brake fluid NISSAN ALMERA N16 2003 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1460 of 3189

AT-4

REMOVAL AND INSTALLATION ...........................410

Removal ...............................................................410

Installation .............................................................411

OVERHAUL .............................................................413

Output Shaft, Idler Gear, Reduction Pinion Gear and

Bearing Retainer ...................................................413

Oil Channel ...........................................................416

Locations of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings ..........................417

DISASSEMBLY .......................................................418

Disassembly .........................................................418

REPAIR FOR COMPONENT PARTS ......................432

Manual Shaft ........................................................432

Oil Pump ...............................................................435

Control Valve Assembly ........................................439

Control Valve Upper Body ....................................449

Control Valve Lower Body ....................................453

Reverse Clutch .....................................................455

High Clutch ...........................................................459

Forward and Overrun Clutches ............................464

Low & Reverse Brake ...........................................470

Rear Internal Gear, Forward Clutch Hub and Over-

run Clutch Hub ......................................................474

Output Shaft, Idler Gear, Reduction Pinion Gear and

Bearing Retainer ...................................................478

Band Servo Piston Assembly ...............................483

Final Drive ............................................................488

ASSEMBLY .............................................................493

Assembly (1) .........................................................493Adjustment (1) .......................................................494

Assembly (2) .........................................................500

Adjustment (2) .......................................................504

Assembly (3) .........................................................508

SERVICE DATA AND SPECIFICATIONS (SDS) ....515

General Specifications ......................................... .515

Shift Schedule .......................................................515

Stall Revolution .....................................................515

Line Pressure ........................................................515

Control Valves .......................................................516

Clutch and Brakes .................................................516

Clutch and Brake Return Springs .........................518

Oil Pump ......................................................

