cooling fan NISSAN ALMERA N16 2003 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1983 of 3189

ATC-3

C

D

E

F

G

H

I

K

L

MA

B

AT C SUNLOAD SENSOR ...............................................117

Removal and Installation ....................................... 117

INTAKE SENSOR CIRCUIT ....................................118

Removal and Installation ....................................... 118

BLOWER UNIT ........................................................119

Removal and Installation ....................................... 119

REMOVAL .......................................................... 119

INSTALLATION .................................................. 119

Disassembly and Assembly .................................. 119

BLOWER MOTOR .................................................. 120

Removal and Installation ...................................... 120

INTAKE DOOR MOTOR ......................................... 121

Removal and Installation ...................................... 121

HEATER & COOLING UNIT ASSEMBLY .............. 122

Removal and Installation ...................................... 122

REMOVAL ......................................................... 122

INSTALLATION ................................................. 123

Disassembly and Assembly ................................. 123

MODE DOOR MOTOR ........................................... 125

Removal and Installation ...................................... 125

AIR MIX DOOR MOTOR ......................................... 126

Removal and Installation ...................................... 126

FAN CONTROL AMPLIFIER .................................. 127

Removal and Installation ...................................... 127

VENTILATION AIR FILTER .................................... 128

Removal and Installation ...................................... 128

FUNCTION ........................................................ 128

REPLACEMENT TIMING .................................. 128

REPLACEMENT AND PROCEDURES ............ 128

HEATER CORE ...................................................... 129

Removal and Installation ...................................... 129

DUCTS AND GRILLES .......................................... 130

Removal and Installation ...................................... 130

VENTILATOR DUCT, DEFROSTER NOZZLE

AND DEFROSTER DUCTS .............................. 130

CENTER VENTILATOR GRILLE ...................... 130

SIDE VENTILATOR GRILLE ............................. 130

FOOT DUCT ..................................................... 130

FLOOR DUCT ................................................... 131

REFRIGERANT LINES ........................................... 132

HFC-134a (R-134a) Service Procedure ............... 132

SETTING OF SERVICE TOOLS AND EQUIP-

MENT ................................................................ 132Components .........................................................134

Compressor ..........................................................136

REMOVAL .........................................................136

INSTALLATION .................................................137

Compressor Clutch .............................................. .138

REMOVAL .........................................................138

INSTALLATION .................................................139

Low-pressure Flexible Hose .................................141

REMOVAL .........................................................141

INSTALLATION .................................................141

High-pressure Flexible Hose ................................141

REMOVAL .........................................................141

INSTALLATION .................................................142

High-pressure Pipe ...............................................142

REMOVAL .........................................................142

INSTALLATION .................................................142

Refrigerant Pressure Sensor ................................142

REMOVAL AND INSTALLATION ......................142

Dual-pressure Switch ...........................................143

REMOVAL AND INSTALLATION ......................143

Condenser Assembly ...........................................143

REMOVAL .........................................................143

INSTALLATION .................................................143

Evaporator ............................................................144

REMOVAL .........................................................144

INSTALLATION .................................................144

Expansion Valve ...................................................144

REMOVAL .........................................................144

INSTALLATION .................................................144

Checking for Refrigerant Leaks ............................145

Checking System for Leaks Using the Fluorescent

Leak Detector .......................................................145

Dye Injection .........................................................146

Electronic Refrigerant Leak Detector ....................146

PRECAUTIONS FOR HANDLING LEAK

DETECTOR .......................................................146

CHECKING PROCEDURE ...............................147

SERVICE DATA AND SPECIFICATIONS (SDS) ....149

Compressor ..........................................................149

Lubricant ...............................................................149

Refrigerant ............................................................149

Engine Idling Speed .............................................149

Belt Tension ..........................................................149

Page 1996 of 3189

ATC-16

REFRIGERATION SYSTEM

CSV613 Variable Displacement Compressor

EJS001Z2

GENERAL INFORMATION

1. The CSV613 compressor differs from previous units. The vent temperatures of the CSV613 compressor

do not drop too far below 5°C (41°F) when:

Evaporator intake air temperature is less than 20°C (68°F).

Engine is running at speeds less than 1,500 rpm.

This is because the CSV613 compressor provides a means of “capacity” control.

2. The CSV613 compressor provides refrigerant control under varying conditions. During cold winters, it may

not produce high refrigerant pressure discharge (compared to previous units) when used with air condi-

tioning systems.

3. A “clanking” sound may occasionally be heard during refrigerant charge. The sound indicates that the tilt

angle of the swash plate has changed and is not a problem.

4. For air conditioning systems with the CSV613 compressor, the clutch remains engaged unless: the sys-

tem main switch, fan switch or ignition switch is turned OFF. When ambient (outside) temperatures are

low or when the amount of refrigerant is insufficient, the clutch is disengaged to protect the compressor.

5. A constant range of suction pressure is maintained when engine speed is greater than a certain value. It

normally ranges from 147 to 177 kPa (1.47 to 1.77 bar, 1.5 to 1.8 kg/cm

2 , 21 to 26 psi) under varying con-

ditions.

