ABS NISSAN ALMERA N16 2003 Electronic User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1007 of 3189

![NISSAN ALMERA N16 2003 Electronic User Guide VSS

EC-677

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

VSSPFP:32702

DescriptionEBS00KLE

NOTE:

If DTC U1000 or U1001 is displayed, first perform the trouble diagnosis for DTC U1000, U1001. Refer NISSAN ALMERA N16 2003 Electronic User Guide VSS

EC-677

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

VSSPFP:32702

DescriptionEBS00KLE

NOTE:

If DTC U1000 or U1001 is displayed, first perform the trouble diagnosis for DTC U1000, U1001. Refer](/img/5/57350/w960_57350-1006.png)

VSS

EC-677

[QG (WITHOUT EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

VSSPFP:32702

DescriptionEBS00KLE

NOTE:

If DTC U1000 or U1001 is displayed, first perform the trouble diagnosis for DTC U1000, U1001. Refer to

EC-492, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

The vehicle speed signal is sent from vehicle speed sensor (models with ABS) or ABS actuator and electric

unit (control unit) (models with ABS) to combination meter. The combination meter then sends a signal to the

ECM through CAN communication line.

Diagnostic ProcedureEBS00KLF

1.CHECK VEHICLE SPEED SIGNAL OVERALL FUNCTION

With CONSULT-II

1. Lift up the vehicle.

2. Start engine.

3. Select “VHCL SPEED SE” in “DATA MONITOR” mode with

CONSULT-II.

4. Make sure that “VHCL SPEED SE” indication exceeds 10 km/h

(6 MPH) when rotating wheels with suitable gear position.

Without CONSULT-II

1. Lift up the vehicle.

2. Start engine.

3. Read vehicle speed with combination meter.

Make sure that vehicle speed indication exceeds 10 km/h (6 MPH) when rotating wheels with suitable

gear position.

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

2.CHECK DTC WITH VEHICLE SPEED SONSOR (MODELS WITHOUT ABS) OR ABS ACTUATOR AND

ELECTRIC UNIT (CONTROL UNIT) (MODELS WITH ABS)

Refer to EL-123 (models without ABS) or EL-124 (models with ABS).

OK or NG

OK >> GO TO 2.

NG >> Repair or replace.

3.CHECK COMBINATION METER

Check combination meter function.

Refer to EL-112.

