radiator NISSAN ALMERA N16 2001 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 7 of 2493

SEF289H

+Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

SGI233

+To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

SGI234

+Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

+Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

+Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

+Replace inner and outer races of tapered roller bearings and

needle bearings as a set.

+Arrange the disassembled parts in accordance with their

assembled locations and sequence.

+Do not touch the terminals of electrical components which use

microcomputers (such as ECMs).

Static electricity may damage internal electronic components.

+After disconnecting vacuum or air hoses, attach a tag to indi-

cate the proper connection.

+Use only the fluids and lubricants specified in this manual.

+Use approved bonding agent, sealants or their equivalents

when required.

+Use tools and recommended special tools where specified for

safe and efficient service repairs.

+When repairing the fuel, oil, water, vacuum or exhaust

systems, check all affected lines for leaks.

+Dispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

PRECAUTIONS

Precautions (Cont'd)

GI-5

Page 58 of 2493

NJMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD Ð engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 78 of 2493

SMA089D

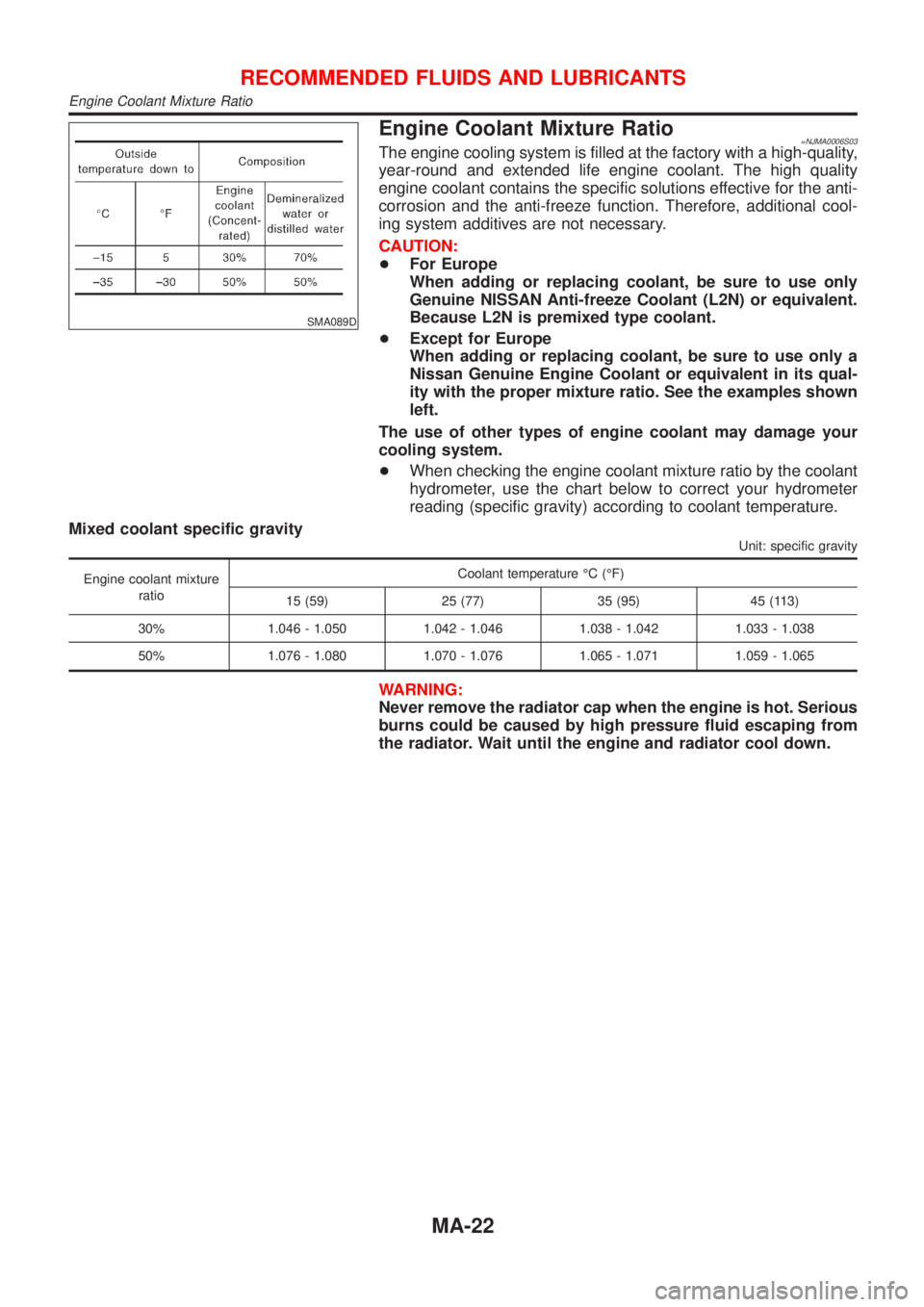

Engine Coolant Mixture Ratio=NJMA0006S03The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality

engine coolant contains the specific solutions effective for the anti-

corrosion and the anti-freeze function. Therefore, additional cool-

ing system additives are not necessary.

CAUTION:

+For Europe

When adding or replacing coolant, be sure to use only

Genuine NISSAN Anti-freeze Coolant (L2N) or equivalent.

Because L2N is premixed type coolant.