In previous compressors, however, suction pressure was reduced with increases in engine speed.

DESCRIPTION

General

The variable compressor is basically a swash plate type that changes piston stroke in response to the required

cooling capacity.

Page 2009 of 3189

TROUBLE DIAGNOSIS

ATC-29

C

D

E

F

G

H

I

K

L

MA

B

AT C

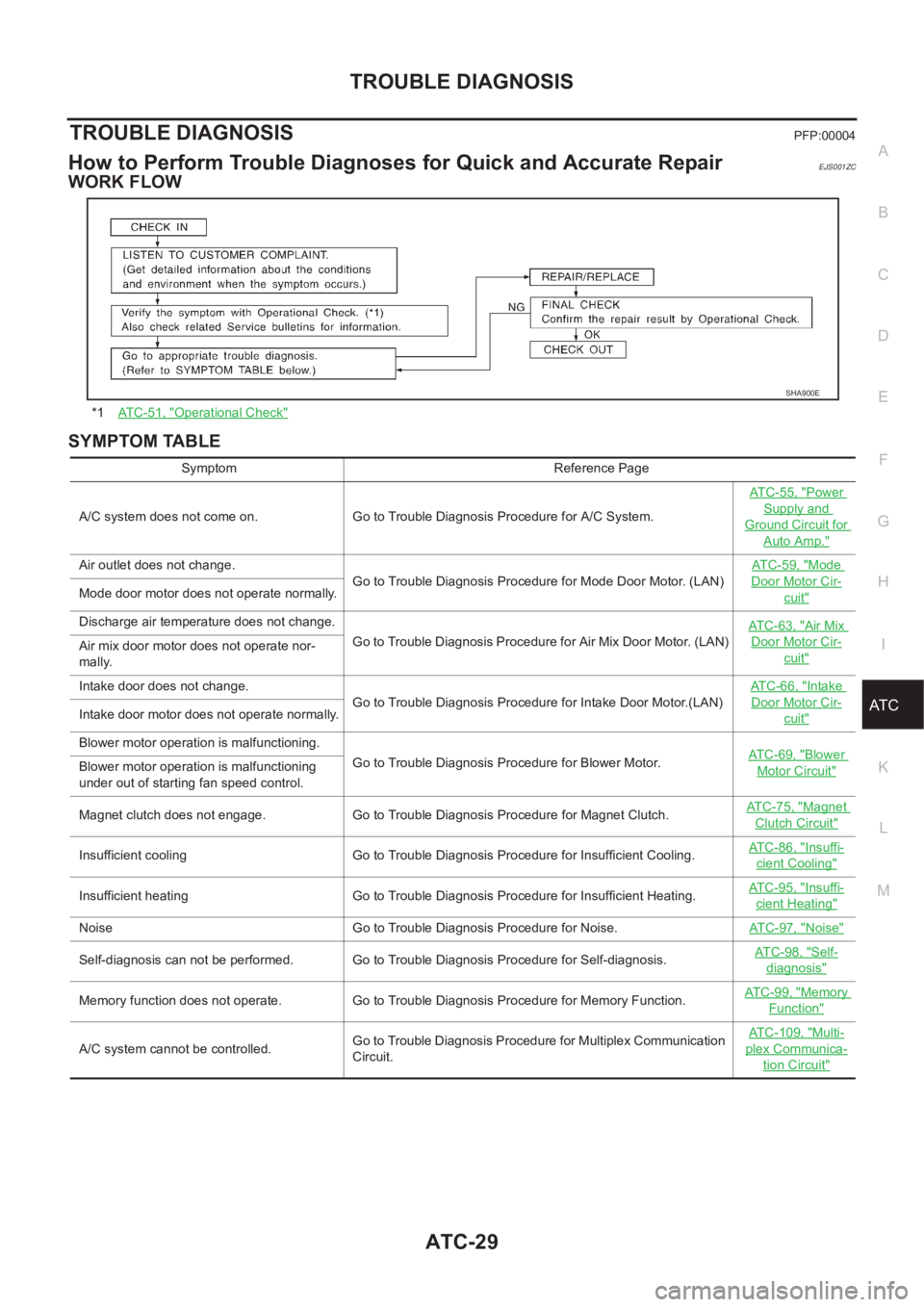

TROUBLE DIAGNOSISPFP:00004

How to Perform Trouble Diagnoses for Quick and Accurate RepairEJS001ZC

WORK FLOW

SYMPTOM TABLE

*1AT C - 5 1 , "Operational Check"

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System.ATC-55, "

Power

Supply and

Ground Circuit for

Auto Amp."

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor. (LAN)AT C - 5 9 , "Mode

Door Motor Cir-

cuit"Mode door motor does not operate normally.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor. (LAN)ATC-63, "

Air Mix

Door Motor Cir-

cuit"Air mix door motor does not operate nor-

mally.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor.(LAN)AT C - 6 6 , "

Intake

Door Motor Cir-

cuit"Intake door motor does not operate normally.