>>INSPECTION END

SEF196Y

Page 1162 of 3189

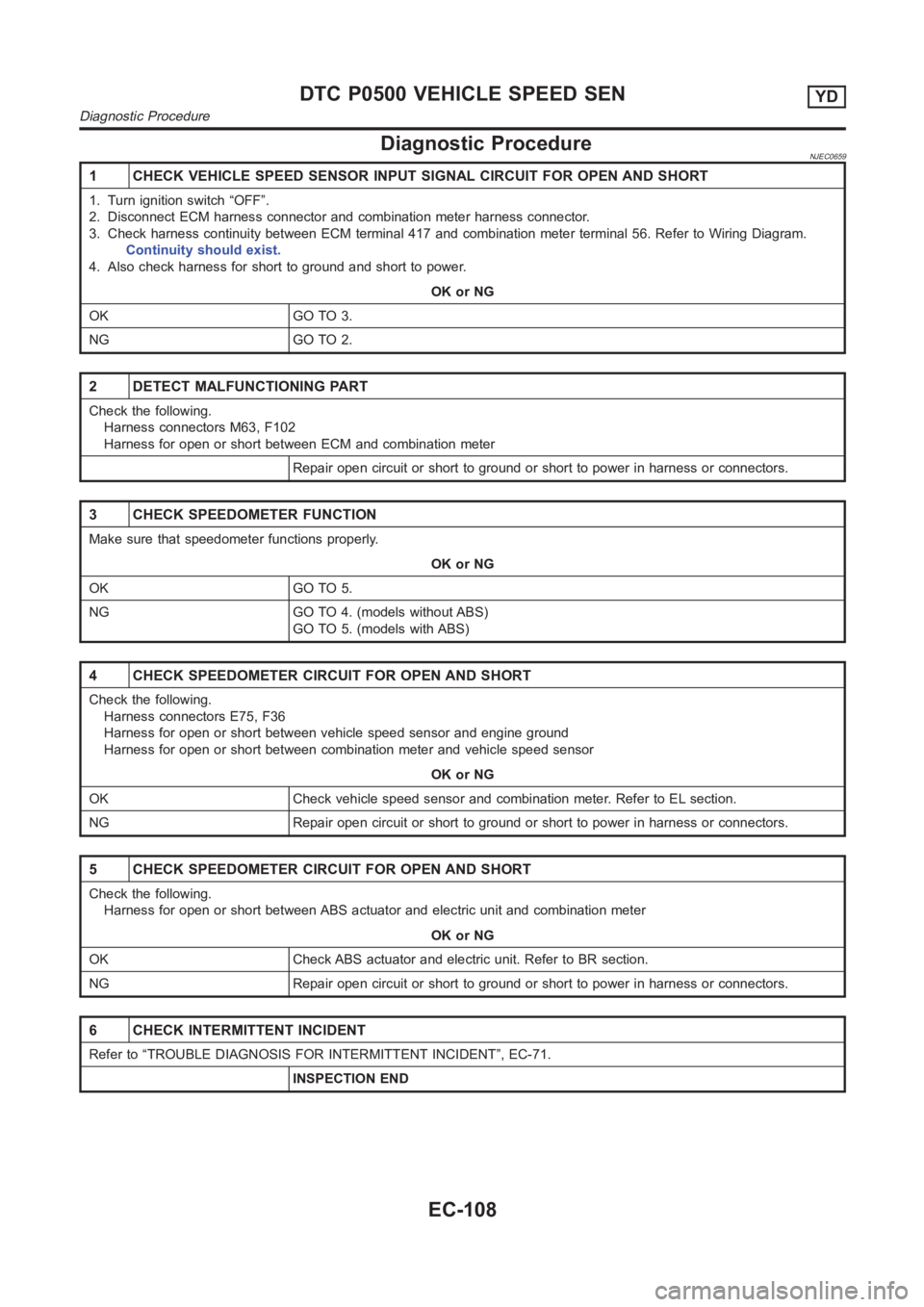

Diagnostic ProcedureNJEC0659

1 CHECK VEHICLE SPEED SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch “OFF”.

2. Disconnect ECM harness connector and combination meter harness connector.

3. Check harness continuity between ECM terminal 417 and combination meter terminal 56. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 3.

NG GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

Harness connectors M63, F102

Harness for open or short between ECM and combination meter

Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK SPEEDOMETER FUNCTION

Make sure that speedometer functions properly.

OK or NG

OK GO TO 5.

NG GO TO 4. (models without ABS)

GO TO 5. (models with ABS)

4 CHECK SPEEDOMETER CIRCUIT FOR OPEN AND SHORT

Check the following.

Harness connectors E75, F36

Harness for open or short between vehicle speed sensor and engine ground

Harness for open or short between combination meter and vehicle speed sensor

OK or NG

OK Check vehicle speed sensor and combination meter. Refer to EL section.

NG Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK SPEEDOMETER CIRCUIT FOR OPEN AND SHORT

Check the following.

Harness for open or short between ABS actuator and electric unit and combination meter

OK or NG

OK Check ABS actuator and electric unit. Refer to BR section.

