oil pressure NISSAN ALMERA TINO 2001 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2770 of 3051

NLMA0004

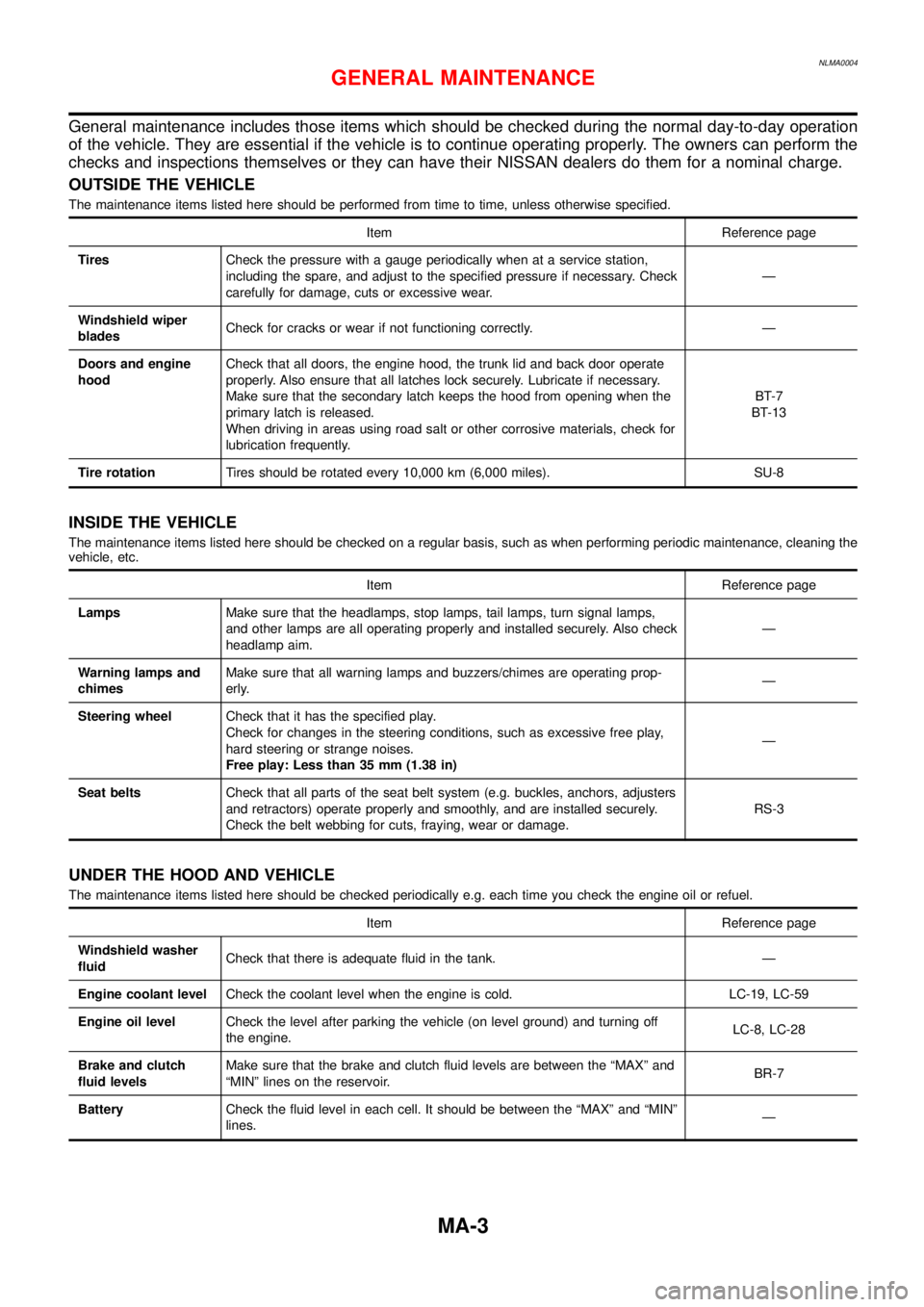

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them for a nominal charge.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

Item Reference page

TiresCheck the pressure with a gauge periodically when at a service station,

including the spare, and adjust to the specified pressure if necessary. Check

carefully for damage, cuts or excessive wear.—

Windshield wiper

bladesCheck for cracks or wear if not functioning correctly. —

Doors and engine

hoodCheck that all doors, the engine hood, the trunk lid and back door operate

properly. Also ensure that all latches lock securely. Lubricate if necessary.

Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for

lubrication frequently.BT-7

BT-13

Tire rotationTires should be rotated every 10,000 km (6,000 miles). SU-8

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the

vehicle, etc.

Item Reference page

LampsMake sure that the headlamps, stop lamps, tail lamps, turn signal lamps,

and other lamps are all operating properly and installed securely. Also check

headlamp aim.—

Warning lamps and

chimesMake sure that all warning lamps and buzzers/chimes are operating prop-

erly.—

Steering wheelCheck that it has the specified play.

Check for changes in the steering conditions, such as excessive free play,

hard steering or strange noises.

Free play: Less than 35 mm (1.38 in)—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters

and retractors) operate properly and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying, wear or damage.RS-3

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the engine oil or refuel.

Item Reference page

Windshield washer

fluidCheck that there is adequate fluid in the tank. —

Engine coolant levelCheck the coolant level when the engine is cold. LC-19, LC-59

Engine oil levelCheck the level after parking the vehicle (on level ground) and turning off

the engine.LC-8, LC-28

Brake and clutch

fluid levelsMake sure that the brake and clutch fluid levels are between the “MAX” and

“MIN” lines on the reservoir.BR-7

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN”

lines.—

GENERAL MAINTENANCE

MA-3

Page 2995 of 3051

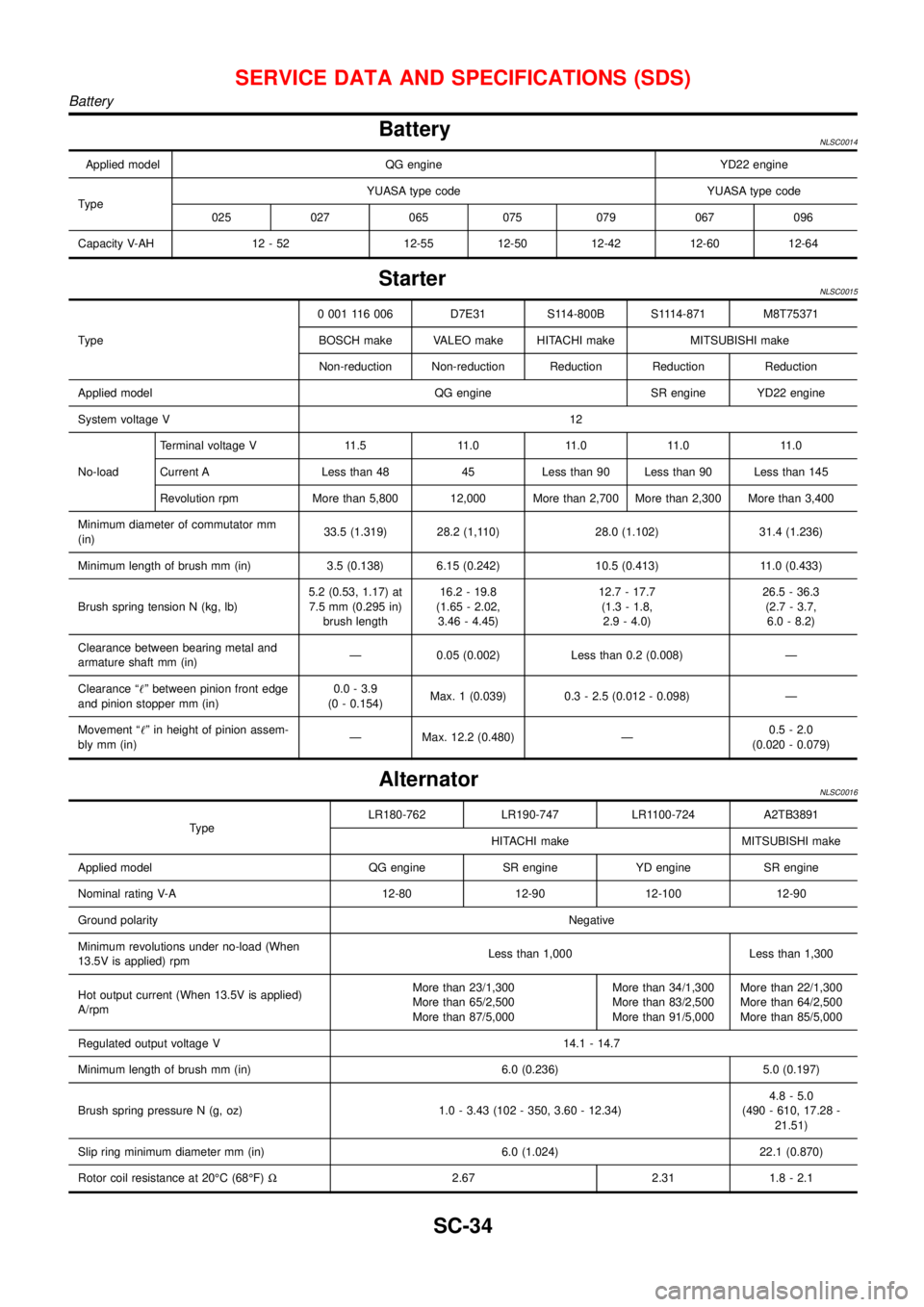

BatteryNLSC0014

Applied model QG engine YD22 engine

TypeYUASA type code YUASA type code

025 027 065 075 079 067 096

Capacity V-AH 12 - 52 12-55 12-50 12-42 12-60 12-64

StarterNLSC0015

Type0 001 116 006 D7E31 S114-800B S1114-871 M8T75371

BOSCH make VALEO make HITACHI make MITSUBISHI make

Non-reduction Non-reduction Reduction Reduction Reduction

Applied model QG engine SR engine YD22 engine

System voltage V12

No-loadTerminal voltage V 11.5 11.0 11.0 11.0 11.0

