boot NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1341 of 3189

SMT143DC

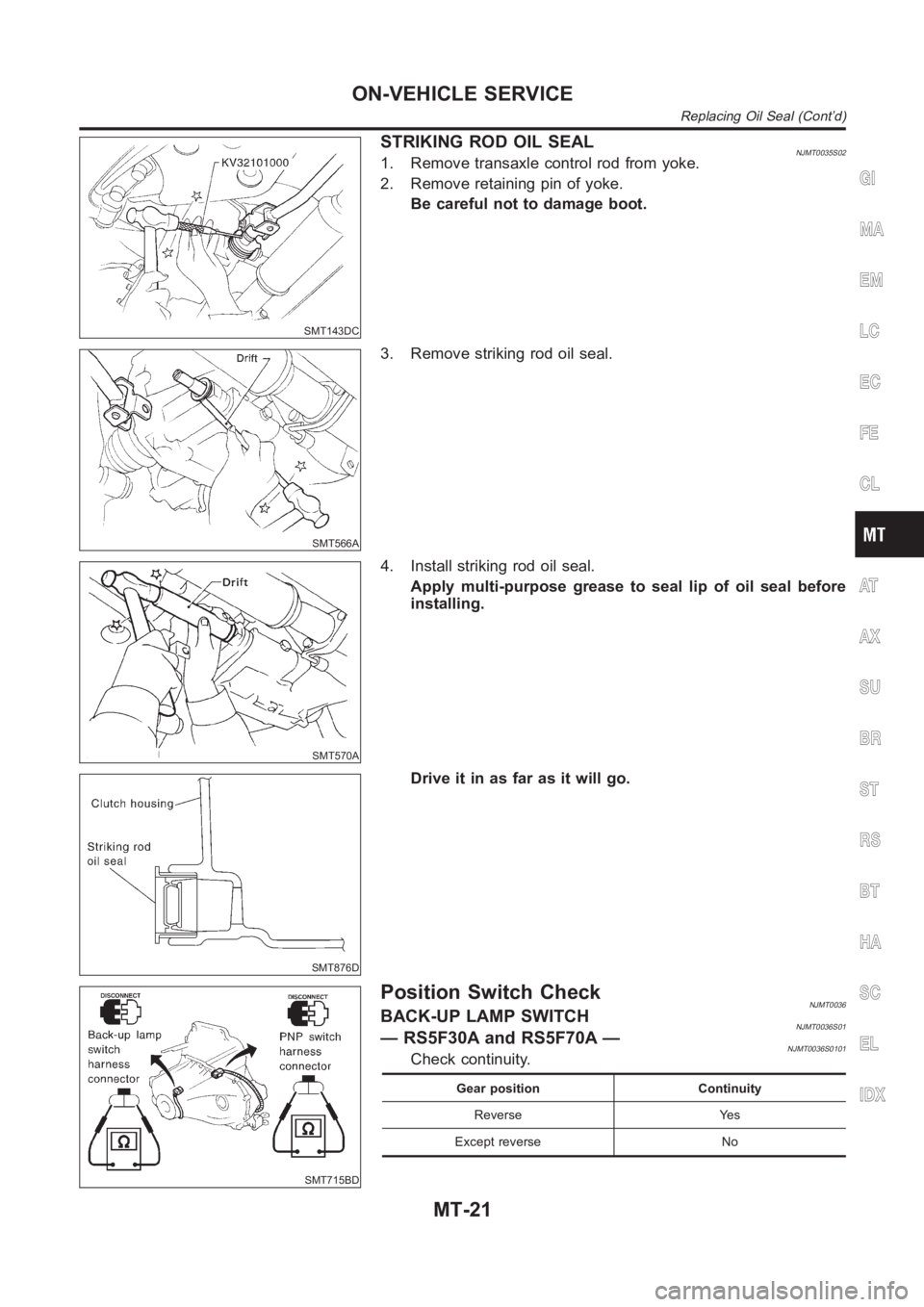

STRIKING ROD OIL SEALNJMT0035S021. Remove transaxle control rod from yoke.

2. Remove retaining pin of yoke.

Be careful not to damage boot.

SMT566A

3. Remove striking rod oil seal.

SMT570A

4. Install striking rod oil seal.

Apply multi-purpose grease to seal lip of oil seal before

installing.

SMT876D

Drive it in as far as it will go.

SMT715BD

Position Switch CheckNJMT0036BACK-UP LAMP SWITCHNJMT0036S01— RS5F30A and RS5F70A —NJMT0036S0101Check continuity.

Gear position Continuity

Reverse Yes

Except reverse No

GI

MA

EM

LC

EC

FE

CL

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON-VEHICLE SERVICE

Replacing Oil Seal (Cont’d)

