ABS NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 38 of 3189

NJGI0007

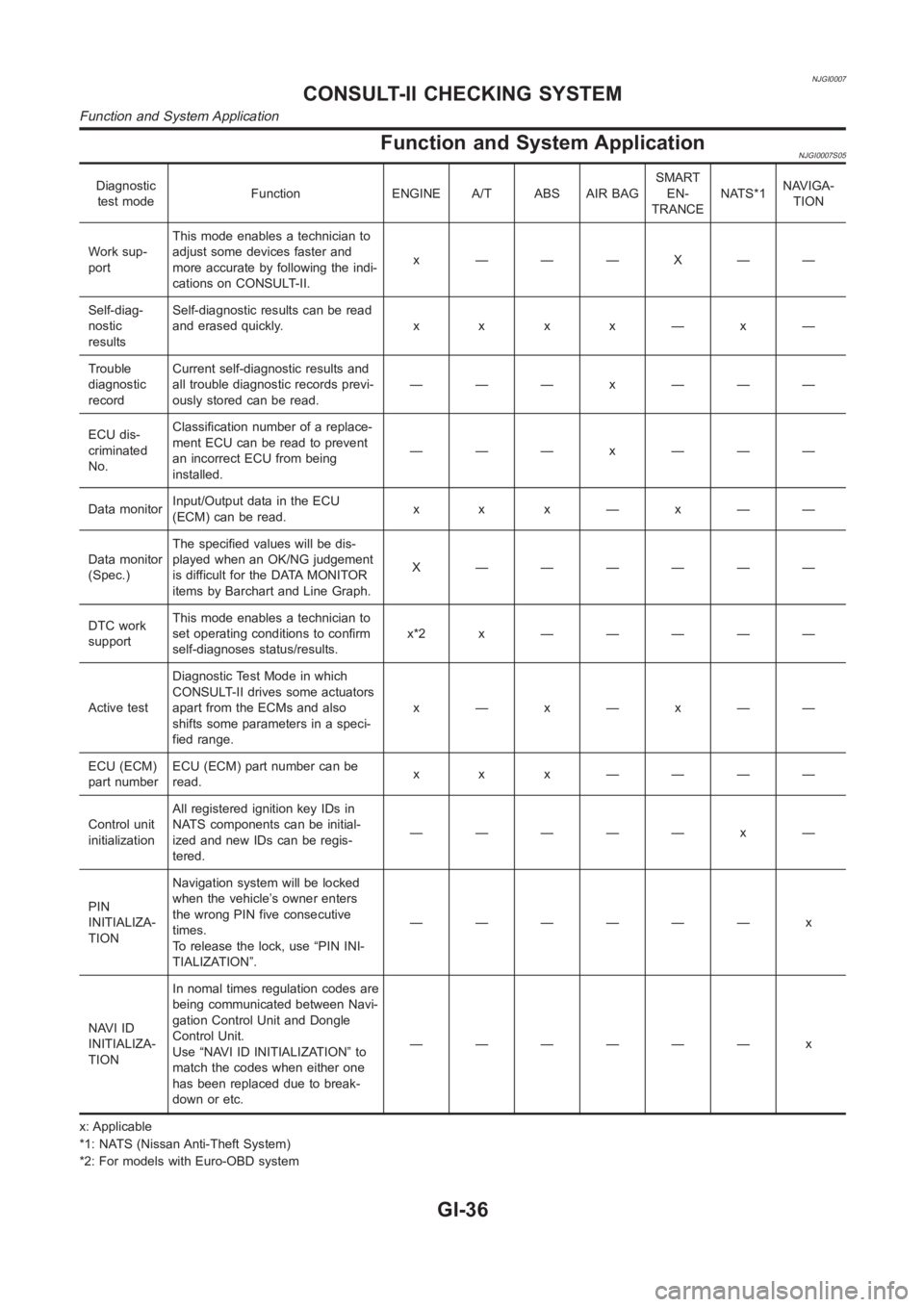

Function and System ApplicationNJGI0007S05

Diagnostic

test modeFunction ENGINE A/T ABS AIR BAGSMART

EN-

TRANCENATS*1NAVIGA-

TION

Work sup-

portThis mode enables a technician to

adjust some devices faster and

more accurate by following the indi-

cations on CONSULT-II.x ———X——

Self-diag-

nostic

resultsSelf-diagnostic results can be read

anderasedquickly. x x x x—x—

Trouble

diagnostic

recordCurrent self-diagnostic results and

all trouble diagnostic records previ-

ously stored can be read.——— x ———

ECU dis-

criminated

No.Classification number of a replace-

ment ECU can be read to prevent

an incorrect ECU from being

installed.——— x ———

Data monitorInput/Output data in the ECU

(ECM) can be read.x x x—x——

Data monitor

(Spec.)The specified values will be dis-

played when an OK/NG judgement

is difficult for the DATA MONITOR

items by Barchart and Line Graph.X ——————

DTC work

supportThis mode enables a technician to

set operating conditions to confirm

self-diagnoses status/results.x*2x —————

Active testDiagnostic Test Mode in which

CONSULT-II drives some actuators

apart from the ECMs and also

shifts some parameters in a speci-

fied range.x—x—x——

ECU (ECM)

part numberECU (ECM) part number can be

read.x x x ————

Control unit

initializationAll registered ignition key IDs in

NATS components can be initial-

ized and new IDs can be regis-

tered.————— x —

PIN

INITIALIZA-

TIONNavigation system will be locked

when the vehicle’s owner enters

the wrong PIN five consecutive

times.

To release the lock, use “PIN INI-

TIALIZATION”.—————— x

NAVI ID

INITIALIZA-

TIONIn nomal times regulation codes are

being communicated between Navi-

gation Control Unit and Dongle

Control Unit.

Use “NAVI ID INITIALIZATION” to

match the codes when either one

has been replaced due to break-

down or etc.—————— x

x: Applicable

*1: NATS (Nissan Anti-Theft System)

