Engine Control NISSAN ALMERA N16 2003 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 339 of 3189

EC-9

C

D

E

F

G

H

I

J

K

L

M

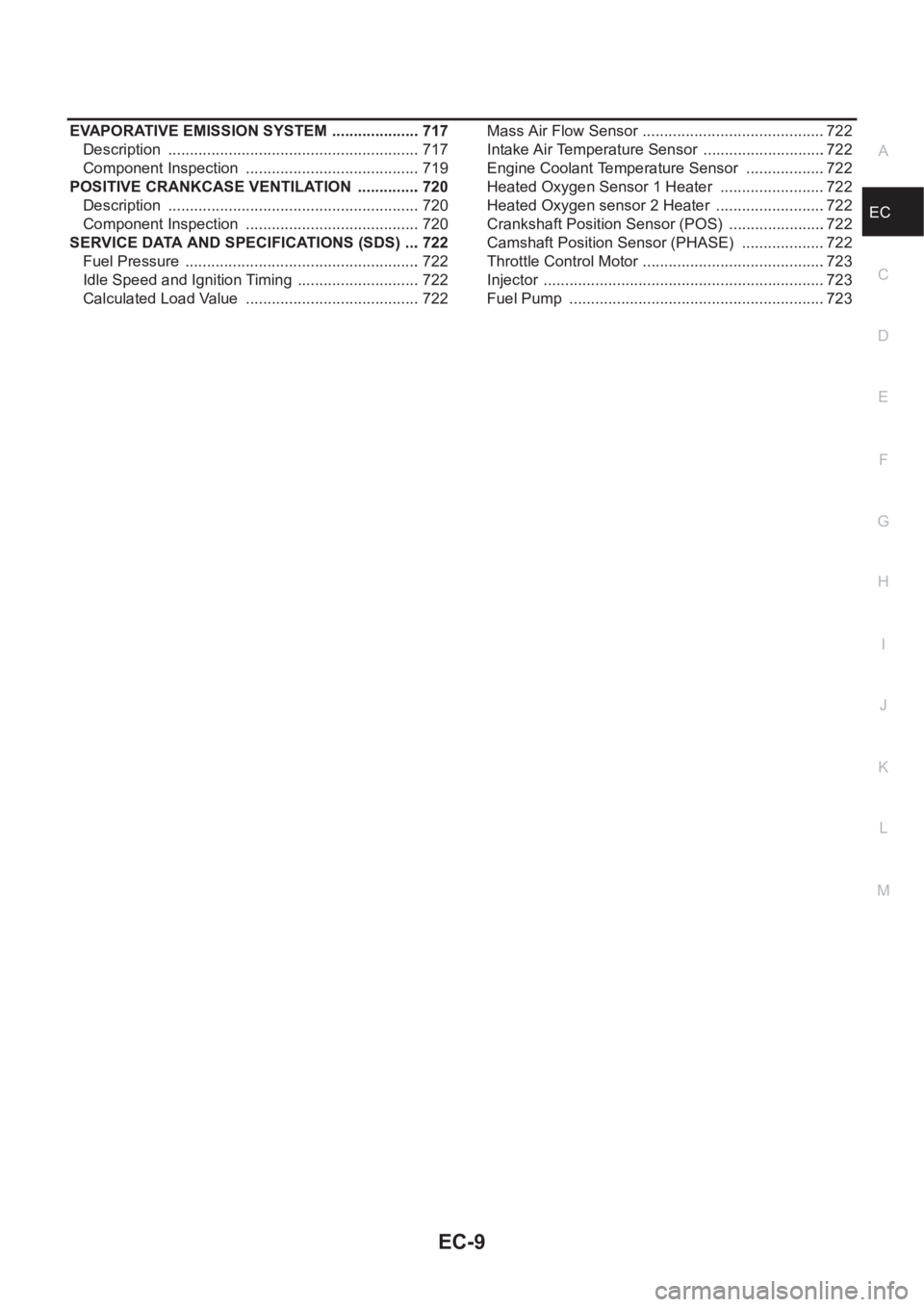

ECA EVAPORATIVE EMISSION SYSTEM ..................... 717

Description ........................................................... 717

Component Inspection ......................................... 719

POSITIVE CRANKCASE VENTILATION ............... 720

Description ........................................................... 720

Component Inspection ......................................... 720

SERVICE DATA AND SPECIFICATIONS (SDS) .... 722

Fuel Pressure ....................................................... 722

Idle Speed and Ignition Timing ............................. 722

Calculated Load Value ......................................... 722Mass Air Flow Sensor ...........................................722

Intake Air Temperature Sensor .............................722

Engine Coolant Temperature Sensor ...................722

Heated Oxygen Sensor 1 Heater .........................722

Heated Oxygen sensor 2 Heater ..........................722

Crankshaft Position Sensor (POS) .......................722

Camshaft Position Sensor (PHASE) ....................722

Throttle Control Motor ...........................................723

Injector ..................................................................723

Fuel Pump ............................................................723

Page 342 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide EC-12

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these nu NISSAN ALMERA N16 2003 Electronic Owners Guide EC-12

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these nu](/img/5/57350/w960_57350-341.png)

EC-12

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*4: When engine is running.

*5: The troubleshooting for this DTC needs CONSULT-II.

*6: When the fail-safe operations for both self-diagnoses occur, the MI illuminates.

