brake sensor NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 67 of 3189

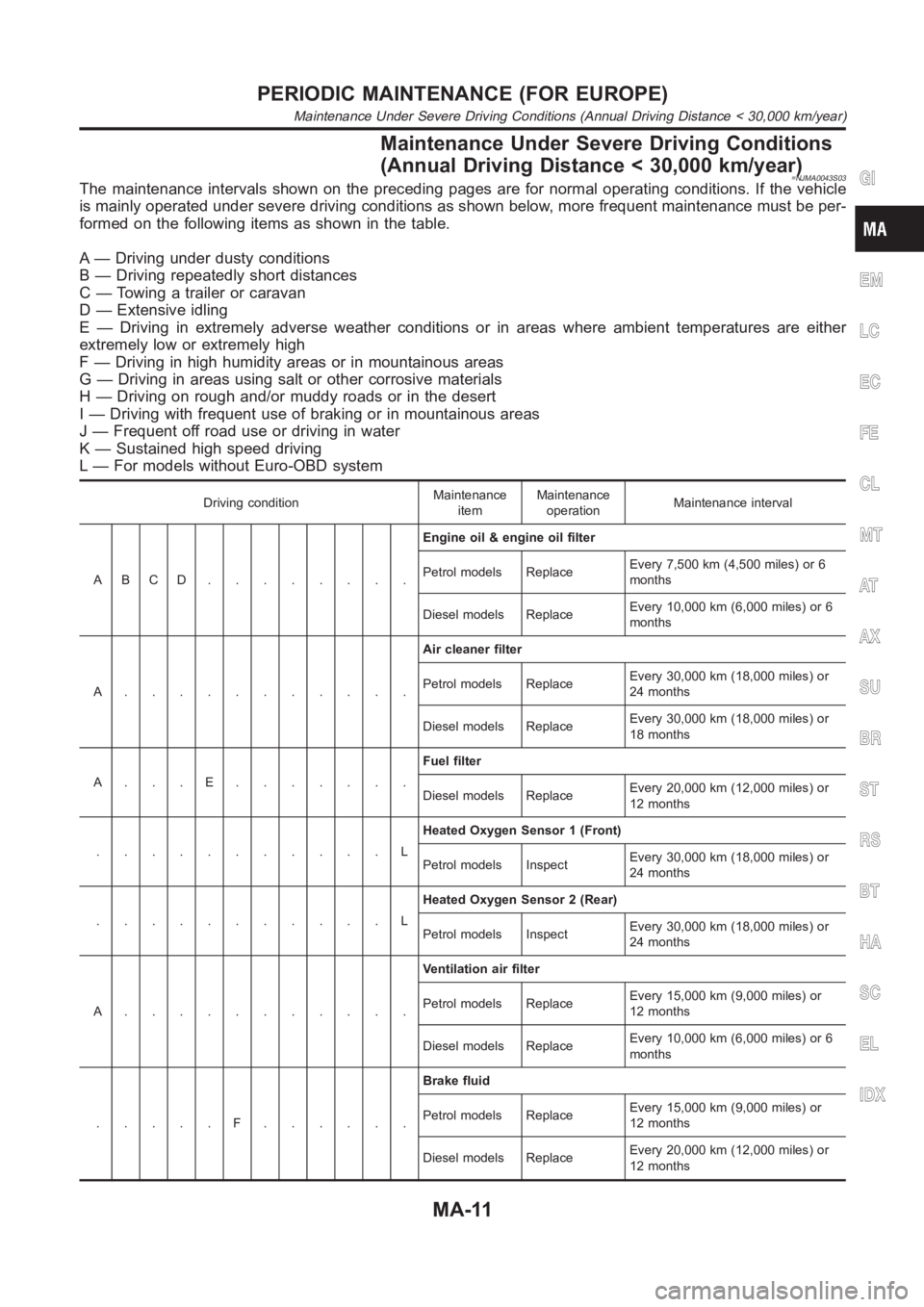

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)

=NJMA0043S03The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K — Sustained high speed driving

L — For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models ReplaceEvery 7,500 km (4,500 miles) or 6

months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or 6

months

A...........Air cleaner filter

Petrol models ReplaceEvery 30,000 km (18,000 miles) or

24 months

Diesel models ReplaceEvery 30,000 km (18,000 miles) or

18 months

A...E.......Fuel filter

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

...........LHeated Oxygen Sensor 1 (Front)

Petrol models InspectEvery 30,000 km (18,000 miles) or

24 months

...........LHeated Oxygen Sensor 2 (Rear)

Petrol models InspectEvery 30,000 km (18,000 miles) or

24 months

A...........Ventilation air filter

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or 6

months

.....F......Brake fluid

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance < 30,000 km/year)

