oil temperature NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 10 of 3189

Do not use gasoline, kerosine, diesel fuel, gas oil, thinners or

solvents for cleaning skin.

If skin disorders develop, obtain medical advice without delay.

Where practicable, degrease components prior to handling.

Where there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields; in addi-

tion an eye wash facility should be provided.

Environmental Protection PrecautionsNJGI0001S0702Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt, check with the

appropriate local authority and/or manufacturer of the approved

appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning the pollution vary between

regions.

PRECAUTIONS FOR FUELNJGI0001S08Gasoline EngineNJGI0001S0803Europe

Models with three way catalyst

Unleaded premium gasoline of at least 95 octane (RON)

If premium gasoline is not available, unleaded regular gaso-

line with an octane rating of 91 (RON) may be temporarily

used, but only under the following precautions:

Have the fuel tank filled only partially with unleaded regu-

lar gasoline, and fill up with premium unleaded gasoline

as soon as possible.

Avoid full throttle driving and abrupt acceleration.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Except For Europe

Models without three way catalyst

Leaded gasoline of at least 91 octane (RON)

Models with three way catalyst

Unleaded gasoline of above 91 octane (RON)

For improved vehicle performance, Nissan recommends the use of

premium unleaded gasoline above 95 octane (RON).

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Diesel Engine*:NJGI0001S0804Diesel fuel of at least 50 cetane

* If two types of diesel fuel are available, use summer or winter

fuel properly according to the following temperature conditions.

Above −7°C (20°F) ... Summer type diesel fuel.

Below −7°C (20°F) ... Winter type diesel fuel.

CAUTION:

Do not use home heating oil, gasoline, or other alternate

PRECAUTIONS

Precautions (Cont’d)

