cooling fan NISSAN ALMERA N16 2003 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1190 of 3189

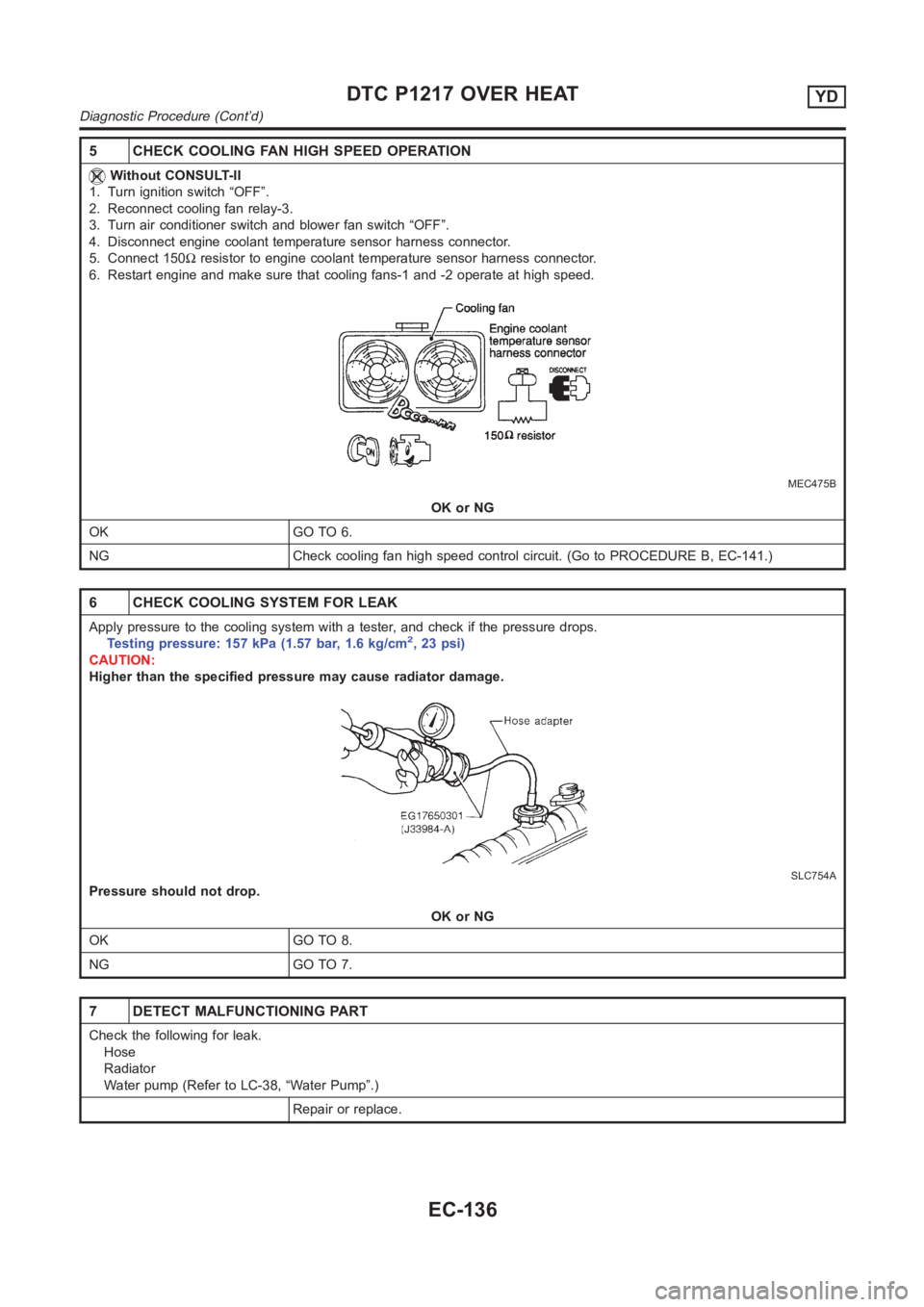

5 CHECK COOLING FAN HIGH SPEED OPERATION

Without CONSULT-II

1. Turn ignition switch “OFF”.

2. Reconnect cooling fan relay-3.

3. Turn air conditioner switch and blower fan switch “OFF”.

4. Disconnect engine coolant temperature sensor harness connector.

5. Connect 150Ωresistor to engine coolant temperature sensor harness connector.

6. Restart engine and make sure that cooling fans-1 and -2 operate at high speed.

MEC475B

OK or NG

OK GO TO 6.

NG Check cooling fan high speed control circuit. (Go to PROCEDURE B, EC-141.)

6 CHECK COOLING SYSTEM FOR LEAK

Apply pressure to the cooling system with a tester, and check if the pressure drops.

Testing pressure: 157 kPa (1.57 bar, 1.6 kg/cm2,23psi)

CAUTION:

Higher than the specified pressure may cause radiator damage.

SLC754A

Pressure should not drop.

OK or NG

OK GO TO 8.

NG GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following for leak.

Hose

Radiator

Water pump (Refer to LC-38, “Water Pump”.)

