speed NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2051 of 3189

TROUBLE DIAGNOSIS

ATC-71

C

D

E

F

G

H

I

K

L

MA

B

AT C

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C (133°F), at which time the blower speed will increase to the objective speed.

Start Up From Usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C button is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

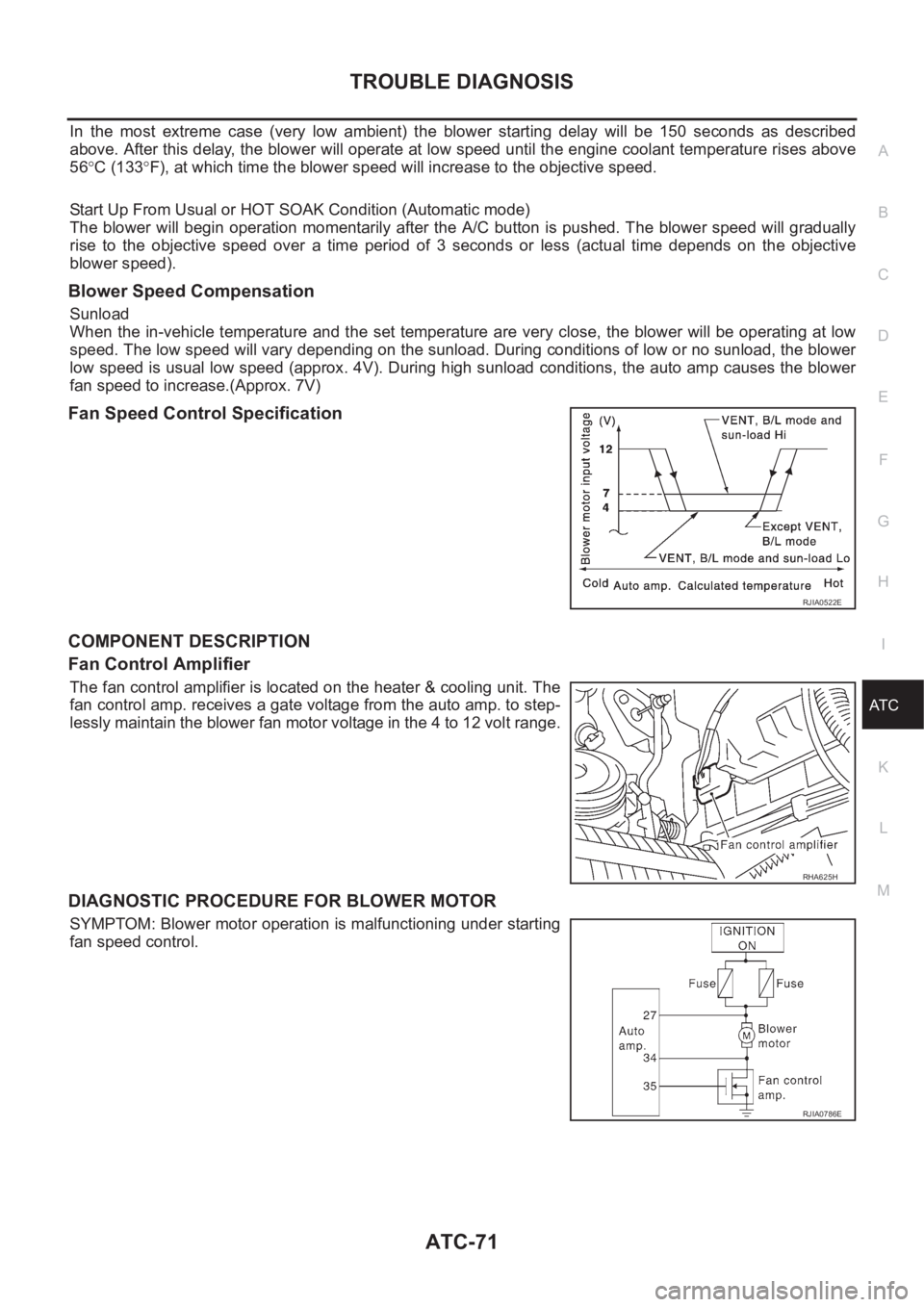

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

low speed is usual low speed (approx. 4V). During high sunload conditions, the auto amp causes the blower

fan speed to increase.(Approx. 7V)