MT-21

Page 1349 of 3189

NJMT0038

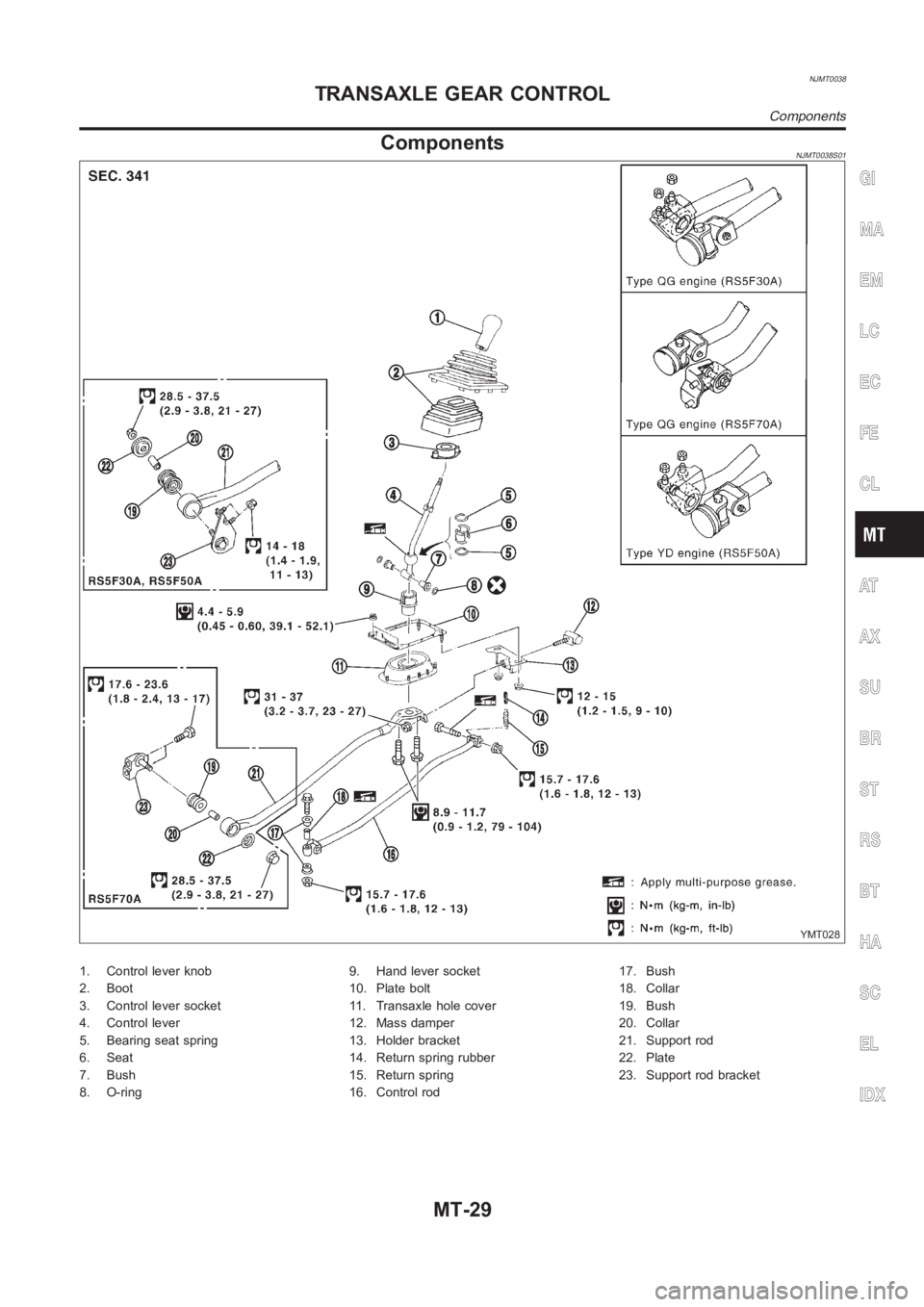

ComponentsNJMT0038S01

YMT028

1. Control lever knob

2. Boot

3. Control lever socket

4. Control lever

5. Bearing seat spring

6. Seat

7. Bush

8. O-ring9. Hand lever socket

10. Plate bolt

11. Transaxle hole cover

12. Mass damper

13. Holder bracket

14. Return spring rubber

15. Return spring

16. Control rod17. Bush

18. Collar

19. Bush

20. Collar

21. Support rod

22. Plate

23. Support rod bracket

GI

MA

EM

LC

EC

FE

CL

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TRANSAXLE GEAR CONTROL

Components

MT-29

Page 1350 of 3189

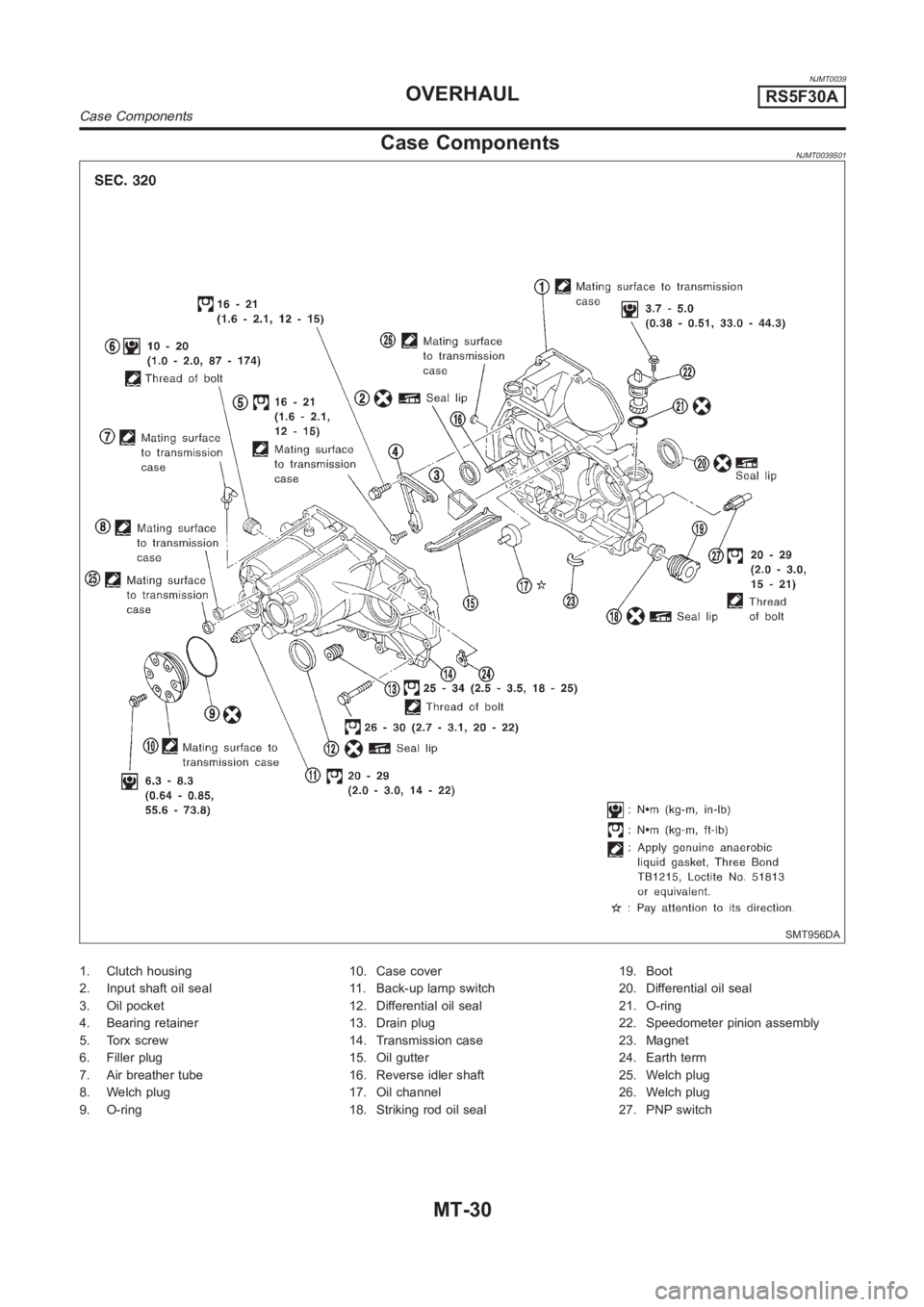

NJMT0039

Case ComponentsNJMT0039S01

SMT956DA

1. Clutch housing

2. Input shaft oil seal

3. Oil pocket

4. Bearing retainer

5. Torx screw

6. Filler plug

7. Air breather tube

8. Welch plug

9. O-ring10. Case cover

11. Back-up lamp switch

12. Differential oil seal

13. Drain plug

14. Transmission case

15. Oil gutter

16. Reverse idler shaft

17. Oil channel

