speed NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2239 of 3189

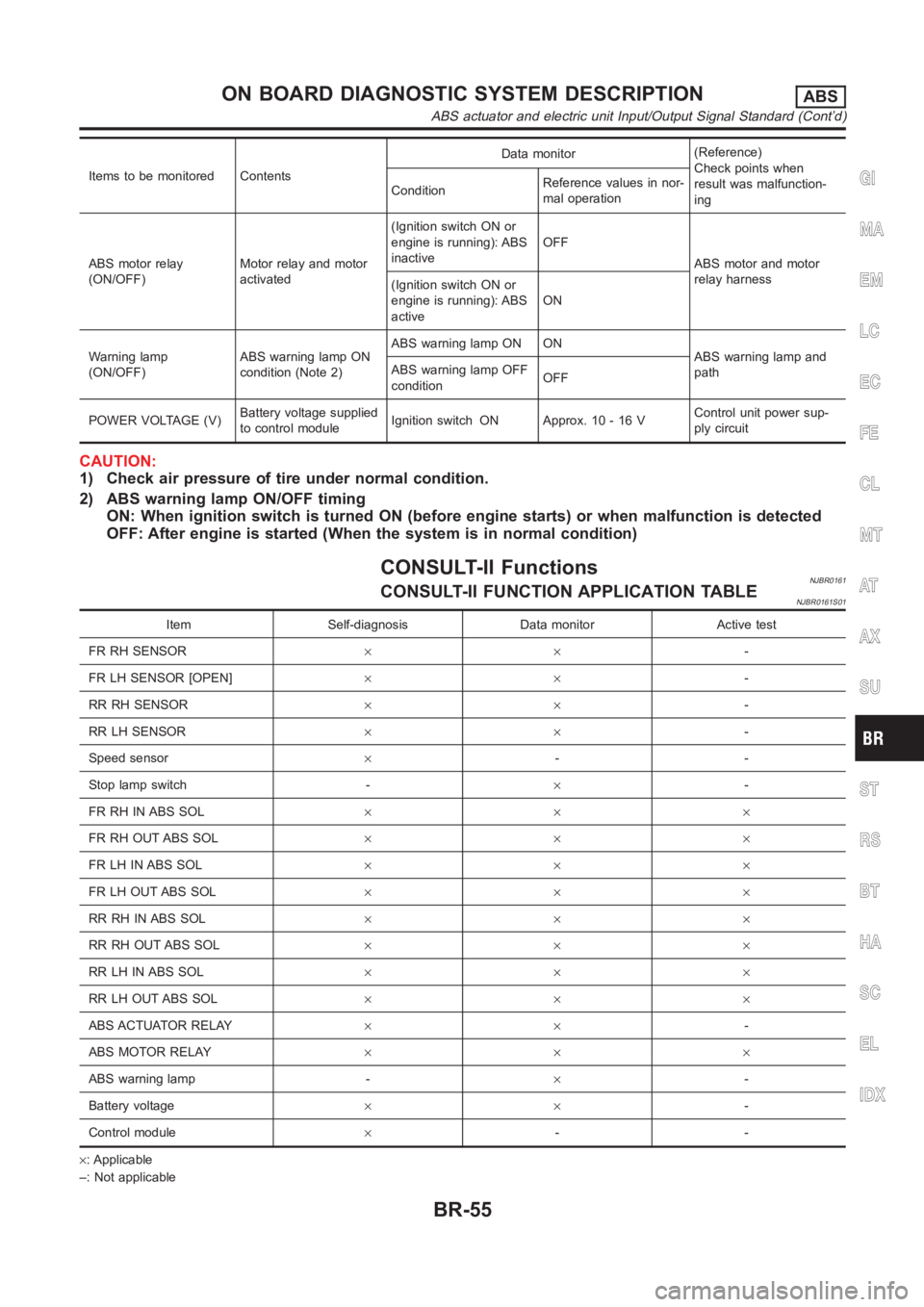

Items to be monitored ContentsData monitor(Reference)

Check points when

result was malfunction-

ing ConditionReference values in nor-

mal operation

ABS motor relay

(ON/OFF)Motor relay and motor

activated(Ignition switch ON or

engine is running): ABS

inactiveOFF

ABS motor and motor

relay harness

(Ignition switch ON or

engine is running): ABS

activeON

Warning lamp

(ON/OFF)ABS warning lamp ON

condition (Note 2)ABS warning lamp ON ON

ABS warning lamp and

path ABS warning lamp OFF

conditionOFF

POWER VOLTAGE (V)Battery voltage supplied

to control moduleIgnition switch ON Approx. 10 - 16 VControl unit power sup-

ply circuit

CAUTION:

1) Check air pressure of tire under normal condition.

2) ABS warning lamp ON/OFF timing

ON: When ignition switch is turned ON (before engine starts) or when malfunction is detected

OFF: After engine is started (When the system is in normal condition)

CONSULT-II FunctionsNJBR0161CONSULT-II FUNCTION APPLICATION TABLENJBR0161S01

Item Self-diagnosis Data monitor Active test

FR RH SENSOR××-

FR LH SENSOR [OPEN]××-

RR RH SENSOR××-

RR LH SENSOR××-

Speed sensor×--

Stop lamp switch -×-

FR RH IN ABS SOL×××

FR RH OUT ABS SOL×××

FR LH IN ABS SOL×××

FR LH OUT ABS SOL×××

RR RH IN ABS SOL×××

RR RH OUT ABS SOL×××

RR LH IN ABS SOL×××

RR LH OUT ABS SOL×××

ABS ACTUATOR RELAY××-

ABS MOTOR RELAY×××

ABS warning lamp -×-

Battery voltage××-

Control module×--

×: Applicable

–: Not applicable

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

ABS actuator and electric unit Input/Output Signal Standard (Cont’d)

BR-55

Page 2242 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual Faulty lines Malfunction detecting condition Check harness

RR RH OUT ABS SOL

[OPEN] [SHORT]At RH rear wheel ABS outlet solenoid valve, following

conditions occur: open circuit, output voltage is abnor NISSAN ALMERA N16 2003 Electronic Repair Manual Faulty lines Malfunction detecting condition Check harness

RR RH OUT ABS SOL

[OPEN] [SHORT]At RH rear wheel ABS outlet solenoid valve, following

conditions occur: open circuit, output voltage is abnor](/img/5/57350/w960_57350-2241.png)

Faulty lines Malfunction detecting condition Check harness

RR RH OUT ABS SOL

[OPEN] [SHORT]At RH rear wheel ABS outlet solenoid valve, following

conditions occur: open circuit, output voltage is abnor-

mally lower or higher than control value by short to

ground on control line.