Blower motor operation is malfunctioning.

Go to Trouble Diagnosis Procedure for Blower Motor.ATC-69, "

Blower

Motor Circuit"Blower motor operation is malfunctioning

under out of starting fan speed control.

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch.AT C - 7 5 , "

Magnet

Clutch Circuit"

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling.AT C - 8 6 , "Insuffi-

cient Cooling"

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating.AT C - 9 5 , "Insuffi-

cient Heating"

Noise Go to Trouble Diagnosis Procedure for Noise.ATC-97, "Noise"

Self-diagnosis can not be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis.AT C - 9 8 , "Self-

diagnosis"

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.AT C - 9 9 , "Memory

Function"

A/C system cannot be controlled.Go to Trouble Diagnosis Procedure for Multiplex Communication

Circuit.ATC-109, "

Multi-

plex Communica-

tion Circuit"

Page 2051 of 3189

TROUBLE DIAGNOSIS

ATC-71

C

D

E

F

G

H

I

K

L

MA

B

AT C

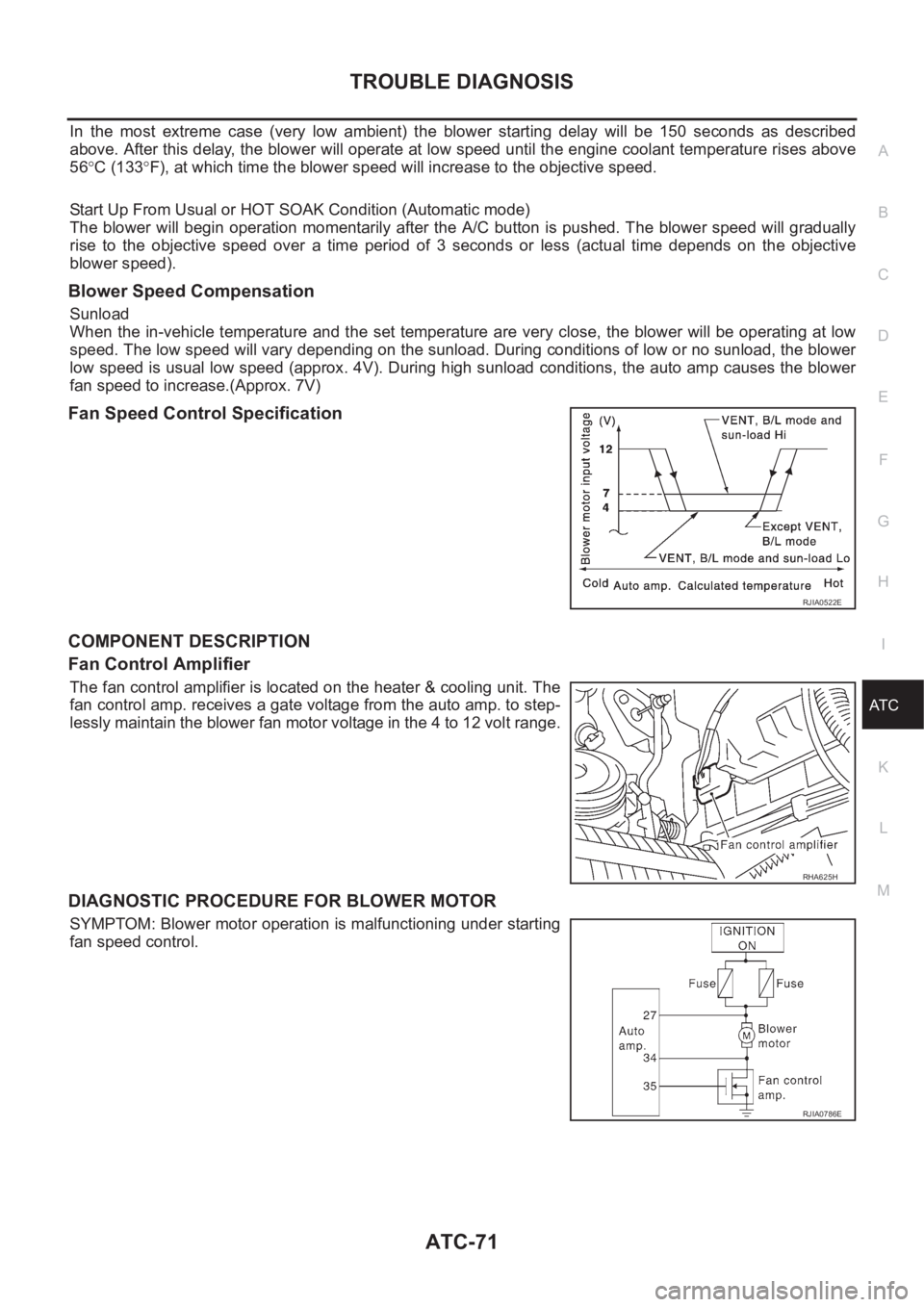

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C (133°F), at which time the blower speed will increase to the objective speed.