+Except for Europe

When adding or replacing coolant, be sure to use only a

Nissan Genuine Engine Coolant or equivalent in its qual-

ity with the proper mixture ratio. See the examples shown

left.

The use of other types of engine coolant may damage your

cooling system.

+When checking the engine coolant mixture ratio by the coolant

hydrometer, use the chart below to correct your hydrometer

reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: specific gravity

Engine coolant mixture

ratioCoolant temperature ÉC (ÉF)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could be caused by high pressure fluid escaping from

the radiator. Wait until the engine and radiator cool down.

RECOMMENDED FLUIDS AND LUBRICANTS

Engine Coolant Mixture Ratio

MA-22

Page 101 of 2493

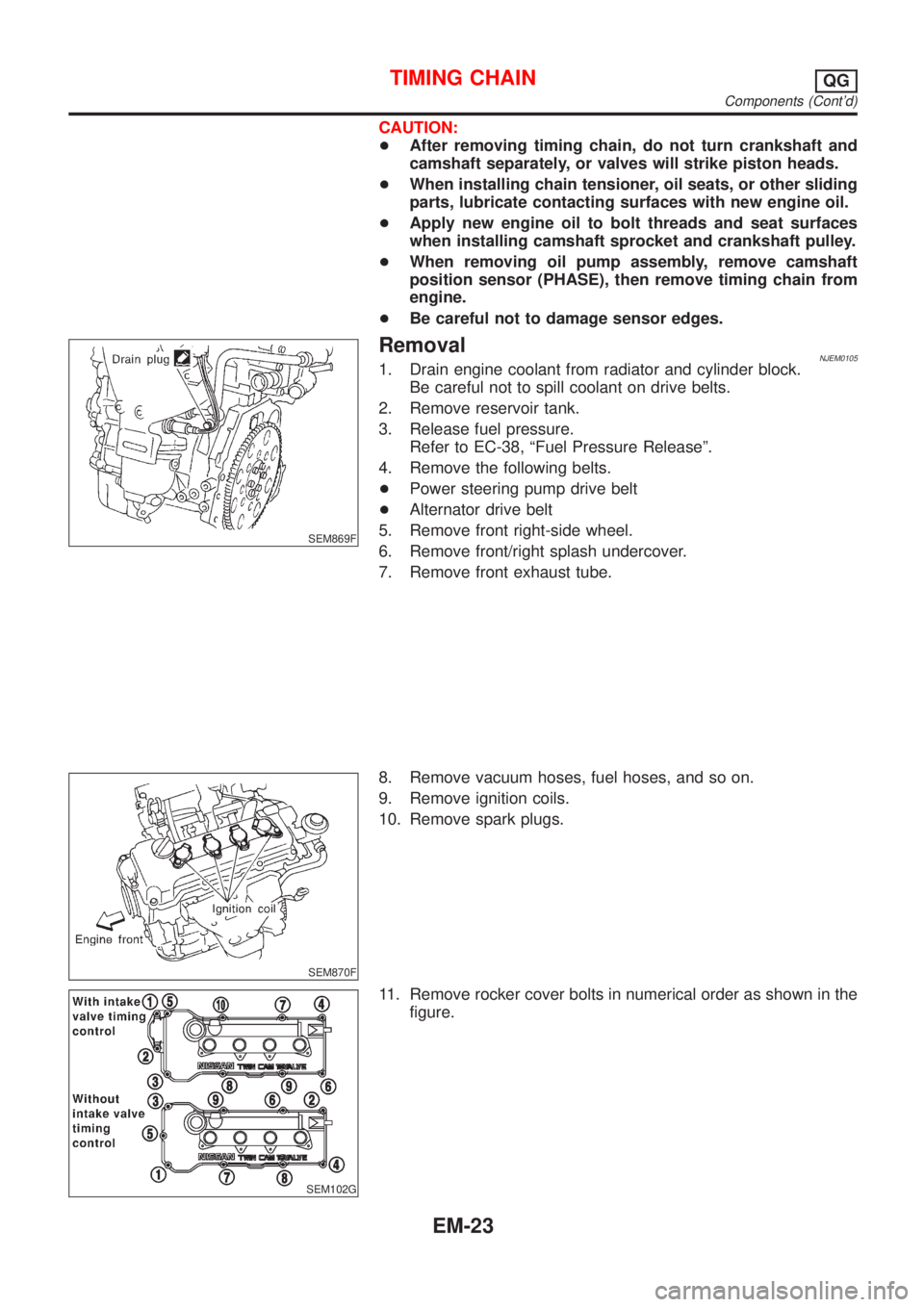

CAUTION:

+After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

+When installing chain tensioner, oil seats, or other sliding

parts, lubricate contacting surfaces with new engine oil.

+Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprocket and crankshaft pulley.

+When removing oil pump assembly, remove camshaft

position sensor (PHASE), then remove timing chain from

engine.

+Be careful not to damage sensor edges.

SEM869F

RemovalNJEM01051. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Remove reservoir tank.

3. Release fuel pressure.

Refer to EC-38, ªFuel Pressure Releaseº.

4. Remove the following belts.

+Power steering pump drive belt

+Alternator drive belt

5. Remove front right-side wheel.

6. Remove front/right splash undercover.

7. Remove front exhaust tube.

SEM870F

8. Remove vacuum hoses, fuel hoses, and so on.

9. Remove ignition coils.

10. Remove spark plugs.

SEM102G

11. Remove rocker cover bolts in numerical order as shown in the

figure.

