engine overheat NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 249 of 2493

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

QG

ENGINE LUBRICATION SYSTEM..................................3

Precautions ..................................................................3

LIQUID GASKET APPLICATION PROCEDURE............3

Preparation ..................................................................3

SPECIAL SERVICE TOOLS........................................3

Lubrication Circuit ........................................................4

Oil Pressure Check......................................................5

Oil Pump ......................................................................5

REMOVAL AND INSTALLATION.................................5

DISASSEMBLY AND ASSEMBLY................................6

INSPECTION.............................................................7

REGULATOR VALVE INSPECTION............................7

Changing Engine Oil....................................................8

Changing Oil Filter .......................................................9

Service Data and Specifications (SDS).....................10

OIL PRESSURE CHECK..........................................10

OIL PUMP INSPECTION..........................................10

REGULATOR VALVE INSPECTION..........................10

OIL CAPACITY........................................................10

ENGINE COOLING SYSTEM........................................ 11

Precautions ................................................................ 11

LIQUID GASKET APPLICATION PROCEDURE.......... 11

Preparation ................................................................ 11

SPECIAL SERVICE TOOLS...................................... 11

Cooling Circuit ...........................................................12

System Check............................................................12

CHECKING COOLING SYSTEM HOSES...................12

CHECKING RADIATOR............................................13

CHECKING RADIATOR CAP....................................13

CHECKING COOLING SYSTEM FOR LEAKS............13

Water Pump ...............................................................14

REMOVAL AND INSTALLATION...............................14

INSPECTION...........................................................14

Thermostat .................................................................15

REMOVAL AND INSTALLATION...............................15

INSPECTION...........................................................16

Radiator .....................................................................16

COMPONENTS.......................................................16

Cooling Fan ...............................................................17

COMPONENTS.......................................................17

CONTROL SYSTEM................................................17

Changing Engine Coolant..........................................17

- DRAINING ENGINE COOLANT -............................17

- REFILLING ENGINE COOLANT -...........................18

- FLUSHING COOLING SYSTEM -............................19

Radiator (Aluminum type) ..........................................20

PREPARATION.......................................................20

DISASSEMBLY........................................................20

ASSEMBLY.............................................................21

INSPECTION...........................................................22

Overheating Cause Analysis .....................................23

Service Data and Specifications (SDS).....................24

THERMOSTAT........................................................24

RADIATOR..............................................................24

COOLANT CAPACITY..............................................24

YD

ENGINE LUBRICATION SYSTEM................................25

Precautions ................................................................25

LIQUID GASKET APPLICATION PROCEDURE..........25

Preparation ................................................................25

SPECIAL SERVICE TOOLS......................................25

Lubrication Circuit ......................................................26

Oil Pressure Check....................................................27

Oil Pump ....................................................................27

REMOVAL AND INSTALLATION...............................27

DISASSEMBLY AND ASSEMBLY..............................28

OIL PUMP INSPECTION..........................................28

REGULATOR VALVE INSPECTION..........................29

Changing Engine Oil..................................................30

Oil Filter Bracket ........................................................31

REMOVAL AND INSTALLATION...............................31

Changing Oil Filter .....................................................31

REMOVAL...............................................................32

INSTALLATION........................................................32

Oil Cooler ...................................................................33

REMOVAL AND INSTALLATION...............................33

Service Data and Specifications (SDS).....................34

OIL PRESSURE CHECK..........................................34

Page 250 of 2493

REGULATOR VALVE INSPECTION..........................34

OIL PUMP INSPECTION..........................................34

ENGINE OIL CAPACITY...........................................34

ENGINE COOLING SYSTEM........................................35

Precautions ................................................................35

LIQUID GASKET APPLICATION PROCEDURE..........35

Preparation ................................................................35

SPECIAL SERVICE TOOLS......................................35

Cooling Circuit ...........................................................36

System Check............................................................37

CHECKING COOLING SYSTEM HOSES...................37

CHECKING RADIATOR............................................37

CHECKING RADIATOR CAP....................................37

CHECKING COOLING SYSTEM FOR LEAKS............38

Water Pump ...............................................................38

REMOVAL AND INSTALLATION...............................38

REMOVAL...............................................................39

INSPECTION...........................................................39

INSTALLATION........................................................39

Thermostat .................................................................40

REMOVAL AND INSTALLATION...............................40

INSPECTION...........................................................41

Radiator .....................................................................41

COMPONENTS.......................................................41

REMOVAL AND INSTALLATION...............................42

Cooling Fan ...............................................................42

COMPONENTS.......................................................42

CONTROL SYSTEM................................................42

Changing Engine Coolant..........................................43

- DRAINING ENGINE COOLANT -............................43

- REFILLING ENGINE COOLANT -...........................43

- FLUSHING COOLING SYSTEM -............................45

Radiator (Aluminum type) ..........................................46

Overheating Cause Analysis .....................................46

Service Data and Specifications (SDS).....................47

THERMOSTAT........................................................47

RADIATOR..............................................................47

ENGINE COOLANT CAPACITY................................47

CONTENTS(Cont'd)

LC-2

Page 267 of 2493

SMA182B

SMA412B

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Coolant capacity (With reservoir tank):

Unit:!(Imp qt)

M/T 6.7 (5-7/8)

A/TFor Sedan 6.6 (5-7/8)

For Hatchback 6.7 (5-7/8)

Reservoir tank capacity:

0.7!(5/8 Imp qt)

+Pour coolant through coolant filler neck slowly to allow air

in system to escape.

