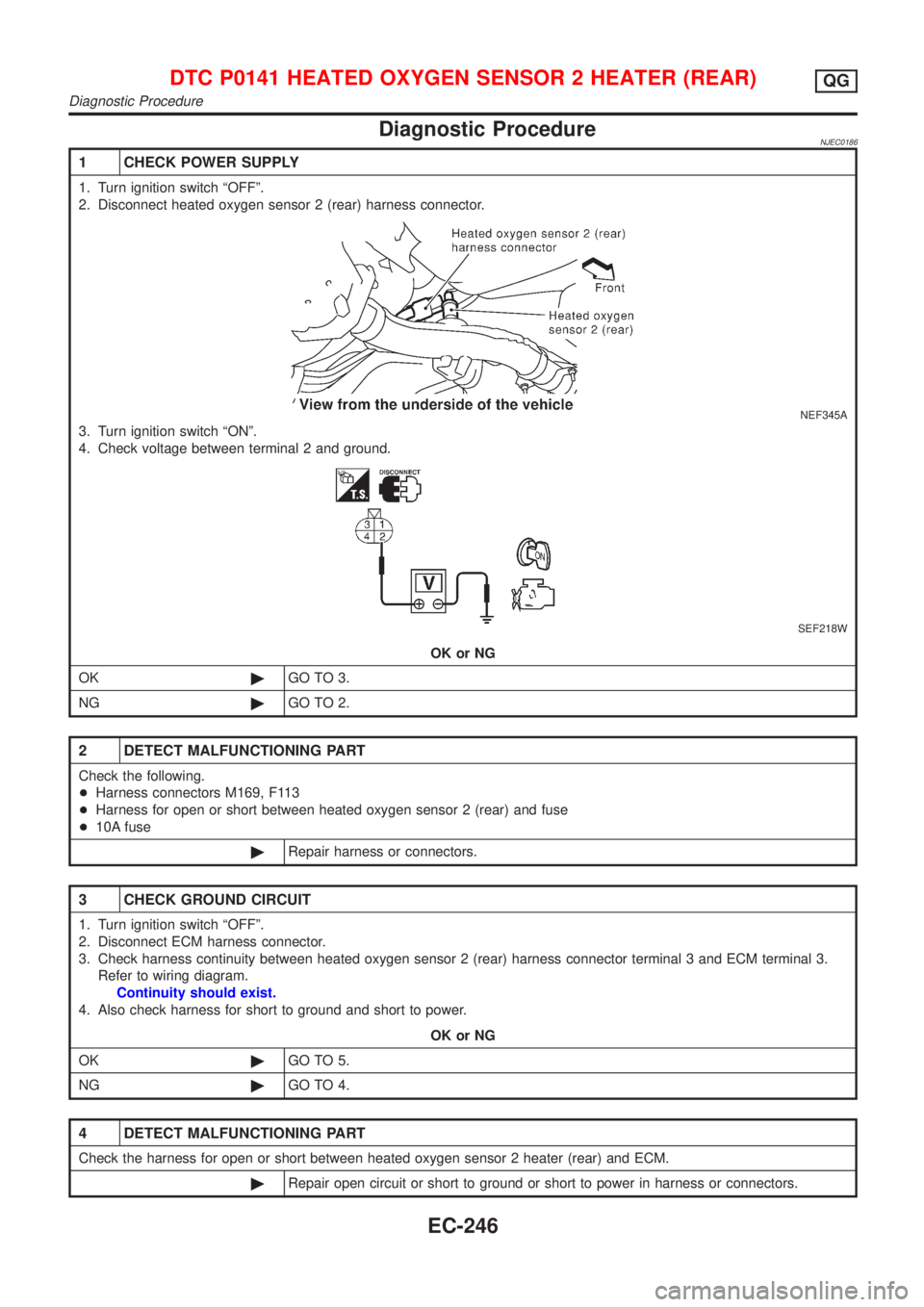

Diagnostic ProcedureNJEC0186

1 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 2 (rear) harness connector.

NEF345A

3. Turn ignition switch ªONº.

4. Check voltage between terminal 2 and ground.

SEF218W

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M169, F113

+Harness for open or short between heated oxygen sensor 2 (rear) and fuse

+10A fuse

©Repair harness or connectors.

3 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 2 (rear) harness connector terminal 3 and ECM terminal 3.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between heated oxygen sensor 2 heater (rear) and ECM.

©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Diagnostic Procedure

EC-246

Page 543 of 2493

5 CHECK HEATED OXYGEN SENSOR 2 HEATER (REAR)

Refer to ªComponent Inspectionº, EC-247.

OK or NG

OK©GO TO 6.

NG©Replace heated oxygen sensor 2 (rear).