TIMING CHAINQG

Components (Cont'd)

EM-23

Page 112 of 2493

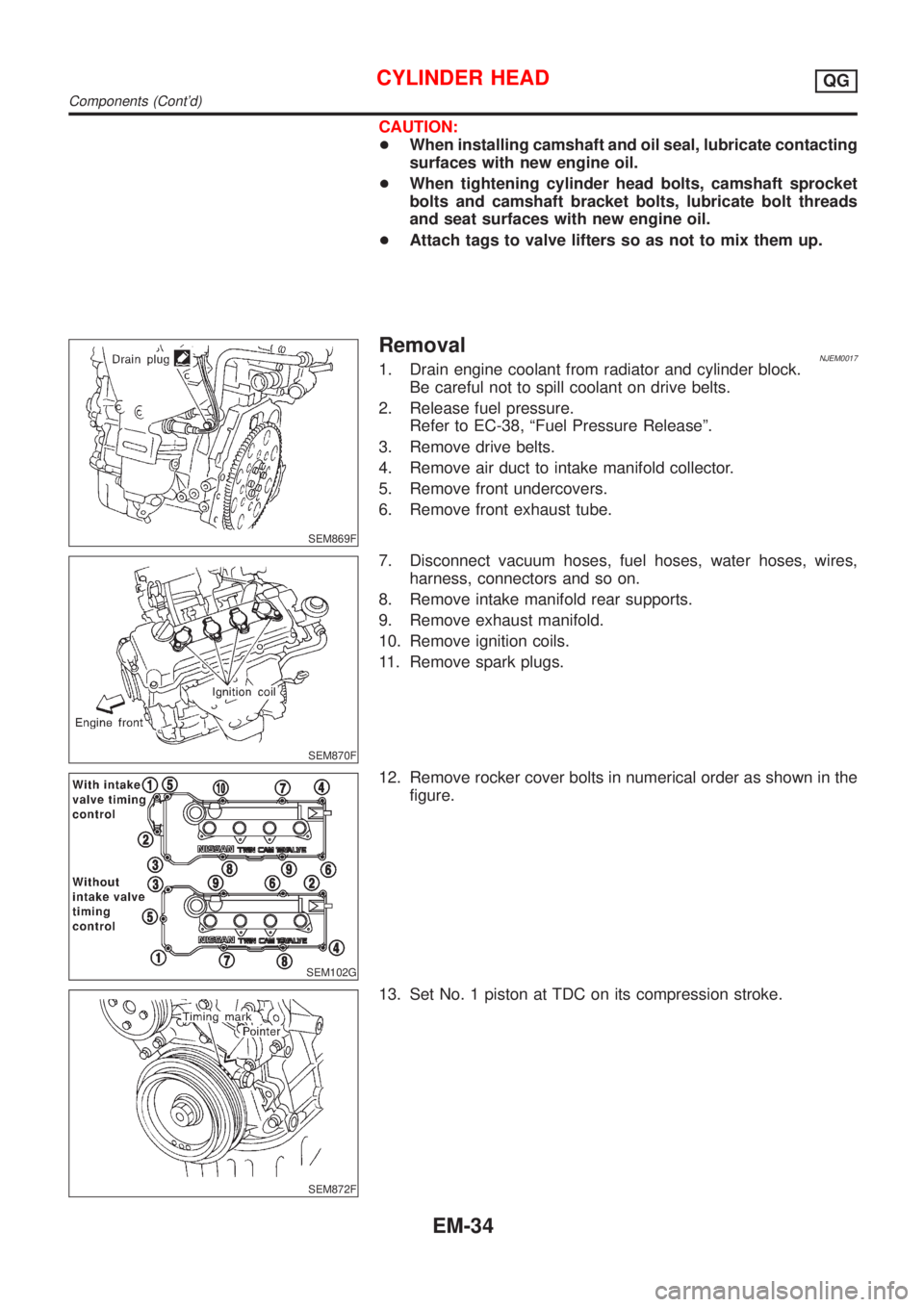

CAUTION:

+When installing camshaft and oil seal, lubricate contacting

surfaces with new engine oil.

+When tightening cylinder head bolts, camshaft sprocket

bolts and camshaft bracket bolts, lubricate bolt threads

and seat surfaces with new engine oil.

+Attach tags to valve lifters so as not to mix them up.

SEM869F

RemovalNJEM00171. Drain engine coolant from radiator and cylinder block.

Be careful not to spill coolant on drive belts.

2. Release fuel pressure.

Refer to EC-38, ªFuel Pressure Releaseº.

3. Remove drive belts.

4. Remove air duct to intake manifold collector.

5. Remove front undercovers.

6. Remove front exhaust tube.

SEM870F

7. Disconnect vacuum hoses, fuel hoses, water hoses, wires,

harness, connectors and so on.

8. Remove intake manifold rear supports.

9. Remove exhaust manifold.

10. Remove ignition coils.

11. Remove spark plugs.

SEM102G

12. Remove rocker cover bolts in numerical order as shown in the

figure.

