OBD port NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 38 of 3189

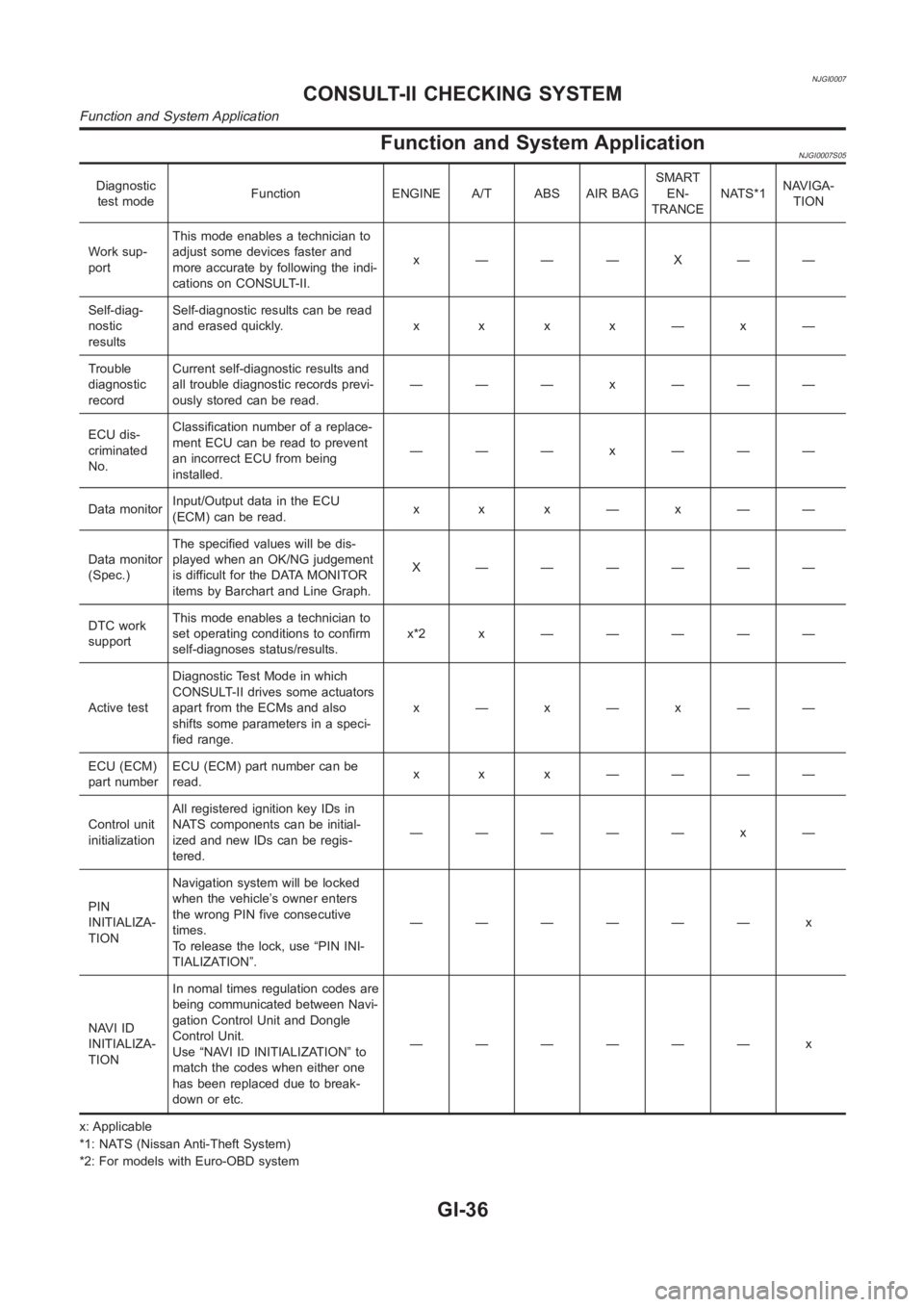

NJGI0007

Function and System ApplicationNJGI0007S05

Diagnostic

test modeFunction ENGINE A/T ABS AIR BAGSMART

EN-

TRANCENATS*1NAVIGA-

TION

Work sup-

portThis mode enables a technician to

adjust some devices faster and

more accurate by following the indi-

cations on CONSULT-II.x ———X——

Self-diag-

nostic

resultsSelf-diagnostic results can be read

anderasedquickly. x x x x—x—

Trouble

diagnostic

recordCurrent self-diagnostic results and

all trouble diagnostic records previ-

ously stored can be read.——— x ———

ECU dis-

criminated

No.Classification number of a replace-

ment ECU can be read to prevent

an incorrect ECU from being

installed.——— x ———

Data monitorInput/Output data in the ECU

(ECM) can be read.x x x—x——

Data monitor

(Spec.)The specified values will be dis-

played when an OK/NG judgement

is difficult for the DATA MONITOR

items by Barchart and Line Graph.X ——————

DTC work

supportThis mode enables a technician to

set operating conditions to confirm

self-diagnoses status/results.x*2x —————

Active testDiagnostic Test Mode in which

CONSULT-II drives some actuators

apart from the ECMs and also

shifts some parameters in a speci-

fied range.x—x—x——

ECU (ECM)

part numberECU (ECM) part number can be

read.x x x ————

Control unit

initializationAll registered ignition key IDs in

NATS components can be initial-

ized and new IDs can be regis-

tered.————— x —

PIN

INITIALIZA-

TIONNavigation system will be locked

when the vehicle’s owner enters

the wrong PIN five consecutive

times.

To release the lock, use “PIN INI-

TIALIZATION”.—————— x

NAVI ID

INITIALIZA-

TIONIn nomal times regulation codes are

being communicated between Navi-

gation Control Unit and Dongle

Control Unit.

Use “NAVI ID INITIALIZATION” to

match the codes when either one

has been replaced due to break-

down or etc.—————— x

x: Applicable

*1: NATS (Nissan Anti-Theft System)

