cooling fan NISSAN ALMERA N16 2003 Electronic Manual Online

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2846 of 3189

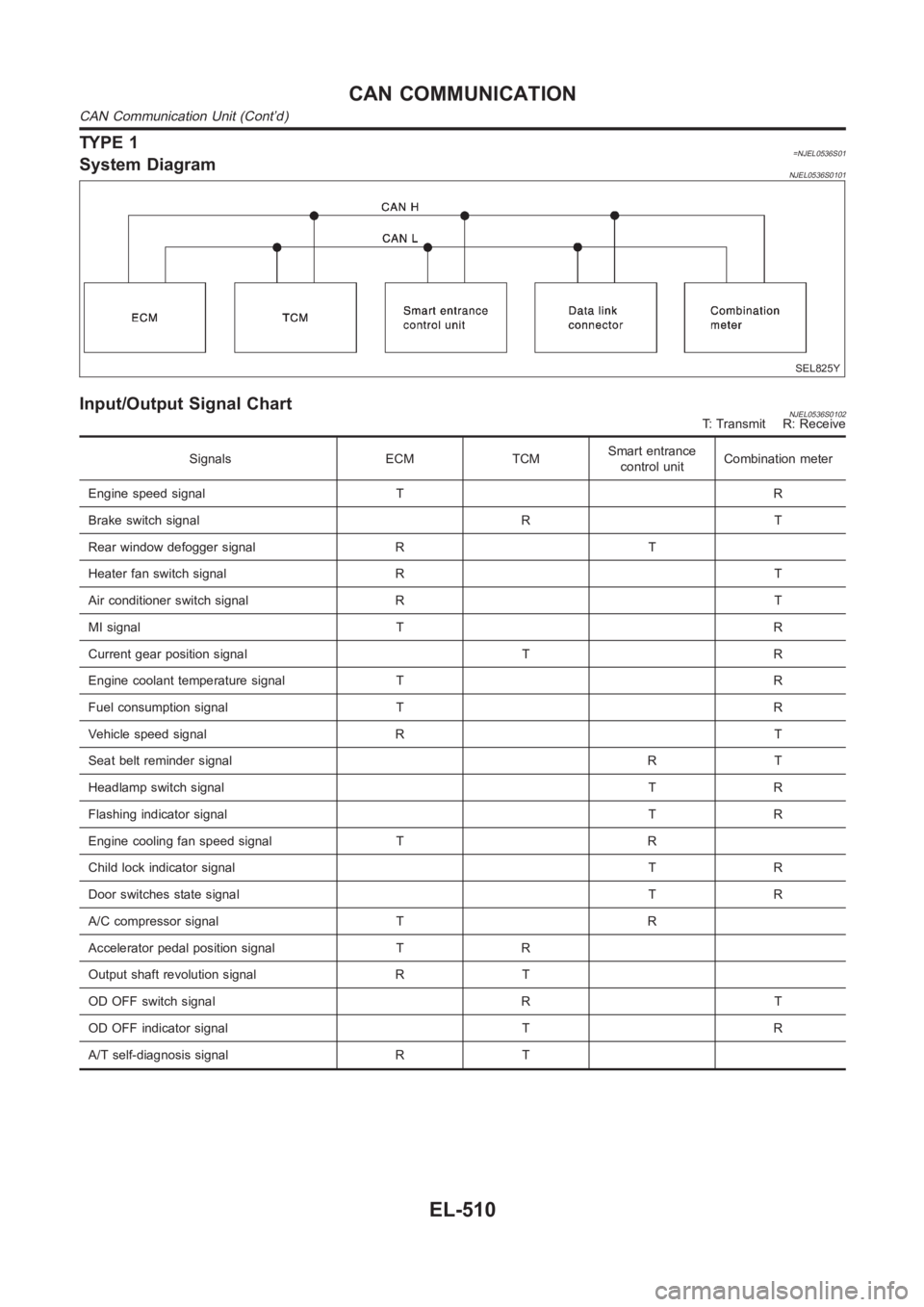

TYPE 1=NJEL0536S01System DiagramNJEL0536S0101

SEL825Y

Input/Output Signal ChartNJEL0536S0102T: Transmit R: Receive

Signals ECM TCMSmart entrance

control unitCombination meter

Engine speed signal T R

Brake switch signal R T

Rear window defogger signal R T

Heater fan switch signal R T

Air conditioner switch signal R T

MI signal T R

Current gear position signal T R

Engine coolant temperature signal T R

Fuel consumption signal T R

Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashing indicator signalTR

Engine cooling fan speed signal T R

Child lock indicator signalTR

Door switches state signal T R

A/C compressor signal T R

Accelerator pedal position signal T R

Output shaft revolution signal R T

OD OFF switch signal R T

OD OFF indicator signal T R

A/T self-diagnosis signal R T

CAN COMMUNICATION

CAN Communication Unit (Cont’d)