SEM872F

13. Set No. 1 piston at TDC on its compression stroke.

CYLINDER HEADQG

Components (Cont'd)

EM-34

Page 128 of 2493

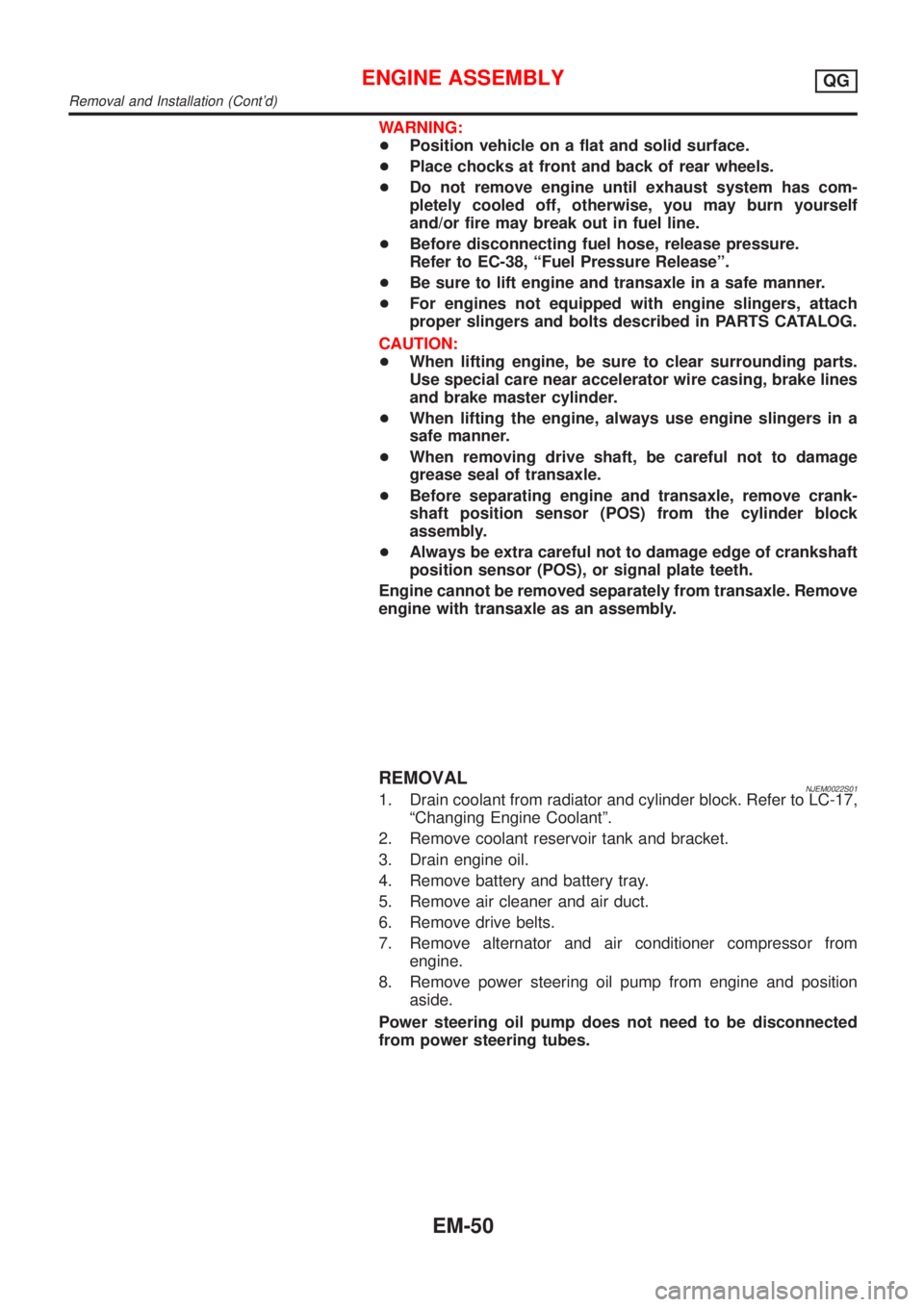

WARNING:

+Position vehicle on a flat and solid surface.

+Place chocks at front and back of rear wheels.

+Do not remove engine until exhaust system has com-

pletely cooled off, otherwise, you may burn yourself

and/or fire may break out in fuel line.

+Before disconnecting fuel hose, release pressure.

Refer to EC-38, ªFuel Pressure Releaseº.

+Be sure to lift engine and transaxle in a safe manner.

+For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

+When lifting engine, be sure to clear surrounding parts.

Use special care near accelerator wire casing, brake lines

and brake master cylinder.

+When lifting the engine, always use engine slingers in a

safe manner.

+When removing drive shaft, be careful not to damage

grease seal of transaxle.

+Before separating engine and transaxle, remove crank-

shaft position sensor (POS) from the cylinder block

assembly.

+Always be extra careful not to damage edge of crankshaft

position sensor (POS), or signal plate teeth.

Engine cannot be removed separately from transaxle. Remove

engine with transaxle as an assembly.

REMOVALNJEM0022S011. Drain coolant from radiator and cylinder block. Refer to LC-17,

ªChanging Engine Coolantº.

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from

engine.

8. Remove power steering oil pump from engine and position

aside.

