Auto transmission NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 8 of 3189

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically. Continued refueling may cause fuel

overflow, resulting in fuel spray and possibly a fire.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do

not carelessly disconnect the harness connectors which are

related to the engine control system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

SGI787

PRECAUTIONS FOR MULTIPORT FUEL INJECTION

SYSTEM OR ENGINE CONTROL SYSTEM

NJGI0001S04Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air

flow sensor.

PRECAUTIONS FOR THREE WAY CATALYSTNJGI0001S05If a large amount of unburned fuel flows into the catalyst, the cata-

lyst temperature will be excessively high. To prevent this, follow the

instructions below:

Use unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

When checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

Do not run engine when the fuel tank level is low, otherwise the

engine may misfire, causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

SMA019D

PRECAUTIONS FOR HOSESNJGI0001S06Hose Removal and InstallationNJGI0001S0601To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

PRECAUTIONS

Precautions (Cont’d)

GI-6

Page 12 of 3189

NJGI0002

The captionsWARNINGandCAUTIONwarm you of steps that must be followed to prevent personal injury

and/or damage to some part of the vehicle.

WARNINGindicates the possibility of personal injury if instructions are not followed.

CAUTIONindicates the possibility of component damage if instructions are not followed.

BOLD TYPED STATEMENTSexceptWARNINGandCAUTIONgive you helpful information.

ALPHABETICAL INDEXis provided at the end of this manual so that you can rapidly find the item and

page you are searching for.

A QUICK REFERENCE INDEX, a black tab (e.g.

) is provided on the first page. You can quickly find

the first page of each section by matching it to the section’s black tab.

THE CONTENTSare listed on the first page of each section.

THE TITLEis indicated on the upper portion of each page and shows the part or system.

THE PAGE NUMBERof each section consists of two letters which designate the particular section and a

number (e.g. “BR-5”).

THE LARGE ILLUSTRATIONSare exploded views (See below.) and contain tightening torques, lubrica-

tion points, section number of thePARTS CATALOG(e.g. SEC. 440) and other information necessary to

perform repairs.

The illustrations should be used in reference to service matters only. When ordering parts, refer to the

appropriatePARTS CATALOG.

SBR364AC

THE SMALL ILLUSTRATIONSshow the important steps such as inspection, use of special tools, knacks

of work and hidden or tricky steps which are not shown in the previous large illustrations.

Assembly, inspection and adjustment procedures for the complicated units such as the automatic transaxle

or transmission, etc. are presented in a step-by-step format where necessary.

TheUNITSgiven in this manual are primarily expressed as the SI UNIT (InternationalSystem of Unit),

and alternatively expressed in the metric system and in the yard/pound system.

“Example”

Tightening torque:

59 - 78 N·m (6.0 - 8.0 kg-m, 43 - 58 ft-lb)

TROUBLE DIAGNOSESare included in sections dealing with complicated components.