NG Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INTERMITTENT INCIDENT

Refer to “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

INSPECTION END

DTC P0500 VEHICLE SPEED SENYD

Diagnostic Procedure

EC-108

Page 1170 of 3189

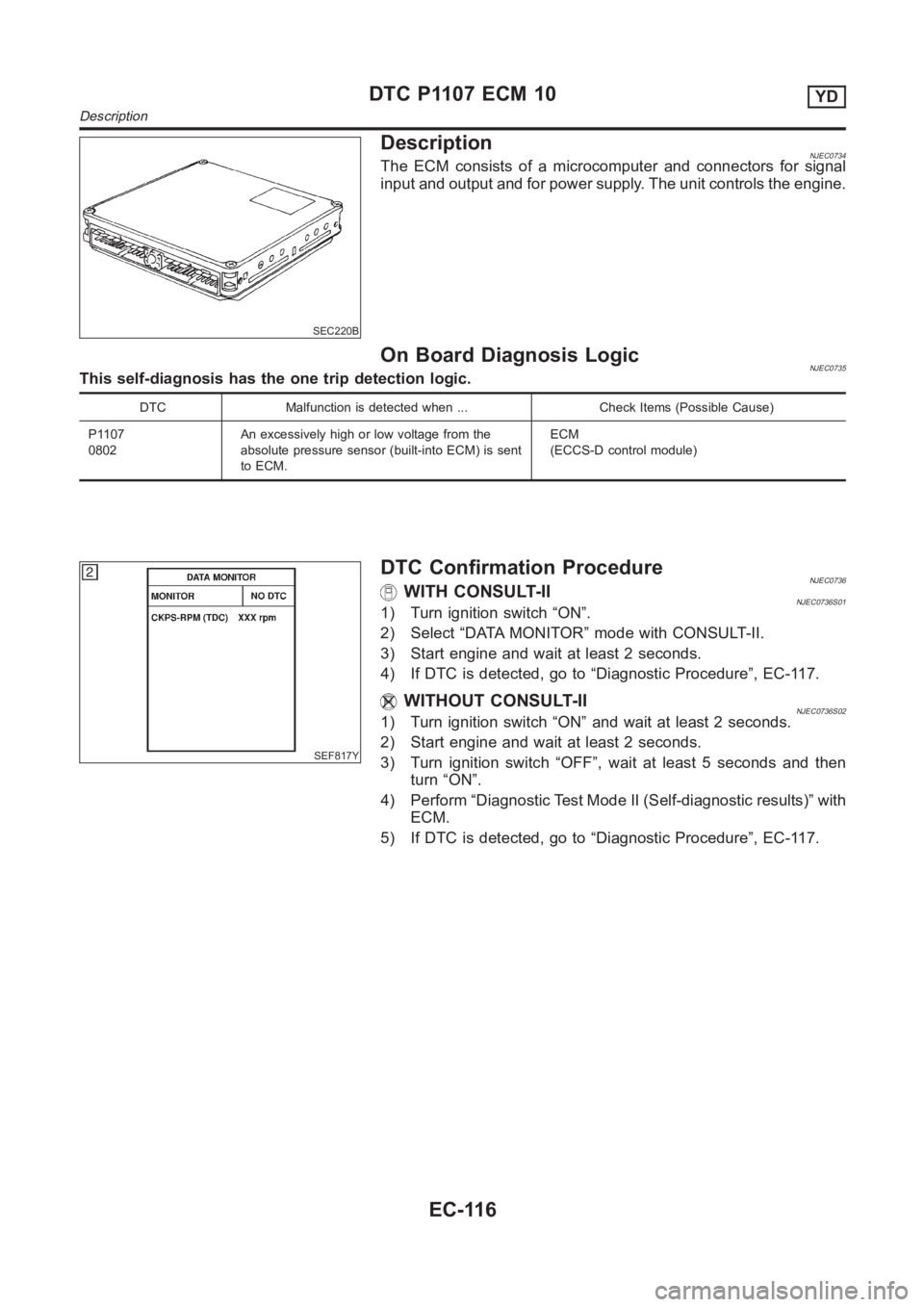

SEC220B

DescriptionNJEC0734The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the engine.

On Board Diagnosis LogicNJEC0735This self-diagnosis has the one trip detection logic.

DTC Malfunction is detected when ... Check Items (Possible Cause)

P1107

0802An excessively high or low voltage from the

absolute pressure sensor (built-into ECM) is sent

to ECM.ECM

(ECCS-D control module)

SEF817Y

DTC Confirmation ProcedureNJEC0736WITH CONSULT-IINJEC0736S011) Turn ignition switch “ON”.