Power steering oil pump does not need to be disconnected

from power steering tubes.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-50

Page 129 of 2493

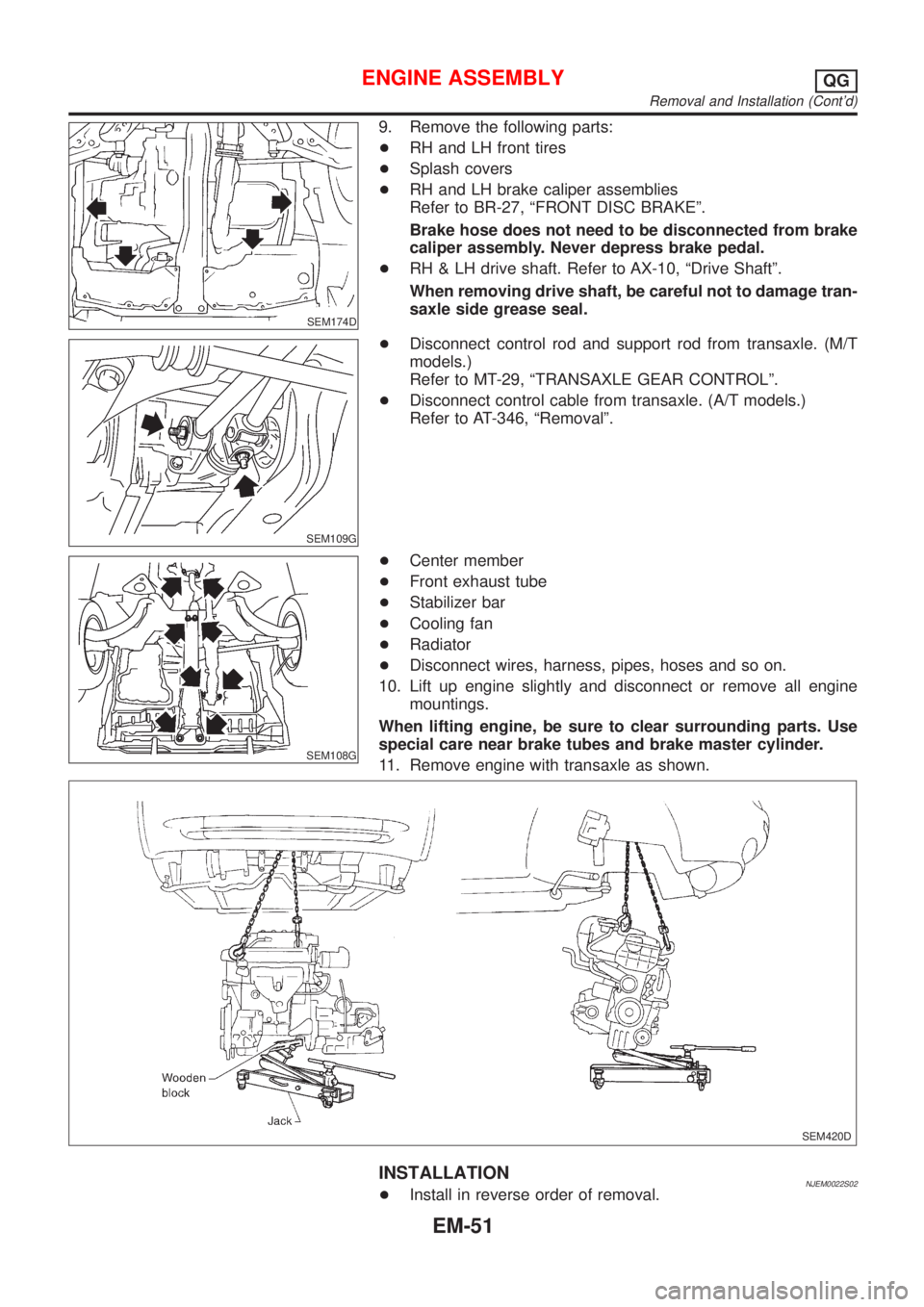

SEM174D

9. Remove the following parts:

+RH and LH front tires

+Splash covers

+RH and LH brake caliper assemblies

Refer to BR-27, ªFRONT DISC BRAKEº.

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

+RH & LH drive shaft. Refer to AX-10, ªDrive Shaftº.

When removing drive shaft, be careful not to damage tran-

saxle side grease seal.

SEM109G

+Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-29, ªTRANSAXLE GEAR CONTROLº.

+Disconnect control cable from transaxle. (A/T models.)

Refer to AT-346, ªRemovalº.

SEM108G

+Center member

+Front exhaust tube

+Stabilizer bar

+Cooling fan

+Radiator

+Disconnect wires, harness, pipes, hoses and so on.

10. Lift up engine slightly and disconnect or remove all engine

mountings.

When lifting engine, be sure to clear surrounding parts. Use

special care near brake tubes and brake master cylinder.

11. Remove engine with transaxle as shown.

SEM420D

INSTALLATIONNJEM0022S02+Install in reverse order of removal.