3. Fill radiator and reservoir tank to specified level.

4. Warm up engine to normal operating temperature without

radiator cap installed.

+If coolant overflows radiator filler hole, install filler cap.

5. Run engine at 2,500 rpm for 10 seconds and return to idle

speed with radiator cap installed.

+Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

6. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

+If necessary, refill radiator up to filler neck with coolant.

7. Refill reservoir tank to MAX level line with coolant.

8. Repeat steps 4 through 7 two or more times with radiator cap

installed until coolant level no longer drops.

9. Check cooling system for leaks with engine running.

10. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater tempera-

ture controller set at several positions between COOL and

HOT.

+Sound may be noticeable at heater water cock.

11. If sound is heard, bleed air from cooling system by repeating

steps 4 through 7 until coolant level no longer drops

+Clean excess coolant from engine.

Ð FLUSHING COOLING SYSTEM ÐNJLC0037S031. Open air relief plug.

2. Fill radiator with water until water spills from the air relief hole,

then close air relief plug. Fill radiator and reservoir tank with

water and reinstall radiator cap.

3. Run engine and warm it up to normal operating temperature.

4. Rev engine two or three times under no-load.

5. Stop engine and wait until it cools down.

6. Drain water.

7. Repeat steps 1 through 6 until clear water begins to drain from

radiator.

ENGINE COOLING SYSTEMQG

Changing Engine Coolant (Cont'd)

LC-19

Page 271 of 2493

SLC934

2. Check for leakage.

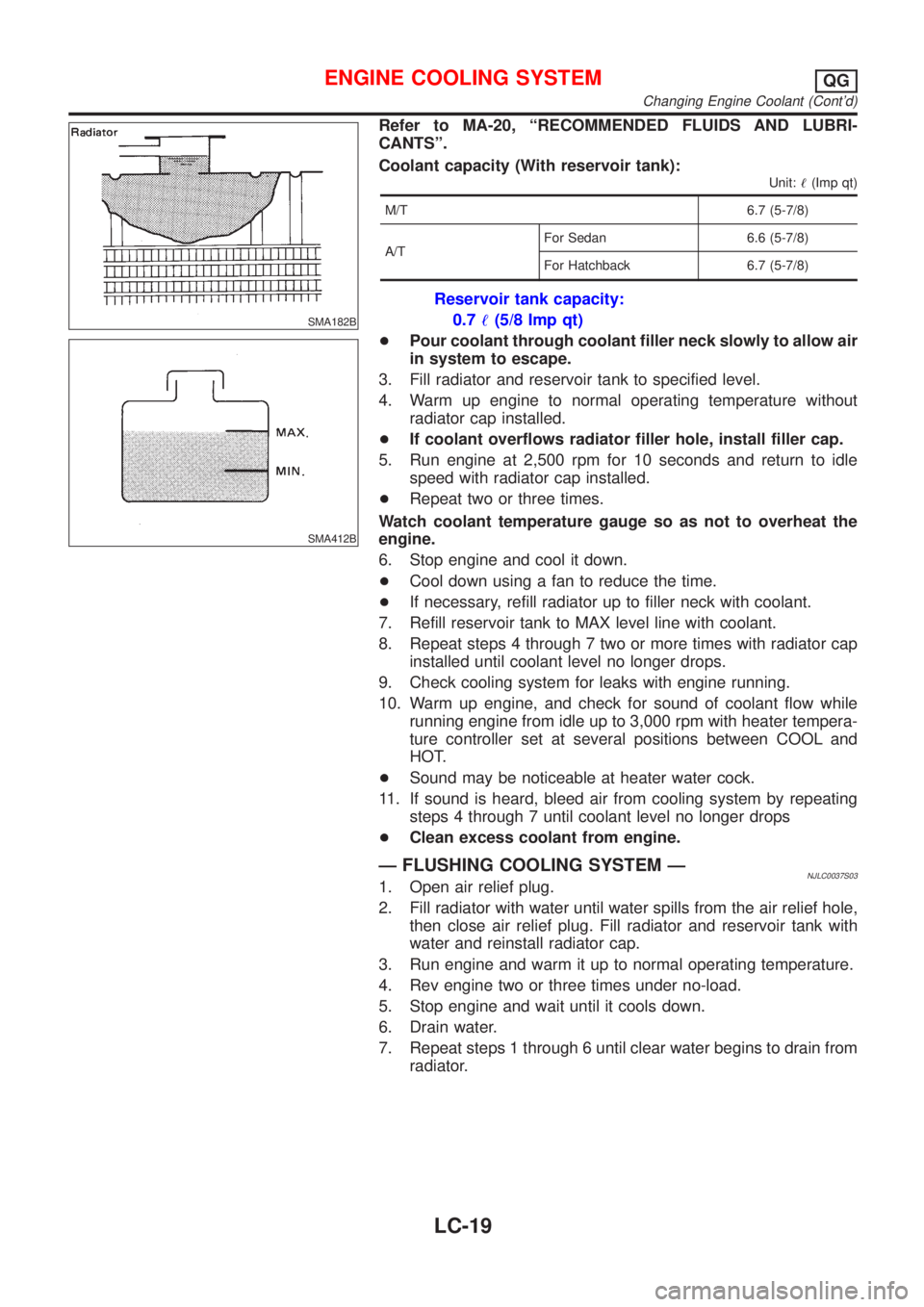

Overheating Cause AnalysisNJLC0028

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, deterio-

ration or improper fitting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deterioration