GI-8

Page 62 of 3189

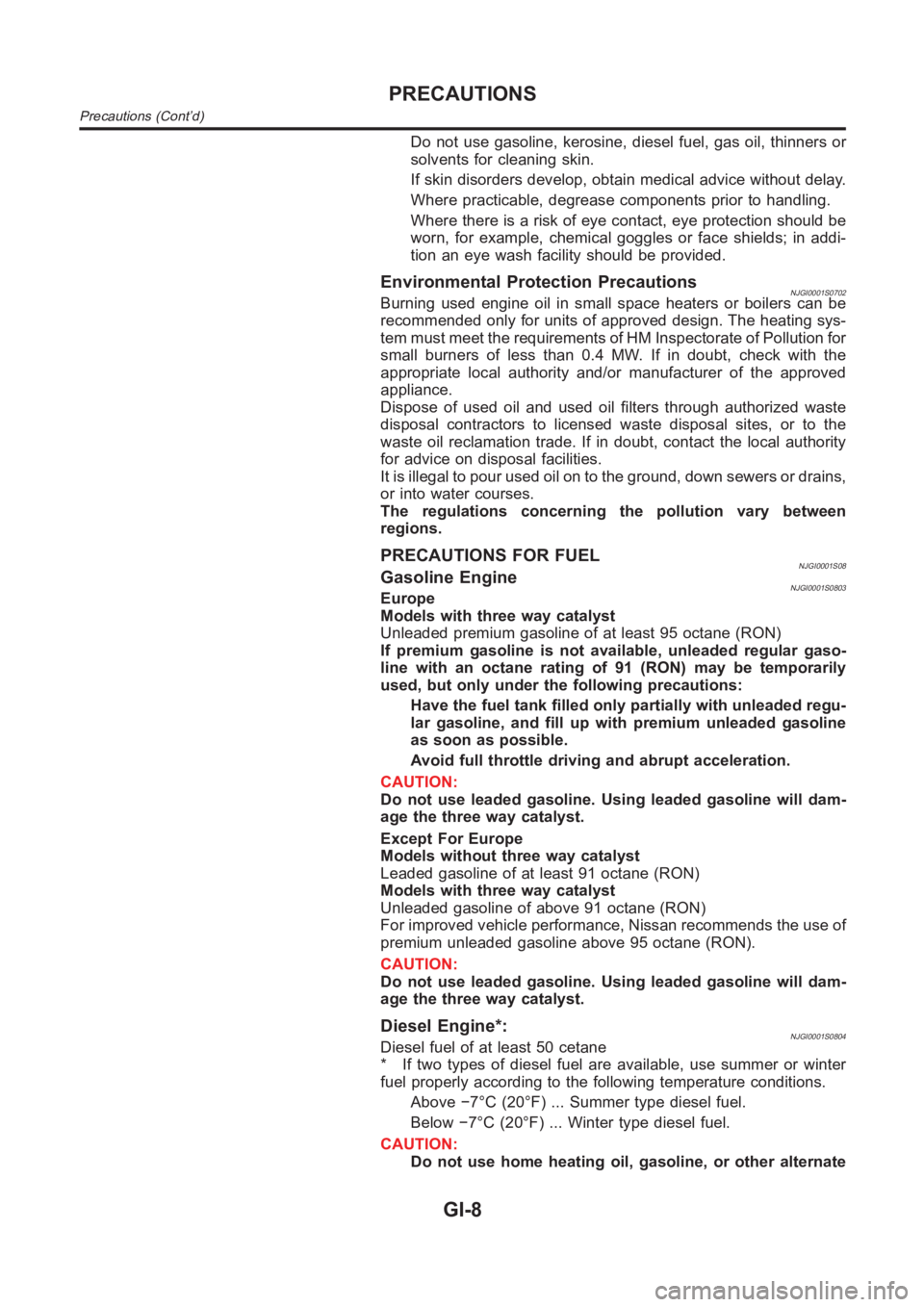

Maintenance Under Severe Driving Conditions=NJMA0005S06The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

Severe driving conditions

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

Maintenance operation: Check = Check and correct or replace as necessary.

Driving condition Maintenance itemMaintenance

operationMaintenance intervalReference

page

A........Aircleaner filter Replace More frequently EM-14

ABCD.....Engine oil & oil filter (Gaso-

line engine)ReplaceEvery 5,000 km (3,000

miles) or 3 monthsLC-8, LC-9

.....F...Brakefluid ReplaceEvery 20,000 km (12,000

miles) or 12 monthsBR-7

..C....H.Automatictransaxlefluid ReplaceEvery 40,000 km (24,000

miles) or 24 monthsAT-13

......GH.Steering gear & linkage, axle

& suspension parts & drive

shaftsCheckEvery 10,000 km (6,000

miles) or 6 monthsST-7, SU-6,

SU-18

A.C...GHIBrake pads, rotors & other

brake componentsCheckEvery 5,000 km (3,000

miles) or 3 monthsBR-27,

BR-31

A.C...GHIBrake linings, drums & other

brake componentsCheckEvery 10,000 km (6,000

miles) or 6 monthsBR-7

......G..Lock,hinges & hood latch LubricateEvery 5,000 km (3,000

miles) or 3 monthsBT-16, BT-7

A........Ventilation air filter Replace More frequentlyHA-95 or

ATC-128

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Maintenance Under Severe Driving Conditions