2) Select “DATA MONITOR” mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to “Diagnostic Procedure”, EC-117.

WITHOUT CONSULT-IINJEC0736S021) Turn ignition switch “ON” and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch “OFF”, wait at least 5 seconds and then

turn “ON”.

4) Perform “Diagnostic Test Mode II (Self-diagnostic results)” with

ECM.

5) If DTC is detected, go to “Diagnostic Procedure”, EC-117.

DTC P1107 ECM 10YD

Description

EC-116

Page 1287 of 3189

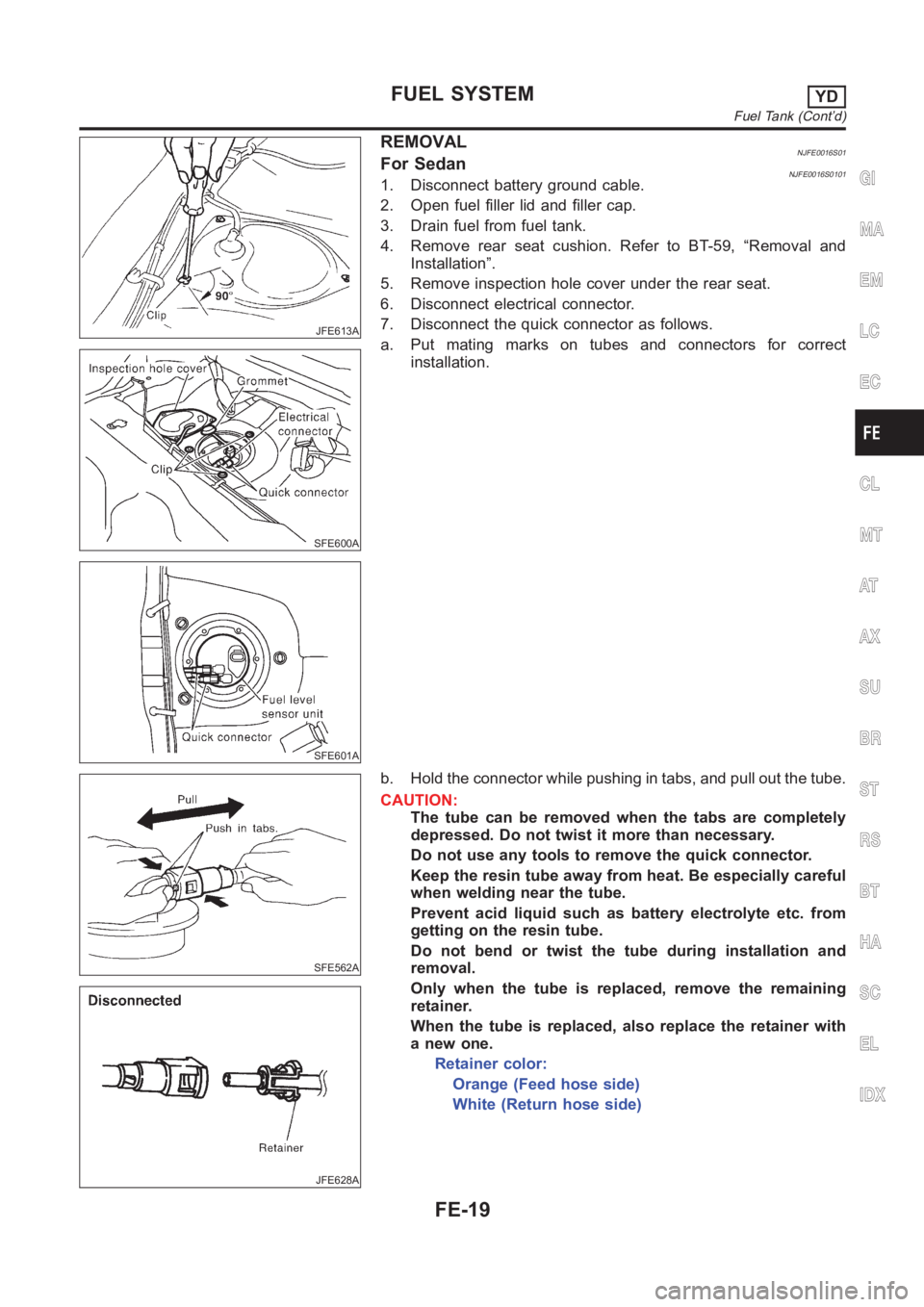

JFE613A

SFE600A

SFE601A

REMOVALNJFE0016S01For SedanNJFE0016S01011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-59, “Removal and

Installation”.

5. Remove inspection hole cover under the rear seat.

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct

installation.

SFE562A

JFE628A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

Do not use any tools to remove the quick connector.

Keep the resin tube away from heat. Be especially careful

when welding near the tube.

Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

Do not bend or twist the tube during installation and

removal.

Only when the tube is replaced, remove the remaining

retainer.

When the tube is replaced, also replace the retainer with

a new one.

Retainer color:

Orange (Feed hose side)

White (Return hose side)

GI

MA

EM

LC

EC

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL SYSTEMYD

Fuel Tank (Cont’d)