Cylinder head gasket dete-

rioration

ENGINE COOLING SYSTEMQG

Radiator (Aluminum type) (Cont'd)

LC-23

Page 272 of 2493

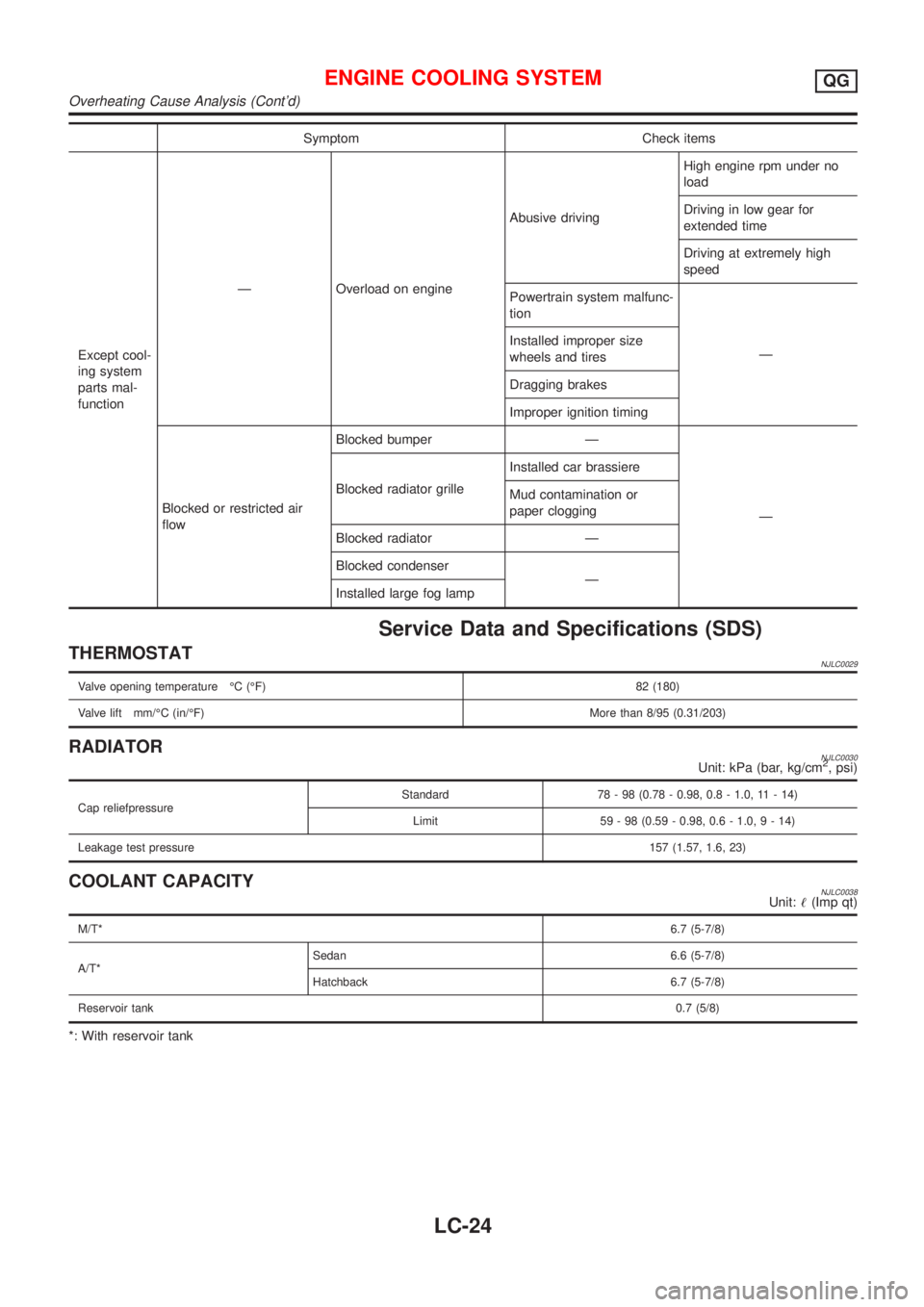

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under no

load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0029

Valve opening temperature ÉC (ÉF) 82 (180)

Valve lift mm/ÉC (in/ÉF)More than 8/95 (0.31/203)

RADIATORNJLC0030Unit: kPa (bar, kg/cm2, psi)

Cap reliefpressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

COOLANT CAPACITYNJLC0038Unit:!(Imp qt)

M/T*6.7 (5-7/8)

A/T*Sedan 6.6 (5-7/8)

Hatchback 6.7 (5-7/8)

Reservoir tank0.7 (5/8)

*: With reservoir tank

ENGINE COOLING SYSTEMQG

Overheating Cause Analysis (Cont'd)