MA-6

Page 67 of 3189

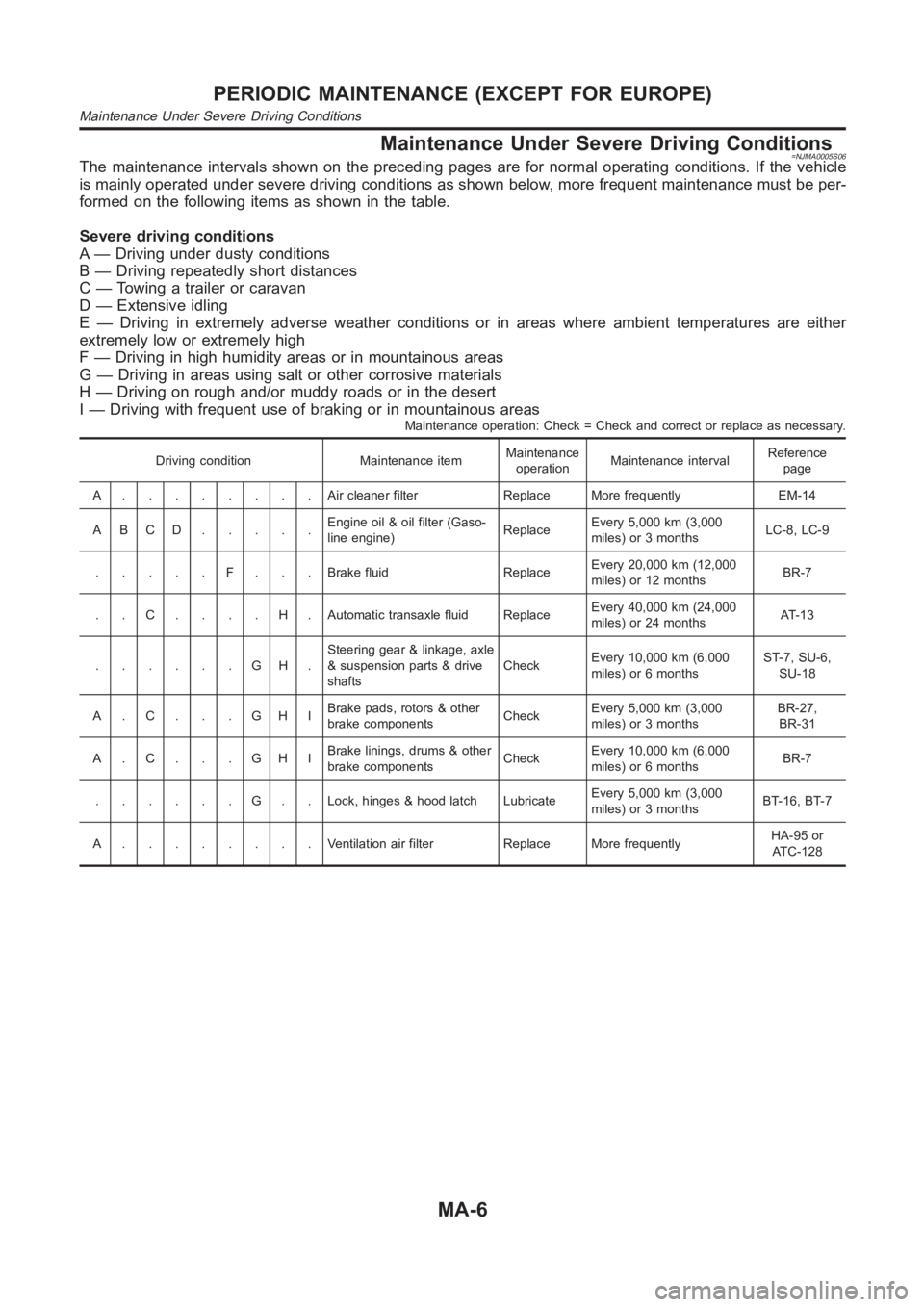

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)

=NJMA0043S03The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K — Sustained high speed driving

L — For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models ReplaceEvery 7,500 km (4,500 miles) or 6

months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or 6

months

A...........Air cleaner filter

Petrol models ReplaceEvery 30,000 km (18,000 miles) or

24 months

Diesel models ReplaceEvery 30,000 km (18,000 miles) or

18 months

A...E.......Fuel filter

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

...........LHeated Oxygen Sensor 1 (Front)

Petrol models InspectEvery 30,000 km (18,000 miles) or

24 months

...........LHeated Oxygen Sensor 2 (Rear)

Petrol models InspectEvery 30,000 km (18,000 miles) or

24 months

A...........Ventilation air filter

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or 6

months

.....F......Brake fluid

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance < 30,000 km/year)