*2: For models with Euro-OBD system

CONSULT-II CHECKING SYSTEM

Function and System Application

GI-36

Page 55 of 3189

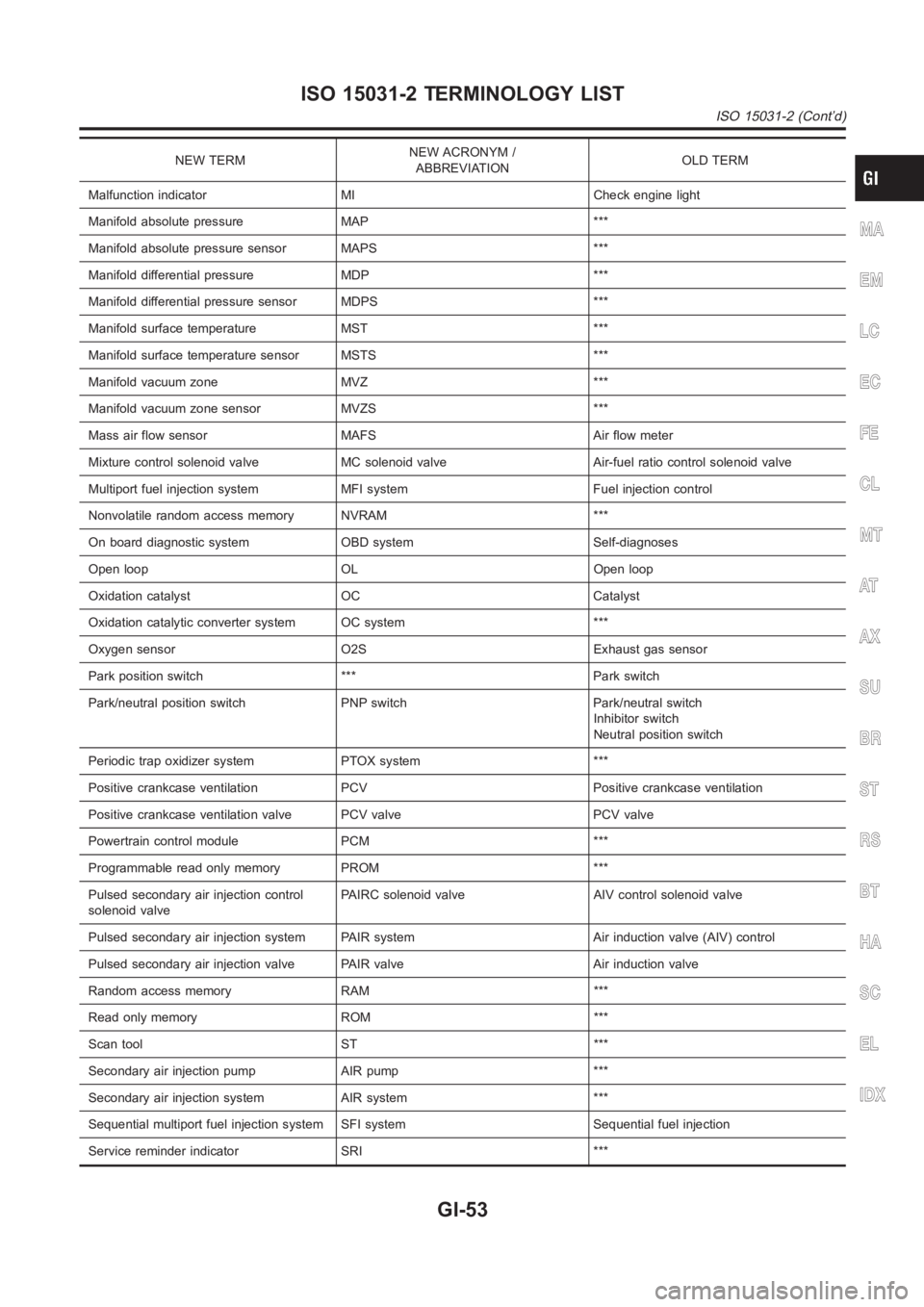

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnoses

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control

solenoid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-53

Page 94 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-16

[QG]

INTAKE MANIFOLD

INTAKE MANIFOLD

PFP:14003

Removal and InstallationEBS00LQ3

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the coolant when the engine is hot.

1. Release NISSAN ALMERA N16 2003 Electronic Repair Manual EM-16

[QG]

INTAKE MANIFOLD

INTAKE MANIFOLD

PFP:14003

Removal and InstallationEBS00LQ3

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the coolant when the engine is hot.

1. Release](/img/5/57350/w960_57350-93.png)

EM-16

[QG]

INTAKE MANIFOLD

INTAKE MANIFOLD

PFP:14003

Removal and InstallationEBS00LQ3

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the coolant when the engine is hot.

1. Release fuel pressure.

Refer to EC-34, "

FUEL PRESSURE RELEASE" (WITH EURO-OBD), EC-427, "FUEL PRESSURE

RELEASE" (WITHOUT EURO-OBD).

2. Remove air duct and air cleaner case.

Refer to EM-14, "

Removal and Installation" .

3. Disconnect harness on engine top surface, and move it aside.

4. Disconnect fuel injector/fuel tube assembly from intake manifold, and move it aside.

●It is not necessary to disconnect fuel hose.

5. Disconnect the following vacuum hoses.