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

SEF221W

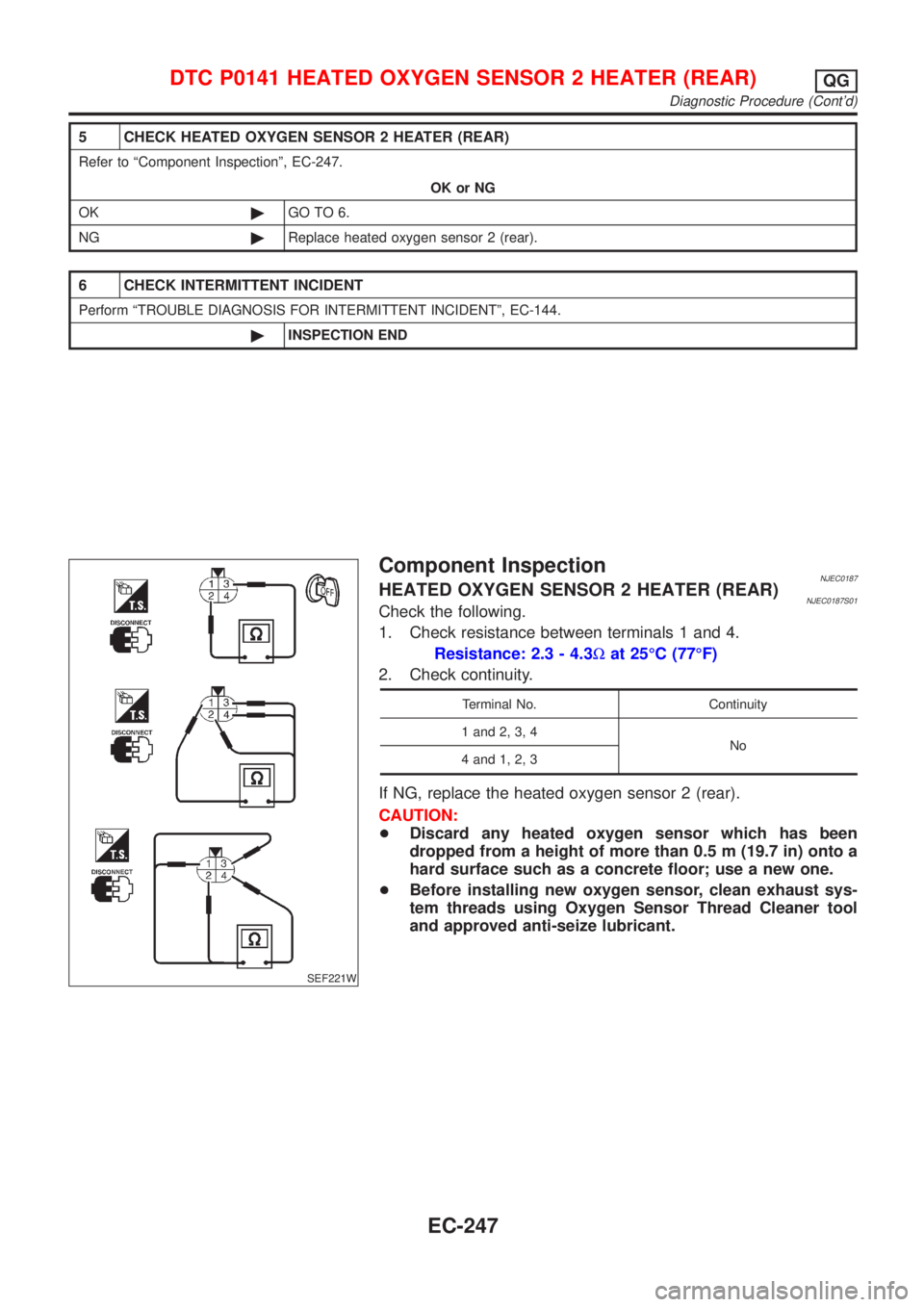

Component InspectionNJEC0187HEATED OXYGEN SENSOR 2 HEATER (REAR)NJEC0187S01Check the following.

1. Check resistance between terminals 1 and 4.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

2. Check continuity.

Terminal No. Continuity

1 and 2, 3, 4

No

4 and 1, 2, 3

If NG, replace the heated oxygen sensor 2 (rear).

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

DTC P0141 HEATED OXYGEN SENSOR 2 HEATER (REAR)QG

Diagnostic Procedure (Cont'd)

EC-247

Page 544 of 2493

On Board Diagnosis LogicNJEC0188With the Air/Fuel Mixture Ratio Self-Learning Control, the actual mixture ratio can be brought closely to the

theoretical mixture ratio based on the mixture ratio feedback signal from the heated oxygen sensor 1 (front).

The ECM calculates the necessary compensation to correct the offset between the actual and the theoretical

ratios.

In case the amount of the compensation value is extremely large (The actual mixture ratio is too lean.), the

ECM judges the condition as the fuel injection system malfunction and lights up the MIL (2 trip detection logic).