EL-510

Page 2847 of 3189

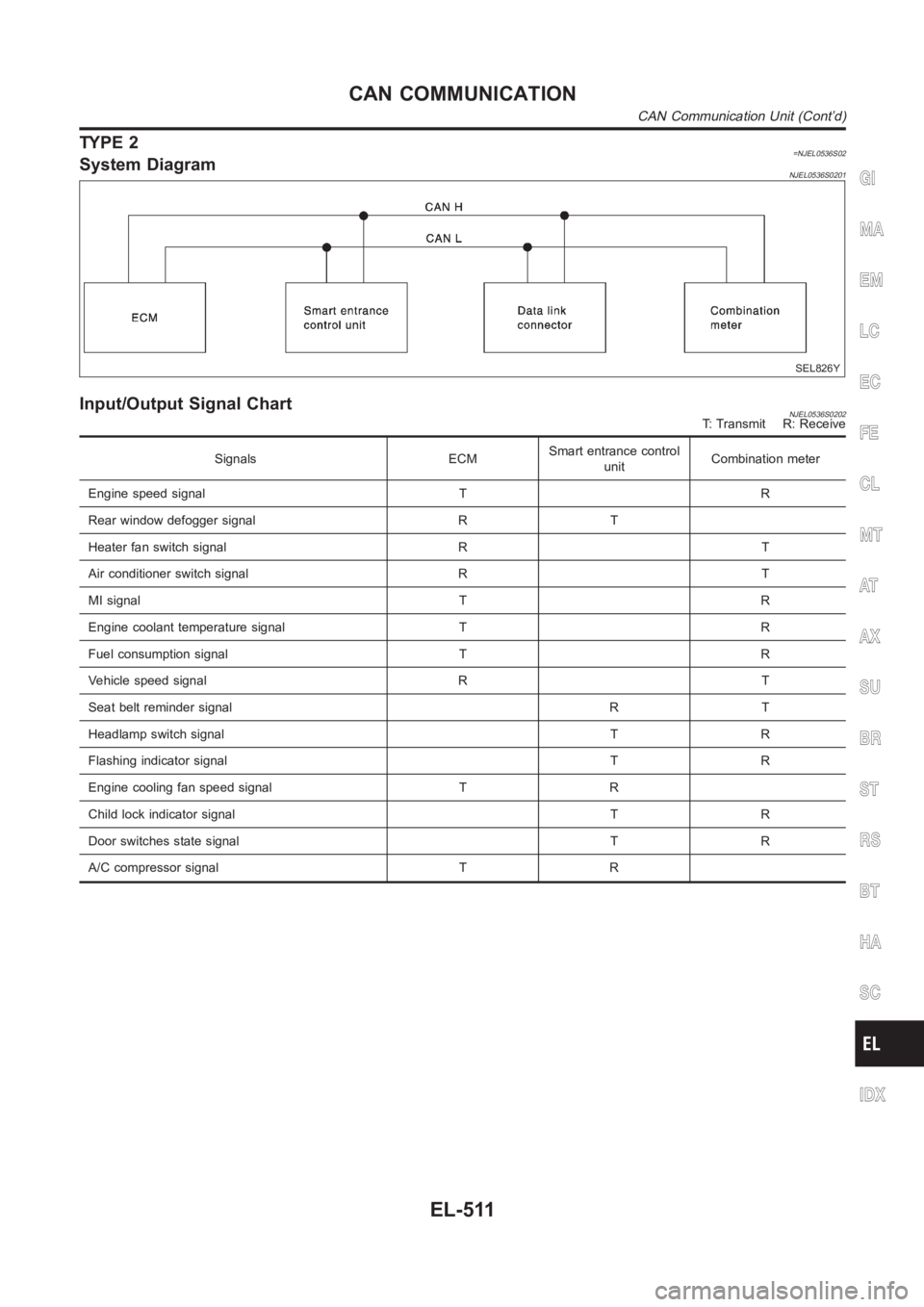

TYPE 2=NJEL0536S02System DiagramNJEL0536S0201

SEL826Y

Input/Output Signal ChartNJEL0536S0202T: Transmit R: Receive

Signals ECMSmart entrance control

unitCombination meter

Engine speed signal T R

Rear window defogger signal R T

Heater fan switch signal R T

Air conditioner switch signal R T

MI signal T R

Engine coolant temperature signal T R

Fuel consumption signal T R

Vehicle speed signal R T

Seat belt reminder signal R T

Headlamp switch signal T R

Flashing indicator signal T R

Engine cooling fan speed signal T R

Child lock indicator signal T R

Door switches state signal T R

A/C compressor signal T R

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

CAN COMMUNICATION

CAN Communication Unit (Cont’d)

EL-511

Page 2935 of 3189

NJEL0311

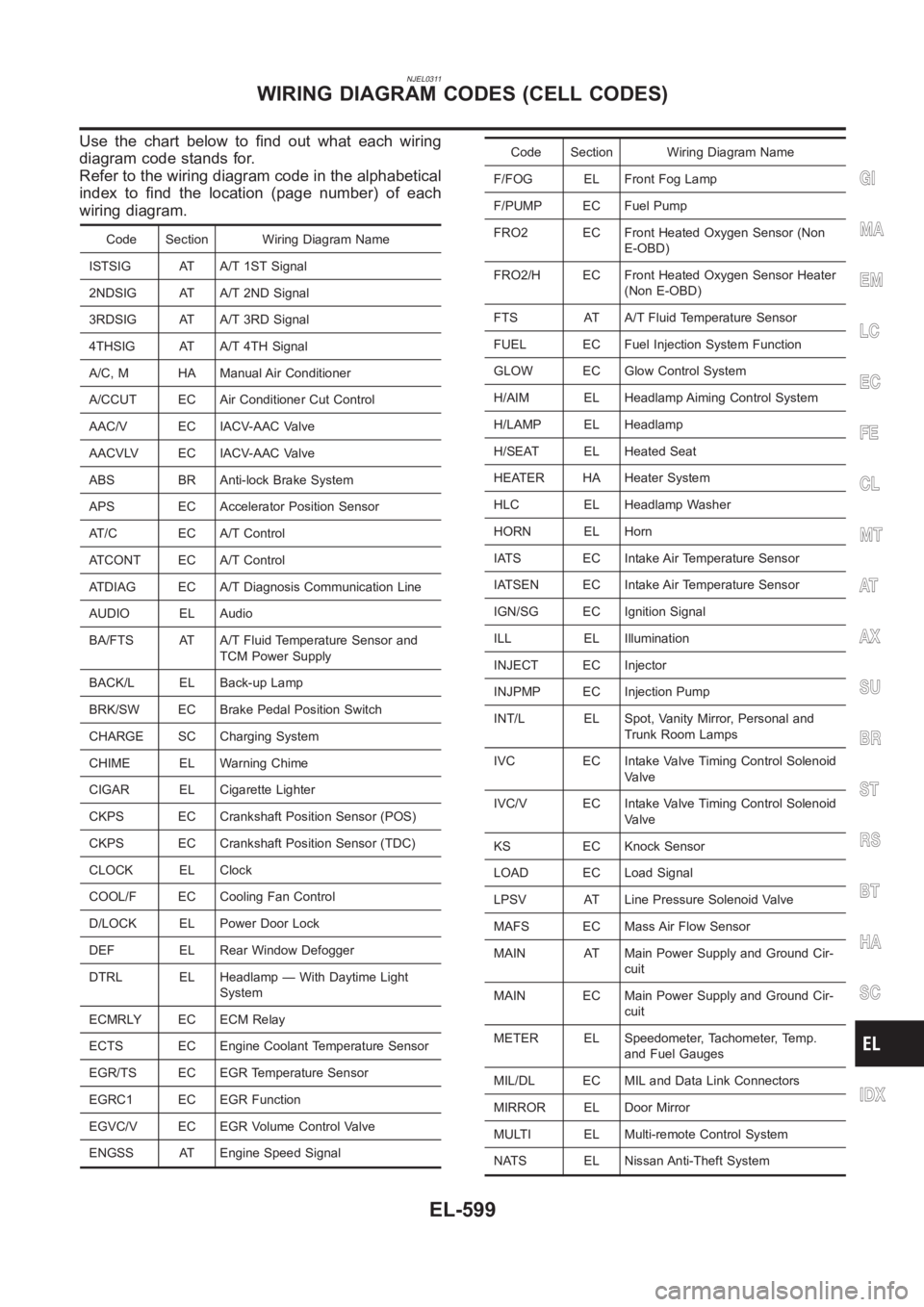

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

ISTSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, M HA Manual Air Conditioner