HOW TO USE THIS MANUAL

GI-10

Page 13 of 3189

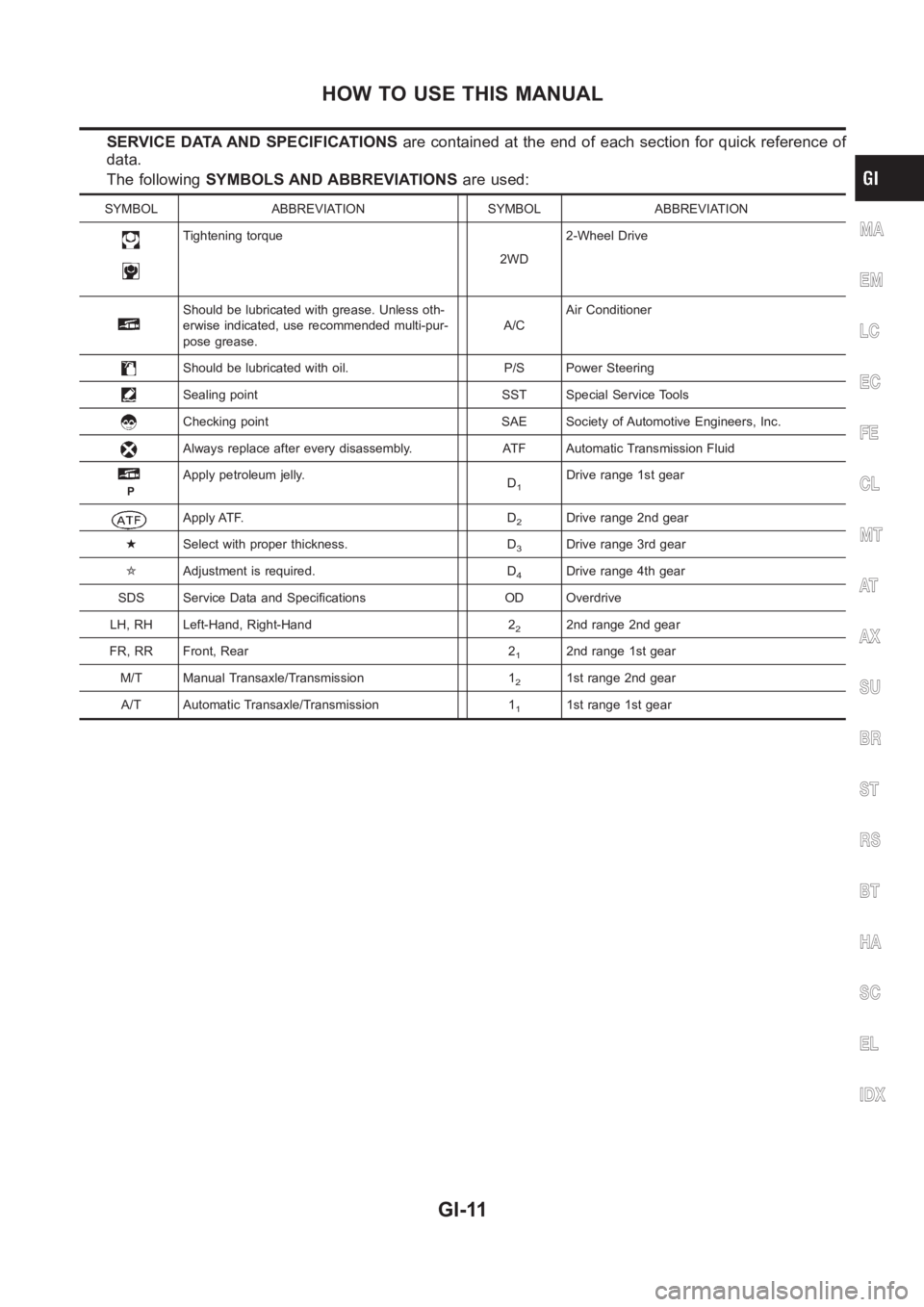

SERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

The followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

P

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

★Select with proper thickness. D

3Drive range 3rd gear

✩Adjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO USE THIS MANUAL

GI-11

Page 50 of 3189

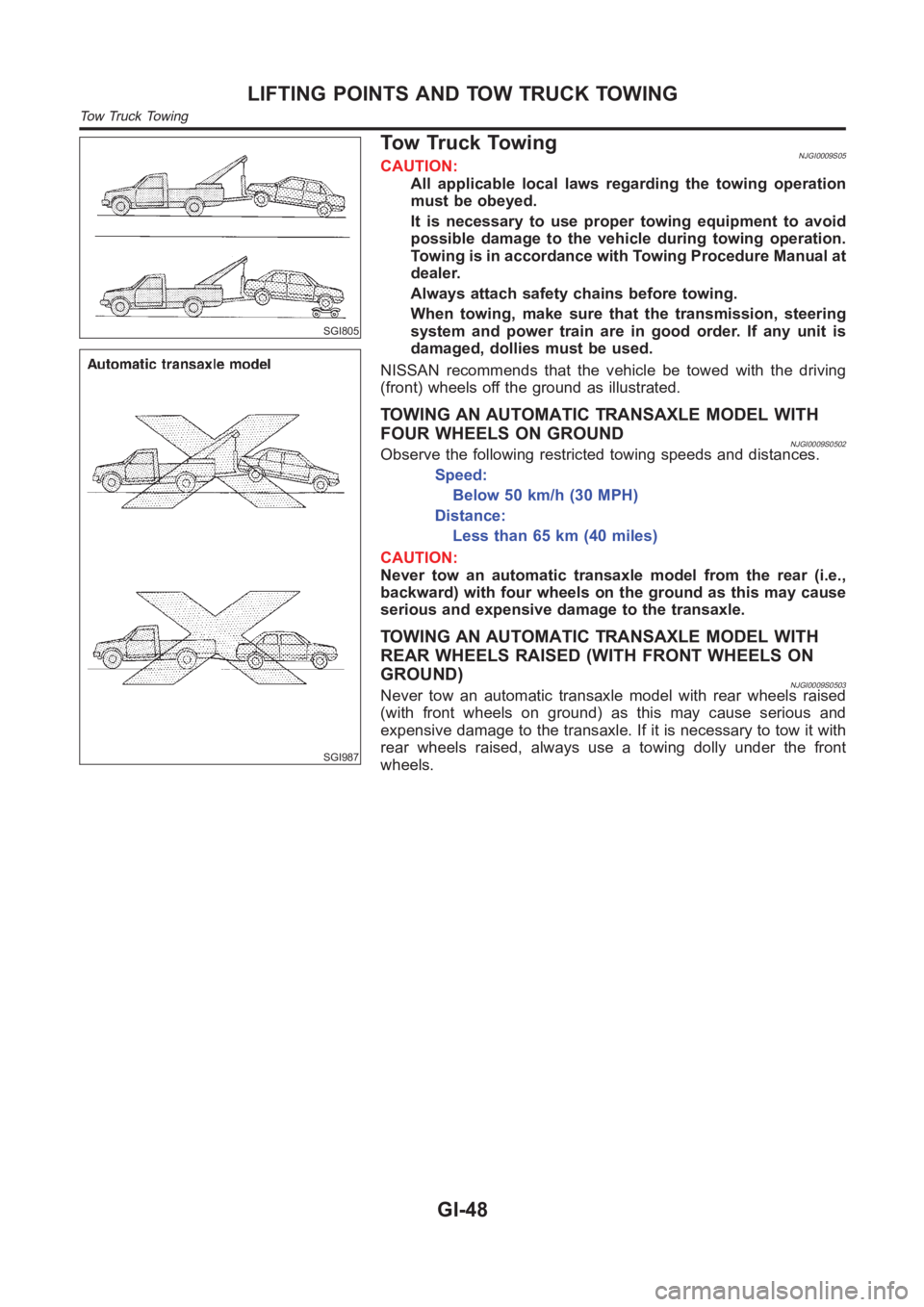

SGI805

SGI987

Tow Truck TowingNJGI0009S05CAUTION:

All applicable local laws regarding the towing operation

must be obeyed.

It is necessary to use proper towing equipment to avoid

possible damage to the vehicle during towing operation.

Towing is in accordance with Towing Procedure Manual at

dealer.

Always attach safety chains before towing.

When towing, make sure that the transmission, steering

system and power train are in good order. If any unit is

damaged, dollies must be used.

NISSAN recommends that the vehicle be towed with the driving

(front) wheels off the ground as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

FOUR WHEELS ON GROUND

NJGI0009S0502Observe the following restricted towing speeds and distances.

Speed:

Below 50 km/h (30 MPH)

Distance:

Less than 65 km (40 miles)

CAUTION:

Never tow an automatic transaxle model from the rear (i.e.,

backward) with four wheels on the ground as this may cause

serious and expensive damage to the transaxle.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH

REAR WHEELS RAISED (WITH FRONT WHEELS ON

GROUND)

NJGI0009S0503Never tow an automatic transaxle model with rear wheels raised

(with front wheels on ground) as this may cause serious and

expensive damage to the transaxle. If it is necessary to tow it with

rear wheels raised, always use a towing dolly under the front

wheels.

LIFTING POINTS AND TOW TRUCK TOWING

Tow Truck Towing

GI-48

Page 58 of 3189

NJMA0036

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard tothe conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 75 of 3189