Sensor Input Signal to ECMECM func-

tionActuator

Heated oxygen sensor 1 (front)Density of oxygen in exhaust gas

(Mixture ratio feedback signal)Fuel injec-

tion & mix-

ture ratio

controlInjectors

DTC No. Malfunction is detected when ... Check Items (Possible Cause)

P0171

0171+Fuel injection system does not operate properly.

+The amount of mixture ratio compensation is too large.

(The mixture ratio is too lean.)+Intake air leaks

+Heated oxygen sensor 1 (front)

+Injectors

+Exhaust gas leaks

+Incorrect fuel pressure

+Lack of fuel

+Mass air flow sensor

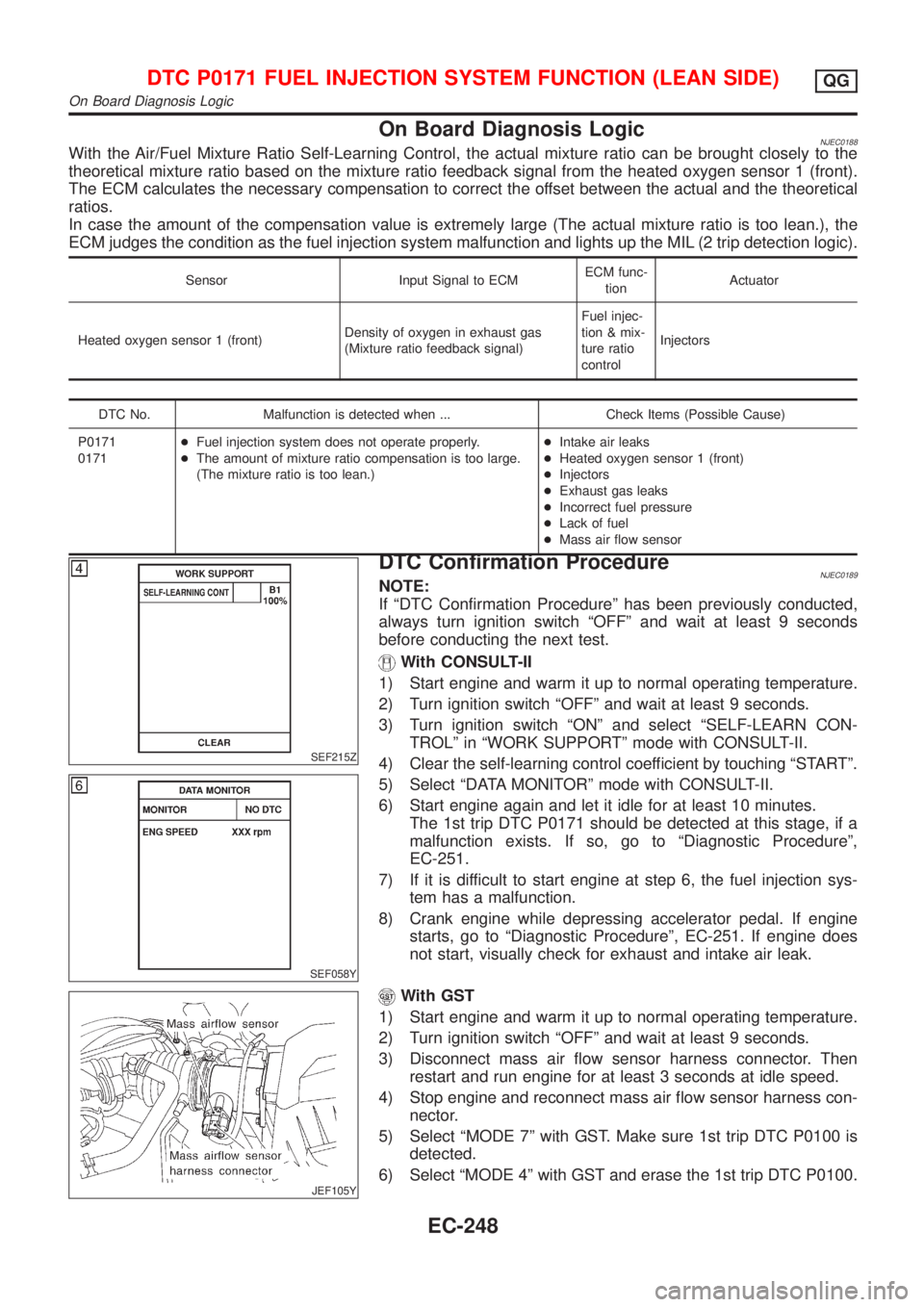

SEF215Z

SEF058Y

DTC Confirmation ProcedureNJEC0189NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 9 seconds

before conducting the next test.

With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Turn ignition switch ªONº and select ªSELF-LEARN CON-

TROLº in ªWORK SUPPORTº mode with CONSULT-II.

4) Clear the self-learning control coefficient by touching ªSTARTº.

5) Select ªDATA MONITORº mode with CONSULT-II.

6) Start engine again and let it idle for at least 10 minutes.

The 1st trip DTC P0171 should be detected at this stage, if a

malfunction exists. If so, go to ªDiagnostic Procedureº,

EC-251.