Start Up From Usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C button is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

low speed is usual low speed (approx. 4V). During high sunload conditions, the auto amp causes the blower

fan speed to increase.(Approx. 7V)

Fan Speed Control Specification

COMPONENT DESCRIPTION

Fan Control Amplifier

The fan control amplifier is located on the heater & cooling unit. The

fan control amp. receives a gate voltage from the auto amp. to step-

lessly maintain the blower fan motor voltage in the 4 to 12 volt range.

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

fan speed control.

RJIA0522E

RHA625H

RJIA0786E

Page 2072 of 3189

ATC-92

TROUBLE DIAGNOSIS

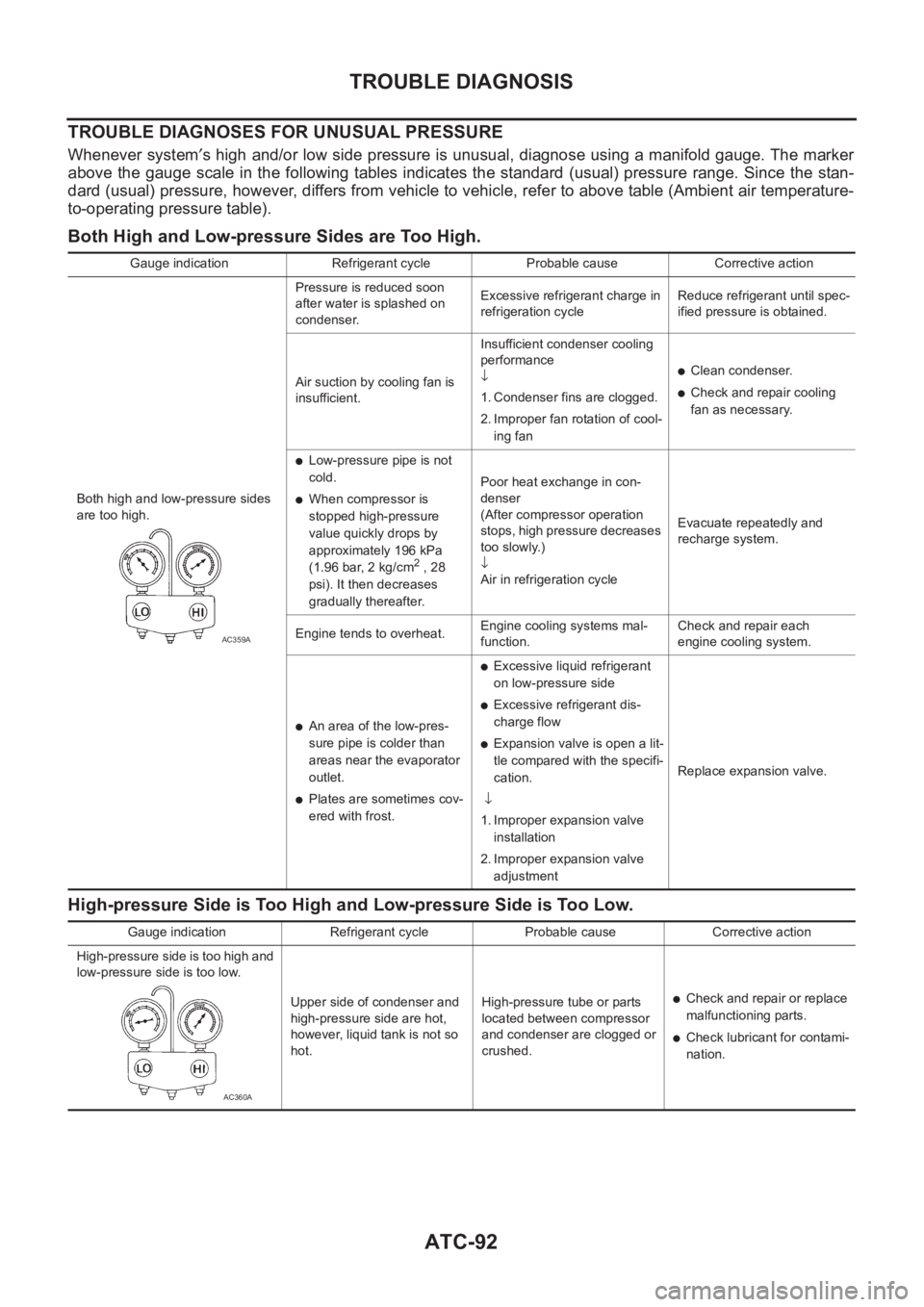

TROUBLE DIAGNOSES FOR UNUSUAL PRESSURE

Whenever system′s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (usual) pressure range. Since the stan-

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High and Low-pressure Sides are Too High.

High-pressure Side is Too High and Low-pressure Side is Too Low.

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure sides

are too high.Pressure is reduced soon

after water is splashed on

condenser.Excessive refrigerant charge in

refrigeration cycleReduce refrigerant until spec-

ified pressure is obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cool-

ing fan

●Clean condenser.