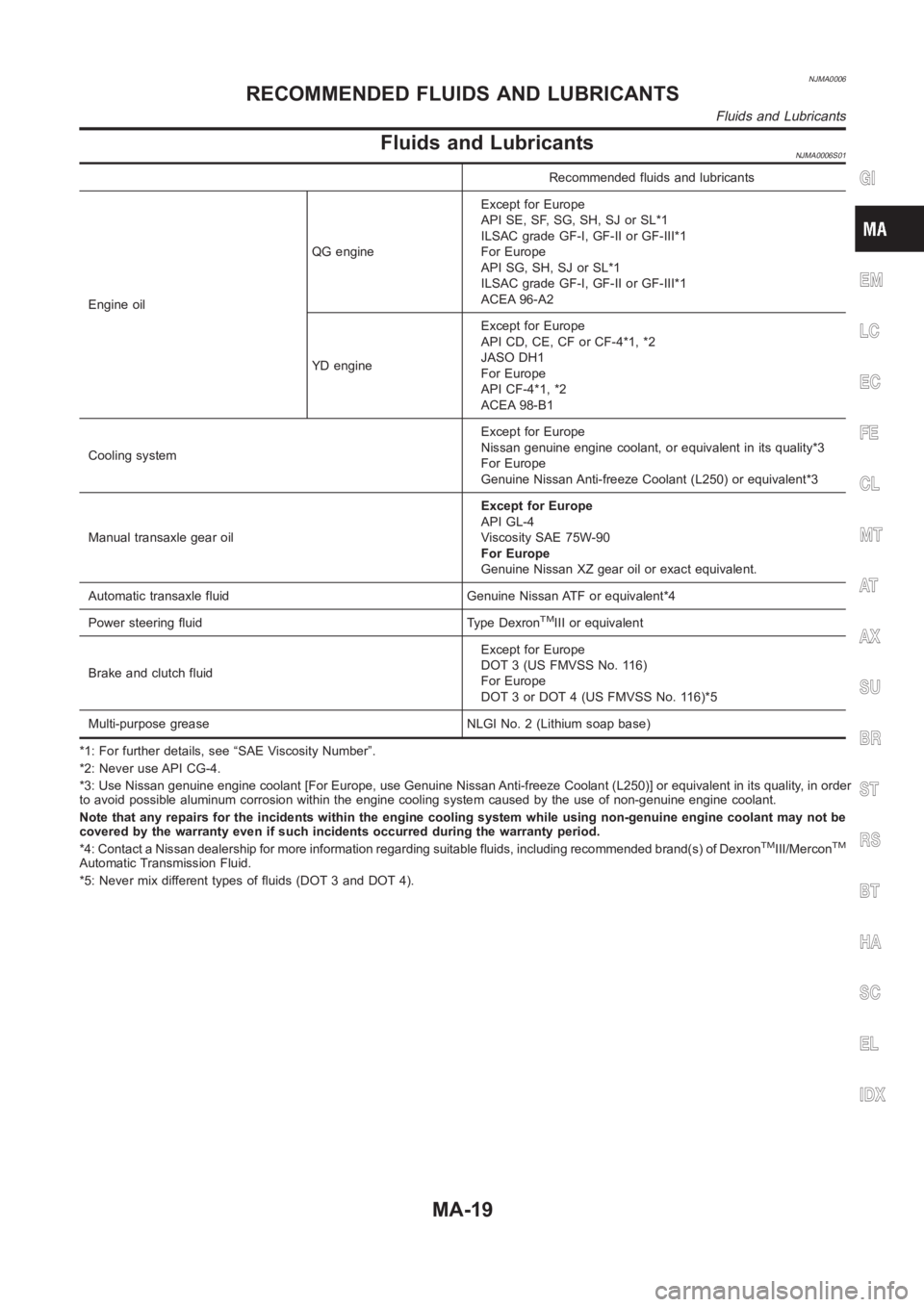

NJMA0006

Fluids and LubricantsNJMA0006S01

Recommended fluids and lubricants

Engine oilQG engineExcept for Europe

API SE, SF, SG, SH, SJ or SL*1

ILSAC grade GF-I, GF-II or GF-III*1

For Europe

API SG, SH, SJ or SL*1

ILSAC grade GF-I, GF-II or GF-III*1

ACEA 96-A2

YD engineExcept for Europe

API CD, CE, CF or CF-4*1, *2

JASO DH1

For Europe

API CF-4*1, *2

ACEA 98-B1

Cooling systemExcept for Europe

Nissan genuine engine coolant, or equivalent in its quality*3

For Europe

Genuine Nissan Anti-freeze Coolant (L250) or equivalent*3

Manual transaxle gear oilExcept for Europe

API GL-4

Viscosity SAE 75W-90

For Europe

Genuine Nissan XZ gear oil or exact equivalent.

Automatic transaxle fluid Genuine Nissan ATF or equivalent*4

Power steering fluid Type Dexron

TMIII or equivalent

Brake and clutch fluidExcept for Europe

DOT 3 (US FMVSS No. 116)

For Europe

DOT 3 or DOT 4 (US FMVSS No. 116)*5

Multi-purpose grease NLGI No. 2 (Lithium soap base)

*1: For further details, see “SAE Viscosity Number”.

*2: Never use API CG-4.

*3: Use Nissan genuine engine coolant [For Europe, use Genuine Nissan Anti-freeze Coolant (L250)] or equivalent in its quality, in order

to avoid possible aluminum corrosion within the engine cooling system caused by the use of non-genuine engine coolant.