.........518

Input Shaft .............................................................518

Planetary carrier ....................................................518

Final Drive .............................................................519

Reduction Pinion Gear ..........................................520

Output Shaft ..........................................................522

Bearing Retainer ...................................................523

Total End Play .......................................................523

Reverse Clutch End Play ......................................523

Accumulator ..........................................................523

Band Servo ...........................................................524

Removal and Installation .......................................524

Shift Solenoid Valves ............................................524

Solenoid Valves ....................................................524

A/T Fluid Temperature Sensor ..............................524

Revolution Sensor .................................................524

Dropping Resistor .................................................524

Page 1469 of 3189

A/T FLUID

AT-13

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T FLUIDPFP:KLE40

Checking A/T FluidECS007NC

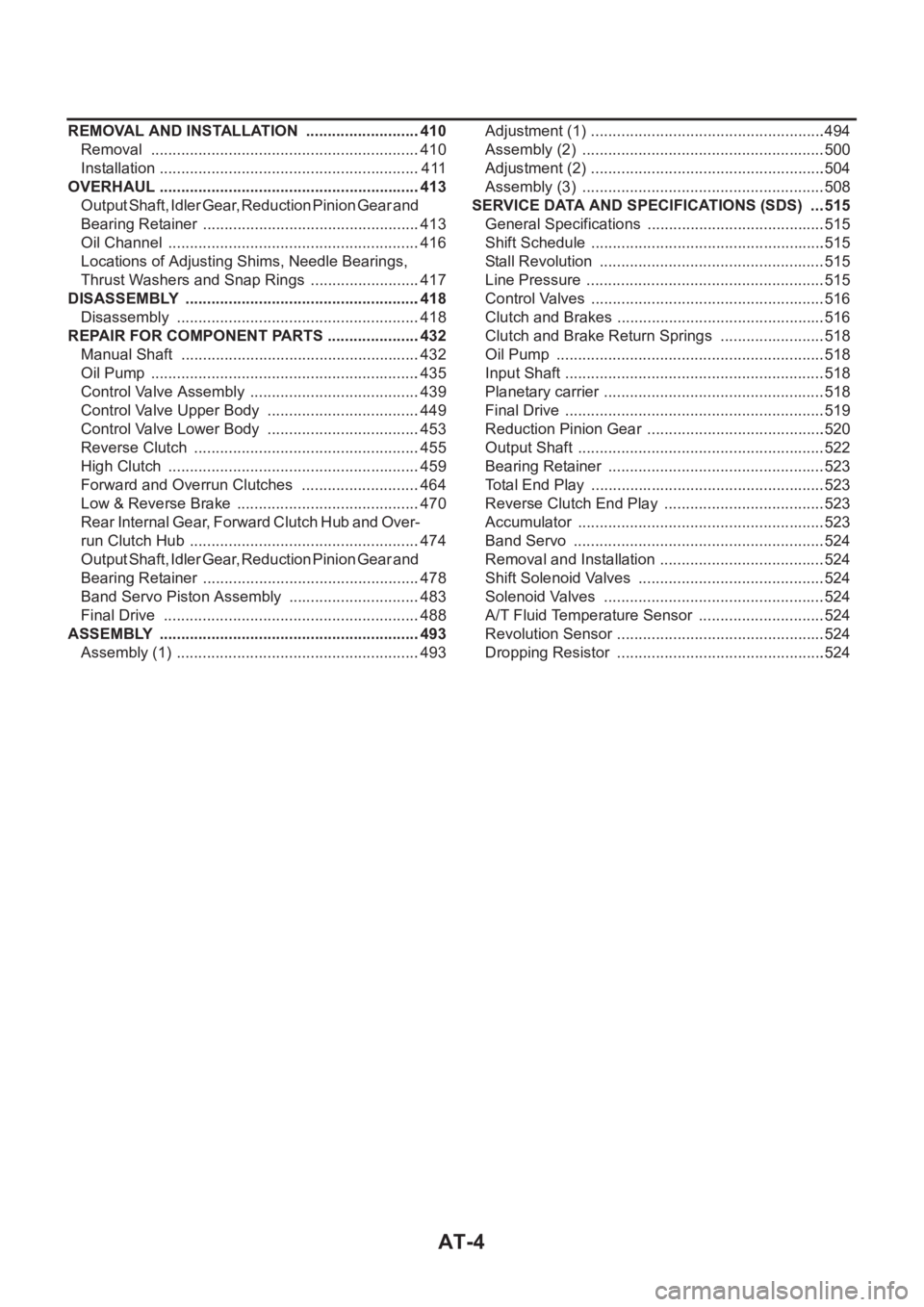

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid temperatures

of 30 to 50°C (86 to 122°F) using “COLD” range on dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in “P” position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of either

range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80°C (122 to 176°F) using “HOT” range on dipstick.

6. Check fluid condition.

●If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair of

A/T.

●If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC-16, "Radi-

ator".