MA-11

Page 73 of 3189

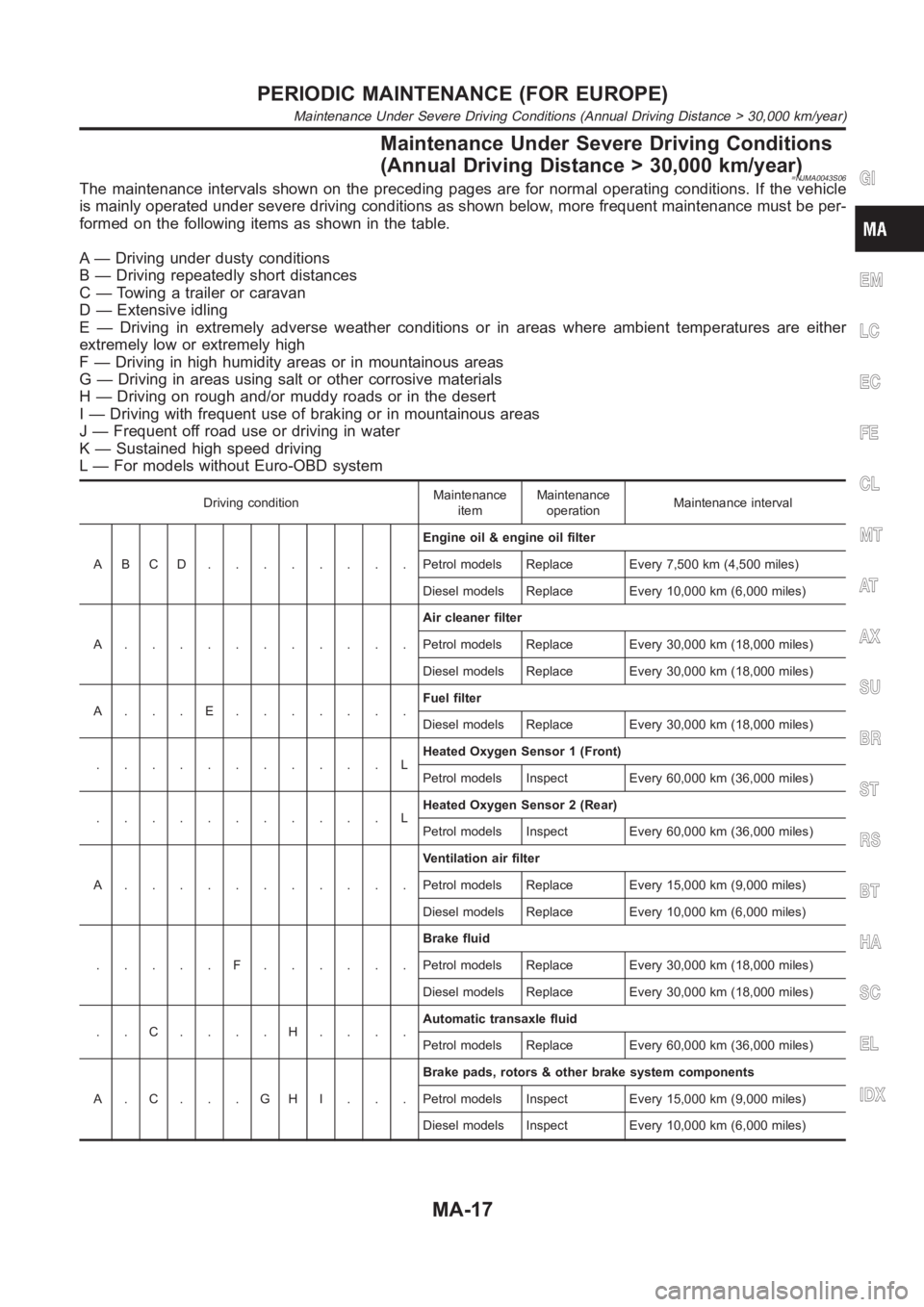

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km/year)

=NJMA0043S06The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A — Driving under dusty conditions

B — Driving repeatedly short distances

C — Towing a trailer or caravan

D — Extensive idling

E — Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F — Driving in high humidity areas or in mountainous areas

G — Driving in areas using salt or other corrosive materials

H — Driving on rough and/or muddy roads or in the desert

I — Driving with frequent use of braking or in mountainous areas

J — Frequent off road use or driving in water

K — Sustained high speed driving

L — For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models Replace Every 7,500 km (4,500 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

A...........Air cleaner filter

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

A...E.......Fuel filter

Diesel models Replace Every 30,000 km (18,000 miles)

...........LHeated Oxygen Sensor 1 (Front)

Petrol models Inspect Every 60,000 km (36,000 miles)

...........LHeated Oxygen Sensor 2 (Rear)

Petrol models Inspect Every 60,000 km (36,000 miles)

A...........Ventilation air filter

Petrol models Replace Every 15,000 km (9,000 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

.....F......Brake fluid

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

..C....H....Automatic transaxle fluid

Petrol models Replace Every 60,000 km (36,000 miles)

A.C...GHI...Brake pads, rotors & other brake system components

Petrol models Inspect Every 15,000 km (9,000 miles)

Diesel models Inspect Every 10,000 km (6,000 miles)

GI

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PERIODIC MAINTENANCE (FOR EUROPE)

Maintenance Under Severe Driving Conditions (Annual Driving Distance > 30,000 km/year)

MA-17

Page 146 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete](/img/5/57350/w960_57350-145.png)

EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has completely cooled off, otherwise, you may burn

yourself and/or fire may break out in fuel line.

●Before disconnecting fuel hose, release pressure.

Refer to EC-34 (WITH EURO-OBD), EC-428 (WITHOUT EURO-OBD).

●Be sure to lift engine and transaxle in a safe manner.

●For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

●When lifting engine, be sure to clear surrounding parts. Use special care near accelerator wire

casing, brake lines and brake master cylinder.

●When lifting the engine, always use engine slingers in a safe manner.

●When removing drive shaft, be careful not to damage grease seal of transaxle.

●Before separating engine and transaxle, remove crankshaft position sensor (POS) from the cylin-

der block assembly.