6. Disconnect blow-by hose (between intake manifold collector and rocker cover).

KBIA1363E

1. Electric throttle control actuator 2. Gasket 3. Intake manifold collector

4.EVAP canister purge volume control

solenoid valve5. Vacuum hose 6. Vacuum hose

7. Hose clamp 8. Intake manifold support (front) 9. Harness bracket

10. Vacuum hose 11. Intake manifold 12. PCV hose

13. Gasket 14. Vacuum hose 15. Gasket

16. Intake manifold support (rear) 17. Harness bracket 18. Intake manifold support (engine rear)

19. Grounding wire

Page 146 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete](/img/5/57350/w960_57350-145.png)

EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has completely cooled off, otherwise, you may burn

yourself and/or fire may break out in fuel line.

●Before disconnecting fuel hose, release pressure.

Refer to EC-34 (WITH EURO-OBD), EC-428 (WITHOUT EURO-OBD).

●Be sure to lift engine and transaxle in a safe manner.

●For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

●When lifting engine, be sure to clear surrounding parts. Use special care near accelerator wire

casing, brake lines and brake master cylinder.

●When lifting the engine, always use engine slingers in a safe manner.

●When removing drive shaft, be careful not to damage grease seal of transaxle.

●Before separating engine and transaxle, remove crankshaft position sensor (POS) from the cylin-

der block assembly.

●Always be extra careful not to damage edge of crankshaft position sensor (POS), or signal plate

teeth.