A/CCUT EC Air Conditioner Cut Control

AAC/V EC IACV-AAC Valve

AACVLV EC IACV-AAC Valve

ABS BR Anti-lock Brake System

APS EC Accelerator Position Sensor

AT/C EC A/T Control

ATCONT EC A/T Control

ATDIAG EC A/T Diagnosis Communication Line

AUDIO EL Audio

BA/FTS AT A/T Fluid Temperature Sensor and

TCM Power Supply

BACK/L EL Back-up Lamp

BRK/SW EC Brake Pedal Position Switch

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CKPS EC Crankshaft Position Sensor (POS)

CKPS EC Crankshaft Position Sensor (TDC)

CLOCK EL Clock

COOL/F EC Cooling Fan Control

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp — With Daytime Light

System

ECMRLY EC ECM Relay

ECTS EC Engine Coolant Temperature Sensor

EGR/TS EC EGR Temperature Sensor

EGRC1 EC EGR Function

EGVC/V EC EGR Volume Control Valve

ENGSS AT Engine Speed Signal

Code Section Wiring Diagram Name

F/FOG EL Front Fog Lamp

F/PUMP EC Fuel Pump

FRO2 EC Front Heated Oxygen Sensor (Non

E-OBD)

FRO2/H EC Front Heated Oxygen Sensor Heater

(Non E-OBD)

FTS AT A/T Fluid Temperature Sensor

FUEL EC Fuel Injection System Function

GLOW EC Glow Control System

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

H/SEAT EL Heated Seat

HEATER HA Heater System

HLC EL Headlamp Washer

HORN EL Horn

IATS EC Intake Air Temperature Sensor

IATSEN EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INJPMP EC Injection Pump

INT/L EL Spot, Vanity Mirror, Personal and

Trunk Room Lamps

IVC EC Intake Valve Timing Control Solenoid

Valve

IVC/V EC Intake Valve Timing Control Solenoid

Valve

KS EC Knock Sensor

LOAD EC Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground Cir-

cuit

MAIN EC Main Power Supply and Ground Cir-

cuit

METER EL Speedometer, Tachometer, Temp.

and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL Nissan Anti-Theft System

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WIRING DIAGRAM CODES (CELL CODES)

EL-599

Page 2954 of 3189

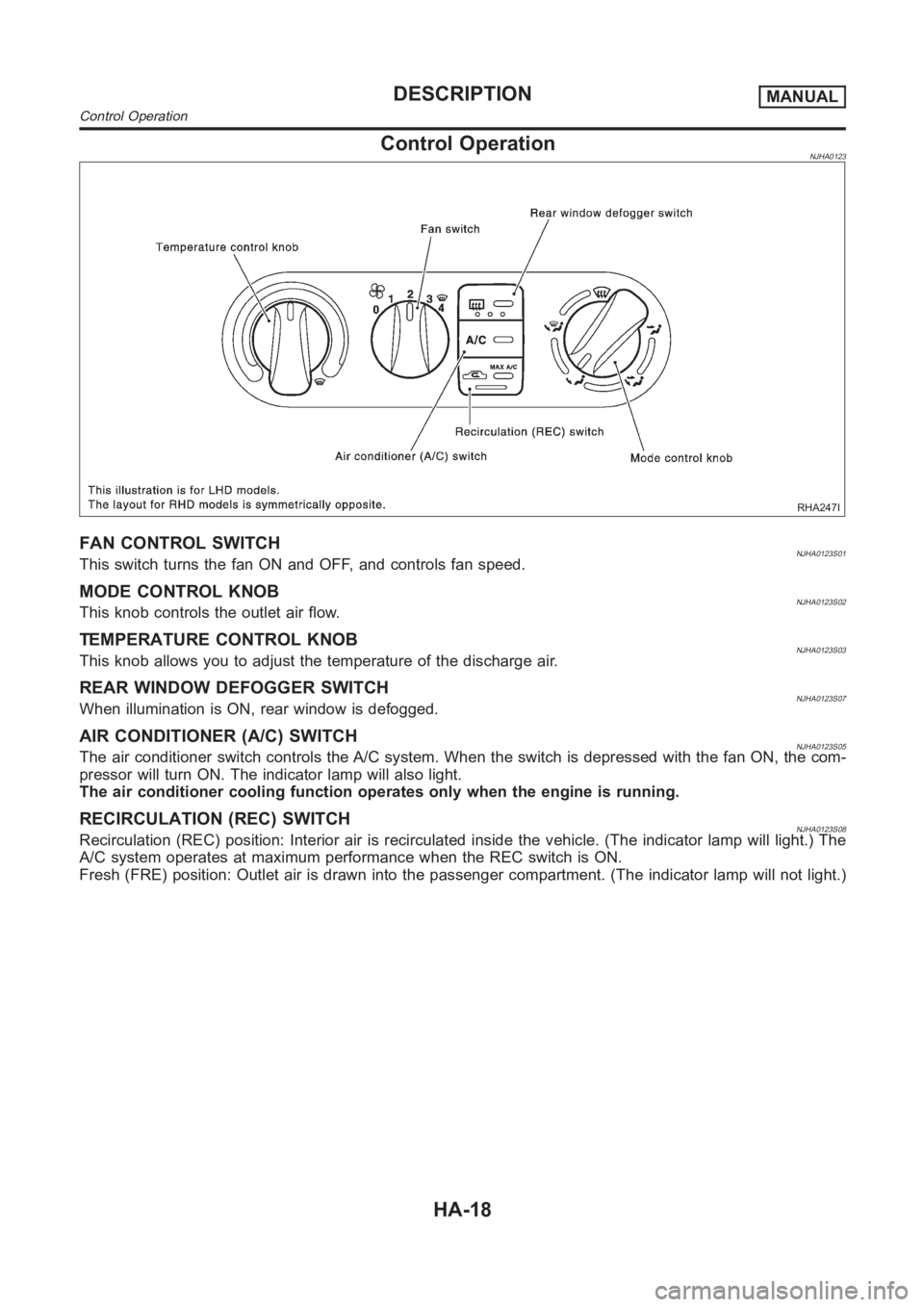

Control OperationNJHA0123

RHA247I

FAN CONTROL SWITCHNJHA0123S01This switch turns the fan ON and OFF, and controls fan speed.