ENGINE ASSEMBLYQG

Removal and Installation (Cont'd)

EM-51

Page 187 of 2493

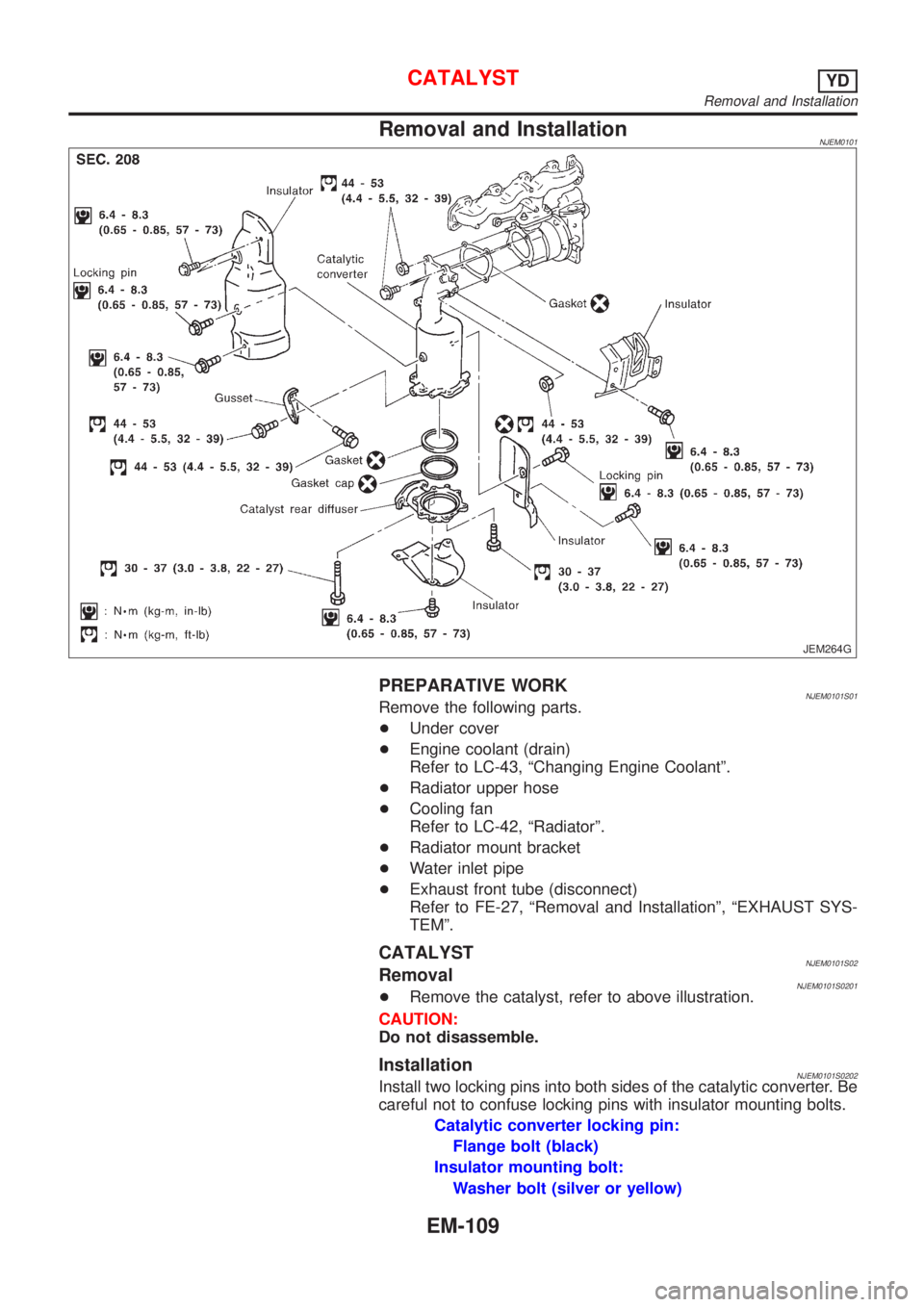

Removal and InstallationNJEM0101

JEM264G

PREPARATIVE WORKNJEM0101S01Remove the following parts.

+Under cover

+Engine coolant (drain)

Refer to LC-43, ªChanging Engine Coolantº.

+Radiator upper hose

+Cooling fan

Refer to LC-42, ªRadiatorº.

+Radiator mount bracket

+Water inlet pipe

+Exhaust front tube (disconnect)

Refer to FE-27, ªRemoval and Installationº, ªEXHAUST SYS-

TEMº.

CATALYSTNJEM0101S02RemovalNJEM0101S0201+Remove the catalyst, refer to above illustration.

CAUTION:

Do not disassemble.

InstallationNJEM0101S0202Install two locking pins into both sides of the catalytic converter. Be

careful not to confuse locking pins with insulator mounting bolts.

Catalytic converter locking pin:

Flange bolt (black)

Insulator mounting bolt:

Washer bolt (silver or yellow)

CATALYSTYD

Removal and Installation

EM-109

Page 215 of 2493

crankshaft position sensor (TDC sensor) from the assem-

bly.

+Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-43, ªChanging Engine Coolantº.

3. Remove the following parts:

+Battery

+RH and LH front wheels

+RH and LH splash covers (combined with undercover)