Current A Less than 48 45 Less than 90 Less than 90 Less than 145

Revolution rpm More than 5,800 12,000 More than 2,700 More than 2,300 More than 3,400

Minimum diameter of commutator mm

(in)33.5 (1.319) 28.2 (1,110) 28.0 (1.102) 31.4 (1.236)

Minimum length of brush mm (in) 3.5 (0.138) 6.15 (0.242) 10.5 (0.413) 11.0 (0.433)

Brush spring tension N (kg, lb)5.2 (0.53, 1.17) at

7.5 mm (0.295 in)

brush length16.2 - 19.8

(1.65 - 2.02,

3.46 - 4.45)12.7 - 17.7

(1.3 - 1.8,

2.9 - 4.0)26.5 - 36.3

(2.7 - 3.7,

6.0 - 8.2)

Clearance between bearing metal and

armature shaft mm (in)—0.05 (0.002) Less than 0.2 (0.008)—

Clearance“!”between pinion front edge

and pinion stopper mm (in)0.0 - 3.9

(0 - 0.154)Max. 1 (0.039) 0.3 - 2.5 (0.012 - 0.098)—

Movement“!”in height of pinion assem-

bly mm (in)—Max. 12.2 (0.480)—0.5 - 2.0

(0.020 - 0.079)

AlternatorNLSC0016

TypeLR180-762 LR190-747 LR1100-724 A2TB3891

HITACHI make MITSUBISHI make

Applied model QG engine SR engine YD engine SR engine

Nominal rating V-A 12-80 12-90 12-100 12-90

Ground polarityNegative

Minimum revolutions under no-load (When

13.5V is applied) rpmLess than 1,000 Less than 1,300

Hot output current (When 13.5V is applied)

A/rpmMore than 23/1,300

More than 65/2,500

More than 87/5,000More than 34/1,300

More than 83/2,500

More than 91/5,000More than 22/1,300

More than 64/2,500

More than 85/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) 6.0 (0.236) 5.0 (0.197)

Brush spring pressure N (g, oz) 1.0 - 3.43 (102 - 350, 3.60 - 12.34)4.8 - 5.0

(490 - 610, 17.28 -

21.51)

Slip ring minimum diameter mm (in) 6.0 (1.024) 22.1 (0.870)

Rotor coil resistance at 20°C (68°F)Ω2.67 2.31 1.8 - 2.1

SERVICE DATA AND SPECIFICATIONS (SDS)

Battery

SC-34

Page 2998 of 3051

Special Service ToolsNLST0004

Tool number

Tool nameDescription

KV48102500

Pressure gauge adapter

NT542

Measuring oil pressure

ST27180001

Steering wheel puller

NT544

Removing steering wheel

HT72520000

Ball joint remover

NT546

Removing ball joint

a: 33 mm (1.30 in)

b: 50 mm (1.97 in)

r: R11.5 mm (0.453 in)

