Combination meter NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 608 of 2493

Diagnostic ProcedureNJEC0278

1 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and combination meter harness connector.

3. Check harness continuity between ECM terminal 86 and meter terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M63, F102

+Harness for open or short between ECM and combination meter

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 CHECK SPEEDOMETER CIRCUIT

Check the following.

+Harness connectors M63, F102

+Harness connectors M169, F113

+Harness for open or short between combination meter and vehicle speed sensor

OK©Check combination meter and vehicle speed sensor. Refer to EL-89, ªMETERS AND

GAUGESº.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

DTC P0500 VEHICLE SPEED SENSOR (VSS)QG

Diagnostic Procedure

EC-312

Page 892 of 2493

Diagnostic ProcedureNJEC0659

1 CHECK VEHICLE SPEED SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and combination meter harness connector.

3. Check harness continuity between ECM terminal 417 and combination meter terminal 4. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M63, F102

+Harness for open or short between ECM and combination meter

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 CHECK SPEEDOMETER CIRCUIT FOR OPEN AND SHORT

Check the following.

+Harness connectors M63, F102

+Harness for open or short between vehicle speed sensor and engine ground

+Harness for open or short between combination meter and vehicle speed sensor

OK or NG

OK©Check vehicle speed sensor and combination meter. Refer to EL section.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-559.

©INSPECTION END

DTC P0500 VEHICLE SPEED SENYD

Diagnostic Procedure

EC-596

Page 978 of 2493

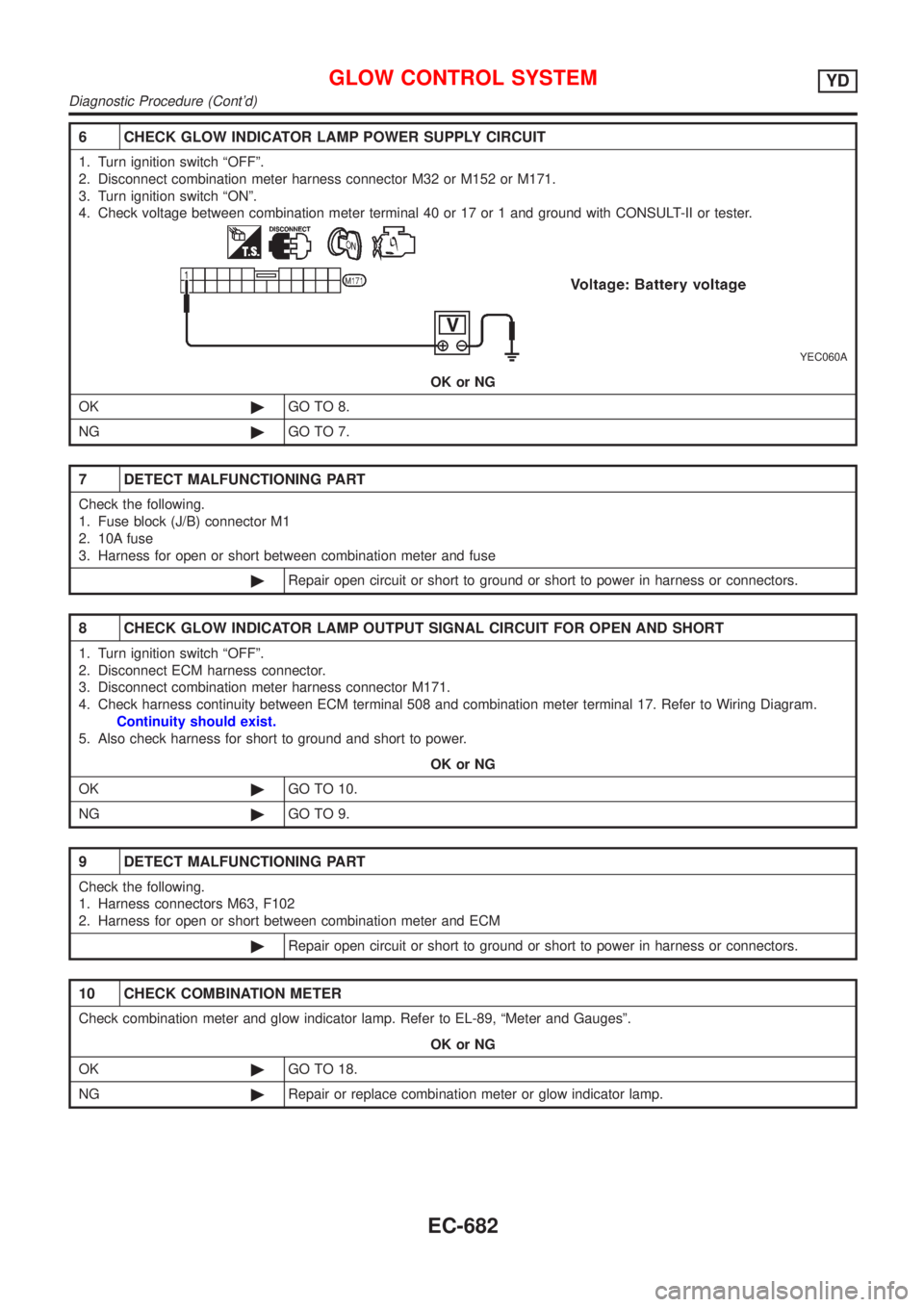

6 CHECK GLOW INDICATOR LAMP POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect combination meter harness connector M32 or M152 or M171.