DTC No. IndexEBS00K2U

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approval number” on the

identification plate. Refer to GI-39.

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-116, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

×: Applicable –: Not applicable TW CATALYST SYS-B1 P0420 0420 2×EC-246

VEH SPD SEN/CIR AT*6P0720 0720 2×AT-123

VEH SPEED SEN/CIRC P0500 0500 2×EC-257

Items

(CONSULT-II screen terms)DTC*

1

TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

DTC*1

Items

(CONSULT-II screen terms)TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

No DTC

Flashing*4NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.–

Flashing*4EC-50

U1000

1000*5CAN COMM CIRCUIT 1×EC-116

U1001

1001*5CAN COMM CIRCUIT 2 –EC-116

P0000 0000NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.––—

P0011 0011 INT/V TIM CONT-B1 2 –EC-119

P0031 0031 HO2S1 HTR (B1) 2×EC-122

P0032 0032 HO2S1 HTR (B1) 2×EC-122

P0037 0037 HO2S2 HTR (B1) 2×EC-128

P0038 0038 HO2S2 HTR (B1) 2×EC-128

P0102 0102 MAF SEN/CIRCUIT 1×EC-134

P0103 0103 MAF SEN/CIRCUIT 1×EC-134

P0112 0112 IAT SEN/CIRCUIT 2×EC-140

P0113 0113 IAT SEN/CIRCUIT 2×EC-140

P0117 0117 ECT SEN/CIRCUIT 1×EC-144

P0118 0118 ECT SEN/CIRCUIT 1×EC-144

P0132 0132 HO2S1 (B1) 2×EC-149

P0133 0133 HO2S1 (B1) 2×EC-155

P0134 0134 HO2S1 (B1) 2×EC-165

P0138 0138 HO2S2 (B1) 2×EC-172

P0139 0139 HO2S2 (B1) 2×EC-178

P0171 0171 FUEL SYS-LEAN-B1 2×EC-186

P0172 0172 FUEL SYS-RICH-B1 2×EC-193

P0221 0221 TP SENSOR 1×EC-199

Page 344 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide EC-14

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these nu NISSAN ALMERA N16 2003 Electronic Owners Guide EC-14

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these nu](/img/5/57350/w960_57350-343.png)

EC-14

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*4: When engine is running.

*5: The trouble shooting for this DTC needs CONSULT-II.