18. Striking rod oil seal19. Boot

20. Differential oil seal

21. O-ring

22. Speedometer pinion assembly

23. Magnet

24. Earth term

25. Welch plug

26. Welch plug

27. PNP switch

OVERHAULRS5F30A

Case Components

MT-30

Page 1374 of 3189

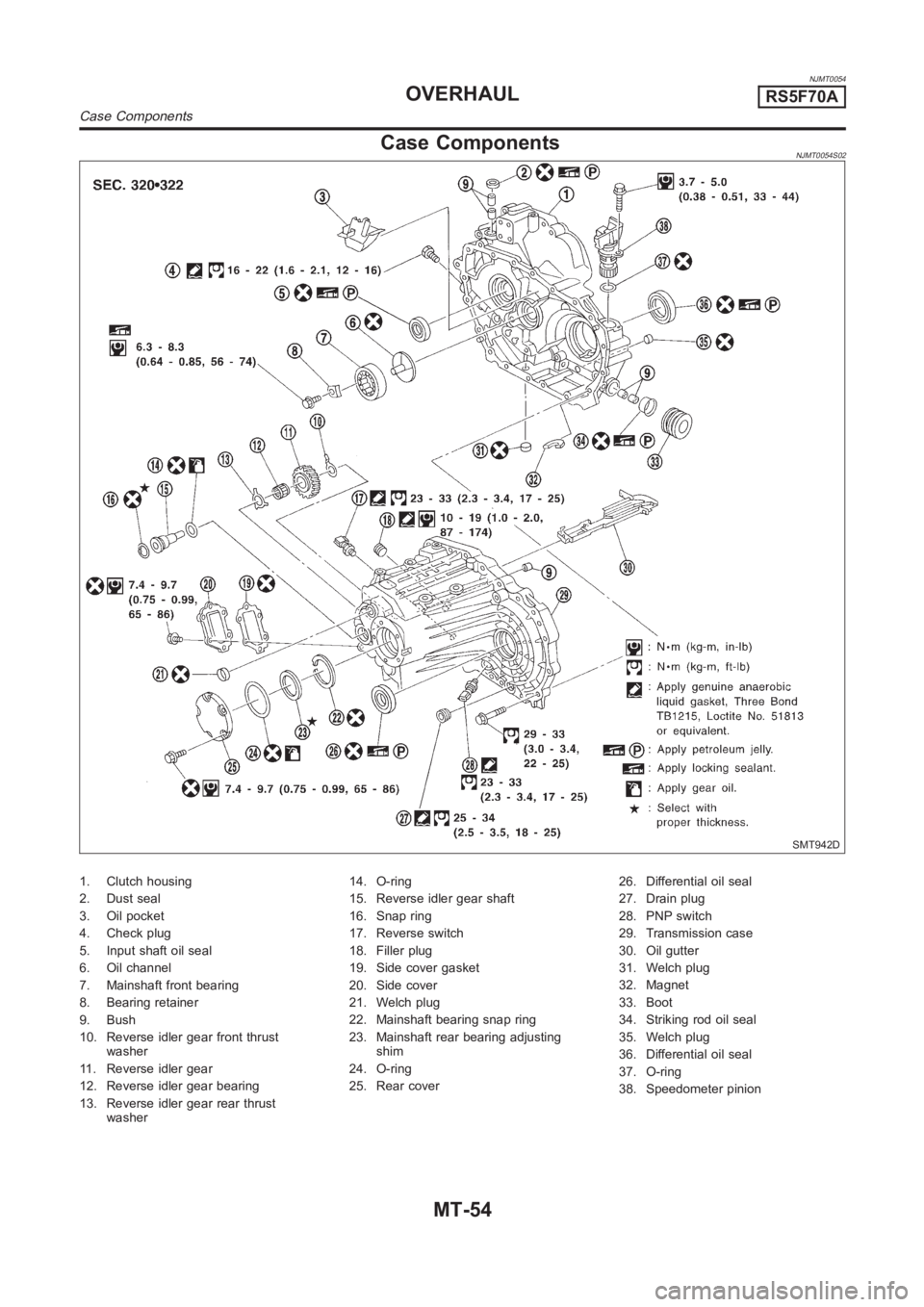

NJMT0054

Case ComponentsNJMT0054S02

SMT942D

1. Clutch housing

2. Dust seal

3. Oil pocket

4. Check plug

5. Input shaft oil seal

6. Oil channel

7. Mainshaft front bearing

8. Bearing retainer

9. Bush

10. Reverse idler gear front thrust

washer

11. Reverse idler gear

12. Reverse idler gear bearing

13. Reverse idler gear rear thrust

washer14. O-ring

15. Reverse idler gear shaft

16. Snap ring

17. Reverse switch

18. Filler plug

19. Side cover gasket

20. Side cover

21. Welch plug

22. Mainshaft bearing snap ring

23. Mainshaft rear bearing adjusting

shim

24. O-ring

25. Rear cover26. Differential oil seal

27. Drain plug

28. PNP switch

29. Transmission case

30. Oil gutter

31. Welch plug

32. Magnet

33. Boot

34. Striking rod oil seal

35. Welch plug