Changing A/T FluidECS007ND

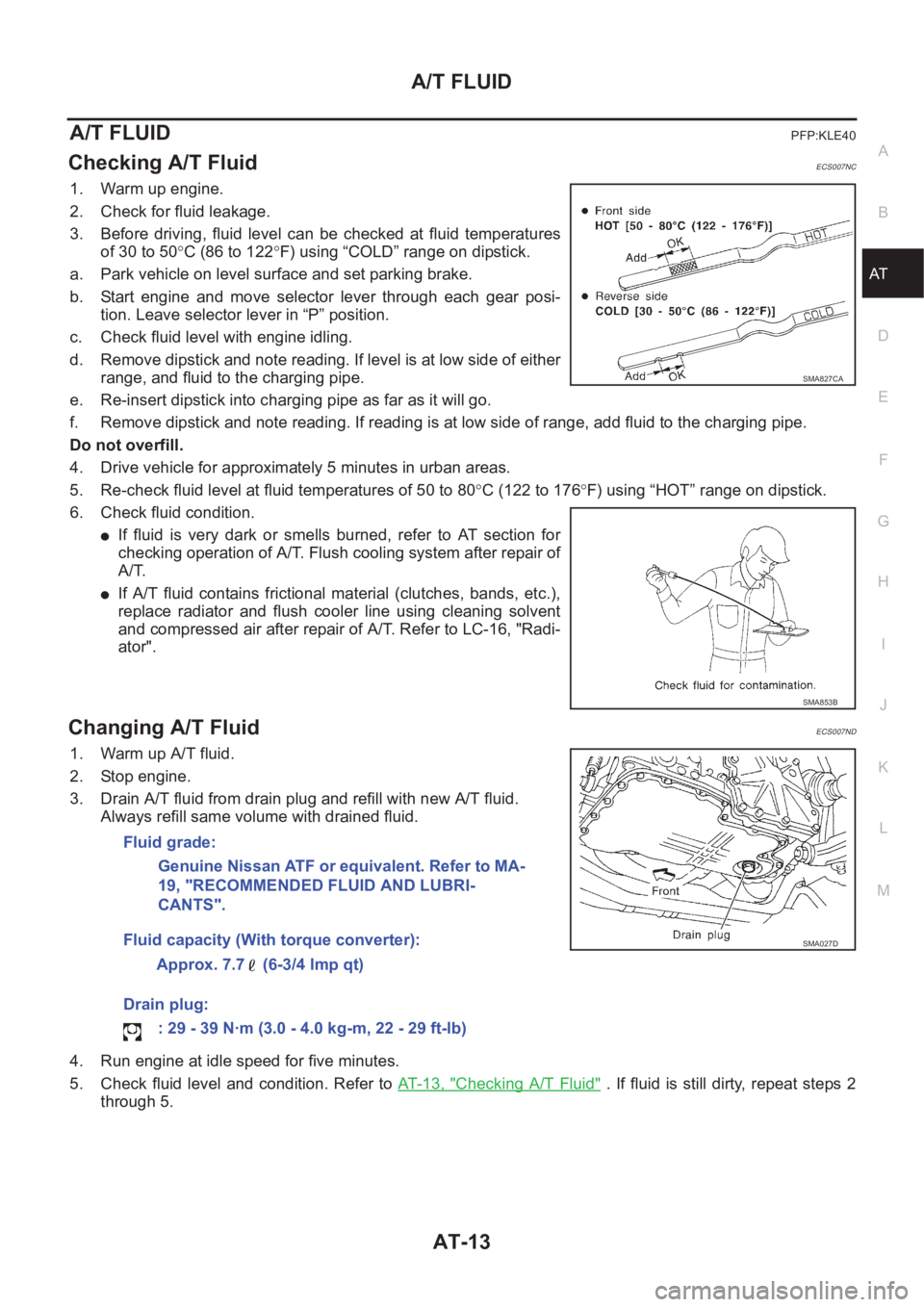

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to AT- 1 3 , "

Checking A/T Fluid" . If fluid is still dirty, repeat steps 2

through 5.

SMA827CA

SMA853B

Fluid grade:

Genuine Nissan ATF or equivalent. Refer to MA-

19, "RECOMMENDED FLUID AND LUBRI-

CANTS".

Fluid capacity (With torque converter):

Approx. 7.7 (6-3/4 lmp qt)

Drain plug:

: 29 - 39 N·m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

SMA027D

Page 1484 of 3189

AT-28

OVERALL SYSTEM

TCM FUNCTION

The function of the TCM is to:

●Receive input signals sent from various switches and sensors.

●Determine required line pressure, shifting point, lock-up operation, and engine brake operation.

●Send required output signals to the respective solenoid valves.