*6: When the fail-safe operations for both self-diagnoses occur, the MI illuminates. P1217 1217 ENG OVER TEMP 1×EC-324

P1223 1223 TP SEN 2/CIRC 1×EC-335

P1224 1224 TP SEN 2/CIRC 1×EC-335

P1225 1225 CTP LEARNING 2 –EC-341

P1226 1226 CTP LEARNING 2 –EC-343

P1227 1227 APP SEN 2/CIRC 1×EC-345

P1228 1228 APP SEN 2/CIRC 1×EC-345

P1229 1229 SENSOR POWER/CIRC 1×EC-352

P1610 - P1615 1610 - 1615 NATS MALFUNCTION 2 –EC-49

P1705 1705 TPV SEN/CIRC A/T 1×AT-181

P1706 1706 P-N POS SW/CIRCUIT 2×EC-356

P1760 1760 O/R CLTCH SOL/CIRC 2×AT-187

P1805 1805 BRAKE SW/CIRCUIT 2 –EC-360

DTC*1

Items

(CONSULT-II screen terms)TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

Page 345 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide PRECAUTIONS

EC-15

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00K2V

The NISSAN ALMERA N16 2003 Electronic Owners Guide PRECAUTIONS

EC-15

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00K2V

The](/img/5/57350/w960_57350-344.png)

PRECAUTIONS

EC-15

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EBS00K2V

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

●To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

●Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

●Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness connec-

tors.

On Board Diagnostic (OBD) System of Engine and A/TEBS00K2W

The ECM has an on board diagnostic system. It will light up the malfunction indicator (MI) to warn the driver of

a malfunction causing emission deterioration.

CAUTION:

●Be sure to turn the ignition switch OFF and disconnect the battery ground cable before any repair

or inspection work. The open/short circuit of related switches, sensors, solenoid valves, etc. will

cause the MI to light up.

●Be sure to connect and lock the connectors securely after work. A loose (unlocked) connector will

cause the MI to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

●Certain systems and components, especially those related to OBD, may use a new style slide-

locking type harness connector. For description and how to disconnect, refer to EL-7.

●Be sure to route and secure the harnesses properly after work. The interference of the harness

with a bracket, etc. may cause the MI to light up due to the short circuit.

●Be sure to connect rubber tubes properly after work. A misconnected or disconnected rubber tube

may cause the MI to light up due to the malfunction of the fuel injection system, etc.

●Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and

TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionEBS00K2X

●Always use a 12 volt battery as power source.

●Do not attempt to disconnect battery cables while engine is

running.

●Before connecting or disconnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect battery

ground cable. Failure to do so may damage the ECM

because battery voltage is applied to ECM even if ignition

switch is turned off.

●Before removing parts, turn ignition switch OFF and then

disconnect battery ground cable.

SEF289H

Page 346 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide EC-16

[QG (WITH EURO-OBD)]

PRECAUTIONS

●Do not disassemble ECM.

●If battery cable is disconnected, the memory will return to

the initial ECM values.

The ECM will now start to self-c NISSAN ALMERA N16 2003 Electronic Owners Guide EC-16

[QG (WITH EURO-OBD)]

PRECAUTIONS

●Do not disassemble ECM.

●If battery cable is disconnected, the memory will return to

the initial ECM values.

The ECM will now start to self-c](/img/5/57350/w960_57350-345.png)

EC-16

[QG (WITH EURO-OBD)]

PRECAUTIONS

●Do not disassemble ECM.

●If battery cable is disconnected, the memory will return to

the initial ECM values.

The ECM will now start to self-control at its initial values.

Engine operation can vary slightly when the cable is dis-

connected. However, this is not an indication of a malfunc-

tion. Do not replace parts because of a slight variation.

●When connecting ECM harness connector, fasten it

securely with levers as far as they will go as shown at right.

●When connecting or disconnecting pin connectors into or

from ECM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on ECM

pin terminal, when connecting pin connectors.

●Securely connect ECM harness connectors.

A poor connection can cause an extremely high (surge)

voltage to develop in coil and condenser, thus resulting in

damage to ICs.