36. Differential oil seal

37. O-ring

38. Speedometer pinion

OVERHAULRS5F70A

Case Components

MT-54

Page 1376 of 3189

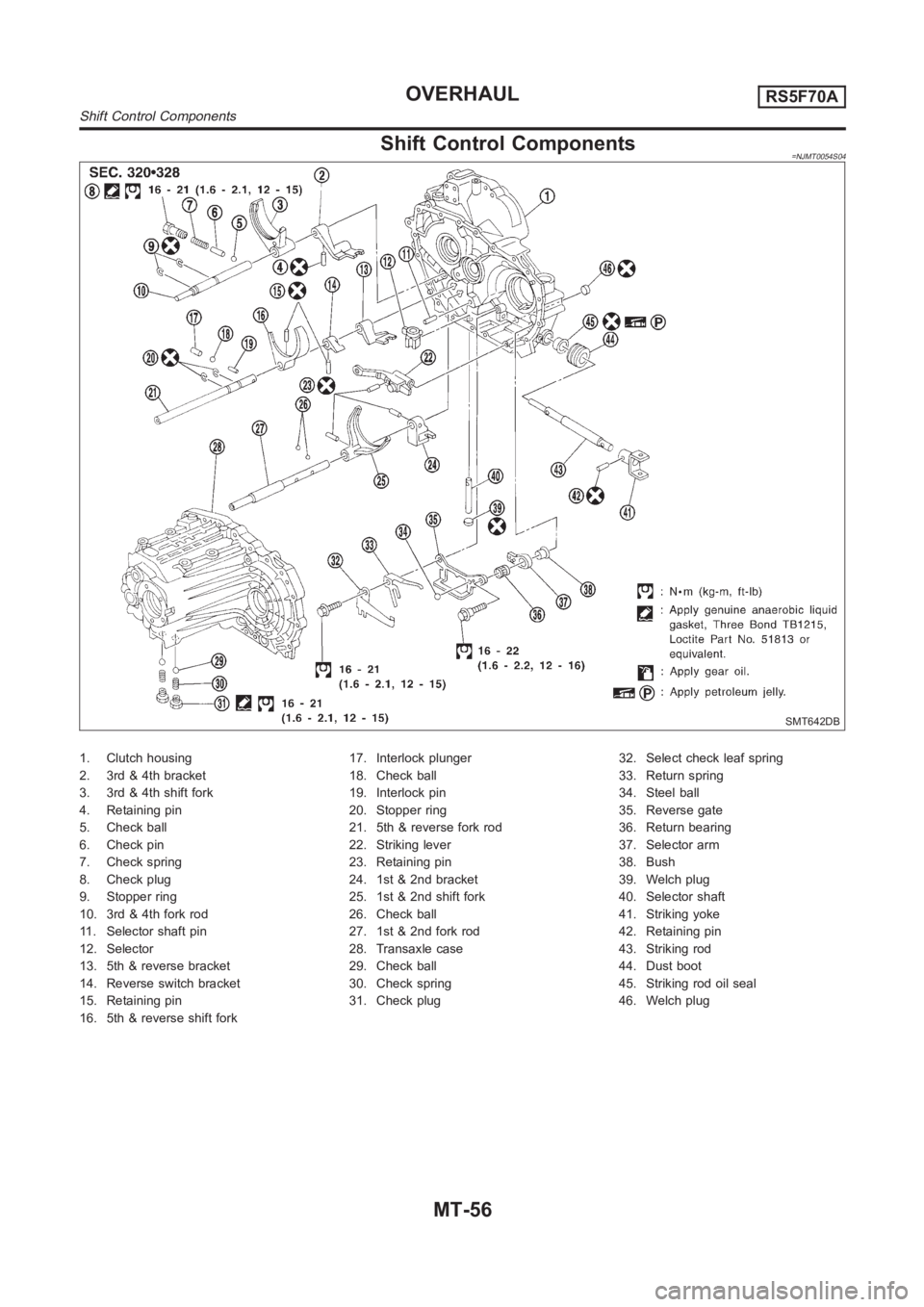

Shift Control Components=NJMT0054S04

SMT642DB

1. Clutch housing

2. 3rd & 4th bracket

3. 3rd & 4th shift fork

4. Retaining pin

5. Check ball

6. Check pin

7. Check spring

8. Check plug

9. Stopper ring

10. 3rd & 4th fork rod

11. Selector shaft pin

12. Selector

13. 5th & reverse bracket

14. Reverse switch bracket

15. Retaining pin

16. 5th & reverse shift fork17. Interlock plunger

18. Check ball

19. Interlock pin

20. Stopper ring

21. 5th & reverse fork rod

22. Striking lever

23. Retaining pin

24. 1st & 2nd bracket

25. 1st & 2nd shift fork

26. Check ball

27. 1st & 2nd fork rod

28. Transaxle case

29. Check ball

30. Check spring

31. Check plug32. Select check leaf spring

33. Return spring

34. Steel ball

35. Reverse gate

36. Return bearing

37. Selector arm

38. Bush

39. Welch plug

40. Selector shaft

41. Striking yoke

42. Retaining pin

43. Striking rod