●Always be extra careful not to damage edge of crankshaft position sensor (POS), or signal plate

teeth.

Engine cannot be removed separately from transaxle. Remove engine with transaxle as an assembly.

REMOVAL

1. Drain coolant from radiator and cylinder block. Refer to LC-17, "Chacking Engine Coolant".

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from engine.

8. Remove power steering oil pump from engine and position aside.

Power steering oil pump does not need to be disconnected from power steering tubes.

9. Remove the following parts:

●RH and LH front tires

●Splash covers

●RH and LH brake caliper assemblies

Refer to BR-28,"Removal".

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

●RH & LH drive shaft. Refer to AX-11, "Removal".

When removing drive shaft, be careful not to damage

transaxle side grease seal.

●Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-26, "Removal".

●Disconnect control cable from transaxle. (A/T models.)

Refer to AT-411, "Removal".

SEM174D

SEM109G

Page 248 of 3189

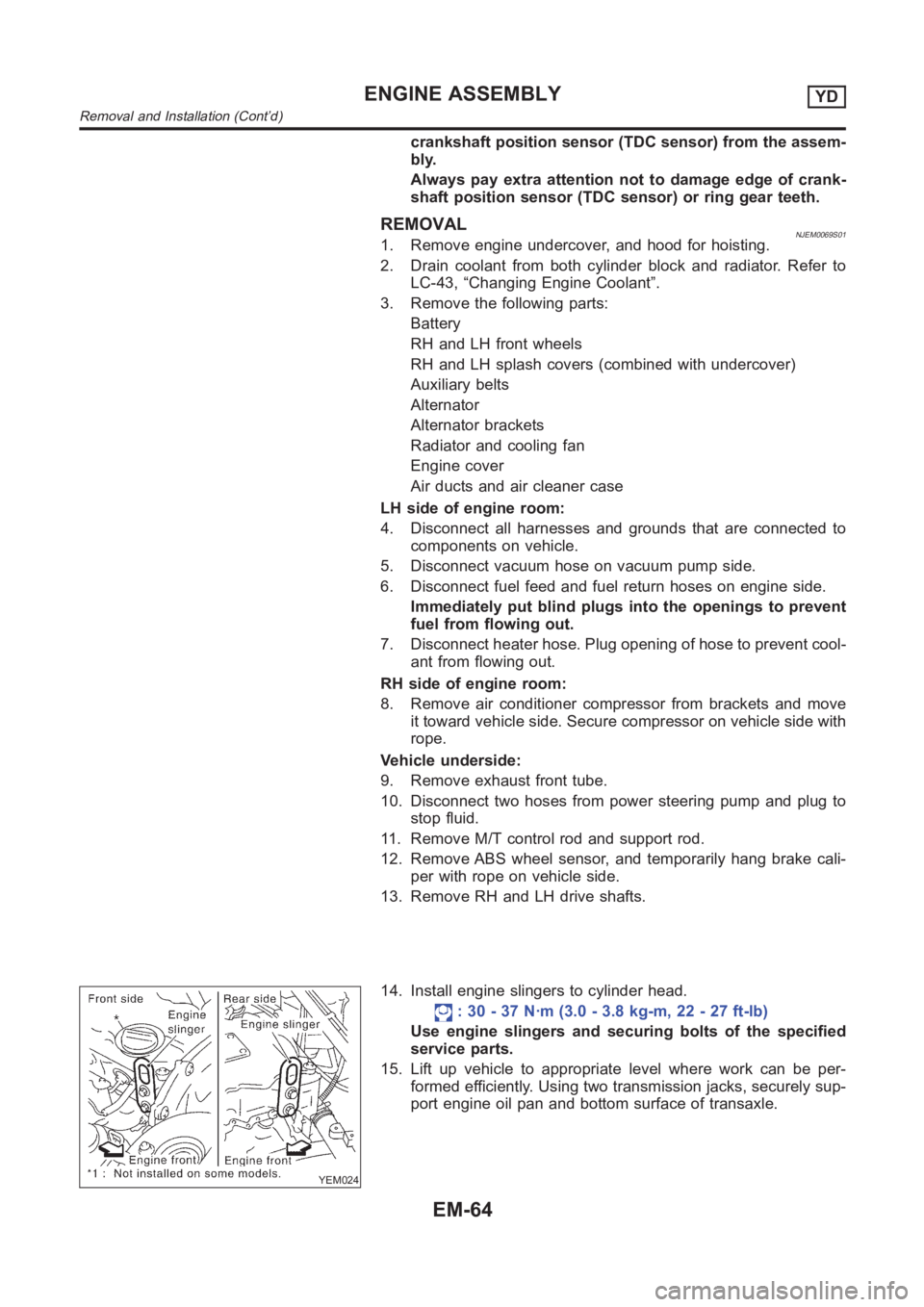

crankshaft position sensor (TDC sensor) from the assem-

bly.

Always pay extra attention not to damage edge of crank-

shaft position sensor (TDC sensor) or ring gear teeth.

REMOVALNJEM0069S011. Remove engine undercover, and hood for hoisting.

2. Drain coolant from both cylinder block and radiator. Refer to

LC-43, “Changing Engine Coolant”.

3. Remove the following parts:

Battery

RH and LH front wheels

RH and LH splash covers (combined with undercover)

Auxiliary belts

Alternator

Alternator brackets

Radiator and cooling fan

Engine cover

Air ducts and air cleaner case

LH side of engine room:

4. Disconnect all harnesses and grounds that are connected to

components on vehicle.