ABS solenoid valve and actua-

tor relay harness

RR LH OUT ABS SOL

[OPEN] [SHORT]At LH rear wheel ABS outlet solenoid valve, following

conditions occur: open circuit, output voltage is abnor-

mally lower or higher than control value by short to

ground on control line.

ABS motor [ON error]ABS actuator motor turned ON when the ABS motor is

controlled OFF.

ABS motor relay and harness

ABS motor [OFF error]ABS actuator motor turned OFF when the ABS motor is

controlled ON.

ABS actuator relay [ON error] ABS actuator relay turned ON wheel it is controlled OFF.

ABS actuator relay and har-

ness ABS ACTUATOR RELAY

[OFF abnormal]ABS actuator relay turned OFF wheel it is controlled ON.

BATTERY VOLTAGE [ABNORMAL]Power source voltage supplied to ABS actuator and elec-

tric unit is abnormally low.ABS actuator and electric unit

power supply circuit

CONTROL UNITFunction of calculation in ABS actuator and electric unit

has failed.ABS actuator and electric unit,

power and ground circuits

(Note 1): When vehicle was stuck on slippery road, and spin its wheels for Approx. 10 - 80 seconds (the period depends on vehicle

speed). ABS warning lamp may come on. However, this is not abnormal.

(Note 2): Repair short circuit in sensor. ABS warning lamp will come on whenignition switch is turned ON. According to self-diagnosis

operation procedure, drive vehicle at Approx. 30 km/h (19 MPH). Then checkABS warning lamp goes out in about one minute.

DATA MONITORNJBR0161S03For details of data monitor function, refer to CONSULT-II

Instruction Manual.

Operation ProcedureNJBR0161S03011. Turn the ignition switch to OFF.

2. Connect CONSULT-II connector to data link connector on

vehicle.

3. Turn ignition switch ON.

MBIB0233E

4. Touch “START (NISSAN BASED VHCL)” on the display.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Functions (Cont’d)

BR-58

Page 2243 of 3189

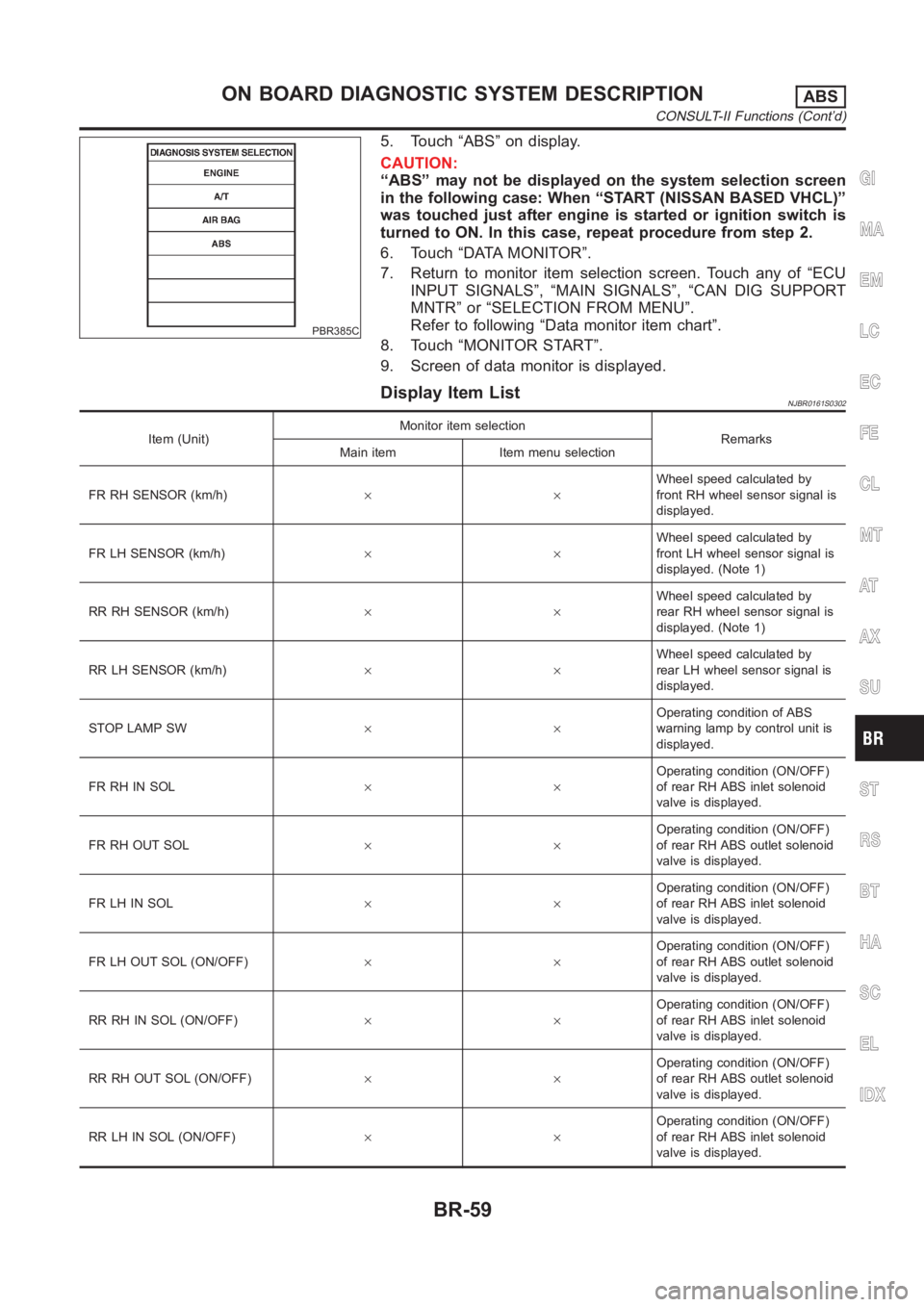

PBR385C

5. Touch “ABS” on display.

CAUTION:

“ABS” may not be displayed on the system selection screen

in the following case: When “START (NISSAN BASED VHCL)”

was touched just after engine is started or ignition switch is

turned to ON. In this case, repeat procedure from step 2.