3. Turn ignition switch ªONº.

4. Check voltage between combination meter terminal 40 or 17 or 1 and ground with CONSULT-II or tester.

YEC060A

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

1. Fuse block (J/B) connector M1

2. 10A fuse

3. Harness for open or short between combination meter and fuse

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK GLOW INDICATOR LAMP OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Disconnect combination meter harness connector M171.

4. Check harness continuity between ECM terminal 508 and combination meter terminal 17. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 10.

NG©GO TO 9.

9 DETECT MALFUNCTIONING PART

Check the following.

1. Harness connectors M63, F102

2. Harness for open or short between combination meter and ECM

©Repair open circuit or short to ground or short to power in harness or connectors.

10 CHECK COMBINATION METER

Check combination meter and glow indicator lamp. Refer to EL-89, ªMeter and Gaugesº.

OK or NG

OK©GO TO 18.

NG©Repair or replace combination meter or glow indicator lamp.

GLOW CONTROL SYSTEMYD

Diagnostic Procedure (Cont'd)

EC-682

Page 1783 of 2493

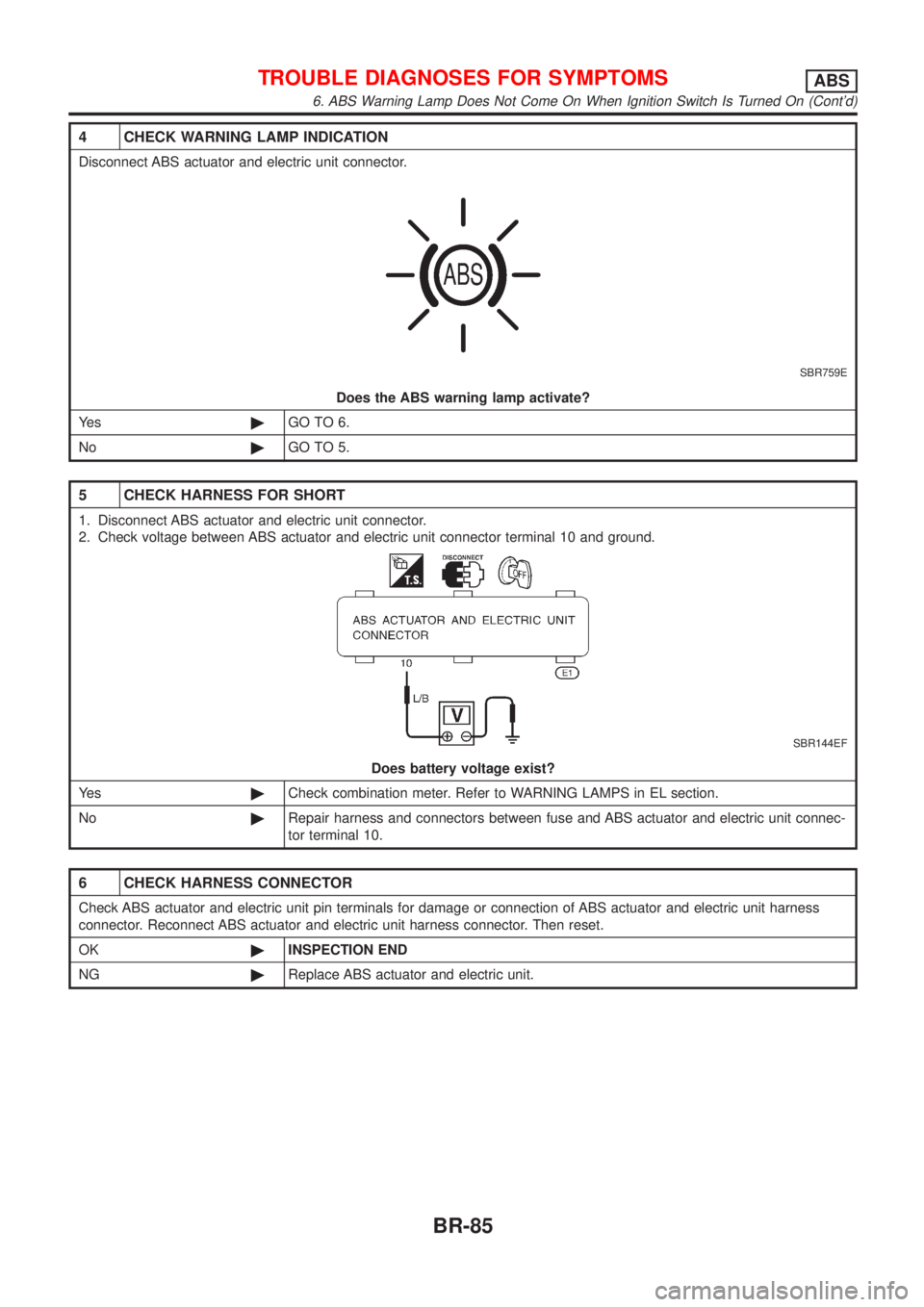

4 CHECK WARNING LAMP INDICATION

Disconnect ABS actuator and electric unit connector.

SBR759E

Does the ABS warning lamp activate?

Ye s©GO TO 6.

No©GO TO 5.

5 CHECK HARNESS FOR SHORT

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector terminal 10 and ground.

SBR144EF

Does battery voltage exist?

Ye s©Check combination meter. Refer to WARNING LAMPS in EL section.

No©Repair harness and connectors between fuse and ABS actuator and electric unit connec-

tor terminal 10.

6 CHECK HARNESS CONNECTOR

Check ABS actuator and electric unit pin terminals for damage or connection of ABS actuator and electric unit harness

connector. Reconnect ABS actuator and electric unit harness connector. Then reset.