INPUT/OUTPUT SIGNAL OF TCM

Control MechanismECS007NK

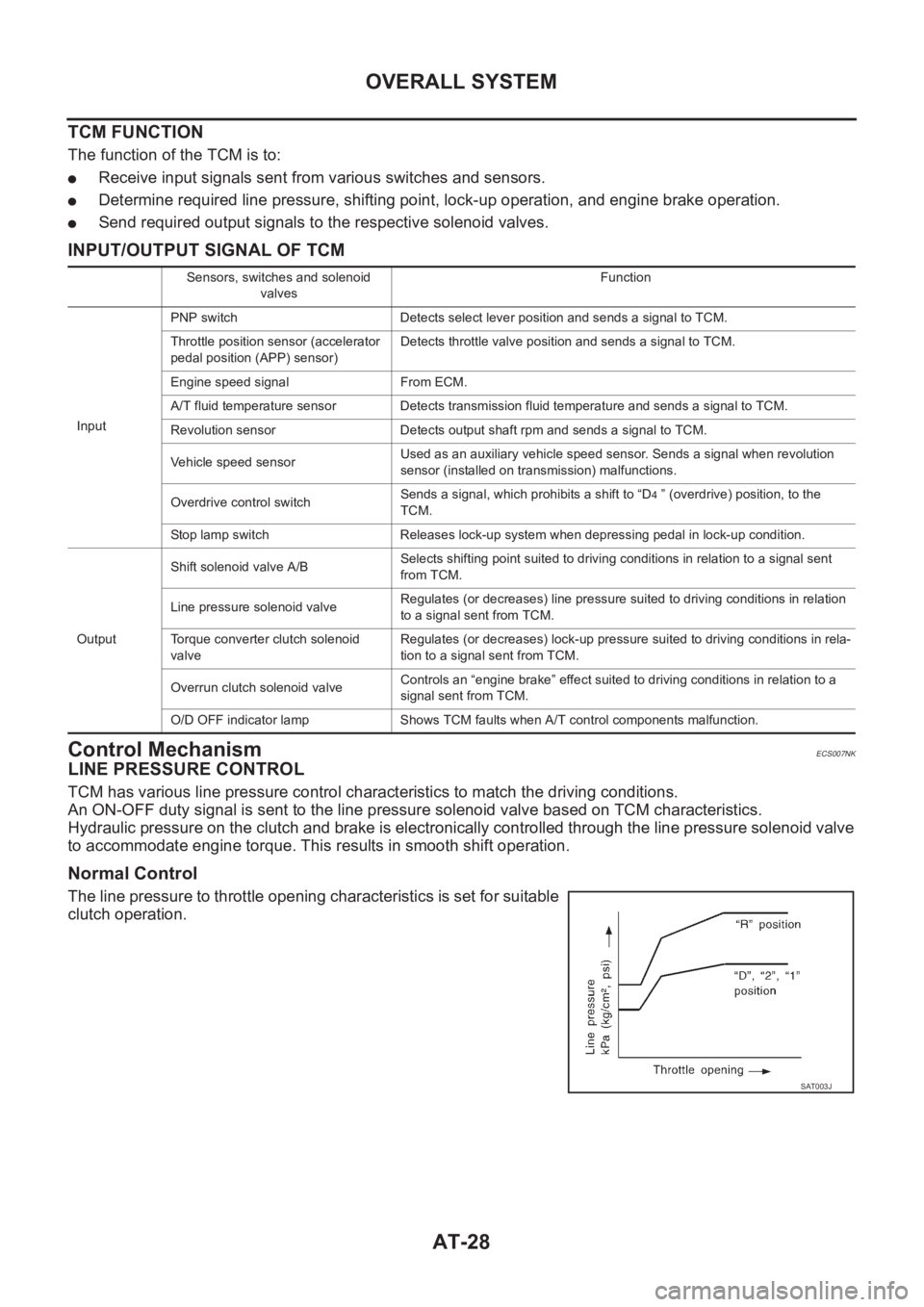

LINE PRESSURE CONTROL

TCM has various line pressure control characteristics to match the driving conditions.

An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics.

Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve

to accommodate engine torque. This results in smooth shift operation.

Normal Control

The line pressure to throttle opening characteristics is set for suitable

clutch operation.

Sensors, switches and solenoid

valvesFunction

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor (accelerator

pedal position (APP) sensor)Detects throttle valve position and sends a signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution

sensor (installed on transmission) malfunctions.