6. Touch “DATA MONITOR”.

7. Return to monitor item selection screen. Touch any of “ECU

INPUT SIGNALS”, “MAIN SIGNALS”, “CAN DIG SUPPORT

MNTR” or “SELECTION FROM MENU”.

Refer to following “Data monitor item chart”.

8. Touch “MONITOR START”.

9. Screen of data monitor is displayed.

Display Item ListNJBR0161S0302

Item (Unit)Monitor item selection

Remarks

Main item Item menu selection

FR RH SENSOR (km/h)××Wheel speed calculated by

front RH wheel sensor signal is

displayed.

FR LH SENSOR (km/h)××Wheel speed calculated by

front LH wheel sensor signal is

displayed. (Note 1)

RR RH SENSOR (km/h)××Wheel speed calculated by

rear RH wheel sensor signal is

displayed. (Note 1)

RR LH SENSOR (km/h)××Wheel speed calculated by

rear LH wheel sensor signal is

displayed.

STOP LAMP SW××Operating condition of ABS

warning lamp by control unit is

displayed.

FR RH IN SOL××Operating condition (ON/OFF)

of rear RH ABS inlet solenoid

valve is displayed.

FR RH OUT SOL××Operating condition (ON/OFF)

of rear RH ABS outlet solenoid

valve is displayed.

FR LH IN SOL××Operating condition (ON/OFF)

of rear RH ABS inlet solenoid

valve is displayed.

FR LH OUT SOL (ON/OFF)××Operating condition (ON/OFF)

of rear RH ABS outlet solenoid

valve is displayed.

RR RH IN SOL (ON/OFF)××Operating condition (ON/OFF)

of rear RH ABS inlet solenoid

valve is displayed.

RR RH OUT SOL (ON/OFF)××Operating condition (ON/OFF)

of rear RH ABS outlet solenoid

valve is displayed.

RR LH IN SOL (ON/OFF)××Operating condition (ON/OFF)

of rear RH ABS inlet solenoid

valve is displayed.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Functions (Cont’d)

BR-59

Page 2252 of 3189

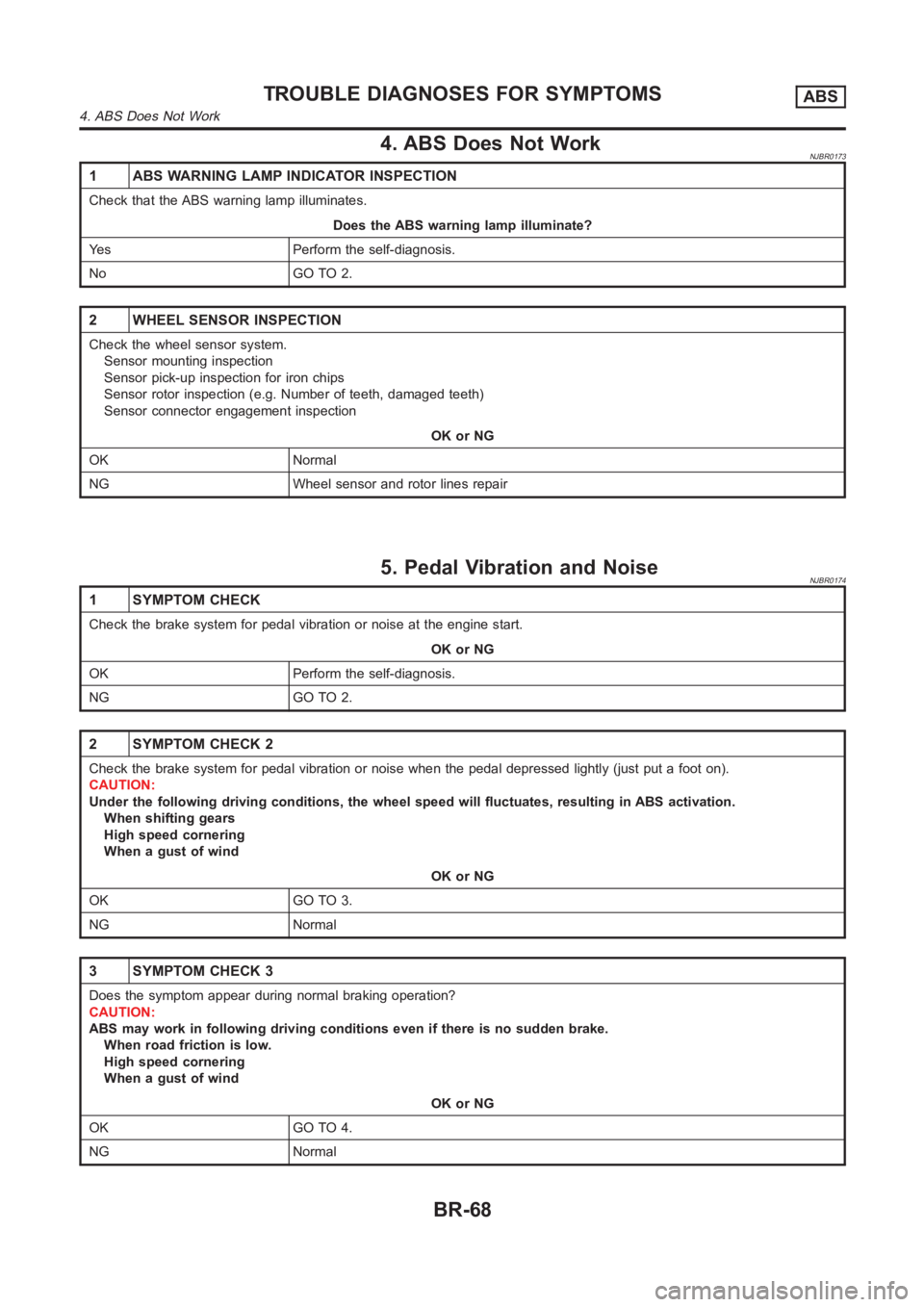

4. ABS Does Not WorkNJBR0173

1 ABS WARNING LAMP INDICATOR INSPECTION

Check that the ABS warning lamp illuminates.