MODE CONTROL KNOBNJHA0123S02This knob controls the outlet air flow.

TEMPERATURE CONTROL KNOBNJHA0123S03This knob allows you to adjust the temperature of the discharge air.

REAR WINDOW DEFOGGER SWITCHNJHA0123S07When illumination is ON, rear window is defogged.

AIR CONDITIONER (A/C) SWITCHNJHA0123S05The air conditioner switch controls the A/C system. When the switch is depressed with the fan ON, the com-

pressor will turn ON. The indicator lamp will also light.

The air conditioner cooling function operates only when the engine is running.

RECIRCULATION (REC) SWITCHNJHA0123S08Recirculation (REC) position: Interior air is recirculated inside the vehicle. (The indicator lamp will light.) The

A/C system operates at maximum performance when the REC switch is ON.

Fresh (FRE) position: Outlet air is drawn into the passenger compartment.(The indicator lamp will not light.)

DESCRIPTIONMANUAL

Control Operation

HA-18

Page 2970 of 3189

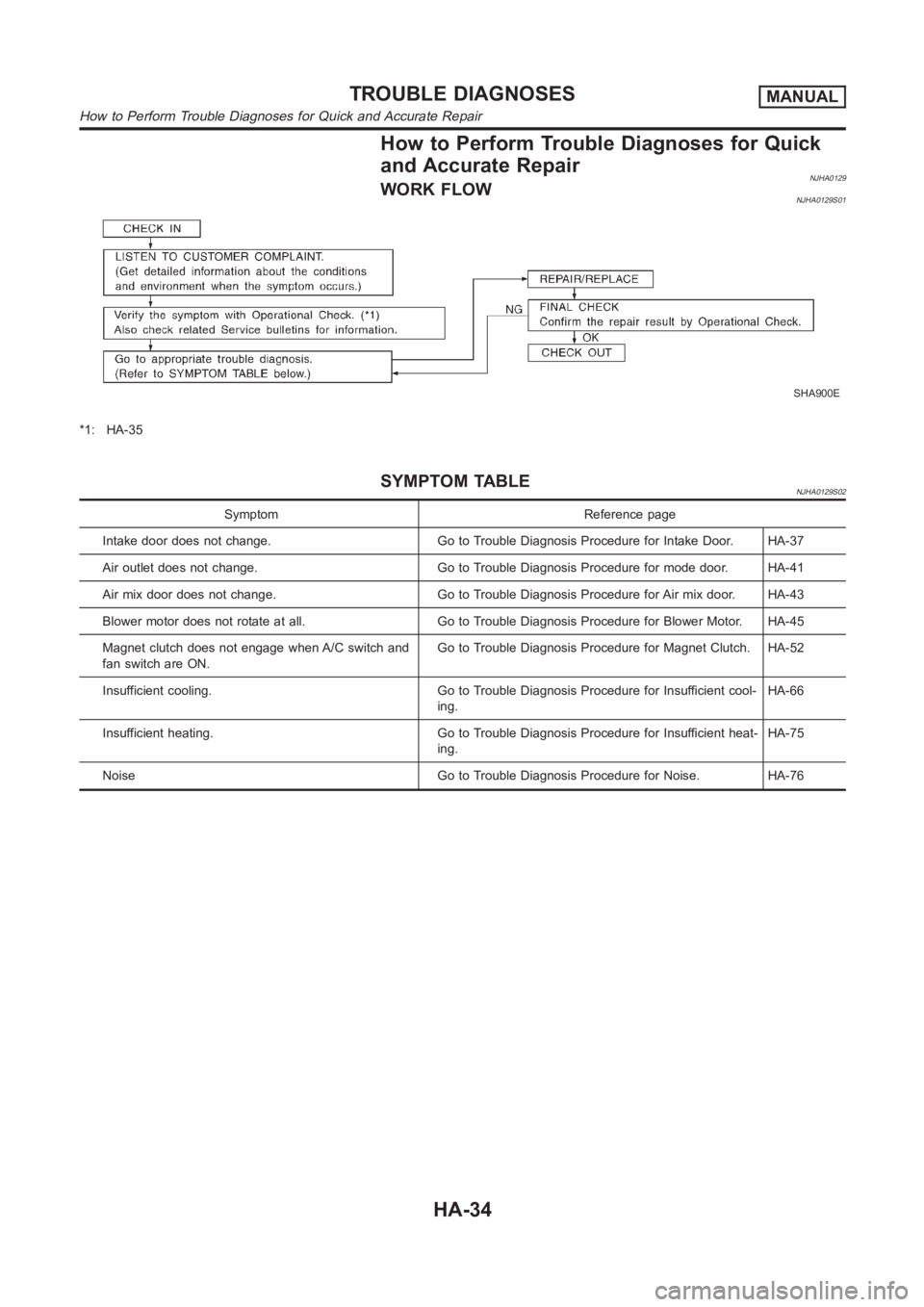

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

NJHA0129WORK FLOWNJHA0129S01

SHA900E

*1: HA-35

SYMPTOM TABLENJHA0129S02

Symptom Reference page

Intake door does not change. Go to Trouble Diagnosis Procedure for Intake Door. HA-37

Air outlet does not change. Go to Trouble Diagnosis Procedure for mode door. HA-41

Air mix door does not change. Go to Trouble Diagnosis Procedure for Air mix door. HA-43

Blower motor does not rotate at all. Go to Trouble Diagnosis Procedure for Blower Motor. HA-45