MA-11

Page 73 of 3189

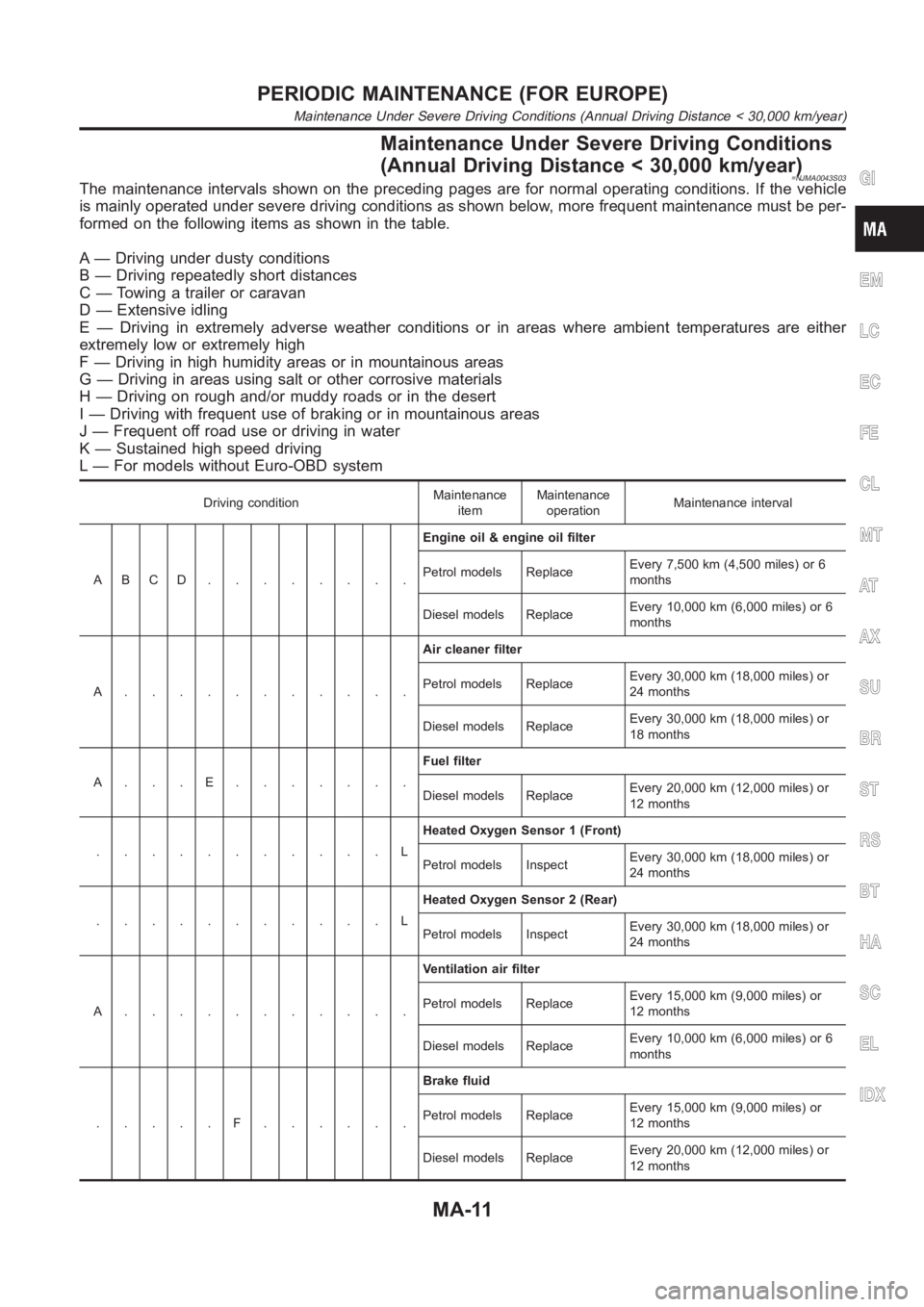

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km/year)

=NJMA0043S06The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K — Sustained high speed driving

L — For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models Replace Every 7,500 km (4,500 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

A...........Air cleaner filter

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

A...E.......Fuel filter

Diesel models Replace Every 30,000 km (18,000 miles)

...........LHeated Oxygen Sensor 1 (Front)

Petrol models Inspect Every 60,000 km (36,000 miles)

...........LHeated Oxygen Sensor 2 (Rear)

Petrol models Inspect Every 60,000 km (36,000 miles)

A...........Ventilation air filter

Petrol models Replace Every 15,000 km (9,000 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

.....F......Brake fluid

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

..C....H....Automatic transaxle fluid

Petrol models Replace Every 60,000 km (36,000 miles)

A.C...GHI...Brake pads, rotors & other brake system components

Petrol models Inspect Every 15,000 km (9,000 miles)

Diesel models Inspect Every 10,000 km (6,000 miles)

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance > 30,000 km/year)

MA-17

Page 138 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-60

[QG]

CYLINDER HEAD

3. Tighten cylinder auxiliary bolts (11) to (14) in numerical order

shown in figure.

●Pay attention to shank length under bolt head. [11: 20 mm

(0.79 in), 12 - 14: NISSAN ALMERA N16 2003 Electronic Repair Manual EM-60

[QG]

CYLINDER HEAD

3. Tighten cylinder auxiliary bolts (11) to (14) in numerical order

shown in figure.

●Pay attention to shank length under bolt head. [11: 20 mm

(0.79 in), 12 - 14:](/img/5/57350/w960_57350-137.png)

EM-60

[QG]

CYLINDER HEAD

3. Tighten cylinder auxiliary bolts (11) to (14) in numerical order

shown in figure.

●Pay attention to shank length under bolt head. [11: 20 mm

(0.79 in), 12 - 14: 25 mm (0.98 in)]

Disassembly and AssemblyEBS00LQJ

CAUTION:

●When installing camshafts, chain tensioners, oil seals or other sliding parts, lubricate contacting

surface with new engine oil.

●Apply new engine oil to threads and seat surface when installing cylinder head, camshaft

sprocket, crankshaft pulley and camshaft bracket.

●Attach tags to valve lifters so as not to mix them up.

DISASSEMBLY

1. Remove adjusting shim (if so equipped) and valve lifter.

●Confirm installation point.

SEM900F

PBIC0973E

1. Cylinder head 2. Valve (INT) 3. Valve (EXH)

4. Valve seat 5. Engine coolant temperature sensor 6. Copper washer

7. Spark plug tube 8. Spark plug

Page 139 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-61

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Remove valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Remove valve collet with magnet driver.

3. Remo NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-61

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Remove valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Remove valve collet with magnet driver.

3. Remo](/img/5/57350/w960_57350-138.png)

CYLINDER HEAD

EM-61

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

2. Remove valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Remove valve collet with magnet driver.

3. Remove valve spring retainer and valve spring.

4. Push valve stem to combustion chamber side, and remove

valve.

●Inspect valve guide clearance before removal. Refer to EM-

63, "VALVE GUIDE CLEARANCE" .

●Confirm installation point.

5. Remove valve oil seal with valve oil seal puller (special service

tool).

6. Remove valve spring seat.

7. When valve seat must be replaced, refer to EM-64, "

VA LV E

SEAT REPLACEMENT" .