44. Dust boot

45. Striking rod oil seal

46. Welch plug

OVERHAULRS5F70A

Shift Control Components

MT-56

Page 1403 of 3189

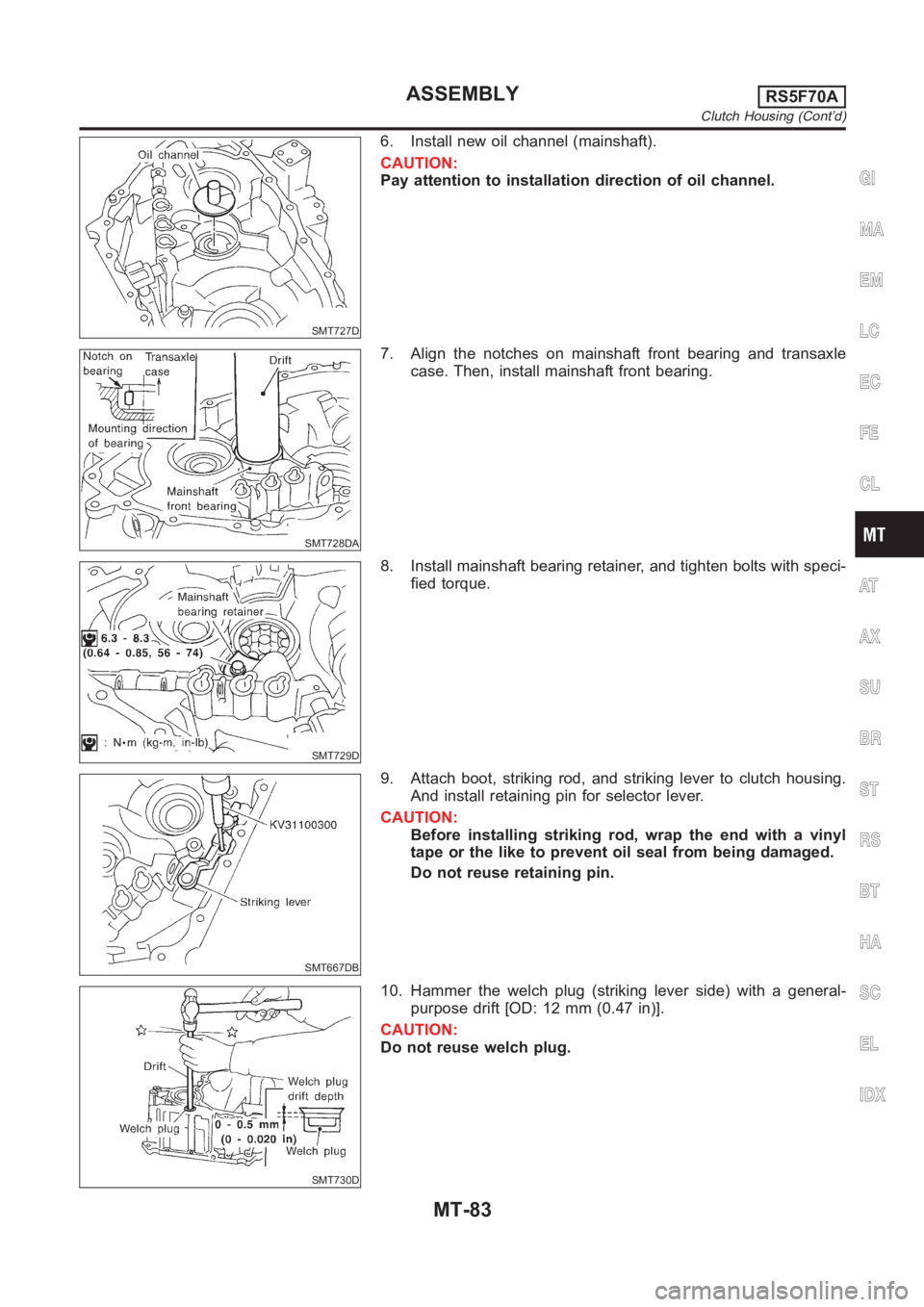

SMT727D

6. Install new oil channel (mainshaft).

CAUTION:

Pay attention to installation direction of oil channel.

SMT728DA

7. Align the notches on mainshaft front bearing and transaxle

case. Then, install mainshaft front bearing.

SMT729D

8. Install mainshaft bearing retainer, and tighten bolts with speci-

fied torque.

SMT667DB

9. Attach boot, striking rod, and striking lever to clutch housing.

And install retaining pin for selector lever.

CAUTION:

Before installing striking rod, wrap the end with a vinyl

tape or the like to prevent oil seal from being damaged.

Do not reuse retaining pin.

SMT730D

10. Hammer the welch plug (striking lever side) with a general-

purpose drift [OD: 12 mm (0.47 in)].

CAUTION:

Do not reuse welch plug.

GI

MA

EM

LC

EC

FE

CL

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ASSEMBLYRS5F70A

Clutch Housing (Cont’d)