OK©INSPECTION END

NG©Replace ABS actuator and electric unit.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

6. ABS Warning Lamp Does Not Come On When Ignition Switch Is Turned On (Cont'd)

BR-85

Page 1784 of 2493

7. ABS Warning Lamp Stays On When Ignition

Switch Is Turned On

=NJBR0110

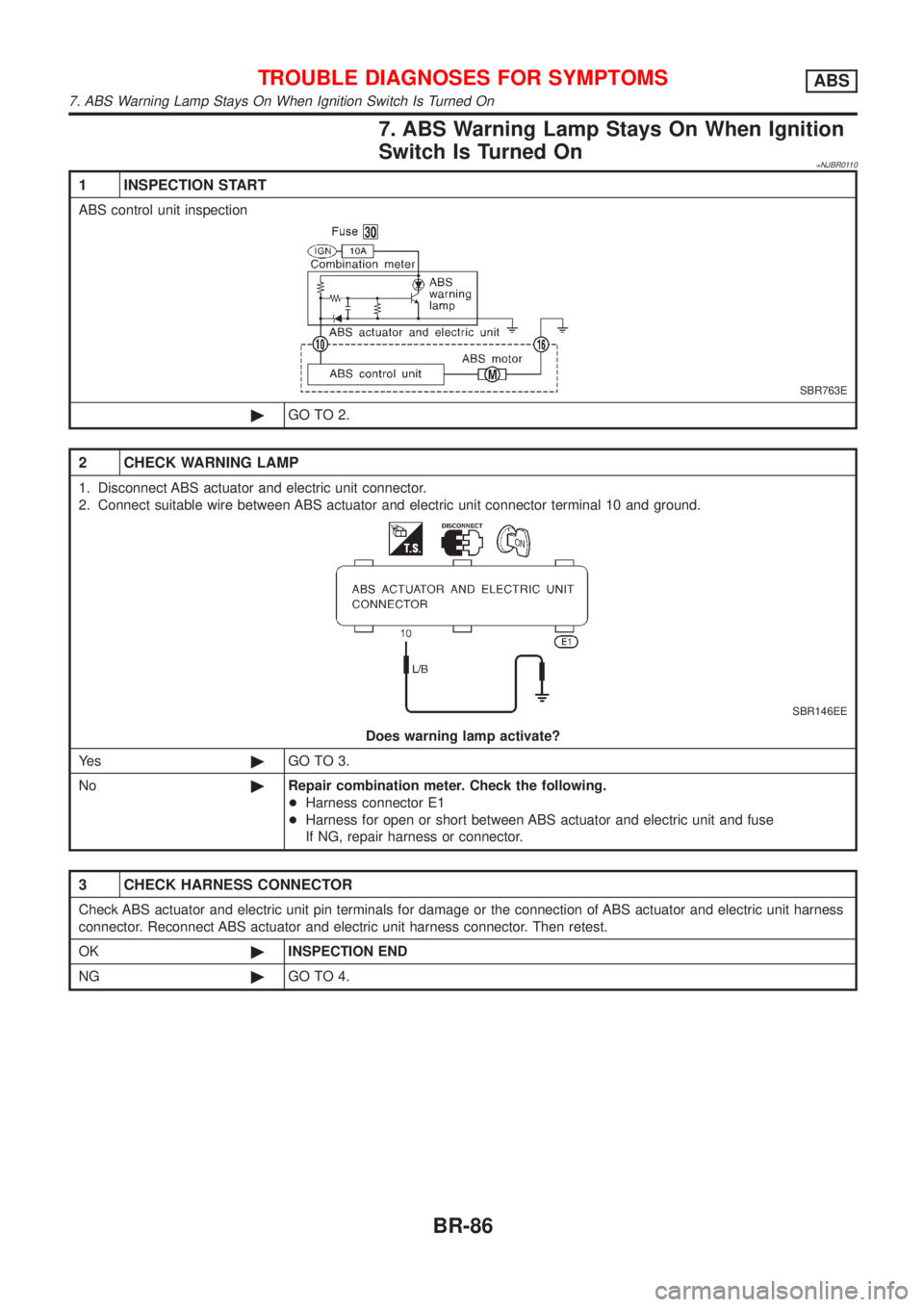

1 INSPECTION START

ABS control unit inspection

SBR763E

©GO TO 2.

2 CHECK WARNING LAMP

1. Disconnect ABS actuator and electric unit connector.

2. Connect suitable wire between ABS actuator and electric unit connector terminal 10 and ground.

SBR146EE

Does warning lamp activate?

Ye s©GO TO 3.

No©Repair combination meter. Check the following.

+Harness connector E1

+Harness for open or short between ABS actuator and electric unit and fuse

If NG, repair harness or connector.

3 CHECK HARNESS CONNECTOR

Check ABS actuator and electric unit pin terminals for damage or the connection of ABS actuator and electric unit harness

connector. Reconnect ABS actuator and electric unit harness connector. Then retest.

OK©INSPECTION END

NG©GO TO 4.