8. When valve guide must be replaced, refer to EM-63, "

VA LV E

GUIDE REPLACEMENT" .

9. Remove spark plug with spark plug wrench (commercial service

tool).

10. Remove engine coolant temperature sensor.

CAUTION:

Do not shock it.

11. Remove spark plug tube, as necessary.

●Using a pair of pliers, pull spark plug tube out of cylinder head.

CAUTION:

●Take care not to damage cylinder head.

●Once removed, a spark plug tube will be deformed and cannot be reused. Do not remove it

unless absolutely necessary.

ASSEMBLY

1. Install valve guide. Refer to EM-63, "VALVE GUIDE REPLACEMENT" .

2. Install valve seat. Refer to EM-64, "

VALVE SEAT REPLACEMENT" .

3. Install valve oil seal.

●Install with valve oil seal drift (special service tool) to match

dimension in illustration.

4. Install valve spring seat.

5. Install valve.

●Install larger diameter to intake side.

6. Install valve spring.

7. Install valve spring retainer.

PBIC1015E

SEM909F

PBIC0576E

Page 140 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-62

[QG]

CYLINDER HEAD

8. Install valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Install valve collet with magnet hand.

●Tap stem edge lightly with pla NISSAN ALMERA N16 2003 Electronic Repair Manual EM-62

[QG]

CYLINDER HEAD

8. Install valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Install valve collet with magnet hand.

●Tap stem edge lightly with pla](/img/5/57350/w960_57350-139.png)

EM-62

[QG]

CYLINDER HEAD

8. Install valve collet.

●Compress valve spring with valve spring compressor (special

service tool). Install valve collet with magnet hand.

●Tap stem edge lightly with plastic hammer after installation to

check its installed condition.

9. Install adjusting shim (if so equipped) and valve lifter.

10. Install engine coolant temperature sensor.

●Apply Genuine Liquid Gasket or equivalent to the thread.

11. Install spark plug tube.

●Press-fit spark plug tube following procedure below.

a. Remove old liquid gasket adhering to cylinder-head mounting

hole.

b. Apply liquid gasket to area within approximately 15 mm (0.59 in)

from edge of spark plug tube press-fit side.

●Use Genuine Liquid Gasket or equivalent.

c. Using a drift, press-fit spark plug tube so that its height “H” is as

specified in the figure.

CAUTION:

●When press-fitting, take care not to deform spark plug tube.

●After press-fitting, wipe off liquid gasket protruding onto cylinder-head upper face.

12. Install spark plug with spark plug wrench (commercial service tool).

Inspection After DisassemblyEBS00LQK

CYLINDER HEAD DISTORTION

1. Wipe off oil and remove water scale (like deposit), gasket,

sealer, carbon, etc with scraper.

CAUTION:

Use utmost care not to allow gasket debris to enter pas-

sages for oil or water.

2. At each of several locations on bottom surface of cylinder head,

measure distortion in six directions.

VALVE DIMENSIONS

Check dimensions of each valve. For dimensions, refer to EM-94,

"VA LV E" .

PBIC1016E

Standard press-fit height “H” :

: 41.0 - 42.0 mm (1.61 - 1.65 in)KBIA1248E

Limit : 0.1 mm (0.004 in)