Overdrive control switchSends a signal, which prohibits a shift to “D

4 ” (overdrive) position, to the

TCM.

Stop lamp switch Releases lock-up system when depressing pedal in lock-up condition.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent

from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation

to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Overrun clutch solenoid valveControls an “engine brake” effect suited to driving conditions in relation to a

signal sent from TCM.

O/D OFF indicator lamp Shows TCM faults when A/T control components malfunction.

SAT003J

Page 1485 of 3189

OVERALL SYSTEM

AT-29

D

E

F

G

H

I

J

K

L

MA

B

AT

Back-up Control (Engine Brake)

If the selector lever is shifted to “2” position while driving in D4 (OD)

or D

3 , great driving force is applied to the clutch inside the transmis-

sion. Clutch operating pressure (line pressure) must be increased to

deal with this driving force.

During Shift Change

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

At Low Fluid Temperature

●Fluid viscosity and frictional characteristics of the clutch facing change with fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to fluid temperature, to stabilize

shifting quality.

●The line pressure is reduced below 60°C (140°F) to prevent

shifting shock due to low viscosity of automatic transmission

fluid when temperature is low.

●Line pressure is increased to a maximum irrespective of the

throttle opening when fluid temperature drops to −10°C (14°F).

This pressure rise is adopted to prevent a delay in clutch and

brake operation due to extreme drop of fluid viscosity at low

temperature.

SAT004J

SAT005J

SAT006J

SAT007J

Page 1514 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual AT-58

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

Diagnostic Worksheet

1.❏ Read the Fail-safe and listen to customer complaints.AT-57, "Infor-

mation from

Customer"

2.❏ CHECK A/T FLUIDA NISSAN ALMERA N16 2003 Electronic Owners Manual AT-58

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

Diagnostic Worksheet

1.❏ Read the Fail-safe and listen to customer complaints.AT-57, "Infor-

mation from

Customer"

2.❏ CHECK A/T FLUIDA](/img/5/57350/w960_57350-1513.png)

AT-58

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

Diagnostic Worksheet

1.❏ Read the Fail-safe and listen to customer complaints.AT-57, "Infor-

mation from

Customer"

2.❏ CHECK A/T FLUIDAT-63, "A/T

Fluid Check"❏ Leakage (Follow specified procedure)

❏ Fluid condition

❏ Fluid level

3.❏ Perform STALL TEST and LINE PRESSURE TEST.AT-64, "

Stall

Te s t",AT- 6 7 ,

"Line Pres-

sure Test"

❏ Stall test — Mark possible damaged components/others.

❏ Torque converter one-way clutch

❏ Reverse clutch

❏ Forward clutch

❏ Overrun clutch

❏ Forward one-way clutch❏ Low & reverse brake

❏ Low one-way clutch

❏ Engine

❏ Line pressure is low

❏ Clutches and brakes except high clutch and

brake band are OK

❏ Line Pressure test — Suspected parts:

4.❏ Perform all ROAD TEST and mark required procedures.AT-68, "

Road

Te s t"

4-

1.Check before engine is started.AT-70, "1.

CHECK

BEFORE

ENGINE IS

STARTED"

❏ SELF-DIAGNOSTIC PROCEDURE/DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCE-

DURE. — Mark detected items.

❏ PNP switch, AT- 111

.

❏ A/T fluid temperature sensor, AT- 11 7

.

❏ Vehicle speed sensor·A/T (Revolution sensor), AT-123

.

❏ Engine speed signal, AT-129

.

❏ Torque converter clutch solenoid valve, AT- 1 5 9

.

❏ Line pressure solenoid valve, AT-164

.

❏ Shift solenoid valve A, AT-171

.

❏ Shift solenoid valve B, AT-176

.

❏ Accelerator pedal position (APP) sensor, AT-181

.

❏ Overrun clutch solenoid valve, AT-187

.

❏ PNP & overdrive control switches, and throttle position sensor, AT- 2 3 7

.