5. Disconnect vacuum hose on vacuum pump side.

6. Disconnect fuel feed and fuel return hoses on engine side.

Immediately put blind plugs into the openings to prevent

fuel from flowing out.

7. Disconnect heater hose. Plug opening of hose to prevent cool-

ant from flowing out.

RH side of engine room:

8. Remove air conditioner compressor from brackets and move

it toward vehicle side. Secure compressor on vehicle side with

rope.

Vehicle underside:

9. Remove exhaust front tube.

10. Disconnect two hoses from power steering pump and plug to

stop fluid.

11. Remove M/T control rod and support rod.

12. Remove ABS wheel sensor, and temporarily hang brake cali-

per with rope on vehicle side.

13. Remove RH and LH drive shafts.

YEM024

14. Install engine slingers to cylinder head.

: 30 - 37 N·m (3.0 - 3.8 kg-m, 22 - 27 ft-lb)

Use engine slingers and securing bolts of the specified

service parts.

15. Lift up vehicle to appropriate level where work can be per-

formed efficiently. Using two transmission jacks, securely sup-

port engine oil pan and bottom surface of transaxle.

ENGINE ASSEMBLYYD

Removal and Installation (Cont’d)

EM-64

Page 335 of 3189

EC-5

C

D

E

F

G

H

I

J

K

L

M

ECA Wiring Diagram .................................................... 353

Diagnostic Procedure ........................................... 354

DTC P1706 PNP SWITCH ...................................... 356

Component Description ........................................ 356

CONSULT-II Reference Value in Data Monitor Mode

. 356

On Board Diagnosis Logic ................................... 356

DTC Confirmation Procedure ............................... 356

Overall Function Check ........................................ 357

Wiring Diagram .................................................... 358

Diagnostic Procedure ........................................... 359

DTC P1805 BRAKE SWITCH ................................ 360

Description ........................................................... 360

CONSULT-II Reference Value in Data Monitor Mode

. 360

On Board Diagnosis Logic ................................... 360

DTC Confirmation Procedure ............................... 360

Wiring Diagram .................................................... 361

Diagnostic Procedure ........................................... 362

Component Inspection ......................................... 364

IGNITION SIGNAL .................................................. 365

Component Description ........................................ 365

Wiring Diagram .................................................... 366

Diagnostic Procedure ........................................... 369

Component Inspection ......................................... 373

Removal and Installation ...................................... 374

INJECTOR CIRCUIT ............................................... 375

Component Description ........................................ 375

CONSULT-II Reference Value in Data Monitor Mode

. 375

Wiring Diagram .................................................... 376

Diagnostic Procedure ........................................... 377

Component Inspection ......................................... 380

Removal and Installation ...................................... 380

FUEL PUMP CIRCUIT ............................................ 381

Description ........................................................... 381

CONSULT-II Reference Value in Data Monitor Mode

. 381

Wiring Diagram .................................................... 382

Diagnostic Procedure ........................................... 383

Component Inspection ......................................... 385

Removal and Installation ...................................... 386

REFRIGERANT PRESSURE SENSOR ................. 387

Component Description ........................................ 387

Wiring Diagram .................................................... 388

Diagnostic Procedure ........................................... 389

Removal and Installation ...................................... 391

ELECTRICAL LOAD SIGNAL ................................ 392

Description ...................................................

........ 392

CONSULT-II Reference Value in Data Monitor Mode

. 392

Wiring Diagram .................................................... 393

Diagnostic Procedure ........................................... 394

MI & DATA LINK CONNECTORS .......................... 397

Wiring Diagram—LHD Models ............................. 397

Wiring Diagram—RHD Models ............................ 398

EVAPORATIVE EMISSION SYSTEM ..................... 399

Description ........................................................... 399

Component Inspection ......................................... 401POSITIVE CRANKCASE VENTILATION ...............402

Description ............................................................402

Component Inspection ..........................................402

SERVICE DATA AND SPECIFICATIONS (SDS) ....404

Fuel Pressure .......................................................404

Idle Speed and Ignition Timing .............................404

Calculated Load Value ..........................................404

Mass Air Flow Sensor ...........................................404

Intake Air Temperature Sensor .............................404

Engine Coolant Temperature Sensor ...................404

Heated Oxygen Sensor 1 Heater .........................404

Heated Oxygen sensor 2 Heater ..........................404

Crankshaft Position Sensor (POS) .......................404

Camshaft Position Sensor (PHASE) ....................404

Throttle Control Motor ...........................................405

Injector ..................................................................405

Fuel Pump ............................................................405

QG (WITHOUT EURO-OBD)

INDEX FOR DTC .....................................................406

Alphabetical Index ................................................406

DTC No. Index ......................................................407

PRECAUTIONS ......................................................409

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ...............................................................409