Note that any repairs for the incidents within the engine cooling system while using non-genuine engine coolant may not be

covered by the warranty even if such incidents occurred during the warranty period.

*4: Contact a Nissan dealership for more information regarding suitable fluids, including recommended brand(s) of Dexron

TMIII/MerconTM

Automatic Transmission Fluid.

*5: Never mix different types of fluids (DOT 3 and DOT 4).

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-19

Page 390 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-60

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using NISSAN ALMERA N16 2003 Electronic Repair Manual EC-60

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using](/img/5/57350/w960_57350-389.png)

EC-60

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

“DIAGNOSTIC WORK SHEET”, EC-61

.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or GST) the (1st trip) DTC and the

(1st trip) freeze frame data, then erase the DTC and the data. (Refer toEC-48, "

HOW TO ERASE EMISSION-

RELATED DIAGNOSTIC INFORMATION" .) The (1st trip) DTC and the (1st trip) freeze frame data can be used when

duplicating the incident at STEP III & IV.

If the incident cannot be verified, perform EC-109, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the customer.

(The “Symptom Matrix Chart” will be useful. See EC-70

.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The “DIAGNOSTIC WORK SHEET” and the freeze frame data are useful to verify the incident. Connect CONSULT-II

to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-109, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) DTC by driving in (or performing) the “DTC Confirmation Procedure”. Check and read the

(1st trip) DTC and (1st trip) freeze frame data by using CONSULT-II or GST.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG)

mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-109, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

In case the “DTC Confirmation Procedure” is not available, perform the “Overall Function Check” instead. The (1st

trip) DTC cannot be displayed by this check, however, this simplified “check” is an effective alternative.

The “NG” result of the “Overall Function Check” is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-65

.) If COSULT-II is available, per-

form “DATA MONITOR (SPEC)” mode with CONSULT-II and proceed to the “TOROUBLE DIAGNOSIS – SPECIFI-

CATION VALUE”. (Refer to EC-105

.) (If malfunction is detected, proceed to “PERAIR/REPLACE”.) Then perform

inspections according to the Symptom Matrix Chart. (Refer to EC-70

.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect the

system for mechanical binding, loose connectors or wiring damage using (tracing) “Harness Layouts”.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR

(AUTO TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CONSULT-II.

Refer to EC-80

, EC-99 .

The “Diagnostic Procedure” in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to “Circuit Inspection” in

GI-22.

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform EC-109, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT" .

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions and

circumstances which resulted in the customer's initial complaint.

Perform the “DTC Confirmation Procedure” and confirm the normal code [DTC No. P0000] is detected. If the incident

is still detected in the final check, perform STEP VI by using a method different from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in ECM

and TCM (Transmission control module). (Refer toEC-48, "

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC

INFORMATION" and AT- 3 9 , "HOW TO ERASE DTC" .)

Page 768 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-438

[QG (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred u NISSAN ALMERA N16 2003 Electronic Repair Manual EC-438

[QG (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred u](/img/5/57350/w960_57350-767.png)

EC-438

[QG (WITHOUT EURO-OBD)]

TROUBLE DIAGNOSIS

Description for Work Flow

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using the

“DIAGNOSTIC WORK SHEET”, EC-440

.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II) the (1st trip) DTC and the (1st

trip) freeze frame data, then erase the DTC and the data. (Refer to EC-430

.) The (1st trip) DTC and the (1st trip)

freeze frame data can be used when duplicating the incident at STEP III & IV.

If the incident cannot be verified, perform EC-485, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the customer.

(The “Symptom Matrix Chart” will be useful. See EC-448

.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The “DIAGNOSTIC WORK SHEET” and the freeze frame data are useful to verify the incident. Connect CONSULT-II

to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-485, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) DTC by driving in (or performing) the “DTC Confirmation Procedure”. Check and read the

(1st trip) DTC and (1st trip) freeze frame data by using CONSULT-II or GST.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO TRIG)

mode and check real time diagnosis results.

If the incident cannot be verified, perform EC-485, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT" .

In case the “DTC Confirmation Procedure” is not available, perform the “Overall Function Check” instead. The (1st

trip) DTC cannot be displayed by this check, however, this simplified “check” is an effective alternative.