KV48103500

Pressure gauge

NT547

Measuring oil pressure

ST3127S000

1 GG91030000

Torque wrench

2 HT62940000

Socket adapter

3 HT62900000

Socket adapter

NT541

Measuring turning torque

Commercial Service ToolNLST0005

Tool number Description

Oil pump attachment

NT774

Disassembling and assembling oil pump

Unit: mm (in)

PREPARATION

Special Service Tools

ST-3

Page 3003 of 3051

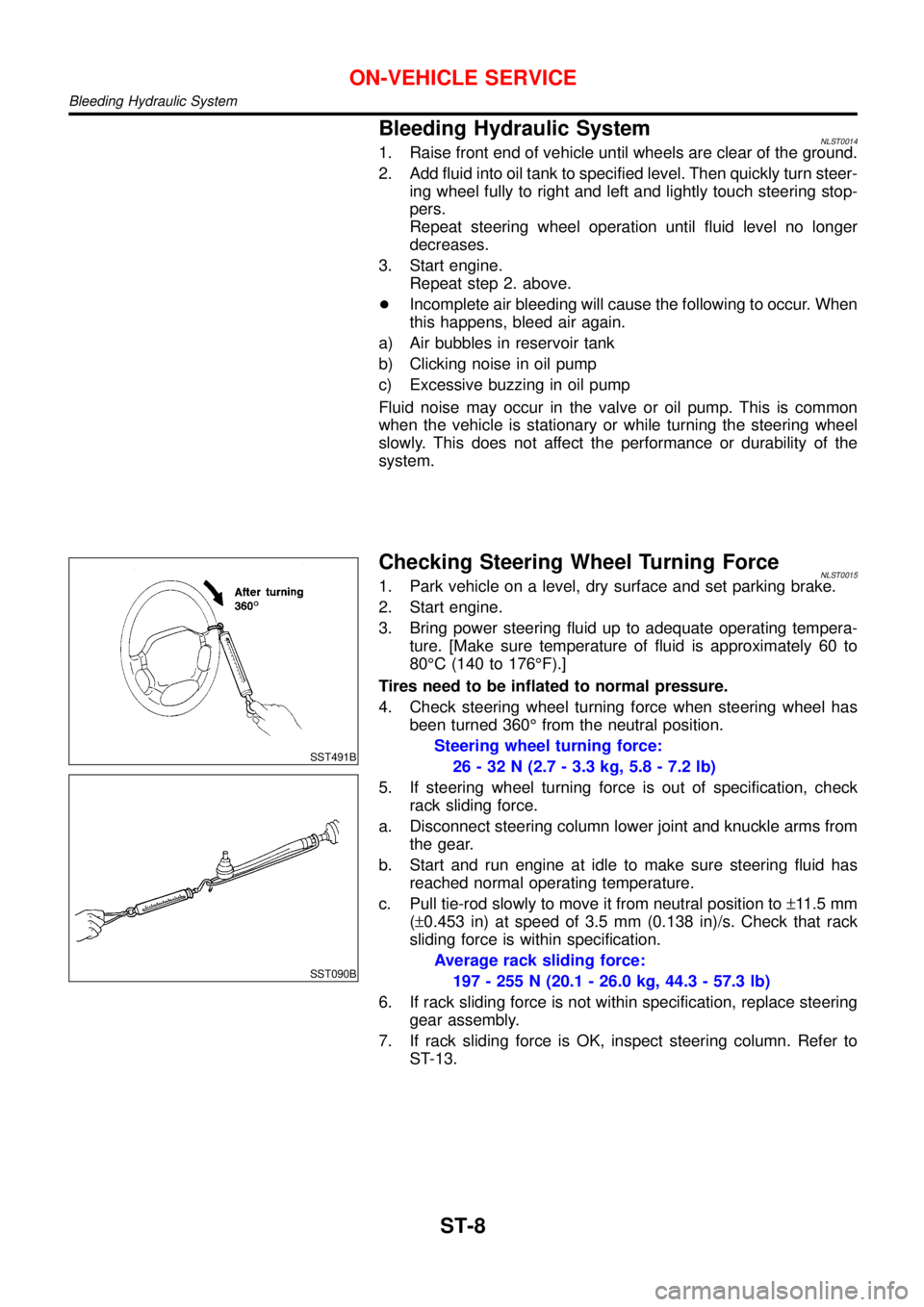

Bleeding Hydraulic SystemNLST00141. Raise front end of vehicle until wheels are clear of the ground.