*2: For models with Euro-OBD system

CONSULT-II CHECKING SYSTEM

Function and System Application

GI-36

Page 55 of 3189

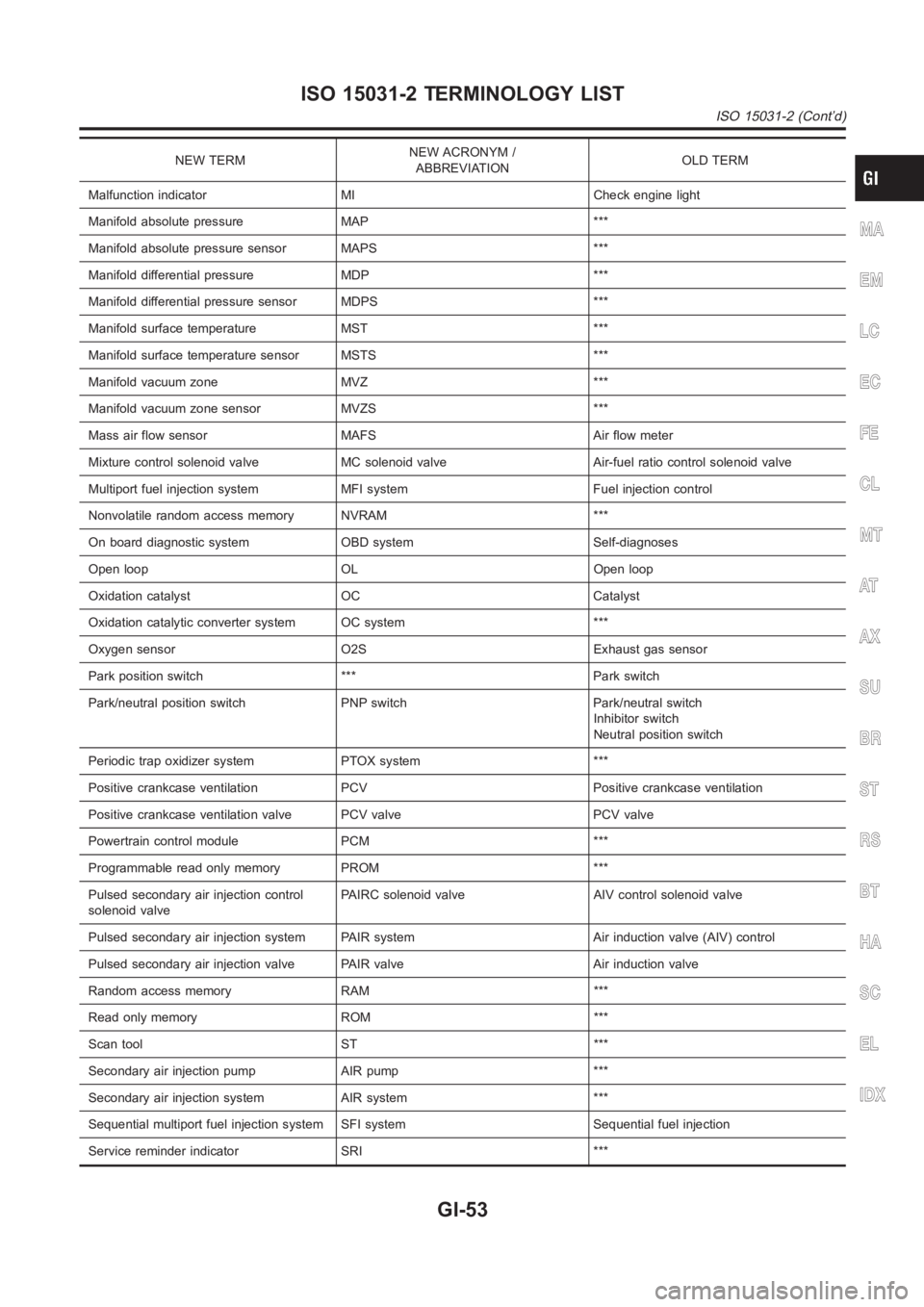

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnoses

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control

solenoid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-53

Page 139 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-61

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Remove valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Remove valve collet with magnet driver.

3. Remo NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-61

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Remove valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Remove valve collet with magnet driver.

3. Remo](/img/5/57350/w960_57350-138.png)

CYLINDER HEAD

EM-61

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Remove valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Remove valve collet with magnet driver.

3. Remove valve spring retainer and valve spring.

4. Push valve stem to combustion chamber side, and remove

valve.

●Inspect valve guide clearance before removal. Refer to EM-

63, "VALVE GUIDE CLEARANCE" .

●Confirm installation point.

5. Remove valve oil seal with valve oil seal puller (special service

tool).

6. Remove valve spring seat.

7. When valve seat must be replaced, refer to EM-64, "

VA LV E

SEAT REPLACEMENT" .

8. When valve guide must be replaced, refer to EM-63, "

VA LV E

GUIDE REPLACEMENT" .

9. Remove spark plug with spark plug wrench (commercial service

tool).

10. Remove engine coolant temperature sensor.

CAUTION:

Do not shock it.

11. Remove spark plug tube, as necessary.

●Using a pair of pliers, pull spark plug tube out of cylinder head.

CAUTION:

●Take care not to damage cylinder head.

●Once removed, a spark plug tube will be deformed and cannot be reused. Do not remove it

unless absolutely necessary.

ASSEMBLY

1. Install valve guide. Refer to EM-63, "VALVE GUIDE REPLACEMENT" .

2. Install valve seat. Refer to EM-64, "

VALVE SEAT REPLACEMENT" .

3. Install valve oil seal.

●Install with valve oil seal drift (special service tool) to match

dimension in illustration.