FE-19

Page 1289 of 3189

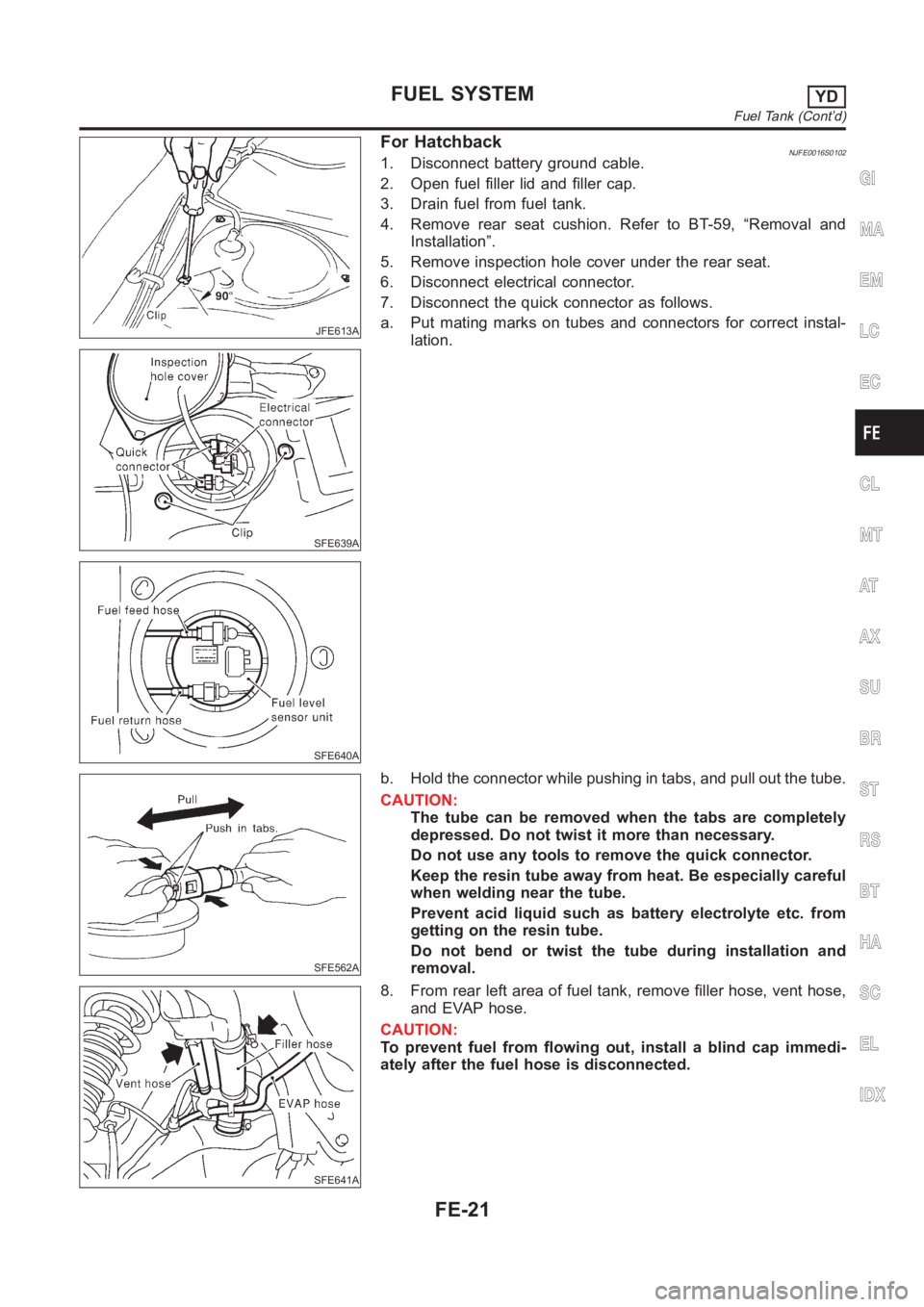

JFE613A

SFE639A

SFE640A

For HatchbackNJFE0016S01021. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Drain fuel from fuel tank.

4. Remove rear seat cushion. Refer to BT-59, “Removal and

Installation”.

5. Remove inspection hole cover under the rear seat.

6. Disconnect electrical connector.

7. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct instal-

lation.

SFE562A

b. Hold the connector while pushing in tabs, and pull out the tube.

CAUTION:

The tube can be removed when the tabs are completely

depressed. Do not twist it more than necessary.

Do not use any tools to remove the quick connector.

Keep the resin tube away from heat. Be especially careful

when welding near the tube.

Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

Do not bend or twist the tube during installation and

removal.

SFE641A

8. From rear left area of fuel tank, remove filler hose, vent hose,

and EVAP hose.

CAUTION:

To prevent fuel from flowing out, install a blind cap immedi-

ately after the fuel hose is disconnected.

GI

MA

EM

LC

EC

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FUEL SYSTEMYD

Fuel Tank (Cont’d)