Magnet clutch does not engage when A/C switch and

fan switch are ON.Go to Trouble Diagnosis Procedure for Magnet Clutch. HA-52

Insufficient cooling. Go to Trouble Diagnosis Procedure for Insufficient cool-

ing.HA-66

Insufficient heating. Go to Trouble Diagnosis Procedure for Insufficientheat-

ing.HA-75

Noise Go to Trouble Diagnosis Procedure for Noise. HA-76

TROUBLE DIAGNOSESMANUAL

How to Perform Trouble Diagnoses for Quick and Accurate Repair

HA-34

Page 2972 of 3189

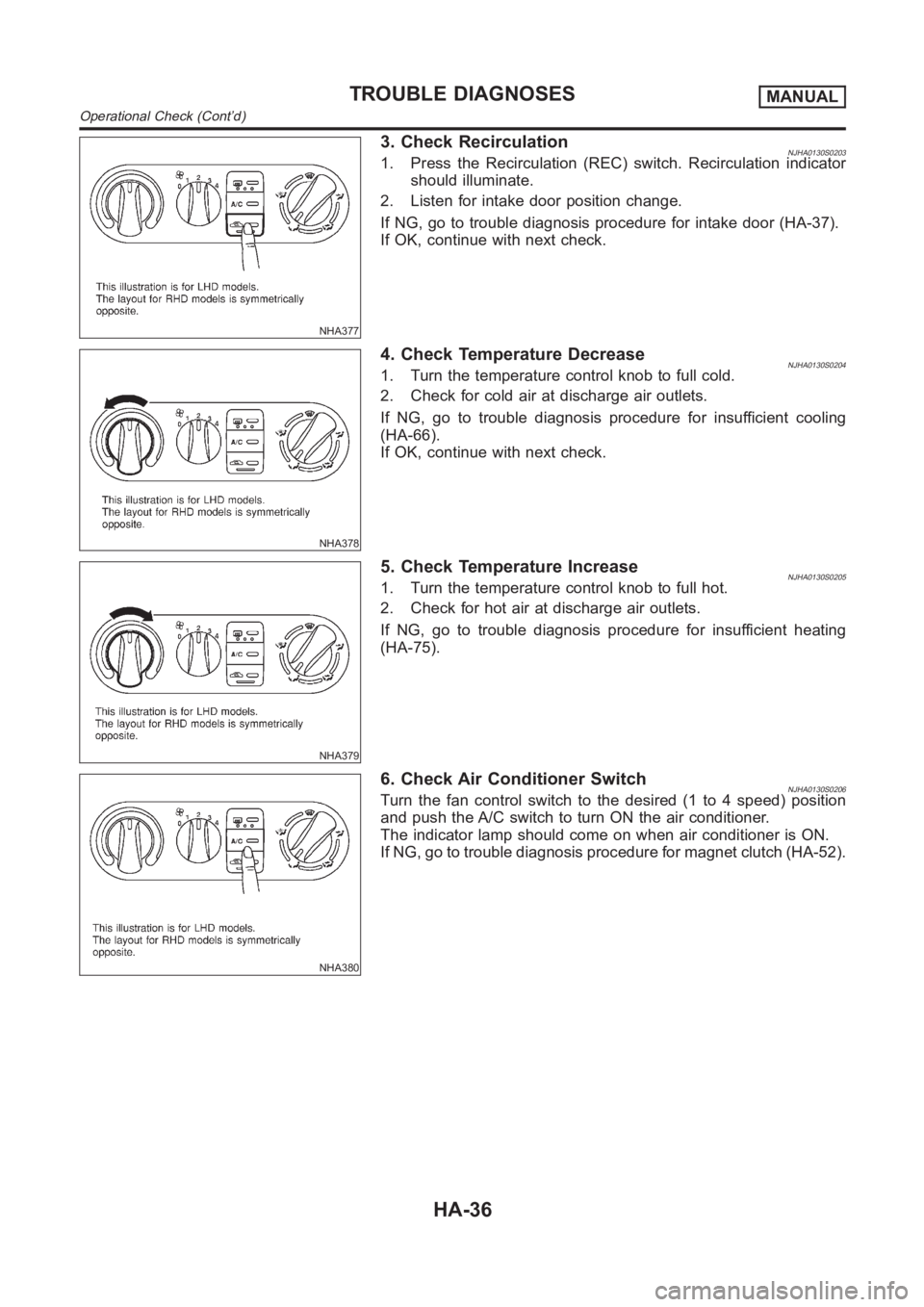

NHA377

3. Check RecirculationNJHA0130S02031. Press the Recirculation (REC) switch. Recirculation indicator

should illuminate.

2. Listen for intake door position change.

If NG, go to trouble diagnosis procedure for intake door (HA-37).

If OK, continue with next check.

NHA378

4. Check Temperature DecreaseNJHA0130S02041. Turn the temperature control knob to full cold.

2. Check for cold air at discharge air outlets.

If NG, go to trouble diagnosis procedure for insufficient cooling

(HA-66).

If OK, continue with next check.

NHA379

5. Check Temperature IncreaseNJHA0130S02051. Turn the temperature control knob to full hot.

2. Check for hot air at discharge air outlets.

If NG, go to trouble diagnosis procedure for insufficient heating

(HA-75).

NHA380

6. Check Air Conditioner SwitchNJHA0130S0206Turn the fan control switch to the desired (1 to 4 speed) position

and push the A/C switch to turn ON the air conditioner.

The indicator lamp should come on when air conditioner is ON.

If NG, go to trouble diagnosis procedure for magnet clutch (HA-52).

TROUBLE DIAGNOSESMANUAL

Operational Check (Cont’d)