4. Install valve spring seat.

5. Install valve.

●Install larger diameter to intake side.

6. Install valve spring.

7. Install valve spring retainer.

PBIC1015E

SEM909F

PBIC0576E

Page 248 of 3189

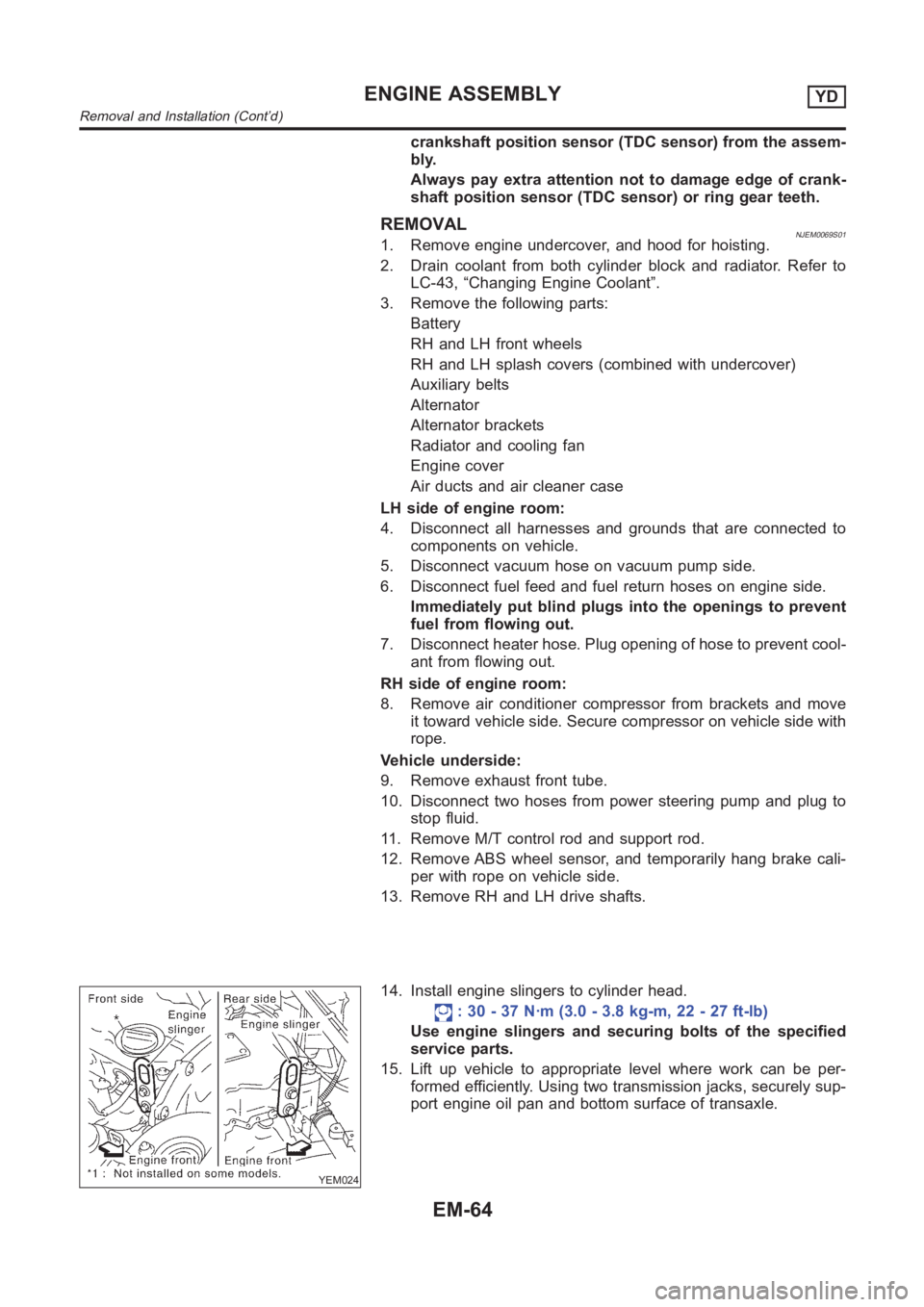

crankshaft position sensor (TDC sensor) from the assem-

bly.

Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-43, “Changing Engine Coolant”.

3. Remove the following parts:

Battery

RH and LH front wheels

RH and LH splash covers (combined with undercover)

Auxiliary belts

Alternator

Alternator brackets

Radiator and cooling fan

Engine cover

Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

YEM024

14. Install engine slingers to cylinder head.

: 30 - 37 N·m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont’d)

EM-64

Page 297 of 3189

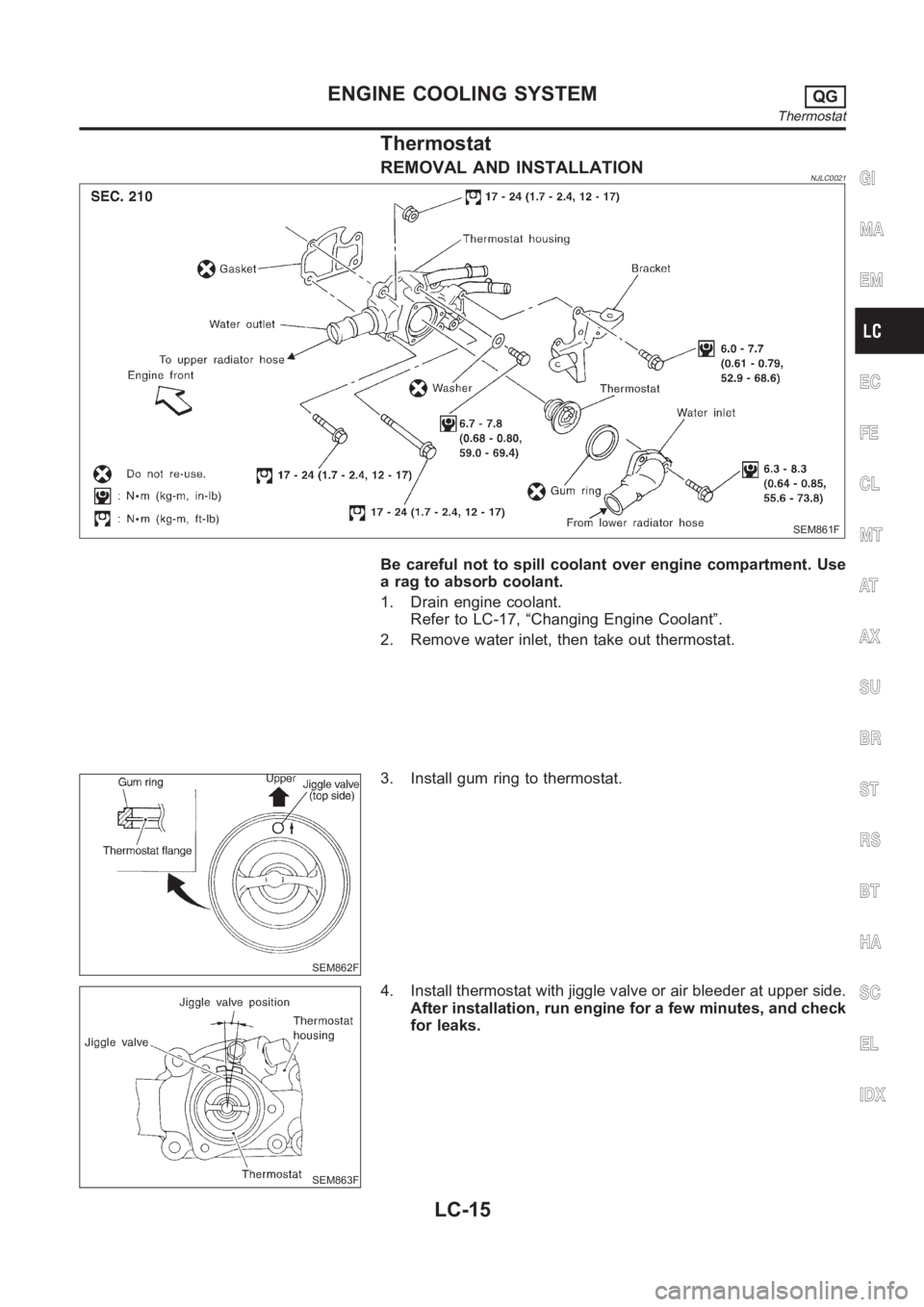

Thermostat

REMOVAL AND INSTALLATIONNJLC0021

SEM861F

Be careful not to spill coolant over engine compartment. Use

a rag to absorb coolant.

1. Drain engine coolant.

Refer to LC-17, “Changing Engine Coolant”.

2. Remove water inlet, then take out thermostat.

SEM862F

3. Install gum ring to thermostat.

SEM863F

4. Install thermostat with jiggle valve or air bleeder at upper side.

After installation, run engine for a few minutes, and check

for leaks.

