check transmission fluid NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 13 of 3189

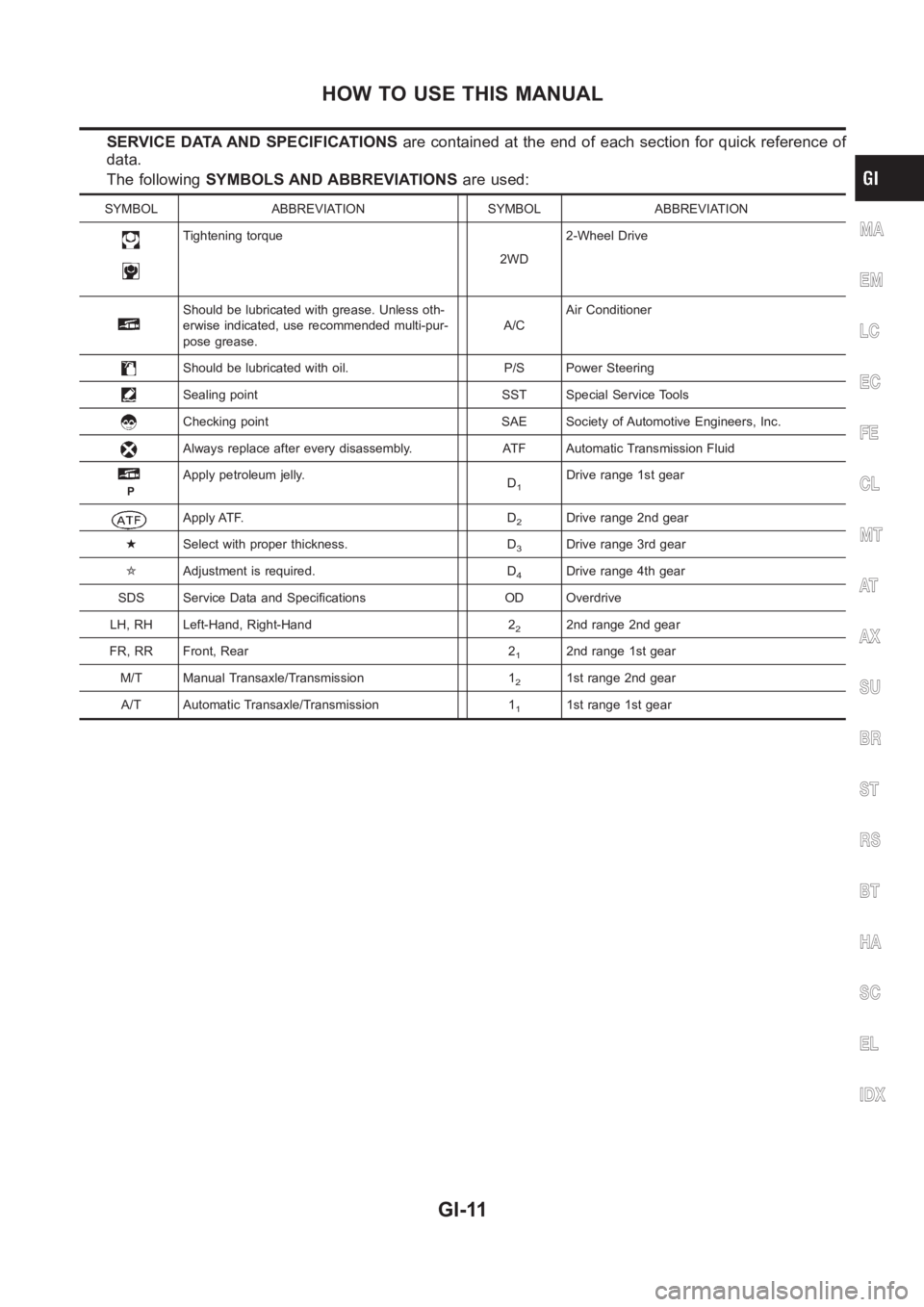

SERVICE DATA AND SPECIFICATIONSare contained at the end of each section for quick reference of

data.