The “NG” result of the “Overall Function Check” is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-443

.) If COSULT-II is available,

perform “DATA MONITOR (SPEC)” mode with CONSULT-II and proceed to the “TOROUBLE DIAGNOSIS – SPECI-

FICATION VALUE”. (Refer to EC-481

.) (If malfunction is detected, proceed to “PERAIR/REPLACE”.) Then perform

inspections according to the Symptom Matrix Chart. (Refer to EC-448

.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes. Inspect the

system for mechanical binding, loose connectors or wiring damage using (tracing) “Harness Layouts”.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in “DATA MONITOR

(AUTO TRIG)” mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CONSULT-II.

Refer to EC-458

, EC-475 .

The “Diagnostic Procedure” in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to “Circuit Inspection” in

GI-22.

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform EC-485, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT" .

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions and

circumstances which resulted in the customer's initial complaint.

Perform the “DTC Confirmation Procedure” and confirm the normal code [DTC No. P0000] is detected. If the incident

is still detected in the final check, perform STEP VI by using a method different from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in ECM

and TCM (Transmission control module). (Refer to EC-430, "

HOW TO ERASE EMISSION-RELATED DIAGNOSTIC

INFORMATION" .)

Page 1457 of 3189

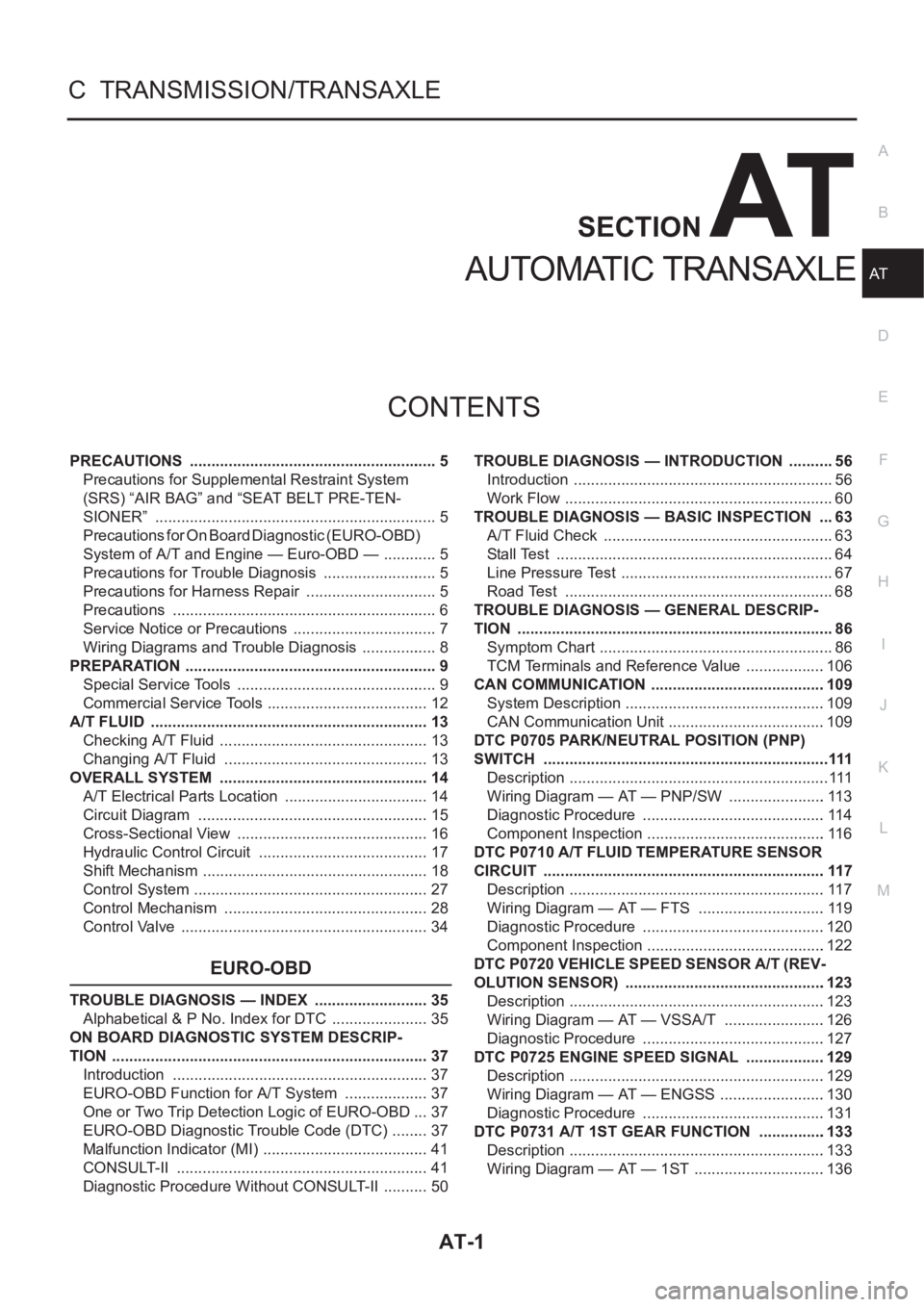

AT-1

AUTOMATIC TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

AT

AUTOMATIC TRANSAXLE

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions for On Board Diagnostic (EURO-OBD)