MT-83

Page 1412 of 3189

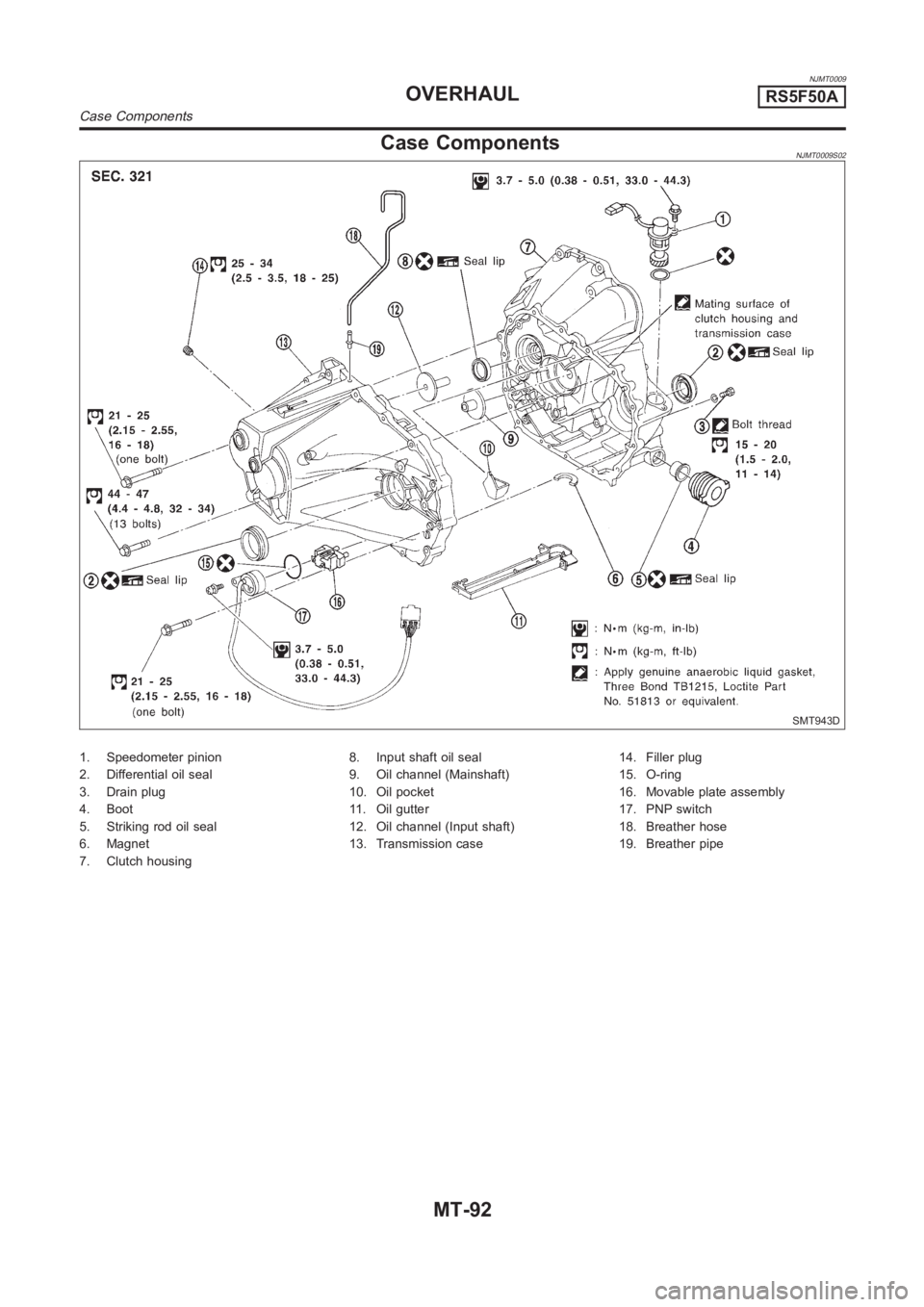

NJMT0009

Case ComponentsNJMT0009S02

SMT943D

1. Speedometer pinion

2. Differential oil seal

3. Drain plug

4. Boot

5. Striking rod oil seal

6. Magnet

7. Clutch housing8. Input shaft oil seal

9. Oil channel (Mainshaft)

10. Oil pocket

11. Oil gutter

12. Oil channel (Input shaft)

13. Transmission case14. Filler plug

15. O-ring

16. Movable plate assembly

17. PNP switch

18. Breather hose

19. Breather pipe

OVERHAULRS5F50A

Case Components

MT-92

Page 2136 of 3189

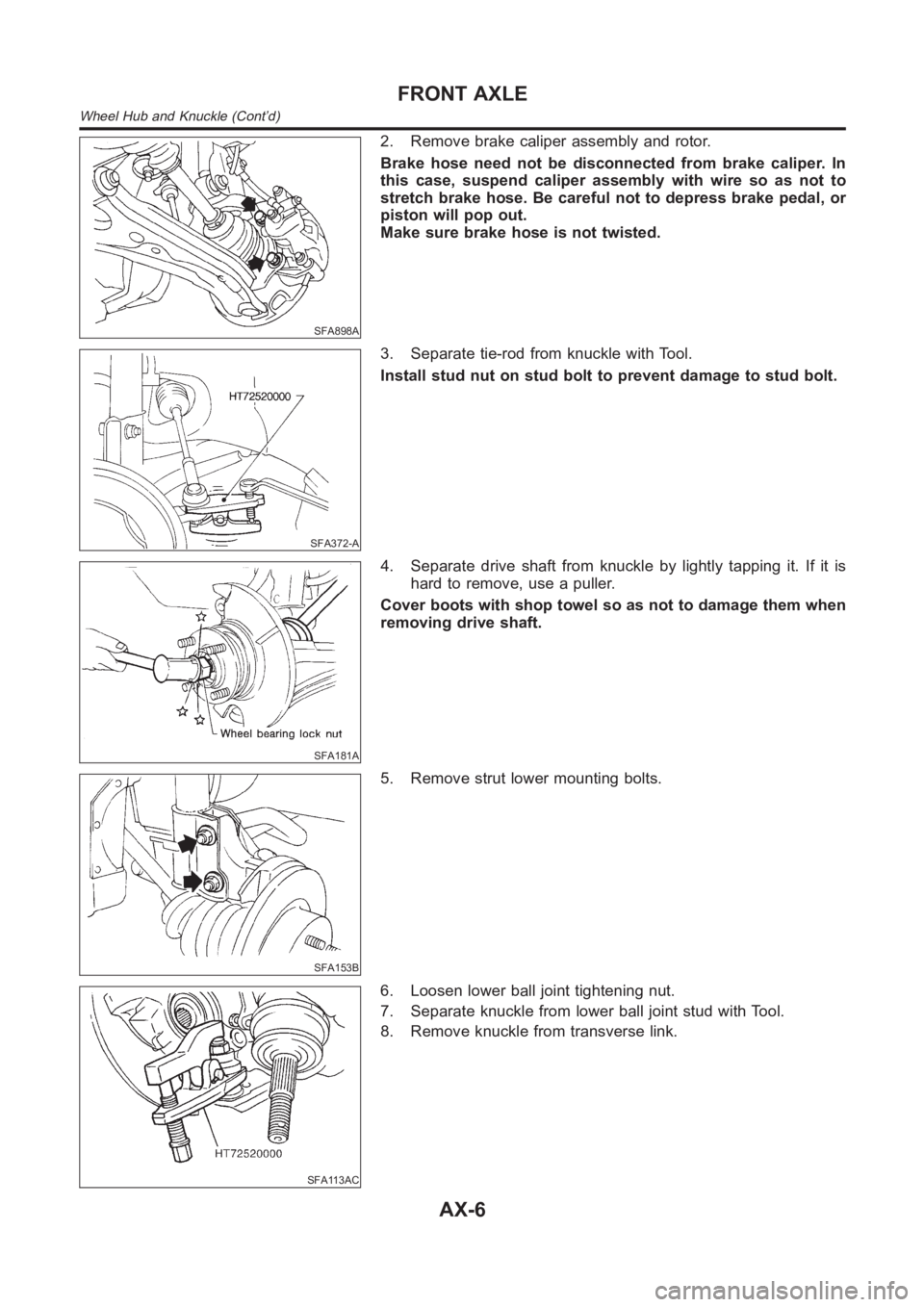

SFA898A

2. Remove brake caliper assembly and rotor.

Brake hose need not be disconnected from brake caliper. In

this case, suspend caliper assembly with wire so as not to