LC-24

Page 290 of 2493

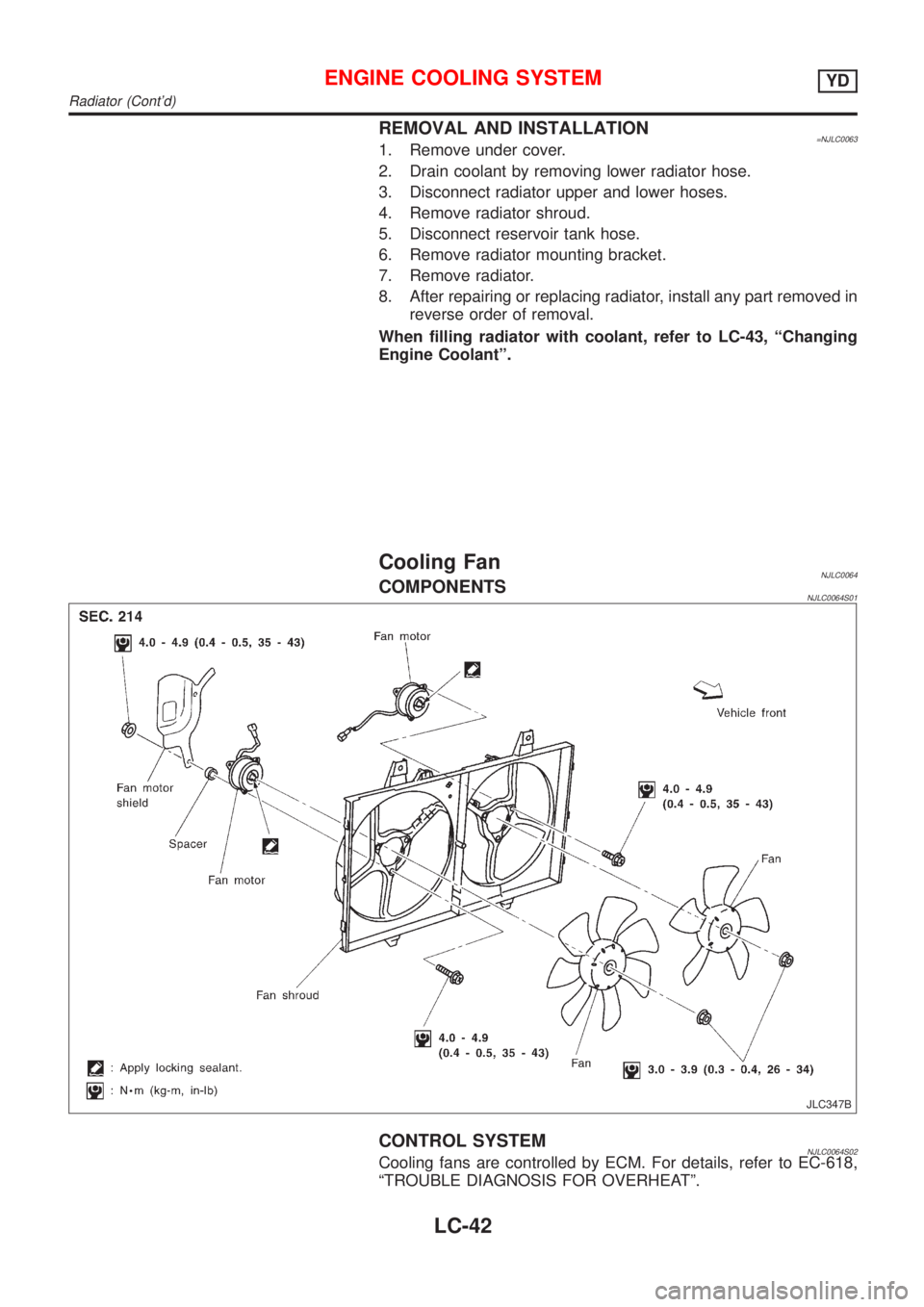

REMOVAL AND INSTALLATION=NJLC00631. Remove under cover.

2. Drain coolant by removing lower radiator hose.

3. Disconnect radiator upper and lower hoses.

4. Remove radiator shroud.

5. Disconnect reservoir tank hose.

6. Remove radiator mounting bracket.

7. Remove radiator.

8. After repairing or replacing radiator, install any part removed in

reverse order of removal.

When filling radiator with coolant, refer to LC-43, ªChanging

Engine Coolantº.

Cooling FanNJLC0064COMPONENTSNJLC0064S01

JLC347B

CONTROL SYSTEMNJLC0064S02Cooling fans are controlled by ECM. For details, refer to EC-618,

ªTROUBLE DIAGNOSIS FOR OVERHEATº.

ENGINE COOLING SYSTEMYD

Radiator (Cont'd)