System of A/T and Engine — Euro-OBD — ............. 5

Precautions for Trouble Diagnosis ........................... 5

Precautions for Harness Repair ............................... 5

Precautions .............................................................. 6

Service Notice or Precautions .................................. 7

Wiring Diagrams and Trouble Diagnosis .................. 8

PREPARATION ........................................................... 9

Special Service Tools ............................................... 9

Commercial Service Tools ...................................... 12

A/T FLUID ................................................................. 13

Checking A/T Fluid ................................................. 13

Changing A/T Fluid ............................................. ... 13

OVERALL SYSTEM ................................................. 14

A/T Electrical Parts Location .................................. 14

Circuit Diagram ...................................................... 15

Cross-Sectional View ............................................. 16

Hydraulic Control Circuit ........................................ 17

Shift Mechanism ..................................................... 18

Control System ....................................................... 27

Control Mechanism ................................................ 28

Control Valve .......................................................... 34

EURO-OBD

TROUBLE DIAGNOSIS — INDEX ........................... 35

Alphabetical & P No. Index for DTC ....................... 35

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION .......................................................................... 37

Introduction ............................................................ 37

EURO-OBD Function for A/T System .................... 37

One or Two Trip Detection Logic of EURO-OBD ... 37

EURO-OBD Diagnostic Trouble Code (DTC) ......... 37

Malfunction Indicator (MI) ....................................... 41

CONSULT-II ........................................................... 41

Diagnostic Procedure Without CONSULT-II ........... 50TROUBLE DIAGNOSIS — INTRODUCTION ........... 56

Introduction ............................................................. 56

Work Flow ............................................................... 60

TROUBLE DIAGNOSIS — BASIC INSPECTION .... 63

A/T Fluid Check ...................................................... 63

Stall Test ................................................................. 64

Line Pressure Test .................................................. 67

Road Test ............................................................... 68

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION .......................................................................... 86

Symptom Chart ....................................................... 86

TCM Terminals and Reference Value ...................106

CAN COMMUNICATION .........................................109

System Description ...............................................109

CAN Communication Unit .....................................109

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH ...................................................................111

Description .............................................................111

Wiring Diagram — AT — PNP/SW .......................113

Diagnostic Procedure ...........................................114

Component Inspection ..........................................116

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................117

Description ............................................................117

Wiring Diagram — AT — FTS ..............................119

Diagnostic Procedure ...........................................120

Component Inspection ..........................................122

DTC P0720 VEHICLE SPEED SENSOR A/T (REV-

OLUTION SENSOR) ...............................................123

Description ............................................................123

Wiring Diagram — AT — VSSA/T ........................126

Diagnostic Procedure ...........................................127

DTC P0725 ENGINE SPEED SIGNAL ...................129

Description ............................................................129

Wiring Diagram — AT — ENGSS .........................130

Diagnostic Procedure ..........................................