GI

MA

EM

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE COOLING SYSTEMQG

Thermostat

LC-15

Page 322 of 3189

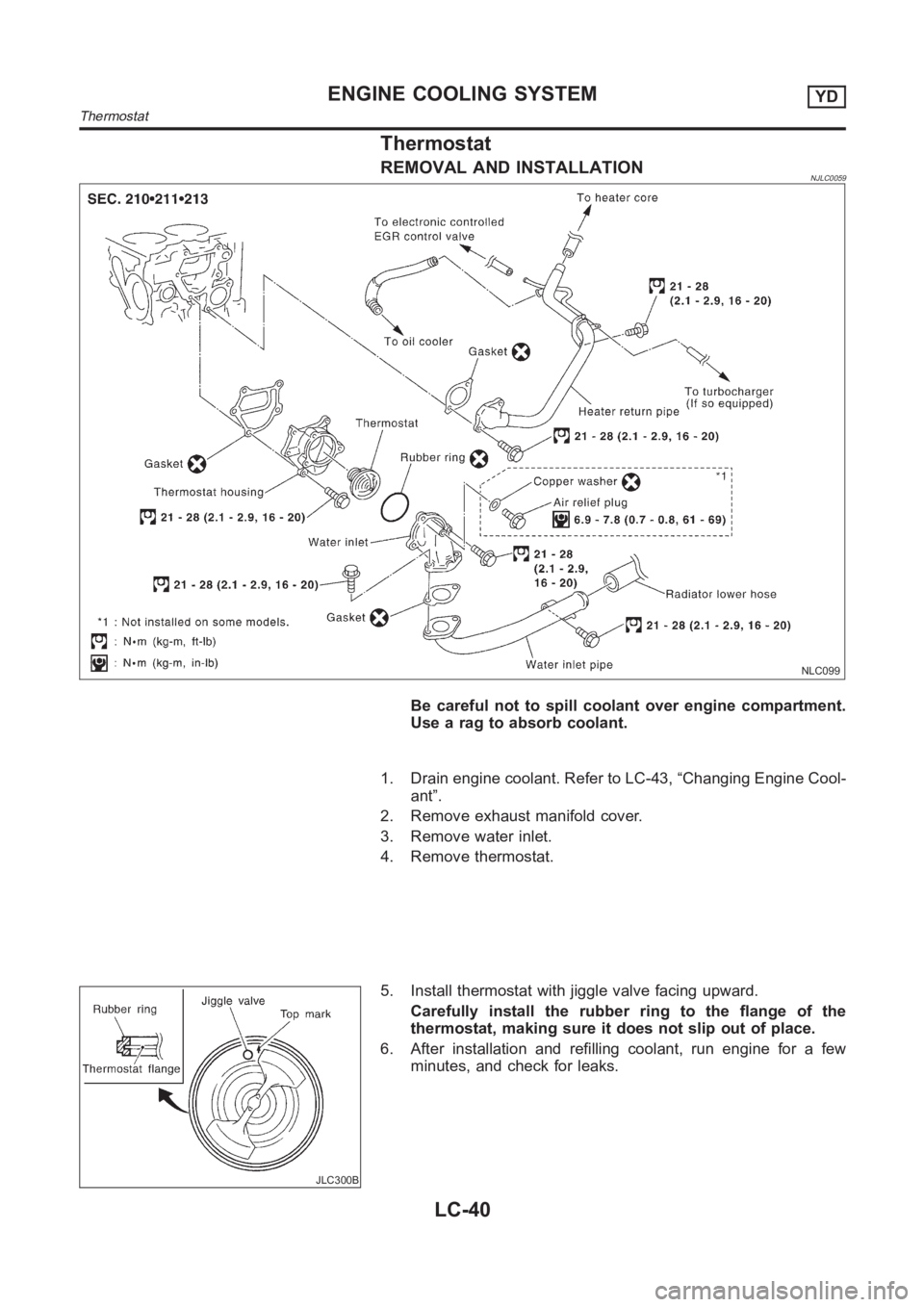

Thermostat

REMOVAL AND INSTALLATIONNJLC0059

NLC099

Be careful not to spill coolant over engine compartment.

Use a rag to absorb coolant.

1. Drain engine coolant. Refer to LC-43, “Changing Engine Cool-

ant”.

2. Remove exhaust manifold cover.

3. Remove water inlet.

4. Remove thermostat.

JLC300B

5. Install thermostat with jiggle valve facing upward.

Carefully install the rubber ring to the flange of the

thermostat, making sure it does not slip out of place.

6. After installation and refilling coolant, run engine for a few

minutes, and check for leaks.

ENGINE COOLING SYSTEMYD

Thermostat

LC-40

Page 357 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM thro NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM thro](/img/5/57350/w960_57350-356.png)

ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

If the engine speed is above 3,950 rpm with no load (for example, in neutral and engine speed over 3,950

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under “Multiport Fuel Injection (MFI) System”, EC-23

.

CAN CommunicationEBS00K39

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

×:ApplicableSensor Input Signal to ECM ECM Function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injectors Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

Vehicle speed signal

*1Vehicle speed

Body type Sedan/ 5DH/B/ 3DH/B

Axle2WD

Engine QG18DE QG15DE/QG18DE

Transmission A/T M/T

Brake controlABS

CAN communication unit

ECM××

TCM×