Fan Speed Control Specification

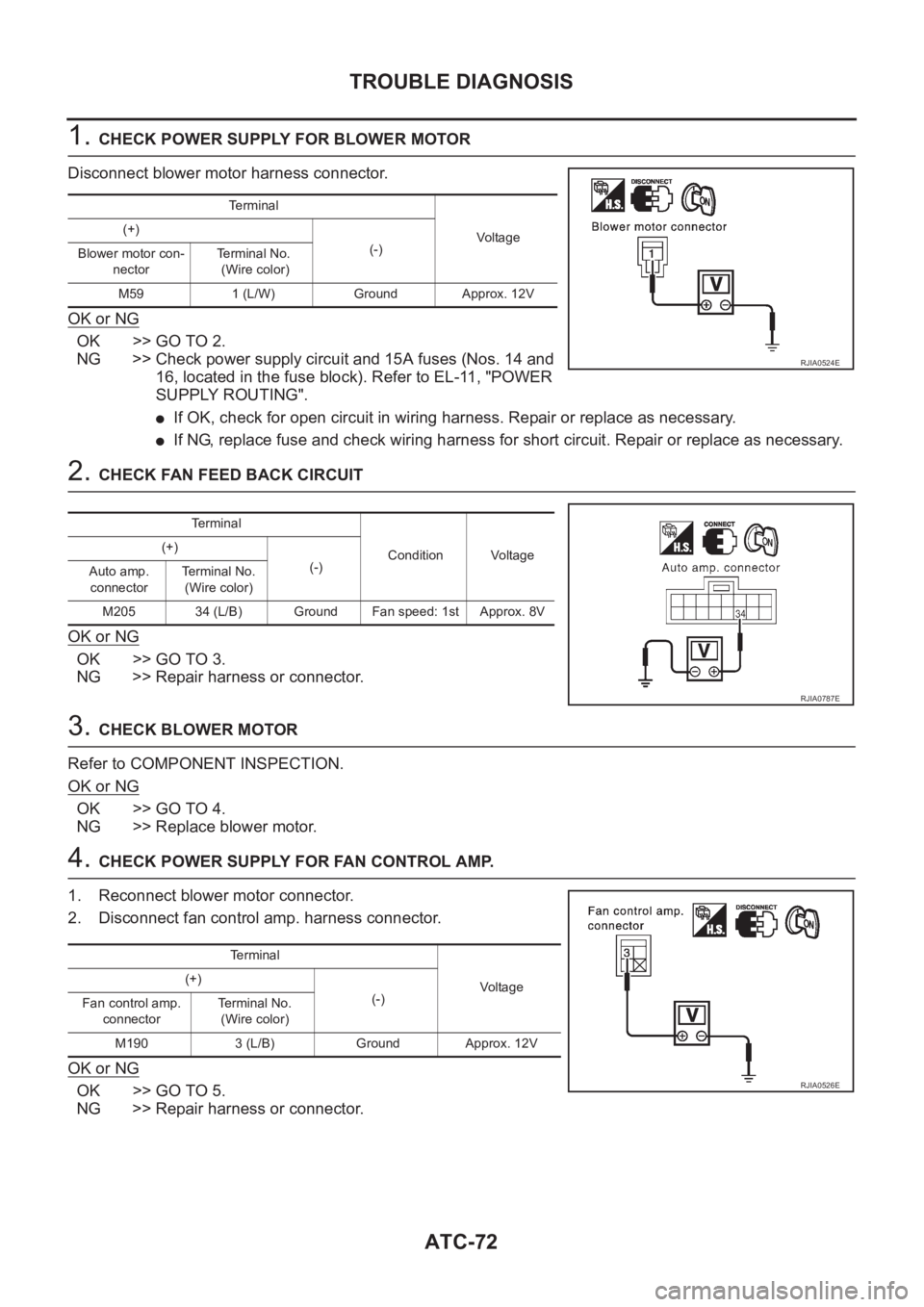

COMPONENT DESCRIPTION

Fan Control Amplifier

The fan control amplifier is located on the heater & cooling unit. The

fan control amp. receives a gate voltage from the auto amp. to step-

lessly maintain the blower fan motor voltage in the 4 to 12 volt range.

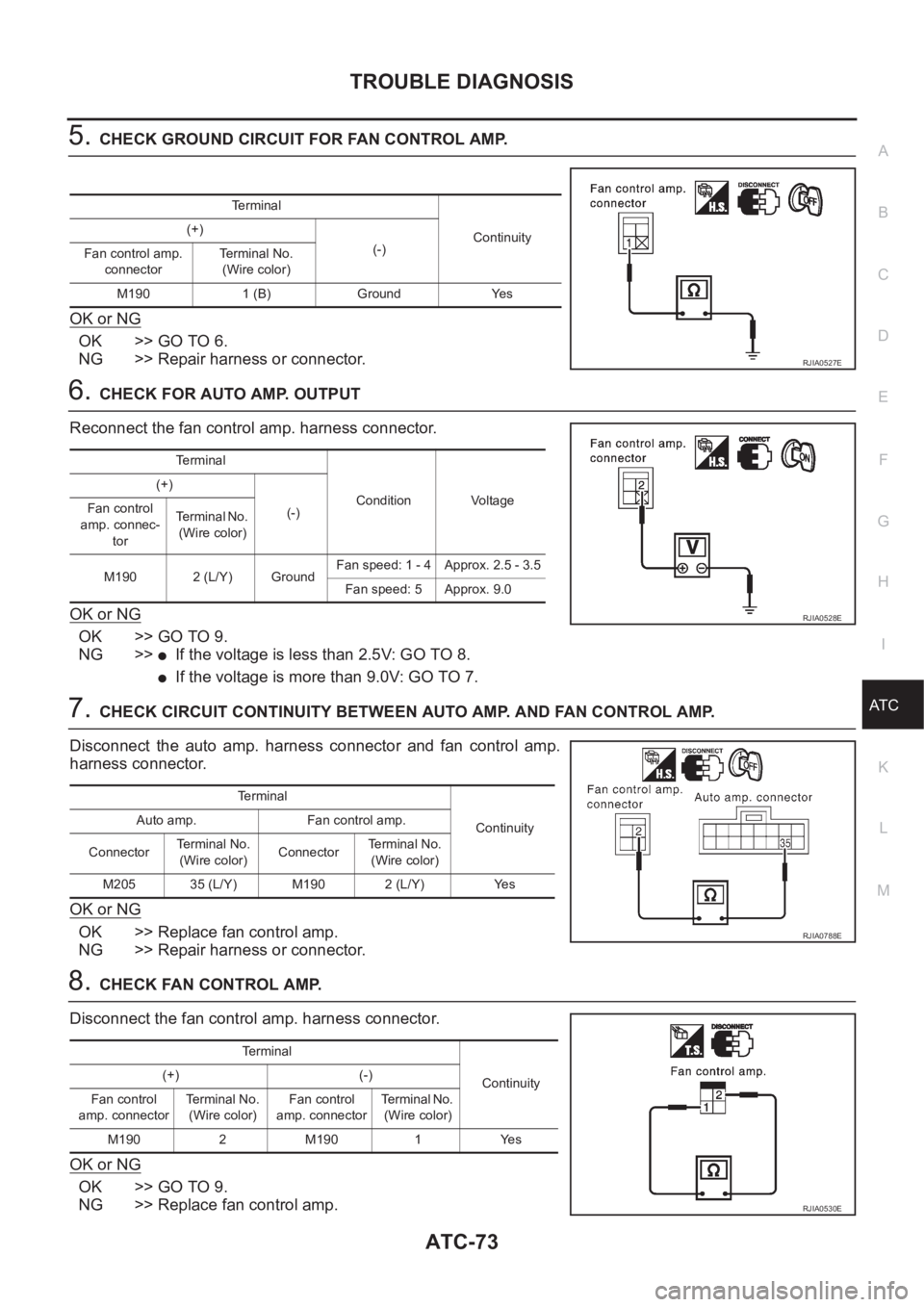

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

fan speed control.

RJIA0522E

RHA625H

RJIA0786E

Page 2052 of 3189

ATC-72

TROUBLE DIAGNOSIS

1. CHECK POWER SUPPLY FOR BLOWER MOTOR

Disconnect blower motor harness connector.