On Board Diagnostic (OBD) System of Engine ....409

Precaution ............................................................409

Wiring Diagrams and Trouble Diagnosis ..............412

PREPARATION .......................................................413

Special Service Tools ...........................................413

Commercial Service Tools ....................................413

ENGINE CONTROL SYSTEM ................................415

System Diagram ...................................................415

Vacuum Hose Drawing .........................................416

System Chart ........................................................417

Multiport Fuel Injection (MFI) System ...................417

Electronic Ignition (EI) System .............................419

Air Conditioning Cut Control .................................420

Fuel Cut Control (at No Load and High Engine

Speed) ..................................................................421

CAN Communication ............................................421

BASIC SERVICE PROCEDURE .............................424

Idle Speed and Ignition Timing Check ..................424

Accelerator Pedal Released Position Learning ....425

Throttle Valve Closed Position Learning ...............425

Idle Air Volume Learning ......................................425

Fuel Pressure Check ............................................427

ON BOARD DIAGNOSTIC (OBD) SYSTEM ..........429

Introduction ...........................................................429

Two Trip Detection Logic ......................................429

Emission-related Diagnostic Information ..............429

NATS (Nissan Anti-theft System) .........................431

Malfunction Indicator (MI) .....................................432

TROUBLE DIAGNOSIS ..........................................436

Trouble Diagnosis Introduction .............................436

DTC Inspection Priority Chart ...............................440

Fail-safe Chart ......................................................441

Page 338 of 3189

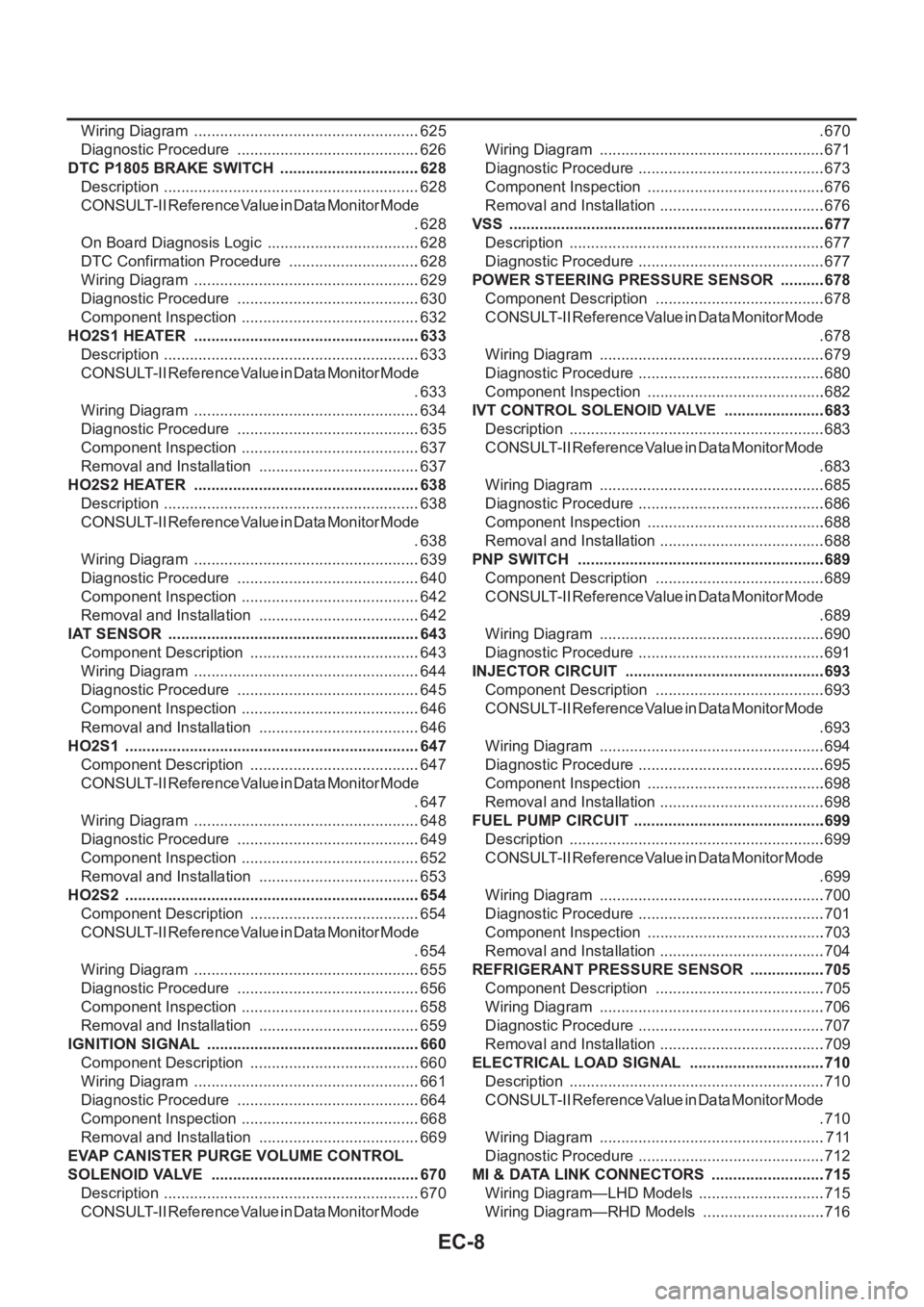

EC-8

Wiring Diagram .....................................................625

Diagnostic Procedure ...........................................626

DTC P1805 BRAKE SWITCH .................................628

Description ............................................................628

CONSULT-II Reference Value in Data Monitor Mode

.628

On Board Diagnosis Logic ....................................628

DTC Confirmation Procedure ...............................628

Wiring Diagram .....................................................629

Diagnostic Procedure ...........................................630

Component Inspection ..........................................632

HO2S1 HEATER .....................................................633

Description ............................................................633

CONSULT-II Reference Value in Data Monitor Mode

.633

Wiring Diagram .....................................................634

Diagnostic Procedure ...........................................635

Component Inspection ..........................................637

Removal and Installation ......................................637

HO2S2 HEATER .....................................................638

Description ............................................................638

CONSULT-II Reference Value in Data Monitor Mode

.638

Wiring Diagram .....................................................639

Diagnostic Procedure ...........................................640

Component Inspection ..........................................642

Removal and Installation ......................................642

IAT SENSOR ...........................................................643

Component Description ........................................643

Wiring Diagram .....................................................644

Diagnostic Procedure ...........................................645

Component Inspection ..........................................646

Removal and Installation ......................................646

HO2S1 .....................................................................647

Component Description ........................................647

CONSULT-II Reference Value in Data Monitor Mode

.647

Wiring Diagram .....................................................648

Diagnostic Procedure ...........................................649

Component Inspection ..........................................652

Removal and Installation ......................................653

HO2S2 .....................................................................654

Component Description ........................................654

CONSULT-II Reference Value in Data Monitor Mode

.654

Wiring Diagram .....................................................655

Diagnostic Procedure ...........................................656

Component Inspection ..........................................658