Repair or replace.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-136

Page 1192 of 3189

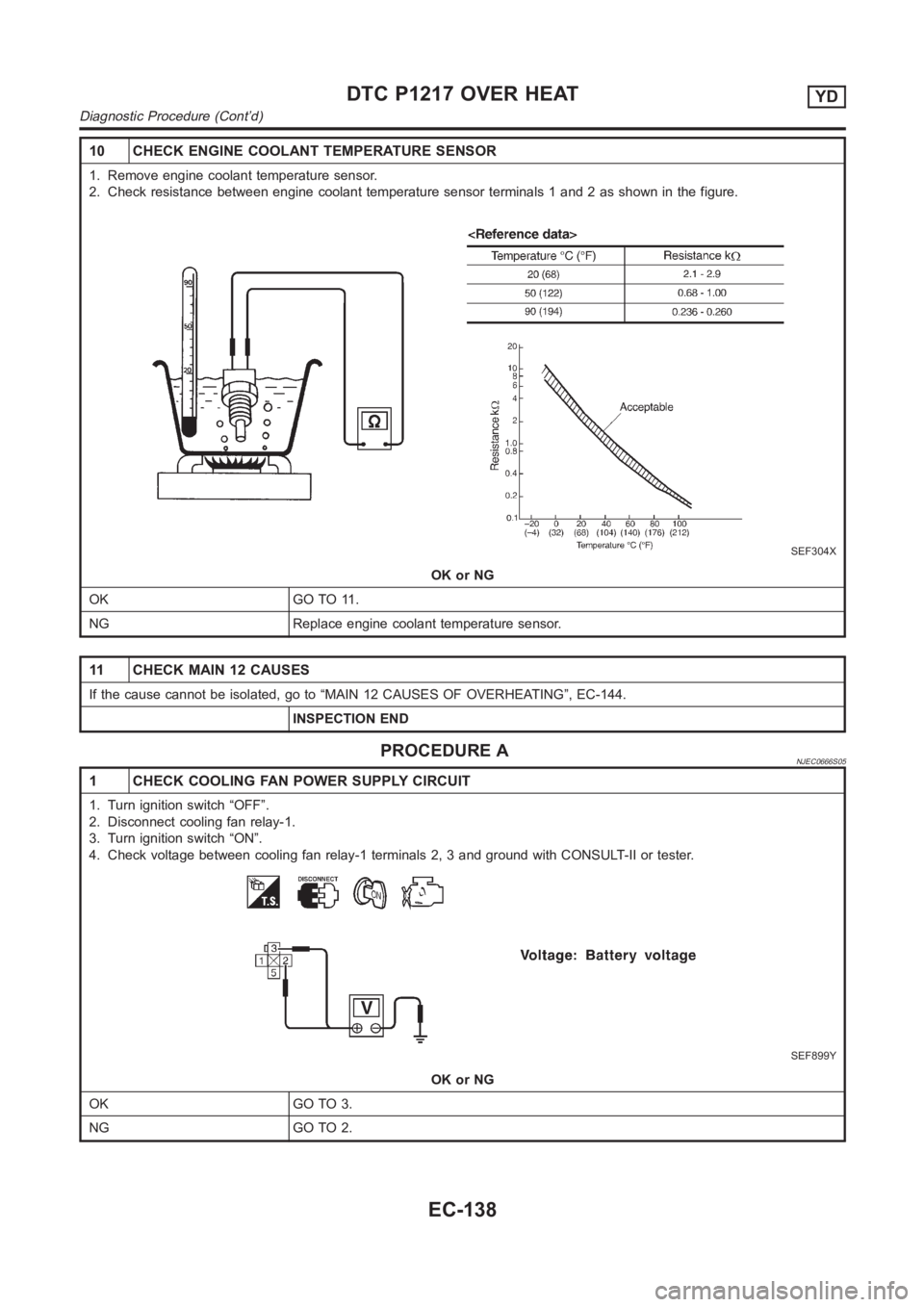

10 CHECK ENGINE COOLANT TEMPERATURE SENSOR

1. Remove engine coolant temperature sensor.

2. Check resistance between engine coolant temperature sensor terminals1 and 2 as shown in the figure.

SEF304X

OK or NG

OK GO TO 11.

NG Replace engine coolant temperature sensor.

11 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to “MAIN 12 CAUSES OF OVERHEATING”, EC-144.

INSPECTION END

PROCEDURE ANJEC0666S05

1 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan relay-1.

3. Turn ignition switch “ON”.

4. Check voltage between cooling fan relay-1 terminals 2, 3 and ground withCONSULT-II or tester.

SEF899Y

OK or NG

OK GO TO 3.

NG GO TO 2.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-138

Page 1193 of 3189

2 DETECT MALFUNCTIONING PART

Check the following.

Fuse block (J/B) connector E104

10A fuse

40A fusible link

Harness for open or short between cooling fan relay-1 and fuse

Harness for open or short between cooling fan relay-1 and battery

Repair open circuit or short to ground or short to power in harness or connectors.