OK or NG

OK >> GO TO 2.

NG >> Check power supply circuit and 15A fuses (Nos. 14 and

16, located in the fuse block). Refer to EL-11, "POWER

SUPPLY ROUTING".

●If OK, check for open circuit in wiring harness. Repair or replace as necessary.

●If NG, replace fuse and check wiring harness for short circuit. Repair or replace as necessary.

2. CHECK FAN FEED BACK CIRCUIT

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3. CHECK BLOWER MOTOR

Refer to COMPONENT INSPECTION.

OK or NG

OK >> GO TO 4.

NG >> Replace blower motor.

4. CHECK POWER SUPPLY FOR FAN CONTROL AMP.

1. Reconnect blower motor connector.

2. Disconnect fan control amp. harness connector.

OK or NG

OK >> GO TO 5.

NG >> Repair harness or connector.

Terminal

Vo l ta g e (+)

(-)

Blower motor con-

nectorTerminal No.

(Wire color)

M59 1 (L/W) Ground Approx. 12V

RJIA0524E

Te r m i n a l

Condition Voltage (+)

(-)

Auto amp.

connectorTerminal No.

(Wire color)

M205 34 (L/B) Ground Fan speed: 1st Approx. 8V

RJIA0787E

Te r m i n a l

Voltag e (+)

(-)

Fan control amp.

connectorTerminal No.

(Wire color)

M190 3 (L/B) Ground Approx. 12V

RJIA0526E

Page 2053 of 3189

TROUBLE DIAGNOSIS

ATC-73

C

D

E

F

G

H

I

K

L

MA

B

AT C

5.CHECK GROUND CIRCUIT FOR FAN CONTROL AMP.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK FOR AUTO AMP. OUTPUT

Reconnect the fan control amp. harness connector.

OK or NG

OK >> GO TO 9.

NG >>

●If the voltage is less than 2.5V: GO TO 8.

●If the voltage is more than 9.0V: GO TO 7.

7.CHECK CIRCUIT CONTINUITY BETWEEN AUTO AMP. AND FAN CONTROL AMP.

Disconnect the auto amp. harness connector and fan control amp.

harness connector.

OK or NG

OK >> Replace fan control amp.

NG >> Repair harness or connector.

8.CHECK FAN CONTROL AMP.

Disconnect the fan control amp. harness connector.

OK or NG

OK >> GO TO 9.

NG >> Replace fan control amp.

Te r m i n a l

Continuity (+)

(-)

Fan control amp.

connectorTerminal No.

(Wire color)

M190 1 (B) Ground Yes

RJIA0527E

Terminal

Condition Voltage (+)

(-) Fan control

amp. connec-

torTe r m i n a l N o .

(Wire color)

M190 2 (L/Y) GroundFan speed: 1 - 4 Approx. 2.5 - 3.5

Fan speed: 5 Approx. 9.0

RJIA0528E

Terminal

Continuity Auto amp. Fan control amp.

ConnectorTerminal No.

(Wire color)Connector Terminal No.

(Wire color)

M205 35 (L/Y) M190 2 (L/Y) Yes

RJIA0788E

Terminal

Continuity (+) (-)

Fan control

amp. connectorTe r m i n a l N o .

(Wire color)Fan control

amp. connectorTerminal No.

(Wire color)