Does the ABS warning lamp illuminate?

Yes Perform the self-diagnosis.

No GO TO 2.

2 WHEEL SENSOR INSPECTION

Check the wheel sensor system.

Sensor mounting inspection

Sensor pick-up inspection for iron chips

Sensor rotor inspection (e.g. Number of teeth, damaged teeth)

Sensor connector engagement inspection

OK or NG

OK Normal

NG Wheel sensor and rotor lines repair

5. Pedal Vibration and NoiseNJBR0174

1 SYMPTOM CHECK

Check the brake system for pedal vibration or noise at the engine start.

OK or NG

OK Perform the self-diagnosis.

NG GO TO 2.

2 SYMPTOM CHECK 2

Check the brake system for pedal vibration or noise when the pedal depressed lightly (just put a foot on).

CAUTION:

Under the following driving conditions, the wheel speed will fluctuates,resulting in ABS activation.

When shifting gears

High speed cornering

When a gust of wind

OK or NG

OK GO TO 3.

NG Normal

3 SYMPTOM CHECK 3

Does the symptom appear during normal braking operation?

CAUTION:

ABS may work in following driving conditions even if there is no sudden brake.

When road friction is low.

High speed cornering

When a gust of wind

OK or NG

OK GO TO 4.

NG Normal

TROUBLE DIAGNOSES FOR SYMPTOMSABS

4. ABS Does Not Work

BR-68

Page 2253 of 3189

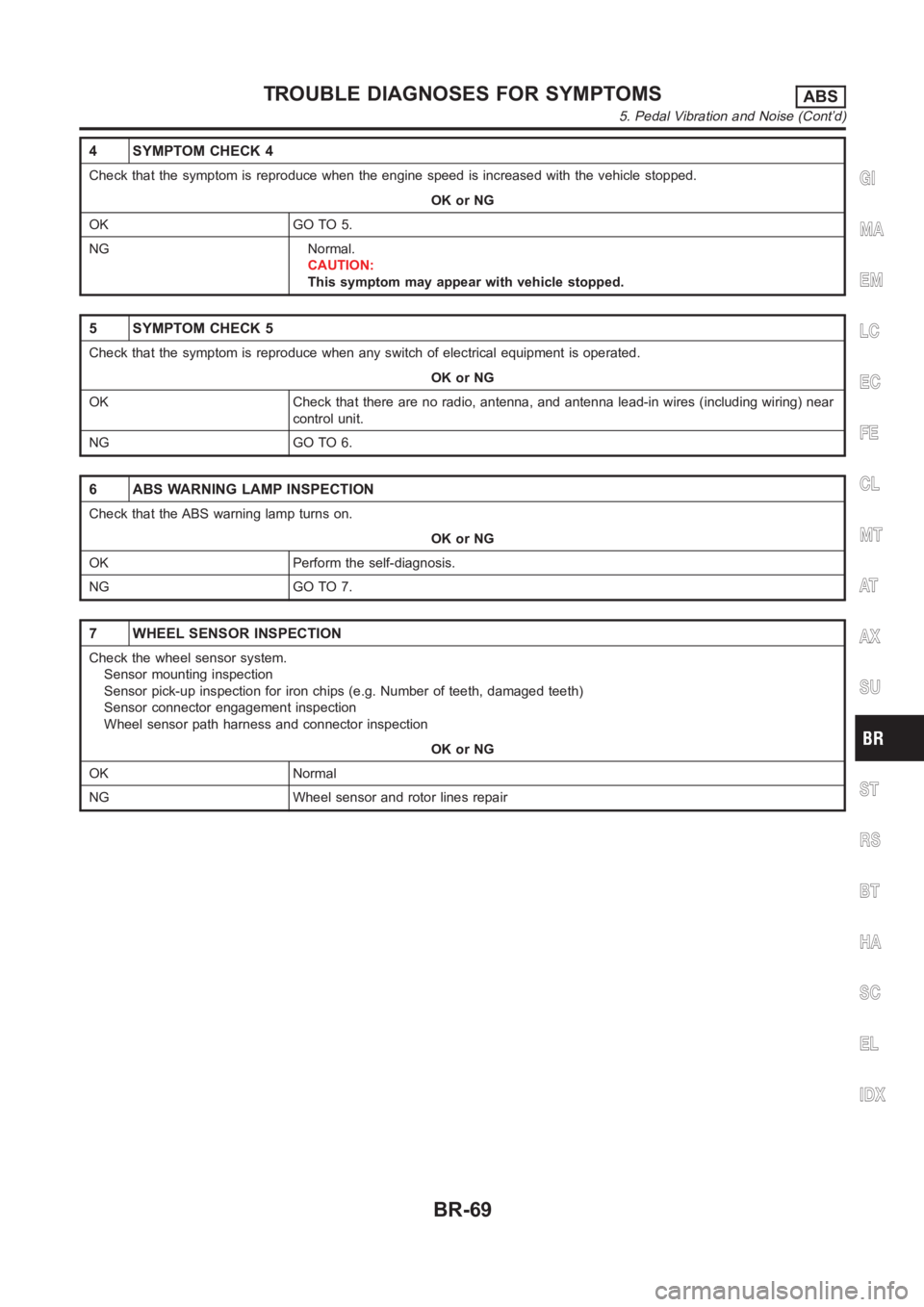

4 SYMPTOM CHECK 4

Check that the symptom is reproduce when the engine speed is increased withthe vehicle stopped.

OK or NG

OK GO TO 5.

NG Normal.

CAUTION:

This symptom may appear with vehicle stopped.