●Check and repair cooling

fan as necessary.

●Low-pressure pipe is not

cold.

●When compressor is

stopped high-pressure

value quickly drops by

approximately 196 kPa

(1.96 bar, 2 kg/cm

2 , 28

psi). It then decreases

gradually thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure decreases

too slowly.)

↓

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair each

engine cooling system.

●An area of the low-pres-

sure pipe is colder than

areas near the evaporator

outlet.

●Plates are sometimes cov-

ered with frost.

●Excessive liquid refrigerant

on low-pressure side

●Excessive refrigerant dis-

charge flow

●Expansion valve is open a lit-

tle compared with the specifi-

cation.

↓

1. Improper expansion valve

installation

2. Improper expansion valve

adjustmentReplace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged or

crushed.

●Check and repair or replace

malfunctioning parts.

●Check lubricant for contami-

nation.

AC360A

Page 2099 of 3189

BLOWER UNIT

ATC-119

C

D

E

F

G

H

I

K

L

MA

B

AT C

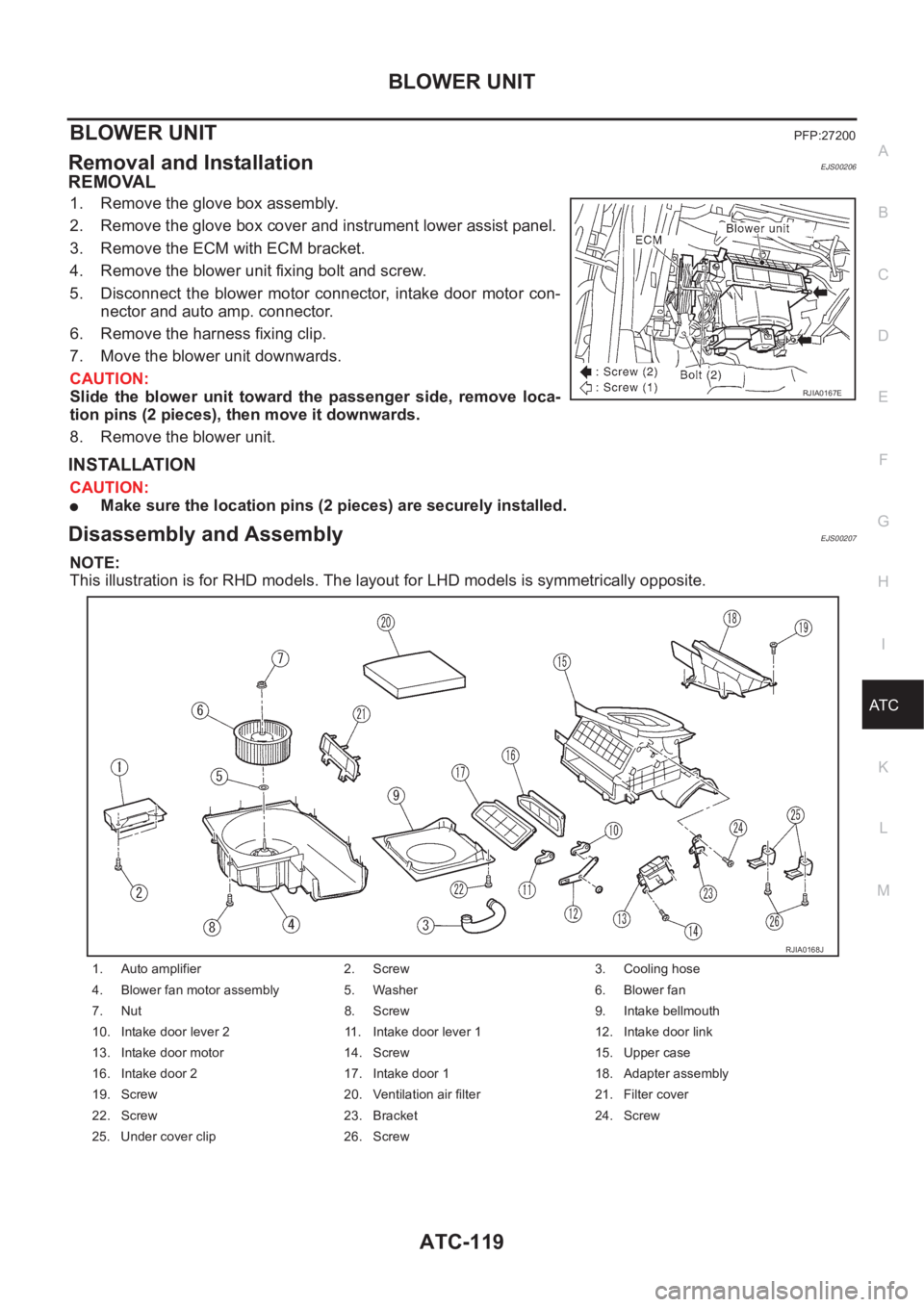

BLOWER UNITPFP:27200

Removal and InstallationEJS00206

REMOVAL

1. Remove the glove box assembly.

2. Remove the glove box cover and instrument lower assist panel.

3. Remove the ECM with ECM bracket.

4. Remove the blower unit fixing bolt and screw.

5. Disconnect the blower motor connector, intake door motor con-

nector and auto amp. connector.