M190 2 M190 1 Yes

RJIA0530E

Page 2070 of 3189

ATC-90

TROUBLE DIAGNOSIS

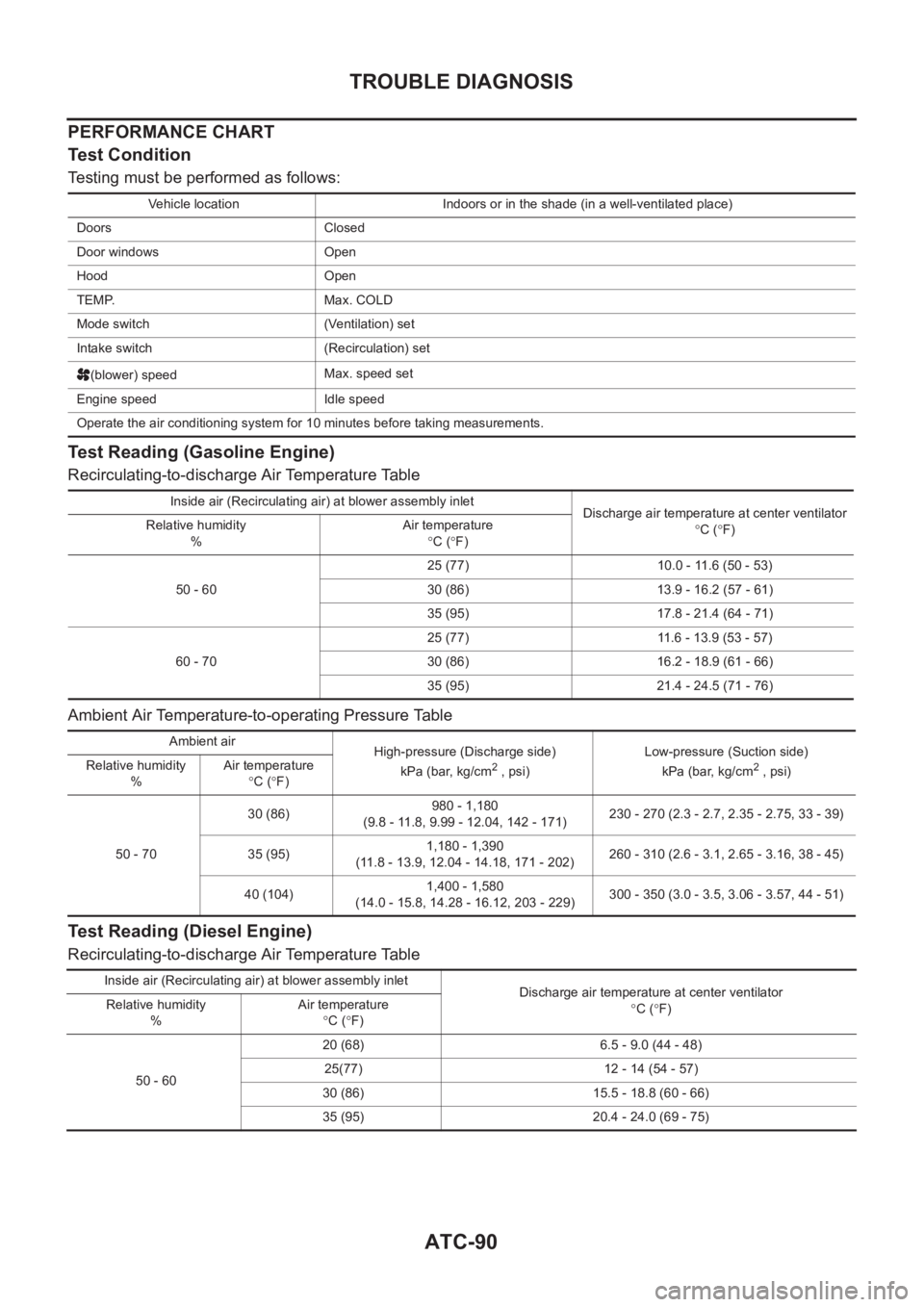

PERFORMANCE CHART

Test Condition

Testing must be performed as follows:

Test Reading (Gasoline Engine)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Test Reading (Diesel Engine)

Recirculating-to-discharge Air Temperature Table

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door windows Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Intake switch (Recirculation) set

(blower) speedMax. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6025 (77) 10.0 - 11.6 (50 - 53)

30 (86) 13.9 - 16.2 (57 - 61)

35 (95) 17.8 - 21.4 (64 - 71)

60 - 7025 (77) 11.6 - 13.9 (53 - 57)

30 (86) 16.2 - 18.9 (61 - 66)

35 (95) 21.4 - 24.5 (71 - 76)

Ambient air

High-pressure (Discharge side)

kPa (bar, kg/cm

2 , psi)Low-pressure (Suction side)

kPa (bar, kg/cm2 , psi) Relative humidity

%Air temperature

°C (°F)

50 - 7030 (86)980 - 1,180

(9.8 - 11.8, 9.99 - 12.04, 142 - 171)230 - 270 (2.3 - 2.7, 2.35 - 2.75, 33 - 39)

35 (95)1,180 - 1,390

(11.8 - 13.9, 12.04 - 14.18, 171 - 202)260 - 310 (2.6 - 3.1, 2.65 - 3.16, 38 - 45)

40 (104)1,400 - 1,580

(14.0 - 15.8, 14.28 - 16.12, 203 - 229)300 - 350 (3.0 - 3.5, 3.06 - 3.57, 44 - 51)

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6020 (68) 6.5 - 9.0 (44 - 48)

25(77) 12 - 14 (54 - 57)

30 (86) 15.5 - 18.8 (60 - 66)

35 (95) 20.4 - 24.0 (69 - 75)

Page 2080 of 3189

ATC-100

TROUBLE DIAGNOSIS

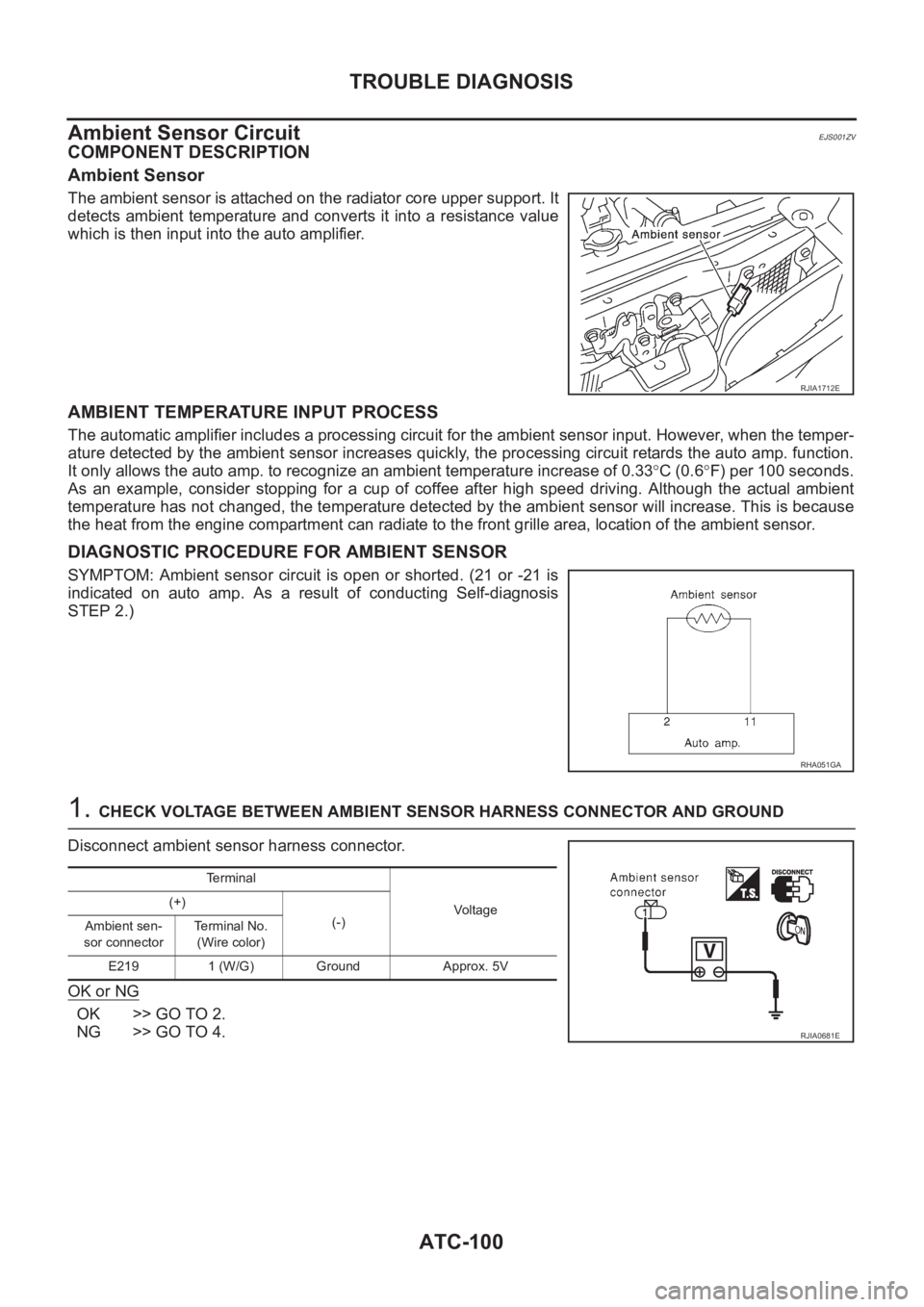

Ambient Sensor Circuit

EJS001ZV

COMPONENT DESCRIPTION

Ambient Sensor

The ambient sensor is attached on the radiator core upper support. It

detects ambient temperature and converts it into a resistance value

which is then input into the auto amplifier.