7) If it is difficult to start engine at step 6, the fuel injection sys-

tem has a malfunction.

8) Crank engine while depressing accelerator pedal. If engine

starts, go to ªDiagnostic Procedureº, EC-251. If engine does

not start, visually check for exhaust and intake air leak.

JEF105Y

With GST

1) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 9 seconds.

3) Disconnect mass air flow sensor harness connector. Then

restart and run engine for at least 3 seconds at idle speed.

4) Stop engine and reconnect mass air flow sensor harness con-

nector.

5) Select ªMODE 7º with GST. Make sure 1st trip DTC P0100 is

detected.

6) Select ªMODE 4º with GST and erase the 1st trip DTC P0100.

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

On Board Diagnosis Logic

EC-248

Page 545 of 2493

7) Start engine again and run it for at least 10 minutes at idle

speed.

8) Select ªMODE 7º with GST. The 1st trip DTC P0171 should be

detected at this stage, if a malfunction exists. If so, go to

ªDiagnostic Procedureº, EC-251.

9) If it is difficult to start engine at step 8, the fuel injection sys-

tem has a malfunction.

10) Crank engine while depressing accelerator pedal. If engine

starts, go to ªDiagnostic Procedureº, EC-251. If engine does

not start, visually check for exhaust and intake air leak.

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

DTC Confirmation Procedure (Cont'd)