Engine cannot be removed separately from transaxle. Remove engine with transaxle as an assembly.

REMOVAL

1. Drain coolant from radiator and cylinder block. Refer to LC-17, "Chacking Engine Coolant".

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from engine.

8. Remove power steering oil pump from engine and position aside.

Power steering oil pump does not need to be disconnected from power steering tubes.

9. Remove the following parts:

●RH and LH front tires

●Splash covers

●RH and LH brake caliper assemblies

Refer to BR-28,"Removal".

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

●RH & LH drive shaft. Refer to AX-11, "Removal".

When removing drive shaft, be careful not to damage

transaxle side grease seal.

●Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-26, "Removal".

●Disconnect control cable from transaxle. (A/T models.)

Refer to AT-411, "Removal".

SEM174D

SEM109G

Page 331 of 3189

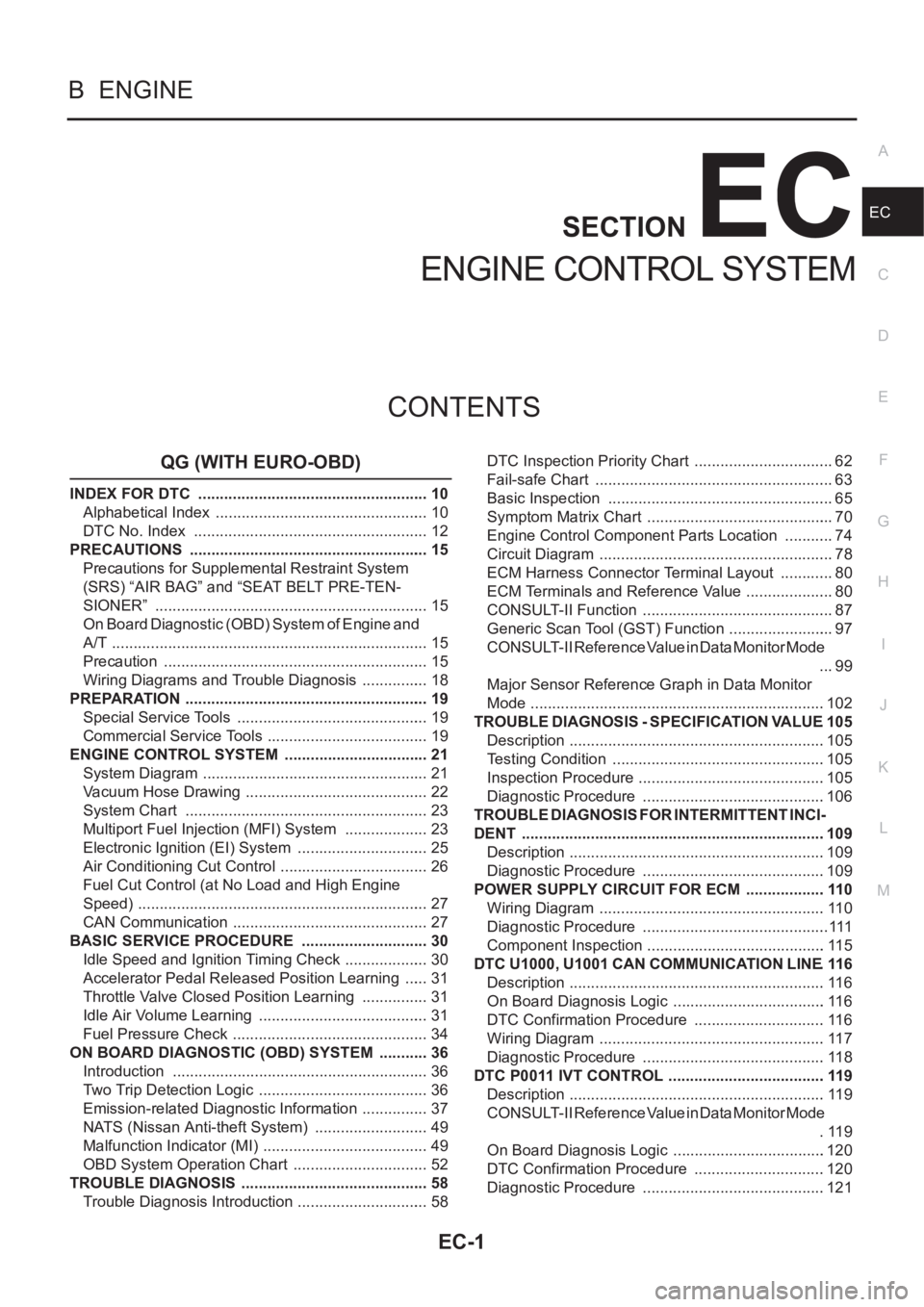

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EC

ENGINE CONTROL SYSTEM

QG (WITH EURO-OBD)