●Keep engine control system harness at least 10 cm (4 in)

away from adjacent harness, to prevent engine control sys-

tem malfunctions due to receiving external noise, degraded

operation of ICs, etc.

●Keep engine control system parts and harness dry.

●Before replacing ECM, perform “ECM Terminals and Refer-

ence Value” inspection and make sure ECM functions prop-

erly. Refer to EC-80, "

ECM Terminals and Reference Value" .

●Handle mass air flow sensor carefully to avoid damage.

●Do not disassemble mass air flow sensor.

●Do not clean mass air flow sensor with any type of deter-

gent.

●Do not disassemble electric throttle control actuator.

●Even a slight leak in the air intake system can cause seri-

ous incidents.

●Do not shock or jar the camshaft position sensor (PHASE),

crankshaft position sensor (POS).

PBIB1164E

MBIB0145E

PBIB0090E

MEF040D

Page 348 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide EC-18

[QG (WITH EURO-OBD)]

PRECAUTIONS

●Do not depress accelerator pedal when starting.

●Immediately after starting, do not rev up engine unneces-

sarily.

●Do not rev up engine just prio NISSAN ALMERA N16 2003 Electronic Owners Guide EC-18

[QG (WITH EURO-OBD)]

PRECAUTIONS

●Do not depress accelerator pedal when starting.

●Immediately after starting, do not rev up engine unneces-

sarily.

●Do not rev up engine just prio](/img/5/57350/w960_57350-347.png)

EC-18

[QG (WITH EURO-OBD)]

PRECAUTIONS

●Do not depress accelerator pedal when starting.

●Immediately after starting, do not rev up engine unneces-

sarily.

●Do not rev up engine just prior to shutdown.

●When installing C.B. ham radio or a mobile phone, be sure

to observe the following as it may adversely affect elec-

tronic control systems depending on installation location.

–Keep the antenna as far as possible from the electronic

control units.

–Keep the antenna feeder line more than 20 cm (8 in) away

from the harness of electronic controls.

Do not let them run parallel for a long distance.

–Adjust the antenna and feeder line so that the standing-

wave radio can be kept smaller.

–Be sure to ground the radio to vehicle body.

Wiring Diagrams and Trouble DiagnosisEBS00K2Y

When you read wiring diagrams, refer to the following:

●GI-12

●EL-11 for power distribution circuit

When you perform trouble diagnosis, refer to the following:

●GI-32

●GI-22

SEF709Y

SEF708Y

Page 351 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide ENGINE CONTROL SYSTEM

EC-21

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

ENGINE CONTROL SYSTEMPFP:23710

System DiagramEBS00K31

MBIB0239E NISSAN ALMERA N16 2003 Electronic Owners Guide ENGINE CONTROL SYSTEM

EC-21

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

ENGINE CONTROL SYSTEMPFP:23710

System DiagramEBS00K31

MBIB0239E](/img/5/57350/w960_57350-350.png)

ENGINE CONTROL SYSTEM

EC-21

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

ENGINE CONTROL SYSTEMPFP:23710

System DiagramEBS00K31

MBIB0239E

Page 352 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide EC-22

[QG (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

Vacuum Hose Drawing

EBS00K33

Refer to EC-21, "System Diagram" for Vacuum Control System.

MBIB0013E NISSAN ALMERA N16 2003 Electronic Owners Guide EC-22

[QG (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

Vacuum Hose Drawing

EBS00K33

Refer to EC-21, "System Diagram" for Vacuum Control System.

MBIB0013E](/img/5/57350/w960_57350-351.png)

EC-22

[QG (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

Vacuum Hose Drawing

EBS00K33

Refer to EC-21, "System Diagram" for Vacuum Control System.

MBIB0013E

Page 353 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide ENGINE CONTROL SYSTEM

EC-23

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS00K34

*1: This sensor is not used to control the engine system under normal conditions.