5 SYMPTOM CHECK 5

Check that the symptom is reproduce when any switch of electrical equipment is operated.

OK or NG

OK Check that there are no radio, antenna, and antenna lead-in wires (including wiring) near

control unit.

NG GO TO 6.

6 ABS WARNING LAMP INSPECTION

Check that the ABS warning lamp turns on.

OK or NG

OK Perform the self-diagnosis.

NG GO TO 7.

7 WHEEL SENSOR INSPECTION

Check the wheel sensor system.

Sensor mounting inspection

Sensor pick-up inspection for iron chips (e.g. Number of teeth, damaged teeth)

Sensor connector engagement inspection

Wheel sensor path harness and connector inspection

OK or NG

OK Normal

NG Wheel sensor and rotor lines repair

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSES FOR SYMPTOMSABS

5. Pedal Vibration and Noise (Cont’d)

BR-69

Page 2339 of 3189

Trouble Diagnoses/YD Engine Models with

Common Rail and K9K Engine Models...................292

POWER DOOR LOCK - SUPER LOCK -...................301

System Description ..................................................301

Schematic <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..........304

Wiring Diagram - S/LOCK - .....................................306

Trouble Diagnosis/QG and YD Engine Models

with Common Rail ...................................................313

Trouble Diagnoses/YD Engine Models without

Common Rail and K9K Engine Models...................339

MULTI-REMOTE CONTROL SYSTEM.......................352

System Description ..................................................352

Wiring Diagram - MULTI - .......................................353

Trouble Diagnoses/QG and YD Engine Models

with Common Rail ...................................................355

Trouble Diagnoses/YD Engine Models without

Common Rail and K9K Engine Models...................360

ID Code Entry Procedure ........................................364

Remote Controller Battery Replacement.................365

THEFT WARNING SYSTEM.......................................366

Wiring Diagram - PRWIRE -....................................366

SMART ENTRANCE CONTROL SYSTEM.................368

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........368

CONSULT-II <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[........369

Schematic <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..........374

Smart Entrance Control Unit Inspection Table ........376

Trouble Diagnoses...................................................378

Power Supply and Ground Circuit Check ...............379

CAN Communication Line Check ............................380

TIME CONTROL UNIT................................................381

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........381

Trouble Diagnoses...................................................382

Schematic <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..........384

NATS (NISSAN ANTI-THEFT SYSTEM).....................386

Component Parts and Harness Connetor

Location <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[............386

System Description ..................................................386

System Composition ................................................387

Wiring Diagram - NATS -.........................................388

CONSULT-II <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[........390

Trouble Diagnoses/QG and YD Engine Models

with Common Rail ...................................................393

How to Replace NATS Antenna Amp ...................... 411

Trouble Diagnoses/YD Engine Models without

Common Rail and K9K Engine Models...................412

How to Replace NATS IMMU ..................................429

NAVIGATION SYSTEM...............................................430

System Description ..................................................430

Precautions for AV and NAVI Control Unit

Replacement <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[........440

Component Parts Location ......................................441

Location of Antenna .................................................441Schematic <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..........442

Wiring Diagram - NAVI - ..........................................443

Wiring Diagram - COMM -.......................................448

Terminals and Reference Value for AV and NAVI

Control Unit <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[..........450

Terminals and Reference Value for Display Unit ....454

Terminals and Reference Value for Multifunction

Switch <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011001100110011[.............456

Self-Diagnosis Function ...........................................457

Self-Diagnosis Mode................................................458

Confirmation/Adjustment Mode ...............................461

Power Supply and Ground Circuit Check ...............467

Check Display Unit, Multifunction Switch Power,

and Ground Circuit ..................................................469

Vehicle Speed Signal Check ...................................471

Illumination Control Signal Check ...........................472

Ignition Signal Check ...............................................473

Reverse Signal Check .............................................474

RGB Screen Is Not Shown......................................475

No Screens Appear .................................................477

Color of RGB Image Is Not Proper .........................477

RGB Screen Is Rolling ............................................482

Guide Sound Is Not Heard ......................................484

Multifunction Switch Controls Are Ineffective

(Rear Defogger Control Excluded) ..........................485

Air Conditioning Controls (Only) Are Ineffective

(Rear Defogger Control Excluded) ..........................489

Rear Defogger Does Not Operate...........................491

Rear Defogger Indicator Lamp Does Not

Illuminate<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.............492

No Fuel Information Is Displayed/No Warning

Message Is Displayed .............................................493

Previous Conditions Are Not Stored........................495

The Position of The Current-Location Mark Is

Not Correct <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.........495

Radio Wave From The GPS Satellite Is Not

Received <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[...........495

Display Does Not Change When Screen

Adjustment Is Performed .........................................496

Day/Night Display Switching Is Not Done. Night

Illumination for AV and NAVI Control Unit Does

Not Illuminate ...........................................................496

On Multifunction Switch, a Specific Switch Does

Not Operate in All Conditions ..................................496

Driving Information Is Inaccurate. Maintenance

Information Is Inaccurate .........................................496

System Does Not Start ............................................497

The Current Position Mark Is in the Wrong Place ..497

The Current-Location Mark Will Not Move

Forward/Backward ...................................................498

The Position of the Current-Location Mark Is Not

Correct <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011[.............498

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CONTENTS(Cont’d)

EL-3

Page 2446 of 3189

Component Parts and Harness Connector

Location

NJEL0441For details, refer to “ELECTRICAL UNIT LOCATION” (EL-543) and

“HARNESS LAYOUT” (EL-550).

System DescriptionNJEL0442UNIFIED CONTROL METERNJEL0442S01Speedometer, odo/trip meter, tachometer, fuel gauge and water temperature gauge are controlled totally

by control unit built-in combination meter.

Digital meter is adopted for odo/trip meter.*

*The record of the odo meter is kept even if the battery cable is disconnected. The record of the trip meter

is erased when the battery cable is disconnected.

Odo/trip meter segment can be checked in diagnosis mode.

Meter/gauge can be checked in diagnosis mode.