.131

DTC P0731 A/T 1ST GEAR FUNCTION ................133

Description ............................................................133

Wiring Diagram — AT — 1ST ...............................136

Page 1475 of 3189

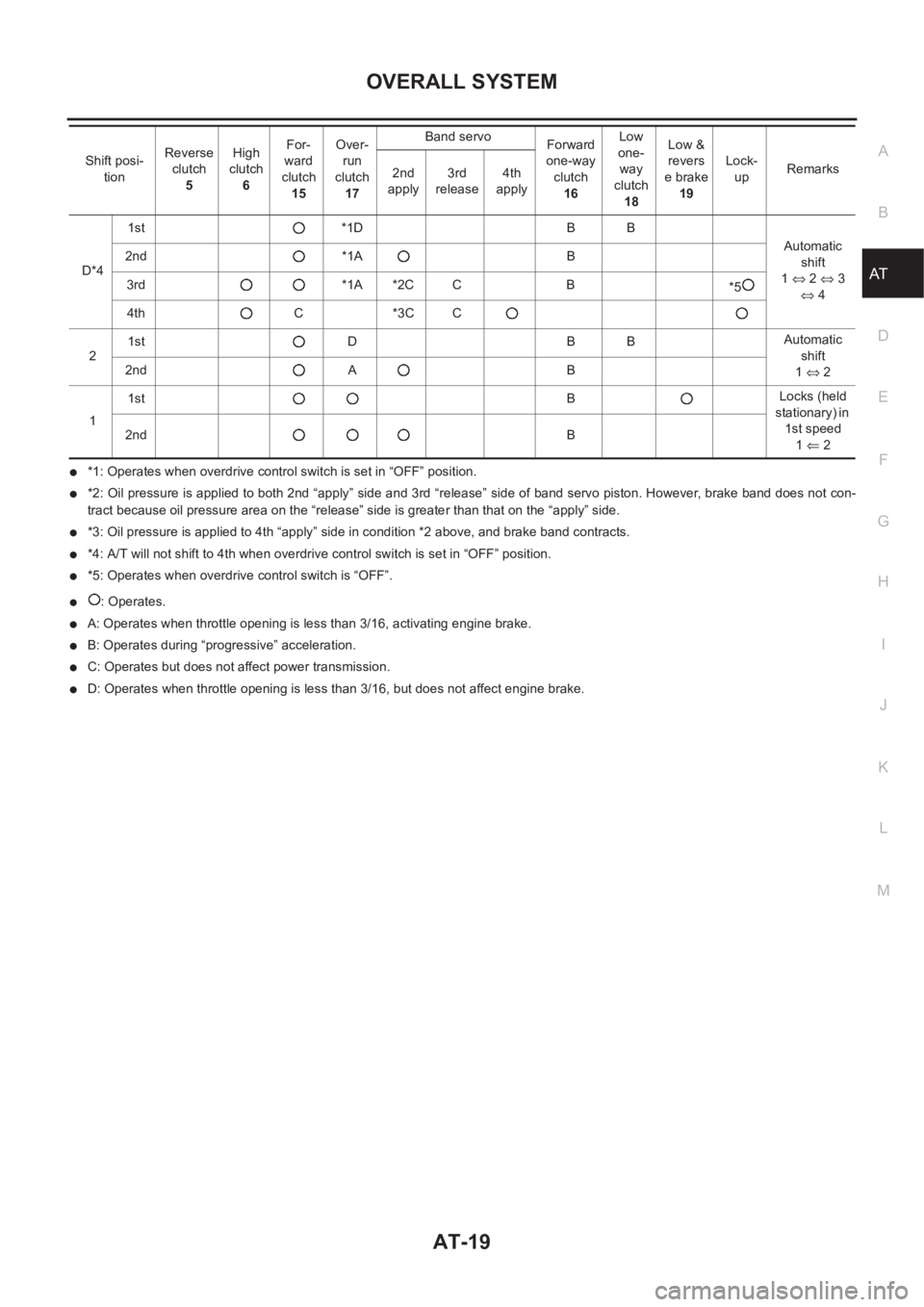

OVERALL SYSTEM

AT-19

D

E

F

G

H

I

J

K

L

MA

B

AT

●*1: Operates when overdrive control switch is set in “OFF” position.

●*2: Oil pressure is applied to both 2nd “apply” side and 3rd “release” side of band servo piston. However, brake band does not con-

tract because oil pressure area on the “release” side is greater than that on the “apply” side.

●*3: Oil pressure is applied to 4th “apply” side in condition *2 above, and brake band contracts.

●*4: A/T will not shift to 4th when overdrive control switch is set in “OFF” position.

●*5: Operates when overdrive control switch is “OFF”.

●: Operates.

●A: Operates when throttle opening is less than 3/16, activating engine brake.

●B: Operates during “progressive” acceleration.

●C: Operates but does not affect power transmission.

●D: Operates when throttle opening is less than 3/16, but does not affect engine brake. D*41st *1D B B

Automatic

shift

1⇔ 2 ⇔ 3

⇔ 4 2nd *1A B

3rd *1A *2C C B

*5

4th C *3C C

21st D B BAutomatic

shift

1⇔ 2 2nd A B

11stBLocks (held

stationary) in

1st speed

1⇐ 2 2ndB Shift posi-

tionReverse

clutch

5High

clutch

6For-

ward

clutch

15Over-

run

clutch

17Band servo

Forward

one-way

clutch

16Low

one-

way

clutch

18Low &

revers

e brake

19Lock-

upRemarks

2nd

apply3rd

release4th

apply