TROUBLE DIAGNOSES FOR SYMPTOMSABS

7. ABS Warning Lamp Stays On When Ignition Switch Is Turned On

BR-86

Page 2100 of 2493

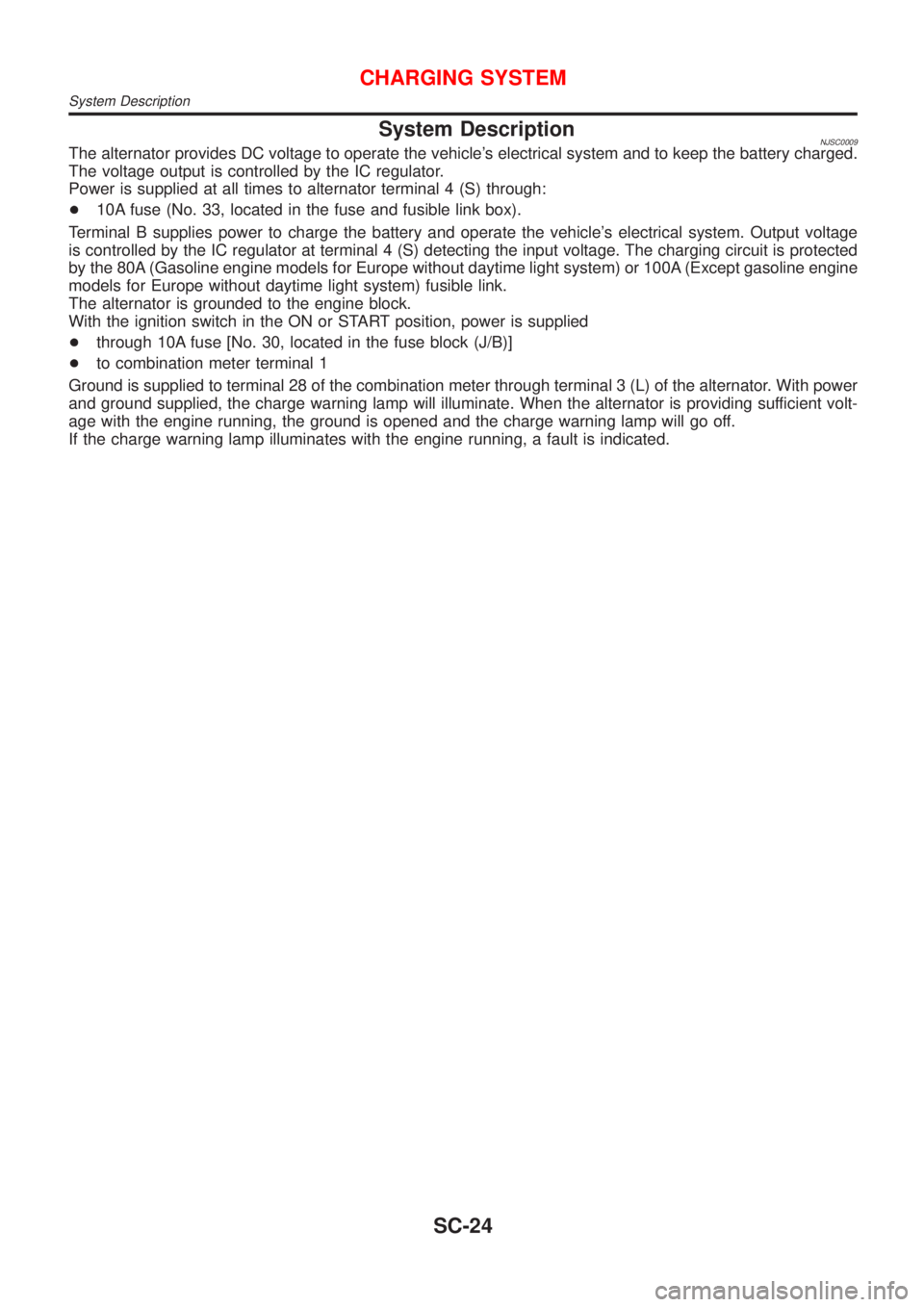

System DescriptionNJSC0009The alternator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to alternator terminal 4 (S) through:

+10A fuse (No. 33, located in the fuse and fusible link box).

Terminal B supplies power to charge the battery and operate the vehicle's electrical system. Output voltage

is controlled by the IC regulator at terminal 4 (S) detecting the input voltage. The charging circuit is protected

by the 80A (Gasoline engine models for Europe without daytime light system) or 100A (Except gasoline engine

models for Europe without daytime light system) fusible link.

The alternator is grounded to the engine block.

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 1

Ground is supplied to terminal 28 of the combination meter through terminal 3 (L) of the alternator. With power

and ground supplied, the charge warning lamp will illuminate. When the alternator is providing sufficient volt-

age with the engine running, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a fault is indicated.