❏ Batt/fluid temp sen (A/T fluid temperature sensor and TCM power source), AT-195

.

❏ Vehicle speed sensor·MTR, AT- 2 0 1

.

❏ CAN communication line, AT-192

.

❏ Control unit (RAM), control unit (ROM), AT- 2 0 5

.

❏ Control unit (EEP ROM), AT- 2 0 7

.

❏ Battery

❏ Others

4-

2.Check at idleAT-71, "

2.

CHECK AT

IDLE"❏ 1. O/D OFF Indicator Lamp Does Not Come On, AT- 2 11 .

❏ 2. Engine Cannot Be Started In “P” And “N” Position, AT- 2 1 2

.

❏ 3. In “P” Position, Vehicle Moves Forward Or Backward When Pushed, AT- 2 1 3

.

❏ 4. In “N” Position, Vehicle Moves, AT- 2 1 4

.

❏ 5. Large Shock. “N” → “R” Position, AT-215

.

❏ 6. Vehicle Does Not Creep Backward In “R” Position, AT- 2 1 6

.

❏ 7. Vehicle Does Not Creep Forward In “D”, “2” Or “1” Position, AT-219

.

Page 1515 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-59

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

4. 4-

3.Cruise testAT- 7 4 , "3.

CRUISE

TEST"

AT- 7 8 ,

"Cruise Test

— Part 1"

Part-1

❏ 8. Vehi NISSAN ALMERA N16 2003 Electronic Owners Manual TROUBLE DIAGNOSIS — INTRODUCTION

AT-59

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

4. 4-

3.Cruise testAT- 7 4 , "3.

CRUISE

TEST"

AT- 7 8 ,

"Cruise Test

— Part 1"

Part-1

❏ 8. Vehi](/img/5/57350/w960_57350-1514.png)

TROUBLE DIAGNOSIS — INTRODUCTION

AT-59

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

4. 4-

3.Cruise testAT- 7 4 , "3.

CRUISE

TEST"

AT- 7 8 ,

"Cruise Test

— Part 1"

Part-1

❏ 8. Vehicle Cannot Be Started From D

1 , AT- 2 2 1 .

❏ 9. A/T Does Not Shift: D

1→ D2 Or Does Not Kickdown: D4→ D2 , AT- 2 2 3 .

❏ 10. A/T Does Not Shift: D

2→ D3 , AT- 2 2 5 .

❏ 11. A/T Does Not Shift: D

3→ D4 , AT-227 .

❏ 12. A/T Does Not Perform Lock-up, AT- 2 3 0

.

❏ 13. A/T Does Not Hold Lock-up Condition, AT- 2 3 1

.

❏ 14. Lock-up Is Not Released, AT- 2 3 2

.

❏ 15. Engine Speed Does Not Return To Idle (Light Braking D

4→ D3 ), AT-233 .

Part-2AT- 8 1 ,

"Cruise Test

— Part 2"❏ 16. Vehicle Does Not Start From D1 , AT- 2 3 4 .

❏ 9. A/T Does Not Shift: D

1→ D2 Or Does Not Kickdown: D4→ D2 , AT- 2 2 3 .

❏ 10. A/T Does Not Shift: D

2→ D3 , AT- 2 2 5 .

❏ 11. A/T Does Not Shift: D

3→ D4 , AT-227 .

Part-3AT- 8 3 ,

"Cruise Test

— Part 3"❏ 17. A/T Does Not Shift: D4→ D3 When Overdrive Control Switch “ON” → “OFF”, AT- 2 3 5 .

❏ 15. Engine Speed Does Not Return To Idle (Light Braking D

4→ D3 ), AT-233 .

❏ 18. A/T Does Not Shift: D

3→ 22 , When Selector Lever “D” → “2” Position, AT-235 .

❏ 15. Engine Speed Does Not Return To Idle (Light Braking D

4→ D3 ), AT-233 .

❏ 19. A/T Does Not Shift: 2

2→ 11 , When Selector Lever “2” → “1” Position, AT-236 .