PBIC0075E

SEM188A

Page 278 of 3189

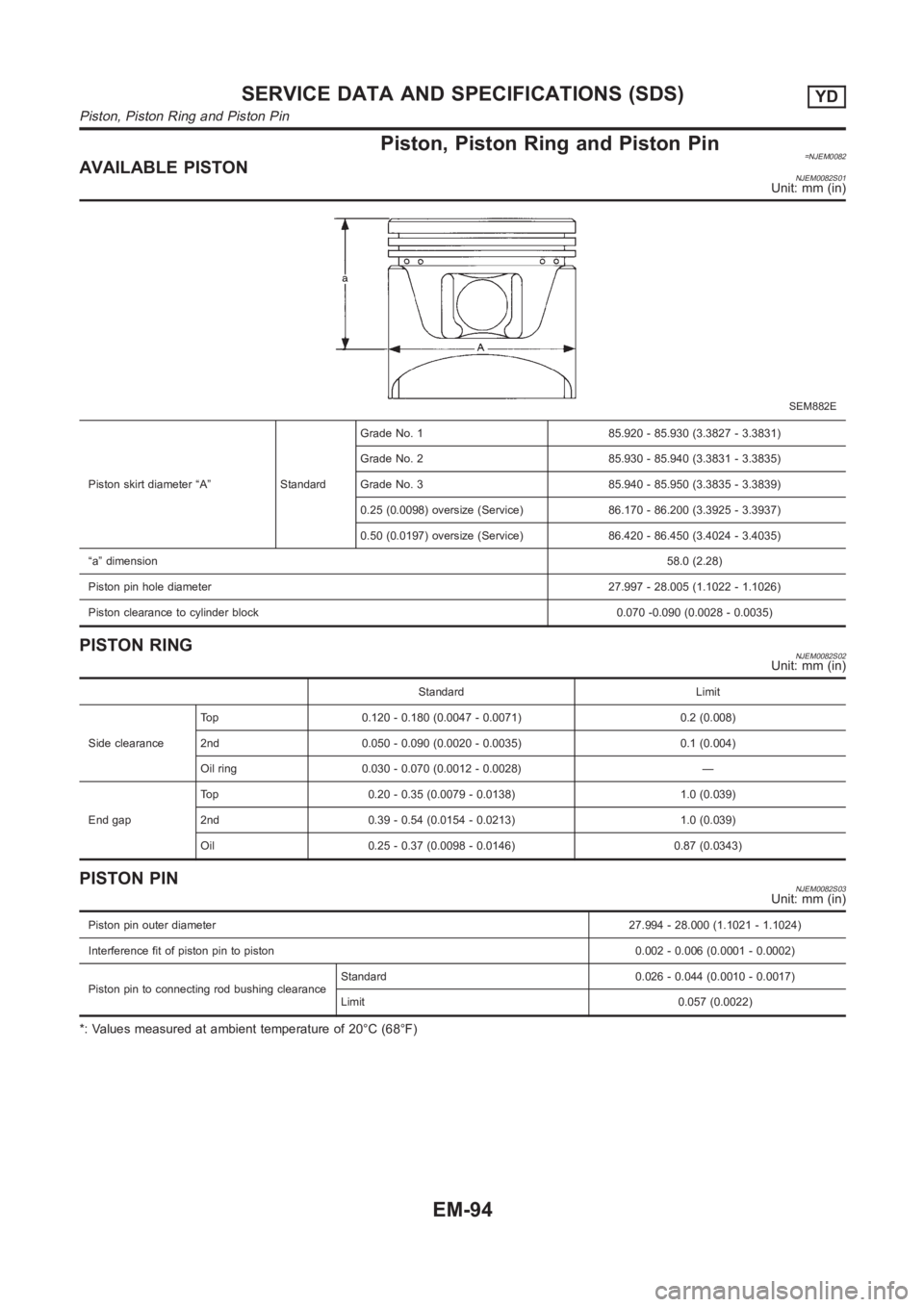

Piston, Piston Ring and Piston Pin=NJEM0082AVAILABLE PISTONNJEM0082S01Unit: mm (in)

SEM882E

Piston skirt diameter “A” StandardGrade No. 1 85.920 - 85.930 (3.3827 - 3.3831)

Grade No. 2 85.930 - 85.940 (3.3831 - 3.3835)

Grade No. 3 85.940 - 85.950 (3.3835 - 3.3839)

0.25 (0.0098) oversize (Service) 86.170 - 86.200 (3.3925 - 3.3937)

0.50 (0.0197) oversize (Service) 86.420 - 86.450 (3.4024 - 3.4035)

“a” dimension58.0 (2.28)

Piston pin hole diameter27.997 - 28.005 (1.1022 - 1.1026)

Piston clearance to cylinder block 0.070 -0.090 (0.0028 - 0.0035)

PISTON RINGNJEM0082S02Unit: mm (in)

Standard Limit

Side clearanceTop 0.120 - 0.180 (0.0047 - 0.0071) 0.2 (0.008)

2nd 0.050 - 0.090 (0.0020 - 0.0035) 0.1 (0.004)

Oil ring 0.030 - 0.070 (0.0012 - 0.0028) —

End gapTop 0.20 - 0.35 (0.0079 - 0.0138) 1.0 (0.039)

2nd 0.39 - 0.54 (0.0154 - 0.0213) 1.0 (0.039)

Oil 0.25 - 0.37 (0.0098 - 0.0146) 0.87 (0.0343)

PISTON PINNJEM0082S03Unit: mm (in)

Piston pin outer diameter27.994 - 28.000 (1.1021 - 1.1024)

Interference fit of piston pin to piston 0.002 - 0.006 (0.0001 - 0.0002)

Piston pin to connecting rod bushing clearanceStandard 0.026 - 0.044 (0.0010 - 0.0017)

Limit 0.057 (0.0022)

*: Values measured at ambient temperature of 20°C (68°F)

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Piston, Piston Ring and Piston Pin