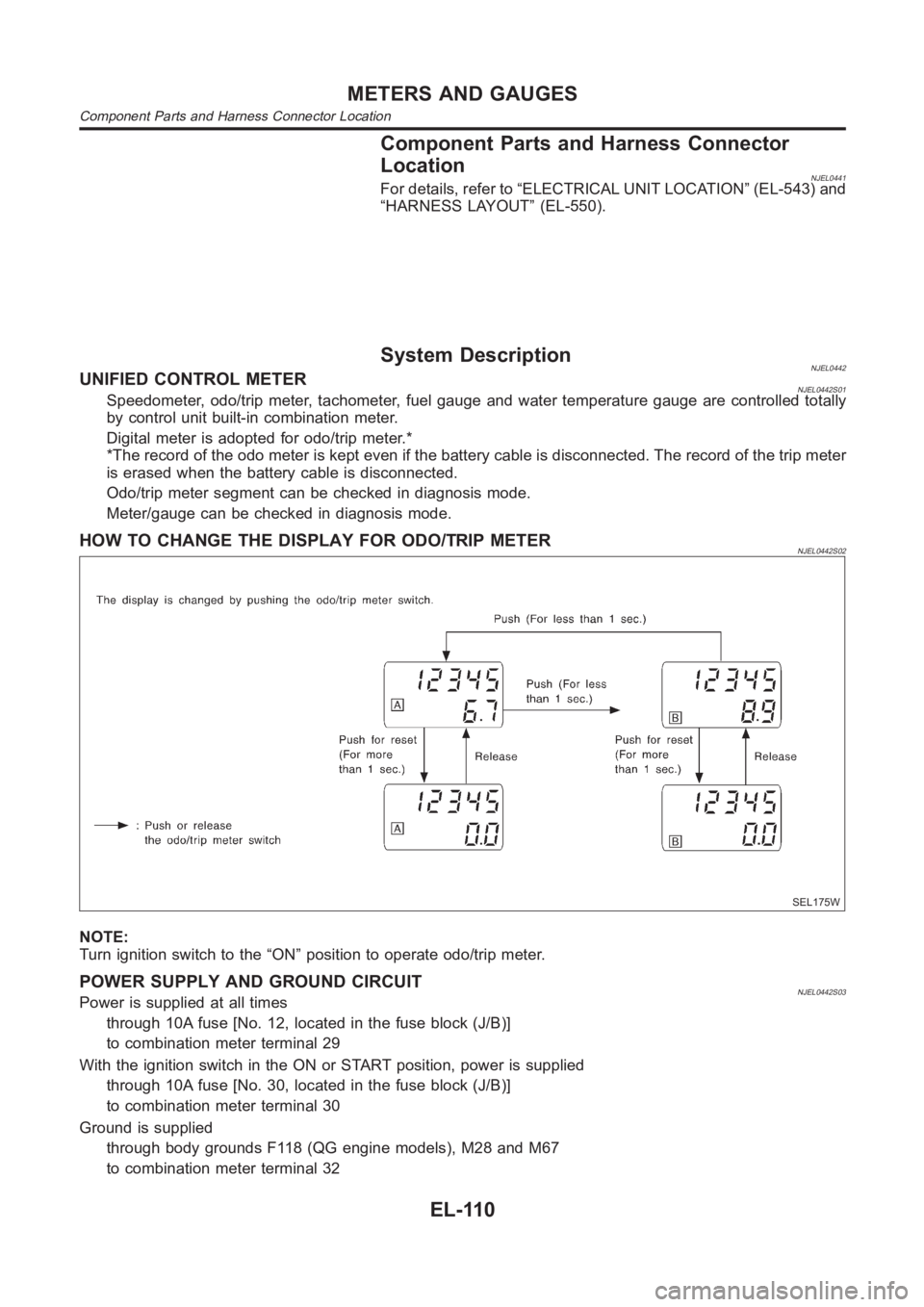

HOW TO CHANGE THE DISPLAY FOR ODO/TRIP METERNJEL0442S02

SEL175W

NOTE:

Turn ignition switch to the “ON” position to operate odo/trip meter.

POWER SUPPLY AND GROUND CIRCUITNJEL0442S03Power is supplied at all times

through 10A fuse [No. 12, located in the fuse block (J/B)]

to combination meter terminal 29

With the ignition switch in the ON or START position, power is supplied

through 10A fuse [No. 30, located in the fuse block (J/B)]

to combination meter terminal 30

Ground is supplied

through body grounds F118 (QG engine models), M28 and M67

to combination meter terminal 32

METERS AND GAUGES

Component Parts and Harness Connector Location

EL-110

Page 2447 of 3189

WATER TEMPERATURE GAUGE (QG AND YD ENGINE MODELS WITH COMMON RAIL)NJEL0442S09The water temperature gauge indicates the engine coolant temperature.

ECM provides a engine coolant temperature signal to combination meter forwater temperature gauge with

CAN communication line.

WATER TEMPERATURE GAUGE (YD ENGINE MODELS WITHOUT COMMON RAIL)NJEL0442S04The water temperature gauge indicates the engine coolant temperature. The reading on the gauge is based

on the resistance of the thermal transmitter.

As the temperature of the coolant increases, the resistance of the thermaltransmitter decreases. A variable

ground is supplied to terminal 35 of the combination meter for the water temperature gauge. The needle on

the gauge moves from “C” to “H”.

TACHOMETER (QG AND YD ENGINE MODELS WITH COMMON RAIL)NJEL0442S10The tachometer indicates engine speed in revolution per minutes (rpm). ECM provides an engine speed sig-

nal to combination meter for tachometer with CAN communication line.

TACHOMETER (YD ENGINE MODELS WITHOUT COMMON RAIL)NJEL0442S05The tachometer indicates engine speed in revolutions per minute (rpm).

The tachometer is regulated by a signal

from terminal 32 (Gasoline engine models) or 439 (Diesel engine models) ofthe ECM

to combination meter terminal 53 for the tachometer.

FUEL GAUGENJEL0442S06The fuel gauge indicates the approximate fuel level in the fuel tank.