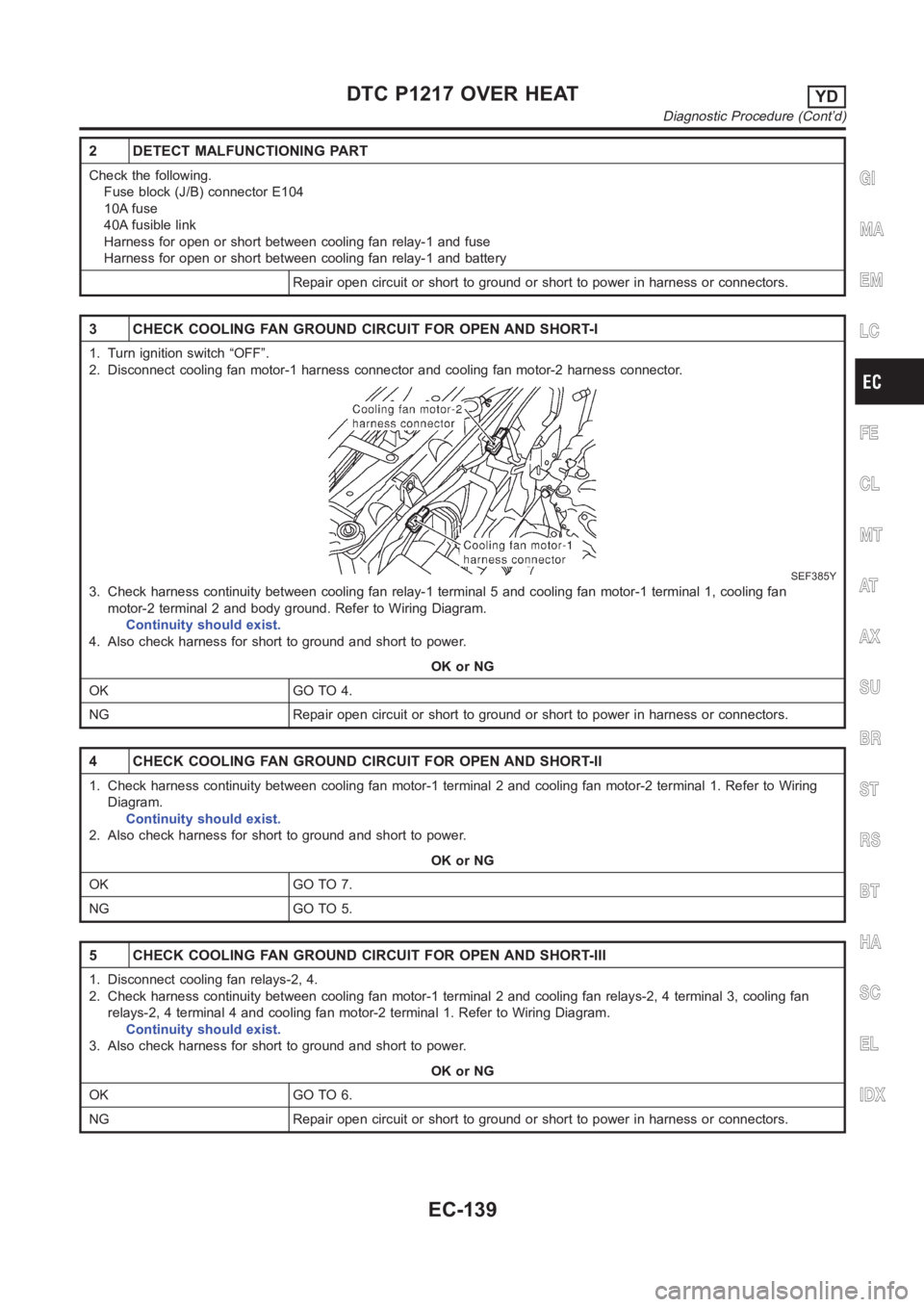

3 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-1 harness connector and cooling fan motor-2 harness connector.

SEF385Y

3. Check harness continuity between cooling fan relay-1 terminal 5 and cooling fan motor-1 terminal 1, cooling fan

motor-2 terminal 2 and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 4.

NG Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-II

1. Check harness continuity between cooling fan motor-1 terminal 2 and cooling fan motor-2 terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 7.

NG GO TO 5.

5 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT-III

1. Disconnect cooling fan relays-2, 4.

2. Check harness continuity between cooling fan motor-1 terminal 2 and cooling fan relays-2, 4 terminal 3, cooling fan

relays-2, 4 terminal 4 and cooling fan motor-2 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 6.

NG Repair open circuit or short to ground or short to power in harness or connectors.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-139