CHARGING SYSTEM

System Description

SC-24

Page 2113 of 2493

ELECTRICAL SYSTEM

SECTION

EL

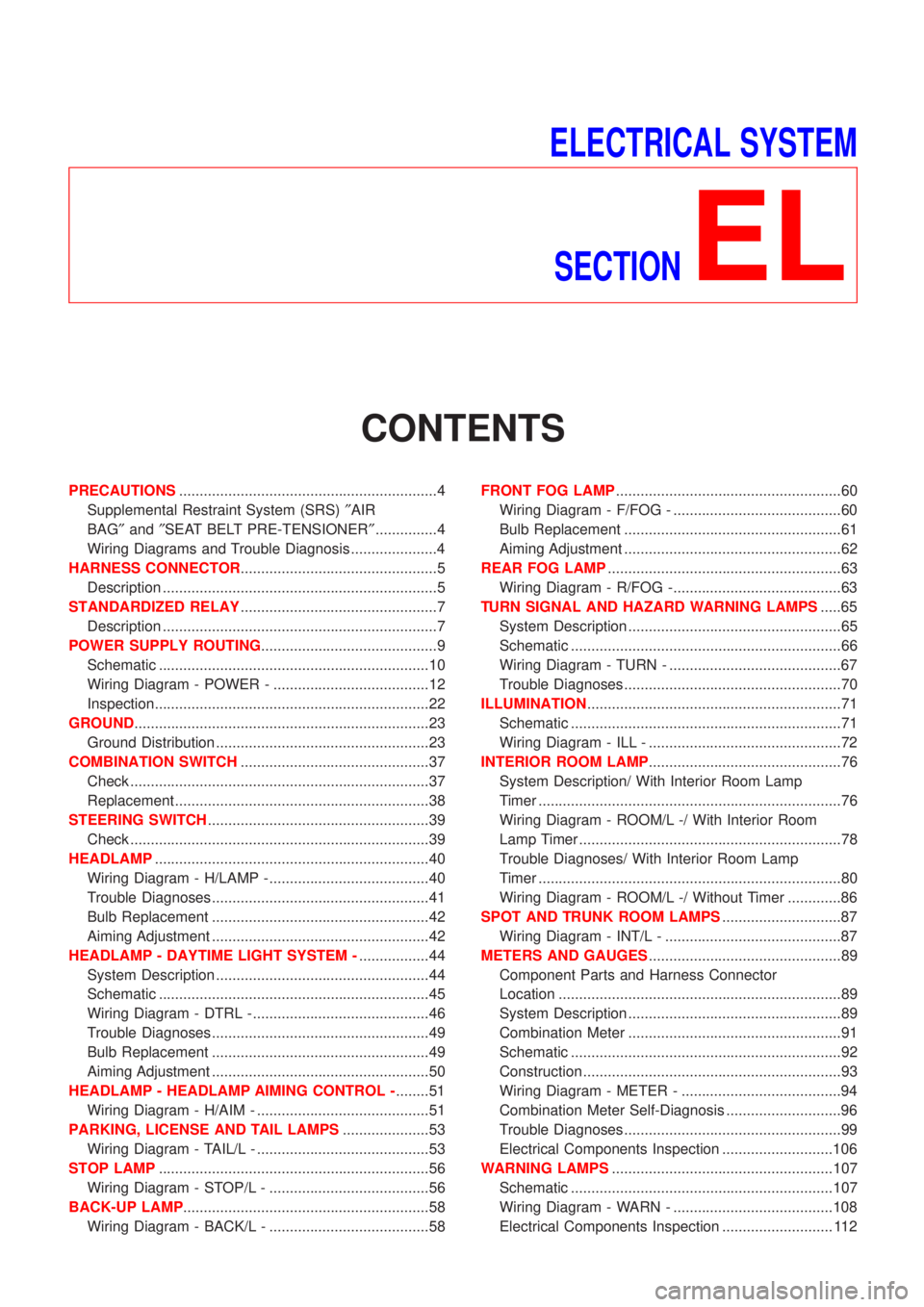

CONTENTS

PRECAUTIONS...............................................................4

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............4

Wiring Diagrams and Trouble Diagnosis .....................4

HARNESS CONNECTOR................................................5

Description ...................................................................5

STANDARDIZED RELAY................................................7

Description ...................................................................7

POWER SUPPLY ROUTING...........................................9

Schematic ..................................................................10

Wiring Diagram - POWER - ......................................12

Inspection...................................................................22

GROUND........................................................................23

Ground Distribution ....................................................23

COMBINATION SWITCH..............................................37

Check .........................................................................37

Replacement ..............................................................38

STEERING SWITCH......................................................39

Check .........................................................................39

HEADLAMP...................................................................40

Wiring Diagram - H/LAMP -.......................................40

Trouble Diagnoses.....................................................41

Bulb Replacement .....................................................42

Aiming Adjustment .....................................................42

HEADLAMP - DAYTIME LIGHT SYSTEM -.................44

System Description ....................................................44

Schematic ..................................................................45

Wiring Diagram - DTRL - ...........................................46

Trouble Diagnoses.....................................................49

Bulb Replacement .....................................................49

Aiming Adjustment .....................................................50

HEADLAMP - HEADLAMP AIMING CONTROL -........51

Wiring Diagram - H/AIM - ..........................................51

PARKING, LICENSE AND TAIL LAMPS.....................53

Wiring Diagram - TAIL/L - ..........................................53

STOP LAMP..................................................................56

Wiring Diagram - STOP/L - .......................................56

BACK-UP LAMP............................................................58

Wiring Diagram - BACK/L - .......................................58FRONT FOG LAMP.......................................................60

Wiring Diagram - F/FOG - .........................................60

Bulb Replacement .....................................................61

Aiming Adjustment .....................................................62

REAR FOG LAMP.........................................................63

Wiring Diagram - R/FOG -.........................................63

TURN SIGNAL AND HAZARD WARNING LAMPS.....65

System Description ....................................................65

Schematic ..................................................................66

Wiring Diagram - TURN - ..........................................67

Trouble Diagnoses.....................................................70

ILLUMINATION..............................................................71

Schematic ..................................................................71

Wiring Diagram - ILL - ...............................................72

INTERIOR ROOM LAMP...............................................76

System Description/ With Interior Room Lamp

Timer ..........................................................................76

Wiring Diagram - ROOM/L -/ With Interior Room

Lamp Timer ................................................................78

Trouble Diagnoses/ With Interior Room Lamp

Timer ..........................................................................80