Removal and Installation ......................................659

IGNITION SIGNAL ..................................................660

Component Description ........................................660

Wiring Diagram .....................................................661

Diagnostic Procedure ...........................................664

Component Inspection ..........................................668

Removal and Installation ......................................669

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE .................................................670

Description ............................................................670

CONSULT-II Reference Value in Data Monitor Mode .670

Wiring Diagram .....................................................671

Diagnostic Procedure ............................................673

Component Inspection ..........................................676

Removal and Installation .......................................676

VSS ..........................................................................677

Description ............................................................677

Diagnostic Procedure ............................................677

POWER STEERING PRESSURE SENSOR ...........678

Component Description ........................................678

CONSULT-II Reference Value in Data Monitor Mode

.678

Wiring Diagram .....................................................679

Diagnostic Procedure ............................................680

Component Inspection ..........................................682

IVT CONTROL SOLENOID VALVE ........................683

Description ............................................................683

CONSULT-II Reference Value in Data Monitor Mode

.683

Wiring Diagram .....................................................685

Diagnostic Procedure ............................................686

Component Inspection ..........................................688

Removal and Installation .......................................688

PNP SWITCH ..........................................................689

Component Description ........................................689

CONSULT-II Reference Value in Data Monitor Mode

.689

Wiring Diagram .....................................................690

Diagnostic Procedure ............................................691

INJECTOR CIRCUIT ...............................................693

Component Description ........................................693

CONSULT-II Reference Value in Data Monitor Mode

.693

Wiring Diagram .....................................................694

Diagnostic Procedure ............................................695

Component Inspection ..........................................698

Removal and Installation ......................................

.698

FUEL PUMP CIRCUIT .............................................699

Description ............................................................699

CONSULT-II Reference Value in Data Monitor Mode

.699

Wiring Diagram .....................................................700

Diagnostic Procedure ............................................701

Component Inspection ..........................................703

Removal and Installation .......................................704

REFRIGERANT PRESSURE SENSOR ..................705

Component Description ........................................705

Wiring Diagram .....................................................706

Diagnostic Procedure ............................................707

Removal and Installation .......................................709

ELECTRICAL LOAD SIGNAL ................................710

Description ............................................................710

CONSULT-II Reference Value in Data Monitor Mode

.710

Wiring Diagram .....................................................711

Diagnostic Procedure ............................................712

MI & DATA LINK CONNECTORS ...........................715

Wiring Diagram—LHD Models ..............................715

Wiring Diagram—RHD Models .............................716

Page 340 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-10

[QG (WITH EURO-OBD)]

INDEX FOR DTC

[QG (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00K2T

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approv NISSAN ALMERA N16 2003 Electronic Repair Manual EC-10

[QG (WITH EURO-OBD)]

INDEX FOR DTC

[QG (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00K2T

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approv](/img/5/57350/w960_57350-339.png)

EC-10

[QG (WITH EURO-OBD)]

INDEX FOR DTC

[QG (WITH EURO-OBD)]INDEX FOR DTCPFP:00024

Alphabetical IndexEBS00K2T

Check if the vehicle is a model with Euro-OBD (E-OBD) system or not by the “Type approval number” on the

identification plate. Refer to GI-39.

NOTE:

If DTC U1000 or U1001 is displayed with other DTC, first perform the trouble diagnosis for DTC U1000,

U1001. Refer to EC-116, "

DTC U1000, U1001 CAN COMMUNICATION LINE" .