+Auxiliary belts

+Alternator

+Alternator brackets

+Radiator and cooling fan

+Engine cover

+Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

+Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

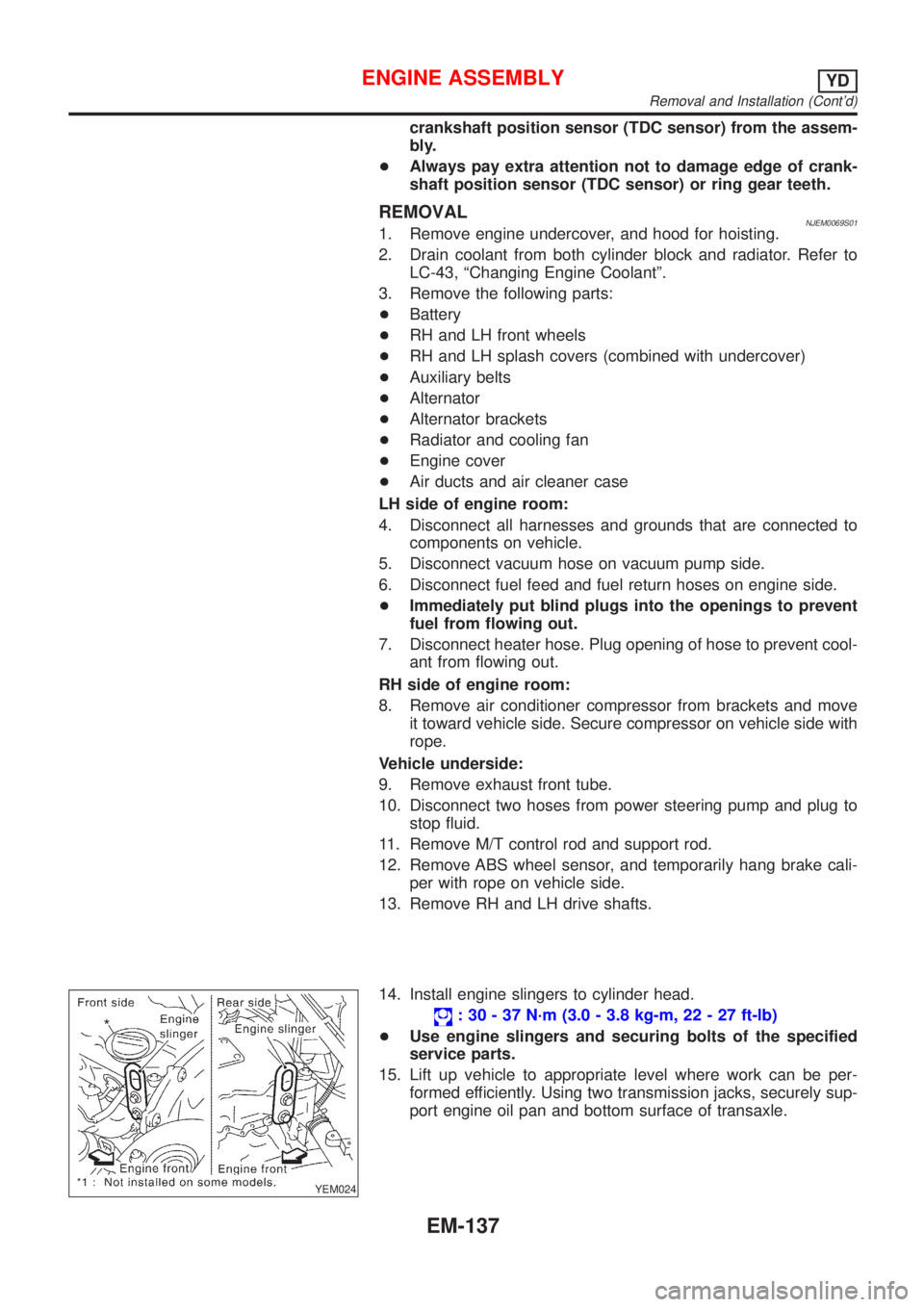

YEM024

14. Install engine slingers to cylinder head.

: 30 - 37 N´m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

+Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont'd)