❏ 20. Vehicle Does Not Decelerate By Engine Brake, AT- 2 3 7

.

❏ 21. TCM Self-diagnosis Does Not Activate (PNP & Overdrive Control Switches, and Throttle Position

Sensor Circuit Checks), AT- 2 3 7

.

❏ SELF-DIAGNOSTIC PROCEDURE/DIAGNOSTIC TROUBLE CODE (DTC) CONFIRMATION PROCE-

DURE — Mark detected items.

❏ PNP switch, AT- 111

.

❏ A/T fluid temperature sensor, AT- 11 7

.

❏ Vehicle speed sensor·A/T (Revolution sensor), AT- 1 2 3

.

❏ Engine speed signal, AT- 1 2 9

.

❏ Torque converter clutch solenoid valve, AT-159

.

❏ Line pressure solenoid valve, AT-164

.

❏ Shift solenoid valve A, AT- 1 7 1

.

❏ Shift solenoid valve B, AT- 1 7 6

.

❏ Accelerator pedal position (APP) sensor, AT-181

.

❏ Overrun clutch solenoid valve, AT- 1 8 7

.

❏ PNP & overdrive control switches, and throttle position sensor, AT- 2 3 7

.

❏ A/T fluid temperature sensor and TCM power source, AT-195

.

❏ Vehicle speed sensor·MTR, AT-201

.

❏ CAN communication line, AT- 1 9 2

❏ Control unit (RAM), control unit (ROM), AT-205 .

❏ Control unit (EEP ROM), AT-207

.

❏ Battery

❏ Others

5.❏ For self-diagnosis NG items, inspect each component. Repair or replace the damaged parts.AT- 5 0 , "

Diag-

nostic Proce-

dure Without

CONSULT-II"

6.❏ Perform all ROAD TEST and re-mark required procedures.AT- 6 8 , "Road

Te s t"

7.❏ Perform DTC CONFIRMATION PROCEDURE for following MI indicating items and check out NG items.

Refer toEC-37, "

Emission-related Diagnostic Information" .EC section

❏ DTC (P0731) A/T 1st gear function, AT- 1 3 3

.

❏ DTC (P0732) A/T 2nd gear function, AT-139

.

❏ DTC (P0733) A/T 3rd gear function, AT- 1 4 5

.

❏ DTC (P0734) A/T 4th gear function, AT- 1 5 1

.

Page 1518 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual AT-62

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

*1:AT-57, "Information from Customer"*2:AT-58, "Diagnostic Worksheet"*3:AT-7, "Service Notice or Precau-

tions"

*4:AT-63, &# NISSAN ALMERA N16 2003 Electronic Owners Manual AT-62

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

*1:AT-57, "Information from Customer"*2:AT-58, "Diagnostic Worksheet"*3:AT-7, "Service Notice or Precau-

tions"

*4:AT-63, &#](/img/5/57350/w960_57350-1517.png)

AT-62

[EURO-OBD]

TROUBLE DIAGNOSIS — INTRODUCTION

*1:AT-57, "Information from Customer"*2:AT-58, "Diagnostic Worksheet"*3:AT-7, "Service Notice or Precau-

tions"

*4:AT-63, "A/T Fluid Check"*5:AT-64, "Stall Test" and AT- 6 7 , "Line Pressure

Te s t"

*6:AT- 6 8 , "Road Test"

*7:AT-41, "CONSULT-II"*8:AT-37, "ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION"

*9:AT- 5 0 , "Diagnostic Procedure

Without CONSULT-II"

*10:AT- 111 , "DTC P0705 PARK/NEU-

TRAL POSITION (PNP) SWITCH"

*11:AT-123, "DTC P0720 VEHICLE SPEED

SENSOR A/T (REVOLUTION SENSOR)"

and AT- 2 0 5 , "DTC CONTROL UNIT (RAM),

CONTROL UNIT (ROM)" to AT-207, "DTC

CONTROL UNIT (EEP ROM)"