×: Applicable –: Not applicable

Items

(CONSULT-II screen terms)DTC*

1

TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

A/T 1ST GR FNCTN P0731 0731 2×AT-133

A/T 2ND GR FNCTN P0732 0732 2×AT-139

A/T 3RD GR FNCTN P0733 0733 2×AT-145

A/T 4TH GR FNCTN P0734 0734 2×AT-151

APP SEN 1/CIRC P0227 0227 1×EC-218

APP SEN 1/CIRC P0228 0228 1×EC-218

APP SEN 2/CIRC P1227 1227 1×EC-345

APP SEN 2/CIRC P1228 1228 1×EC-345

APP SENSOR P0226 0226 1×EC-211

ATF TEMP SEN/CIRC P0710 0710 2×AT- 11 7

BRAKE SW/CIRCUIT P1805 1805 2 –EC-360

CAN COMM CIRCUIT U1000

1000*51×EC-116

CAN COMM CIRCUIT U1001

1001*52–EC-116

CKP SEN/CIRCUIT P0335 0335 2×EC-234

CMP SEN/CIRC-B1 P0340 0340 2×EC-240

CTP LEARNING P1225 1225 2 –EC-341

CTP LEARNING P1226 1226 2 –EC-343

CYL 1 MISFIRE P0301 0301 2×EC-225

CYL 2 MISFIRE P0302 0302 2×EC-225

CYL 3 MISFIRE P0303 0303 2×EC-225

CYL 4 MISFIRE P0304 0304 2×EC-225

ECM P0605 0605 1 or 2× or –EC-265

ECM BACK UP/CIRC P1065 1065 2×EC-268

ECT SEN/CIRCUIT P0117 0117 1×EC-144

ECT SEN/CIRCUIT P0118 0118 1×EC-144

ENG OVER TEMP P1217 1217 1×EC-324

ENGINE SPEED SIG P0725 0725 1×AT-129

ETC ACTR P1121 1121 1 or 2×EC-276

ETC FUNCTION/CIRC P1122 1122 1×EC-278

ETC MOT P1128 1128 1×EC-291

ETC MOT PWR P1124 1124 1×EC-285

ETC MOT PWR P1126 1126 1×EC-285

FUEL SYS-LEAN-B1 P0171 0171 2×EC-186

FUEL SYS-RICH-B1 P0172 0172 2×EC-193

HO2S1 (B1) P0132 0132 2×EC-149

Page 344 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-14

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these nu NISSAN ALMERA N16 2003 Electronic Repair Manual EC-14

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these nu](/img/5/57350/w960_57350-343.png)

EC-14

[QG (WITH EURO-OBD)]

INDEX FOR DTC

*1: 1st trip DTC No. is the same as DTC No.

*2: These numbers are prescribed by ISO 15031-5.

*3: In Diagnostic Test Mode II (Self-diagnostic results), these numbers are controlled by NISSAN.

*4: When engine is running.

*5: The trouble shooting for this DTC needs CONSULT-II.

*6: When the fail-safe operations for both self-diagnoses occur, the MI illuminates. P1217 1217 ENG OVER TEMP 1×EC-324

P1223 1223 TP SEN 2/CIRC 1×EC-335

P1224 1224 TP SEN 2/CIRC 1×EC-335

P1225 1225 CTP LEARNING 2 –EC-341

P1226 1226 CTP LEARNING 2 –EC-343

P1227 1227 APP SEN 2/CIRC 1×EC-345

P1228 1228 APP SEN 2/CIRC 1×EC-345

P1229 1229 SENSOR POWER/CIRC 1×EC-352

P1610 - P1615 1610 - 1615 NATS MALFUNCTION 2 –EC-49

P1705 1705 TPV SEN/CIRC A/T 1×AT-181

P1706 1706 P-N POS SW/CIRCUIT 2×EC-356

P1760 1760 O/R CLTCH SOL/CIRC 2×AT-187

P1805 1805 BRAKE SW/CIRCUIT 2 –EC-360

DTC*1

Items

(CONSULT-II screen terms)TripMI lighting

upReference page

CONSULT-II

GST*

2ECM*3

Page 357 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM thro NISSAN ALMERA N16 2003 Electronic Repair Manual ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM thro](/img/5/57350/w960_57350-356.png)

ENGINE CONTROL SYSTEM

EC-27

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fuel Cut Control (at No Load and High Engine Speed)EBS00K38

INPUT/OUTPUT SIGNAL CHART

*1: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

If the engine speed is above 3,950 rpm with no load (for example, in neutral and engine speed over 3,950

rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies based on engine speed.

Fuel cut will operate until the engine speed reaches 1,500 rpm, then fuel cut is cancelled.

NOTE:

This function is different from deceleration control listed under “Multiport Fuel Injection (MFI) System”, EC-23

.

CAN CommunicationEBS00K39

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

CAN COMMUNICATION UNIT

×:ApplicableSensor Input Signal to ECM ECM Function Actuator

Park/neutral position (PNP) switch Neutral position

Fuel cut control Fuel injectors Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Engine coolant temperature sensor Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)Engine speed

Vehicle speed signal

*1Vehicle speed

Body type Sedan/ 5DH/B/ 3DH/B

Axle2WD

Engine QG18DE QG15DE/QG18DE

Transmission A/T M/T

Brake controlABS

CAN communication unit

ECM××

TCM×

Smart entrance control unit××

Data link connector××

Combination meter××

CAN communication type EC-28, "

Type 1"EC-29, "Ty p e 2"

Page 393 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-63

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fail-safe ChartEBS00K3N

●When the DTC listed below is detected, the ECM enters fail-safe mode and the MI lights up.

Priority De NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS

EC-63

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fail-safe ChartEBS00K3N

●When the DTC listed below is detected, the ECM enters fail-safe mode and the MI lights up.