HA-36

Page 3005 of 3189

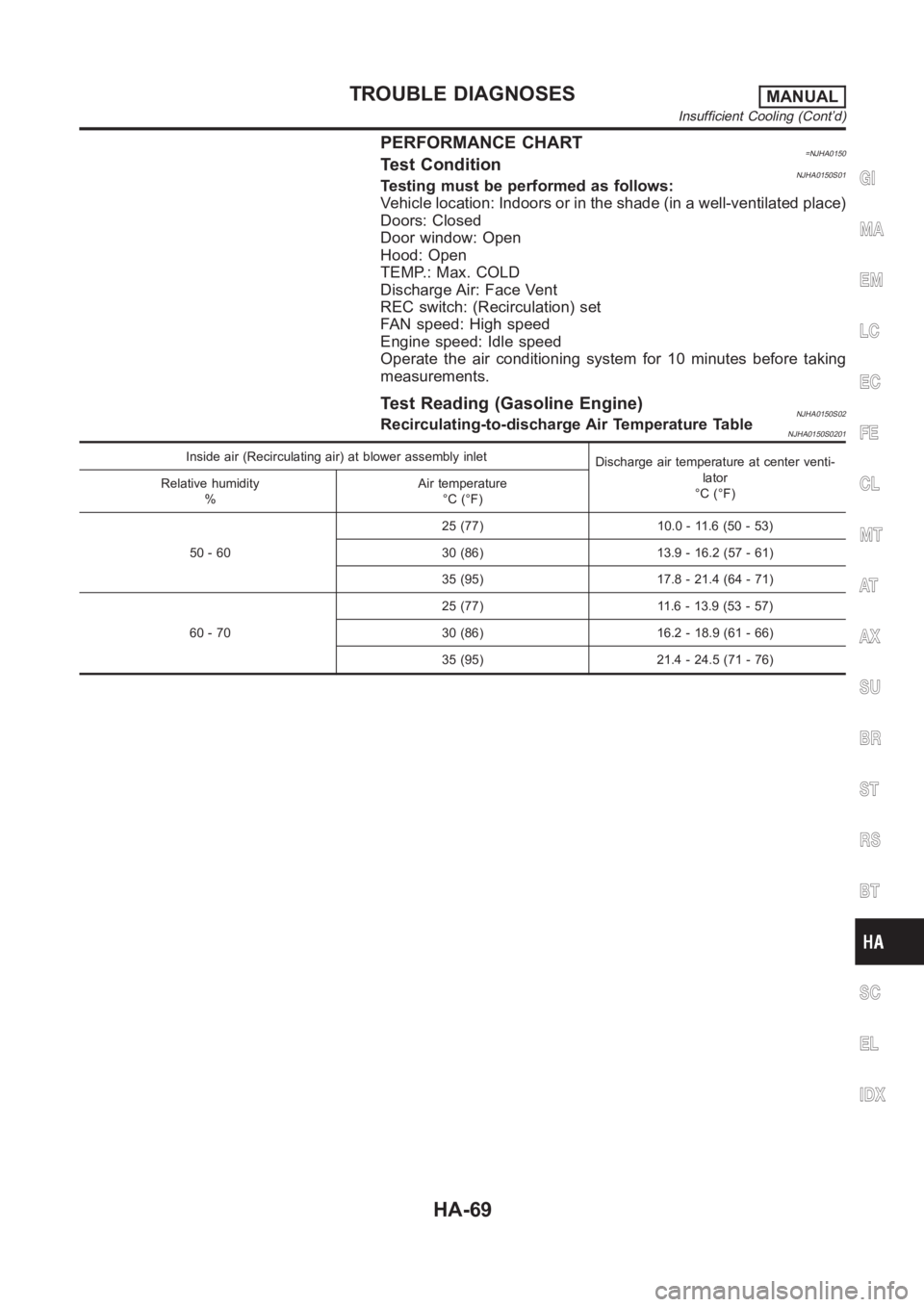

PERFORMANCE CHART=NJHA0150Test ConditionNJHA0150S01Testing must be performed as follows:

Vehicle location: Indoors or in the shade (in a well-ventilated place)

Doors: Closed

Door window: Open

Hood: Open

TEMP.: Max. COLD

Discharge Air: Face Vent

REC switch: (Recirculation) set

FAN speed: High speed

Engine speed: Idle speed

Operate the air conditioning system for 10 minutes before taking

measurements.

Test Reading (Gasoline Engine)NJHA0150S02Recirculating-to-discharge Air Temperature TableNJHA0150S0201

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center venti-

lator

°C (°F) Relative humidity

%Air temperature

°C (°F)

50 - 6025 (77) 10.0 - 11.6 (50 - 53)

30 (86) 13.9 - 16.2 (57 - 61)

35 (95) 17.8 - 21.4 (64 - 71)

60 - 7025 (77) 11.6 - 13.9 (53 - 57)

30 (86) 16.2 - 18.9 (61 - 66)

35 (95) 21.4 - 24.5 (71 - 76)

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSESMANUAL

Insufficient Cooling (Cont’d)