Page 1194 of 3189

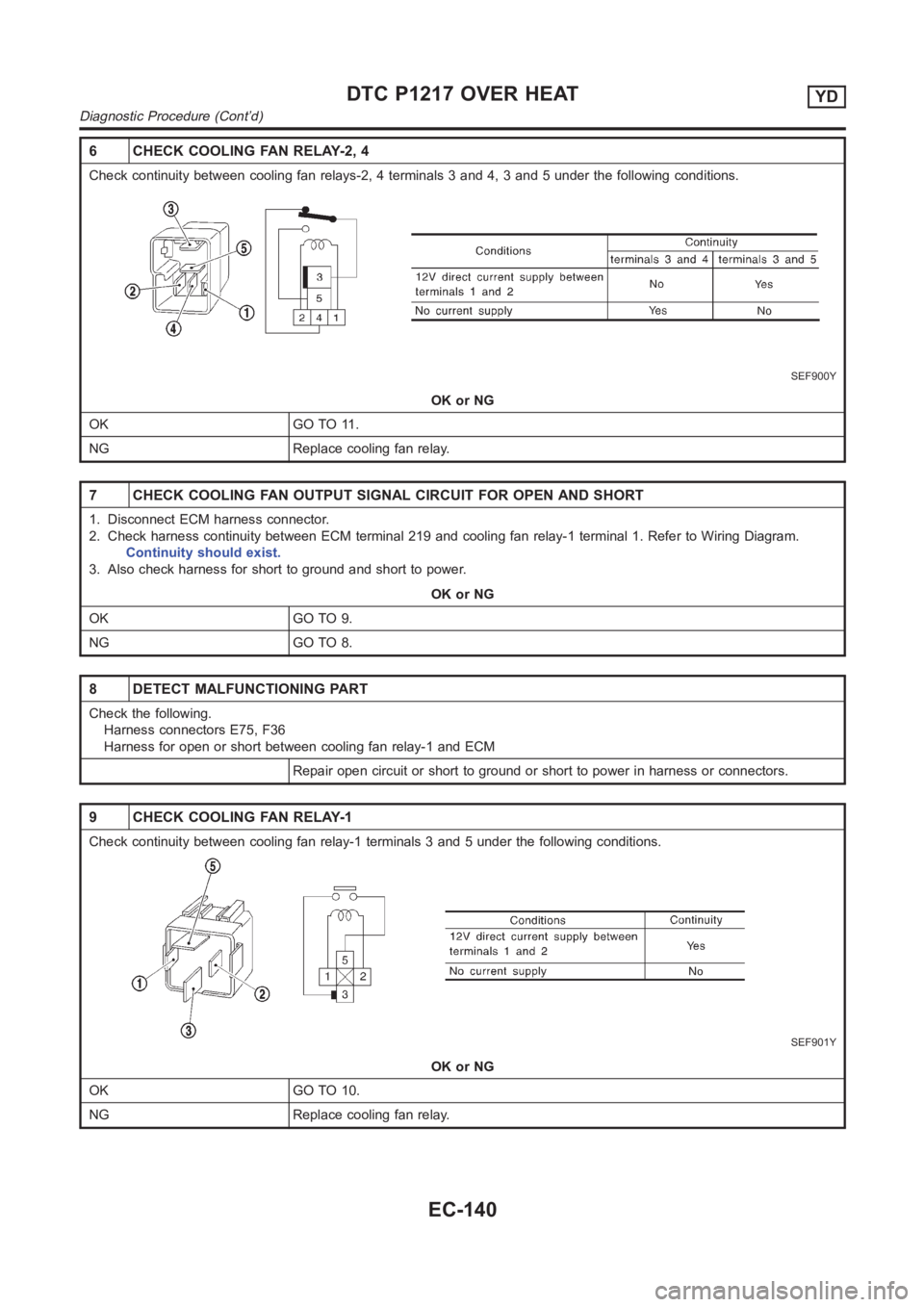

6 CHECK COOLING FAN RELAY-2, 4

Check continuity between cooling fan relays-2, 4 terminals 3 and 4, 3 and 5 under the following conditions.

SEF900Y

OK or NG

OK GO TO 11.

NG Replace cooling fan relay.

7 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 219 and cooling fan relay-1 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 9.

NG GO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E75, F36

Harness for open or short between cooling fan relay-1 and ECM

Repair open circuit or short to ground or short to power in harness or connectors.

9 CHECK COOLING FAN RELAY-1

Check continuity between cooling fan relay-1 terminals 3 and 5 under the following conditions.

SEF901Y

OK or NG

OK GO TO 10.

NG Replace cooling fan relay.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-140