EC-249

Page 546 of 2493

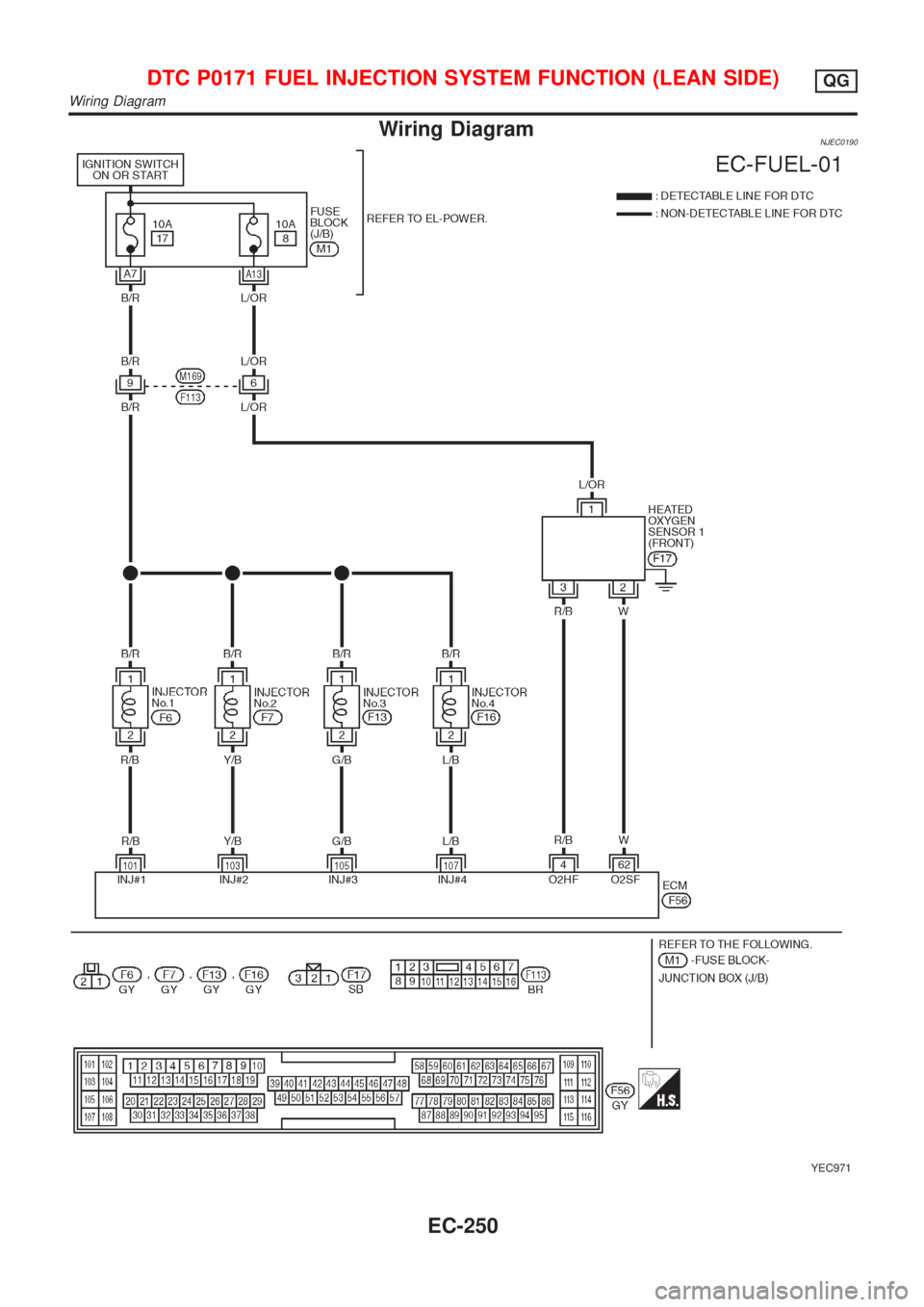

Wiring DiagramNJEC0190

YEC971

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

Wiring Diagram

EC-250

Page 547 of 2493

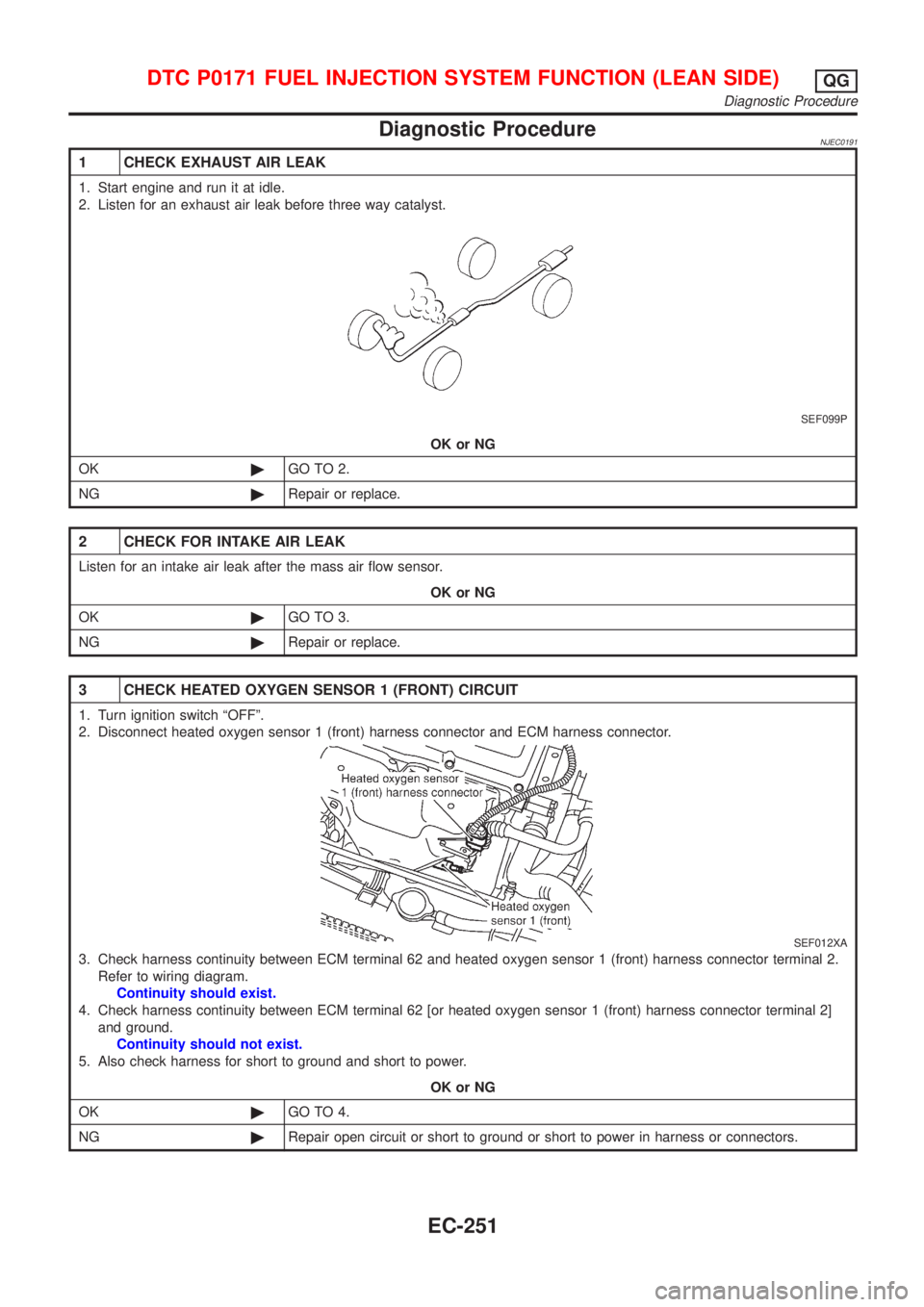

Diagnostic ProcedureNJEC0191

1 CHECK EXHAUST AIR LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust air leak before three way catalyst.

SEF099P

OK or NG

OK©GO TO 2.

NG©Repair or replace.

2 CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK©GO TO 3.

NG©Repair or replace.

3 CHECK HEATED OXYGEN SENSOR 1 (FRONT) CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector and ECM harness connector.

SEF012XA

3. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Check harness continuity between ECM terminal 62 [or heated oxygen sensor 1 (front) harness connector terminal 2]

and ground.