6. Remove the harness fixing clip.

7. Move the blower unit downwards.

CAUTION:

Slide the blower unit toward the passenger side, remove loca-

tion pins (2 pieces), then move it downwards.

8. Remove the blower unit.

INSTALLATION

CAUTION:

●Make sure the location pins (2 pieces) are securely installed.

Disassembly and AssemblyEJS00207

NOTE:

This illustration is for RHD models. The layout for LHD models is symmetrically opposite.

RJIA0167E

1. Auto amplifier 2. Screw 3. Cooling hose

4. Blower fan motor assembly 5. Washer 6. Blower fan

7. Nut 8. Screw 9. Intake bellmouth

10. Intake door lever 2 11. Intake door lever 1 12. Intake door link

13. Intake door motor 14. Screw 15. Upper case

16. Intake door 2 17. Intake door 1 18. Adapter assembly

19. Screw 20. Ventilation air filter 21. Filter cover

22. Screw 23. Bracket 24. Screw

25. Under cover clip 26. Screw

RJIA0168J

Page 2100 of 3189

ATC-120

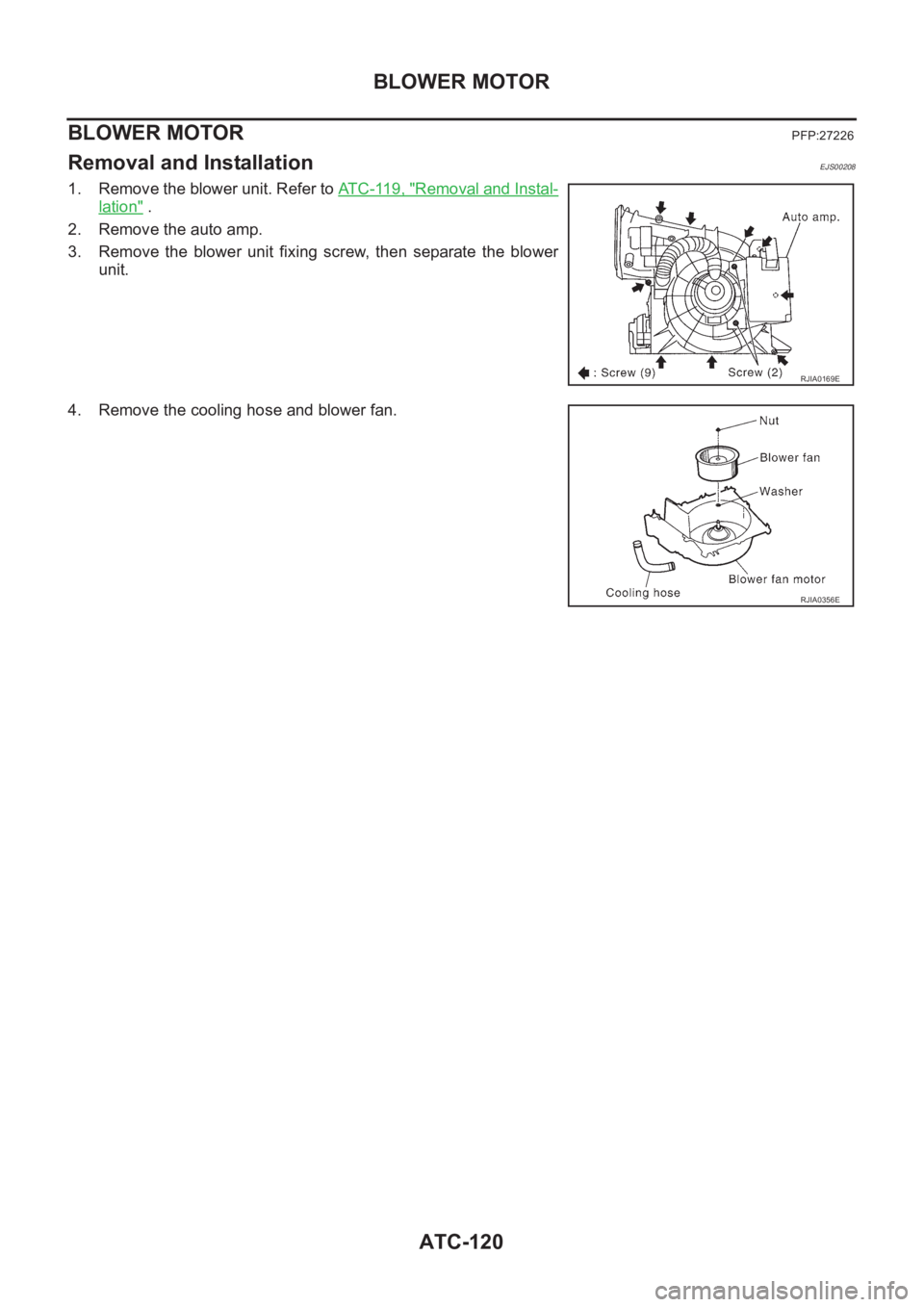

BLOWER MOTOR

BLOWER MOTOR

PFP:27226

Removal and InstallationEJS00208

1. Remove the blower unit. Refer to AT C - 11 9 , "Removal and Instal-

lation" .