FE-21

Page 1300 of 3189

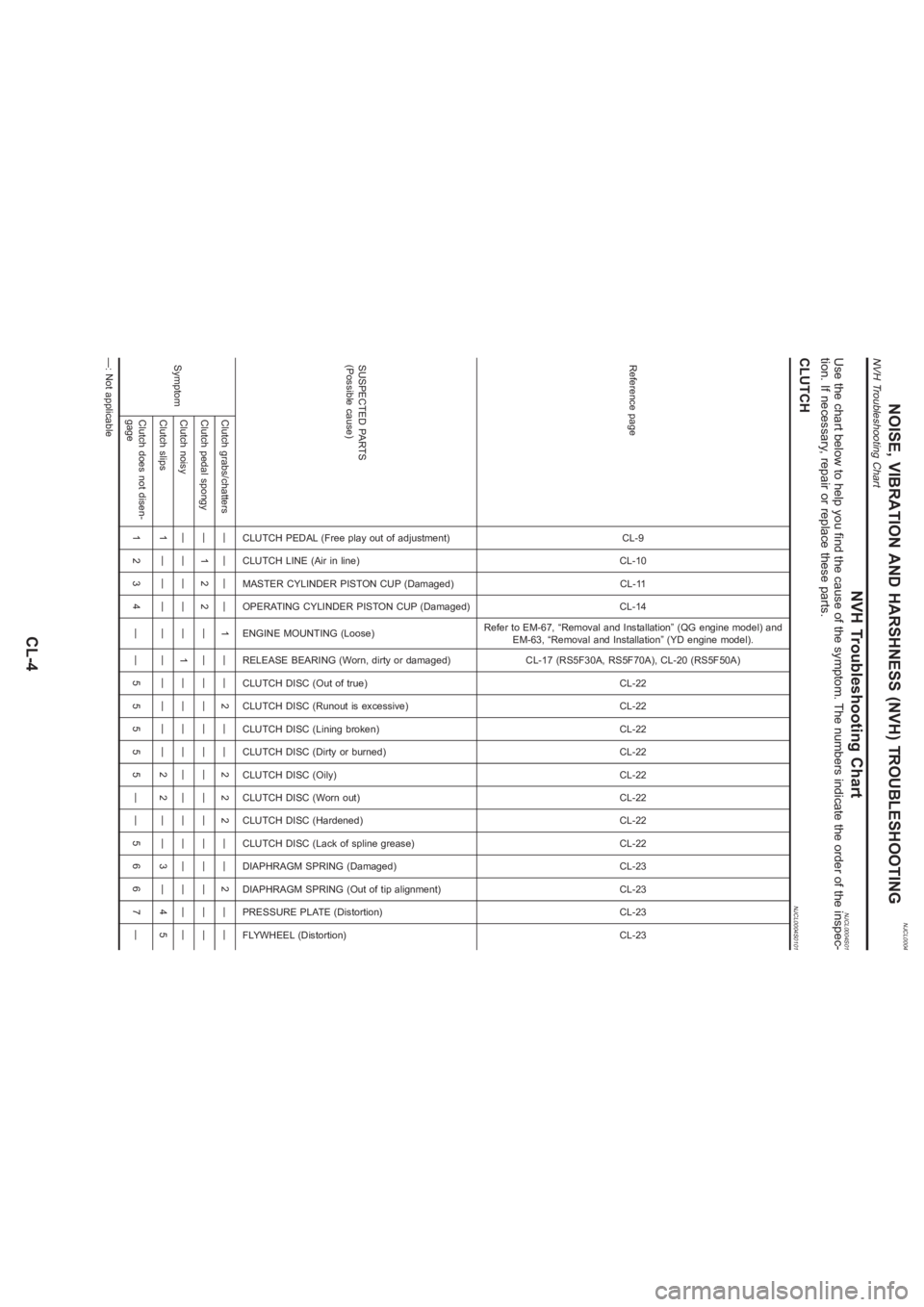

NJCL0004

NVH Troubleshooting Chart

NJCL0004S01

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.CLUTCH

NJCL0004S0101

Reference page

CL-9

CL-10

CL-11

CL-14

Refer to EM-67, “Removal and Installation” (QG engine model) and

EM-63, “Removal and Installation” (YD engine model).

CL-17 (RS5F30A, RS5F70A), CL-20 (RS5F50A)

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-23

CL-23

CL-23

CL-23

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters———— 1 —— 2 —— 2 2 2 —— 2 ——

Clutch pedal spongy — 1 2 2 ——————————————

Clutch noisy———— — 1 ————————————

Clutch slips 1 — — — —————— 2 2 —— 3 — 4 5

Clutch does not disen-

gage1234 ——55555——5667—

—: Not applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

CL-4

Page 1565 of 3189

![NISSAN ALMERA N16 2003 Electronic User Guide CAN COMMUNICATION

AT-109

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATIONPFP:23710

System DescriptionECS007O2

CAN (Controller Area Network) is a serial communication line for real time applicati NISSAN ALMERA N16 2003 Electronic User Guide CAN COMMUNICATION

AT-109

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATIONPFP:23710

System DescriptionECS007O2

CAN (Controller Area Network) is a serial communication line for real time applicati](/img/5/57350/w960_57350-1564.png)

CAN COMMUNICATION

AT-109

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATIONPFP:23710

System DescriptionECS007O2

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitECS007O3

×:Applicable

TYPE1

System diagram

Input/output signal chart

T: Transmit R: Receive Body type Sedan/ 5DH/B/ 3DH/B

Axle2WD

Engine QG18DE QG15DE/QG18DE

Transmission A/T M/T

Brake controlABS

CAN communication unit

ECM××

TCM×

Smart entrance control unit××

Data link connector××

Combination meter××

CAN communication type AT-109, "