Smart entrance control unit××

Data link connector××

Combination meter××

CAN communication type EC-28, "

Type 1"EC-29, "Ty p e 2"

Page 587 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0500 VSS

EC-257

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0500 VSSPFP:32702

DescriptionEBS00K8V

NOTE:

If DTC P0500 is displayed with DTC U1000 or U1001, first perform the trouble diagno NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0500 VSS

EC-257

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0500 VSSPFP:32702

DescriptionEBS00K8V

NOTE:

If DTC P0500 is displayed with DTC U1000 or U1001, first perform the trouble diagno](/img/5/57350/w960_57350-586.png)

DTC P0500 VSS

EC-257

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

DTC P0500 VSSPFP:32702

DescriptionEBS00K8V

NOTE:

If DTC P0500 is displayed with DTC U1000 or U1001, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-116, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

The vehicle speed signal is sent from vehicle speed sensor (models without ABS) or ABS actuator and electric

unit (control unit) (models with ABS) to combination meter. The combination meter then sends a signal to the

ECM through CAN communication line.

On Board Diagnosis LogicEBS00K8W

DTC Confirmation ProcedureEBS00K8X

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously conducted, always turn ignition switch “OFF” and wait at

least 10 seconds before conducting the next test.

TESTING CONDITION:

Steps 1 and 2 may be conducted with the drive wheels lifted in the shop or by driving the vehicle. If a

road test is expected to be easier, it is unnecessary to lift the vehicle.