stretch brake hose. Be careful not to depress brake pedal, or

piston will pop out.

Make sure brake hose is not twisted.

SFA372-A

3. Separate tie-rod from knuckle with Tool.

Install stud nut on stud bolt to prevent damage to stud bolt.

SFA181A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them when

removing drive shaft.

SFA153B

5. Remove strut lower mounting bolts.

SFA113AC

6. Loosen lower ball joint tightening nut.

7. Separate knuckle from lower ball joint stud with Tool.

8. Remove knuckle from transverse link.

FRONT AXLE

Wheel Hub and Knuckle (Cont’d)

AX-6

Page 2140 of 3189

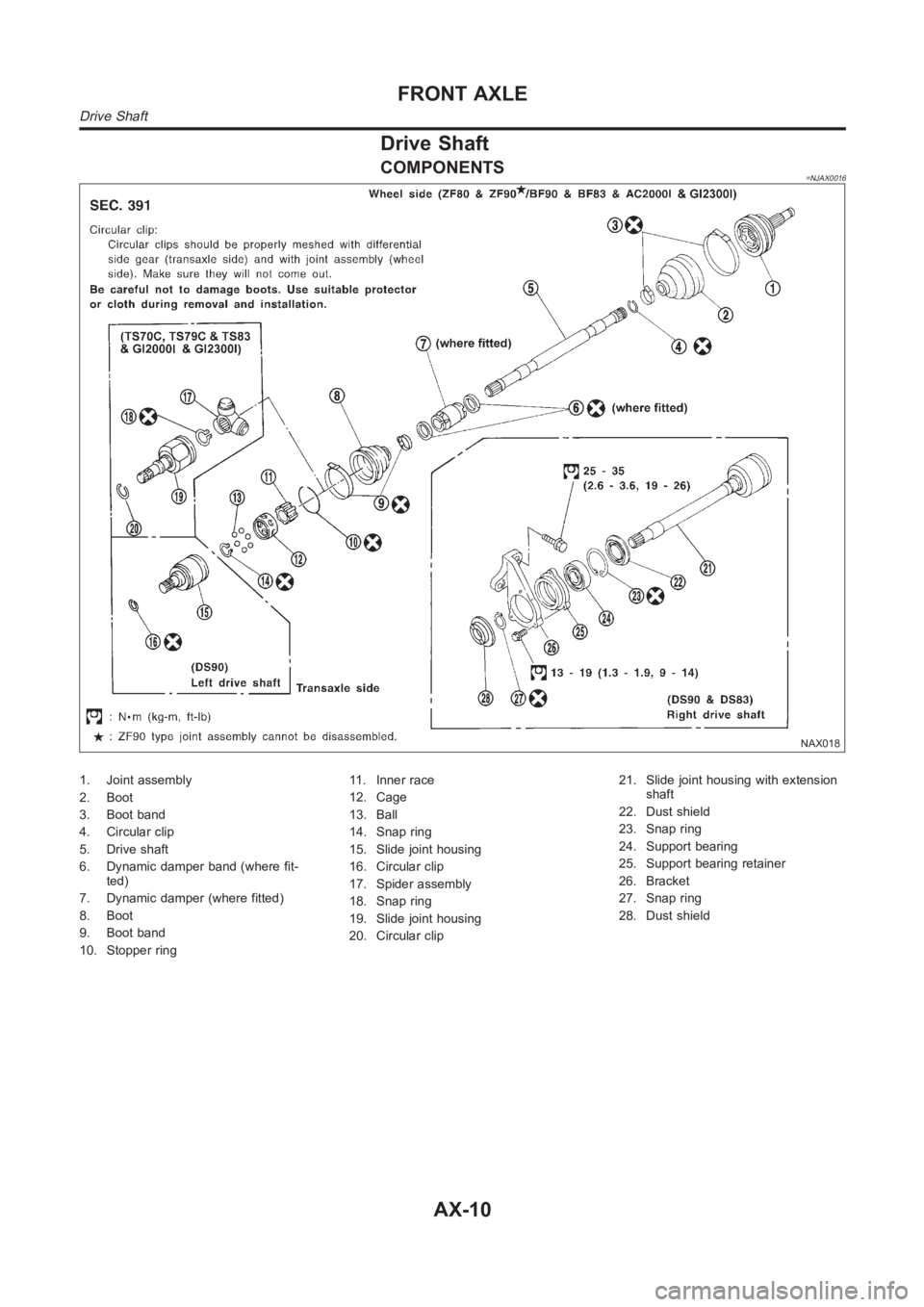

Drive Shaft

COMPONENTS=NJAX0016

NAX018

1. Joint assembly

2. Boot

3. Boot band

4. Circular clip

5. Drive shaft

6. Dynamic damper band (where fit-

ted)