Priority De](/img/5/57350/w960_57350-392.png)

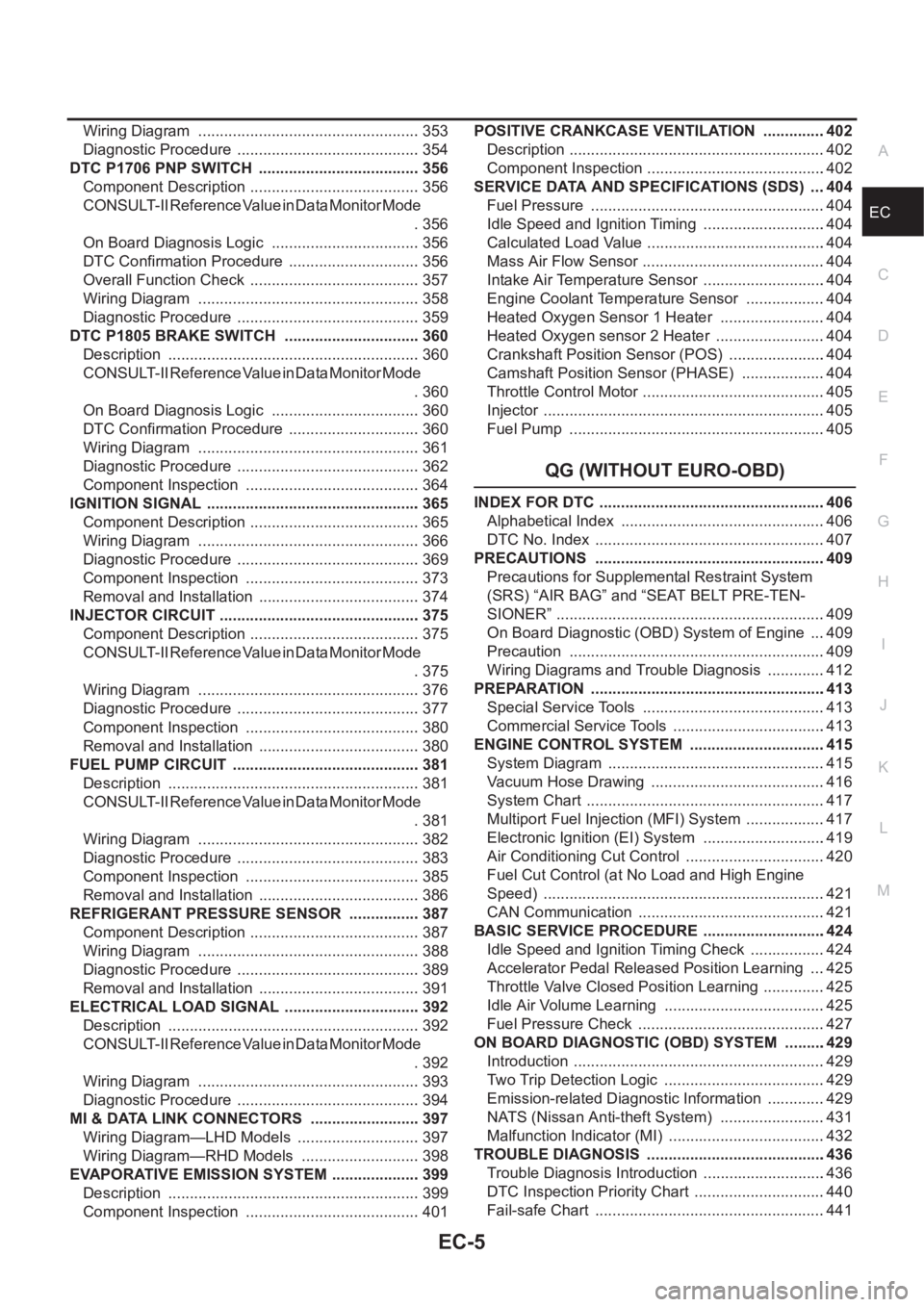

TROUBLE DIAGNOSIS

EC-63

[QG (WITH EURO-OBD)]

C

D

E

F

G

H

I

J

K

L

MA

EC

Fail-safe ChartEBS00K3N

●When the DTC listed below is detected, the ECM enters fail-safe mode and the MI lights up.

Priority Detected items (DTC)

1

●U1000 U1001 CAN communication line

●P0102 P0103 Mass air flow sensor

●P0112 P0113 Intake air temperature sensor

●P0117 P0118 Engine coolant temperature sensor

●P0221 P0222 P0223 P1223 P1224 P1225 P1226 P1229 Throttle position sensor

●P0226 P0227 P0228 P1227 P1228 Accelerator pedal position sensor

●P0327 P0328 Knock sensor

●P0335 Crankshaft position sensor (POS)

●P0340 Camshaft position sensor (PHASE)

●P0500 Vehicle speed sensor

●P0705 Park/Neutral position (PNP) switch

●P0605 ECM

●P1610-P1615 NATS

●P1706 Park/Neutral position (PNP) switch

2

●P0031 P0032 Heated oxygen sensor 1 heater

●P0037 P0038 Heated oxygen sensor 2 heater

●P0132 P0133 P0134 P1143 P1144 Heated oxygen sensor 1

●P0138 P0139 P1146 P1147 Heated oxygen sensor 2

●P0550 Power steering pressure sensor

●P0710-P0725 P0740-P0755 P1705 P1760 A/T related sensors and solenoid valves

●P1065 ECM power supply

●P 1111 I n ta k e v a l v e t i m i n g c o n t r o l s o l e n o i d v a l v e

●P1122 Electric throttle control function

●P1124 P1126 P1128 Electric throttle control actuator

●P1805 Brake switch

3

●P0011 Intake valve timing control

●P0171 P0172 Fuel injection system function

●P0300 - P0304 Misfire

●P0420 Three way catalyst function

●P0444 EVAP canister purge volume control solenoid valve

●P0731-P0734 A/T function

●P1121 Electric throttle control actuator

●P1217 Engine over temperature (OVERHEAT)

DTC No. Detected items Engine operating condition in fail-safe mode

P0102

P0103Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.