Wiring Diagram - ROOM/L -/ Without Timer .............86

SPOT AND TRUNK ROOM LAMPS.............................87

Wiring Diagram - INT/L - ...........................................87

METERS AND GAUGES...............................................89

Component Parts and Harness Connector

Location .....................................................................89

System Description ....................................................89

Combination Meter ....................................................91

Schematic ..................................................................92

Construction ...............................................................93

Wiring Diagram - METER - .......................................94

Combination Meter Self-Diagnosis ............................96

Trouble Diagnoses.....................................................99

Electrical Components Inspection ...........................106

WARNING LAMPS......................................................107

Schematic ................................................................107

Wiring Diagram - WARN - .......................................108

Electrical Components Inspection ........................... 112

Page 2153 of 2493

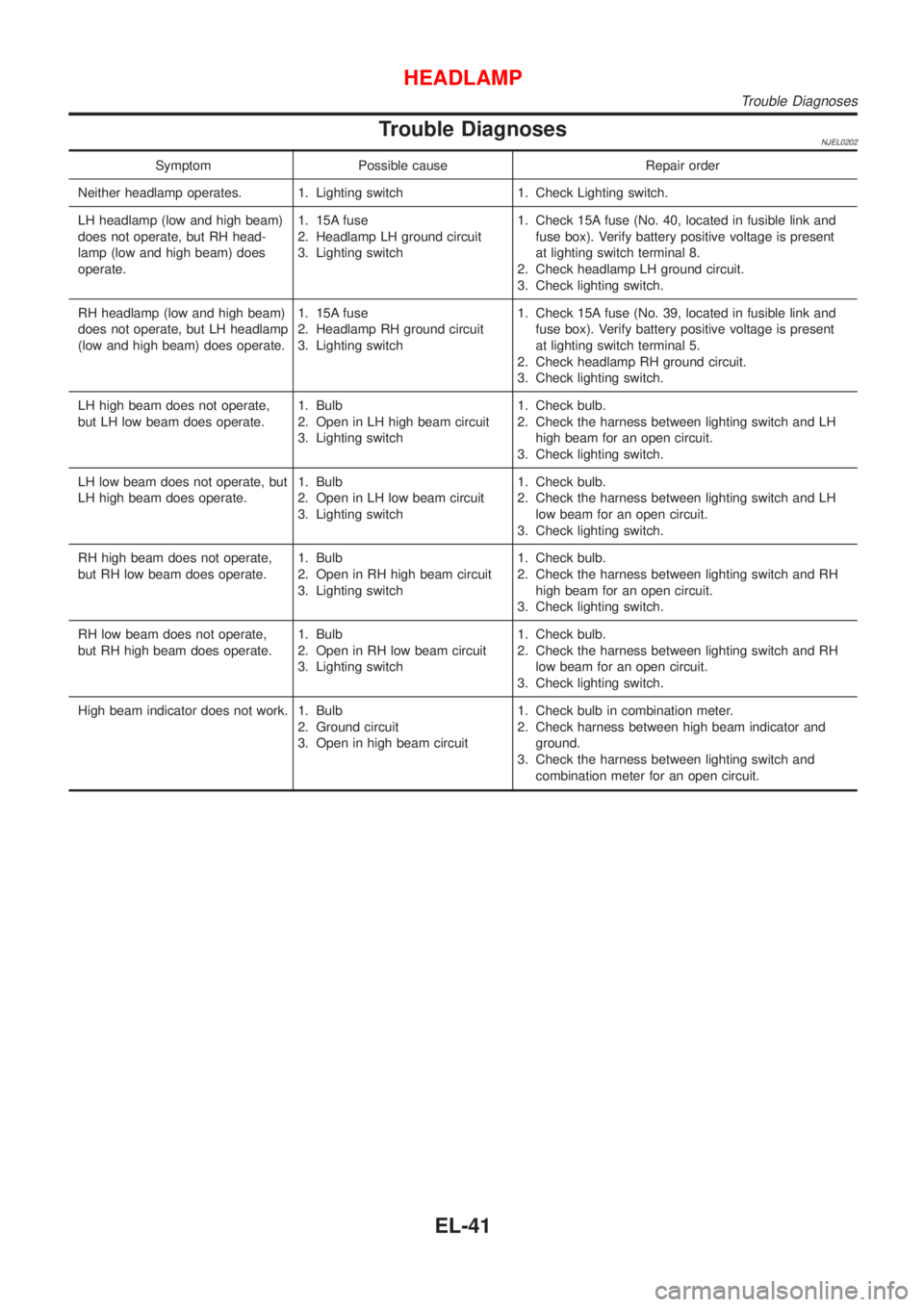

Trouble DiagnosesNJEL0202

Symptom Possible cause Repair order

Neither headlamp operates. 1. Lighting switch 1. Check Lighting switch.

LH headlamp (low and high beam)

does not operate, but RH head-

lamp (low and high beam) does

operate.1. 15A fuse

2. Headlamp LH ground circuit

3. Lighting switch1. Check 15A fuse (No. 40, located in fusible link and

fuse box). Verify battery positive voltage is present

at lighting switch terminal 8.

2. Check headlamp LH ground circuit.

3. Check lighting switch.

RH headlamp (low and high beam)

does not operate, but LH headlamp

(low and high beam) does operate.1. 15A fuse

2. Headlamp RH ground circuit

3. Lighting switch1. Check 15A fuse (No. 39, located in fusible link and

fuse box). Verify battery positive voltage is present

at lighting switch terminal 5.

2. Check headlamp RH ground circuit.

3. Check lighting switch.

LH high beam does not operate,

but LH low beam does operate.1. Bulb

2. Open in LH high beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and LH

high beam for an open circuit.

3. Check lighting switch.

LH low beam does not operate, but

LH high beam does operate.1. Bulb

2. Open in LH low beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and LH

low beam for an open circuit.