HA-69

Page 3007 of 3189

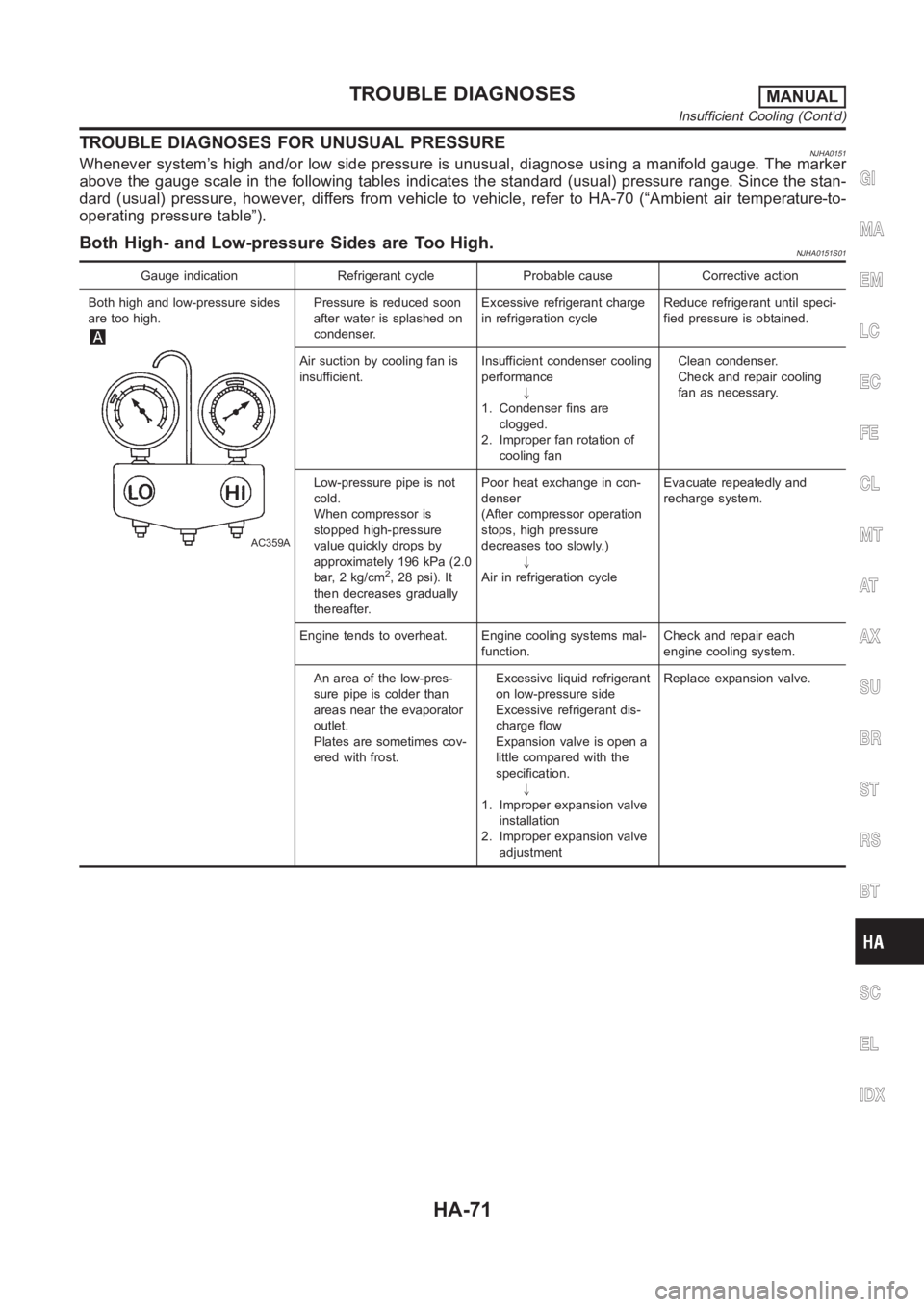

TROUBLE DIAGNOSES FOR UNUSUAL PRESSURENJHA0151Whenever system’s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the stan-

dard (usual) pressure, however, differs from vehicle to vehicle, refer toHA-70 (“Ambient air temperature-to-

operating pressure table”).

Both High- and Low-pressure Sides are Too High.NJHA0151S01

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure sides

are too high.

AC359A

Pressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge

in refrigeration cycleReduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

"

1. Condenser fins are

clogged.

2. Improper fan rotation of

cooling fanClean condenser.

Check and repair cooling

fan as necessary.

Low-pressure pipe is not

cold.

When compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa (2.0

bar, 2 kg/cm

2, 28 psi). It

then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure

decreases too slowly.)

"

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems mal-

function.Check and repair each

engine cooling system.

An area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

Plates are sometimes cov-

ered with frost.Excessive liquid refrigerant

on low-pressure side

Excessive refrigerant dis-

charge flow

Expansion valve is open a

little compared with the

specification.

"

1. Improper expansion valve

installation

2. Improper expansion valve

adjustmentReplace expansion valve.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

TROUBLE DIAGNOSESMANUAL

Insufficient Cooling (Cont’d)

HA-71

Page 3029 of 3189

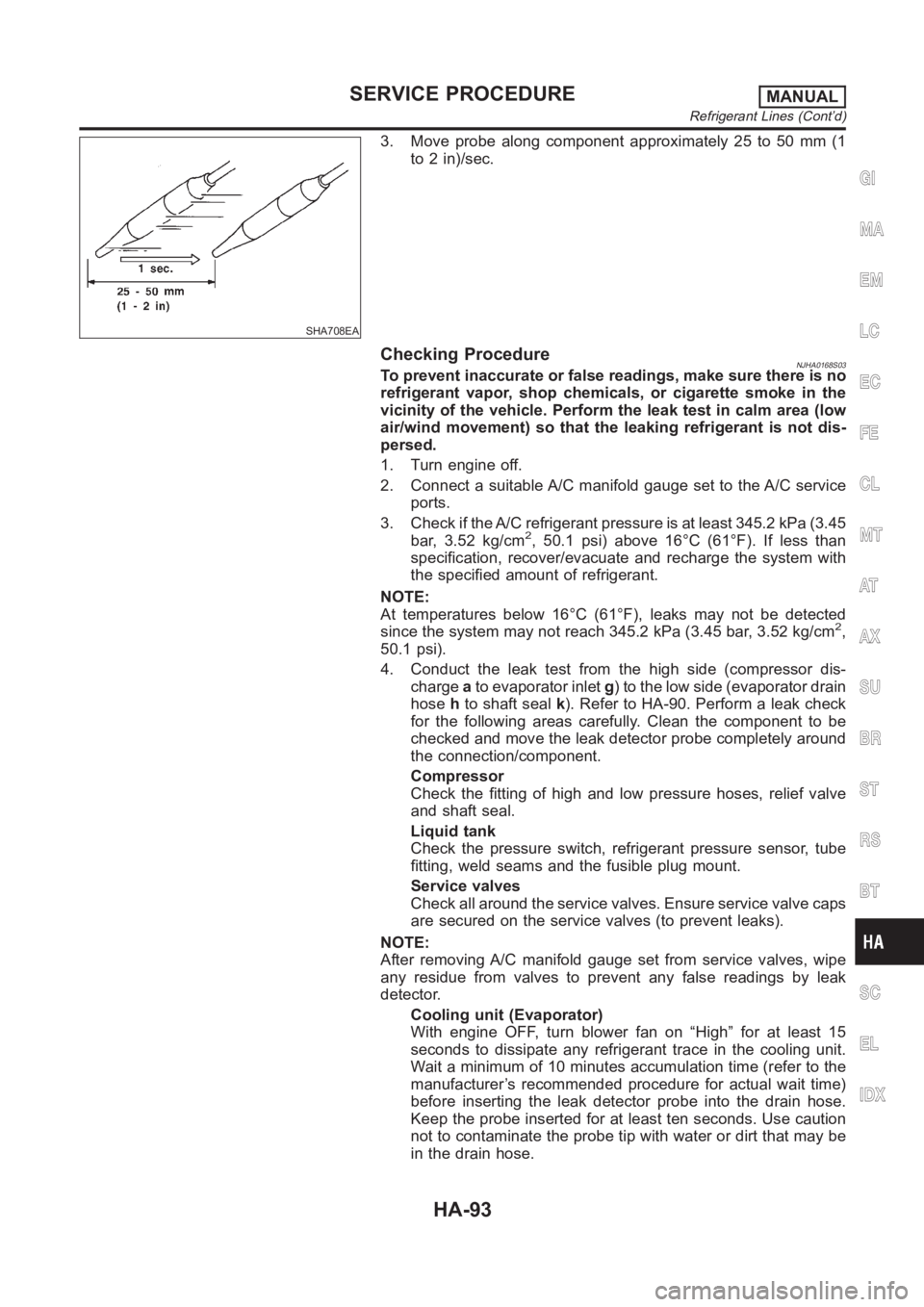

SHA708EA

3. Move probe along component approximately 25 to 50 mm (1

to 2 in)/sec.

Checking ProcedureNJHA0168S03To prevent inaccurate or false readings, make sure there is no

refrigerant vapor, shop chemicals, or cigarette smoke in the

vicinity of the vehicle. Perform the leak test in calm area (low

air/wind movement) so that the leaking refrigerant is not dis-

persed.

1. Turn engine off.

2. Connect a suitable A/C manifold gauge set to the A/C service

ports.