The followingSYMBOLS AND ABBREVIATIONSare used:

SYMBOL ABBREVIATION SYMBOL ABBREVIATION

Tightening torque

2WD2-Wheel Drive

Should be lubricated with grease. Unless oth-

erwise indicated, use recommended multi-pur-

pose grease.A/CAir Conditioner

Should be lubricated with oil. P/S Power Steering

Sealing point SST Special Service Tools

Checking point SAE Society of Automotive Engineers, Inc.

Always replace after every disassembly. ATF Automatic Transmission Fluid

P

Apply petroleum jelly.

D1Drive range 1st gear

Apply ATF. D2Drive range 2nd gear

★Select with proper thickness. D

3Drive range 3rd gear

✩Adjustment is required. D

4Drive range 4th gear

SDS Service Data and Specifications OD Overdrive

LH, RH Left-Hand, Right-Hand 2

22nd range 2nd gear

FR, RR Front, Rear 2

12nd range 1st gear

M/T Manual Transaxle/Transmission 1

21st range 2nd gear

A/T Automatic Transaxle/Transmission 1

11st range 1st gear

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO USE THIS MANUAL

GI-11

Page 58 of 3189

NJMA0036

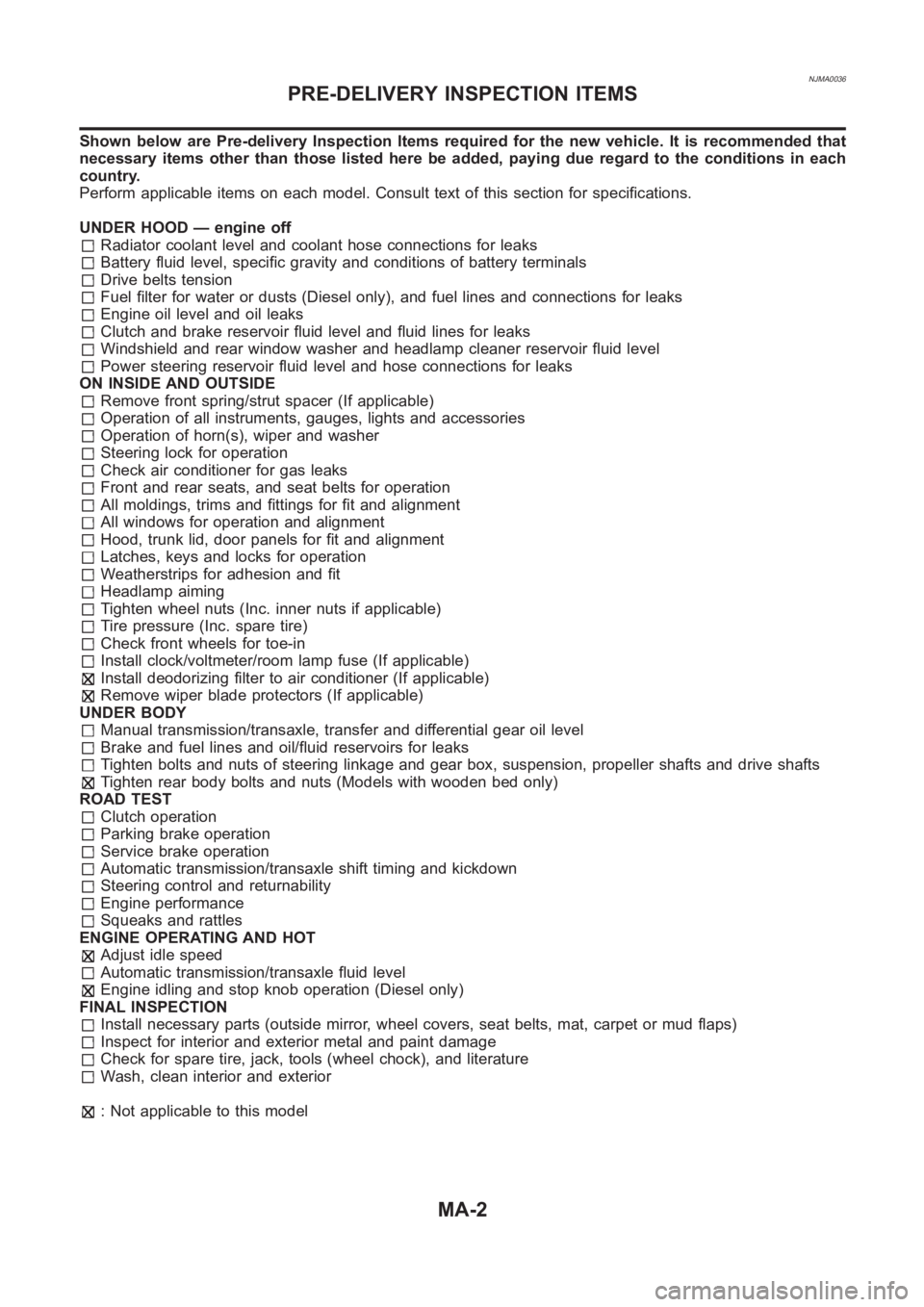

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard tothe conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 362 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-32

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle NISSAN ALMERA N16 2003 Electronic Repair Manual EC-32

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelle](/img/5/57350/w960_57350-361.png)

EC-32

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

PREPARATION

Before performing “Idle Air Volume Learning”, make sure that all of the following conditions are satisfied.

Learning will be cancelled if any of the following conditions are missed for even a moment.

●Battery voltage: More than 12.9V (At idle)

●Engine coolant temperature: 70 - 95°C (158 - 203°F)

●PNP switch: ON

●Electric load switch: OFF

(Air conditioner, headlamp, rear window defogger)

On vehicles equipped with daytime light systems, set lighting switch to the 1st position to light

only small lamps.

●Steering wheel: Neutral (Straight-ahead position)

●Vehicle speed: Stopped

●Transmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” system indicates less than 0.9V.