EM-94

Page 287 of 3189

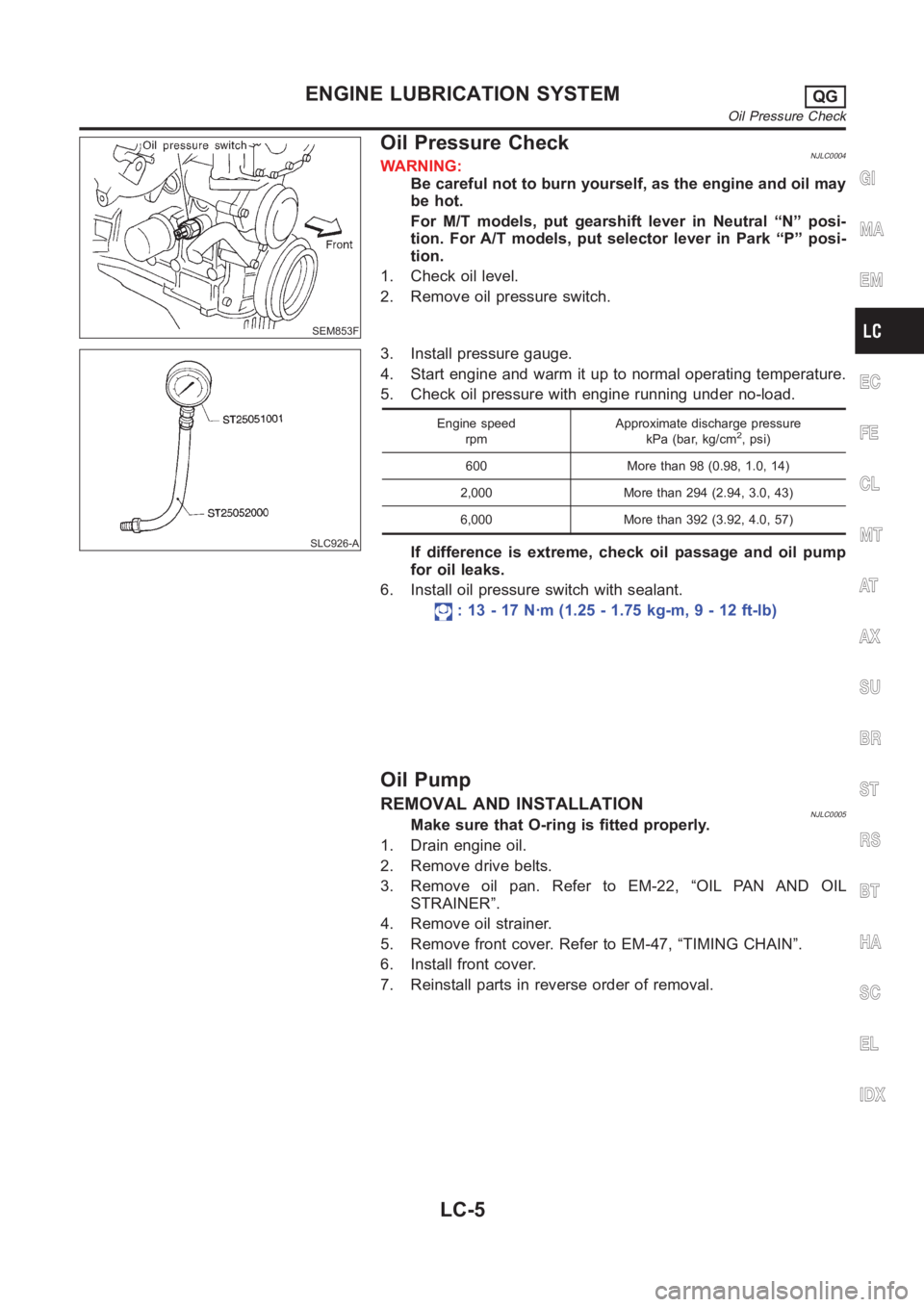

SEM853F

Oil Pressure CheckNJLC0004WARNING:

Be careful not to burn yourself, as the engine and oil may

be hot.

For M/T models, put gearshift lever in Neutral “N” posi-

tion. For A/T models, put selector lever in Park “P” posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

SLC926-A

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

600 More than 98 (0.98, 1.0, 14)

2,000 More than 294 (2.94, 3.0, 43)

6,000 More than 392 (3.92, 4.0, 57)

If difference is extreme, check oil passage and oil pump

for oil leaks.

6. Install oil pressure switch with sealant.

: 13 - 17 N·m (1.25 - 1.75 kg-m, 9 - 12 ft-lb)

Oil Pump

REMOVAL AND INSTALLATIONNJLC0005Make sure that O-ring is fitted properly.

1. Drain engine oil.

2. Remove drive belts.

3. Remove oil pan. Refer to EM-22, “OIL PAN AND OIL

STRAINER”.