LC-42

Page 292 of 2493

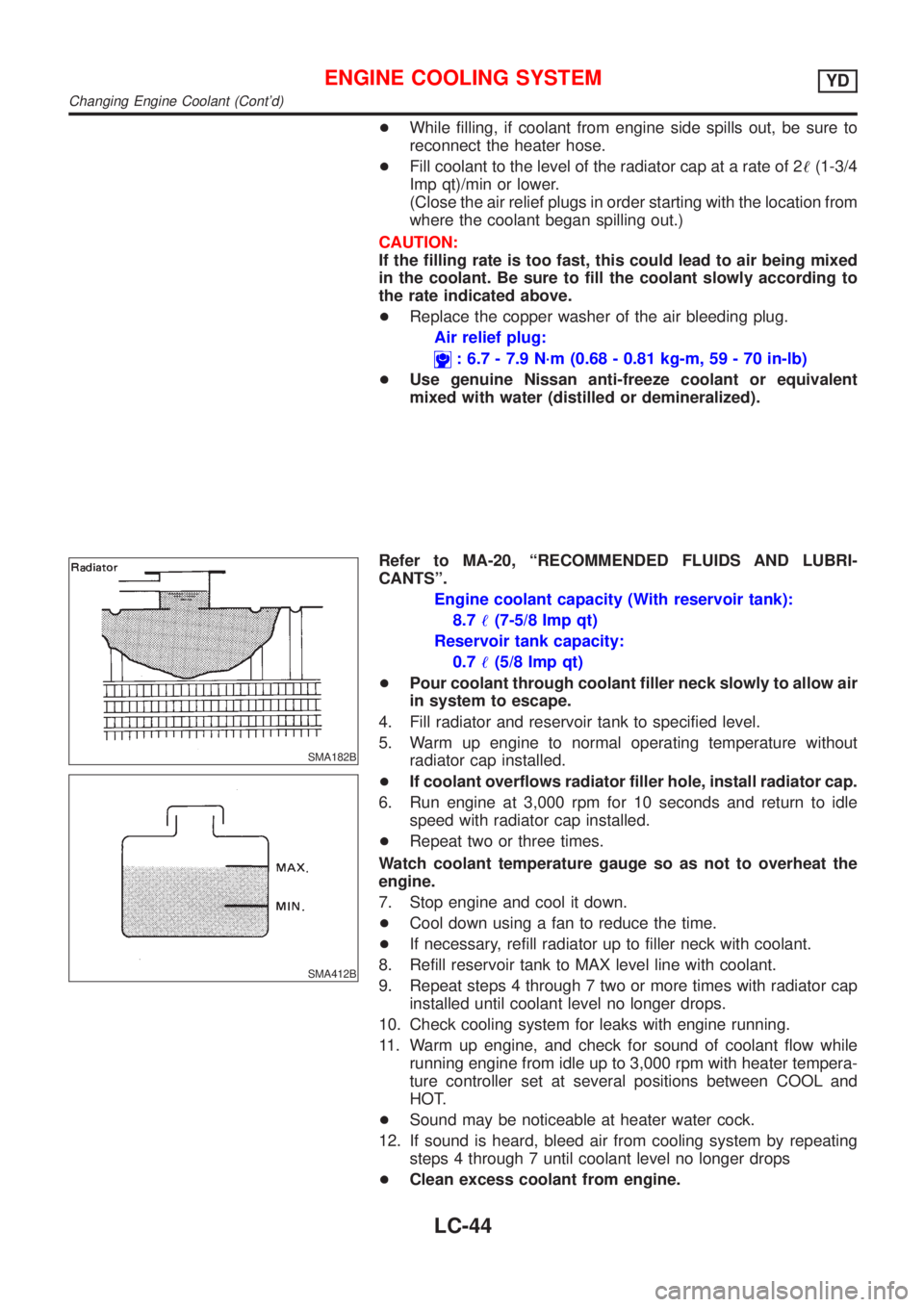

+While filling, if coolant from engine side spills out, be sure to

reconnect the heater hose.

+Fill coolant to the level of the radiator cap at a rate of 2!(1-3/4

Imp qt)/min or lower.

(Close the air relief plugs in order starting with the location from

where the coolant began spilling out.)

CAUTION:

If the filling rate is too fast, this could lead to air being mixed

in the coolant. Be sure to fill the coolant slowly according to

the rate indicated above.

+Replace the copper washer of the air bleeding plug.

Air relief plug:

: 6.7 - 7.9 N´m (0.68 - 0.81 kg-m, 59 - 70 in-lb)

+Use genuine Nissan anti-freeze coolant or equivalent

mixed with water (distilled or demineralized).

SMA182B

SMA412B

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Engine coolant capacity (With reservoir tank):

8.7!(7-5/8 Imp qt)

Reservoir tank capacity:

0.7!(5/8 Imp qt)

+Pour coolant through coolant filler neck slowly to allow air

in system to escape.

4. Fill radiator and reservoir tank to specified level.

5. Warm up engine to normal operating temperature without

radiator cap installed.

+If coolant overflows radiator filler hole, install radiator cap.

6. Run engine at 3,000 rpm for 10 seconds and return to idle

speed with radiator cap installed.

+Repeat two or three times.

Watch coolant temperature gauge so as not to overheat the

engine.

7. Stop engine and cool it down.

+Cool down using a fan to reduce the time.

+If necessary, refill radiator up to filler neck with coolant.

8. Refill reservoir tank to MAX level line with coolant.

9. Repeat steps 4 through 7 two or more times with radiator cap

installed until coolant level no longer drops.

10. Check cooling system for leaks with engine running.

11. Warm up engine, and check for sound of coolant flow while

running engine from idle up to 3,000 rpm with heater tempera-

ture controller set at several positions between COOL and

HOT.

+Sound may be noticeable at heater water cock.

12. If sound is heard, bleed air from cooling system by repeating

steps 4 through 7 until coolant level no longer drops

+Clean excess coolant from engine.