2. Add fluid into oil tank to specified level. Then quickly turn steer-

ing wheel fully to right and left and lightly touch steering stop-

pers.

Repeat steering wheel operation until fluid level no longer

decreases.

3. Start engine.

Repeat step 2. above.

+Incomplete air bleeding will cause the following to occur. When

this happens, bleed air again.

a) Air bubbles in reservoir tank

b) Clicking noise in oil pump

c) Excessive buzzing in oil pump

Fluid noise may occur in the valve or oil pump. This is common

when the vehicle is stationary or while turning the steering wheel

slowly. This does not affect the performance or durability of the

system.

SST491B

SST090B

Checking Steering Wheel Turning ForceNLST00151. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to adequate operating tempera-

ture. [Make sure temperature of fluid is approximately 60 to

80°C (140 to 176°F).]

Tires need to be inflated to normal pressure.

4. Check steering wheel turning force when steering wheel has

been turned 360°from the neutral position.

Steering wheel turning force:

26 - 32 N (2.7 - 3.3 kg, 5.8 - 7.2 lb)

5. If steering wheel turning force is out of specification, check

rack sliding force.

a. Disconnect steering column lower joint and knuckle arms from

the gear.

b. Start and run engine at idle to make sure steering fluid has

reached normal operating temperature.

c. Pull tie-rod slowly to move it from neutral position to±11.5 mm

(±0.453 in) at speed of 3.5 mm (0.138 in)/s. Check that rack

sliding force is within specification.

Average rack sliding force:

197 - 255 N (20.1 - 26.0 kg, 44.3 - 57.3 lb)

6. If rack sliding force is not within specification, replace steering

gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ST-13.