INDEX FOR DTC ...................................................... 10

Alphabetical Index .................................................. 10

DTC No. Index ....................................................... 12

PRECAUTIONS ........................................................ 15

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 15

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 15

Precaution .............................................................. 15

Wiring Diagrams and Trouble Diagnosis ................ 18

PREPARATION ......................................................... 19

Special Service Tools ............................................. 19

Commercial Service Tools ...................................... 19

ENGINE CONTROL SYSTEM .................................. 21

System Diagram ..................................................... 21

Vacuum Hose Drawing ........................................... 22

System Chart ......................................................... 23

Multiport Fuel Injection (MFI) System .................... 23

Electronic Ignition (EI) System ............................... 25

Air Conditioning Cut Control ................................... 26

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 27

CAN Communication .............................................. 27

BASIC SERVICE PROCEDURE .............................. 30

Idle Speed and Ignition Timing Check .................... 30

Accelerator Pedal Released Position Learning ...... 31

Throttle Valve Closed Position Learning ................ 31

Idle Air Volume Learning ........................................ 31

Fuel Pressure Check .............................................. 34

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 36

Introduction ............................................................ 36

Two Trip Detection Logic ........................................ 36

Emission-related Diagnostic Information ................ 37

NATS (Nissan Anti-theft System) ........................... 49

Malfunction Indicator (MI) ....................................... 49

OBD System Operation Chart ................................ 52

TROUBLE DIAGNOSIS ............................................ 58

Trouble Diagnosis Introduction ............................... 58DTC Inspection Priority Chart ................................. 62

Fail-safe Chart ........................................................ 63

Basic Inspection ..................................................... 65

Symptom Matrix Chart ............................................ 70

Engine Control Component Parts Location ............ 74

Circuit Diagram ....................................................... 78

ECM Harness Connector Terminal Layout ............. 80

ECM Terminals and Reference Value ..................