For A/T models without CONSULT-II and M/T models, drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. Perform EC-31, "Accelerator Pedal Released Position Learning" .

2. Perform EC-31, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic “PREPARATION” (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

SEF217Z

SEF454Y

Page 756 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-426

[QG (WITHOUT EURO-OBD)]

BASIC SERVICE PROCEDURE

●Transmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” syste NISSAN ALMERA N16 2003 Electronic Repair Manual EC-426

[QG (WITHOUT EURO-OBD)]

BASIC SERVICE PROCEDURE

●Transmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” syste](/img/5/57350/w960_57350-755.png)

EC-426

[QG (WITHOUT EURO-OBD)]

BASIC SERVICE PROCEDURE

●Transmission: Warmed-up

For A/T models with CONSULT-II, drive vehicle until “FLUID TEMP SE” in “DATA MONITOR” mode of “A/

T” system indicates less than 0.9V.

For A/T models without CONSULT-II and M/T models, drive vehicle for 10 minutes.

OPERATION PROCEDURE

With CONSULT-II

1. Perform EC-425, "Accelerator Pedal Released Position Learning" .

2. Perform EC-425, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

4. Check that all items listed under the topic “PREPARATION” (previously mentioned) are in good order.

5. Select “IDLE AIR VOL LEARN” in “WORK SUPPORT” mode.

6. Touch “START” and wait 20 seconds.

7. Make sure that “CMPLT” is displayed on CONSULT-II screen. If

“CMPLT” is not displayed, “Idle Air Volume Learning” will not be

carried out successfully. In this case, find the cause of the inci-

dent by referring to the “Diagnostic Procedure” below.

8. Rev up the engine two or three times and make sure that idle

speed and ignition timing are within the specifications.

Without CONSULT-II

NOTE:

●It is better to count the time accurately with a clock.

●It is impossible to switch the diagnostic mode when an accelerator pedal position sensor circuit

has a malfunction.

1. Perform EC-425, "

Accelerator Pedal Released Position Learning" .

2. Perform EC-425, "

Throttle Valve Closed Position Learning" .

3. Start engine and warm it up to normal operating temperature.

SEF217Z

SEF454Y

ITEM SPECIFICATION

Idle speed M/T: 700±50 rpm

A/T: 800±50 rpm (in “P” or “N” position)

Ignition timing M/T: 8±5° BTDC

A/T: 10±5° BTDC (in “P” or “N” position)