WITH CONSULT-II

1. Start engine.

2. Read “VHCL SPEED SE” in “DATA MONITOR” mode with CONSULT-II. The vehicle speed on CONSULT-

II should exceed 10 km/h (6 MPH) when rotating wheels with suitable gear position.

If NG, go to EC-259, "

Diagnostic Procedure" .

If OK, go to following step.

3. Select “DATA MONITOR” mode with CONSULT-II.

4. Warm engine up to normal operating temperature.

5. Maintain the following conditions for at least 60 consecutive sec-

onds.

6. If 1st trip DTC is detected, go to EC-259, "

Diagnostic Procedure" .

DTC No. Trouble diagnosis name DTC detecting condition Possible cause

P0500

0500Vehicle speed sensorThe almost 0 km/h (0 MPH) signal from

vehicle speed sensor is sent to ECM

even when vehicle is being driven.

●Harness or connectors

(The vehicle speed sensor circuit is open or

shorted)

●Harness or connectors

(The CAN communication line is open or

shorted.)

●Vehicle speed sensor (models without ABS)

●ABS actuator and electric unit (control unit)

(models with ABS)

●Combination meter

ENG SPEED More than 2,400 rpm (QG15DE models)

More then 2,100 rpm (QG18DE A/T models)

More then 2,700 rpm (QG18DE M/T models)

COOLAN TEMP/S More than 70°C (158°F)

B/FUEL SCHDL More than 4.6 msec (QG15DE models)

More than 5.2 msec (QG18DE A/T models)

More than 4.3 msec (QG18DE M/T models

Selector lever Suitable position

PW/ST SIGNAL OFF

SEF196Y

Page 589 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0500 VSS

EC-259

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

WITH GST

1. Lift up drive wheels.

2. Start engine.

3. Read vehicle speed signal in “MODE 1” with GST.

The vehicle speed signal NISSAN ALMERA N16 2003 Electronic Repair Manual DTC P0500 VSS

EC-259

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

WITH GST

1. Lift up drive wheels.

2. Start engine.

3. Read vehicle speed signal in “MODE 1” with GST.

The vehicle speed signal](/img/5/57350/w960_57350-588.png)

DTC P0500 VSS

EC-259

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

WITH GST

1. Lift up drive wheels.

2. Start engine.

3. Read vehicle speed signal in “MODE 1” with GST.

The vehicle speed signal on GST should be able to exceed 10 km/h (6 MPH) when rotating wheels with

suitable gear position.

4. If NG, go to EC-259, "

Diagnostic Procedure" .

Diagnostic ProcedureEBS00K8Z

1.CHECK DTC WITH VEHICLE SPEED SONSOR (MODELS WITHOUT ABS) OR ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) (MODELS WITH ABS)

Refer to EL-123 (models without ABS) or EL-124 (models with ABS).

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

2.CHECK COMBINATION METER

Check combination meter function.

Refer to EL-112.

>>INSPECTION END

Page 751 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-421

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00KEF

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-421

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00KEF

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM](/img/5/57350/w960_57350-750.png)

ENGINE CONTROL SYSTEM

EC-421

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00KEF

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

If the engine speed is above 3,950 rpm with no load (for example, in neutral and engine speed over 3,950

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under “Multiport Fuel Injection (MFI) System”, EC-417

.

CAN CommunicationEBS00KEG

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

×:ApplicableSensor Input Signal to ECM ECM function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injectors Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

Vehicle speed signal

*1Vehicle speed

Body type Sedan/ 5DH/B/ 3DH/B

Axle2WD

Engine QG18DE QG15DE/QG18DE

Transmission A/T M/T

Brake controlABS

CAN communication unit

ECM××

TCM×

Data link connector××

Smart entrance control unit××

Combination meter××

CAN communication type EC-422, "

Ty p e 1"EC-423, "Type 2"