3. Check lighting switch.

RH high beam does not operate,

but RH low beam does operate.1. Bulb

2. Open in RH high beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and RH

high beam for an open circuit.

3. Check lighting switch.

RH low beam does not operate,

but RH high beam does operate.1. Bulb

2. Open in RH low beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and RH

low beam for an open circuit.

3. Check lighting switch.

High beam indicator does not work. 1. Bulb

2. Ground circuit

3. Open in high beam circuit1. Check bulb in combination meter.

2. Check harness between high beam indicator and

ground.

3. Check the harness between lighting switch and

combination meter for an open circuit.

HEADLAMP

Trouble Diagnoses

EL-41

Page 2182 of 2493

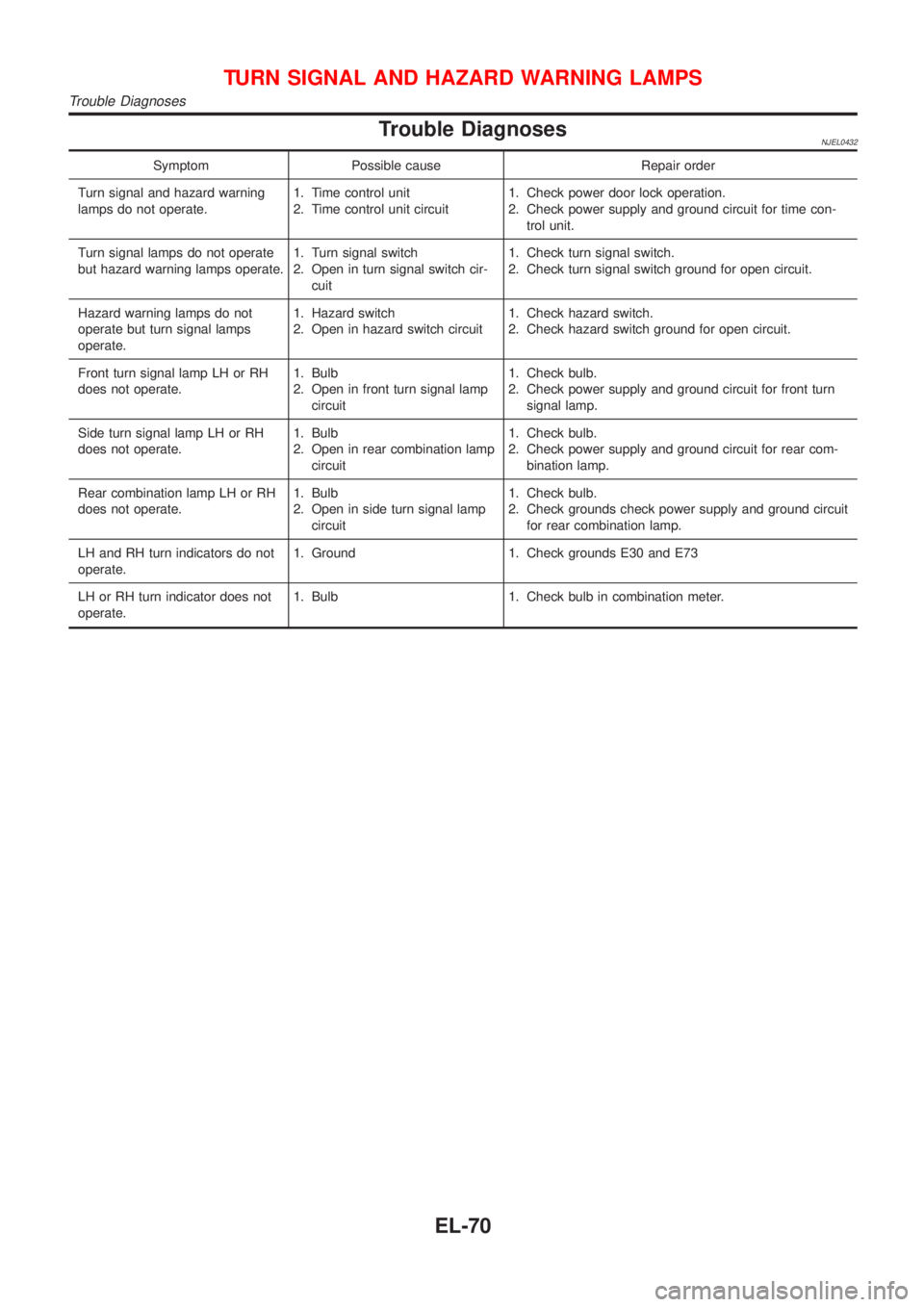

Trouble DiagnosesNJEL0432

Symptom Possible cause Repair order

Turn signal and hazard warning

lamps do not operate.1. Time control unit

2. Time control unit circuit1. Check power door lock operation.

2. Check power supply and ground circuit for time con-

trol unit.

Turn signal lamps do not operate

but hazard warning lamps operate.1. Turn signal switch

2. Open in turn signal switch cir-

cuit1. Check turn signal switch.

2. Check turn signal switch ground for open circuit.

Hazard warning lamps do not

operate but turn signal lamps

operate.1. Hazard switch

2. Open in hazard switch circuit1. Check hazard switch.

2. Check hazard switch ground for open circuit.

Front turn signal lamp LH or RH

does not operate.1. Bulb

2. Open in front turn signal lamp

circuit1. Check bulb.

2. Check power supply and ground circuit for front turn

signal lamp.

Side turn signal lamp LH or RH

does not operate.1. Bulb

2. Open in rear combination lamp

circuit1. Check bulb.