MBIB0238E

Page 1457 of 3189

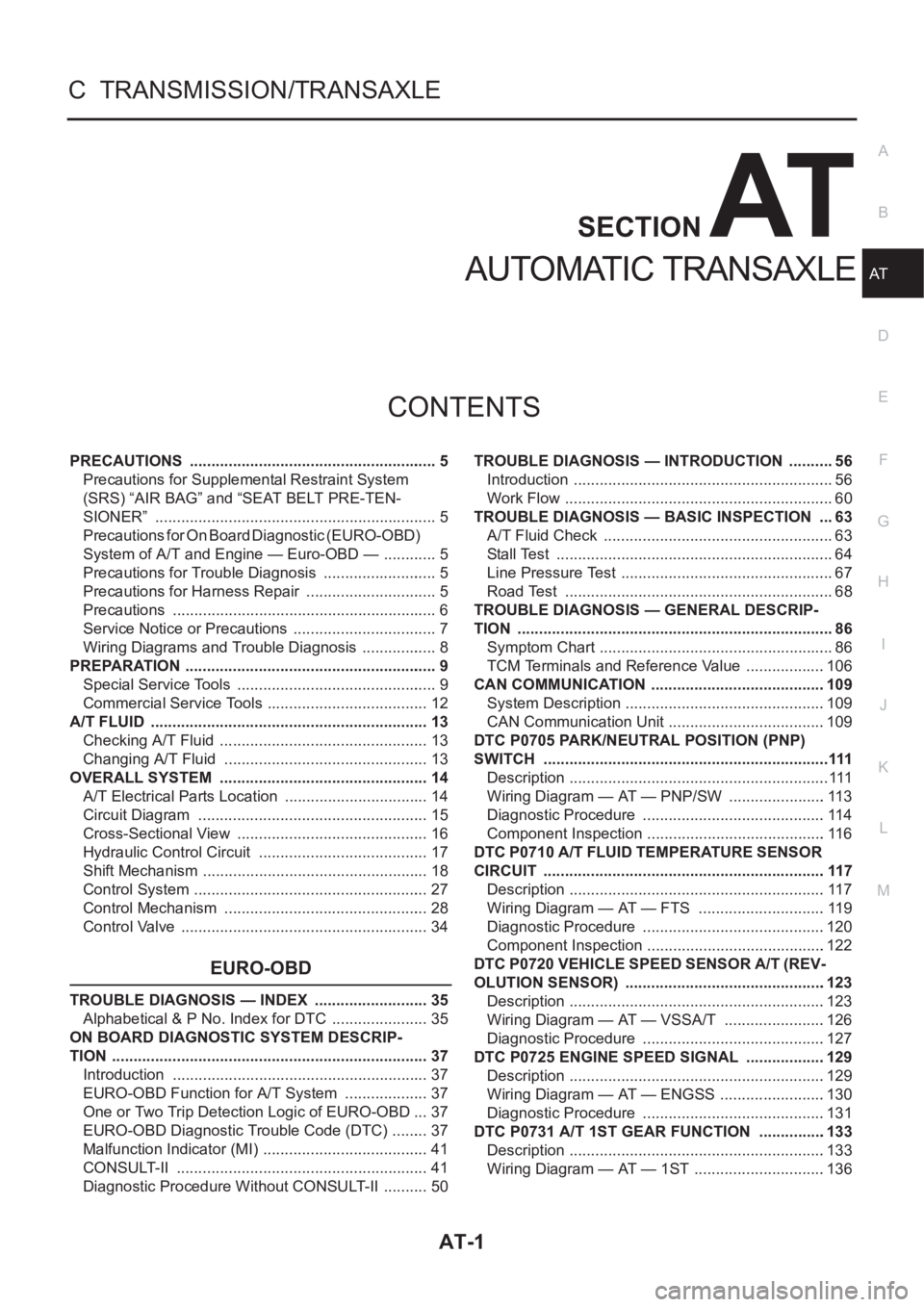

AT-1

AUTOMATIC TRANSAXLE

C TRANSMISSION/TRANSAXLE

CONTENTS

D

E

F

G

H

I

J

K

L

M

SECTION

A

B

AT

AUTOMATIC TRANSAXLE

PRECAUTIONS .......................................................... 5

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 5

Precautions for On Board Diagnostic (EURO-OBD)