Continuity should not exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

Diagnostic Procedure

EC-251

Page 548 of 2493

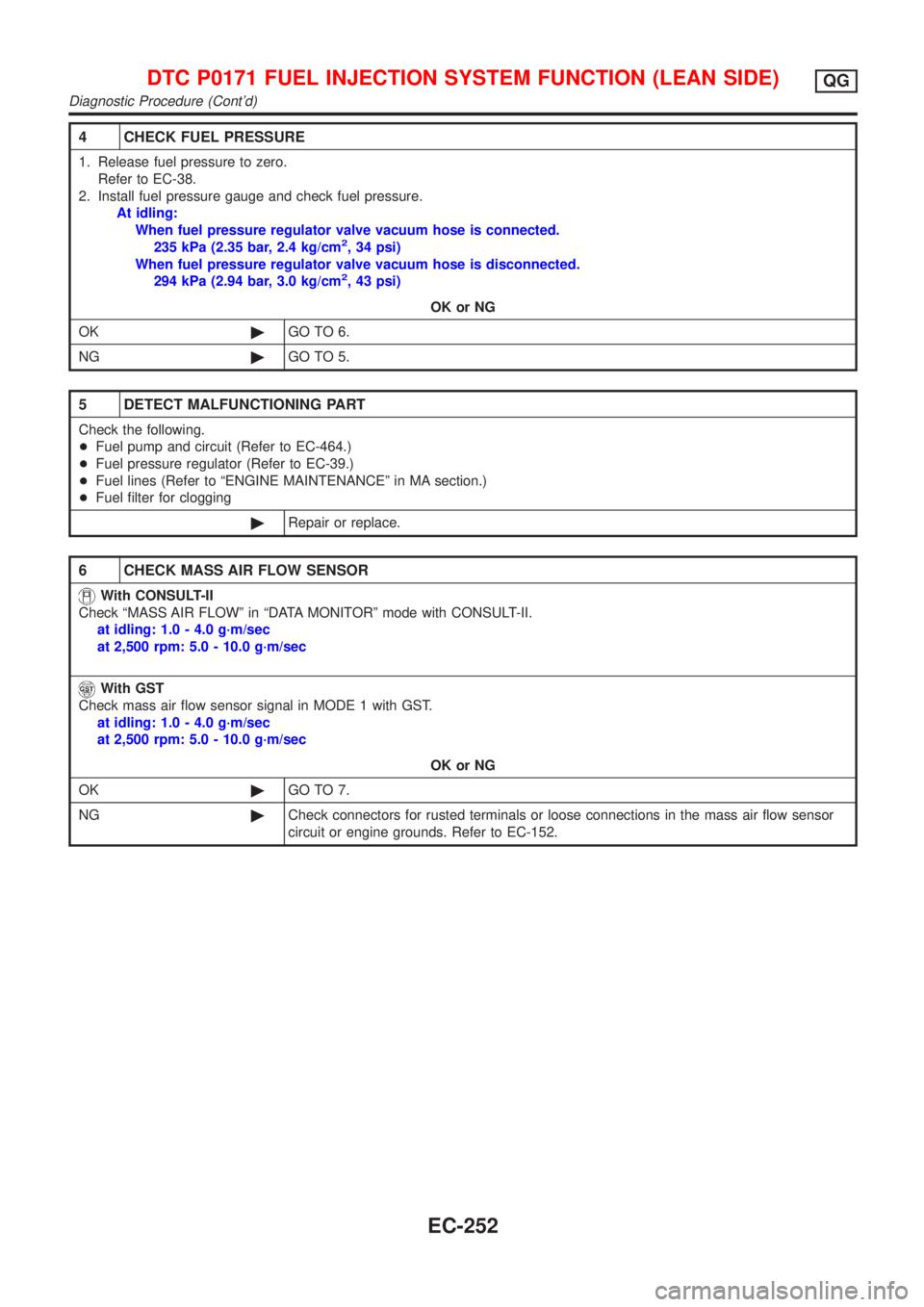

4 CHECK FUEL PRESSURE

1. Release fuel pressure to zero.

Refer to EC-38.

2. Install fuel pressure gauge and check fuel pressure.

At idling:

When fuel pressure regulator valve vacuum hose is connected.

235 kPa (2.35 bar, 2.4 kg/cm

2, 34 psi)

When fuel pressure regulator valve vacuum hose is disconnected.

294 kPa (2.94 bar, 3.0 kg/cm

2, 43 psi)

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Fuel pump and circuit (Refer to EC-464.)

+Fuel pressure regulator (Refer to EC-39.)

+Fuel lines (Refer to ªENGINE MAINTENANCEº in MA section.)

+Fuel filter for clogging

©Repair or replace.