*12:AT- 2 11 , "1. O/D OFF Indicator

Lamp Does Not Come On"

*13:AT-237, "20. Vehicle Does Not

Decelerate By Engine Brake"

*14:AT-86, "Symptom Chart"*15:AT- 3 9 , "HOW TO ERASE DTC"

*16:AT- 111 , "DTC P0705 PARK/NEU-

TRAL POSITION (PNP) SWITCH"

*17:AT-123, "DTC P0720 VEHICLE SPEED

SENSOR A/T (REVOLUTION SENSOR)"

and AT- 2 0 5 , "DTC CONTROL UNIT (RAM),

CONTROL UNIT (ROM)" to AT-207, "DTC

CONTROL UNIT (EEP ROM)"

*18:EC-429, "Emission-related Diag-

nostic Information"

Page 1519 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-63

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007NW

FLUID LEAKAGE CHECK

1. Clean area suspected of NISSAN ALMERA N16 2003 Electronic Owners Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-63

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007NW

FLUID LEAKAGE CHECK

1. Clean area suspected of](/img/5/57350/w960_57350-1518.png)

TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-63

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007NW

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fluid leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to AT-13, "Checking A/T Fluid" .

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 1520 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Stall Test

ECS007NX

STALL TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minut NISSAN ALMERA N16 2003 Electronic Owners Manual AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Stall Test

ECS007NX

STALL TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minut](/img/5/57350/w960_57350-1519.png)

AT-64

[EURO-OBD]

TROUBLE DIAGNOSIS — BASIC INSPECTION

Stall Test

ECS007NX

STALL TEST PROCEDURE

1. Check A/T fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

●It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in D

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately release

throttle.

●During test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

8. Move selector lever to “N” position.

9. Cool off ATF.

●Run engine at idle for at least one minute.

10. Repeat steps 5 through 9 with selector lever in “2”, “1” and “R”

positions.ATF operating temperature:

50 - 80°C (122 - 176°F)

SAT647B

SAT513G

SAT514G

QG18DE 2,300 - 2,750 rpm

SAT771B

Page 1521 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-65

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

JUDGEMENT OF STALL TEST

The test result and possible damaged components relating to each result are shown in the illus NISSAN ALMERA N16 2003 Electronic Owners Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-65

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

JUDGEMENT OF STALL TEST

The test result and possible damaged components relating to each result are shown in the illus](/img/5/57350/w960_57350-1520.png)

TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-65

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

JUDGEMENT OF STALL TEST

The test result and possible damaged components relating to each result are shown in the illustrations on next

page.

In order to pinpoint the possible damaged components, follow the WORK FLOW shown in AT-60, "

Work Flow"

(EURO-OBD).

NOTE:

Stall revolution is too high in “D”, “2” or “1” position:

●Slippage occurs in 1st gear but not in 2nd and 3rd gears...... Low one-way clutch slippage

●Slippage occurs in the following gears:

1st through 3rd gears in “D” position and engine brake functions with overdrive control switch set to

“OFF”.

1st and 2nd gears in “2” position and engine brake functions with accelerator pedal released (fully closed

throttle)...... Forward clutch or forward one-way clutch slippage

Stall revolution is too high in R position:

●Engine brake does not function in “1” position...... Low & reverse brake slippage

●Engine brake functions in “1” position...... Reverse clutch slippage

Stall revolution within specifications:

●Vehicle does not achieve speed of more than 80 km/h (50 MPH)...... One-way clutch seizure in torque

converter housing

CAUTION:

Be careful since automatic fluid temperature increases abnormally.

●Slippage occurs in 3rd and 4th gears in “D” position...... High clutch slippage

●Slippage occurs in 2nd and 4th gear in “D” position...... Brake band slippage

●Engine brake does not function in 2nd and 3rd gears in “D” position, 2nd gear in “2” position, and 1st gear

in “1” position with overdrive control switch set to “OFF”.

Stall revolution less than specifications:

●Poor acceleration during starts...... One-way clutch seizure in torque converter