System of A/T and Engine — Euro-OBD — ............. 5

Precautions for Trouble Diagnosis ........................... 5

Precautions for Harness Repair ............................... 5

Precautions .............................................................. 6

Service Notice or Precautions .................................. 7

Wiring Diagrams and Trouble Diagnosis .................. 8

PREPARATION ........................................................... 9

Special Service Tools ............................................... 9

Commercial Service Tools ...................................... 12

A/T FLUID ................................................................. 13

Checking A/T Fluid ................................................. 13

Changing A/T Fluid ............................................. ... 13

OVERALL SYSTEM ................................................. 14

A/T Electrical Parts Location .................................. 14

Circuit Diagram ...................................................... 15

Cross-Sectional View ............................................. 16

Hydraulic Control Circuit ........................................ 17

Shift Mechanism ..................................................... 18

Control System ....................................................... 27

Control Mechanism ................................................ 28

Control Valve .......................................................... 34

EURO-OBD

TROUBLE DIAGNOSIS — INDEX ........................... 35

Alphabetical & P No. Index for DTC ....................... 35

ON BOARD DIAGNOSTIC SYSTEM DESCRIP-

TION .......................................................................... 37

Introduction ............................................................ 37

EURO-OBD Function for A/T System .................... 37

One or Two Trip Detection Logic of EURO-OBD ... 37

EURO-OBD Diagnostic Trouble Code (DTC) ......... 37

Malfunction Indicator (MI) ....................................... 41

CONSULT-II ........................................................... 41

Diagnostic Procedure Without CONSULT-II ........... 50TROUBLE DIAGNOSIS — INTRODUCTION ........... 56

Introduction ............................................................. 56

Work Flow ............................................................... 60

TROUBLE DIAGNOSIS — BASIC INSPECTION .... 63

A/T Fluid Check ...................................................... 63

Stall Test ................................................................. 64

Line Pressure Test .................................................. 67

Road Test ............................................................... 68

TROUBLE DIAGNOSIS — GENERAL DESCRIP-

TION .......................................................................... 86

Symptom Chart ....................................................... 86

TCM Terminals and Reference Value ...................106

CAN COMMUNICATION .........................................109

System Description ...............................................109

CAN Communication Unit .....................................109

DTC P0705 PARK/NEUTRAL POSITION (PNP)

SWITCH ...................................................................111

Description .............................................................111

Wiring Diagram — AT — PNP/SW .......................113

Diagnostic Procedure ...........................................114

Component Inspection ..........................................116

DTC P0710 A/T FLUID TEMPERATURE SENSOR

CIRCUIT ..................................................................117

Description ............................................................117

Wiring Diagram — AT — FTS ..............................119

Diagnostic Procedure ...........................................120

Component Inspection ..........................................122

DTC P0720 VEHICLE SPEED SENSOR A/T (REV-

OLUTION SENSOR) ...............................................123

Description ............................................................123

Wiring Diagram — AT — VSSA/T ........................126

Diagnostic Procedure ...........................................127

DTC P0725 ENGINE SPEED SIGNAL ...................129

Description ............................................................129

Wiring Diagram — AT — ENGSS .........................130

Diagnostic Procedure ..........................................

.131

DTC P0731 A/T 1ST GEAR FUNCTION ................133

Description ............................................................133

Wiring Diagram — AT — 1ST ...............................136

Page 1519 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-63

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007NW

FLUID LEAKAGE CHECK

1. Clean area suspected of NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-63

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007NW

FLUID LEAKAGE CHECK

1. Clean area suspected of](/img/5/57350/w960_57350-1518.png)

TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-63

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007NW

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fluid leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to AT-13, "Checking A/T Fluid" .

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 1555 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-99

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Races extremely fast or slips in

changing from “D

4 ” or “D3 ” to “D1 ”

when depressing accelerator p NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-99

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Races extremely fast or slips in

changing from “D

4 ” or “D3 ” to “D1 ”

when depressing accelerator p](/img/5/57350/w960_57350-1554.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-99

[EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Races extremely fast or slips in

changing from “D

4 ” or “D3 ” to “D1 ”

when depressing accelerator pedal.ON vehicle1. Fluid levelAT-63, "

FLUID LEVEL

CHECK"

2. Throttle position sensor [Accelerator

pedal position (APP) sensor]AT-181, "

DTC P1705

ACCELERATOR PEDAL

POSITION (APP) SEN-

SOR"

3. Line pressure testAT-67, "Line Pressure Test"

4. Line pressure solenoid valveAT-164, "

DTC P0745 LINE

PRESSURE SOLENOID

VA LV E"