7. Dynamic damper (where fitted)

8. Boot

9. Boot band

10. Stopper ring11. Inner race

12. Cage

13. Ball

14. Snap ring

15. Slide joint housing

16. Circular clip

17. Spider assembly

18. Snap ring

19. Slide joint housing

20. Circular clip21. Slide joint housing with extension

shaft

22. Dust shield

23. Snap ring

24. Support bearing

25. Support bearing retainer

26. Bracket

27. Snap ring

28. Dust shield

FRONT AXLE

Drive Shaft

AX-10

Page 2141 of 3189

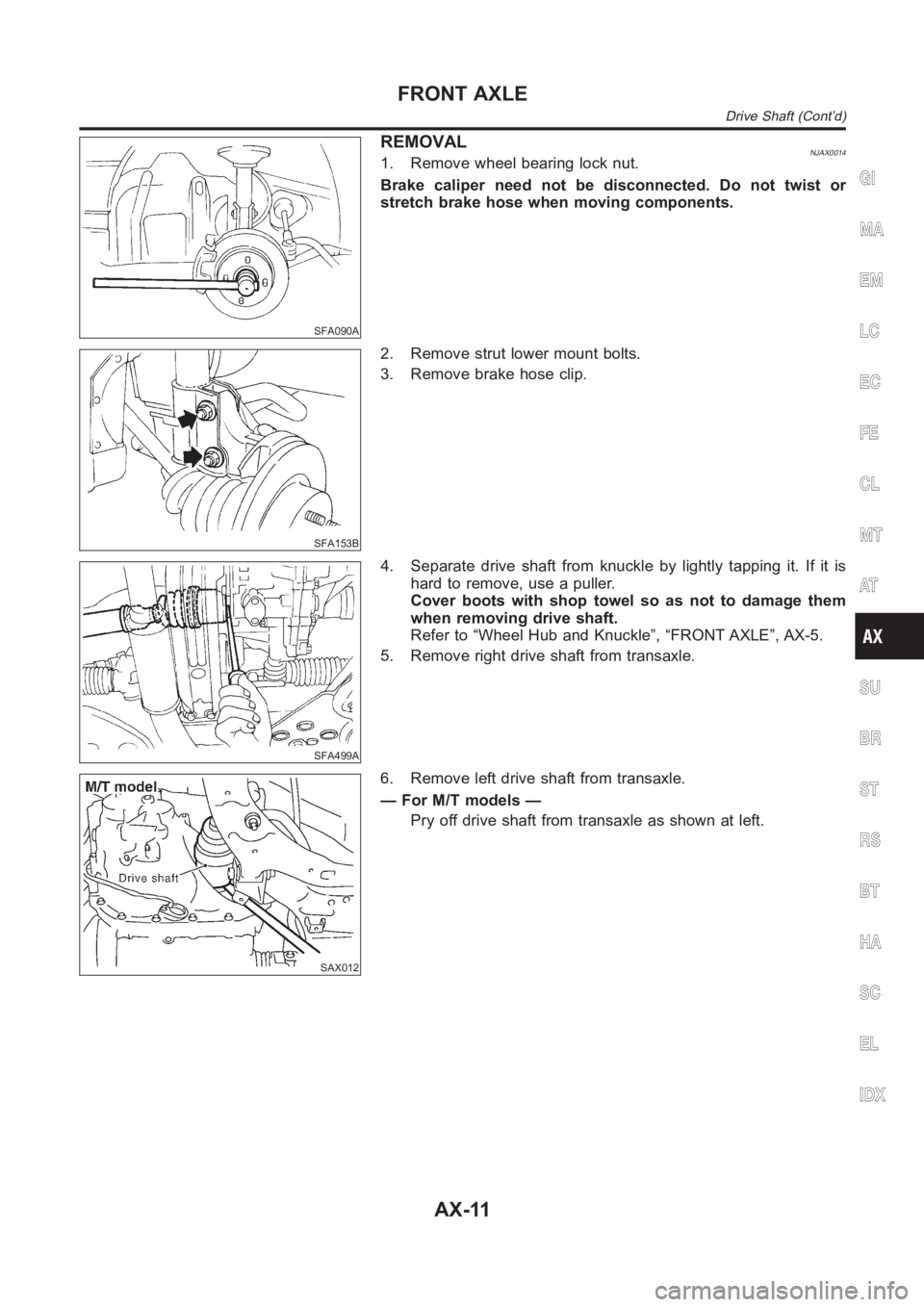

SFA090A

REMOVALNJAX00141. Remove wheel bearing lock nut.

Brake caliper need not be disconnected. Do not twist or

stretch brake hose when moving components.

SFA153B

2. Remove strut lower mount bolts.

3. Remove brake hose clip.

SFA499A

4. Separate drive shaft from knuckle by lightly tapping it. If it is

hard to remove, use a puller.

Cover boots with shop towel so as not to damage them

when removing drive shaft.

Refer to “Wheel Hub and Knuckle”, “FRONT AXLE”, AX-5.

5. Remove right drive shaft from transaxle.

SAX012

6. Remove left drive shaft from transaxle.

— For M/T models —

Pry off drive shaft from transaxle as shown at left.

GI

MA

EM

LC

EC

FE

CL

MT

AT

SU

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT AXLE

Drive Shaft (Cont’d)

AX-11