TYPE1"AT-110, "TYPE 2"

SEL825Y

Signals ECM TCMSmart entrance

control unitCombination meter

Engine speed signal T R

Brake switch signal R T

Rear window defogger signal R T

Heater fan switch signal R T

Air conditioner switch signal R T

MI signal T R

Current gear position signal T R

Engine coolant temperature signal T R

Fuel consumption signal T R

Page 1761 of 3189

![NISSAN ALMERA N16 2003 Electronic User Guide CAN COMMUNICATION

AT-305

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATIONPFP:23710

System DescriptionECS007QX

CAN (Controller Area Network) is a serial communication line for real time app NISSAN ALMERA N16 2003 Electronic User Guide CAN COMMUNICATION

AT-305

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATIONPFP:23710

System DescriptionECS007QX

CAN (Controller Area Network) is a serial communication line for real time app](/img/5/57350/w960_57350-1760.png)

CAN COMMUNICATION

AT-305

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

CAN COMMUNICATIONPFP:23710

System DescriptionECS007QX

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN Communication UnitECS007QY

×:Applicable

TYPE 1

System diagram

Input/output signal chart

T: Transmit R: Receive Body type Sedan/ 5DH/B/ 3DH/B

Axle2WD

Engine QG18DE QG15DE/QG18DE

Transmission A/T M/T

Brake controlABS

CAN communication unit

ECM××

TCM×

Smart entrance control unit××

Data link connector××

Combination meter××

CAN communication type AT-305, "

TYPE 1"AT- 3 0 6 , "TYPE 2"

SEL825Y

Signals ECM TCMSmart entrance

control unitCombination meter

Engine speed signal T R

Brake switch signal R T

Rear window defogger signal R T

Heater fan switch signal R T

Air conditioner switch signal R T

MI signal T R

Current gear position signal T R

Engine coolant temperature signal T R

Fuel consumption signal T R

Page 1860 of 3189

![NISSAN ALMERA N16 2003 Electronic User Guide AT-404

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS007SW

CAUTION:

●Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

fer NISSAN ALMERA N16 2003 Electronic User Guide AT-404

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS007SW

CAUTION:

●Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

fer](/img/5/57350/w960_57350-1859.png)

AT-404

[ALL]

KEY INTERLOCK CABLE

KEY INTERLOCK CABLE

PFP:34908

ComponentsECS007SW

CAUTION:

●Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or inter-

ference with adjacent parts.

●After installing key interlock cable to control device, make sure that casing cap and bracket are

firmly secured in their positions.

RemovalECS007SX

1. Unlock slider by squeezing lock tabs on slider from adjuster

holder and remove interlock rod from cable.

SAT996J

SAT853J

Page 1984 of 3189

ATC-4

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EJS001YP

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

●To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

●Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

●Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harness connec-

tors.

Precautions for Working with HFC-134a (R-134a)EJS001YQ

WARNING:

●Use only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor malfunction is likely to occur.

●The specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

–When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

–When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possi-

ble to minimize the entry of moisture into system.

–Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

–Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove HFC-134a (R-134a) from the A/C system, using certified service equipment meet-

ing requirements of SAE J2210 HFC-134a (R-134a) recycling equipment, or J2209 HFC-134a (R-

134a) recovery equipment. If accidental system discharge occurs, ventilate work area before

resuming service. Additional health and safety information may be obtained from refrigerant and

lubricant manufacturers.

–Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

General Refrigerant PrecautionsEJS001YR

WARNING:

●Do not release refrigerant into the air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

●Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or

air conditioning system.

●Do not store or heat refrigerant containers above 52°C (125°F).

●Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

●Do not intentionally drop, puncture, or incinerate refrigerant containers.

●Keep refrigerant away from open flames: poisonous gas will be produced if refrigerant burns.

●Refrigerant will displace oxygen, therefore be certain to work in well ventilated areas to prevent

suffocation.

●Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condi-

tioning systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a)