Page 1195 of 3189

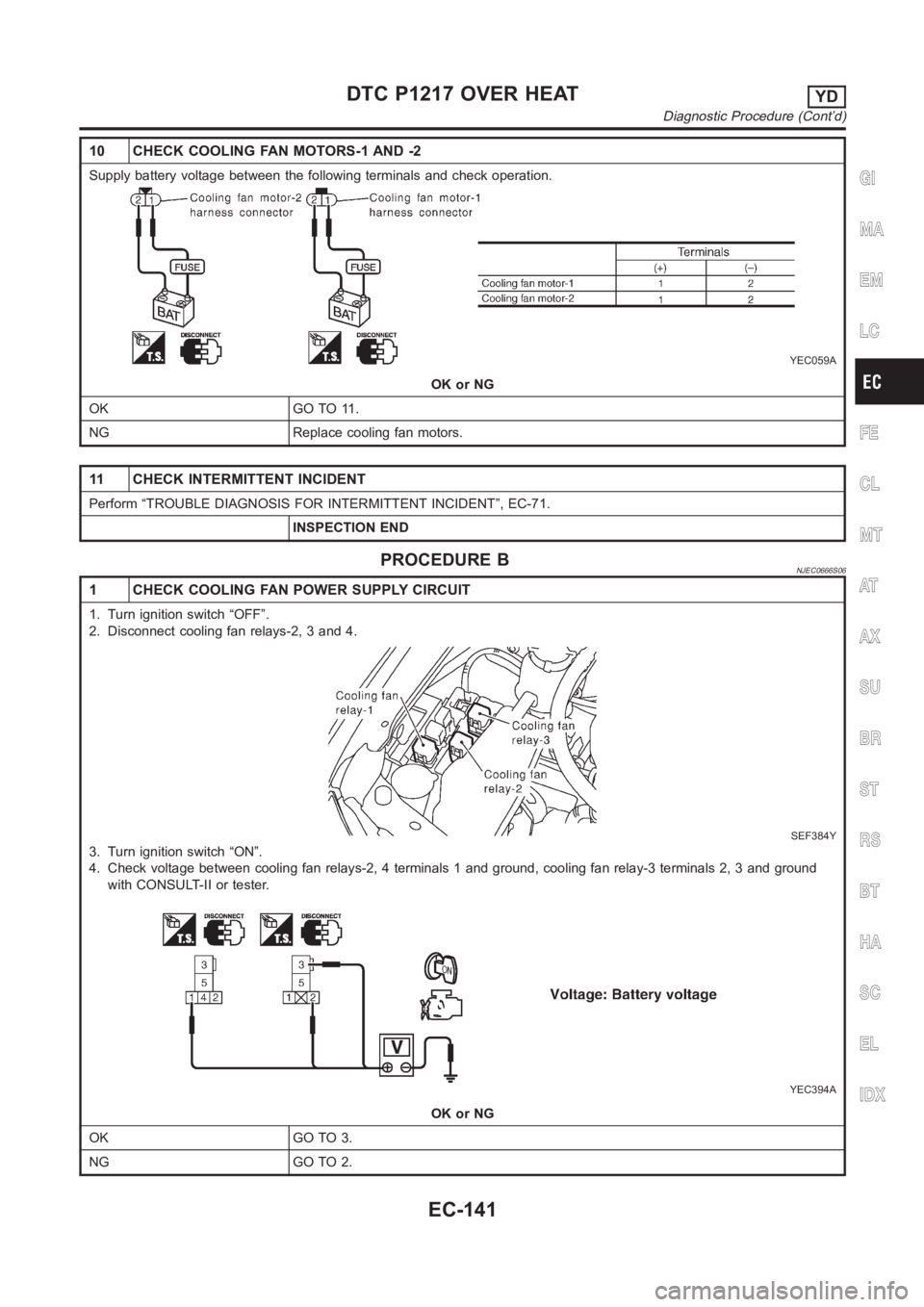

10 CHECK COOLING FAN MOTORS-1 AND -2

Supply battery voltage between the following terminals and check operation.

YEC059A

OK or NG

OK GO TO 11.

NG Replace cooling fan motors.

11 CHECK INTERMITTENT INCIDENT

Perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

INSPECTION END

PROCEDURE BNJEC0666S06

1 CHECK COOLING FAN POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan relays-2, 3 and 4.

SEF384Y

3. Turn ignition switch “ON”.

4. Check voltage between cooling fan relays-2, 4 terminals 1 and ground, cooling fan relay-3 terminals 2, 3 and ground

with CONSULT-II or tester.

YEC394A

OK or NG

OK GO TO 3.