ENGINE COOLING SYSTEMYD

Changing Engine Coolant (Cont'd)

LC-44

Page 294 of 2493

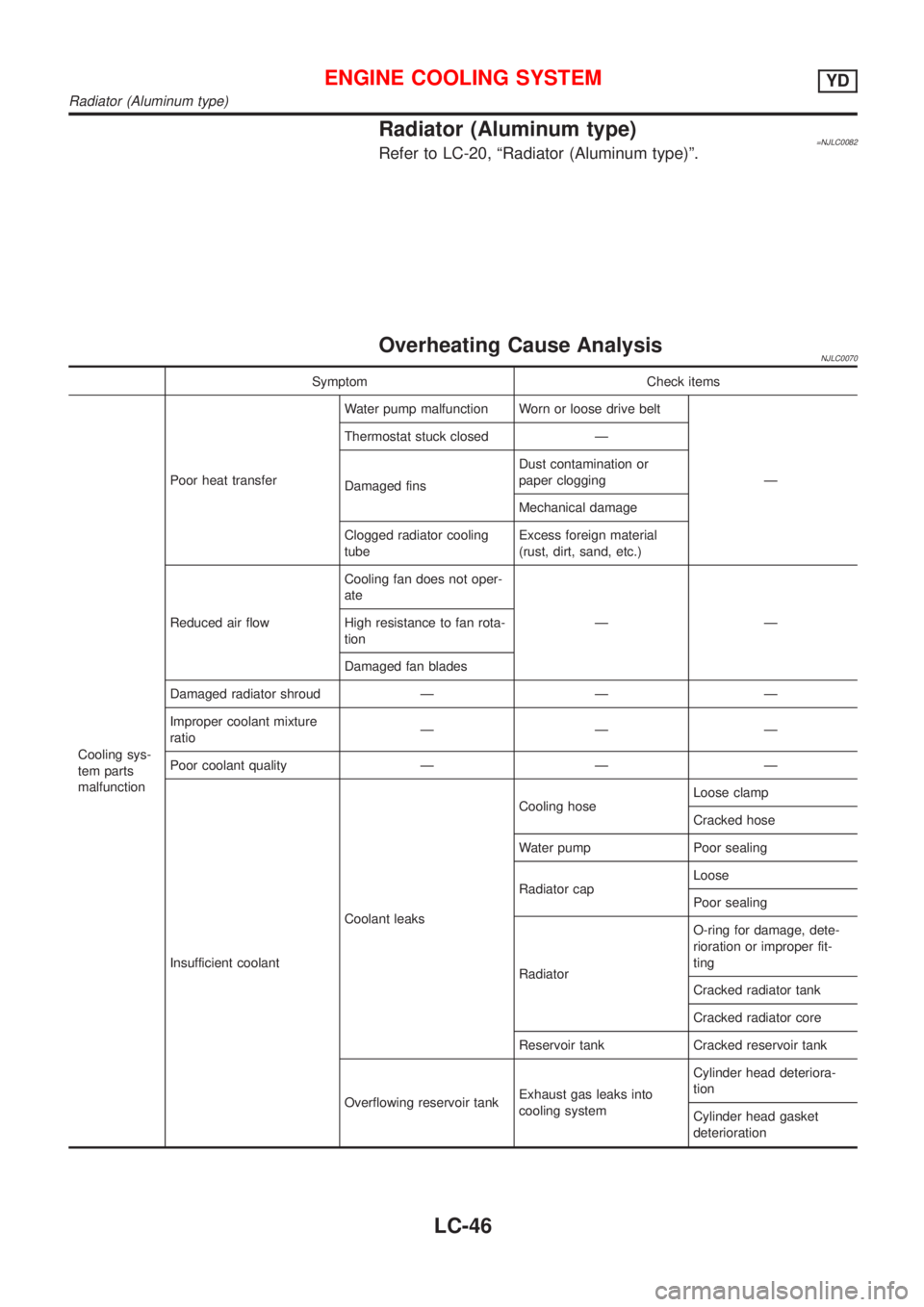

Radiator (Aluminum type)=NJLC0082Refer to LC-20, ªRadiator (Aluminum type)º.

Overheating Cause AnalysisNJLC0070

Symptom Check items

Cooling sys-

tem parts

malfunctionPoor heat transferWater pump malfunction Worn or loose drive belt

Ð Thermostat stuck closed Ð

Damaged finsDust contamination or

paper clogging

Mechanical damage

Clogged radiator cooling

tubeExcess foreign material

(rust, dirt, sand, etc.)

Reduced air flowCooling fan does not oper-

ate

ÐÐ High resistance to fan rota-

tion

Damaged fan blades

Damaged radiator shroud Ð Ð Ð

Improper coolant mixture

ratioÐÐÐ

Poor coolant quality Ð Ð Ð

Insufficient coolantCoolant leaksCooling hoseLoose clamp

Cracked hose

Water pump Poor sealing

Radiator capLoose

Poor sealing

RadiatorO-ring for damage, dete-

rioration or improper fit-

ting

Cracked radiator tank

Cracked radiator core

Reservoir tank Cracked reservoir tank

Overflowing reservoir tankExhaust gas leaks into

cooling systemCylinder head deteriora-

tion

Cylinder head gasket

deterioration

ENGINE COOLING SYSTEMYD

Radiator (Aluminum type)