5. Control valve assemblyAT-406, "

Control Valve

Assembly and Accumula-

tors"

OFF vehicle6. Forward clutchAT-464, "

Forward and

Overrun Clutches"

7. Forward one-way clutchAT-413, "OVERHAUL"

8. Low one-way clutchAT-413, "

OVERHAUL",AT-

417, "Locations of Adjust-

ing Shims, Needle Bear-

ings, Thrust Washers and

Snap Rings"

Vehicle will not run in any position.ON vehicle1. Fluid levelAT-63, "

FLUID LEVEL

CHECK"

2. Control cable adjustmentAT-408, "Control Cable

Adjustment"

3. Line pressure testAT-67, "Line Pressure Test"

4. Line pressure solenoid valveAT-164, "

DTC P0745 LINE

PRESSURE SOLENOID

VA LV E"

OFF vehicle5. Oil pumpAT-435, "

Oil Pump"

6. High clutchAT-459, "High Clutch"

7. Brake bandAT-483, "Band Servo Pis-

ton Assembly"

8. Low & reverse brakeAT-470, "Low & Reverse

Brake"

9. Torque converterAT-417, "

Locations of

Adjusting Shims, Needle

Bearings, Thrust Washers

and Snap Rings"

10. Parking componentsAT-413, "

Output Shaft, Idler

Gear, Reduction Pinion

Gear and Bearing

Retainer"

Transmission noise in “D”, “2”, “1”

and “R” positions.ON vehicle 1. Fluid levelAT-63, "

FLUID LEVEL

CHECK"

OFF vehicle 2. Torque converterAT-417, "

Locations of

Adjusting Shims, Needle

Bearings, Thrust Washers

and Snap Rings"

Symptom Condition Diagnostic ItemReference Page

EURO-OBD

Page 1558 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual AT-102

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Large shock changing from “12 ” to

“1

1 ” in “1” position.ON vehicle 1. Control valve assemblyAT-406, "

Control Valve

Asse NISSAN ALMERA N16 2003 Electronic Repair Manual AT-102

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Large shock changing from “12 ” to

“1

1 ” in “1” position.ON vehicle 1. Control valve assemblyAT-406, "

Control Valve

Asse](/img/5/57350/w960_57350-1557.png)

AT-102

[EURO-OBD]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

Large shock changing from “12 ” to

“1

1 ” in “1” position.ON vehicle 1. Control valve assemblyAT-406, "

Control Valve

Assembly and Accumula-

tors"

OFF vehicle 2. Low & reverse brakeAT-470, "Low & Reverse

Brake"

Transmission overheats.ON vehicle1. Fluid levelAT- 6 3 , "

FLUID LEVEL

CHECK"

2. Engine idling rpmEC-30, "Idle Speed and

Ignition Timing Check"

3. Throttle position sensor [Accelerator

pedal position (APP) sensor]AT-181, "

DTC P1705

ACCELERATOR PEDAL

POSITION (APP) SEN-

SOR"

4. Line pressure testAT- 6 7 , "Line Pressure Test"

5. Line pressure solenoid valveAT-164, "

DTC P0745 LINE

PRESSURE SOLENOID

VA LV E"

6. Control valve assemblyAT-406, "

Control Valve

Assembly and Accumula-

tors"

OFF vehicle7. Oil pumpAT-435, "

Oil Pump"

8. Reverse clutchAT-455, "Reverse Clutch"

9. High clutchAT-459, "High Clutch"

10. Brake bandAT-483, "Band Servo Pis-

ton Assembly"

11. Forward clutchAT-464, "Forward and

Overrun Clutches"

12. Overrun clutchAT-464, "Forward and

Overrun Clutches"

13. Low & reverse brakeAT-470, "Low & Reverse

Brake"

14. Torque converterAT-417, "

Locations of

Adjusting Shims, Needle

Bearings, Thrust Washers

and Snap Rings"

ATF shoots out during operation.