NG GO TO 2.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-141

Page 1196 of 3189

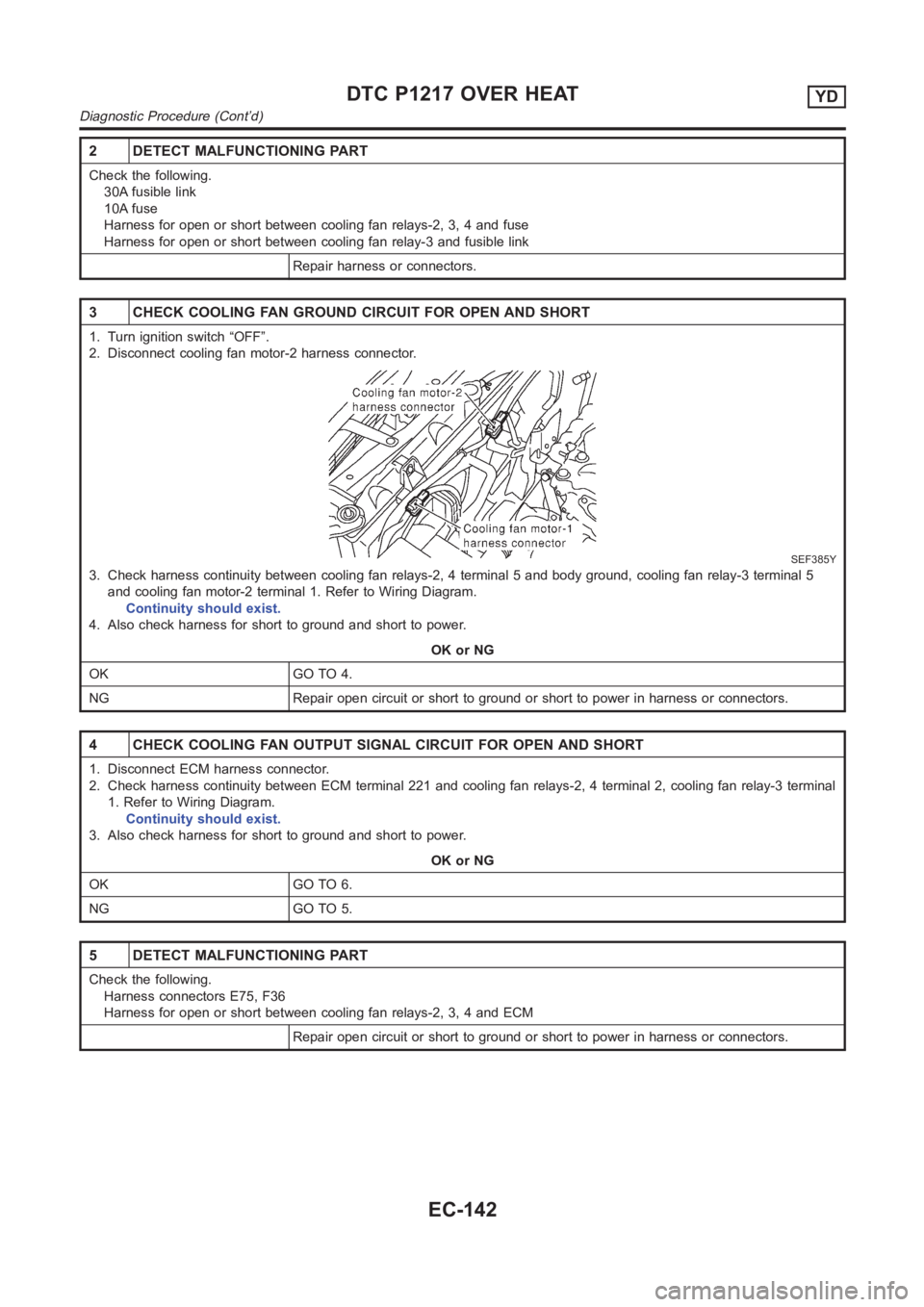

2 DETECT MALFUNCTIONING PART

Check the following.

30A fusible link

10A fuse

Harness for open or short between cooling fan relays-2, 3, 4 and fuse

Harness for open or short between cooling fan relay-3 and fusible link

Repair harness or connectors.

3 CHECK COOLING FAN GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch “OFF”.

2. Disconnect cooling fan motor-2 harness connector.

SEF385Y

3. Check harness continuity between cooling fan relays-2, 4 terminal 5 andbody ground, cooling fan relay-3 terminal 5

and cooling fan motor-2 terminal 1. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 4.

NG Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK COOLING FAN OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 221 and cooling fan relays-2, 4 terminal 2, cooling fan relay-3 terminal

1. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 6.