AMBIENT TEMPERATURE INPUT PROCESS

The automatic amplifier includes a processing circuit for the ambient sensor input. However, when the temper-

ature detected by the ambient sensor increases quickly, the processing circuit retards the auto amp. function.

It only allows the auto amp. to recognize an ambient temperature increase of 0.33°C (0.6°F) per 100 seconds.

As an example, consider stopping for a cup of coffee after high speed driving. Although the actual ambient

temperature has not changed, the temperature detected by the ambient sensor will increase. This is because

the heat from the engine compartment can radiate to the front grille area, location of the ambient sensor.

DIAGNOSTIC PROCEDURE FOR AMBIENT SENSOR

SYMPTOM: Ambient sensor circuit is open or shorted. (21 or -21 is

indicated on auto amp. As a result of conducting Self-diagnosis

STEP 2.)

1. CHECK VOLTAGE BETWEEN AMBIENT SENSOR HARNESS CONNECTOR AND GROUND

Disconnect ambient sensor harness connector.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

RJIA1712E

RHA051GA

Terminal

Voltage (+)

(-)

Ambient sen-

sor connectorTerminal No.

(Wire color)

E219 1 (W/G) Ground Approx. 5V

RJIA0681E

Page 2127 of 3189

REFRIGERANT LINES

ATC-147

C

D

E

F

G

H

I

K

L

MA

B

AT C

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set to the A/C service ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2 , 50 psi) above 16°C

(61°F). If less than specification, recover/evacuate and recharge the system with the specified amount of

refrigerant.

NOTE:

At temperatures below 16°C (61°F), leaks may not be detected since the system may not reach 345 kPa (3.54

kg/cm

2 , 50 psi).

4. Conduct the leak test from the high side (compressor discharge a to evaporator inlet f) to the low side

(evaporator drain hose g to shaft seal i). Refer to AT C - 1 3 4 , "

Components" . Perform a leak check for the

following areas carefully. Clean the component to be checked and move the leak detected probe com-

pletely around the connection/component. ATC-134, "

Components" .

Compressor

Check the fitting of high and low pressure hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer′s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Face mode

c. Intake position: Recirculation

d. Max cold temperature

e. Fan speed: High

SHA708E

Page 2129 of 3189

SERVICE DATA AND SPECIFICATIONS (SDS)