*2: The signals are se NISSAN ALMERA N16 2003 Electronic Owners Guide ENGINE CONTROL SYSTEM

EC-23

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS00K34

*1: This sensor is not used to control the engine system under normal conditions.

*2: The signals are se](/img/5/57350/w960_57350-352.png)

ENGINE CONTROL SYSTEM

EC-23

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS00K34

*1: This sensor is not used to control the engine system under normal conditions.

*2: The signals are sent to the ECM through CAN communication line.

*3: The output signals are sent from the ECM through CAN communication line.

Multiport Fuel Injection (MFI) SystemEBS00K35

INPUT/OUTPUT SIGNAL CHART

*1: Under normal conditions, this sensor is not for engine control operation.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

Input (Sensor) ECM Function Output (Actuator)

●Camshaft position sensor (PHASE)

●Crankshaft position sensor (POS)

●Mass air flow sensor

●Engine coolant temperature sensor

●Heated oxygen sensor 1

●Throttle position sensor

●Accelerator pedal position sensor

●Park/neutral position (PNP) switch

●Intake air temperature sensor

●Power steering pressure sensor

●Ignition switch

●Stop lamp switch

●Battery voltage

●Knock sensor

●Refrigerant pressure sensor

●Heated oxygen sensor 2*1

●TCM (Transmission control module)*2

●Air conditioner switch*2

●Vehicle speed signal*2

●Electrical load signal*2

Fuel injection & mixture ratio control Fuel injectors

Electronic ignition system Power transistor

Fuel pump control Fuel pump relay

On board diagnostic system

MI (On the instrument panel)

*3

Intake valve timing controlIntake valve timing control solenoid

valve

Heated oxygen sensor 1 heater control Heated oxygen sensor 1 heater

Heated oxygen sensor 2 heater control Heated oxygen sensor 2 heater

EVAP canister purge flow controlEVAP canister purge volume control

solenoid valve

Air conditioning cut control

Air conditioner relay

*3

Cooling fan control

Cooling fan relay*3

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

*3 and piston position

Fuel injection & mixture

ratio controlFuel injectors Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage

*3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2

*1Density of oxygen in exhaust gas

Vehicle speed signal

*2Vehicle speed

Air conditioner switch

*2Air conditioner operation

Page 354 of 3189

![NISSAN ALMERA N16 2003 Electronic Owners Guide EC-24

[QG (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and i NISSAN ALMERA N16 2003 Electronic Owners Guide EC-24

[QG (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and i](/img/5/57350/w960_57350-353.png)

EC-24

[QG (WITH EURO-OBD)]

ENGINE CONTROL SYSTEM

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from the crankshaft position sensor (POS), the camshaft

position sensor (PHASE) and the mass air flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

●During warm-up

●When starting the engine

●During acceleration

●Hot-engine operation

●When selector lever is changed from “N” to “D” (A/T models)

●High-load, high-speed operation

●During deceleration

●During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

The mixture ratio feedback system provides the best air-fuel mixture ratio for driveability and emission control.

The three way catalyst (manifold) can then better reduce CO, HC and NOx emissions. This system uses

heated oxygen sensor 1 in the exhaust manifold to monitor if the engine operation is rich or lean. The ECM

adjusts the injection pulse width according to the sensor voltage signal. For more information about heated

oxygen sensor 1, refer to EC-155

. This maintains the mixture ratio within the range of stoichiometric (ideal air-

fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the three way catalyst (manifold). Even if the switching

characteristics of heated oxygen sensor 1 shift, the air-fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

●Deceleration and acceleration

●High-load, high-speed operation

●Malfunction of heated oxygen sensor 1 or its circuit

●Insufficient activation of heated oxygen sensor 1 at low engine coolant temperature

●High engine coolant temperature

●During warm-up

●After shifting from “N” to “D” (A/T models)

●When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal transmitted from heated oxygen

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the basic mixture ratio is not necessarily controlled as orig-

PBIB0121E