3. Check if the A/C refrigerant pressure is at least 345.2 kPa (3.45

bar, 3.52 kg/cm

2, 50.1 psi) above 16°C (61°F). If less than

specification, recover/evacuate and recharge the system with

the specified amount of refrigerant.

NOTE:

At temperatures below 16°C (61°F), leaks may not be detected

since the system may not reach 345.2 kPa (3.45 bar, 3.52 kg/cm

2,

50.1 psi).

4. Conduct the leak test from the high side (compressor dis-

chargeato evaporator inletg) to the low side (evaporator drain

hosehto shaft sealk). Refer to HA-90. Perform a leak check

for the following areas carefully. Clean the component to be

checked and move the leak detector probe completely around

the connection/component.

Compressor

Check the fitting of high and low pressure hoses, relief valve

and shaft seal.

Liquid tank

Check the pressure switch, refrigerant pressure sensor, tube

fitting, weld seams and the fusible plug mount.

Service valves

Check all around the service valves. Ensure service valve caps

are secured on the service valves (to prevent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe

any residue from valves to prevent any false readings by leak

detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15

seconds to dissipate any refrigerant trace in the cooling unit.

Wait a minimum of 10 minutes accumulation time (refer to the

manufacturer’s recommended procedure for actual wait time)

before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least ten seconds. Use caution

not to contaminate the probe tip with water or dirt that may be

in the drain hose.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

SC

EL

IDX

SERVICE PROCEDUREMANUAL

Refrigerant Lines (Cont’d)

HA-93

Page 3178 of 3189

COOL/F - Wiring diagram

(QG engine)................................EC-328, EC-601

COOL/F - Wiring diagram (YD engine) ........EC-130

Coolant mixture ratio......................................MA-21

Cooling circuit (engine).............................LC-12, 36

Cooling fan control (YD engine)...................EC-130

Cooling fan control system .......................LC-17, 42

Cooling fan motor (QG engine) .....EC-335, EC-608

Coupling sleeve (M/T)........................MT-31, 55, 93

Crankcase emission control system -

See positive crankcase ventilation

(YD engine).................................................EC-19

Crankcase ventilation system - See

Positive crankcase ventilation

(QG engine)................................EC-403, EC-722

Crankcase ventilation system - See

Positive crankcase ventilation

(YD engine).................................................EC-19

Crankshaft (QG engine).................................EM-71

Crankshaft (YD engine) .................................EM-75

Crankshaft position sensor (POS)

(QG engine)................................EC-235, EC-556

Crankshaft position sensor (TDC)

(YD engine).................................................EC-99

Cylinder block (QG engine) ...........................EM-70

Cylinder block (YD engine) ............................EM-66

Cylinder block boring (QG engine) ................EM-88

Cylinder block boring(QR) .............................EM-89

Cylinder head (QG engine)............................EM-57

Cylinder head (YD engine) ............................EM-45

Cylinder head bolt tightening

(QG engine)................................................EM-59

D

Data link connector

(QG engine) ...EC-398, EC-399, EC-717, EC-718

Data link connector for Consult

(QG engine)..................................EC-90, EC-468

Data link connector for Consult

(YD engine).................................................EC-39

Daytime light system.......................................EL-46

DEF - Wiring diagram ...................................EL-176

Diagnosis sensor unit .....................................RS-26

Diagnostic trouble code (DTC) for OBD

system (QG engine) ......................EC-10, EC-39,

EC-407, EC-430

Diagnostic trouble code (DTC) for OBD

system (YD engine) ................................EC-4, 34

Diagnostic trouble code (DTC) inspec-

tion priority chart (QG engine) .....EC-62, EC-441

Differential gear (FF M/T) ....MT-31, 43, 55, 93, 107

Dimensions <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.GI-44

Dome light - See Interior lamp .......................EL-80

Door glass <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[.BT-17

Door lock <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..BT-21

Door mirror <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[.BT-72

Door trim <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011001100110011[..BT-39

Door, front <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011[..BT-16

Door, rear <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

11001100110011[..BT-16Drive belt (QG engine) ...................................EM-11

Drive shaft (front)............................................AX-10

Dropping resistor (A/T) ....................AT-171, AT-395

DTC work support (QG engine) .....................EC-97

Dual pressure switch (manual A/C) ...............HA-12

Dual pressure switch ......ATC-15, ATC-86, ATC-144

Duct and grilles...........................................ATC-131

E

ECCS-D control module

(YD engine) ........EC-66, 116, 175, 177, 181, 183

ECM input/output signal

(QG engine)..................................EC-81, EC-460

ECM input/output signal (YD engine) ............EC-66

ECM power supply

(QG engine) ...EC-111, EC-269, EC-488, EC-573

ECM/PW - Wiring diagram

(QG engine)................................EC-270, EC-574

ECTS - Wiring diagram

(QG engine)................................EC-147, EC-505

ECTS - Wiring diagram (YD engine)..............EC-84

EGR volume control valve (YD engine) .......EC-197

EGRC1 - Wiring diagram (YD engine) .........EC-199

Electric sun roof ............................................EL-249

Electric throttle control actuator

(QG engine) ................EC-277, EC-279, EC-292,

EC-577, EC-580, EC-593

Electrical diagnoses.........................................GI-22

Electrical load signal circuit

(QG engine)................................EC-393, EC-712

Electrical unit ................................................Foldout

Electrical units location .................................EL-543

Electronic fuel injection pump

(YD engine) ...............EC-25, 118, 124, 145, 151,

157, 163, 169, 185

Electronic ignition (EI) system

(QG engine)..................................EC-25, EC-420

Engine compartment .......................................BT-75

Engine control circuit diagram

(QG engine)..................................EC-79, EC-458

Engine control circuit diagram

(YD engine).................................................EC-14

Engine control component parts loca-

tion (QG engine)...........................EC-75, EC-454

Engine control component parts loca-

tion (YD engine) ..........................................EC-11

Engine control module (ECM)

(QG engine)................................EC-266, EC-570

Engine control module (ECM)

(YD engine) ........EC-66, 116, 175, 177, 181, 183

Engine control system diagram and

chart (QG engine) ........................EC-21, EC-416

Engine control system diagram and

chart (YD engine) .......................................EC-15

Engine coolant temperature sensor

(ECTS) (QG engine) ..................EC-145, EC-503

Engine coolant temperature sensor

(ECTS) (YD engine) ...................................EC-84

ALPHABETICAL INDEX

IDX-4