... 80

CONSULT-II Function ............................................. 87

Generic Scan Tool (GST) Function ......................... 97

CONSULT-II Reference Value in Data Monitor Mode

... 99

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................102

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .105

Description ............................................................105

Testing Condition ..................................................105

Inspection Procedure ............................................105

Diagnostic Procedure ...........................................106

TROUBLE DIAGNOSIS FOR INTERMITTENT INCI-

DENT .......................................................................109

Description ............................................................109

Diagnostic Procedure ...........................................109

POWER SUPPLY CIRCUIT FOR ECM ...................110

Wiring Diagram .....................................................110

Diagnostic Procedure ............................................111

Component Inspection ..........................................115

DTC U1000, U1001 CAN COMMUNICATION LINE .116

Description ............................................................116

On Board Diagnosis Logic ....................................116

DTC Confirmation Procedure ...............................116

Wiring Diagram .....................................................117

Diagnostic Procedure ...........................................118

DTC P0011 IVT CONTROL .....................................119

Description ............................................................119

CONSULT-II Reference Value in Data Monitor Mode

.119

On Board Diagnosis Logic ....................................120

DTC Confirmation Procedure ...............................120

Diagnostic Procedure ...........................................121

Page 335 of 3189

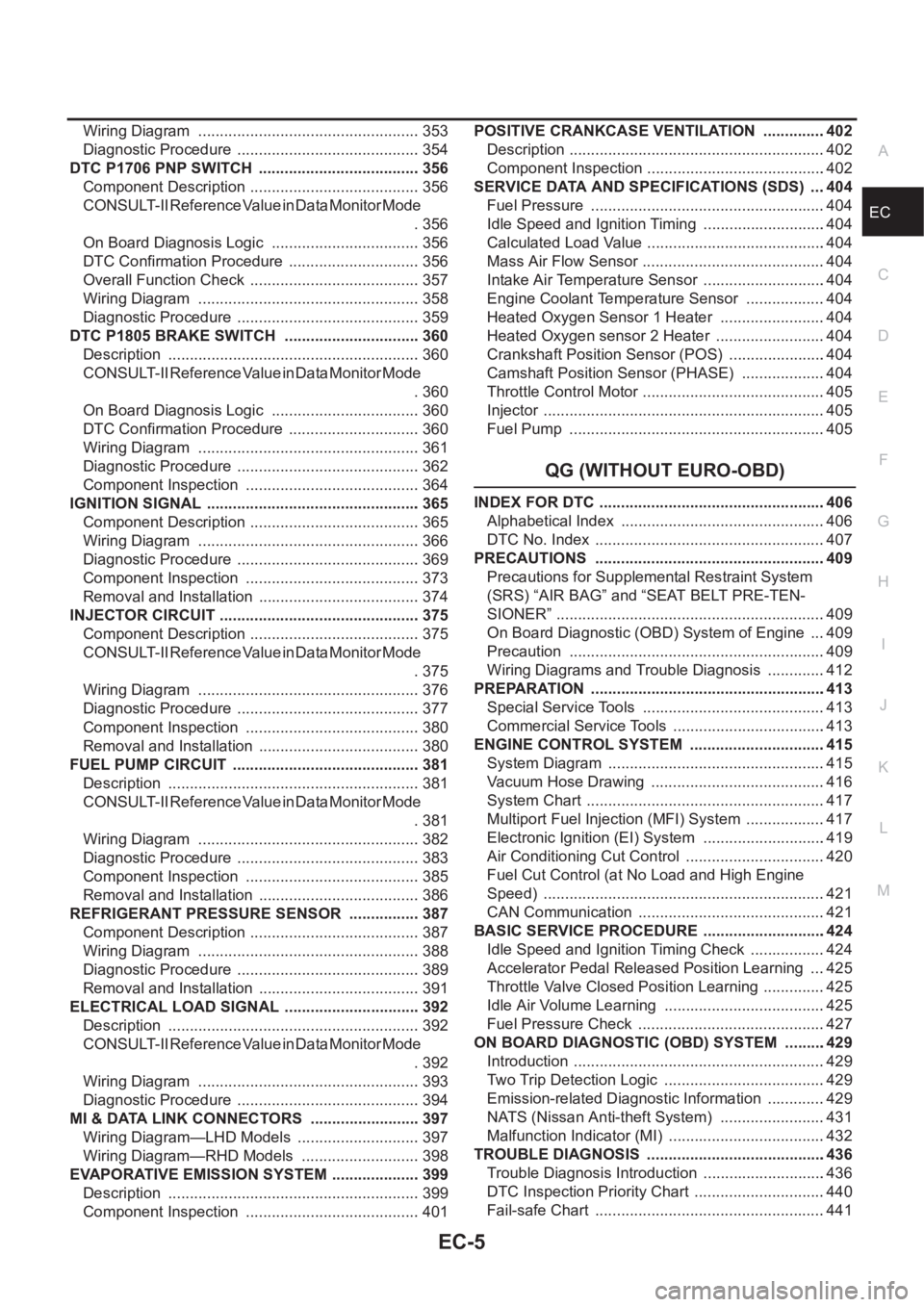

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA Wiring Diagram .................................................... 353