NG GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

Harness connectors E75, F36

Harness for open or short between cooling fan relays-2, 3, 4 and ECM

Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-142

Page 1197 of 3189

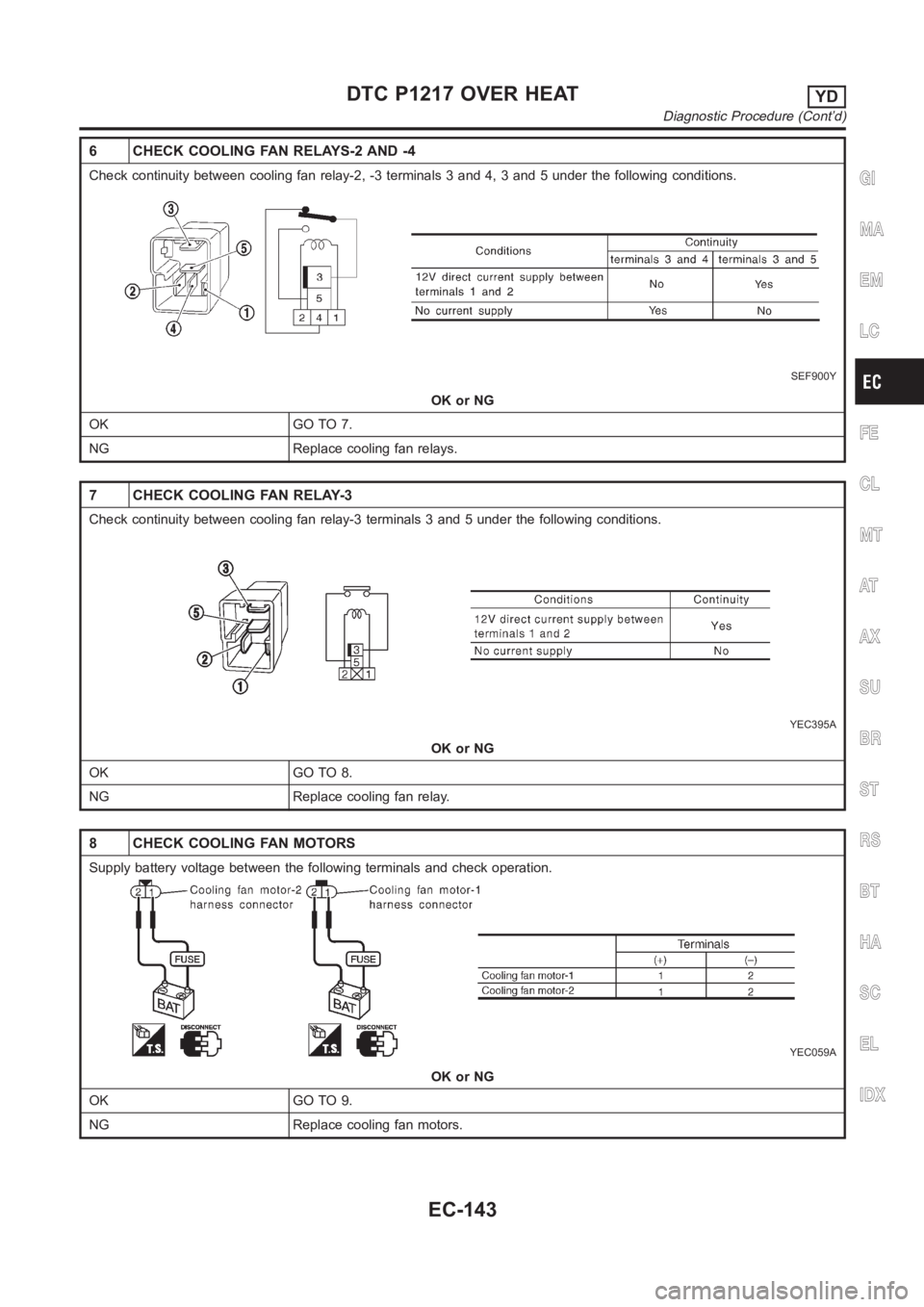

6 CHECK COOLING FAN RELAYS-2 AND -4

Check continuity between cooling fan relay-2, -3 terminals 3 and 4, 3 and 5 under the following conditions.

SEF900Y

OK or NG

OK GO TO 7.

NG Replace cooling fan relays.

7 CHECK COOLING FAN RELAY-3

Check continuity between cooling fan relay-3 terminals 3 and 5 under the following conditions.

YEC395A

OK or NG

OK GO TO 8.

NG Replace cooling fan relay.

8 CHECK COOLING FAN MOTORS

Supply battery voltage between the following terminals and check operation.

YEC059A

OK or NG

OK GO TO 9.

NG Replace cooling fan motors.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-143

Page 1198 of 3189

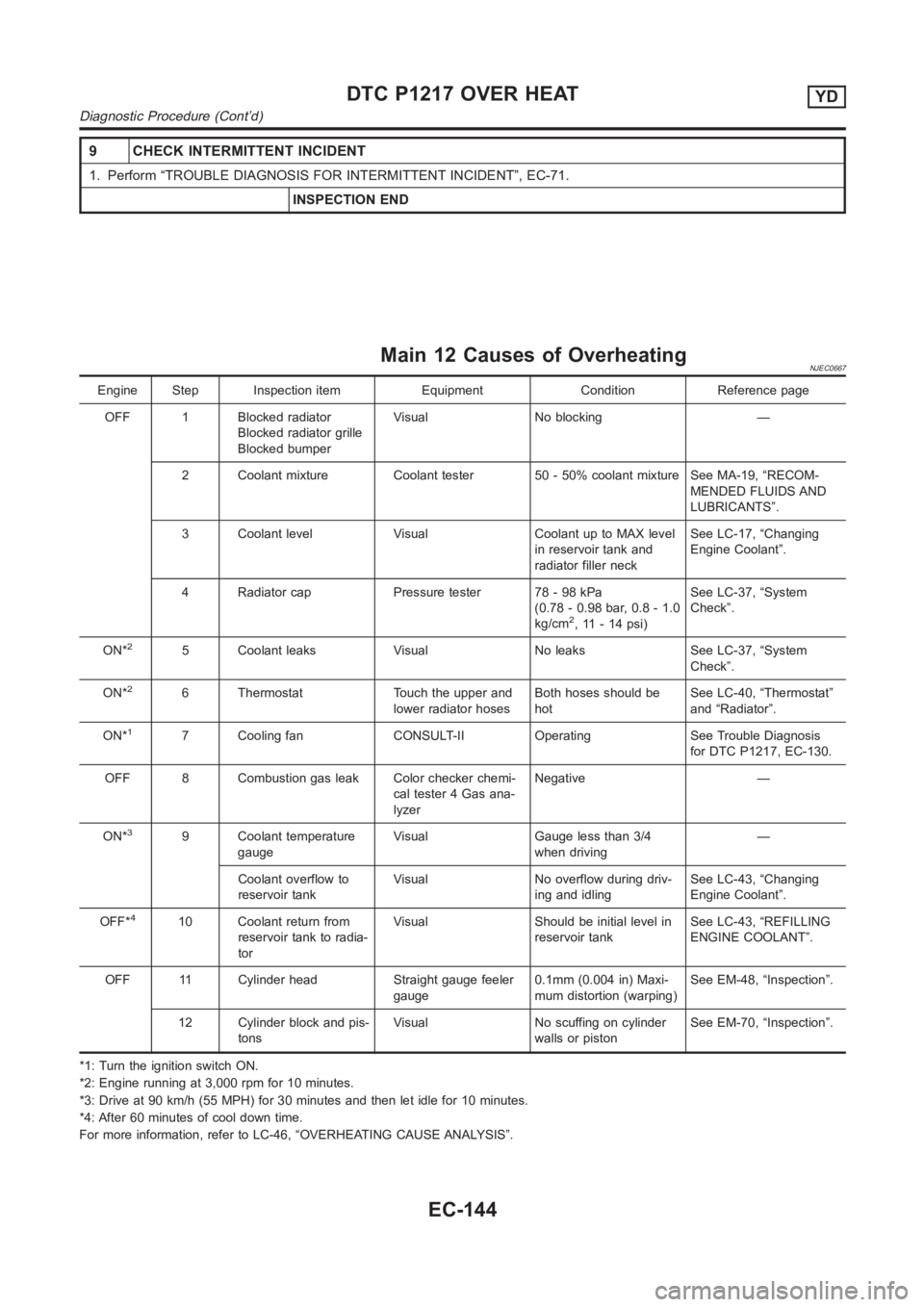

9 CHECK INTERMITTENT INCIDENT

1. Perform “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

INSPECTION END

Main 12 Causes of OverheatingNJEC0667

Engine Step Inspection item Equipment Condition Reference page

OFF 1 Blocked radiator

Blocked radiator grille

Blocked bumperVisual No blocking —

2 Coolant mixture Coolant tester 50 - 50% coolant mixture See MA-19, “RECOM-

MENDED FLUIDS AND

LUBRICANTS”.