2. Check power supply and ground circuit for rear com-

bination lamp.

Rear combination lamp LH or RH

does not operate.1. Bulb

2. Open in side turn signal lamp

circuit1. Check bulb.

2. Check grounds check power supply and ground circuit

for rear combination lamp.

LH and RH turn indicators do not

operate.1. Ground 1. Check grounds E30 and E73

LH or RH turn indicator does not

operate.1. Bulb 1. Check bulb in combination meter.

TURN SIGNAL AND HAZARD WARNING LAMPS

Trouble Diagnoses

EL-70

Page 2201 of 2493

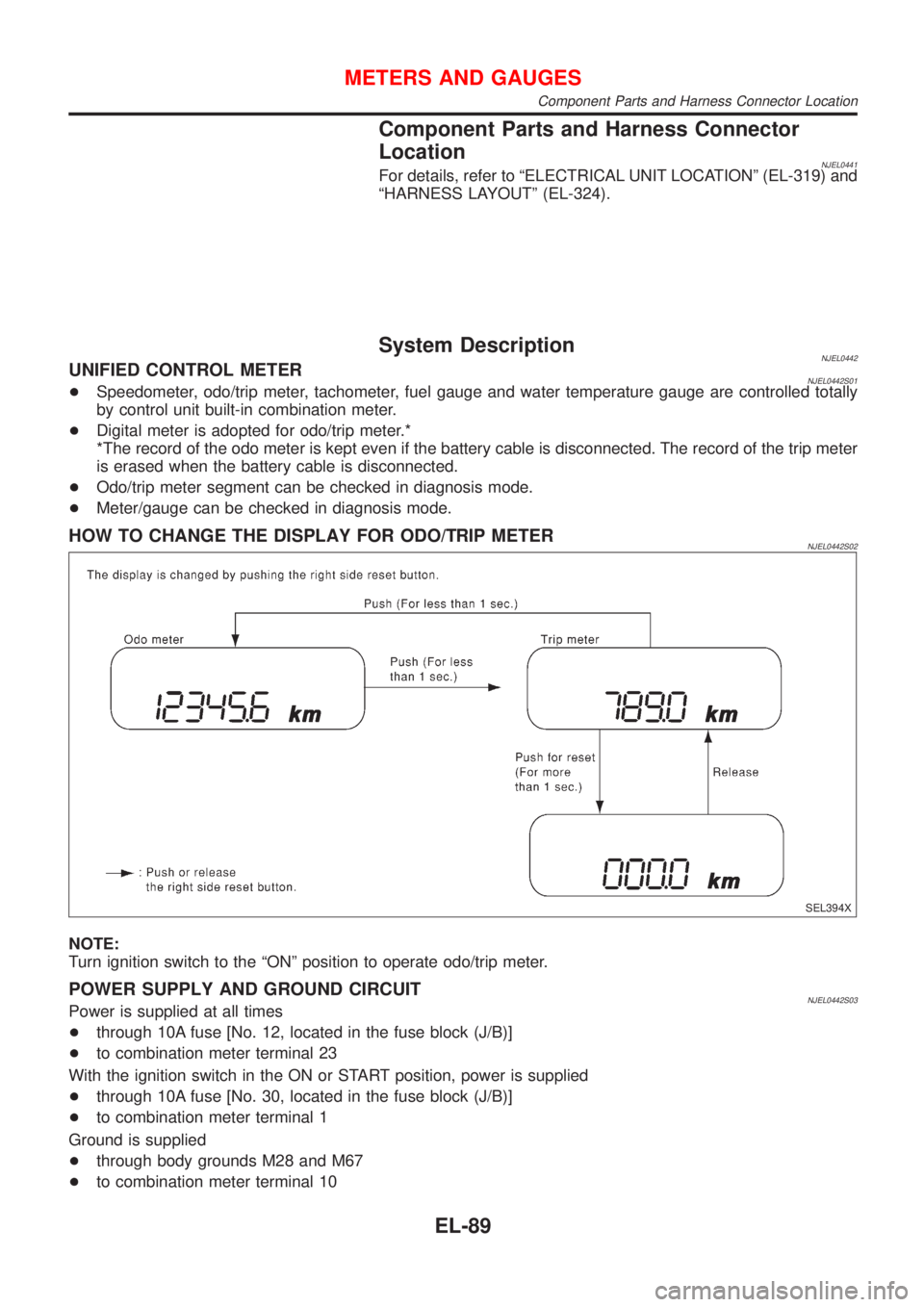

Component Parts and Harness Connector

Location

NJEL0441For details, refer to ªELECTRICAL UNIT LOCATIONº (EL-319) and

ªHARNESS LAYOUTº (EL-324).

System DescriptionNJEL0442UNIFIED CONTROL METERNJEL0442S01+Speedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by control unit built-in combination meter.

+Digital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

+Odo/trip meter segment can be checked in diagnosis mode.

+Meter/gauge can be checked in diagnosis mode.

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METERNJEL0442S02

SEL394X

NOTE:

Turn ignition switch to the ªONº position to operate odo/trip meter.

POWER SUPPLY AND GROUND CIRCUITNJEL0442S03Power is supplied at all times

+through 10A fuse [No. 12, located in the fuse block (J/B)]

+to combination meter terminal 23

With the ignition switch in the ON or START position, power is supplied

+through 10A fuse [No. 30, located in the fuse block (J/B)]

+to combination meter terminal 1

Ground is supplied

+through body grounds M28 and M67

+to combination meter terminal 10

METERS AND GAUGES

Component Parts and Harness Connector Location

EL-89