LC-46

Page 295 of 2493

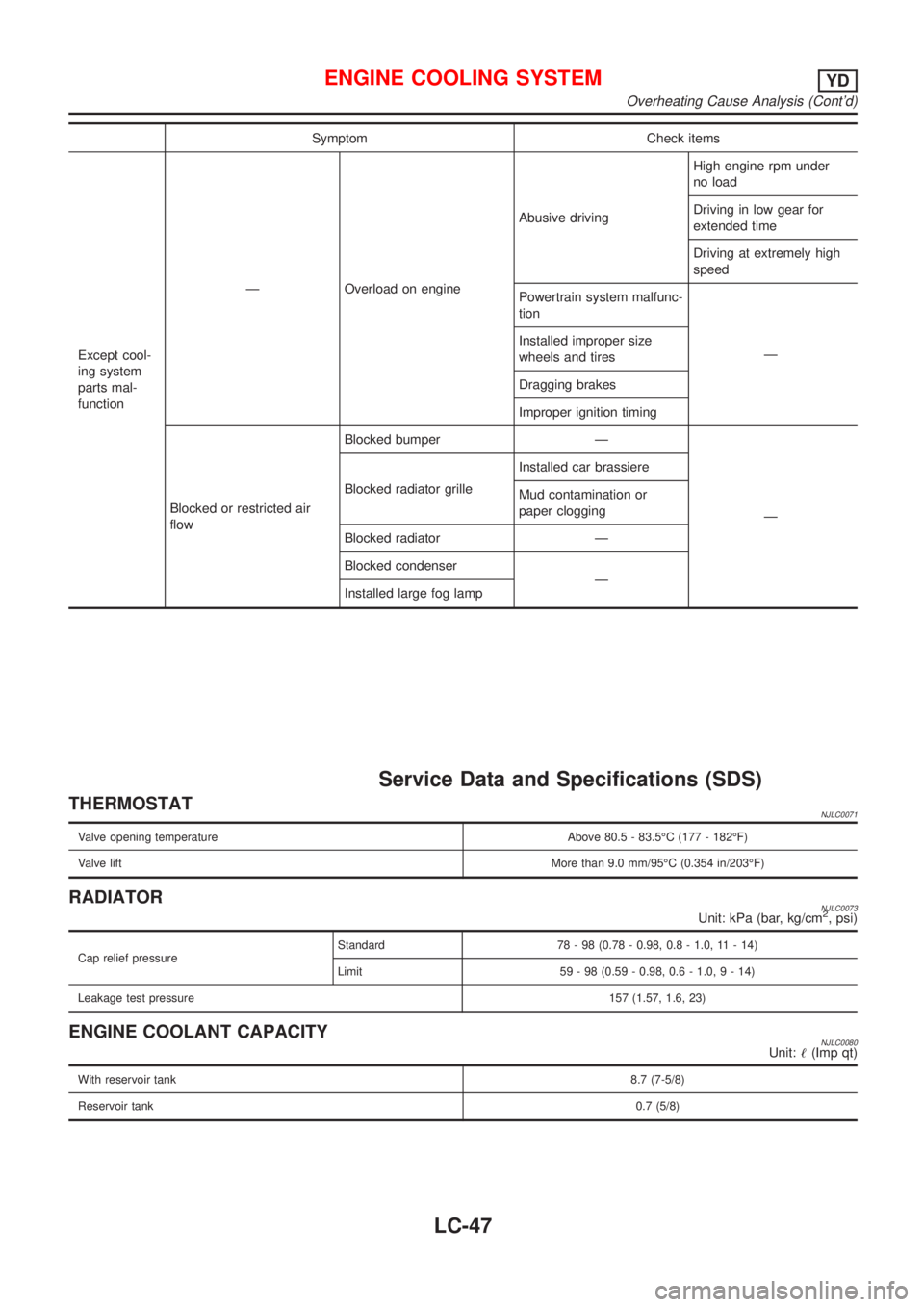

Symptom Check items

Except cool-

ing system

parts mal-

functionÐ Overload on engineAbusive drivingHigh engine rpm under

no load

Driving in low gear for

extended time

Driving at extremely high

speed

Powertrain system malfunc-

tion

Ð Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flowBlocked bumper Ð

Ð Blocked radiator grilleInstalled car brassiere

Mud contamination or

paper clogging

Blocked radiator Ð

Blocked condenser

Ð

Installed large fog lamp

Service Data and Specifications (SDS)

THERMOSTATNJLC0071

Valve opening temperature Above 80.5 - 83.5ÉC (177 - 182ÉF)

Valve liftMore than 9.0 mm/95ÉC (0.354 in/203ÉF)

RADIATORNJLC0073Unit: kPa (bar, kg/cm2, psi)

Cap relief pressureStandard 78 - 98 (0.78 - 0.98, 0.8 - 1.0, 11 - 14)

Limit 59 - 98 (0.59 - 0.98, 0.6 - 1.0,9-14)

Leakage test pressure157 (1.57, 1.6, 23)

ENGINE COOLANT CAPACITYNJLC0080Unit:!(Imp qt)

With reservoir tank8.7 (7-5/8)

Reservoir tank0.7 (5/8)

ENGINE COOLING SYSTEMYD

Overheating Cause Analysis (Cont'd)