Diagnostic Procedure ........................................... 354

DTC P1706 PNP SWITCH ...................................... 356

Component Description ........................................ 356

CONSULT-II Reference Value in Data Monitor Mode

. 356

On Board Diagnosis Logic ................................... 356

DTC Confirmation Procedure ............................... 356

Overall Function Check ........................................ 357

Wiring Diagram .................................................... 358

Diagnostic Procedure ........................................... 359

DTC P1805 BRAKE SWITCH ................................ 360

Description ........................................................... 360

CONSULT-II Reference Value in Data Monitor Mode

. 360

On Board Diagnosis Logic ................................... 360

DTC Confirmation Procedure ............................... 360

Wiring Diagram .................................................... 361

Diagnostic Procedure ........................................... 362

Component Inspection ......................................... 364

IGNITION SIGNAL .................................................. 365

Component Description ........................................ 365

Wiring Diagram .................................................... 366

Diagnostic Procedure ........................................... 369

Component Inspection ......................................... 373

Removal and Installation ...................................... 374

INJECTOR CIRCUIT ............................................... 375

Component Description ........................................ 375

CONSULT-II Reference Value in Data Monitor Mode

. 375

Wiring Diagram .................................................... 376

Diagnostic Procedure ........................................... 377

Component Inspection ......................................... 380

Removal and Installation ...................................... 380

FUEL PUMP CIRCUIT ............................................ 381

Description ........................................................... 381

CONSULT-II Reference Value in Data Monitor Mode

. 381

Wiring Diagram .................................................... 382

Diagnostic Procedure ........................................... 383

Component Inspection ......................................... 385

Removal and Installation ...................................... 386

REFRIGERANT PRESSURE SENSOR ................. 387

Component Description ........................................ 387

Wiring Diagram .................................................... 388

Diagnostic Procedure ........................................... 389

Removal and Installation ...................................... 391

ELECTRICAL LOAD SIGNAL ................................ 392

Description ...................................................

........ 392

CONSULT-II Reference Value in Data Monitor Mode

. 392

Wiring Diagram .................................................... 393

Diagnostic Procedure ........................................... 394

MI & DATA LINK CONNECTORS .......................... 397

Wiring Diagram—LHD Models ............................. 397

Wiring Diagram—RHD Models ............................ 398

EVAPORATIVE EMISSION SYSTEM ..................... 399

Description ........................................................... 399

Component Inspection ......................................... 401POSITIVE CRANKCASE VENTILATION ...............402

Description ............................................................402

Component Inspection ..........................................402

SERVICE DATA AND SPECIFICATIONS (SDS) ....404

Fuel Pressure .......................................................404

Idle Speed and Ignition Timing .............................404

Calculated Load Value ..........................................404

Mass Air Flow Sensor ...........................................404

Intake Air Temperature Sensor .............................404

Engine Coolant Temperature Sensor ...................404

Heated Oxygen Sensor 1 Heater .........................404

Heated Oxygen sensor 2 Heater ..........................404

Crankshaft Position Sensor (POS) .......................404

Camshaft Position Sensor (PHASE) ....................404

Throttle Control Motor ...........................................405

Injector ..................................................................405

Fuel Pump ............................................................405

QG (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................406

Alphabetical Index ................................................406

DTC No. Index ......................................................407

PRECAUTIONS ......................................................409

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................409

On Board Diagnostic (OBD) System of Engine ....409

Precaution ............................................................409

Wiring Diagrams and Trouble Diagnosis ..............412

PREPARATION .......................................................413

Special Service Tools ...........................................413

Commercial Service Tools ....................................413

ENGINE CONTROL SYSTEM ................................415

System Diagram ...................................................415

Vacuum Hose Drawing .........................................416

System Chart ........................................................417

Multiport Fuel Injection (MFI) System ...................417

Electronic Ignition (EI) System .............................419

Air Conditioning Cut Control .................................420

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................421

CAN Communication ............................................421

BASIC SERVICE PROCEDURE .............................424

Idle Speed and Ignition Timing Check ..................424

Accelerator Pedal Released Position Learning ....425

Throttle Valve Closed Position Learning ...............425

Idle Air Volume Learning ......................................425

Fuel Pressure Check ............................................427

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........429

Introduction ...........................................................429

Two Trip Detection Logic ......................................429

Emission-related Diagnostic Information ..............429

NATS (Nissan Anti-theft System) .........................431

Malfunction Indicator (MI) .....................................432

TROUBLE DIAGNOSIS ..........................................436

Trouble Diagnosis Introduction .............................436

DTC Inspection Priority Chart ...............................440

Fail-safe Chart ......................................................441

Page 353 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-23

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS00K34

*1: This sensor is not used to control the engine system under normal conditions.

*2: The signals are se NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-23

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS00K34

*1: This sensor is not used to control the engine system under normal conditions.

*2: The signals are se](/img/5/57350/w960_57350-352.png)

ENGINE CONTROL SYSTEM

EC-23

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

System ChartEBS00K34

*1: This sensor is not used to control the engine system under normal conditions.

*2: The signals are sent to the ECM through CAN communication line.