ON-VEHICLE SERVICE

Bleeding Hydraulic System

ST-8

Page 3004 of 3051

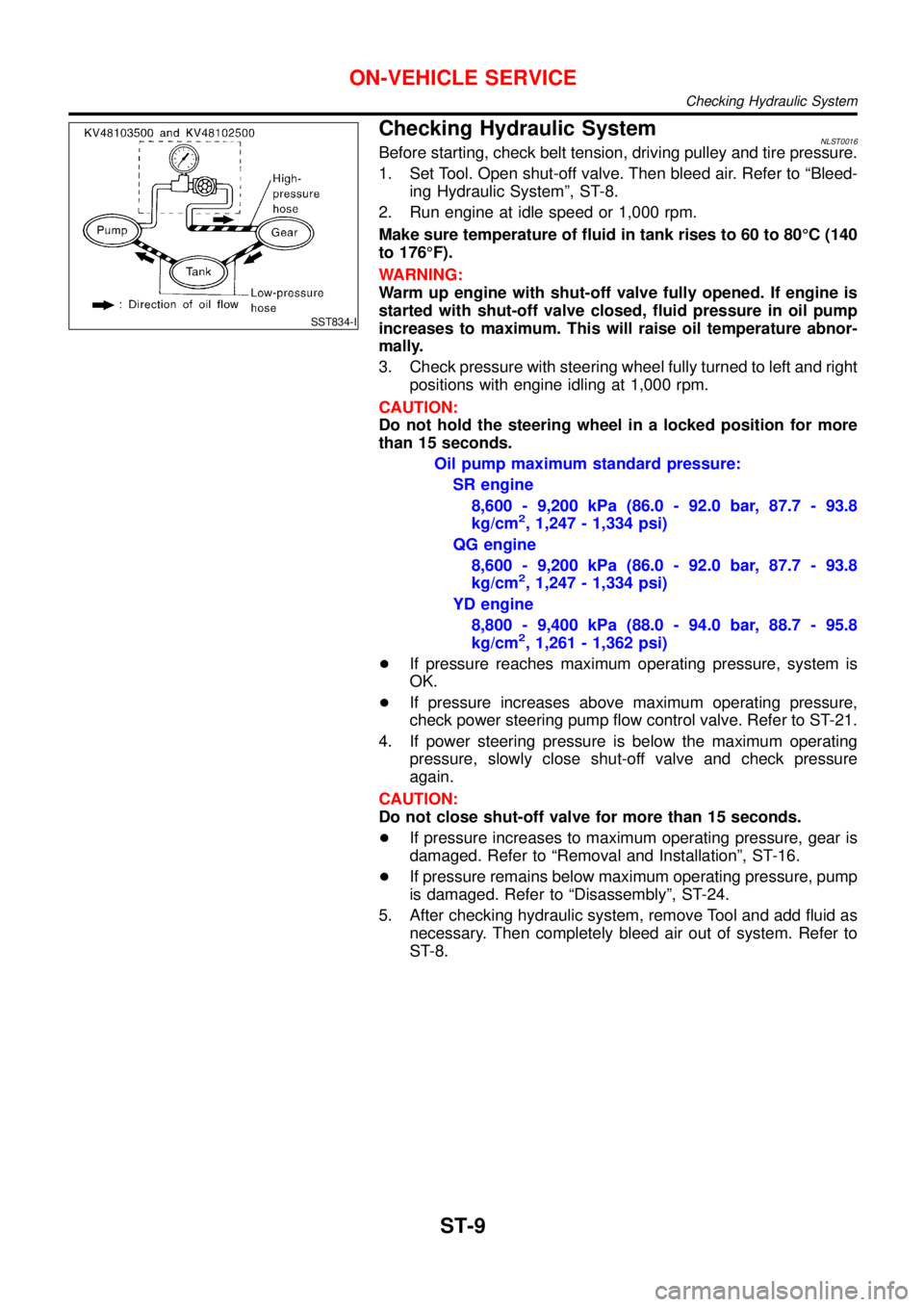

SST834-I

Checking Hydraulic SystemNLST0016Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air. Refer to“Bleed-

ing Hydraulic System”, ST-8.

2. Run engine at idle speed or 1,000 rpm.

Make sure temperature of fluid in tank rises to 60 to 80°C (140

to 176°F).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in oil pump

increases to maximum. This will raise oil temperature abnor-

mally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Oil pump maximum standard pressure:

SR engine

8,600 - 9,200 kPa (86.0 - 92.0 bar, 87.7 - 93.8

kg/cm

2, 1,247 - 1,334 psi)

QG engine

8,600 - 9,200 kPa (86.0 - 92.0 bar, 87.7 - 93.8

kg/cm

2, 1,247 - 1,334 psi)

YD engine

8,800 - 9,400 kPa (88.0 - 94.0 bar, 88.7 - 95.8

kg/cm

2, 1,261 - 1,362 psi)

+If pressure reaches maximum operating pressure, system is

OK.

+If pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-21.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

+If pressure increases to maximum operating pressure, gear is

damaged. Refer to“Removal and Installation”, ST-16.

+If pressure remains below maximum operating pressure, pump

is damaged. Refer to“Disassembly”, ST-24.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-8.