The fuel gauge is regulated by a variable ground signal supplied

from body grounds F118 (QG engine models), M28 and M67

through terminals 33 and 32 of combination meter,

through terminal 1 of the fuel level sensor unit and

through terminal 4 of the fuel level sensor unit

to combination meter terminal 34 for the fuel gauge.

SPEEDOMETER (MODELS WITH ABS)NJEL0442S11The combination meter receives a signal from the ABS actuator and electricunit. The speedometer converts

the signal into the vehicle speed displayed.

SPEEDOMETER (MODELS WITHOUT ABS)NJEL0442S07The combination meter provides a voltage signal to the vehicle speed sensor for the speedometer.

The voltage is supplied

from combination meter terminal 13 for the speedometer

to terminal 1 of the vehicle speed sensor.

Ground is supplied

from body grounds F118 (QG engine models), M28 and M67

through terminals 32 and 14 of combination meter

to teminal 2 of the vehicle speed sensor.

The speedometer converts the voltage into the vehicle speed displayed.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

METERS AND GAUGES

System Description (Cont’d)

EL-111

Page 2453 of 3189

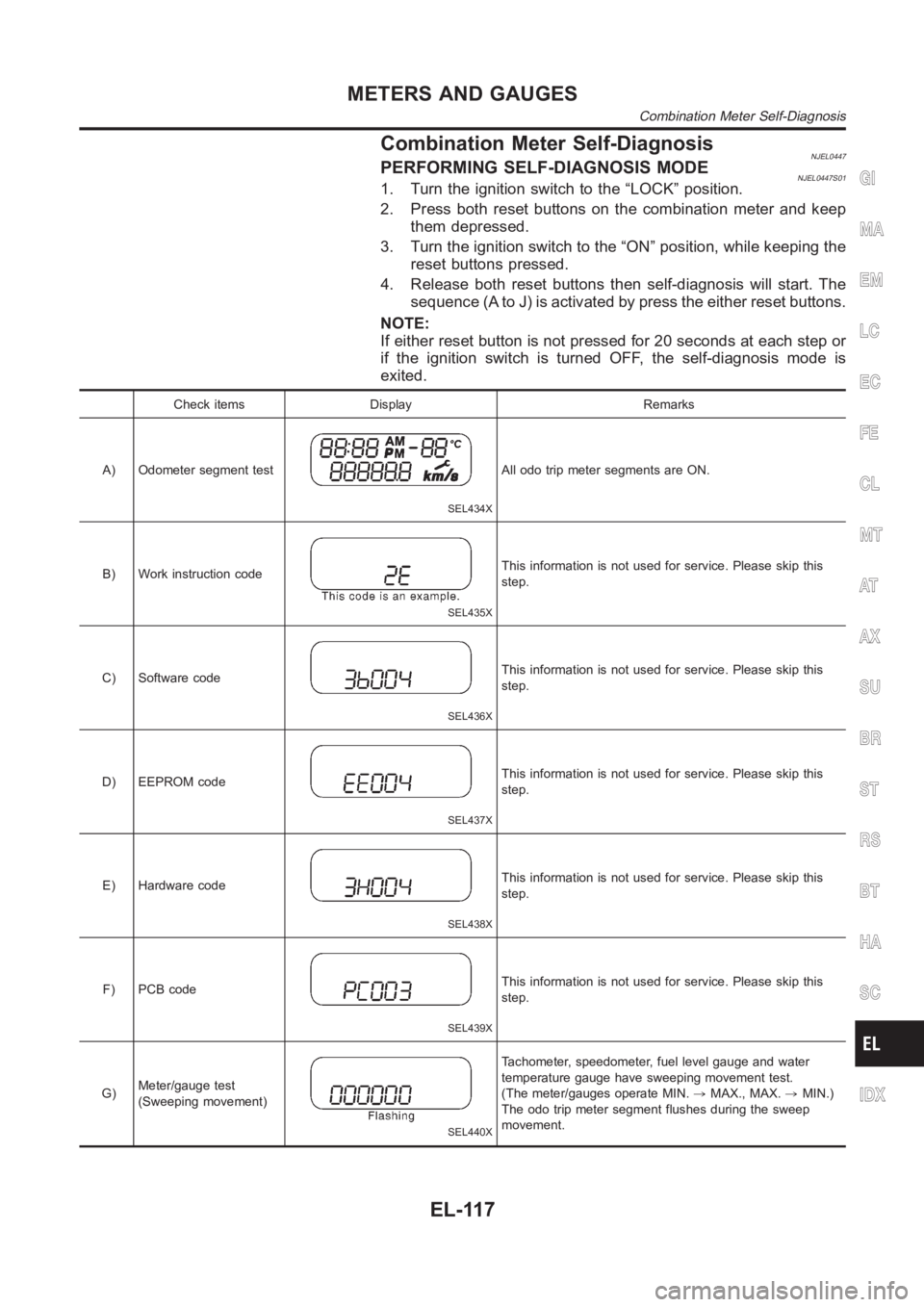

Combination Meter Self-DiagnosisNJEL0447PERFORMING SELF-DIAGNOSIS MODENJEL0447S011. Turn the ignition switch to the “LOCK” position.

2. Press both reset buttons on the combination meter and keep

them depressed.

3. Turn the ignition switch to the “ON” position, while keeping the

reset buttons pressed.

4. Release both reset buttons then self-diagnosis will start. The

sequence (A to J) is activated by press the either reset buttons.

NOTE:

If either reset button is not pressed for 20 seconds at each step or

if the ignition switch is turned OFF, the self-diagnosis mode is

exited.

Check items Display Remarks

A) Odometer segment test

SEL434X

All odo trip meter segments are ON.

B) Work instruction code

SEL435X

This information is not used for service. Please skip this

step.

C) Software code

SEL436X

This information is not used for service. Please skip this

step.

D) EEPROM code

SEL437X

This information is not used for service. Please skip this

step.

E) Hardware code

SEL438X

This information is not used for service. Please skip this

step.

F) PCB code

SEL439X

This information is not used for service. Please skip this

step.

G)Meter/gauge test

(Sweeping movement)

SEL440X

Tachometer, speedometer, fuel level gauge and water

temperature gauge have sweeping movement test.