White smoke emitted from exhaust

pipe during operation.ON vehicle 1. Fluid levelAT- 6 3 , "

FLUID LEVEL

CHECK"

OFF vehicle2. Reverse clutchAT-455, "

Reverse Clutch"

3. High clutchAT-459, "High Clutch"

4. Brake bandAT-483, "Band Servo Pis-

ton Assembly"

5. Forward clutchAT-464, "Forward and

Overrun Clutches"

6. Overrun clutchAT-464, "Forward and

Overrun Clutches"

7. Low & reverse brakeAT-470, "Low & Reverse

Brake"

Symptom Condition Diagnostic ItemReference Page

EURO-OBD

Page 1717 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-261

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007QR

FLUID LEAKAGE CHECK

1. Clean area suspe NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-261

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007QR

FLUID LEAKAGE CHECK

1. Clean area suspe](/img/5/57350/w960_57350-1716.png)

TROUBLE DIAGNOSIS — BASIC INSPECTION

AT-261

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

TROUBLE DIAGNOSIS — BASIC INSPECTIONPFP:00000

A/T Fluid CheckECS007QR

FLUID LEAKAGE CHECK

1. Clean area suspected of leaking. — for example, mating surface

of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in “D” posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fluid leakage.

FLUID CONDITION CHECK

FLUID LEVEL CHECK

Refer to AT- 2 6 1 , "A/T Fluid Check" .

SAT767B

SAT288G

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination — Road water

entering through filler tube or breather

Varnished fluid, light to dark brown and

tackyOxidation — Over or under filling, —

Overheating

SAT638A

Page 1751 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-295

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Races extremely fast or slips in

changing from “D

4 ” or “D3 ” to “D1 ”

when depressing accele NISSAN ALMERA N16 2003 Electronic Repair Manual TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-295

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Races extremely fast or slips in

changing from “D

4 ” or “D3 ” to “D1 ”

when depressing accele](/img/5/57350/w960_57350-1750.png)

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

AT-295

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

Races extremely fast or slips in

changing from “D

4 ” or “D3 ” to “D1 ”

when depressing accelerator pedal.ON vehicle1. Fluid levelAT- 2 6 1 , "

FLUID LEVEL

CHECK"

2. Throttle position sensor (Accelerator

pedal position (APP) sensor)AT- 3 5 2 , "ACCELE

RATOR PEDAL POSI-

TION (APP) SENSOR"

3. Line pressure testAT- 2 6 5 , "Line Pressure

Te s t"

4. Line pressure solenoid valveAT- 3 8 8 , "

LINE PRES-

SURE SOLENOID

VA LV E"

5. Control valve assemblyAT- 4 0 6 , "

Control Valve

Assembly and Accumula-

tors"

OFF vehicle6. Forward clutchAT- 4 6 4 , "

Forward and

Overrun Clutches"

7. Forward one-way clutchAT- 4 1 3 , "OVERHAUL"

8. Low one-way clutchAT- 4 1 3 , "

OVERHAUL",

AT- 4 1 7 , "

Locations of

Adjusting Shims, Needle

Bearings, Thrust Washers

and Snap Rings"

Vehicle will not run in any position.ON vehicle1. Fluid levelAT- 2 6 1 , "

FLUID LEVEL

CHECK"

2. Control cable adjustmentAT- 4 0 8 , "Control Cable

Adjustment"

3. Line pressure testAT- 2 6 5 , "Line Pressure

Te s t"

4. Line pressure solenoid valveAT- 3 8 8 , "

LINE PRES-

SURE SOLENOID

VA LV E"

OFF vehicle5. Oil pumpAT- 4 3 5 , "

Oil Pump"

6. High clutchAT- 4 5 9 , "High Clutch"

7. Brake bandAT- 4 8 3 , "Band Servo Pis-

ton Assembly"

8. Low & reverse brakeAT- 4 7 0 , "Low & Reverse

Brake"

9. Torque converterAT- 4 1 7 , "

Locations of

Adjusting Shims, Needle

Bearings, Thrust Washers

and Snap Rings"

10. Parking componentsAT- 4 7 8 , "

Output Shaft,

Idler Gear, Reduction Pin-

ion Gear and Bearing

Retainer"

Transmission noise in “D”, “2”, “1” and

“R” positions.ON vehicle 1. Fluid levelAT- 2 6 1 , "

FLUID LEVEL

CHECK"

OFF vehicle 2. Torque converterAT- 4 1 7 , "

Locations of

Adjusting Shims, Needle

Bearings, Thrust Washers

and Snap Rings"

Symptom Condition Diagnostic Item Reference Page