ATC-149

C

D

E

F

G

H

I

K

L

MA

B

AT C

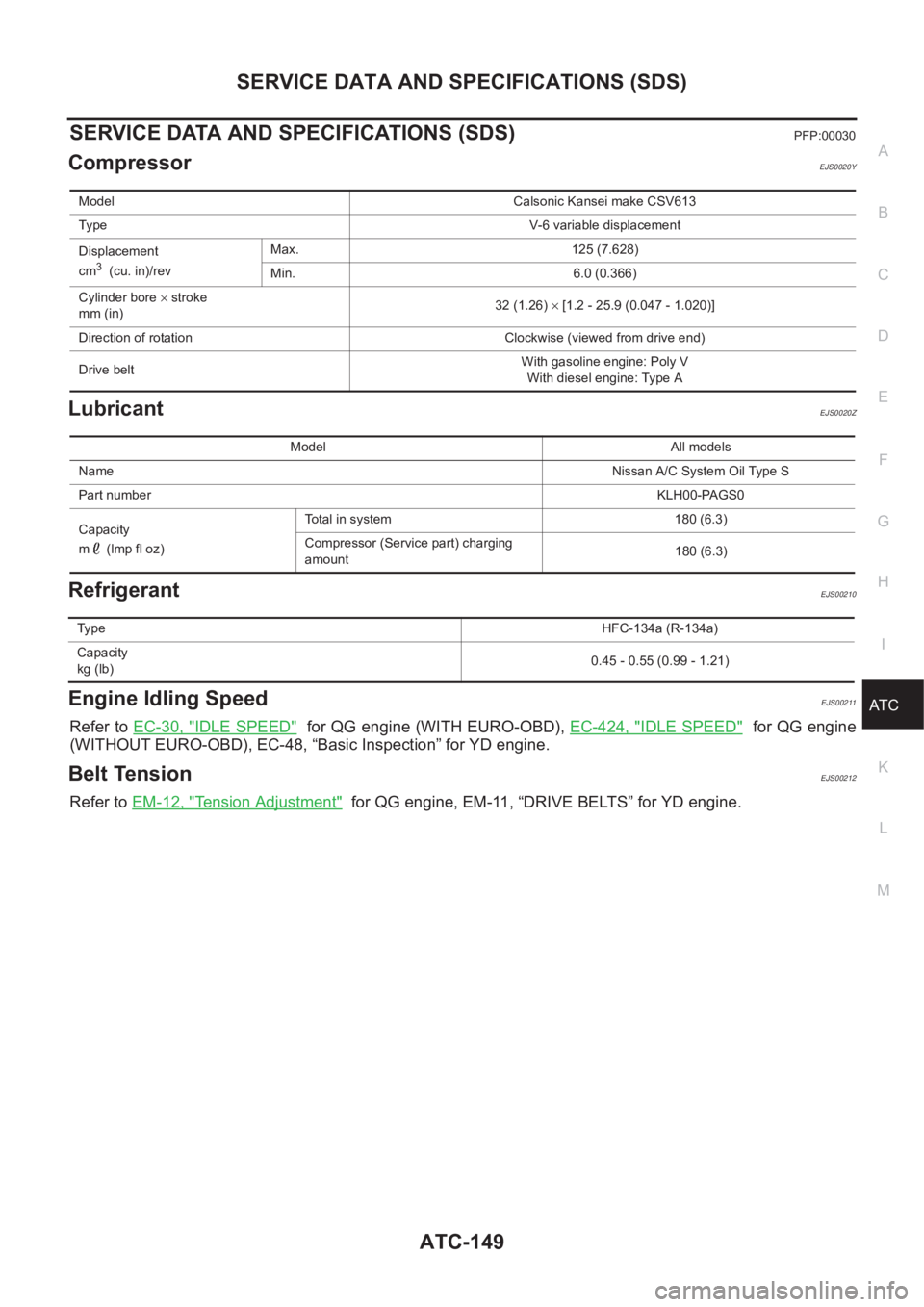

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

CompressorEJS0020Y

LubricantEJS0020Z

RefrigerantEJS00210

Engine Idling SpeedEJS00211

Refer to EC-30, "IDLE SPEED" for QG engine (WITH EURO-OBD), EC-424, "IDLE SPEED" for QG engine

(WITHOUT EURO-OBD), EC-48, “Basic Inspection” for YD engine.

Belt TensionEJS00212

Refer to EM-12, "Tension Adjustment" for QG engine, EM-11, “DRIVE BELTS” for YD engine.

Model Calsonic Kansei make CSV613

TypeV-6 variable displacement

Displacement

cm

3 (cu. in)/revMax. 125 (7.628)

Min. 6.0 (0.366)

Cylinder bore × stroke

mm (in)32 (1.26) × [1.2 - 25.9 (0.047 - 1.020)]

Direction of rotation Clockwise (viewed from drive end)

Drive beltWith gasoline engine: Poly V

With diesel engine: Type A

Model All models

NameNissan A/C System Oil Type S

Part numberKLH00-PAGS0

Capacity

m (lmp fl oz)Total in system 180 (6.3)

Compressor (Service part) charging

amount180 (6.3)

Ty p eHFC-134a (R-134a)

Capacity

kg (lb)0.45 - 0.55 (0.99 - 1.21)

Page 2229 of 3189

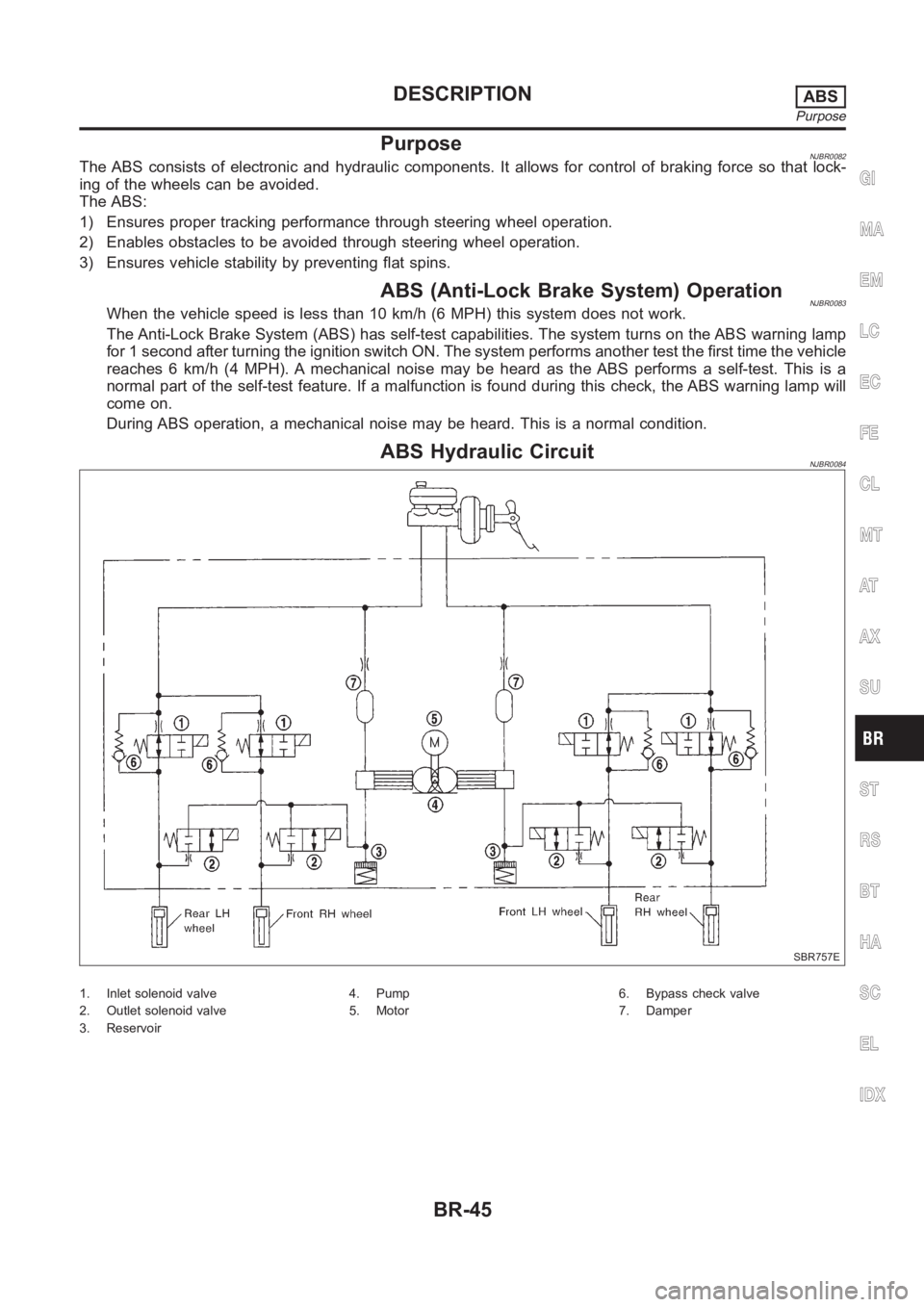

PurposeNJBR0082The ABS consists of electronic and hydraulic components. It allows for control of braking force so that lock-

ing of the wheels can be avoided.