ON-VEHICLE SERVICE

Checking Hydraulic System

ST-9

Page 3023 of 3051

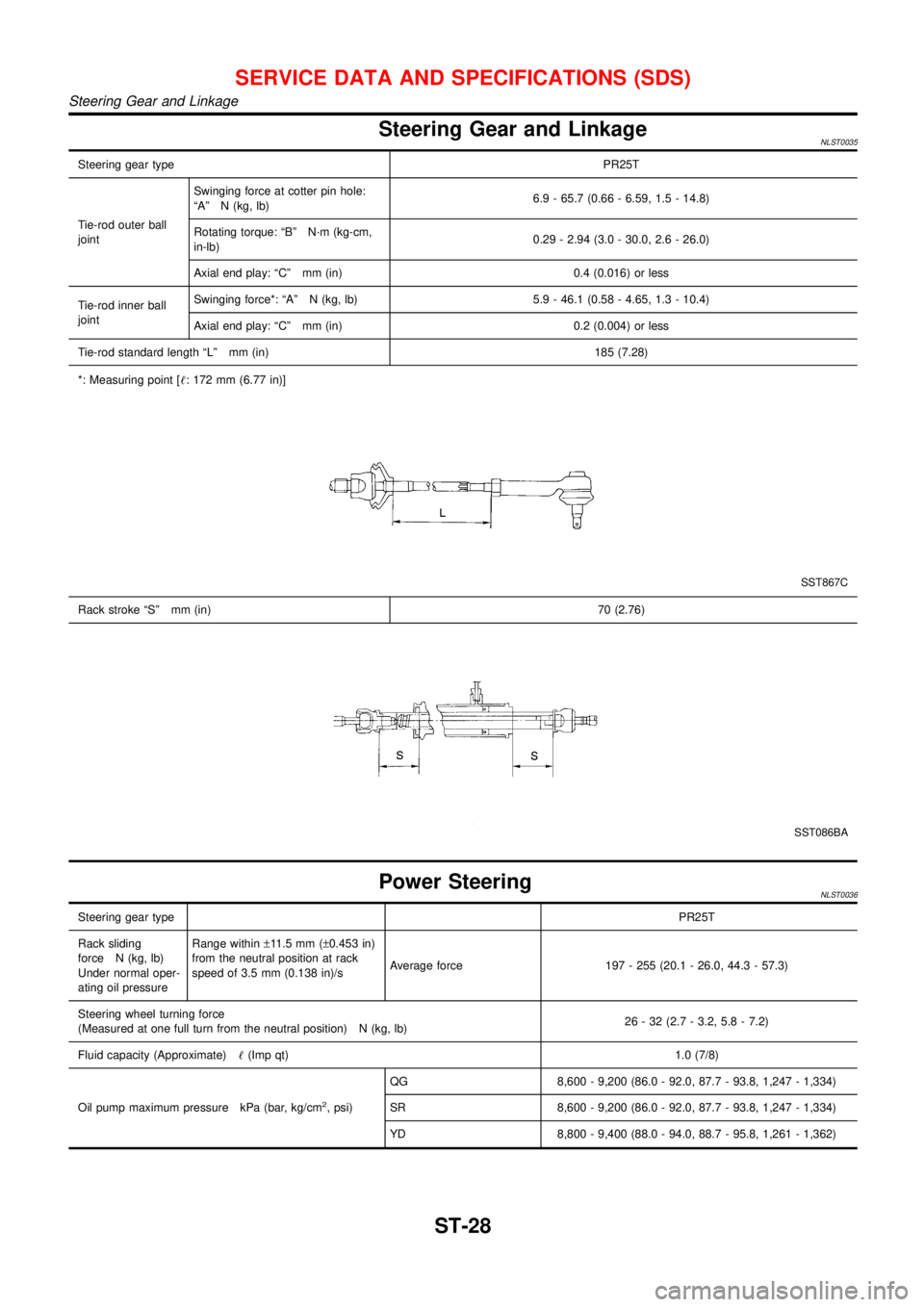

Steering Gear and LinkageNLST0035

Steering gear typePR25T

Tie-rod outer ball

jointSwinging force at cotter pin hole:

“A”N (kg, lb)6.9 - 65.7 (0.66 - 6.59, 1.5 - 14.8)

Rotating torque:“B”N·m (kg-cm,

in-lb)0.29 - 2.94 (3.0 - 30.0, 2.6 - 26.0)

Axial end play:“C”mm (in) 0.4 (0.016) or less

Tie-rod inner ball

jointSwinging force*:“A”N (kg, lb) 5.9 - 46.1 (0.58 - 4.65, 1.3 - 10.4)

Axial end play:“C”mm (in) 0.2 (0.004) or less

Tie-rod standard length“L”mm (in) 185 (7.28)

*: Measuring point [!: 172 mm (6.77 in)]

SST867C

Rack stroke“S”mm (in)70 (2.76)

SST086BA

Power SteeringNLST0036

Steering gear typePR25T

Rack sliding

force N (kg, lb)

Under normal oper-

ating oil pressureRange within±11.5 mm (±0.453 in)

from the neutral position at rack

speed of 3.5 mm (0.138 in)/sAverage force 197 - 255 (20.1 - 26.0, 44.3 - 57.3)

Steering wheel turning force

(Measured at one full turn from the neutral position) N (kg, lb)26 - 32 (2.7 - 3.2, 5.8 - 7.2)

Fluid capacity (Approximate)!(Imp qt)1.0 (7/8)

Oil pump maximum pressure kPa (bar, kg/cm

2, psi)QG 8,600 - 9,200 (86.0 - 92.0, 87.7 - 93.8, 1,247 - 1,334)

SR 8,600 - 9,200 (86.0 - 92.0, 87.7 - 93.8, 1,247 - 1,334)

YD 8,800 - 9,400 (88.0 - 94.0, 88.7 - 95.8, 1,261 - 1,362)

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering Gear and Linkage

ST-28