6 CHECK MASS AIR FLOW SENSOR

With CONSULT-II

Check ªMASS AIR FLOWº in ªDATA MONITORº mode with CONSULT-II.

at idling: 1.0 - 4.0 g´m/sec

at 2,500 rpm: 5.0 - 10.0 g´m/sec

With GST

Check mass air flow sensor signal in MODE 1 with GST.

at idling: 1.0 - 4.0 g´m/sec

at 2,500 rpm: 5.0 - 10.0 g´m/sec

OK or NG

OK©GO TO 7.

NG©Check connectors for rusted terminals or loose connections in the mass air flow sensor

circuit or engine grounds. Refer to EC-152.

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

Diagnostic Procedure (Cont'd)

EC-252

Page 549 of 2493

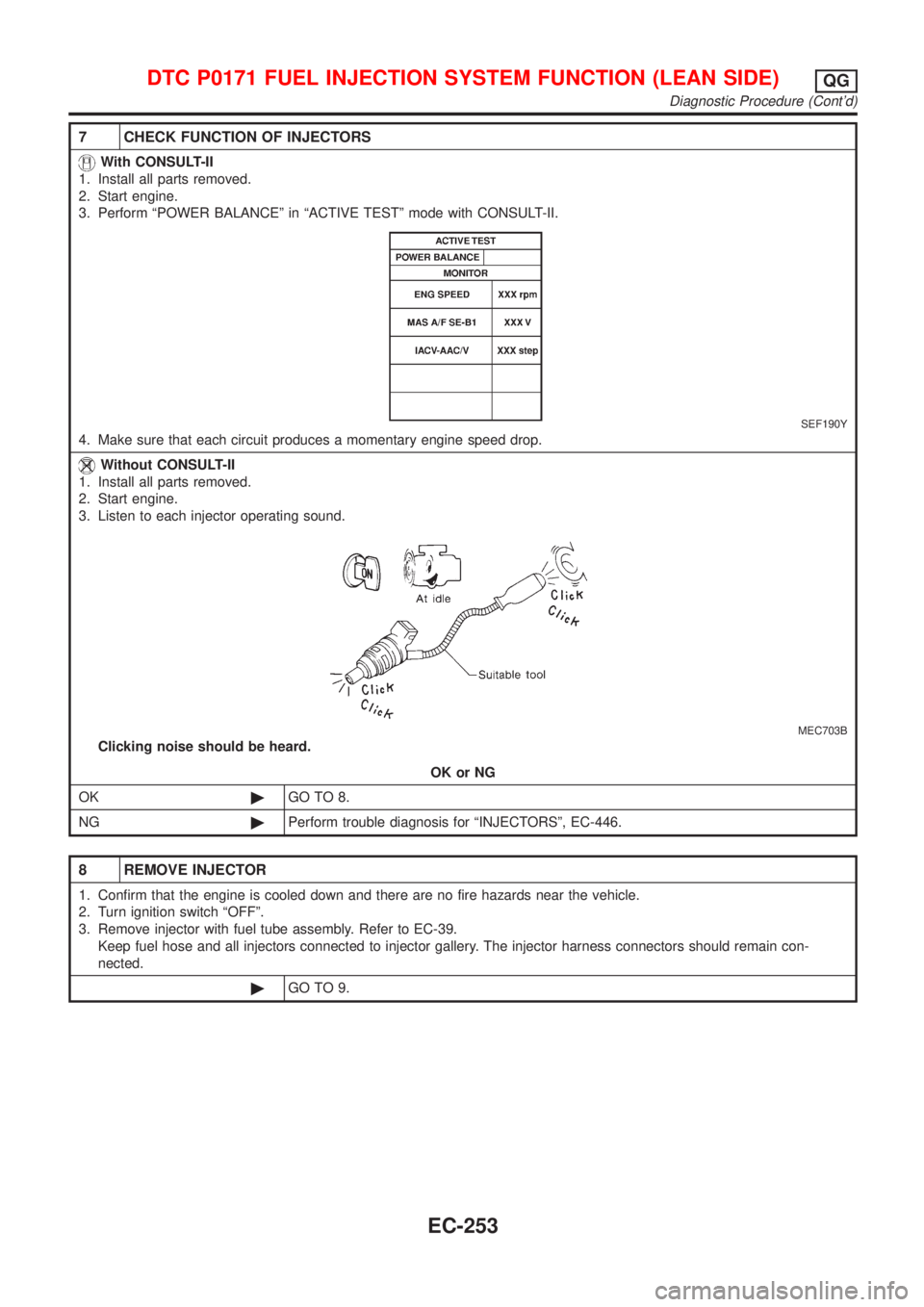

7 CHECK FUNCTION OF INJECTORS

With CONSULT-II

1. Install all parts removed.

2. Start engine.

3. Perform ªPOWER BALANCEº in ªACTIVE TESTº mode with CONSULT-II.

SEF190Y

4. Make sure that each circuit produces a momentary engine speed drop.

Without CONSULT-II

1. Install all parts removed.

2. Start engine.

3. Listen to each injector operating sound.

MEC703B

Clicking noise should be heard.

OK or NG

OK©GO TO 8.