The ABS:

1) Ensures proper tracking performance through steering wheel operation.

2) Enables obstacles to be avoided through steering wheel operation.

3) Ensures vehicle stability by preventing flat spins.

ABS (Anti-Lock Brake System) OperationNJBR0083When the vehicle speed is less than 10 km/h (6 MPH) this system does not work.

The Anti-Lock Brake System (ABS) has self-test capabilities. The system turns on the ABS warning lamp

for 1 second after turning the ignition switch ON. The system performs another test the first time the vehicle

reaches 6 km/h (4 MPH). A mechanical noise may be heard as the ABS performs a self-test. This is a

normal part of the self-test feature. If a malfunction is found during thischeck, the ABS warning lamp will

come on.

During ABS operation, a mechanical noise may be heard. This is a normal condition.

ABS Hydraulic CircuitNJBR0084

SBR757E

1. Inlet solenoid valve

2. Outlet solenoid valve

3. Reservoir4. Pump

5. Motor6. Bypass check valve

7. Damper

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

DESCRIPTIONABS

Purpose

BR-45

Page 2230 of 3189

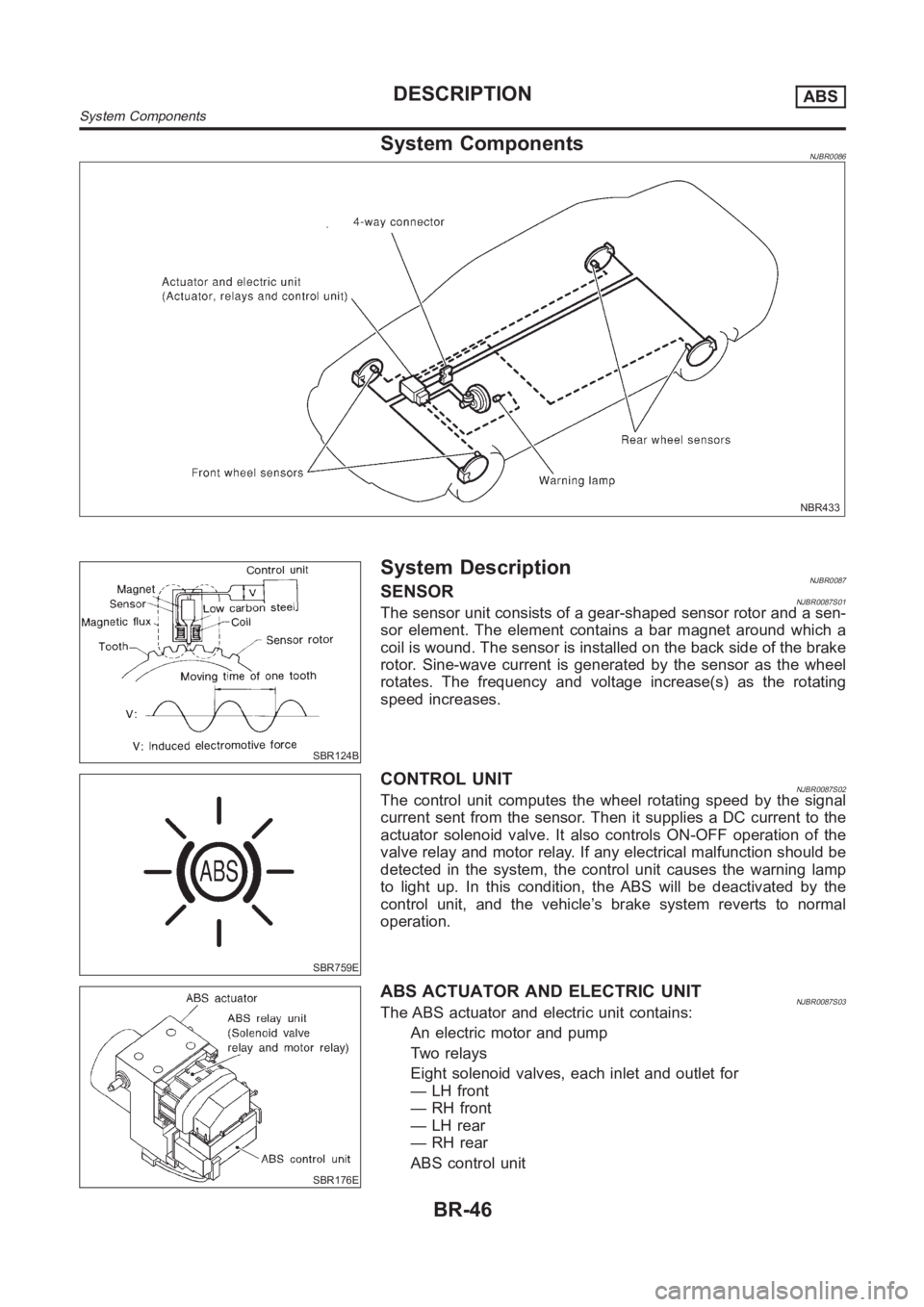

System ComponentsNJBR0086

NBR433

SBR124B

System DescriptionNJBR0087SENSORNJBR0087S01The sensor unit consists of a gear-shaped sensor rotor and a sen-

sor element. The element contains a bar magnet around which a

coil is wound. The sensor is installed on the back side of the brake

rotor. Sine-wave current is generated by the sensor as the wheel

rotates. The frequency and voltage increase(s) as the rotating

speed increases.

SBR759E

CONTROL UNITNJBR0087S02The control unit computes the wheel rotating speed by the signal

current sent from the sensor. Then it supplies a DC current to the

actuator solenoid valve. It also controls ON-OFF operation of the

valve relay and motor relay. If any electrical malfunction should be

detected in the system, the control unit causes the warning lamp

to light up. In this condition, the ABS will be deactivated by the

control unit, and the vehicle’s brake system reverts to normal

operation.