EM-137

Page 249 of 2493

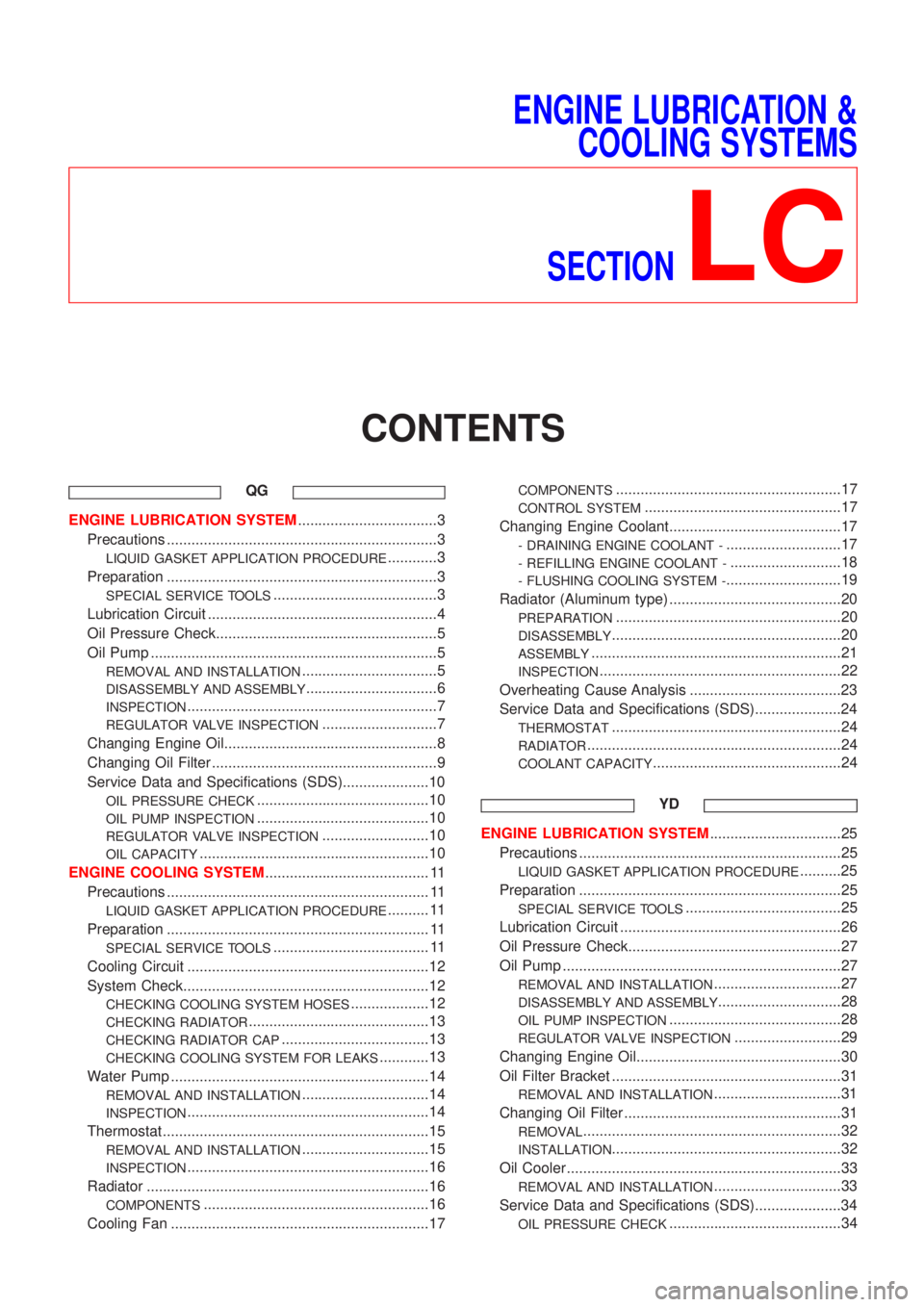

ENGINE LUBRICATION &

COOLING SYSTEMS

SECTION

LC

CONTENTS

QG

ENGINE LUBRICATION SYSTEM..................................3

Precautions ..................................................................3

LIQUID GASKET APPLICATION PROCEDURE............3

Preparation ..................................................................3

SPECIAL SERVICE TOOLS........................................3

Lubrication Circuit ........................................................4

Oil Pressure Check......................................................5

Oil Pump ......................................................................5

REMOVAL AND INSTALLATION.................................5

DISASSEMBLY AND ASSEMBLY................................6

INSPECTION.............................................................7

REGULATOR VALVE INSPECTION............................7

Changing Engine Oil....................................................8

Changing Oil Filter .......................................................9

Service Data and Specifications (SDS).....................10

OIL PRESSURE CHECK..........................................10

OIL PUMP INSPECTION..........................................10

REGULATOR VALVE INSPECTION..........................10

OIL CAPACITY........................................................10

ENGINE COOLING SYSTEM........................................ 11

Precautions ................................................................ 11

LIQUID GASKET APPLICATION PROCEDURE.......... 11

Preparation ................................................................ 11

SPECIAL SERVICE TOOLS...................................... 11

Cooling Circuit ...........................................................12

System Check............................................................12

CHECKING COOLING SYSTEM HOSES...................12

CHECKING RADIATOR............................................13

CHECKING RADIATOR CAP....................................13

CHECKING COOLING SYSTEM FOR LEAKS............13

Water Pump ...............................................................14

REMOVAL AND INSTALLATION...............................14

INSPECTION...........................................................14

Thermostat .................................................................15

REMOVAL AND INSTALLATION...............................15

INSPECTION...........................................................16

Radiator .....................................................................16

COMPONENTS.......................................................16

Cooling Fan ...............................................................17

COMPONENTS.......................................................17

CONTROL SYSTEM................................................17

Changing Engine Coolant..........................................17

- DRAINING ENGINE COOLANT -............................17

- REFILLING ENGINE COOLANT -...........................18

- FLUSHING COOLING SYSTEM -............................19

Radiator (Aluminum type) ..........................................20

PREPARATION.......................................................20

DISASSEMBLY........................................................20

ASSEMBLY.............................................................21

INSPECTION...........................................................22

Overheating Cause Analysis .....................................23

Service Data and Specifications (SDS).....................24

THERMOSTAT........................................................24

RADIATOR..............................................................24

COOLANT CAPACITY..............................................24

YD

ENGINE LUBRICATION SYSTEM................................25

Precautions ................................................................25

LIQUID GASKET APPLICATION PROCEDURE..........25

Preparation ................................................................25

SPECIAL SERVICE TOOLS......................................25

Lubrication Circuit ......................................................26

Oil Pressure Check....................................................27

Oil Pump ....................................................................27

REMOVAL AND INSTALLATION...............................27

DISASSEMBLY AND ASSEMBLY..............................28

OIL PUMP INSPECTION..........................................28

REGULATOR VALVE INSPECTION..........................29

Changing Engine Oil..................................................30

Oil Filter Bracket ........................................................31

REMOVAL AND INSTALLATION...............................31

Changing Oil Filter .....................................................31

REMOVAL...............................................................32

INSTALLATION........................................................32

Oil Cooler ...................................................................33

REMOVAL AND INSTALLATION...............................33

Service Data and Specifications (SDS).....................34

OIL PRESSURE CHECK..........................................34