LC-47

Page 418 of 2493

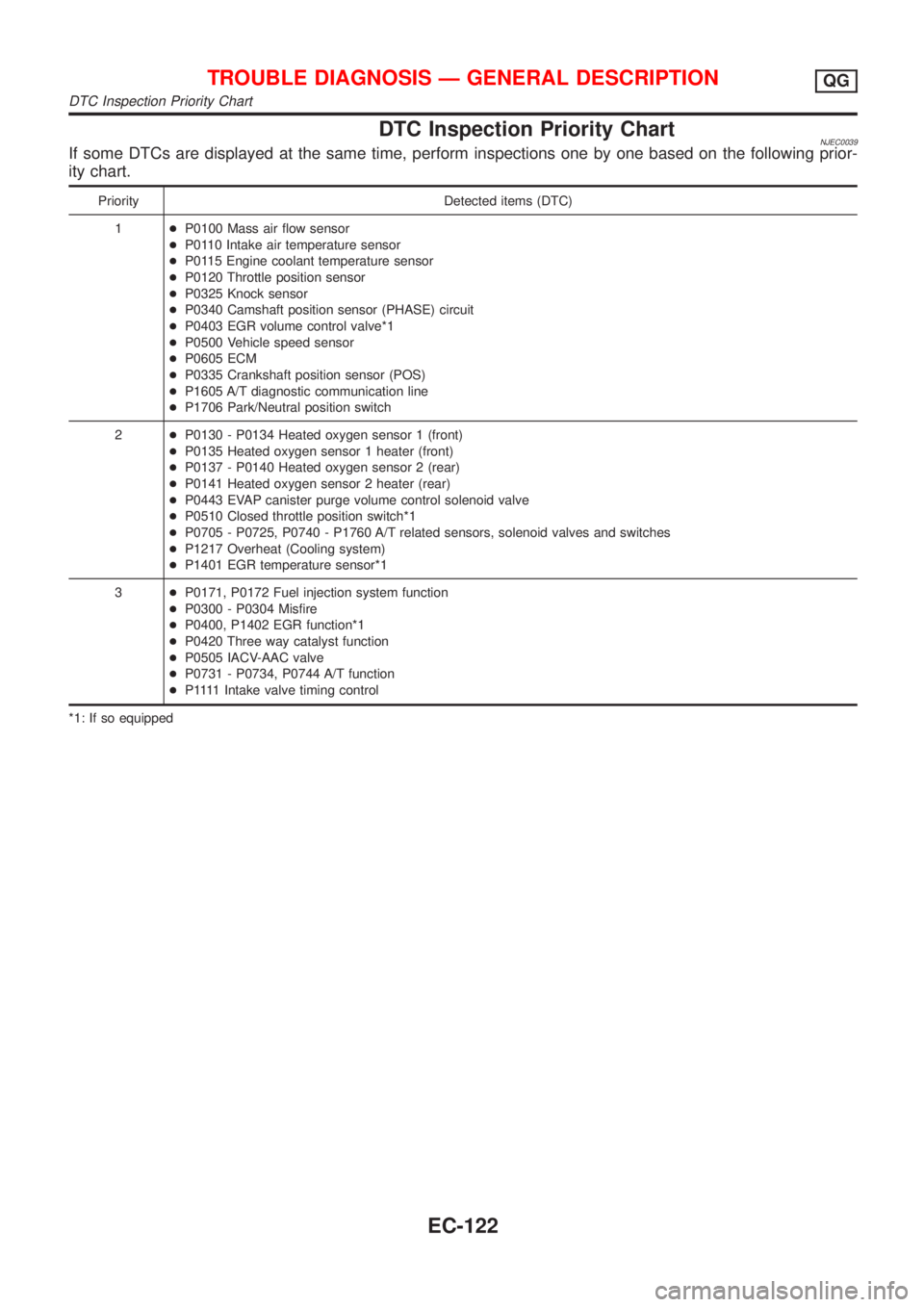

DTC Inspection Priority ChartNJEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1+P0100 Mass air flow sensor

+P0110 Intake air temperature sensor

+P0115 Engine coolant temperature sensor

+P0120 Throttle position sensor

+P0325 Knock sensor

+P0340 Camshaft position sensor (PHASE) circuit

+P0403 EGR volume control valve*1

+P0500 Vehicle speed sensor

+P0605 ECM

+P0335 Crankshaft position sensor (POS)

+P1605 A/T diagnostic communication line

+P1706 Park/Neutral position switch

2+P0130 - P0134 Heated oxygen sensor 1 (front)

+P0135 Heated oxygen sensor 1 heater (front)

+P0137 - P0140 Heated oxygen sensor 2 (rear)

+P0141 Heated oxygen sensor 2 heater (rear)

+P0443 EVAP canister purge volume control solenoid valve

+P0510 Closed throttle position switch*1

+P0705 - P0725, P0740 - P1760 A/T related sensors, solenoid valves and switches

+P1217 Overheat (Cooling system)

+P1401 EGR temperature sensor*1

3+P0171, P0172 Fuel injection system function

+P0300 - P0304 Misfire

+P0400, P1402 EGR function*1

+P0420 Three way catalyst function

+P0505 IACV-AAC valve

+P0731 - P0734, P0744 A/T function

+P 1111Intake valve timing control

*1: If so equipped

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONQG

DTC Inspection Priority Chart

EC-122