*3: The output signals are sent from the ECM through CAN communication line.

Multiport Fuel Injection (MFI) SystemEBS00K35

INPUT/OUTPUT SIGNAL CHART

*1: Under normal conditions, this sensor is not for engine control operation.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

Input (Sensor) ECM Function Output (Actuator)

●Camshaft position sensor (PHASE)

●Crankshaft position sensor (POS)

●Mass air flow sensor

●Engine coolant temperature sensor

●Heated oxygen sensor 1

●Throttle position sensor

●Accelerator pedal position sensor

●Park/neutral position (PNP) switch

●Intake air temperature sensor

●Power steering pressure sensor

●Ignition switch

●Stop lamp switch

●Battery voltage

●Knock sensor

●Refrigerant pressure sensor

●Heated oxygen sensor 2*1

●TCM (Transmission control module)*2

●Air conditioner switch*2

●Vehicle speed signal*2

●Electrical load signal*2

Fuel injection & mixture ratio control Fuel injectors

Electronic ignition system Power transistor

Fuel pump control Fuel pump relay

On board diagnostic system

MI (On the instrument panel)

*3

Intake valve timing controlIntake valve timing control solenoid

valve

Heated oxygen sensor 1 heater control Heated oxygen sensor 1 heater

Heated oxygen sensor 2 heater control Heated oxygen sensor 2 heater

EVAP canister purge flow controlEVAP canister purge volume control

solenoid valve

Air conditioning cut control

Air conditioner relay

*3

Cooling fan control

Cooling fan relay*3

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

*3 and piston position

Fuel injection & mixture

ratio controlFuel injectors Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Heated oxygen sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage

*3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2

*1Density of oxygen in exhaust gas

Vehicle speed signal

*2Vehicle speed

Air conditioner switch

*2Air conditioner operation

Page 355 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-25

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during opera NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-25

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during opera](/img/5/57350/w960_57350-354.png)

ENGINE CONTROL SYSTEM

EC-25

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot film) and characteristic changes

during operation (i.e., injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value compared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensation used to maintain the mixture ratio at its theoretical

value. The signal from heated oxygen sensor 1 indicates whether the mixture ratio is RICH or LEAN compared

to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an

increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation carried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycle according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration or operation of the engine at excessively high speeds.

Electronic Ignition (EI) SystemEBS00K36

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

*2: ECM determines the start signal status by the signals of engine speed and battery voltage.

SEF337W

Sensor Input Signal to ECM ECM Function Actuator

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

*2 and piston position

Ignition timing control Power transistor Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Knock sensor Engine knocking

Park/neutral position (PNP) switch Gear position

Battery

Battery voltage

*2

Vehicle speed signal*1Vehicle speed

Page 357 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM thro NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM thro](/img/5/57350/w960_57350-356.png)

ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

If the engine speed is above 3,950 rpm with no load (for example, in neutral and engine speed over 3,950

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under “Multiport Fuel Injection (MFI) System”, EC-23

.

CAN CommunicationEBS00K39

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

×:ApplicableSensor Input Signal to ECM ECM Function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injectors Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

Vehicle speed signal

*1Vehicle speed

Body type Sedan/ 5DH/B/ 3DH/B

Axle2WD

Engine QG18DE QG15DE/QG18DE

Transmission A/T M/T

Brake controlABS

CAN communication unit

ECM××

TCM×

Smart entrance control unit××

Data link connector××

Combination meter××

CAN communication type EC-28, "

Type 1"EC-29, "Ty p e 2"

Page 362 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-32

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle NISSAN ALMERA N16 2003 Electronic Repair Manual EC-32

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle](/img/5/57350/w960_57350-361.png)

EC-32

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

●Battery voltage: More than 12.9V (At idle)

●Engine coolant temperature: 70 - 95°C (158 - 203°F)

●PNP switch: ON

●Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting switch to the 1st position to light

only small lamps.

●Steering wheel: Neutral (Straight-ahead position)

●Vehicle speed: Stopped

●Transmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” system indicates less than 0.9V.

For A/T models without CONSULT-II and M/T models, drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. Perform EC-31, "Accelerator Pedal Released Position Learning" .

2. Perform EC-31, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic “PREPARATION” (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

SEF217Z

SEF454Y