(The meter/gauges operate MIN.,MAX., MAX.,MIN.)

The odo trip meter segment flushes during the sweep

movement.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

METERS AND GAUGES

Combination Meter Self-Diagnosis

EL-117

Page 2454 of 3189

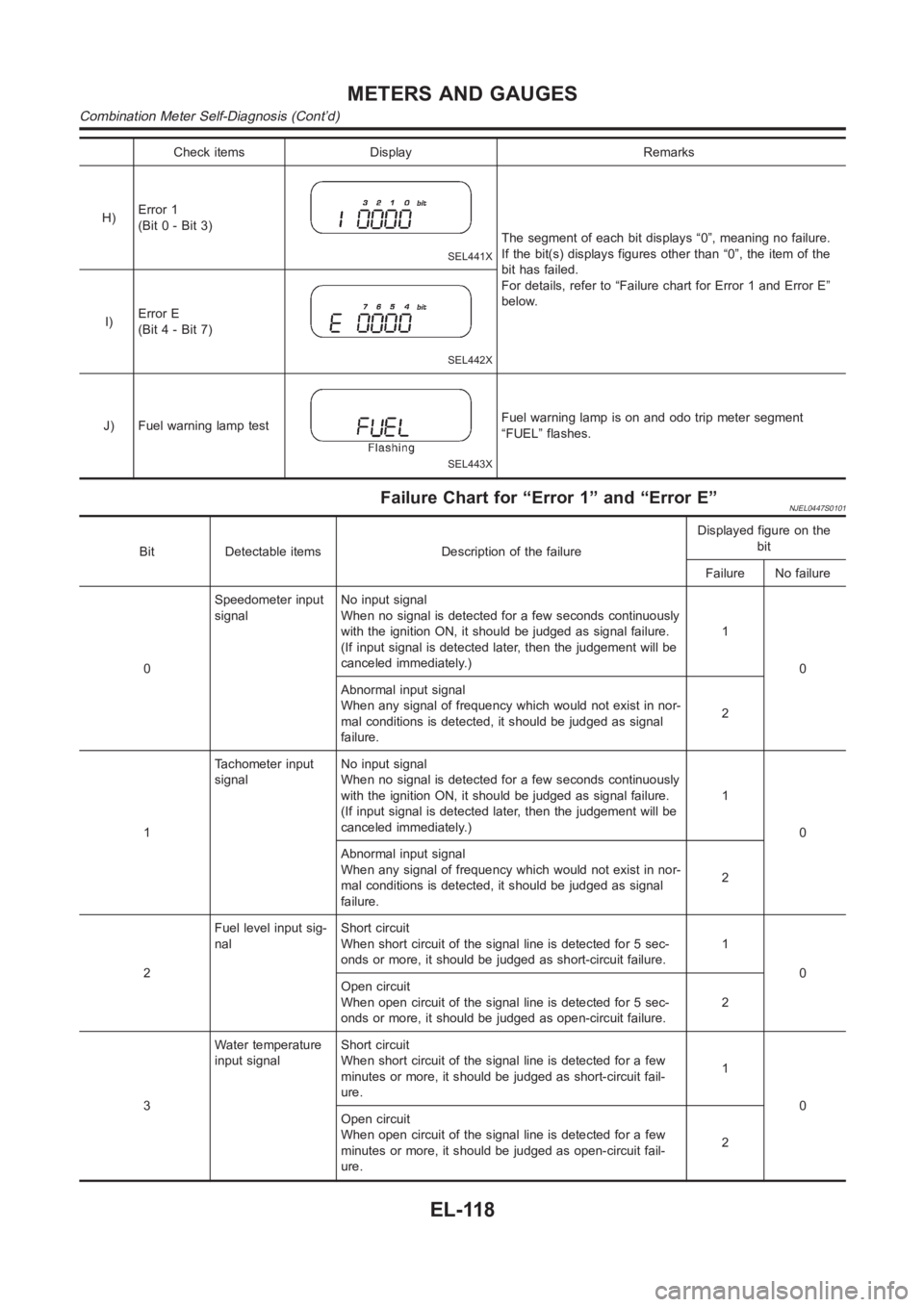

Check items Display Remarks

H)Error 1

(Bit 0 - Bit 3)

SEL441X

The segment of each bit displays “0”, meaning no failure.

If the bit(s) displays figures other than “0”, the item of the

bit has failed.

For details, refer to “Failure chart for Error 1 and Error E”

below.

I)Error E

(Bit 4 - Bit 7)

SEL442X

J) Fuel warning lamp test

SEL443X

Fuel warning lamp is on and odo trip meter segment

“FUEL” flashes.

Failure Chart for “Error 1” and “Error E”NJEL0447S0101

Bit Detectable items Description of the failureDisplayed figure on the

bit

Failure No failure

0Speedometer input

signalNo input signal

When no signal is detected for a few seconds continuously

with the ignition ON, it should be judged as signal failure.

(If input signal is detected later, then the judgement will be

canceled immediately.)1

0

Abnormal input signal

When any signal of frequency which would not exist in nor-

mal conditions is detected, it should be judged as signal

failure.2

1Tachometer input

signalNo input signal

When no signal is detected for a few seconds continuously

with the ignition ON, it should be judged as signal failure.

(If input signal is detected later, then the judgement will be

canceled immediately.)1

0

Abnormal input signal

When any signal of frequency which would not exist in nor-

mal conditions is detected, it should be judged as signal

failure.2

2Fuel level input sig-

nalShort circuit

When short circuit of the signal line is detected for 5 sec-

onds or more, it should be judged as short-circuit failure.1

0

Open circuit

When open circuit of the signal line is detected for 5 sec-

onds or more, it should be judged as open-circuit failure.2

3Water temperature

input signalShort circuit

When short circuit of the signal line is detected for a few

minutes or more, it should be judged as short-circuit fail-

ure.1

0

Open circuit

When open circuit of the signal line is detected for a few

minutes or more, it should be judged as open-circuit fail-

ure.2

METERS AND GAUGES

Combination Meter Self-Diagnosis (Cont’d)

EL-118