2. Remove the auto amp.

3. Remove the blower unit fixing screw, then separate the blower

unit.

4. Remove the cooling hose and blower fan.

RJIA0169E

RJIA0356E

Page 2104 of 3189

ATC-124

HEATER & COOLING UNIT ASSEMBLY

16. Mode door link 2 17. Screw 18. Mode door lever 1

19. Fan control amp. 20. Screw 21. Mode door motor

22. Screw 23. Screw 24. Air mix door motor

25. Screw 26. Actuator bracket 27. Screw

28. Mode door link 29. Air mix door lever 30. Screw

31. Heater core 32. Evaporator 33. Expansion valve

34. Bolt 35. Cooler grommet 36. Instrument bracket

37. Drain hose 38. Lower case 39. Screw

Page 2127 of 3189

REFRIGERANT LINES

ATC-147

C

D

E

F

G

H

I

K

L

MA

B

AT C

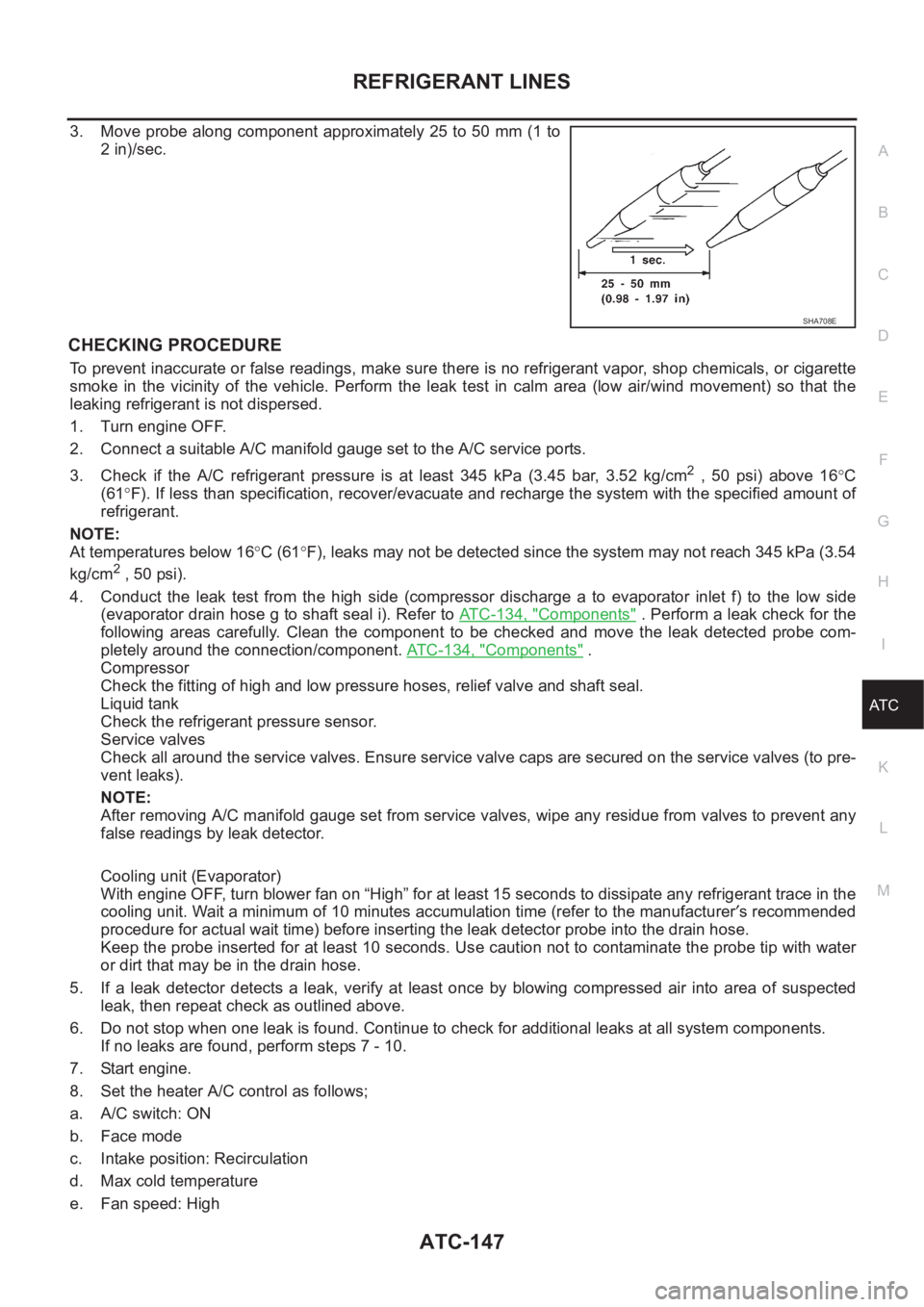

3. Move probe along component approximately 25 to 50 mm (1 to

2 in)/sec.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set to the A/C service ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2 , 50 psi) above 16°C

(61°F). If less than specification, recover/evacuate and recharge the system with the specified amount of

refrigerant.