4. Remove oil strainer.

5. Remove front cover. Refer to EM-47, “TIMING CHAIN”.

6. Install front cover.

7. Reinstall parts in reverse order of removal.

GI

MA

EM

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE LUBRICATION SYSTEMQG

Oil Pressure Check

LC-5

Page 298 of 3189

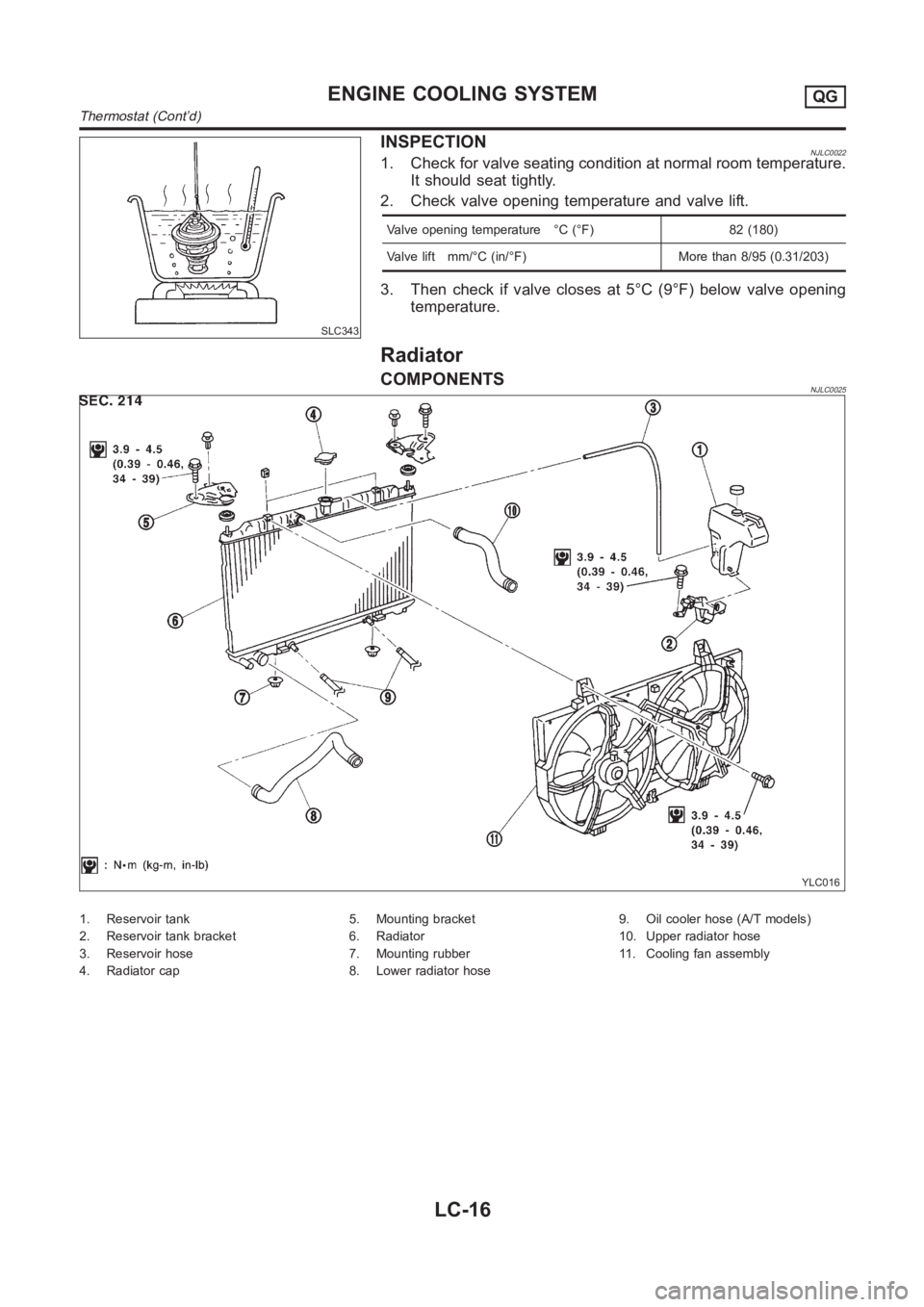

SLC343

INSPECTIONNJLC00221. Check for valve seating condition at normal room temperature.

It should seat tightly.

2. Check valve opening temperature and valve lift.

Valve opening temperature °C (°F) 82 (180)

Valve lift mm/°C (in/°F) More than 8/95 (0.31/203)

3. Then check if valve closes at 5°C (9°F) below valve opening

temperature.

Radiator

COMPONENTSNJLC0025

YLC016

1. Reservoir tank

2. Reservoir tank bracket

3. Reservoir hose

4. Radiator cap5. Mounting bracket

6. Radiator

7. Mounting rubber

8. Lower radiator hose9. Oil cooler hose (A/T models)

10. Upper radiator hose

11. Cooling fan assembly

ENGINE COOLING SYSTEMQG

Thermostat (Cont’d)

LC-16