NG©Perform trouble diagnosis for ªINJECTORSº, EC-446.

8 REMOVE INJECTOR

1. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

2. Turn ignition switch ªOFFº.

3. Remove injector with fuel tube assembly. Refer to EC-39.

Keep fuel hose and all injectors connected to injector gallery. The injector harness connectors should remain con-

nected.

©GO TO 9.

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

Diagnostic Procedure (Cont'd)

EC-253

Page 550 of 2493

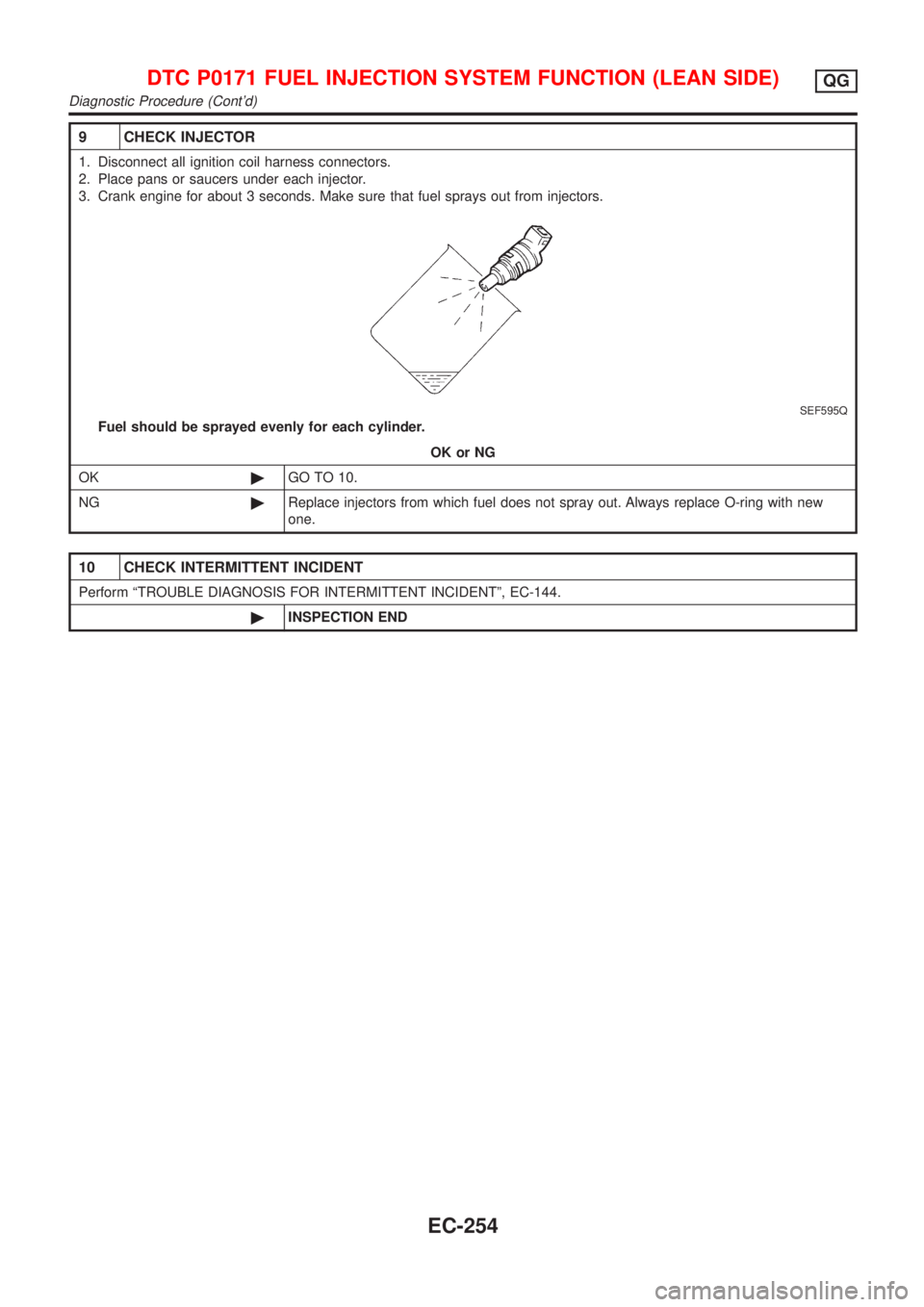

9 CHECK INJECTOR

1. Disconnect all ignition coil harness connectors.

2. Place pans or saucers under each injector.

3. Crank engine for about 3 seconds. Make sure that fuel sprays out from injectors.

SEF595Q

Fuel should be sprayed evenly for each cylinder.

OK or NG

OK©GO TO 10.

NG©Replace injectors from which fuel does not spray out. Always replace O-ring with new

one.

10 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

DTC P0171 FUEL INJECTION SYSTEM FUNCTION (LEAN SIDE)QG

Diagnostic Procedure (Cont'd)

EC-254