NOTE:

At temperatures below 16°C (61°F), leaks may not be detected since the system may not reach 345 kPa (3.54

kg/cm

2 , 50 psi).

4. Conduct the leak test from the high side (compressor discharge a to evaporator inlet f) to the low side

(evaporator drain hose g to shaft seal i). Refer to AT C - 1 3 4 , "

Components" . Perform a leak check for the

following areas carefully. Clean the component to be checked and move the leak detected probe com-

pletely around the connection/component. ATC-134, "

Components" .

Compressor

Check the fitting of high and low pressure hoses, relief valve and shaft seal.

Liquid tank

Check the refrigerant pressure sensor.

Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to pre-

vent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at least 15 seconds to dissipate any refrigerant trace in the

cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer′s recommended

procedure for actual wait time) before inserting the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use caution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

6. Do not stop when one leak is found. Continue to check for additional leaks at all system components.

If no leaks are found, perform steps 7 - 10.

7. Start engine.

8. Set the heater A/C control as follows;

a. A/C switch: ON

b. Face mode

c. Intake position: Recirculation

d. Max cold temperature

e. Fan speed: High

SHA708E

Page 2713 of 3189

![NISSAN ALMERA N16 2003 Electronic Manual PDF Terminal

No.Wire

colorConnections Operated condition Voltage (Approximate values)

24 BRWasher switch

(Headlamp washer switch)[Head lamp switch 1st or 2nd posi-

tion]

Washer switch OFF,ON12V,0V

25 G/OR NISSAN ALMERA N16 2003 Electronic Manual PDF Terminal

No.Wire

colorConnections Operated condition Voltage (Approximate values)

24 BRWasher switch

(Headlamp washer switch)[Head lamp switch 1st or 2nd posi-

tion]

Washer switch OFF,ON12V,0V

25 G/OR](/img/5/57350/w960_57350-2712.png)

Terminal

No.Wire

colorConnections Operated condition Voltage (Approximate values)

24 BRWasher switch

(Headlamp washer switch)[Head lamp switch 1st or 2nd posi-

tion]

Washer switch OFF,ON12V,0V

25 G/ORCombination switch

(Turn signal switch)Turn signal switch:

Neutral,Left turn position12V,0V

26 L/BCombination switch

(Turn signal switch)Turn signal switch:

Neutral,Right turn position12V,0V

27 Y/BVehicle security horn relay

(RHD models)When theft warning system:

Armed,Disarmed0V,12V

28 R/Y Interior room lampWhen interior lamp is operated using

remote controller (Lamp switch in

“DOOR” position)12V,0V

29 Y/G Ignition key switch Ignition key is in “ON” position 12V

30 G/R Hazard switch Hazard switch: OFF,ON 12V,0V

31 W Rear window defogger relay[Ignition switch “ON”]

Rear window defogger switch:

OFF,ON12V,0V

32 LG/B Cooling fan relay[Ignition switch“ ON”]

Cooling fan: Operating,Not operat-

ing0V,12V

33 LG/R Cooling fan relay[Ignition switch “ON”]

Cooling fan: Operating,Not operat-

ing0V,12V

34 L/Y Security indicator Ignition switch ON,OFF 12V,0V

39 BR/WRear door switch

(Passenger side)Rear door LH or RH: Open,Closed 0V,12V

41 L Air conditioner relay[Engine is running]

Air conditioner switch: ON,

OFF12V,0V

43 R/WFront door switch

(Driver side)Front door (Driver side):

Open,Closed12V,0V

44 R/WFront door switch

(Passenger side)Front door (Passenger side):

Open,Closed0V,12V

45 R/YRear door switch

(Driver side)Rear door LH or RH: Open,Closed 0V,12V

49 W/L Power source — 12V

50 GPower door super lock actuator

(Rear)Remote controller door lock switch:

Free,Press0V,12V

51 L/R Driver door lock actuatorDoor lock & unlock switch:

Free,Lock0V,12V

52 W/R Door lock actuatorsDoor lock & unlock switch:

Free,Unlock0V,12V

53 B Ground — 0V

54 R/B Door lock actuatorsDoor lock & unlock switch:

Free,Unlock0V,12V

55 W/BPower door super lock actuator

(Front)Remote controller door lock switch:

Free,Unlock0V,12V

56 R/B Power source — 12V

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

SMART ENTRANCE CONTROL SYSTEM

Smart Entrance Control Unit Inspection Table (Cont’d)

EL-377