3 Coolant level Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee LC-17, “Changing

Engine Coolant”.

4 Radiator cap Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)See LC-37, “System

Check”.

ON*

25 Coolant leaks Visual No leaks See LC-37, “System

Check”.

ON*

26 Thermostat Touch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-40, “Thermostat”

and “Radiator”.

ON*

17 Cooling fan CONSULT-II Operating See Trouble Diagnosis

for DTC P1217, EC-130.

OFF 8 Combustion gas leak Color checker chemi-

cal tester 4 Gas ana-

lyzerNegative —

ON*

39 Coolant temperature

gaugeVisual Gauge less than 3/4

when driving—

Coolant overflow to

reservoir tankVisual No overflow during driv-

ing and idlingSee LC-43, “Changing

Engine Coolant”.

OFF*

410 Coolant return from

reservoir tank to radia-

torVisual Should be initial level in

reservoir tankSee LC-43, “REFILLING

ENGINE COOLANT”.

OFF 11 Cylinder head Straight gauge feeler

gauge0.1mm (0.004 in) Maxi-

mum distortion (warping)See EM-48, “Inspection”.

12 Cylinder block and pis-

tonsVisual No scuffing on cylinder

walls or pistonSee EM-70, “Inspection”.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to LC-46, “OVERHEATING CAUSE ANALYSIS”.

DTC P1217 OVER HEATYD

Diagnostic Procedure (Cont’d)

EC-144

Page 1566 of 3189

![NISSAN ALMERA N16 2003 Electronic Manual PDF AT-110

[EURO-OBD]

CAN COMMUNICATION

TYPE 2

System diagram

Input/output signal chart

T: Transmit R: Receive Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashing indi NISSAN ALMERA N16 2003 Electronic Manual PDF AT-110

[EURO-OBD]

CAN COMMUNICATION

TYPE 2

System diagram

Input/output signal chart

T: Transmit R: Receive Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashing indi](/img/5/57350/w960_57350-1565.png)

AT-110

[EURO-OBD]

CAN COMMUNICATION

TYPE 2

System diagram

Input/output signal chart

T: Transmit R: Receive Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashing indicator signalTR

Engine cooling fan speed signal T R

Child lock indicator signalTR

Door switches state signalTR

A/C compressor signal T R

Accelerator pedal position signal T R

Output shaft revolution signal R T

OD OFF switch signal R T

OD OFF indicator signal T R

A/T self-diagnosis signal R TSignals ECM TCMSmart entrance

control unitCombination meter

SEL826Y

Signals ECMSmart entrance control

unitCombination meter

Engine speed signal T R

Rear window defogger signal R T

Heater fan switch signal R T

Air conditioner switch signal R T

MI signal T R

Engine coolant temperature signal T R

Fuel consumption signal T R

Vehicle speed signal R T

Seat belt reminder signal R T

Headlamp switch signal T R

Flashing indicator signal T R

Engine cooling fan speed signal T R

Child lock indicator signal T R

Door switches state signal T R

A/C compressor signal T R

Page 1762 of 3189

![NISSAN ALMERA N16 2003 Electronic Manual PDF AT-306

[EXC.F/EURO-OBD]

CAN COMMUNICATION

TYPE 2

System diagram

Input/output signal chart

T: Transmit R: Receive Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashin NISSAN ALMERA N16 2003 Electronic Manual PDF AT-306

[EXC.F/EURO-OBD]

CAN COMMUNICATION

TYPE 2

System diagram

Input/output signal chart

T: Transmit R: Receive Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashin](/img/5/57350/w960_57350-1761.png)

AT-306

[EXC.F/EURO-OBD]

CAN COMMUNICATION

TYPE 2

System diagram

Input/output signal chart

T: Transmit R: Receive Vehicle speed signal R T

Seat belt reminder signalRT

Headlamp switch signalTR

Flashing indicator signalTR

Engine cooling fan speed signal T R

Child lock indicator signalTR

Door switches state signalTR

A/C compressor signal T R

Accelerator pedal position signal T R

Output shaft revolution signal R T

OD OFF switch signal R T

OD OFF indicator signal T R

A/T self-diagnosis signal R TSignals ECM TCMSmart entrance

control unitCombination meter

SEL826Y

Signals ECMSmart entrance control

unitCombination meter

Engine speed signal T R

Rear window defogger signal R T

Heater fan switch signal R T

Air conditioner switch signal R T

MI signal T R

Engine coolant temperature signal T R

Fuel consumption signal T R

Vehicle speed signal R T

Seat belt reminder signal R T

Headlamp switch signal T R

Flashing indicator signal T R

Engine cooling fan speed signal T R

Child lock indicator signal T R

Door switches state signal T R

A/C compressor signal T R