SBR176E

ABS ACTUATOR AND ELECTRIC UNITNJBR0087S03The ABS actuator and electric unit contains:

An electric motor and pump

Two relays

Eight solenoid valves, each inlet and outlet for

— LH front

—RHfront

— LH rear

— RH rear

ABS control unit

DESCRIPTIONABS

System Components

BR-46

Page 2238 of 3189

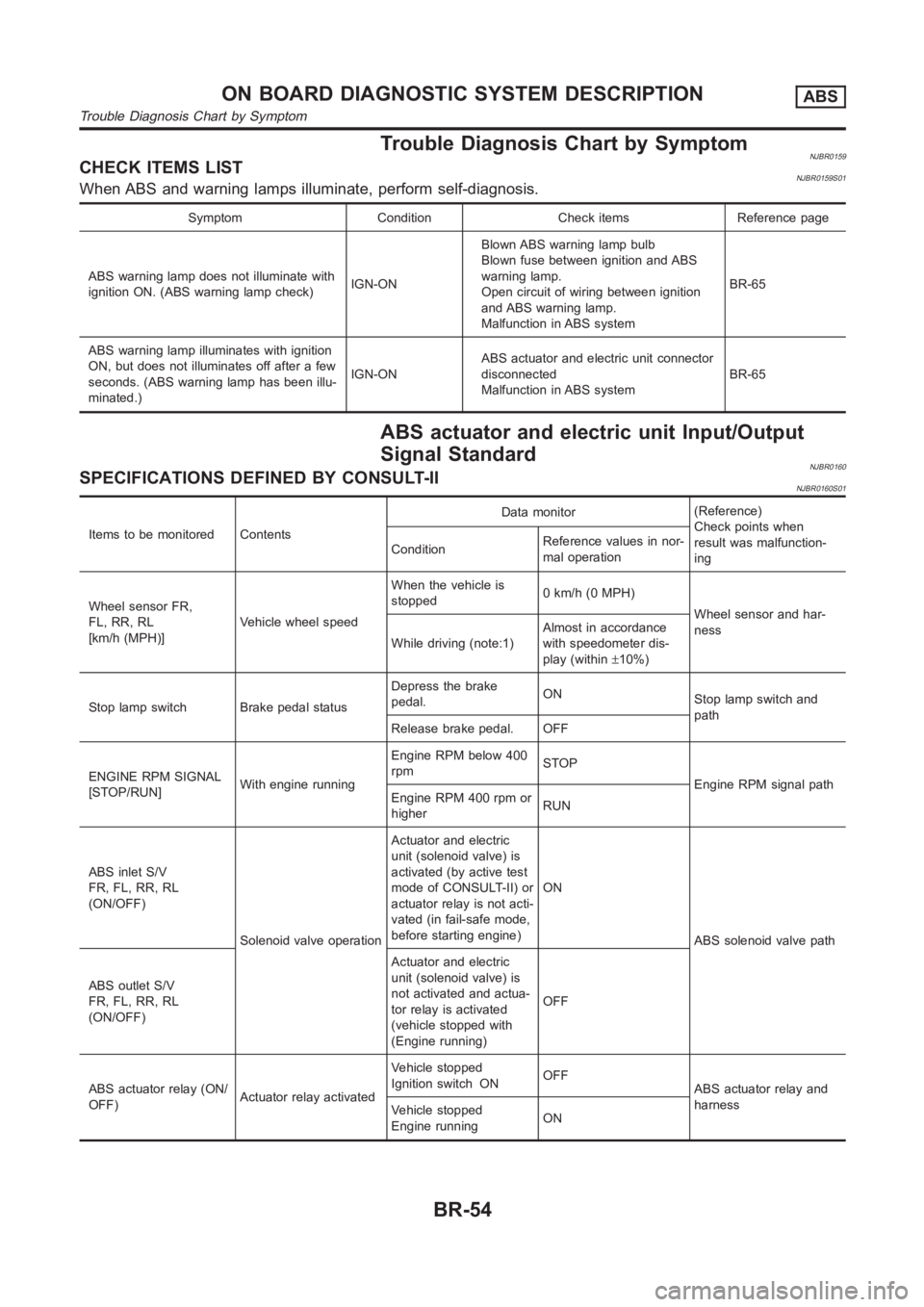

Trouble Diagnosis Chart by SymptomNJBR0159CHECK ITEMS LISTNJBR0159S01When ABS and warning lamps illuminate, perform self-diagnosis.

Symptom Condition Check items Reference page

ABS warning lamp does not illuminate with

ignition ON. (ABS warning lamp check)IGN-ONBlown ABS warning lamp bulb

Blown fuse between ignition and ABS

warning lamp.

Open circuit of wiring between ignition

and ABS warning lamp.

Malfunction in ABS systemBR-65

ABS warning lamp illuminates with ignition

ON, but does not illuminates off after a few

seconds. (ABS warning lamp has been illu-

minated.)IGN-ONABS actuator and electric unit connector

disconnected

Malfunction in ABS systemBR-65

ABS actuator and electric unit Input/Output

Signal Standard

NJBR0160SPECIFICATIONS DEFINED BY CONSULT-IINJBR0160S01

Items to be monitored ContentsData monitor(Reference)

Check points when

result was malfunction-

ing ConditionReference values in nor-

mal operation

Wheel sensor FR,

FL, RR, RL

[km/h (MPH)]Vehicle wheel speedWhen the vehicle is

stopped0 km/h (0 MPH)

Wheel sensor and har-

ness

While driving (note:1)Almost in accordance

with speedometer dis-

play (within±10%)

Stop lamp switch Brake pedal statusDepress the brake

pedal.ON

Stop lamp switch and

path

Release brake pedal. OFF

ENGINE RPM SIGNAL

[STOP/RUN]With engine runningEngine RPM below 400

rpmSTOP

Engine RPM signal path

Engine RPM 400 rpm or

higherRUN

ABS inlet S/V

FR, FL, RR, RL

(ON/OFF)

Solenoid valve operationActuator and electric

unit (solenoid valve) is

activated (by active test

mode of CONSULT-II) or

actuator relay is not acti-

vated (in fail-safe mode,

before starting engine)ON

ABS solenoid valve path

ABS outlet S/V

FR, FL, RR, RL

(ON/OFF)Actuator and electric

unit (solenoid valve) is

not activated and actua-

tor relay is activated

(vehicle stopped with

(Engine running)OFF

ABS actuator relay (ON/

OFF)Actuator relay activatedVehicle stopped

Ignition switch ONOFF

ABS actuator relay and

harness

Vehicle stopped

Engine runningON

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

Trouble Diagnosis Chart by Symptom

BR-54